Gear box CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 25 of 1938

boxes behind the front wheels and forward of the

rear wheels inboard of the rocker panel weld seam.

TOWINGÐFRONT WHEEL LIFT

Chrysler Corporation recommends that a vehicle be

towed with the front end lifted, whenever possible. A

90 cm (36 in.) length of 4x4 wood beam can be placed

between the wheel lift device and the bottom of the

fascia to prevent damage to vehicle during the lifting

operation. The beam can removed after lifting the

front of the vehicle.

TOWINGÐREAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²3-speed automatic transaxle vehicles can be flat

towed at speeds not to exceed 40 km/h (25 mph) for

not more than 25 km (15 miles). The steering column

must be unlocked and gear selector in neutral.

²4-speed electronic automatic transaxle vehicles

can be flat towed at speeds not to exceed 72 km/h (44

mph) for not more than 160 km (100 miles). The

steering column must be unlocked and gear selector

in neutral.

HOISTING RECOMMENDATIONS

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT ORSECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

CAUTION: Do not position hoisting device on sus-

pension components or front crossmember, dam-

age to vehicle can result.

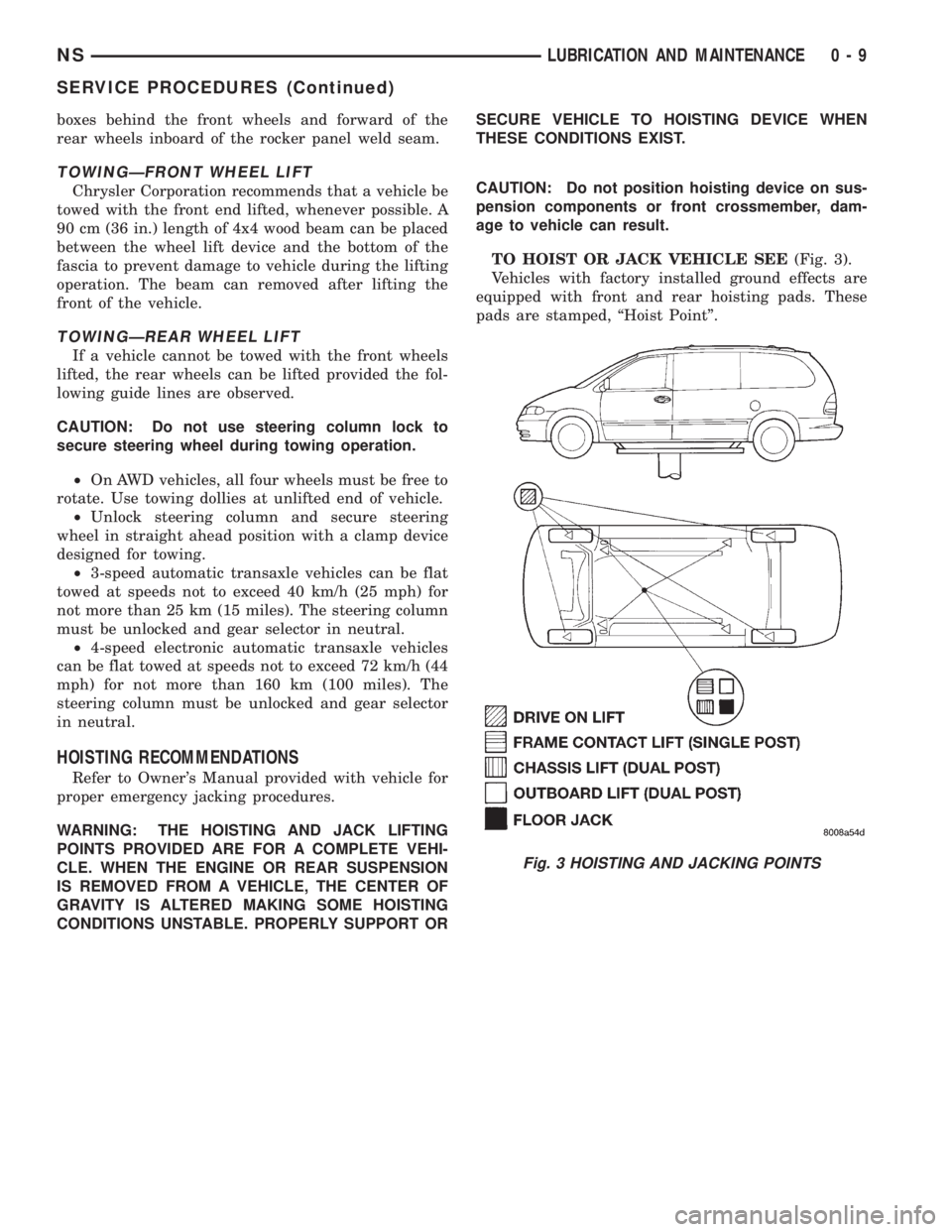

TO HOIST OR JACK VEHICLE SEE(Fig. 3).

Vehicles with factory installed ground effects are

equipped with front and rear hoisting pads. These

pads are stamped, ªHoist Pointº.

Fig. 3 HOISTING AND JACKING POINTS

NSLUBRICATION AND MAINTENANCE 0 - 9

SERVICE PROCEDURES (Continued)

Page 32 of 1938

NS vehicles can be tied to a flat bed device using

the reinforced loops located under the front and rear

bumpers on the drivers side of the vehicle. There are

also four reinforced elongated holes for T or R-hooks

located on the bottom of the front frame rail torque

boxes behind the front wheels and forward of the

rear wheels inboard of the rocker panel weld seam.

TOWINGÐFRONT WHEEL LIFT

Chrysler International recommends that a vehicle

be towed with the front end lifted, whenever possible.

A 90 cm (36 in.) length of 4x4 wood beam can be

placed between the wheel lift device and the bottom

of the fascia to prevent damage to vehicle during the

lifting operation. The beam can removed after lifting

the front of the vehicle.

TOWINGÐREAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²4-speed electronic automatic transaxle vehicles

can be flat towed at speeds not to exceed 72 km/h (44

mph) for not more than 160 km (100 miles). The

steering column must be unlocked and gear selector

in neutral.

