CD changer CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 227 of 1938

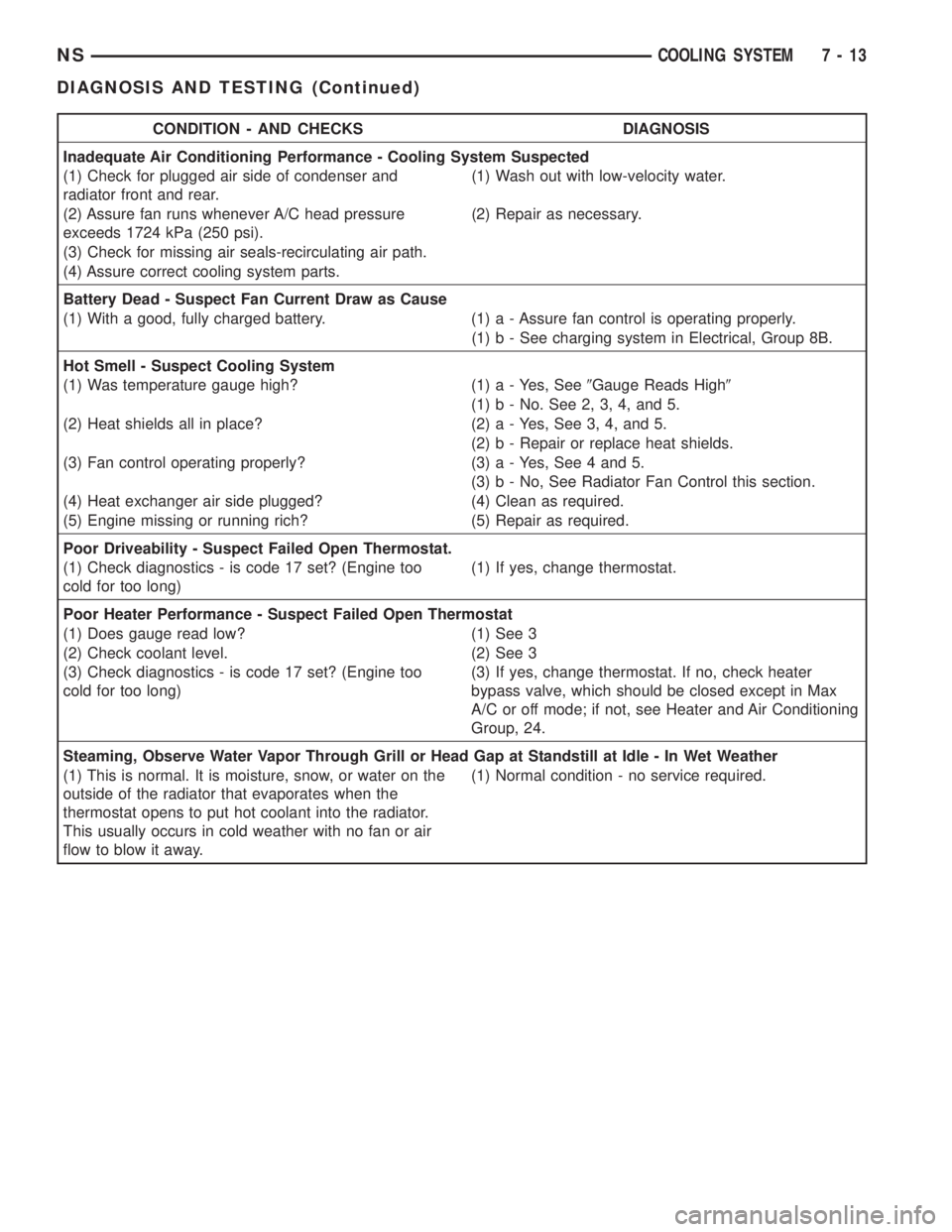

CONDITION - AND CHECKS DIAGNOSIS

Inadequate Air Conditioning Performance - Cooling System Suspected

(1) Check for plugged air side of condenser and

radiator front and rear.(1) Wash out with low-velocity water.

(2) Assure fan runs whenever A/C head pressure

exceeds 1724 kPa (250 psi).(2) Repair as necessary.

(3) Check for missing air seals-recirculating air path.

(4) Assure correct cooling system parts.

Battery Dead - Suspect Fan Current Draw as Cause

(1) With a good, fully charged battery. (1) a - Assure fan control is operating properly.

(1) b - See charging system in Electrical, Group 8B.

Hot Smell - Suspect Cooling System

(1) Was temperature gauge high? (1) a - Yes, See9Gauge Reads High9

(1) b - No. See 2, 3, 4, and 5.

(2) Heat shields all in place? (2) a - Yes, See 3, 4, and 5.

(2) b - Repair or replace heat shields.

(3) Fan control operating properly? (3) a - Yes, See 4 and 5.

(3) b - No, See Radiator Fan Control this section.

(4) Heat exchanger air side plugged? (4) Clean as required.

(5) Engine missing or running rich? (5) Repair as required.

Poor Driveability - Suspect Failed Open Thermostat.

(1) Check diagnostics - is code 17 set? (Engine too

cold for too long)(1) If yes, change thermostat.

Poor Heater Performance - Suspect Failed Open Thermostat

(1) Does gauge read low? (1) See 3

(2) Check coolant level. (2) See 3

(3) Check diagnostics - is code 17 set? (Engine too

cold for too long)(3) If yes, change thermostat. If no, check heater

bypass valve, which should be closed except in Max

A/C or off mode; if not, see Heater and Air Conditioning

Group, 24.

