coolant level CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 19 of 1938

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

SCHEDULE ± A.......................... 3SCHEDULE ± B.......................... 4

UNSCHEDULED INSPECTION............... 3

GENERAL INFORMATION

INTRODUCTION

Service and maintenance procedures for compo-

nents and systems listed in Schedule ± A or B can be

found by using the Group Tab Locator index at the

front of this manual. If it is not clear which group

contains the information needed, refer to the index at

the back of this manual.

There are two maintenance schedules that show

proper service based on the conditions that the vehi-

cle is subjected to.

Schedule ±A, lists scheduled maintenance to be

performed when the vehicle is used for general trans-

portation.

Schedule ±B, lists maintenance intervals for vehi-

cles that are operated under the conditions listed at

the beginning of the Maintenance Schedule section.

Use the schedule that best describes your driving

conditions.

Where time and mileage are listed, follow the

interval that occurs first.

UNSCHEDULED INSPECTION

At Each Stop for Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.

²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check rubber seals on each side of the radiator

for proper fit.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on Schedule ± A (7,500 miles) or every other

interval shown on Schedule ± B (6,000 miles).

²Check the coolant level, hoses, and clamps.

²If your mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

²Replace engine oil filter on 2.4L engines.

SCHEDULE ± A

7,500 Miles (12 000 km) or at 6 months

²Change engine oil.

15,000 Miles (24 000 km) or at 12 months

²Change engine oil.

²Replace engine oil filter.

22,500 Miles (36 000 km) or at 18 months

²Change engine oil.

²Inspect brake linings.

30,000 Miles (48 000 km) or at 24 months

²Change engine oil.

²Change automatic transmission fluid.

²Replace engine oil filter.

²Replace air cleaner element.

²Inspect tie rod ends and boot seals.

37,500 Miles (60 000 km) or at 30 months

²Change engine oil.

45,000 Miles (72 000 km) or at 36 months

²Change engine oil.

²Replace engine oil filter.

²Inspect brake linings.

²Flush and replace engine coolant at 36 months,

regardless of mileage.

NSLUBRICATION AND MAINTENANCE 0 - 3

Page 27 of 1938

LUBRICATION AND MAINTENANCE

CONTENTS

page page

GENERAL INFORMATION.................. 1

JUMP STARTING, HOISTING AND TOWING . . . 5MAINTENANCE SCHEDULES............... 2

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

ENGINE OIL Ð GASOLINE ENGINES........ 1

ENGINE OILÐDIESEL ENGINES............ 1FLUID CAPACITIES...................... 1

MANUAL TRANSMISSION FLUID

(A-558 and A-598 Models)................ 1

GENERAL INFORMATION

ENGINE OIL Ð GASOLINE ENGINES

Use only oils conforming to API (American Petro-

leum Institute) Quality SJ and Energy Conserving II,

or SH and Energy Conserving II, or ACEA A1±96.

SAE VISCOSITY GRADE

To assure of properly formulated engine oils, it is

recommended that SAE Grade 5W-30 engine oils that

meet Chrysler material standard MS-6395, be used.

SAE Grade 10W-30 oils are also acceptable when the

temperatures do not fall below 0ÉC. In areas where

these grades are not generally available, higher SAE

grades may be used.

Lubricants which have both an SAE grade number

and the proper API service classification shown on

the container should be used.

ENGINE OILÐDIESEL ENGINES

Use only Diesel Engine Oil meeting standardMIL-

2104Cor API ClassificationSG/CDorCCMC PD2.

SAE VISCOSITY GRADE

CAUTION: Low viscosity oils must have the proper

API quality or the CCMC G5 designation.

To assure of properly formulated engine oils, it is recom-

mended that SAE Grade 15W-40 engine oils that meet

Chrysler material standard MS-6395, be used. European

Grade 10W-40 oils are also acceptable.

Oils of the SAE 5W-30 or 10W-30 grade number

are preferred when minimum temperatures consis-

tently fall below -12ÉC.

MANUAL TRANSMISSION FLUID (A-558 and A-598

Models)

Use only SAE 10W-40 engine oils carrying the

European CCMC-G5 classification to fill the A-598

5±speed manual transmission.

FLUID CAPACITIES

Fuel Tank.............................76L

2.0L Gasoline Engine Oil with Filter........4.3L

2.5L VM Diesel Engine Oil With Filter......6.5L

2.0L Gasoline Engine Cooling System*.......6.0L

2.5L VM Diesel Engine Cooling System*....10.0 L

TransmissionÐ5-Speed Manual............2.2L

* Includes heater and coolant recovery tank filled

to Max level. Add 2.76L if equipped with Rear

Heater.

NS/GSLUBRICATION AND MAINTENANCE 0 - 1

Page 28 of 1938

MAINTENANCE SCHEDULES

INDEX

page page

GENERAL INFORMATION

MAINTENANCE SCHEDULE............... 2

MAINTENANCE SCHEDULEÐ

DIESEL ENGINE....................... 2SCHEDULEÐA (DIESEL).................. 2

SCHEDULEÐB (DIESEL).................. 3

UNSCHEDULED INSPECTION.............. 2

GENERAL INFORMATION

MAINTENANCE SCHEDULE

Refer to the 1998 GS Service Manual for Gasoline

Engine and non-engine related Maintenance Sched-

ules.

MAINTENANCE SCHEDULEÐDIESEL ENGINE

The following are engine related Maintenance

items which are unique to Diesel engine-equipped

vehicles. Refer to the 1998 GS Service Manual for

Gasoline Engine and non-engine related Maintenance

Schedules.

The service intervals are based on odometer read-

ings in kilometers. There are two maintenance sched-

ules that show proper service intervals. Use the

schedule that best describes the conditions the vehi-

cle is operated under.Schedule-Alists all the sched-

uled maintenance to be performed under normal

operating conditions.Schedule-Bis the schedule for

vehicles that are operated under one or more of the

following conditions:

²Day and night temperatures are below freezing.