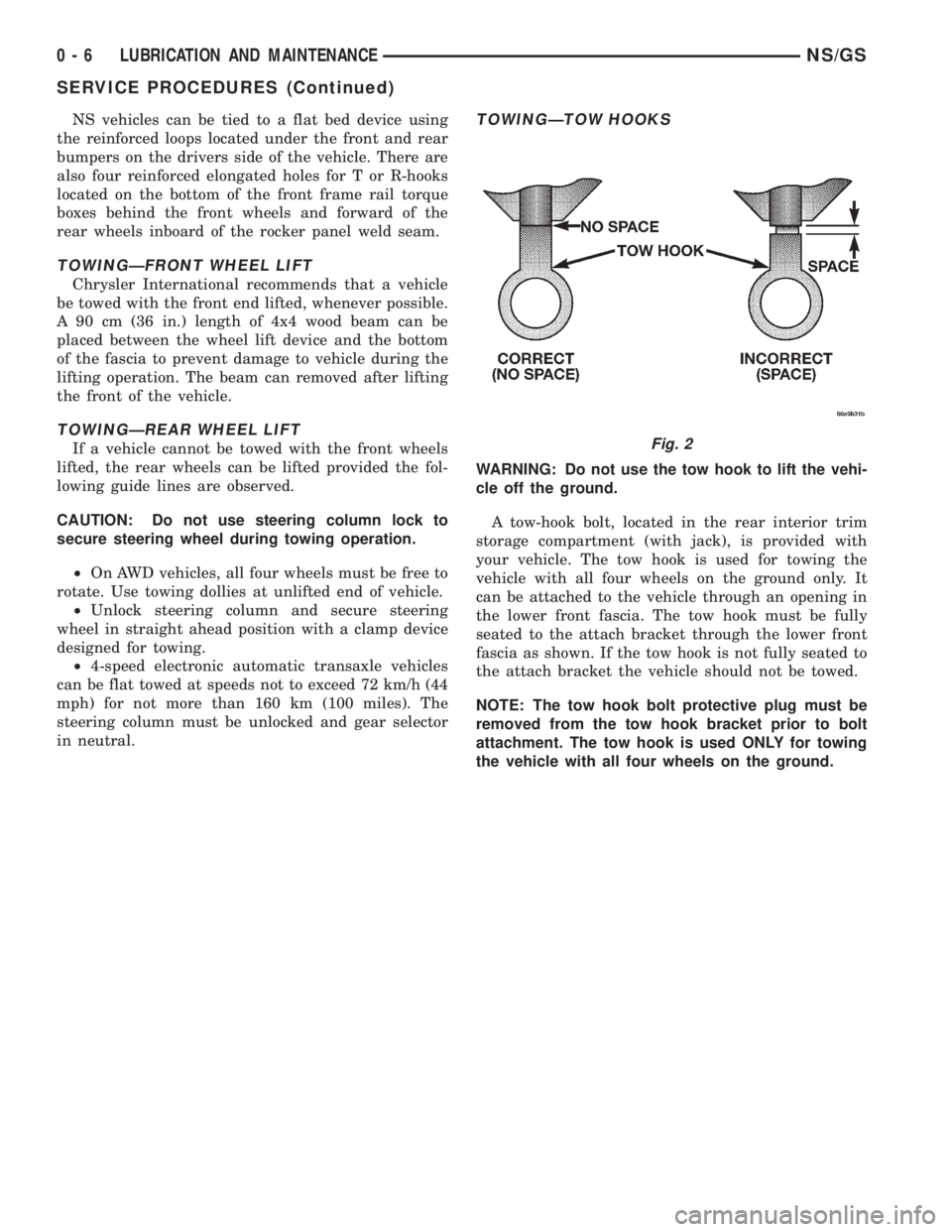

TOWINGÐTOW HOOKS

WARNING: Do not use the tow hook to lift the vehi-

cle off the ground.

A tow-hook bolt, located in the rear interior trim

storage compartment (with jack), is provided with

your vehicle. The tow hook is used for towing the

vehicle with all four wheels on the ground only. It

can be attached to the vehicle through an opening in

the lower front fascia. The tow hook must be fully

seated to the attach bracket through the lower front

fascia as shown. If the tow hook is not fully seated to

the attach bracket the vehicle should not be towed.

NOTE: The tow hook bolt protective plug must be

removed from the tow hook bracket prior to bolt

attachment. The tow hook is used ONLY for towing

the vehicle with all four wheels on the ground.

Fig. 2

0 - 6 LUBRICATION AND MAINTENANCENS/GS

SERVICE PROCEDURES (Continued)

Page 196 of 1938

Upon application of the brake pedal, the lever

should move down, turning the star wheel. A definite

rotation of the star wheel should be seen if the auto-

matic adjuster is working properly. If no rotation of

the star wheel is observed when the pedal is consec-

utively pressed and released, the respective drum

will have to be removed and the adjuster serviced.

MASTER CYLINDER FLUID LEVEL CHECK

The master cylinder used in this vehicle has the

same fluid level markings as the master cylinders

used in other brake systems on the side of the fluid

resevoir. Refer to the Master Cylinder Fluid Level

Check in the Diagnosis and Testing section of group

5 for more information

REMOVAL AND INSTALLATION

FRONT PARK BRAKE CABLE AND LEVER

ASSEMBLY-RHD&LHD VEHICLES

REMOVE

(1) Raise vehicle on jackstands or centered on a

hoist. See Hoisting in the Lubrication and Mainte-

nance group of this service manual.

(2) Remove the intermediate and left rear park

brake cable from the park brake cable equalizer (Fig.

2).

(3) Remove the front park cable housing retainer

from body outrigger bracket (Fig. 3). Cable is remov-

able by sliding a 14 mm box wrench over cable

retainer and compressing the three retaining fingers.

Alternate method is to use an aircraft type hose

clamp and screwdriver.(4) Remove the two (2) retaining nuts and (2)

retaining bolts from the bottom of the parking brake/

gearshift lever bracket.

(5) Lower vehicle.

(6) Carefully lift the base of the gearshift boot

from the gearshift console to access the screws (Fig.

4).