Steaming, Observe Water Vapor Through Grill or Head Gap at Standstill at Idle - In Wet Weather

(1) This is normal. It is moisture, snow, or water on the

outside of the radiator that evaporates when the

thermostat opens to put hot coolant into the radiator.

This usually occurs in cold weather with no fan or air

flow to blow it away.(1) Normal condition - no service required.

NSCOOLING SYSTEM 7 - 13

DIAGNOSIS AND TESTING (Continued)

Page 403 of 1938

AUDIO SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

ANTENNA.............................. 1

CHOKEÐINFINITY SPEAKERS.............. 2

INTERFERENCE ELIMINATION.............. 1

NAME BRAND SPEAKER RELAY............ 3

RADIO IGNITION INTERFERENCE........... 2

RADIOS................................ 1

REMOTE RADIO SWITCHES................ 3

DIAGNOSIS AND TESTING

ANTENNA.............................. 3AUDIO SYSTEM......................... 4

RADIO................................. 4

REMOTE RADIO SWITCHES................ 6

REMOVAL AND INSTALLATION

ANTENNA EXTENSION CABLE.............. 7

ANTENNA MAST AND CABLE LEAD......... 7

D±PILLAR SPEAKER.................... 10

FRONT DOOR SPEAKER................... 9

INSTRUMENT PANEL SPEAKER............. 8

QUARTER PANEL SPEAKER............... 10

RADIO/TAPE/CD PLAYER.................. 8

REMOTE RADIO SWITCHES................ 9

GENERAL INFORMATION

INTRODUCTION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with the vehicle.

NS vehicles are equipped with an Ignition Off

Draw (IOD) fuse in the power distribution center

located in the engine compartment. After the IOD

fuse or battery has been disconnected, the radio sta-

tion sets and clock will require resetting.

DESCRIPTION AND OPERATION

ANTENNA

All models use a fixed-length stainless steel rod-

type antenna mast, installed at the right front fender

of the vehicle. The antenna mast is connected to the

center wire of the coaxial antenna cable, and is not

grounded to any part of the vehicle.

To eliminate static, the antenna base must have a

good ground. The coaxial antenna cable shield (the

outer wire mesh of the cable) is grounded to the

antenna base and the radio chassis.

The antenna coaxial cable has an additional dis-

connect, located near the right end of the instrument

panel. This additional disconnect allows the instru-

ment panel assembly to be removed and installed

without removing the radio.

The factory-installed Electronically Tuned Radios

(ETRs) automatically compensate for radio antenna

trim. Therefore, no antenna trimmer adjustment isrequired or possible when replacing the receiver or

the antenna.

INTERFERENCE ELIMINATION

Some components used on the vehicles are

equipped with a capacitor to suppress radio fre-

quency interference/static.

Capacitors are mounted in various locations inter-

nal to the generator, instrument cluster and wind-

shield wiper motor.

To eliminate radio interference, ground straps are

used in different areas of the vehicle. These ground

circuits should be securely tightened to assure good

metal to metal contact. The ground straps conduct

very small high frequency electrical signals to ground

and require clean surface contact area. The radio

ground is supplied from the instrument panel har-

ness and is attached to the rear of the radio. Some

engines have other ground straps to eliminate fur-

ther radio interference:

²Radio chassis to instrument panel structure

²Engine to dash panel

²Engine to chassis

²A/C h valve to dash panel

Radio resistance type spark plug cables in the high

tension circuit of the ignition system complete the

interference suppression. Faulty or deteriorated

spark plug wires should be replaced.

RADIOS

Available factory-installed radio receivers for this

model include an AM/FM/cassette (RAS sales code),

an AM/FM/cassette/5-band graphic equalizer with CD

changer control feature (RBN sales code), an AM/FM/

NSAUDIO SYSTEMS 8F - 1

Page 405 of 1938

bracket behind the junction block/body control mod-

ule (Fig. 5).

REMOTE RADIO SWITCHES

A remote radio control switch option is available on

LXI models sold in North America with the AM/FM/

cassette/5-band graphic equalizer with CD changer

control feature (RBN sales code), or the AM/FM/CD/

cassette/3-band graphic equalizer (RAZ sales code)

radio receivers. Two rocker-type switches are

mounted on the back (instrument panel side) of the

steering wheel spokes. The switch on the left spoke is

the seek switch and has seek up, seek down, and pre-

set station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions (Fig. 6).

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the propermessages on the Chrysler Collision Detection (CCD)

data bus network to the radio receiver. For diagnosis

of the BCM or the CCD data bus, the use of a DRB

scan tool and the proper Diagnostic Procedures man-

ual are recommended. For more information on the

operation of the remote radio switch controls, refer to

the owner's manual in the vehicle glove box.

NAME BRAND SPEAKER RELAY

Relay is located in the junction block. To test relay

refer to the Audio Diagnostic Test Procedures or use

a known good relay.

DIAGNOSIS AND TESTING

ANTENNA

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

The following four tests are used to diagnose the

antenna with an ohmmeter:

²Test 1- Mast to ground test

²Test 2- Tip-of-mast to tip-of-conductor test

²Test 3- Body ground to battery ground test

²Test 4- Body ground to coaxial shield test.

The ohmmeter test lead connections for each test

are shown in Antenna Tests (Fig. 7).