²Stop and go driving.

²Long periods of engine idling.

²Driving in dusty conditions.

²Short trips of less than 5 miles.

²Operation at sustained high speeds during hot

weather above 32ÉC (90ÉF).

²Taxi, police or delivery service.

²Trailer towing.

UNSCHEDULED INSPECTION

At Each Stop for Fuel

²Check engine oil level, add as required.

²Check windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear

or damage.

²Inspect battery and clean and tighten terminals

as required.²Check fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check rubber seals on each side of the radiator

for proper fit.

At Each Oil Change

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on ScheduleÐA (7,500 miles) or every other

interval shown on ScheduleÐ B (6,000 miles).

²Check the coolant level, hoses, and clamps.

²If your mileage is less than 7,500 miles (12 000

km) yearly, replace the engine oil filter at each oil

change.

²Replace engine oil filter.

SCHEDULEÐA (DIESEL)

1 000 KM

²Change engine oil.

²Change engine oil filter.

²Check all fluid levels.

²Check correct torque, intake manifold mounting

nuts.

²Check correct torque, exhaust manifold mount-

ing nuts.

²Check correct torque, turbocharger mounting

nuts.

²Check correct torque, water manifold bolts.

10 000 KM

²Change engine oil.

²Change engine oil filter.

20 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

0 - 2 LUBRICATION AND MAINTENANCENS/GS

Page 29 of 1938

²Check drive belt tension.

²Check glow plug operation.

30 000 KM

²Change engine oil.

²Change engine oil filter.

40 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Replace fuel filter/water separator element.**

50 000 KM

²Change engine oil.

²Change engine oil filter.

60 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check glow plug operation.

²Replace drive belt.

²Check engine smoke.

²Replace engine coolant.

70 000 KM

²Change engine oil.

²Change engine oil filter.

80 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

²Replace fuel filter/water separator element.**

90 000 KM

²Change engine oil.

²Change engine oil filter.

100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

EVERY 40 000 KM AFTER 80 000 KM

²Replace fuel filter/water separator element.**

**The fuel filter/water separator element should be

replaced once a year if the vehicle is driven less than

40 000 km annually or if power loss from fuel star-

vation is detected.

EVERY 10 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

EVERY 20 000 KM AFTER 100 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

SCHEDULEÐB (DIESEL)

500 KM

²Check correct torque, intake manifold mounting

nuts.

²Check correct torque, exhaust manifold mount-

ing nuts.

²Check correct torque, turbocharger mounting

nuts.

²Check correct torque, water manifold bolts.

1 000 KM

²Change engine oil.

²Change engine oil filter.

²Check all fluid levels.

5 000 KM

²Change engine oil.

²Change engine oil filter.

10 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

15 000 KM

²Change engine oil.

²Change engine oil filter.

20 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

²Check drive belt tension.

²Check glow plug operation.

25 000 KM

²Change engine oil.

²Change engine oil filter.

30 000 KM

²Change engine oil.

²Change engine oil filter.

²Replace air filter element.

NS/GSLUBRICATION AND MAINTENANCE 0 - 3

GENERAL INFORMATION (Continued)