Fig. 2 Park Brake Cable Attachment To Equalizer

Fig. 3 Front Park Brake Cable Attachment To Body

Fig. 4 Console and Gearshift boot

5 - 2 BRAKESNS/GS

DIAGNOSIS AND TESTING (Continued)

Page 197 of 1938

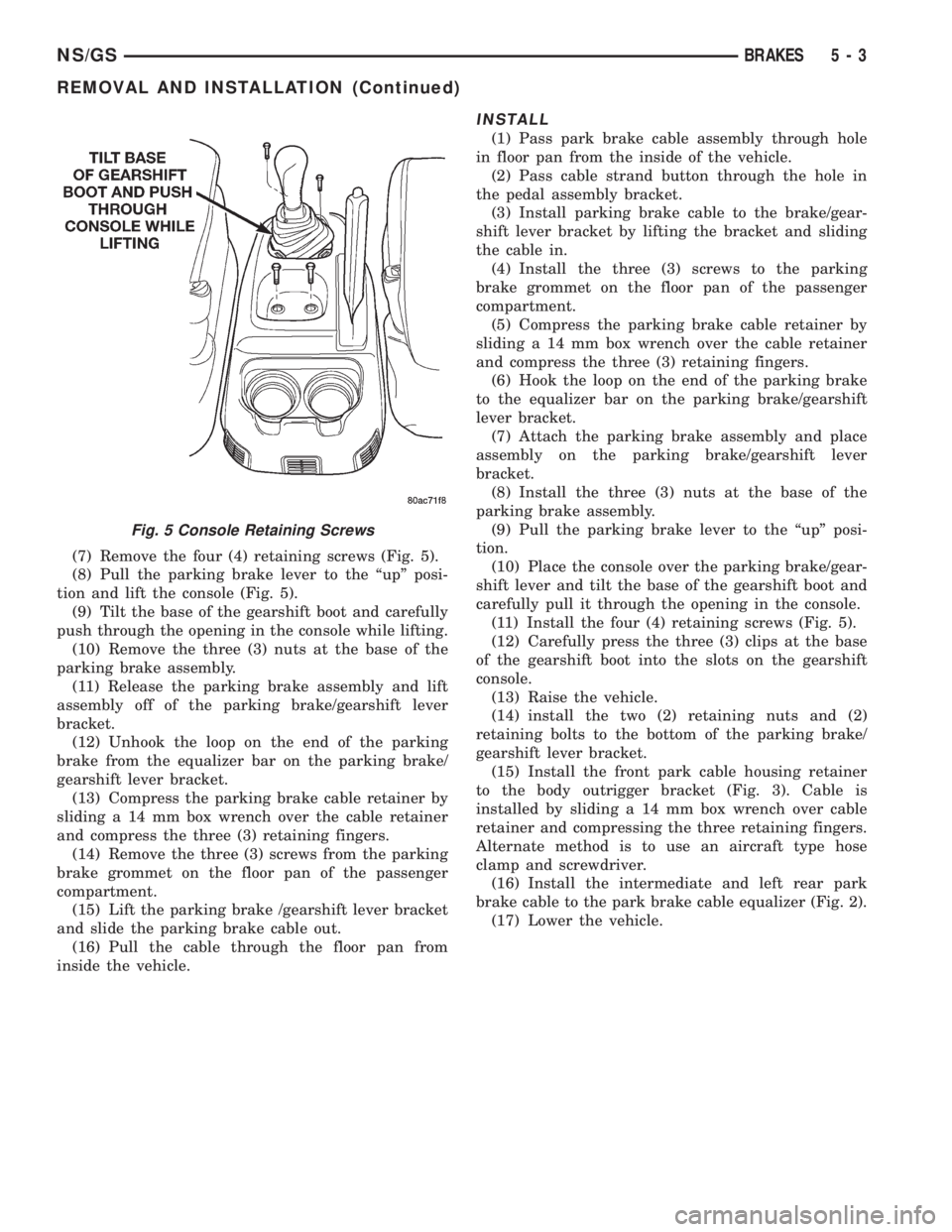

(7) Remove the four (4) retaining screws (Fig. 5).

(8) Pull the parking brake lever to the ªupº posi-

tion and lift the console (Fig. 5).

(9) Tilt the base of the gearshift boot and carefully

push through the opening in the console while lifting.

(10) Remove the three (3) nuts at the base of the

parking brake assembly.

(11) Release the parking brake assembly and lift

assembly off of the parking brake/gearshift lever

bracket.

(12) Unhook the loop on the end of the parking

brake from the equalizer bar on the parking brake/

gearshift lever bracket.

(13) Compress the parking brake cable retainer by

sliding a 14 mm box wrench over the cable retainer

and compress the three (3) retaining fingers.

(14) Remove the three (3) screws from the parking

brake grommet on the floor pan of the passenger

compartment.

(15) Lift the parking brake /gearshift lever bracket

and slide the parking brake cable out.

(16) Pull the cable through the floor pan from

inside the vehicle.

INSTALL

(1) Pass park brake cable assembly through hole

in floor pan from the inside of the vehicle.

(2) Pass cable strand button through the hole in

the pedal assembly bracket.

(3) Install parking brake cable to the brake/gear-

shift lever bracket by lifting the bracket and sliding

the cable in.

(4) Install the three (3) screws to the parking

brake grommet on the floor pan of the passenger

compartment.

(5) Compress the parking brake cable retainer by

sliding a 14 mm box wrench over the cable retainer

and compress the three (3) retaining fingers.

(6) Hook the loop on the end of the parking brake

to the equalizer bar on the parking brake/gearshift

lever bracket.

(7) Attach the parking brake assembly and place

assembly on the parking brake/gearshift lever

bracket.

(8) Install the three (3) nuts at the base of the

parking brake assembly.

(9) Pull the parking brake lever to the ªupº posi-

tion.

(10) Place the console over the parking brake/gear-

shift lever and tilt the base of the gearshift boot and

carefully pull it through the opening in the console.

(11) Install the four (4) retaining screws (Fig. 5).

(12) Carefully press the three (3) clips at the base

of the gearshift boot into the slots on the gearshift

console.

(13) Raise the vehicle.

(14) install the two (2) retaining nuts and (2)

retaining bolts to the bottom of the parking brake/

gearshift lever bracket.

(15) Install the front park cable housing retainer

to the body outrigger bracket (Fig. 3). Cable is

installed by sliding a 14 mm box wrench over cable

retainer and compressing the three retaining fingers.

Alternate method is to use an aircraft type hose

clamp and screwdriver.

(16) Install the intermediate and left rear park

brake cable to the park brake cable equalizer (Fig. 2).

(17) Lower the vehicle.

Fig. 5 Console Retaining Screws

NS/GSBRAKES 5 - 3

REMOVAL AND INSTALLATION (Continued)

Page 361 of 1938

(8) Using the indicator adjuster thumbwheel on

the indicator clip below the steering column. Rotate

the indicator thumbwheel to position the indicator

calibration arrow to the center of the N slot on the

instrument cluster mask.

(9) After the indicator has been properly adjusted,

move the shift lever through each gear position to

verify the appropriate gear position has been selected

and the slot is fully covered by the indicator. The left

edge of the indicator will just peek at the left edge of

the P slot in Park.

(10) If the indicator is not covering each of the

selected gear positions when selected, place the shift

lever back into neutral N and readjust the indicator.

Repeat the process until each gear is covered when

selected.

(11) Install the metal knee blocker panel.

(12) Install the lower steering column cover.