NOTE: This model has a two-piece antenna coaxial

cable. Tests 2 and 4 must be conducted in two

steps to isolate a coaxial cable problem; from the

coaxial cable connection under the right end of the

instrument panel near the right cowl side panel to

the antenna base, and then from the coaxial cable

connection to the radio chassis connection.

TEST 1

Test 1 determines if the antenna mast is insulated

from the base. Proceed as follows:

(1) Unplug the antenna coaxial cable connector

from the radio chassis and isolate.

(2) Connect one ohmmeter test lead to the tip of

the antenna mast. Connect the other test lead to the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

Fig. 5 Choke Location

Fig. 6 Remote Radio Switch Operational View

NSAUDIO SYSTEMS 8F - 3

DESCRIPTION AND OPERATION (Continued)

Page 1476 of 1938

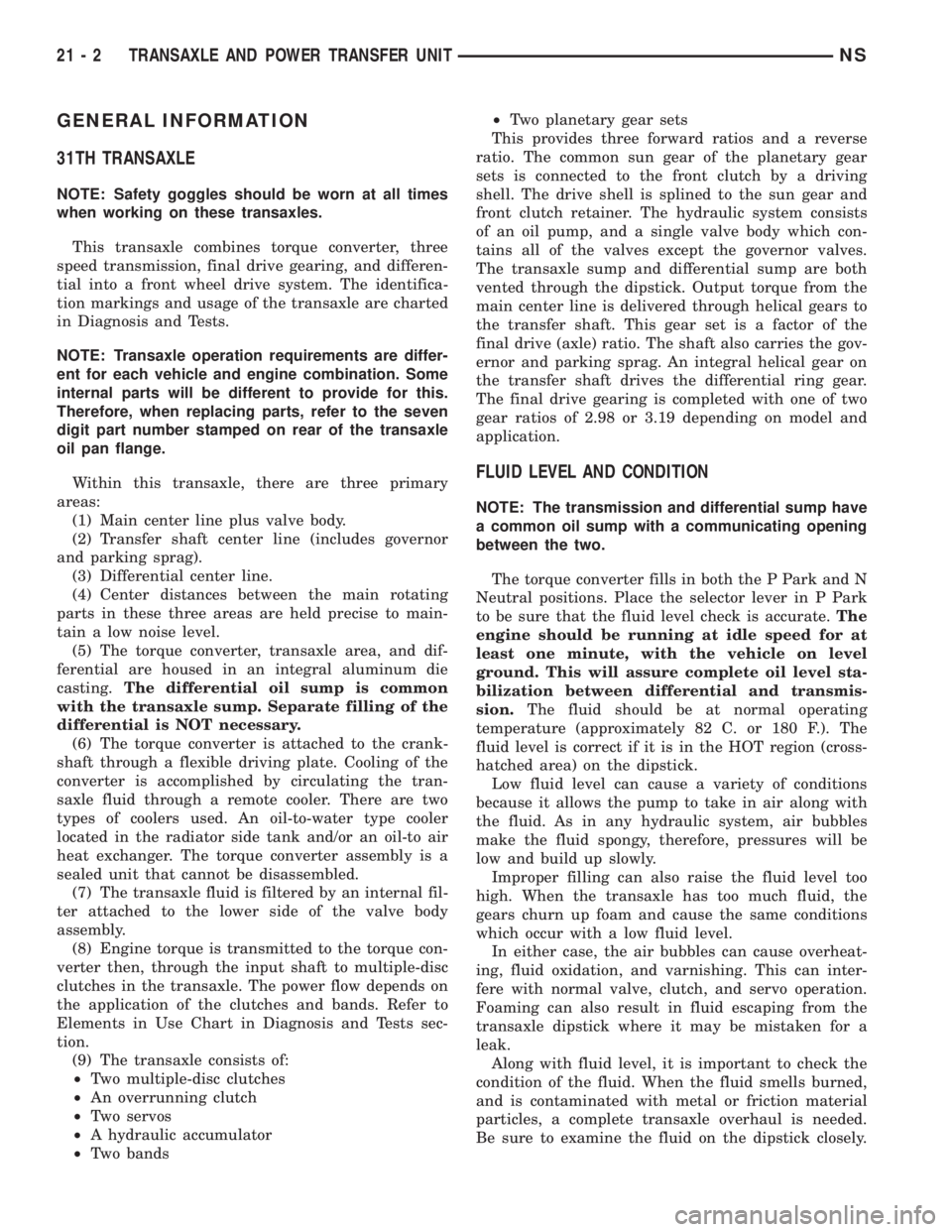

GENERAL INFORMATION

31TH TRANSAXLE

NOTE: Safety goggles should be worn at all times

when working on these transaxles.

This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system. The identifica-

tion markings and usage of the transaxle are charted

in Diagnosis and Tests.

NOTE: Transaxle operation requirements are differ-

ent for each vehicle and engine combination. Some

internal parts will be different to provide for this.

Therefore, when replacing parts, refer to the seven

digit part number stamped on rear of the transaxle

oil pan flange.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

(4) Center distances between the main rotating

parts in these three areas are held precise to main-

tain a low noise level.

(5) The torque converter, transaxle area, and dif-

ferential are housed in an integral aluminum die

casting.The differential oil sump is common

with the transaxle sump. Separate filling of the

differential is NOT necessary.