Page 215 of 1938

COOLING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

ACCESSORY DRIVE BELTS................ 1

AUTOMATIC TRANSMISSION OIL COOLERÐ

2.4L................................. 3

COOLANT RECOVERY SYSTEM (CRS)....... 3

COOLANT.............................. 3

COOLING SYSTEM....................... 2

ENGINE BLOCK HEATER.................. 5

ENGINE THERMOSTAT.................... 3

RADIATOR PRESSURE CAP................ 4

RADIATOR............................. 3

WATER PUMPS......................... 3

DESCRIPTION AND OPERATION

COOLANT PERFORMANCE................. 6

RADIATOR HOSES AND CLAMPS........... 6

WATER PIPESÐ3.0L ENGINE.............. 6

WATER PUMPÐ3.3/3.8L ENGINES.......... 7

WATER PUMPÐ2.4L ENGINE.............. 6

WATER PUMPÐ3.0L ENGINE.............. 6

DIAGNOSIS AND TESTING

ACCESSORY DRIVE BELT.................. 7

COOLING SYSTEM DIAGNOSIS............. 8

DEAERATION.......................... 16

ELECTRIC FAN MOTOR TEST.............. 14

LOW COOLANT LEVEL AERATION.......... 15

PRESSURE TESTING RADIATOR CAP....... 15

RADIATOR CAP TO FILLER NECK SEAL

PRESSURE RELIEF CHECK.............. 15

RADIATOR COOLANT FLOW TEST.......... 14

RADIATOR FAN CONTROL................ 14

TEMPERATURE GAUGE INDICATION........ 16

TESTING COOLING SYSTEM FOR LEAKS.... 14

SERVICE PROCEDURES

COOLANT LEVEL CHECKÐROUTINE........ 16

COOLANT LEVEL SERVICE................ 16COOLANTÐADDING ADDITIONAL.......... 16

COOLING SYSTEMÐDRAINING............ 16

COOLING SYSTEMÐREFILLING........... 16

REMOVAL AND INSTALLATION

ACCESSORY DRIVE BELTSÐ2.4L.......... 23

ACCESSORY DRIVE BELTSÐ3.0L.......... 24

ACCESSORY DRIVE BELTÐ3.3/3.8L........ 24

ENGINE BLOCK HEATER................. 23

FAN MODULE.......................... 22

RADIATOR DRAINCOCK.................. 21

RADIATOR............................ 21

THERMOSTATÐ2.4L ENGINE............. 19

THERMOSTATÐ3.0L ENGINE............. 20

THERMOSTATÐ3.3/3.8L ENGINES......... 20

WATER PUMP INLET TUBEÐ2.4L ENGINE . . . 17

WATER PUMPÐ3.3/3.8L ENGINES......... 19

WATER PUMPÐ2.4L ENGINE............ 17

WATER PUMPÐ3.0L ENGINE............. 18

CLEANING AND INSPECTION

ACCESSORY DRIVE BELT................. 25

CHEMICAL CLEANING................... 25

COOLING SYSTEM CLEANING............. 25

RADIATOR PRESSURE CAP............... 25

REVERSE FLUSHING THE ENGINE......... 25

REVERSE FLUSHING THE RADIATOR....... 25

WATER PUMP......................... 24

ADJUSTMENTS

BELT TENSION CHART................... 26

BELT TENSION GAUGE METHOD........... 26

PROPER BELT TENSION................. 25

SPECIFICATIONS

COOLING SYSTEM CAPACITY............. 26

TORQUE CHART........................ 26

SPECIAL TOOLS

COOLING............................. 26

GENERAL INFORMATION

ACCESSORY DRIVE BELTS

The accessory drive system utilizes two different

style of drive belts. The conventional V-belt and the

Poly-V belt are used to drive the generator, air con-

ditioning compressor, power steering pump and waterpump. Satisfactory performance of these belts

depends on belt condition and proper belt tension.

Belt tensioning should be performed with the aid of a

Burroughs gauge Special Tool C-4162. Because of

space limitations in the engine compartment, the use

of the gauge may be restricted. Raise the vehicle on a

hoist and then remove the splash shield to gain

access to the drive belts.

NSCOOLING SYSTEM 7 - 1

Page 216 of 1938

COOLING SYSTEM

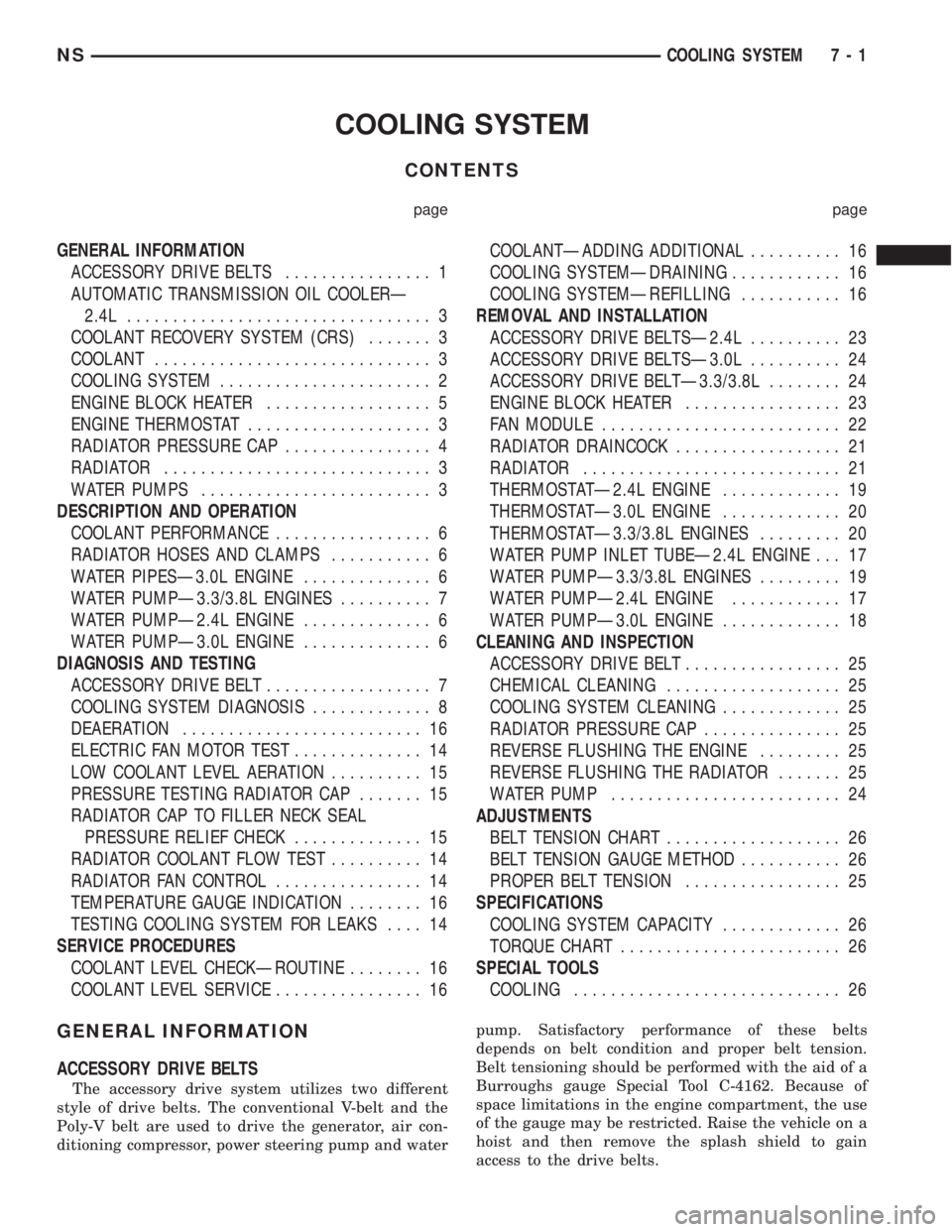

The cooling system has a radiator, coolant, electric fan

motor, shroud, pressure cap, thermostat, coolant reserve

system, transmission oil cooler, a water pump to circulate

the coolant, hoses, and clamps to complete the circuit.

²When Engine is cold: thermostat is closed, cool-

ing system has no flow through the radiator. The

coolant bypass flows through the engine only.

²

When Engine is warm: thermostat is open, cooling

system has bypass flow and coolant flow through radia-

tor.

