fuel tank removal CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 171 of 1938

fluid accumulators temporarily store brake fluid that

is decayed from the wheel brakes during an ABS

cycle. This stored brake fluid is then used by the

pump in the HCU to provide build pressure for the

brake hydraulic system.

Additionally on vehicles that are equipped with

only ABS (non-traction control vehicles) there is a

mini brake fluid accumulator on the secondary

hydraulic circuit which protects the master cylinder's

seals during an ABS stop. There is also a noise

damping chamber on the primary hydraulic circuit.

On ABS equipped vehicles with traction control, in

addition to the brake fluid accumulators there are

also two noise damping chambers in the HCU.

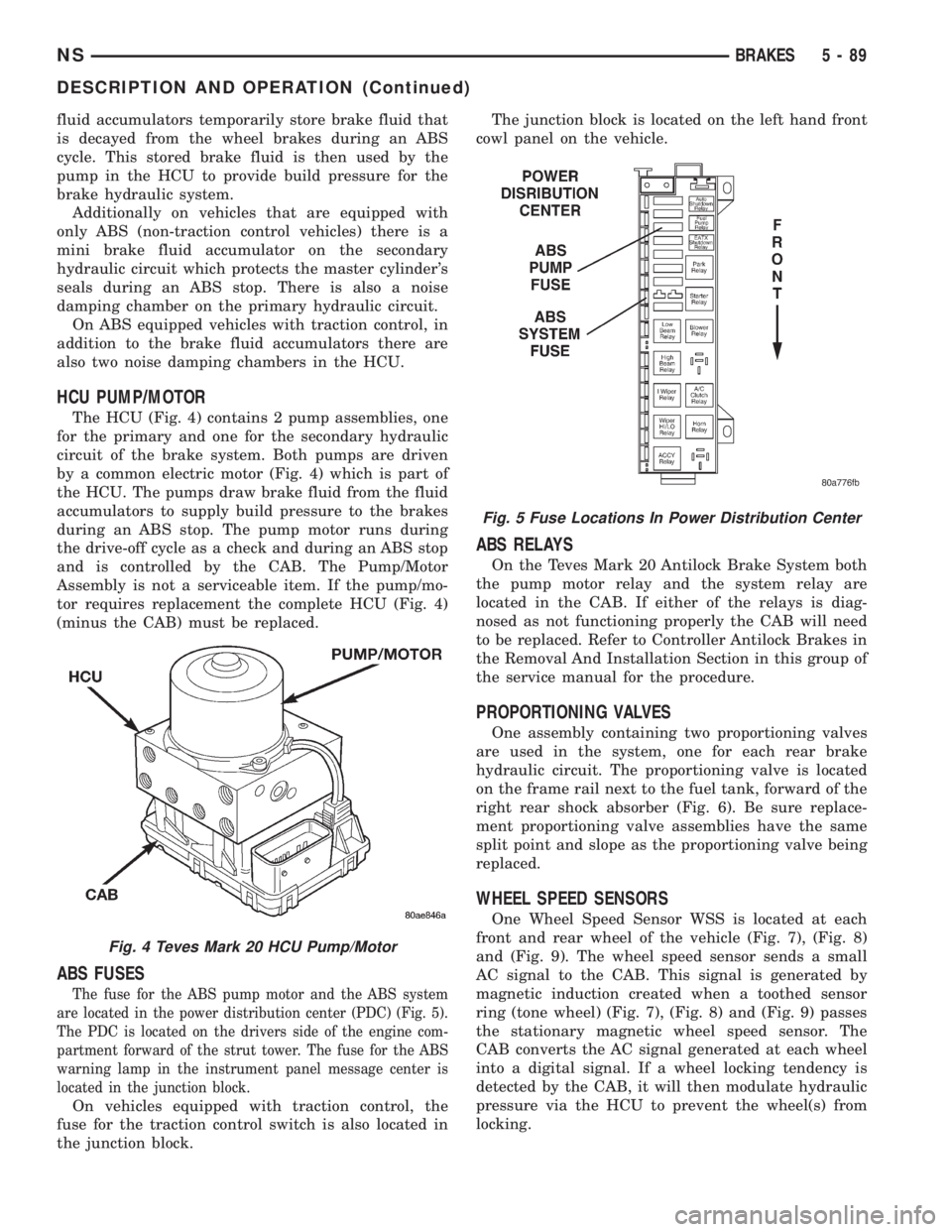

HCU PUMP/MOTOR

The HCU (Fig. 4) contains 2 pump assemblies, one

for the primary and one for the secondary hydraulic

circuit of the brake system. Both pumps are driven

by a common electric motor (Fig. 4) which is part of

the HCU. The pumps draw brake fluid from the fluid

accumulators to supply build pressure to the brakes

during an ABS stop. The pump motor runs during

the drive-off cycle as a check and during an ABS stop

and is controlled by the CAB. The Pump/Motor

Assembly is not a serviceable item. If the pump/mo-

tor requires replacement the complete HCU (Fig. 4)

(minus the CAB) must be replaced.