(6) The torque converter is attached to the crank-

shaft through a flexible driving plate. Cooling of the

converter is accomplished by circulating the tran-

saxle fluid through a remote cooler. There are two

types of coolers used. An oil-to-water type cooler

located in the radiator side tank and/or an oil-to air

heat exchanger. The torque converter assembly is a

sealed unit that cannot be disassembled.

(7) The transaxle fluid is filtered by an internal fil-

ter attached to the lower side of the valve body

assembly.

(8) Engine torque is transmitted to the torque con-

verter then, through the input shaft to multiple-disc

clutches in the transaxle. The power flow depends on

the application of the clutches and bands. Refer to

Elements in Use Chart in Diagnosis and Tests sec-

tion.

(9) The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The drive shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump, and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor of the

final drive (axle) ratio. The shaft also carries the gov-

ernor and parking sprag. An integral helical gear on

the transfer shaft drives the differential ring gear.

The final drive gearing is completed with one of two

gear ratios of 2.98 or 3.19 depending on model and

application.

FLUID LEVEL AND CONDITION

NOTE: The transmission and differential sump have

a common oil sump with a communicating opening

between the two.

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground. This will assure complete oil level sta-

bilization between differential and transmis-

sion.The fluid should be at normal operating

temperature (approximately 82 C. or 180 F.). The

fluid level is correct if it is in the HOT region (cross-

hatched area) on the dipstick.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, the air bubbles can cause overheat-

ing, fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and servo operation.

Foaming can also result in fluid escaping from the

transaxle dipstick where it may be mistaken for a

leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed.

Be sure to examine the fluid on the dipstick closely.

21 - 2 TRANSAXLE AND POWER TRANSFER UNITNS

Page 1490 of 1938

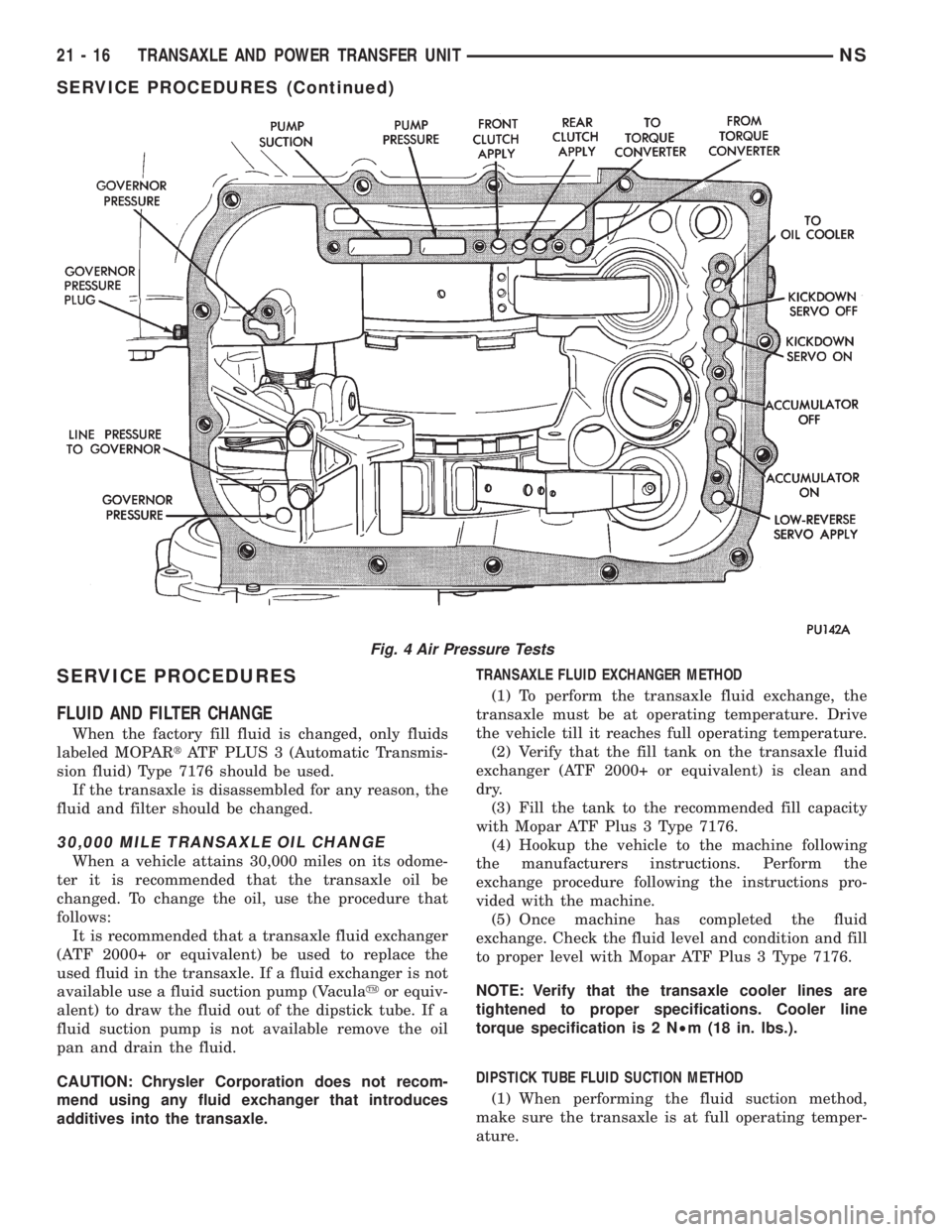

SERVICE PROCEDURES

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only fluids

labeled MOPARtATF PLUS 3 (Automatic Transmis-

sion fluid) Type 7176 should be used.