Its primary purpose is to maintain engine temper-

ature in a range that will provide satisfactory engine

performance and emission levels under all expected

driving conditions. It also provides hot water (cool-

ant) for heater performance and cooling for automatic

transmission oil. It does this by transferring heat

from engine metal to coolant, moving this heated

coolant to the radiator, and then transferring this

heat to the ambient air.

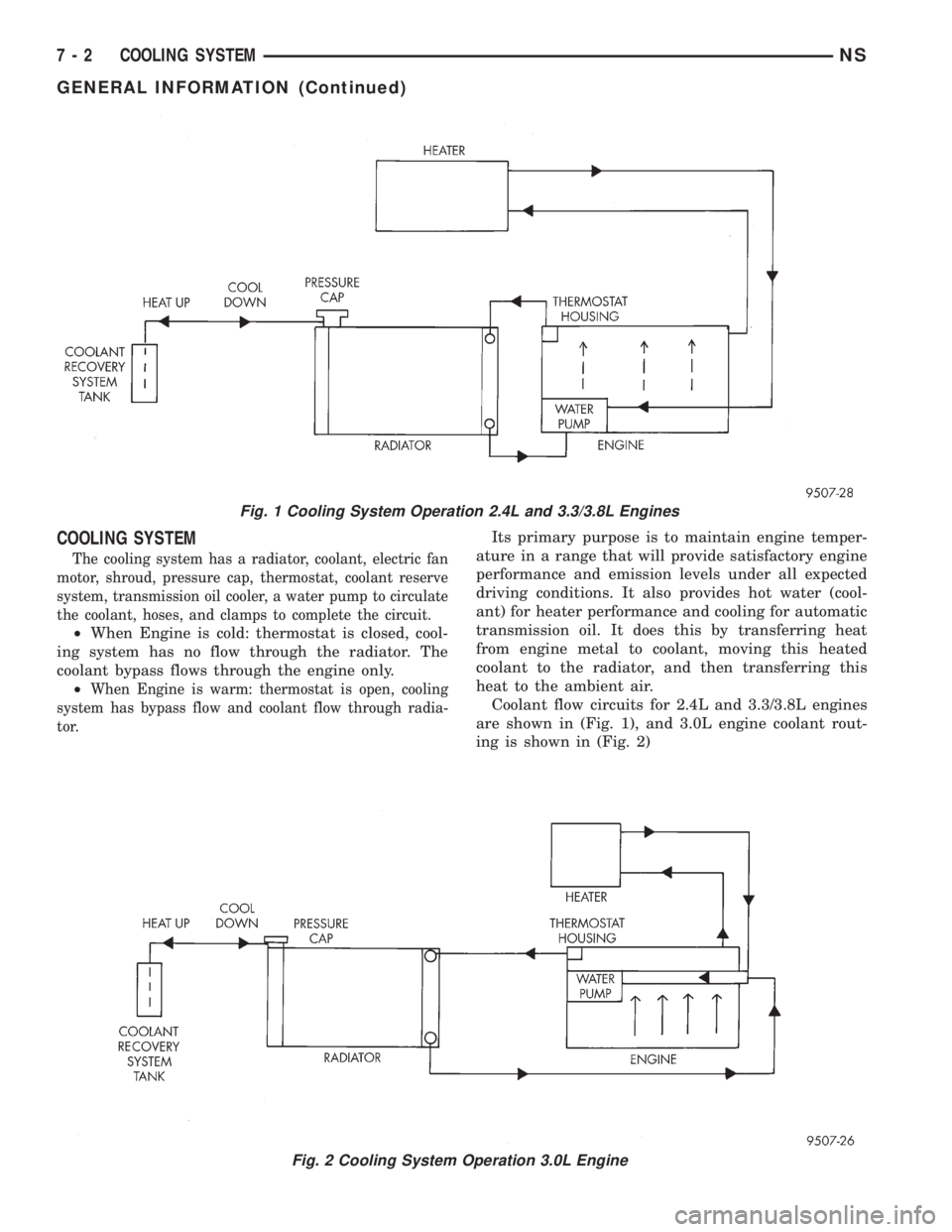

Coolant flow circuits for 2.4L and 3.3/3.8L engines

are shown in (Fig. 1), and 3.0L engine coolant rout-

ing is shown in (Fig. 2)

Fig. 1 Cooling System Operation 2.4L and 3.3/3.8L Engines

Fig. 2 Cooling System Operation 3.0L Engine

7 - 2 COOLING SYSTEMNS

GENERAL INFORMATION (Continued)