INSTRUMENT PANEL

The instrument panel is removed as a unit. The

steering column and wiring harnesses are assembled

into the panel before installation. Service procedures

for interior trim not related to the instrument panel

can be found in Group 23, Body.

REMOVAL

(1) Disconnect the battery, negative cable first.

(2) Remove the lower console.

(3) Remove the screw holding the lower heat duct

to the instrument panel support (Fig. 26).

(4) Disconnect the heat duct from the vehicle.

(5) Remove the bolts holding the lower supports to

the instrument panel frame (Fig. 27).(6) Remove the bolts holding the lower supports to

the floor pan.

(7) Remove the right and left end covers.

(8) Disconnect the wire connectors from the Pas-

senger Airbag Module.

(9) Remove the front door sill trim covers.

(10) Remove the A-pillar trim covers.

(11) Remove the glove box.

(12) Disconnect the antenna lead connector from

behind the glove box.

(13) Remove the lower steering column cover.

(14) Remove the knee blocker panel.

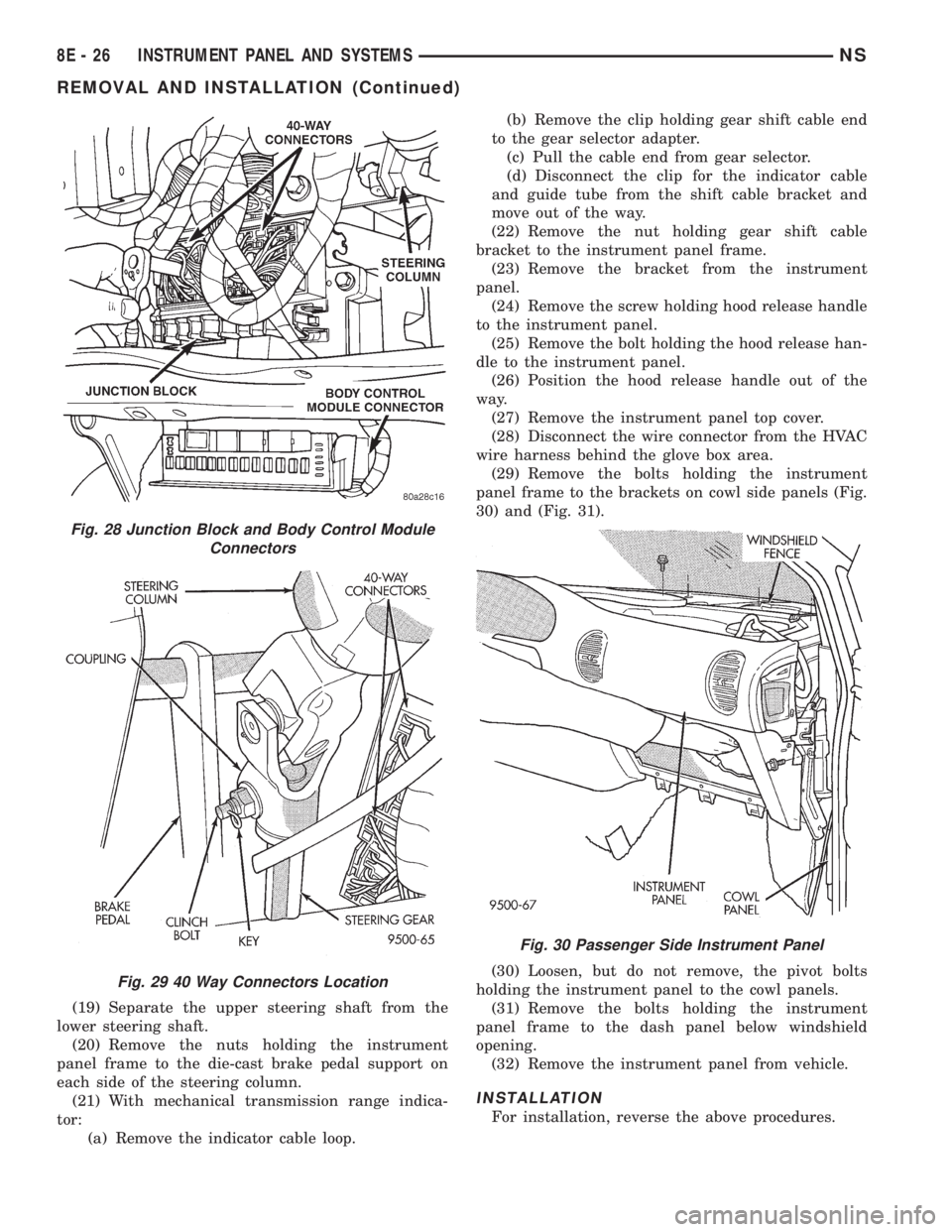

(15) Disconnect the lower two, forty pin wire har-

ness connectors, from the main Junction Block near

left cowl side panel (Fig. 28).

(16) Disconnect the instrument panel wire harness

connector from the bottom of Body Control Module.

(17) Disconnect the two forty pin connectors from

the right of the steering column (Fig. 29).

(18) Remove the clinch bolt holding upper the

steering shaft to the lower steering shaft (Fig. 29).

Fig. 25 Range Indicator Cable

Fig. 26 Heat Duct

Fig. 27 Lower Supports

NSINSTRUMENT PANEL AND SYSTEMS 8E - 25

REMOVAL AND INSTALLATION (Continued)

Page 362 of 1938

(19) Separate the upper steering shaft from the

lower steering shaft.

(20) Remove the nuts holding the instrument

panel frame to the die-cast brake pedal support on

each side of the steering column.

(21) With mechanical transmission range indica-

tor:

(a) Remove the indicator cable loop.(b) Remove the clip holding gear shift cable end

to the gear selector adapter.

(c) Pull the cable end from gear selector.

(d) Disconnect the clip for the indicator cable

and guide tube from the shift cable bracket and

move out of the way.

(22) Remove the nut holding gear shift cable

bracket to the instrument panel frame.

(23) Remove the bracket from the instrument

panel.

(24) Remove the screw holding hood release handle

to the instrument panel.

(25) Remove the bolt holding the hood release han-

dle to the instrument panel.

(26) Position the hood release handle out of the

way.

(27) Remove the instrument panel top cover.

(28) Disconnect the wire connector from the HVAC

wire harness behind the glove box area.

(29) Remove the bolts holding the instrument

panel frame to the brackets on cowl side panels (Fig.

30) and (Fig. 31).

(30) Loosen, but do not remove, the pivot bolts

holding the instrument panel to the cowl panels.