If the transaxle is disassembled for any reason, the

fluid and filter should be changed.

30,000 MILE TRANSAXLE OIL CHANGE

When a vehicle attains 30,000 miles on its odome-

ter it is recommended that the transaxle oil be

changed. To change the oil, use the procedure that

follows:

It is recommended that a transaxle fluid exchanger

(ATF 2000+ or equivalent) be used to replace the

used fluid in the transaxle. If a fluid exchanger is not

available use a fluid suction pump (Vaculayor equiv-

alent) to draw the fluid out of the dipstick tube. If a

fluid suction pump is not available remove the oil

pan and drain the fluid.

CAUTION: Chrysler Corporation does not recom-

mend using any fluid exchanger that introduces

additives into the transaxle.TRANSAXLE FLUID EXCHANGER METHOD

(1) To perform the transaxle fluid exchange, the

transaxle must be at operating temperature. Drive

the vehicle till it reaches full operating temperature.

(2) Verify that the fill tank on the transaxle fluid

exchanger (ATF 2000+ or equivalent) is clean and

dry.

(3) Fill the tank to the recommended fill capacity

with Mopar ATF Plus 3 Type 7176.

(4) Hookup the vehicle to the machine following

the manufacturers instructions. Perform the

exchange procedure following the instructions pro-

vided with the machine.

(5) Once machine has completed the fluid

exchange. Check the fluid level and condition and fill

to proper level with Mopar ATF Plus 3 Type 7176.

NOTE: Verify that the transaxle cooler lines are

tightened to proper specifications. Cooler line

torque specification is 2 N²m (18 in. lbs.).

DIPSTICK TUBE FLUID SUCTION METHOD

(1) When performing the fluid suction method,

make sure the transaxle is at full operating temper-

ature.

Fig. 4 Air Pressure Tests

21 - 16 TRANSAXLE AND POWER TRANSFER UNITNS

SERVICE PROCEDURES (Continued)

Page 1538 of 1938

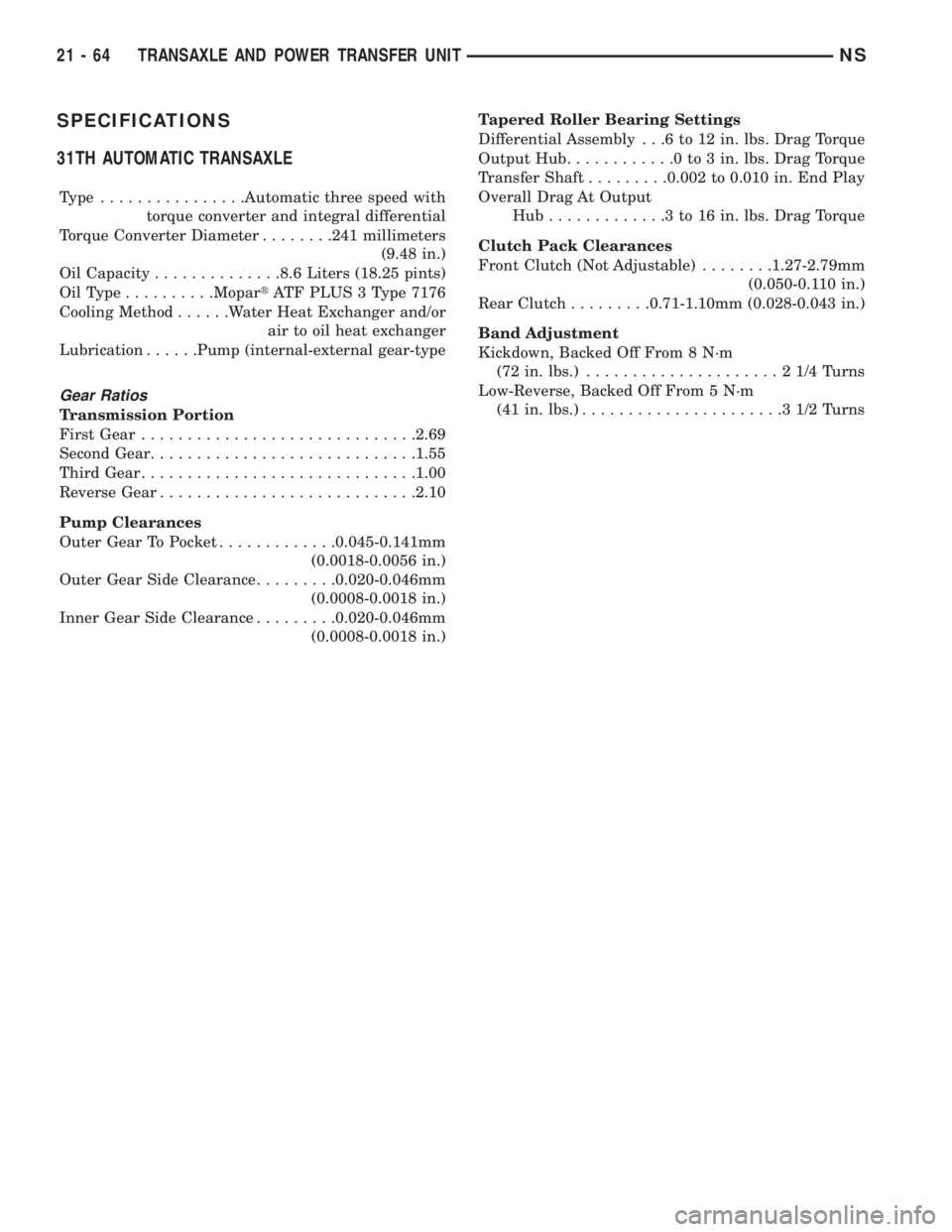

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE

Type ................Automatic three speed with

torque converter and integral differential

Torque Converter Diameter........241 millimeters

(9.48 in.)