Page 217 of 1938

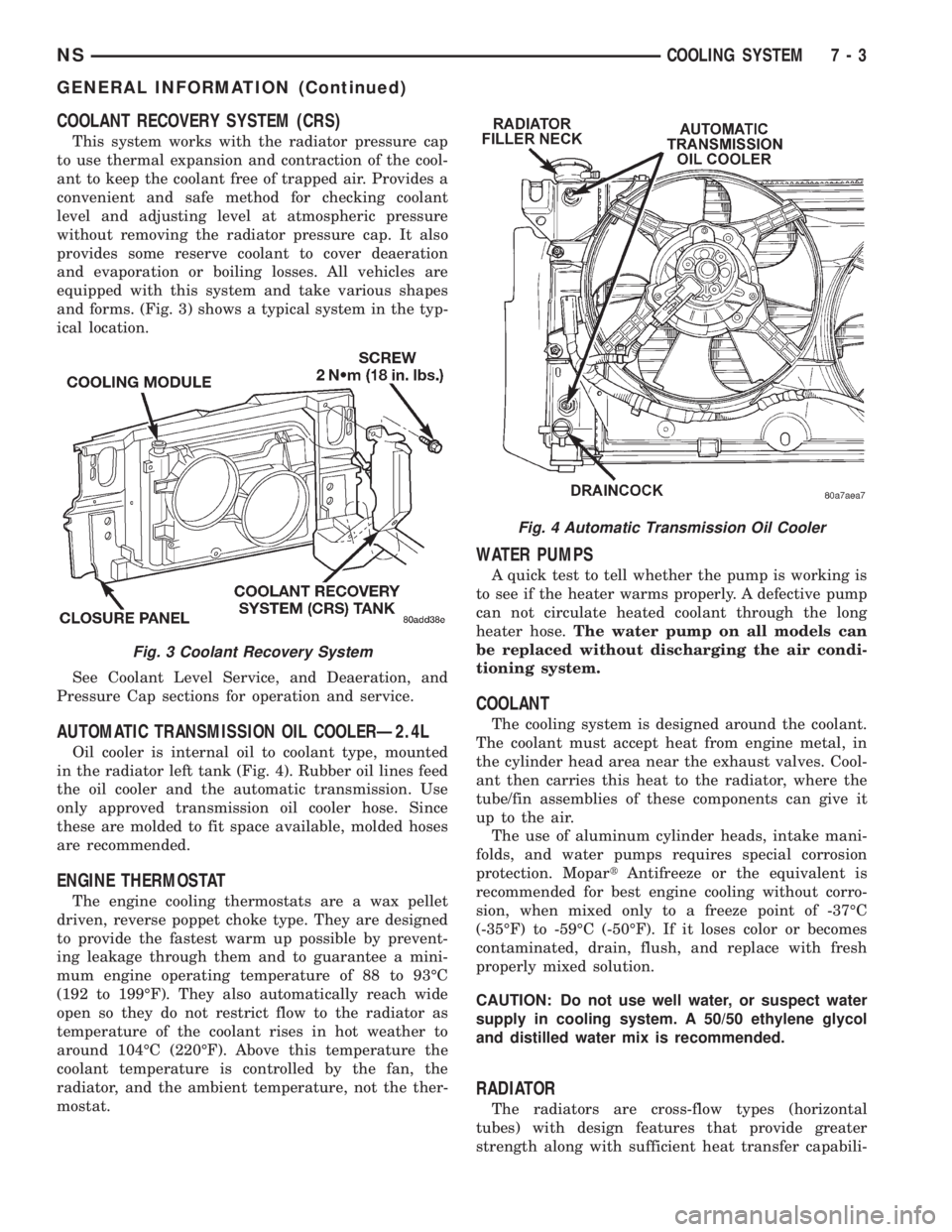

COOLANT RECOVERY SYSTEM (CRS)

This system works with the radiator pressure cap

to use thermal expansion and contraction of the cool-

ant to keep the coolant free of trapped air. Provides a

convenient and safe method for checking coolant

level and adjusting level at atmospheric pressure

without removing the radiator pressure cap. It also

provides some reserve coolant to cover deaeration

and evaporation or boiling losses. All vehicles are

equipped with this system and take various shapes

and forms. (Fig. 3) shows a typical system in the typ-

ical location.

See Coolant Level Service, and Deaeration, and

Pressure Cap sections for operation and service.