(31) Remove the bolts holding the instrument

panel frame to the dash panel below windshield

opening.

(32) Remove the instrument panel from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Fig. 28 Junction Block and Body Control Module

Connectors

Fig. 29 40 Way Connectors Location

Fig. 30 Passenger Side Instrument Panel

8E - 26 INSTRUMENT PANEL AND SYSTEMSNS

REMOVAL AND INSTALLATION (Continued)

Page 393 of 1938

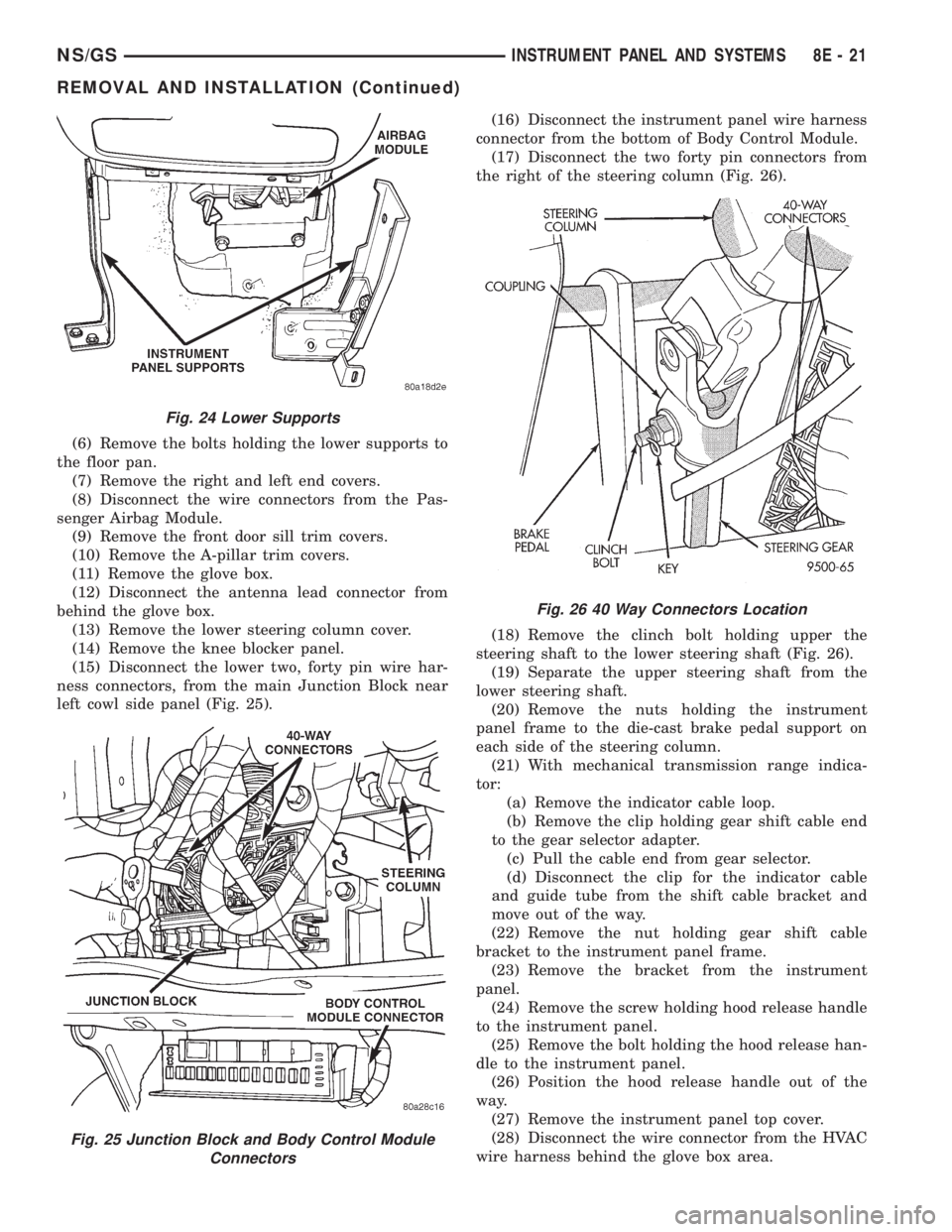

(6) Remove the bolts holding the lower supports to

the floor pan.

(7) Remove the right and left end covers.

(8) Disconnect the wire connectors from the Pas-

senger Airbag Module.

(9) Remove the front door sill trim covers.

(10) Remove the A-pillar trim covers.

(11) Remove the glove box.

(12) Disconnect the antenna lead connector from

behind the glove box.

(13) Remove the lower steering column cover.

(14) Remove the knee blocker panel.

(15) Disconnect the lower two, forty pin wire har-

ness connectors, from the main Junction Block near

left cowl side panel (Fig. 25).(16) Disconnect the instrument panel wire harness

connector from the bottom of Body Control Module.

(17) Disconnect the two forty pin connectors from

the right of the steering column (Fig. 26).

(18) Remove the clinch bolt holding upper the

steering shaft to the lower steering shaft (Fig. 26).

(19) Separate the upper steering shaft from the

lower steering shaft.

(20) Remove the nuts holding the instrument

panel frame to the die-cast brake pedal support on

each side of the steering column.

(21) With mechanical transmission range indica-

tor:

(a) Remove the indicator cable loop.

(b) Remove the clip holding gear shift cable end

to the gear selector adapter.

(c) Pull the cable end from gear selector.

(d) Disconnect the clip for the indicator cable

and guide tube from the shift cable bracket and

move out of the way.

(22) Remove the nut holding gear shift cable

bracket to the instrument panel frame.

(23) Remove the bracket from the instrument

panel.

(24) Remove the screw holding hood release handle

to the instrument panel.

(25) Remove the bolt holding the hood release han-

dle to the instrument panel.

(26) Position the hood release handle out of the

way.

(27) Remove the instrument panel top cover.

(28) Disconnect the wire connector from the HVAC

wire harness behind the glove box area.

Fig. 24 Lower Supports

Fig. 25 Junction Block and Body Control Module

Connectors

Fig. 26 40 Way Connectors Location

NS/GSINSTRUMENT PANEL AND SYSTEMS 8E - 21

REMOVAL AND INSTALLATION (Continued)

Page 1474 of 1938

(4) Raise the front wheels off the ground.

(5) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops at least 20 times.

(6) Check the fluid level add if necessary.

(7) Lower the vehicle, start the engine and turn

the steering wheel slowly from lock to lock.

(8) Stop the engine and check the fluid level and

refill as required.

(9) If the fluid is extremely foamy or milky look-

ing, allow the vehicle to stand a few minutes and

repeat the procedure.