Oil Capacity..............8.6 Liters (18.25 pints)

OilType..........MopartATF PLUS 3 Type 7176

Cooling Method......Water Heat Exchanger and/or

air to oil heat exchanger

Lubrication......Pump (internal-external gear-type

Gear Ratios

Transmission Portion

First Gear..............................2.69

Second Gear.............................1.55

Third Gear..............................1.00

Reverse Gear............................2.10

Pump Clearances

Outer Gear To Pocket.............0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)Tapered Roller Bearing Settings

Differential Assembly . . .6 to 12 in. lbs. Drag Torque

Output Hub............0to3in.lbs. Drag Torque

Transfer Shaft.........0.002 to 0.010 in. End Play

Overall Drag At Output

Hub.............3to16in.lbs. Drag Torque

Clutch Pack Clearances

Front Clutch (Not Adjustable)........1.27-2.79mm

(0.050-0.110 in.)

Rear Clutch.........0.71-1.10mm (0.028-0.043 in.)

Band Adjustment

Kickdown, Backed Off From 8 N´m

(72 in. lbs.).....................21/4Turns

Low-Reverse, Backed Off From 5 N´m

(41 in. lbs.)......................31/2Turns

21 - 64 TRANSAXLE AND POWER TRANSFER UNITNS

Page 1553 of 1938

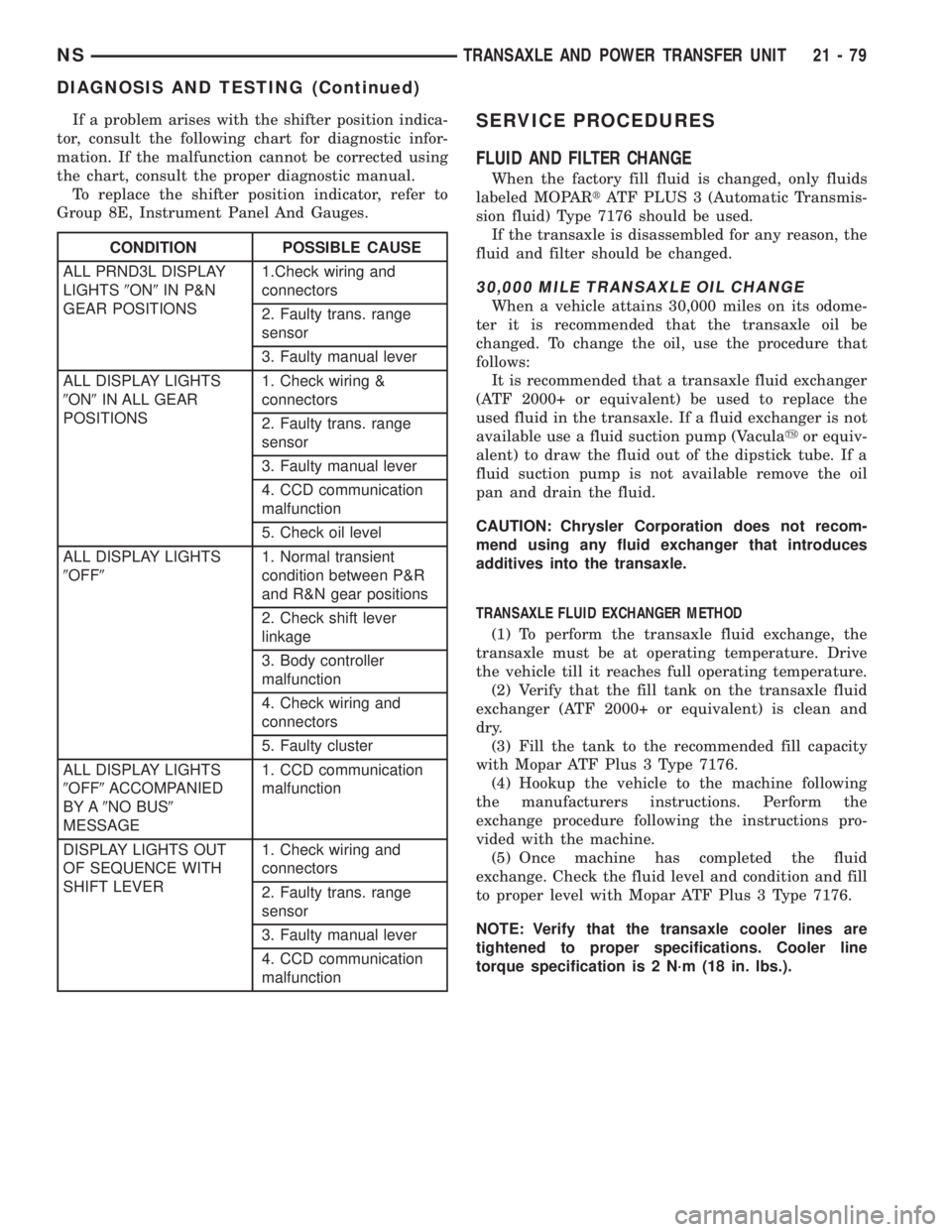

If a problem arises with the shifter position indica-

tor, consult the following chart for diagnostic infor-

mation. If the malfunction cannot be corrected using

the chart, consult the proper diagnostic manual.