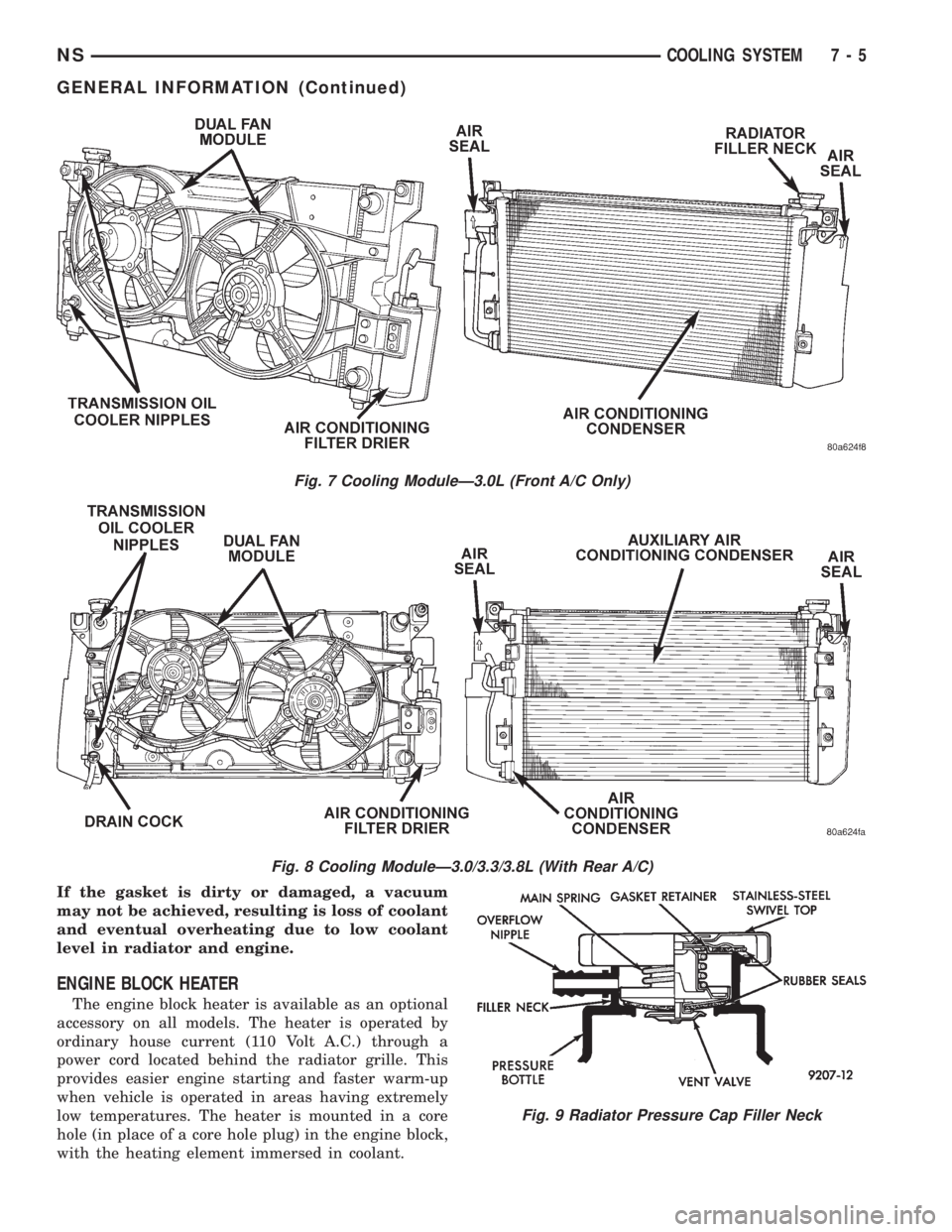

AUTOMATIC TRANSMISSION OIL COOLERÐ2.4L

Oil cooler is internal oil to coolant type, mounted

in the radiator left tank (Fig. 4). Rubber oil lines feed

the oil cooler and the automatic transmission. Use

only approved transmission oil cooler hose. Since

these are molded to fit space available, molded hoses

are recommended.

ENGINE THERMOSTAT

The engine cooling thermostats are a wax pellet

driven, reverse poppet choke type. They are designed

to provide the fastest warm up possible by prevent-

ing leakage through them and to guarantee a mini-

mum engine operating temperature of 88 to 93ÉC

(192 to 199ÉF). They also automatically reach wide

open so they do not restrict flow to the radiator as

temperature of the coolant rises in hot weather to

around 104ÉC (220ÉF). Above this temperature the

coolant temperature is controlled by the fan, the

radiator, and the ambient temperature, not the ther-

mostat.

WATER PUMPS

A quick test to tell whether the pump is working is

to see if the heater warms properly. A defective pump

can not circulate heated coolant through the long

heater hose.The water pump on all models can

be replaced without discharging the air condi-

tioning system.

COOLANT

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves. Cool-

ant then carries this heat to the radiator, where the

tube/fin assemblies of these components can give it

up to the air.

The use of aluminum cylinder heads, intake mani-

folds, and water pumps requires special corrosion

protection. MopartAntifreeze or the equivalent is

recommended for best engine cooling without corro-

sion, when mixed only to a freeze point of -37ÉC

(-35ÉF) to -59ÉC (-50ÉF). If it loses color or becomes

contaminated, drain, flush, and replace with fresh

properly mixed solution.

CAUTION: Do not use well water, or suspect water

supply in cooling system. A 50/50 ethylene glycol

and distilled water mix is recommended.

RADIATOR

The radiators are cross-flow types (horizontal

tubes) with design features that provide greater

strength along with sufficient heat transfer capabili-

Fig. 3 Coolant Recovery System

Fig. 4 Automatic Transmission Oil Cooler

NSCOOLING SYSTEM 7 - 3

GENERAL INFORMATION (Continued)

Page 219 of 1938

If the gasket is dirty or damaged, a vacuum

may not be achieved, resulting is loss of coolant

and eventual overheating due to low coolant

level in radiator and engine.

ENGINE BLOCK HEATER

The engine block heater is available as an optional

accessory on all models. The heater is operated by

ordinary house current (110 Volt A.C.) through a

power cord located behind the radiator grille. This

provides easier engine starting and faster warm-up

when vehicle is operated in areas having extremely

low temperatures. The heater is mounted in a core

hole (in place of a core hole plug) in the engine block,

with the heating element immersed in coolant.

Fig. 7 Cooling ModuleÐ3.0L (Front A/C Only)

Fig. 8 Cooling ModuleÐ3.0/3.3/3.8L (With Rear A/C)

Fig. 9 Radiator Pressure Cap Filler Neck

NSCOOLING SYSTEM 7 - 5

GENERAL INFORMATION (Continued)

Page 227 of 1938

CONDITION - AND CHECKS DIAGNOSIS

Inadequate Air Conditioning Performance - Cooling System Suspected

(1) Check for plugged air side of condenser and

radiator front and rear.(1) Wash out with low-velocity water.

(2) Assure fan runs whenever A/C head pressure

exceeds 1724 kPa (250 psi).(2) Repair as necessary.

(3) Check for missing air seals-recirculating air path.

(4) Assure correct cooling system parts.

Battery Dead - Suspect Fan Current Draw as Cause

(1) With a good, fully charged battery. (1) a - Assure fan control is operating properly.

(1) b - See charging system in Electrical, Group 8B.

Hot Smell - Suspect Cooling System

(1) Was temperature gauge high? (1) a - Yes, See9Gauge Reads High9

(1) b - No. See 2, 3, 4, and 5.

(2) Heat shields all in place? (2) a - Yes, See 3, 4, and 5.

(2) b - Repair or replace heat shields.

(3) Fan control operating properly? (3) a - Yes, See 4 and 5.

(3) b - No, See Radiator Fan Control this section.

(4) Heat exchanger air side plugged? (4) Clean as required.

(5) Engine missing or running rich? (5) Repair as required.

Poor Driveability - Suspect Failed Open Thermostat.

(1) Check diagnostics - is code 17 set? (Engine too

cold for too long)(1) If yes, change thermostat.

Poor Heater Performance - Suspect Failed Open Thermostat

(1) Does gauge read low? (1) See 3

(2) Check coolant level. (2) See 3

(3) Check diagnostics - is code 17 set? (Engine too

cold for too long)(3) If yes, change thermostat. If no, check heater

bypass valve, which should be closed except in Max

A/C or off mode; if not, see Heater and Air Conditioning

Group, 24.

Steaming, Observe Water Vapor Through Grill or Head Gap at Standstill at Idle - In Wet Weather

(1) This is normal. It is moisture, snow, or water on the

outside of the radiator that evaporates when the

thermostat opens to put hot coolant into the radiator.