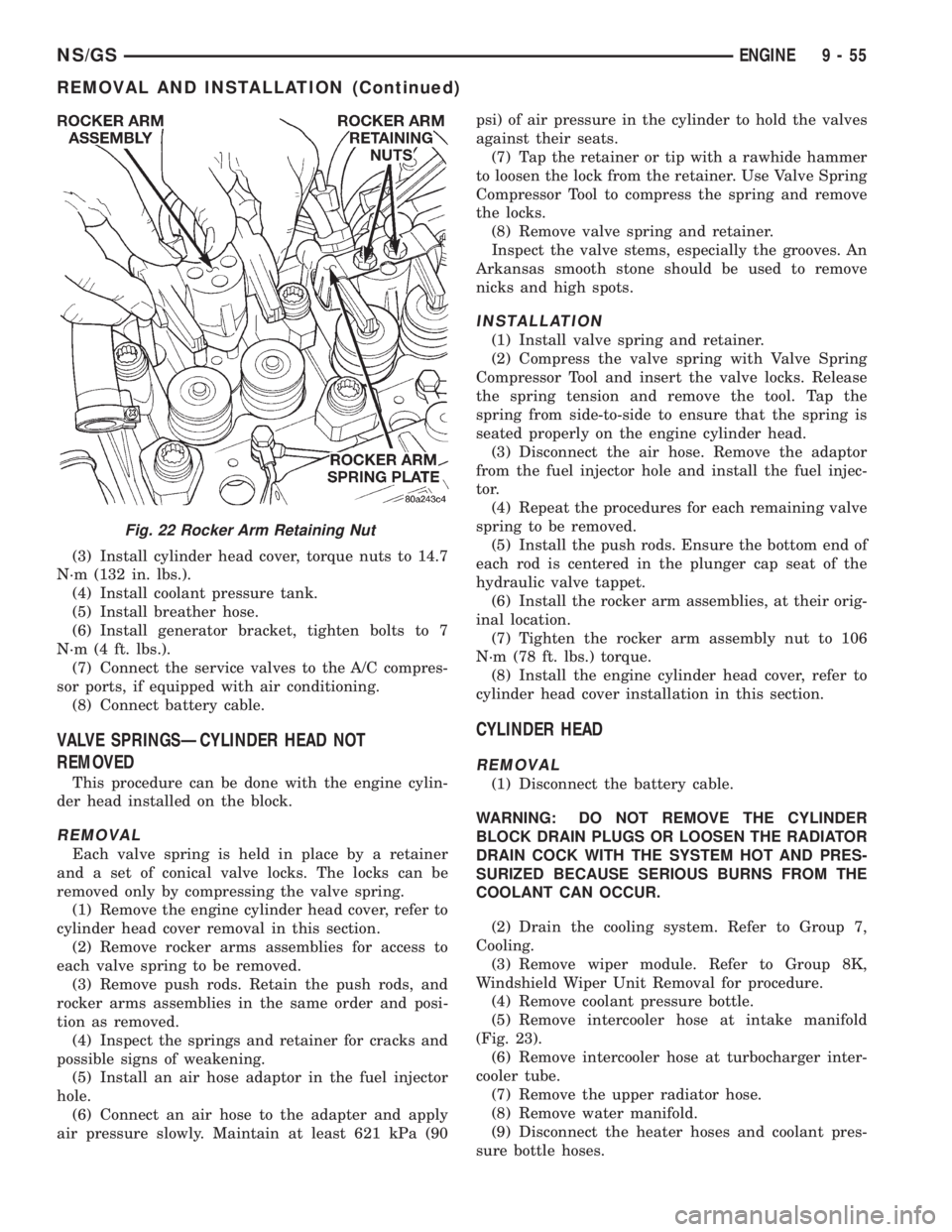

ABS FUSES

The fuse for the ABS pump motor and the ABS system

are located in the power distribution center (PDC) (Fig. 5).

The PDC is located on the drivers side of the engine com-

partment forward of the strut tower. The fuse for the ABS

warning lamp in the instrument panel message center is

located in the junction block.