CAUTION: Do not run a vehicle with foamy fluid for

an extended period. This may cause pump damage.

REMOVAL AND INSTALLATION

POWER STEERING PUMPÐ2.5L DIESEL

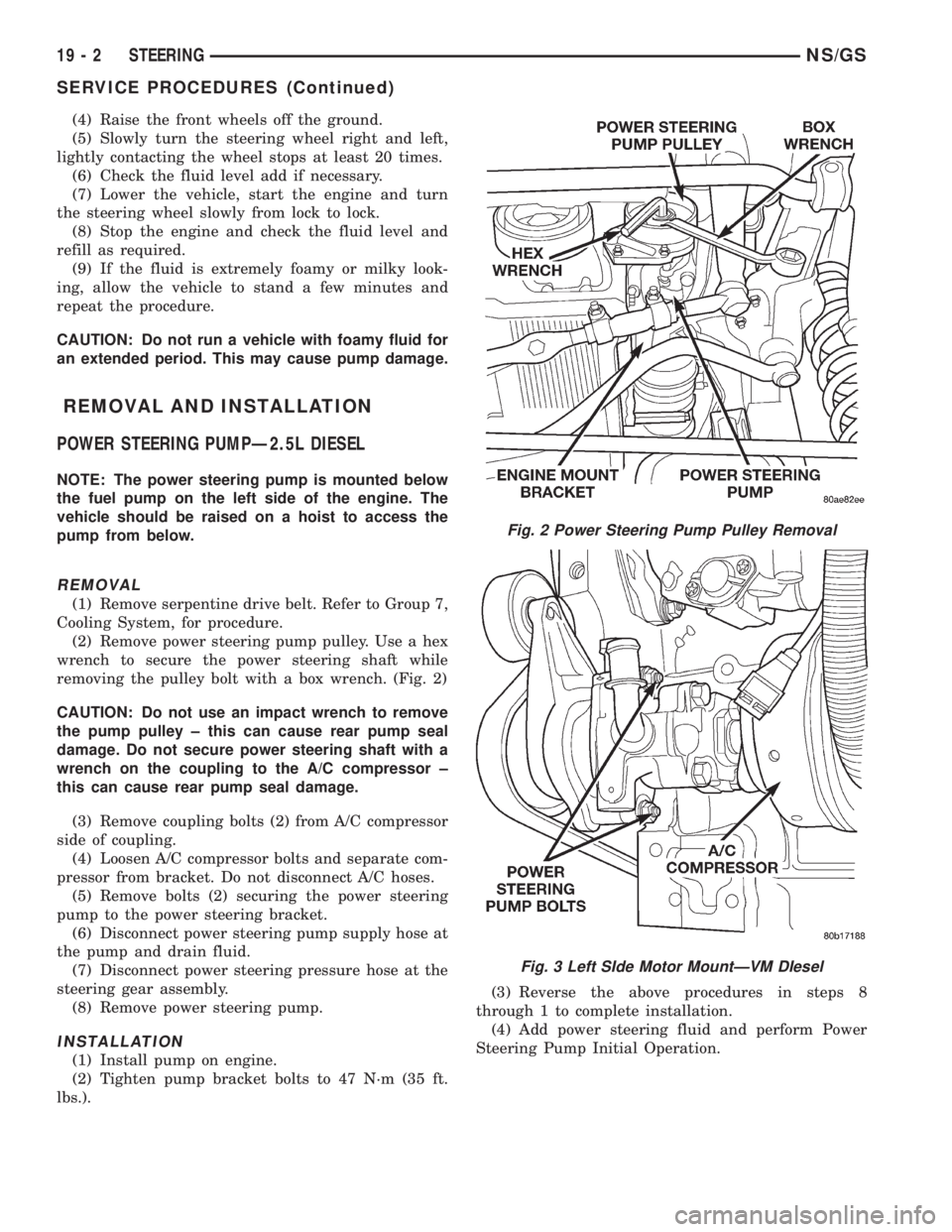

NOTE: The power steering pump is mounted below

the fuel pump on the left side of the engine. The

vehicle should be raised on a hoist to access the

pump from below.

REMOVAL

(1) Remove serpentine drive belt. Refer to Group 7,

Cooling System, for procedure.

(2) Remove power steering pump pulley. Use a hex

wrench to secure the power steering shaft while

removing the pulley bolt with a box wrench. (Fig. 2)

CAUTION: Do not use an impact wrench to remove

the pump pulley ± this can cause rear pump seal

damage. Do not secure power steering shaft with a

wrench on the coupling to the A/C compressor ±

this can cause rear pump seal damage.

(3) Remove coupling bolts (2) from A/C compressor

side of coupling.

(4) Loosen A/C compressor bolts and separate com-

pressor from bracket. Do not disconnect A/C hoses.

(5) Remove bolts (2) securing the power steering

pump to the power steering bracket.

(6) Disconnect power steering pump supply hose at

the pump and drain fluid.

(7) Disconnect power steering pressure hose at the

steering gear assembly.

(8) Remove power steering pump.