This usually occurs in cold weather with no fan or air

flow to blow it away.(1) Normal condition - no service required.

NSCOOLING SYSTEM 7 - 13

DIAGNOSIS AND TESTING (Continued)

Page 229 of 1938

WARNING: WITH TOOL IN PLACE, PRESSURE

WILL BUILD UP FAST. EXCESSIVE PRESSURE

BUILT UP, BY CONTINUOUS ENGINE OPERATION,

MUST BE RELEASED TO A SAFE PRESSURE

POINT. NEVER PERMIT PRESSURE TO EXCEED 138

kPa (20 psi).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam emits from the tail pipe, it may

indicate a coolant leak caused by a faulty head gas-

ket, cracked engine block, or cracked cylinder head.

There may be internal leaks that can be deter-

mined by removing the oil dipstick. If water globules

appear intermixed with the oil it will indicate an

internal leak in the engine. If there is an internal

leak, the engine must be disassembled for repair.

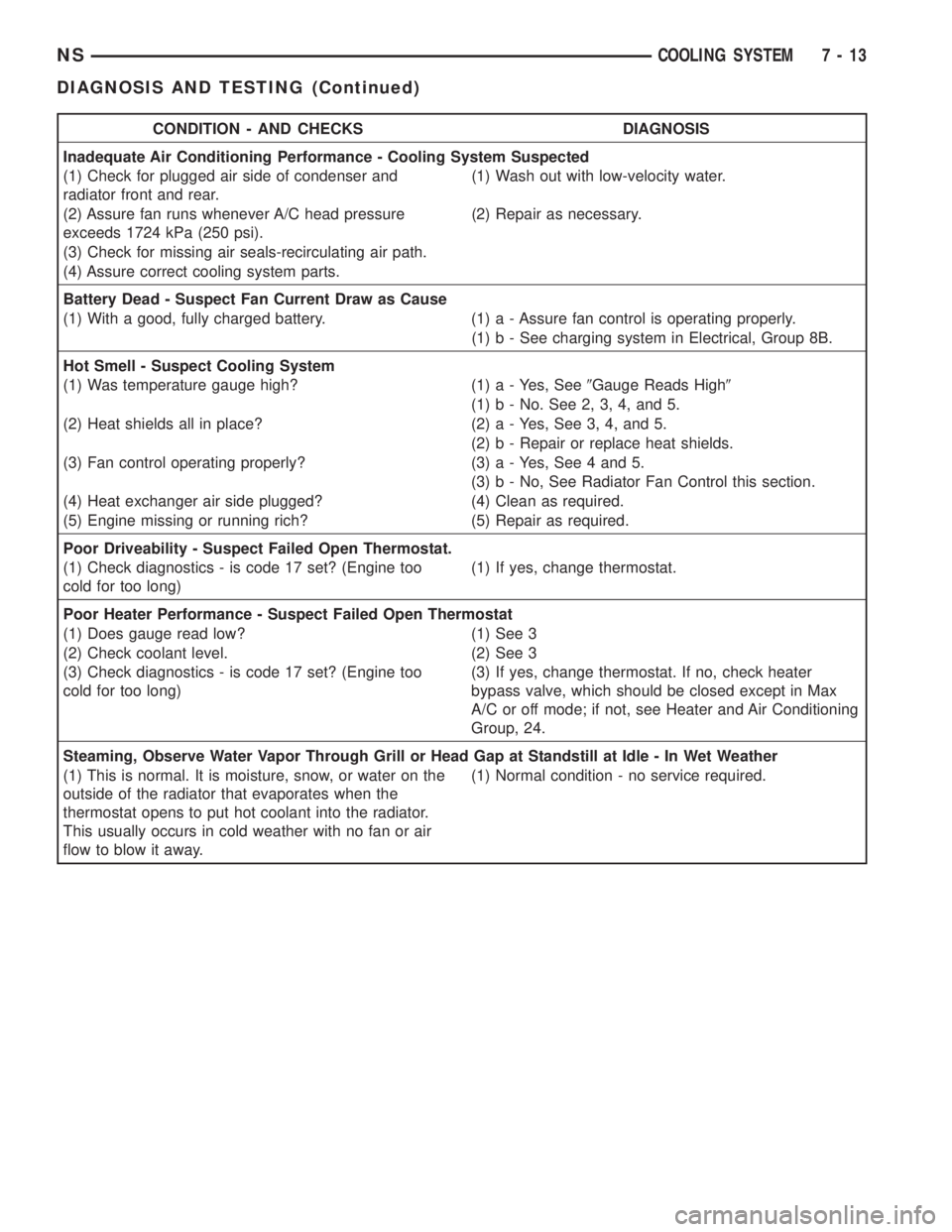

RADIATOR CAP TO FILLER NECK SEAL PRESSURE

RELIEF CHECK

The pressure cap upper gasket (seal) pressure

relief can be checked by removing the overflow hose

at the radiator filler neck nipple (Fig. 13). Attach the

Radiator Pressure Tool to the filler neck nipple and

pump air into the radiator. Pressure cap upper gas-

ket should relieve at 69-124 kPa (10-18 psi) and hold

pressure at 55 kPa (8 psi) minimum.

WARNING: THE WARNING WORDS ªDO NOT

OPEN HOTº ON THE RADIATOR PRESSURE CAP IS

A SAFETY PRECAUTION. WHEN HOT, PRESSURE

BUILDS UP IN COOLING SYSTEM. TO PREVENT

SCALDING OR INJURY, THE RADIATOR CAP

SHOULD NOT BE REMOVED WHILE THE SYSTEM

IS HOT OR UNDER PRESSURE.

There is no need to remove the radiator cap at any

timeexceptfor the following purposes:

(1) Check and adjust coolant freeze point. By add-

ing or subtracting coolant through CRS bottle.

(2) Refill system with new coolant.

(3) Conducting service procedures.