On vehicles equipped with traction control, the

fuse for the traction control switch is also located in

the junction block.The junction block is located on the left hand front

cowl panel on the vehicle.

ABS RELAYS

On the Teves Mark 20 Antilock Brake System both

the pump motor relay and the system relay are

located in the CAB. If either of the relays is diag-

nosed as not functioning properly the CAB will need

to be replaced. Refer to Controller Antilock Brakes in

the Removal And Installation Section in this group of

the service manual for the procedure.

PROPORTIONING VALVES

One assembly containing two proportioning valves

are used in the system, one for each rear brake

hydraulic circuit. The proportioning valve is located

on the frame rail next to the fuel tank, forward of the

right rear shock absorber (Fig. 6). Be sure replace-

ment proportioning valve assemblies have the same

split point and slope as the proportioning valve being

replaced.

WHEEL SPEED SENSORS

One Wheel Speed Sensor WSS is located at each

front and rear wheel of the vehicle (Fig. 7), (Fig. 8)

and (Fig. 9). The wheel speed sensor sends a small

AC signal to the CAB. This signal is generated by

magnetic induction created when a toothed sensor

ring (tone wheel) (Fig. 7), (Fig. 8) and (Fig. 9) passes

the stationary magnetic wheel speed sensor. The

CAB converts the AC signal generated at each wheel

into a digital signal. If a wheel locking tendency is

detected by the CAB, it will then modulate hydraulic

pressure via the HCU to prevent the wheel(s) from

locking.

Fig. 4 Teves Mark 20 HCU Pump/Motor

Fig. 5 Fuse Locations In Power Distribution Center

NSBRAKES 5 - 89

DESCRIPTION AND OPERATION (Continued)

Page 1233 of 1938

(3) Install cylinder head cover, torque nuts to 14.7

N´m (132 in. lbs.).

(4) Install coolant pressure tank.

(5) Install breather hose.

(6) Install generator bracket, tighten bolts to 7

N´m (4 ft. lbs.).

(7) Connect the service valves to the A/C compres-

sor ports, if equipped with air conditioning.

(8) Connect battery cable.

VALVE SPRINGSÐCYLINDER HEAD NOT

REMOVED

This procedure can be done with the engine cylin-

der head installed on the block.

REMOVAL

Each valve spring is held in place by a retainer

and a set of conical valve locks. The locks can be

removed only by compressing the valve spring.

(1) Remove the engine cylinder head cover, refer to

cylinder head cover removal in this section.