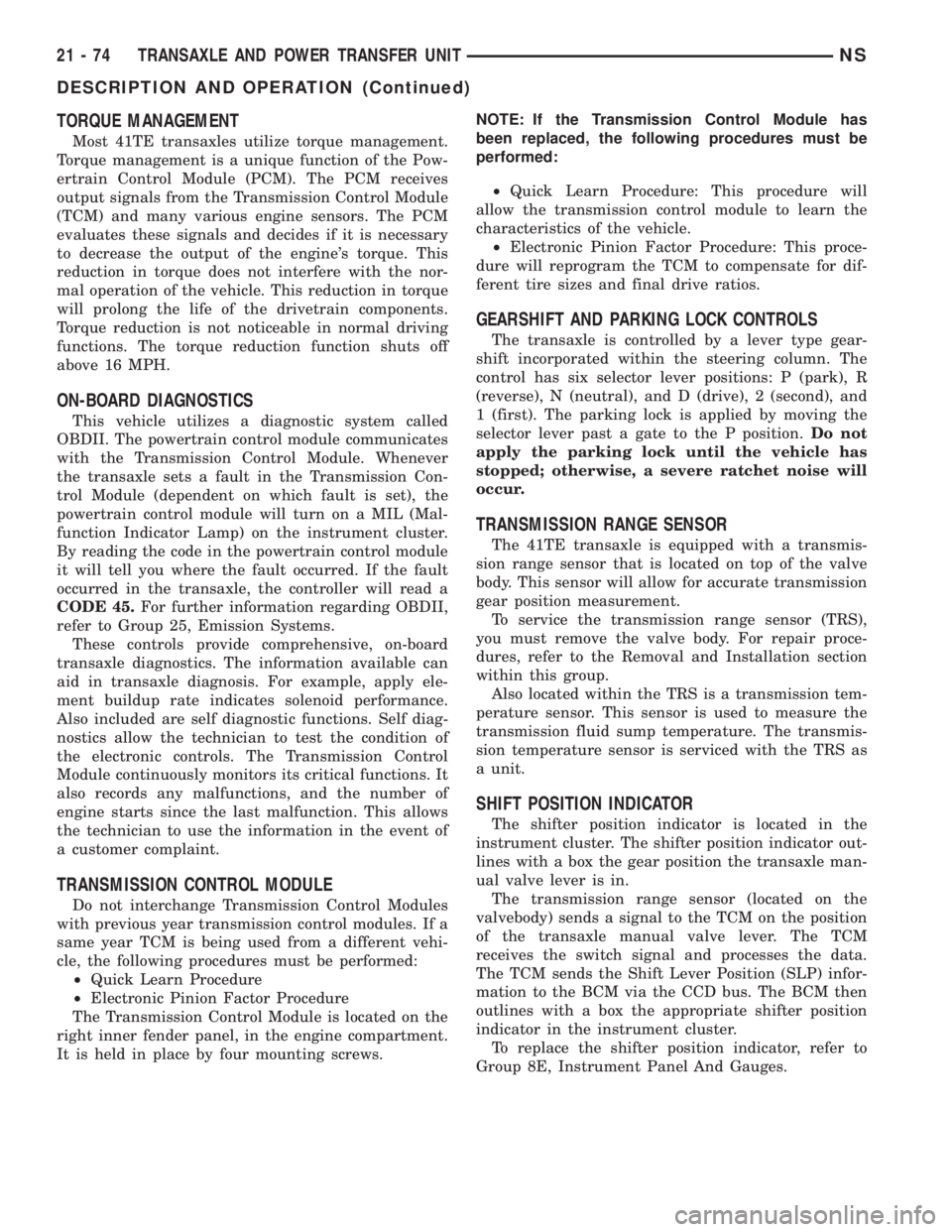

INSTALLATION

(1) Install pump on engine.

(2) Tighten pump bracket bolts to 47 N´m (35 ft.

lbs.).(3) Reverse the above procedures in steps 8

through 1 to complete installation.

(4) Add power steering fluid and perform Power

Steering Pump Initial Operation.

Fig. 2 Power Steering Pump Pulley Removal

Fig. 3 Left SIde Motor MountÐVM DIesel

19 - 2 STEERINGNS/GS

SERVICE PROCEDURES (Continued)

Page 1548 of 1938

TORQUE MANAGEMENT

Most 41TE transaxles utilize torque management.

Torque management is a unique function of the Pow-

ertrain Control Module (PCM). The PCM receives

output signals from the Transmission Control Module

(TCM) and many various engine sensors. The PCM

evaluates these signals and decides if it is necessary

to decrease the output of the engine's torque. This

reduction in torque does not interfere with the nor-

mal operation of the vehicle. This reduction in torque

will prolong the life of the drivetrain components.

Torque reduction is not noticeable in normal driving

functions. The torque reduction function shuts off

above 16 MPH.

ON-BOARD DIAGNOSTICS

This vehicle utilizes a diagnostic system called

OBDII. The powertrain control module communicates

with the Transmission Control Module. Whenever

the transaxle sets a fault in the Transmission Con-

trol Module (dependent on which fault is set), the

powertrain control module will turn on a MIL (Mal-

function Indicator Lamp) on the instrument cluster.

By reading the code in the powertrain control module

it will tell you where the fault occurred. If the fault

occurred in the transaxle, the controller will read a

CODE 45.For further information regarding OBDII,

refer to Group 25, Emission Systems.

These controls provide comprehensive, on-board

transaxle diagnostics. The information available can

aid in transaxle diagnosis. For example, apply ele-

ment buildup rate indicates solenoid performance.

Also included are self diagnostic functions. Self diag-

nostics allow the technician to test the condition of

the electronic controls. The Transmission Control

Module continuously monitors its critical functions. It

also records any malfunctions, and the number of

engine starts since the last malfunction. This allows

the technician to use the information in the event of

a customer complaint.

TRANSMISSION CONTROL MODULE

Do not interchange Transmission Control Modules

with previous year transmission control modules. If a

same year TCM is being used from a different vehi-

cle, the following procedures must be performed:

²Quick Learn Procedure

²Electronic Pinion Factor Procedure

The Transmission Control Module is located on the

right inner fender panel, in the engine compartment.

It is held in place by four mounting screws.NOTE: If the Transmission Control Module has

been replaced, the following procedures must be

performed:

²Quick Learn Procedure: This procedure will

allow the transmission control module to learn the

characteristics of the vehicle.

²Electronic Pinion Factor Procedure: This proce-

dure will reprogram the TCM to compensate for dif-

ferent tire sizes and final drive ratios.

GEARSHIFT AND PARKING LOCK CONTROLS

The transaxle is controlled by a lever type gear-

shift incorporated within the steering column. The

control has six selector lever positions: P (park), R

(reverse), N (neutral), and D (drive), 2 (second), and

1 (first). The parking lock is applied by moving the

selector lever past a gate to the P position.Do not

apply the parking lock until the vehicle has

stopped; otherwise, a severe ratchet noise will

occur.

TRANSMISSION RANGE SENSOR

The 41TE transaxle is equipped with a transmis-

sion range sensor that is located on top of the valve

body. This sensor will allow for accurate transmission

gear position measurement.

To service the transmission range sensor (TRS),

you must remove the valve body. For repair proce-

dures, refer to the Removal and Installation section

within this group.

Also located within the TRS is a transmission tem-

perature sensor. This sensor is used to measure the

transmission fluid sump temperature. The transmis-

sion temperature sensor is serviced with the TRS as

a unit.

SHIFT POSITION INDICATOR

The shifter position indicator is located in the

instrument cluster. The shifter position indicator out-

lines with a box the gear position the transaxle man-

ual valve lever is in.

The transmission range sensor (located on the

valvebody) sends a signal to the TCM on the position

of the transaxle manual valve lever. The TCM

receives the switch signal and processes the data.

The TCM sends the Shift Lever Position (SLP) infor-

mation to the BCM via the CCD bus. The BCM then

outlines with a box the appropriate shifter position

indicator in the instrument cluster.

To replace the shifter position indicator, refer to

Group 8E, Instrument Panel And Gauges.