To replace the shifter position indicator, refer to

Group 8E, Instrument Panel And Gauges.SERVICE PROCEDURES

FLUID AND FILTER CHANGE

When the factory fill fluid is changed, only fluids

labeled MOPARtATF PLUS 3 (Automatic Transmis-

sion fluid) Type 7176 should be used.

If the transaxle is disassembled for any reason, the

fluid and filter should be changed.

30,000 MILE TRANSAXLE OIL CHANGE

When a vehicle attains 30,000 miles on its odome-

ter it is recommended that the transaxle oil be

changed. To change the oil, use the procedure that

follows:

It is recommended that a transaxle fluid exchanger

(ATF 2000+ or equivalent) be used to replace the

used fluid in the transaxle. If a fluid exchanger is not

available use a fluid suction pump (Vaculayor equiv-

alent) to draw the fluid out of the dipstick tube. If a

fluid suction pump is not available remove the oil

pan and drain the fluid.

CAUTION: Chrysler Corporation does not recom-

mend using any fluid exchanger that introduces

additives into the transaxle.

TRANSAXLE FLUID EXCHANGER METHOD

(1) To perform the transaxle fluid exchange, the

transaxle must be at operating temperature. Drive

the vehicle till it reaches full operating temperature.

(2) Verify that the fill tank on the transaxle fluid

exchanger (ATF 2000+ or equivalent) is clean and

dry.

(3) Fill the tank to the recommended fill capacity

with Mopar ATF Plus 3 Type 7176.

(4) Hookup the vehicle to the machine following

the manufacturers instructions. Perform the

exchange procedure following the instructions pro-

vided with the machine.

(5) Once machine has completed the fluid

exchange. Check the fluid level and condition and fill

to proper level with Mopar ATF Plus 3 Type 7176.

NOTE: Verify that the transaxle cooler lines are

tightened to proper specifications. Cooler line

torque specification is 2 N´m (18 in. lbs.).

CONDITION POSSIBLE CAUSE

ALL PRND3L DISPLAY

LIGHTS9ON9IN P&N

GEAR POSITIONS1.Check wiring and

connectors

2. Faulty trans. range

sensor

3. Faulty manual lever

ALL DISPLAY LIGHTS

9ON9IN ALL GEAR

POSITIONS1. Check wiring &

connectors

2. Faulty trans. range

sensor

3. Faulty manual lever

4. CCD communication

malfunction

5. Check oil level

ALL DISPLAY LIGHTS

9OFF91. Normal transient

condition between P&R

and R&N gear positions

2. Check shift lever

linkage

3. Body controller

malfunction

4. Check wiring and

connectors

5. Faulty cluster

ALL DISPLAY LIGHTS

9OFF9ACCOMPANIED

BY A9NO BUS9

MESSAGE1. CCD communication

malfunction

DISPLAY LIGHTS OUT

OF SEQUENCE WITH

SHIFT LEVER1. Check wiring and

connectors

2. Faulty trans. range

sensor

3. Faulty manual lever

4. CCD communication

malfunction

NSTRANSAXLE AND POWER TRANSFER UNIT 21 - 79

DIAGNOSIS AND TESTING (Continued)