(4) Checking for vacuum leaks.WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE REMOVING

CAP. THEN PLACE A SHOP TOWEL OVER THE CAP

AND WITHOUT PUSHING DOWN ROTATE COUN-

TERCLOCKWISE TO THE FIRST STOP. ALLOW FLU-

IDS TO ESCAPE THROUGH THE OVERFLOW TUBE

AND WHEN THE SYSTEM STOPS PUSHING COOL-

ANT AND STEAM INTO THE CRS TANK AND PRES-

SURE DROPS PUSH DOWN AND REMOVE THE CAP

COMPLETELY. SQUEEZING THE RADIATOR INLET

HOSE WITH A SHOP TOWEL (TO CHECK PRES-

SURE) BEFORE AND AFTER TURNING TO THE

FIRST STOP IS RECOMMENDED.

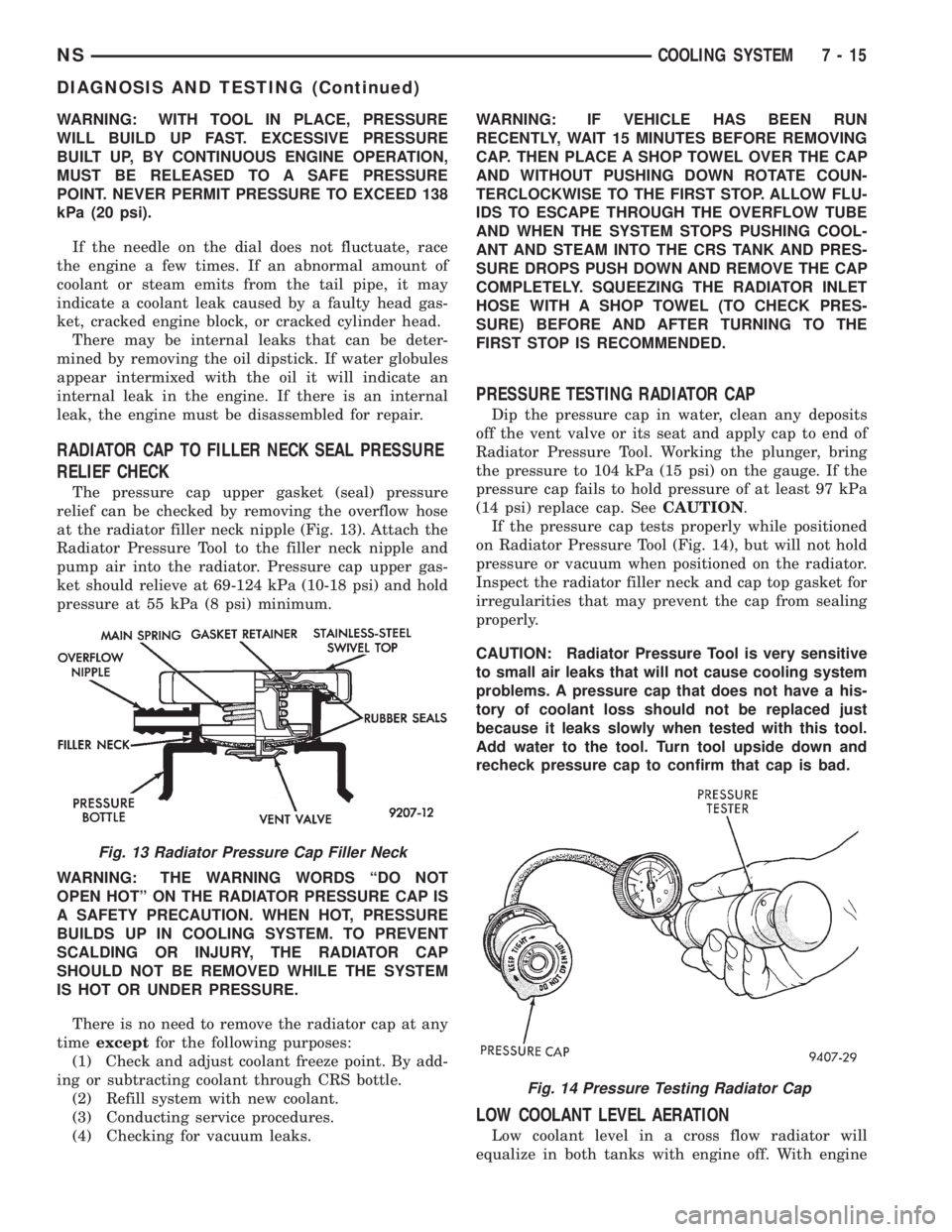

PRESSURE TESTING RADIATOR CAP

Dip the pressure cap in water, clean any deposits

off the vent valve or its seat and apply cap to end of

Radiator Pressure Tool. Working the plunger, bring

the pressure to 104 kPa (15 psi) on the gauge. If the

pressure cap fails to hold pressure of at least 97 kPa

(14 psi) replace cap. SeeCAUTION.

If the pressure cap tests properly while positioned

on Radiator Pressure Tool (Fig. 14), but will not hold

pressure or vacuum when positioned on the radiator.

Inspect the radiator filler neck and cap top gasket for

irregularities that may prevent the cap from sealing

properly.

CAUTION: Radiator Pressure Tool is very sensitive

to small air leaks that will not cause cooling system

problems. A pressure cap that does not have a his-

tory of coolant loss should not be replaced just

because it leaks slowly when tested with this tool.

Add water to the tool. Turn tool upside down and

recheck pressure cap to confirm that cap is bad.

LOW COOLANT LEVEL AERATION

Low coolant level in a cross flow radiator will

equalize in both tanks with engine off. With engine

Fig. 13 Radiator Pressure Cap Filler Neck

Fig. 14 Pressure Testing Radiator Cap

NSCOOLING SYSTEM 7 - 15

DIAGNOSIS AND TESTING (Continued)