21 - 74 TRANSAXLE AND POWER TRANSFER UNITNS

DESCRIPTION AND OPERATION (Continued)

Page 1708 of 1938

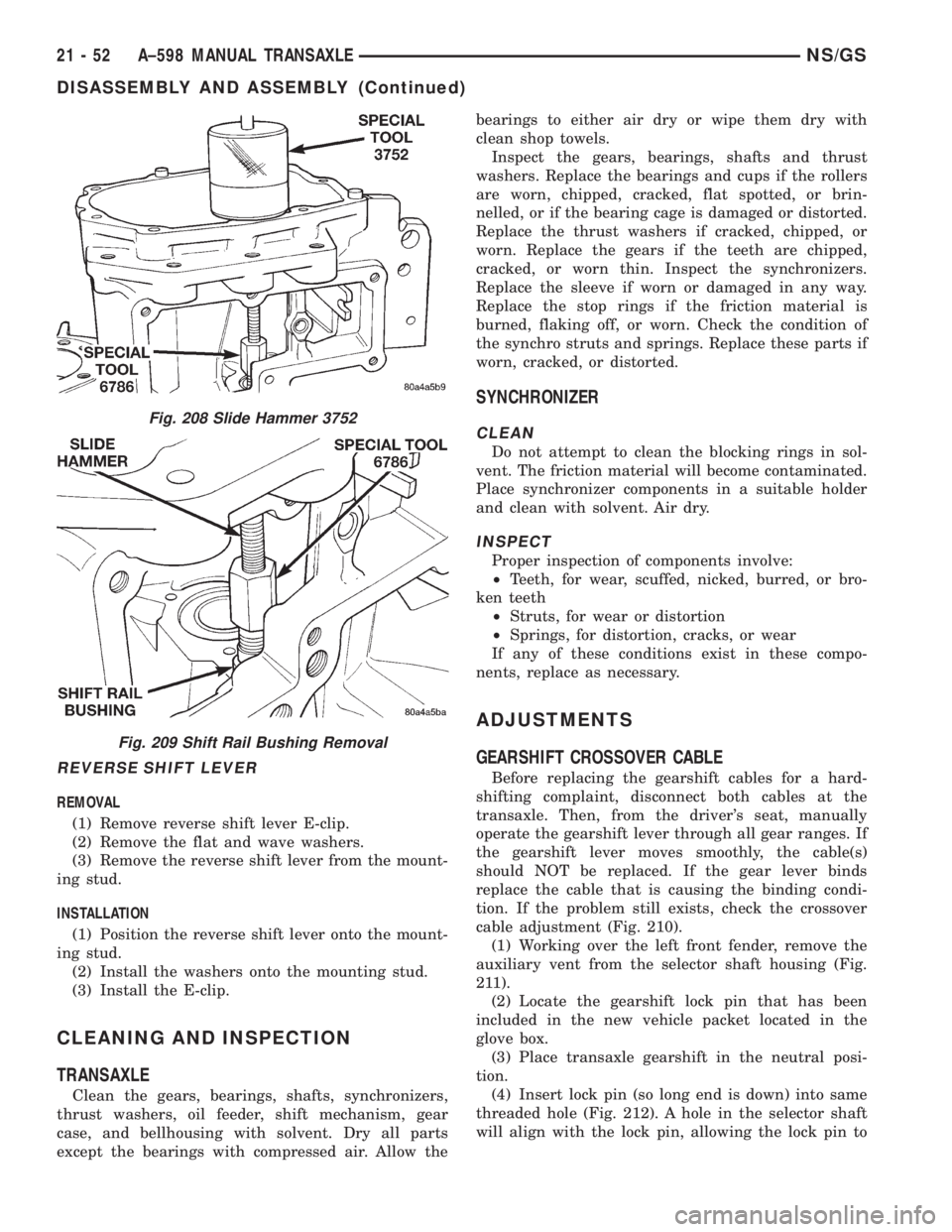

REVERSE SHIFT LEVER

REMOVAL

(1) Remove reverse shift lever E-clip.

(2) Remove the flat and wave washers.

(3) Remove the reverse shift lever from the mount-

ing stud.

INSTALLATION

(1) Position the reverse shift lever onto the mount-

ing stud.

(2) Install the washers onto the mounting stud.

(3) Install the E-clip.

CLEANING AND INSPECTION

TRANSAXLE

Clean the gears, bearings, shafts, synchronizers,

thrust washers, oil feeder, shift mechanism, gear

case, and bellhousing with solvent. Dry all parts

except the bearings with compressed air. Allow thebearings to either air dry or wipe them dry with

clean shop towels.

Inspect the gears, bearings, shafts and thrust

washers. Replace the bearings and cups if the rollers

are worn, chipped, cracked, flat spotted, or brin-

nelled, or if the bearing cage is damaged or distorted.

Replace the thrust washers if cracked, chipped, or

worn. Replace the gears if the teeth are chipped,

cracked, or worn thin. Inspect the synchronizers.

Replace the sleeve if worn or damaged in any way.

Replace the stop rings if the friction material is

burned, flaking off, or worn. Check the condition of

the synchro struts and springs. Replace these parts if

worn, cracked, or distorted.

SYNCHRONIZER

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECT

Proper inspection of components involve:

²Teeth, for wear, scuffed, nicked, burred, or bro-

ken teeth

²Struts, for wear or distortion

²Springs, for distortion, cracks, or wear

If any of these conditions exist in these compo-

nents, replace as necessary.

ADJUSTMENTS

GEARSHIFT CROSSOVER CABLE

Before replacing the gearshift cables for a hard-

shifting complaint, disconnect both cables at the

transaxle. Then, from the driver's seat, manually

operate the gearshift lever through all gear ranges. If

the gearshift lever moves smoothly, the cable(s)

should NOT be replaced. If the gear lever binds

replace the cable that is causing the binding condi-

tion. If the problem still exists, check the crossover

cable adjustment (Fig. 210).

(1) Working over the left front fender, remove the

auxiliary vent from the selector shaft housing (Fig.

211).

(2) Locate the gearshift lock pin that has been

included in the new vehicle packet located in the

glove box.

(3) Place transaxle gearshift in the neutral posi-

tion.

(4) Insert lock pin (so long end is down) into same

threaded hole (Fig. 212). A hole in the selector shaft

will align with the lock pin, allowing the lock pin to

Fig. 208 Slide Hammer 3752

Fig. 209 Shift Rail Bushing Removal

21 - 52 A±598 MANUAL TRANSAXLENS/GS

DISASSEMBLY AND ASSEMBLY (Continued)