Page 1632 of 1938

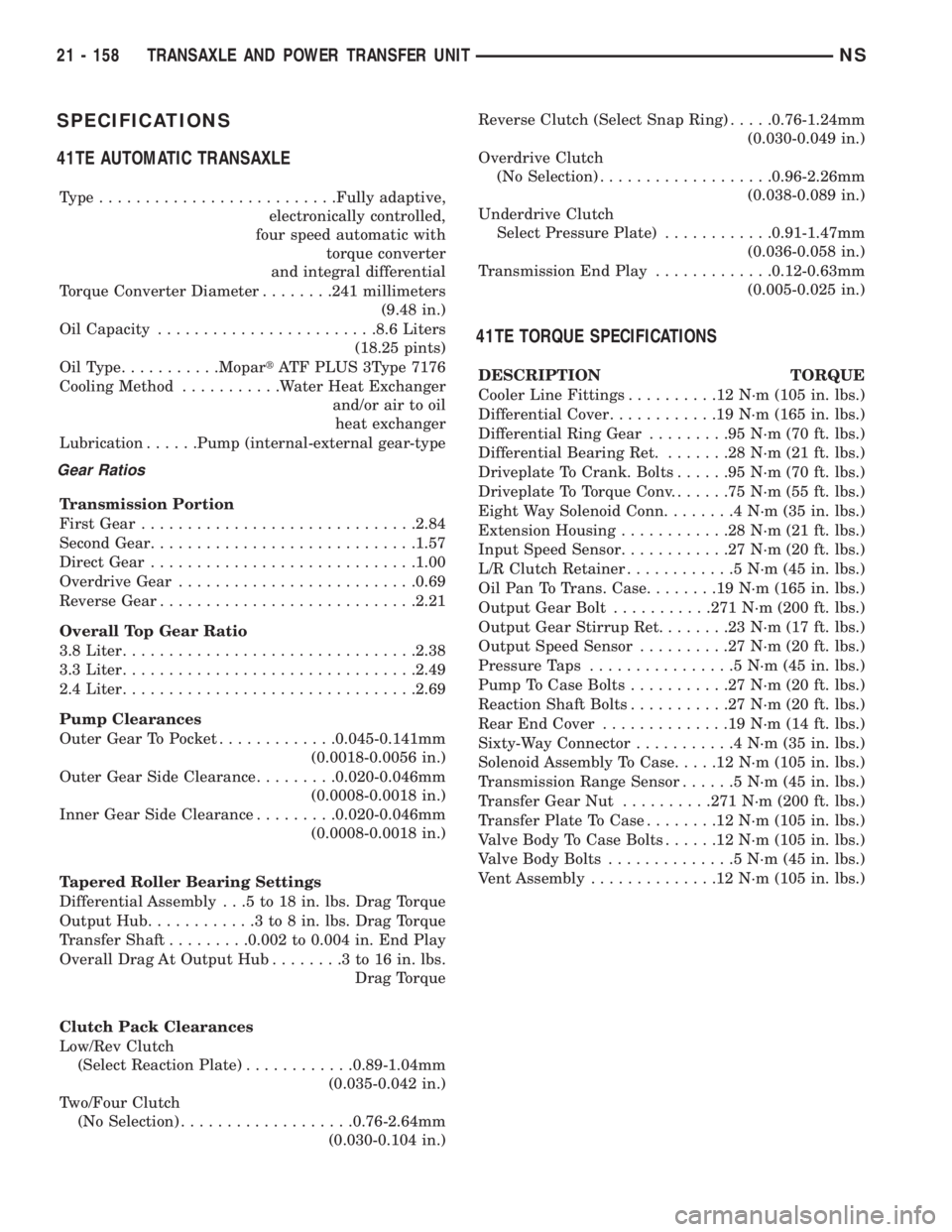

SPECIFICATIONS

41TE AUTOMATIC TRANSAXLE

Type..........................Fully adaptive,

electronically controlled,

four speed automatic with

torque converter

and integral differential

Torque Converter Diameter........241 millimeters

(9.48 in.)

Oil Capacity........................8.6 Liters

(18.25 pints)

OilType...........MopartATF PLUS 3Type 7176

Cooling Method...........Water Heat Exchanger

and/or air to oil

heat exchanger

Lubrication......Pump (internal-external gear-type

Gear Ratios

Transmission Portion

First Gear..............................2.84

Second Gear.............................1.57

Direct Gear.............................1.00

Overdrive Gear..........................0.69

Reverse Gear............................2.21

Overall Top Gear Ratio

3.8 Liter................................2.38

3.3 Liter................................2.49

2.4 Liter................................2.69

Pump Clearances

Outer Gear To Pocket.............0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Tapered Roller Bearing Settings

Differential Assembly . . .5 to 18 in. lbs. Drag Torque

Output Hub............3to8in.lbs. Drag Torque

Transfer Shaft.........0.002 to 0.004 in. End Play

Overall Drag At Output Hub........3to16in.lbs.

Drag Torque

Clutch Pack Clearances

Low/Rev Clutch

(Select Reaction Plate)............0.89-1.04mm

(0.035-0.042 in.)

Two/Four Clutch

(No Selection)...................0.76-2.64mm

(0.030-0.104 in.)Reverse Clutch (Select Snap Ring).....0.76-1.24mm

(0.030-0.049 in.)

Overdrive Clutch

(No Selection)...................0.96-2.26mm

(0.038-0.089 in.)

Underdrive Clutch

Select Pressure Plate)............0.91-1.47mm

(0.036-0.058 in.)

Transmission End Play.............0.12-0.63mm

(0.005-0.025 in.)

41TE TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Cooler Line Fittings..........12N´m(105 in. lbs.)

Differential Cover............19N´m(165 in. lbs.)

Differential Ring Gear.........95N´m(70ft.lbs.)

Differential Bearing Ret........28N´m(21ft.lbs.)

Driveplate To Crank. Bolts......95N´m(70ft.lbs.)

Driveplate To Torque Conv.......75N´m(55ft.lbs.)

Eight Way Solenoid Conn........4N´m(35in.lbs.)

Extension Housing............28N´m(21ft.lbs.)

Input Speed Sensor............27N´m(20ft.lbs.)

L/R Clutch Retainer............5N´m(45in.lbs.)

Oil Pan To Trans. Case........19N´m(165 in. lbs.)

Output Gear Bolt...........271 N´m (200 ft. lbs.)

Output Gear Stirrup Ret........23N´m(17ft.lbs.)

Output Speed Sensor..........27N´m(20ft.lbs.)

Pressure Taps................5N´m(45in.lbs.)

Pump To Case Bolts...........27N´m(20ft.lbs.)

Reaction Shaft Bolts...........27N´m(20ft.lbs.)

Rear End Cover..............19N´m(14ft.lbs.)

Sixty-Way Connector...........4N´m(35in.lbs.)

Solenoid Assembly To Case.....12N´m(105 in. lbs.)

Transmission Range Sensor......5N´m(45in.lbs.)

Transfer Gear Nut..........271 N´m (200 ft. lbs.)

Transfer Plate To Case........12N´m(105 in. lbs.)

Valve Body To Case Bolts......12N´m(105 in. lbs.)

Valve Body Bolts..............5N´m(45in.lbs.)

Vent Assembly..............12N´m(105 in. lbs.)

21 - 158 TRANSAXLE AND POWER TRANSFER UNITNS