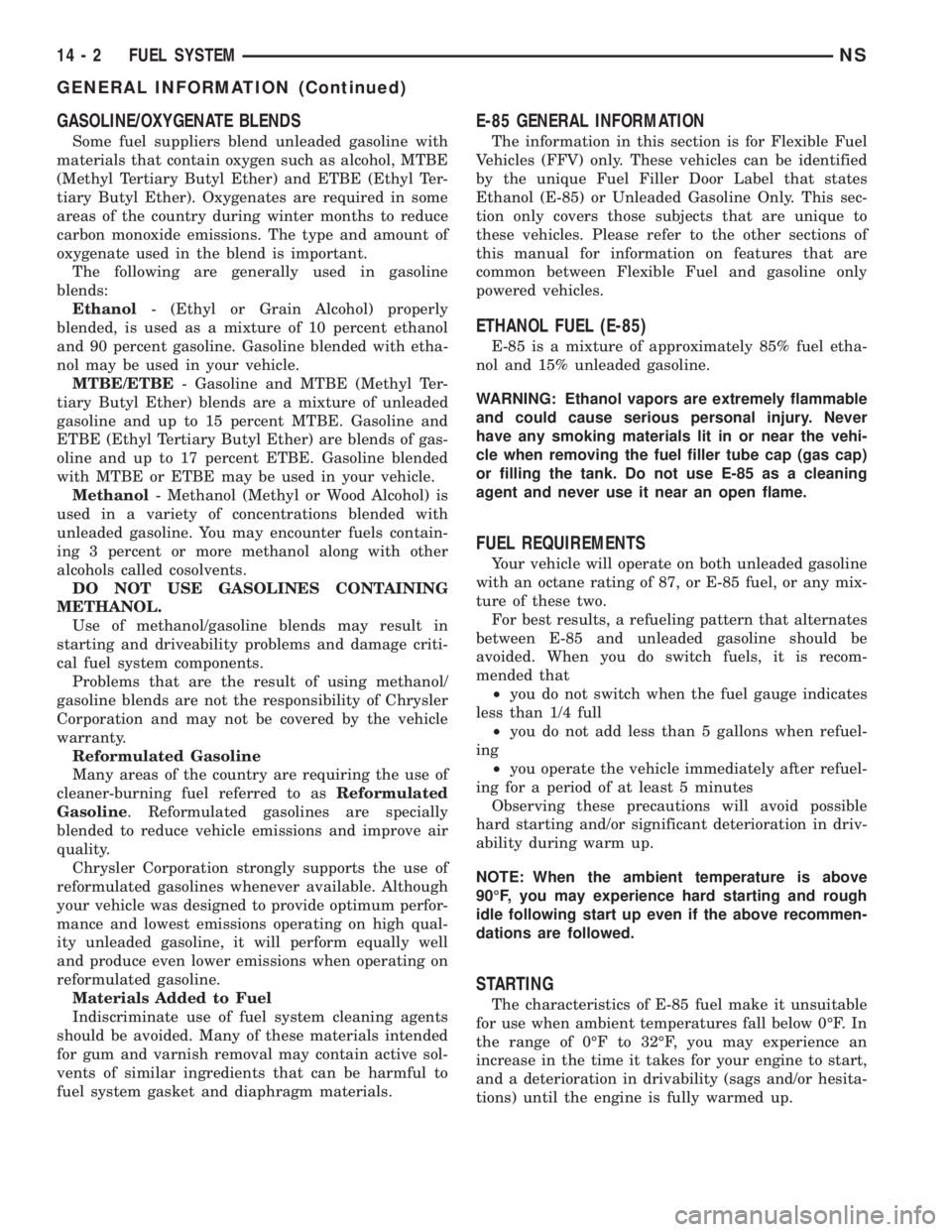

(2) Remove rocker arms assemblies for access to

each valve spring to be removed.

(3) Remove push rods. Retain the push rods, and

rocker arms assemblies in the same order and posi-

tion as removed.

(4) Inspect the springs and retainer for cracks and

possible signs of weakening.

(5) Install an air hose adaptor in the fuel injector

hole.

(6) Connect an air hose to the adapter and apply

air pressure slowly. Maintain at least 621 kPa (90psi) of air pressure in the cylinder to hold the valves

against their seats.

(7) Tap the retainer or tip with a rawhide hammer

to loosen the lock from the retainer. Use Valve Spring

Compressor Tool to compress the spring and remove

the locks.

(8) Remove valve spring and retainer.

Inspect the valve stems, especially the grooves. An

Arkansas smooth stone should be used to remove

nicks and high spots.

INSTALLATION

(1) Install valve spring and retainer.

(2) Compress the valve spring with Valve Spring

Compressor Tool and insert the valve locks. Release

the spring tension and remove the tool. Tap the

spring from side-to-side to ensure that the spring is

seated properly on the engine cylinder head.

(3) Disconnect the air hose. Remove the adaptor

from the fuel injector hole and install the fuel injec-

tor.

(4) Repeat the procedures for each remaining valve

spring to be removed.

(5) Install the push rods. Ensure the bottom end of

each rod is centered in the plunger cap seat of the

hydraulic valve tappet.

(6) Install the rocker arm assemblies, at their orig-

inal location.

(7) Tighten the rocker arm assembly nut to 106

N´m (78 ft. lbs.) torque.

(8) Install the engine cylinder head cover, refer to

cylinder head cover installation in this section.

CYLINDER HEAD

REMOVAL

(1) Disconnect the battery cable.

WARNING: DO NOT REMOVE THE CYLINDER

BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR

DRAIN COCK WITH THE SYSTEM HOT AND PRES-

SURIZED BECAUSE SERIOUS BURNS FROM THE

COOLANT CAN OCCUR.

(2) Drain the cooling system. Refer to Group 7,

Cooling.

(3) Remove wiper module. Refer to Group 8K,

Windshield Wiper Unit Removal for procedure.

(4) Remove coolant pressure bottle.

(5) Remove intercooler hose at intake manifold

(Fig. 23).

(6) Remove intercooler hose at turbocharger inter-

cooler tube.

(7) Remove the upper radiator hose.

(8) Remove water manifold.

(9) Disconnect the heater hoses and coolant pres-

sure bottle hoses.

Fig. 22 Rocker Arm Retaining Nut

NS/GSENGINE 9 - 55

REMOVAL AND INSTALLATION (Continued)

Page 1296 of 1938

GASOLINE/OXYGENATE BLENDS

Some fuel suppliers blend unleaded gasoline with

materials that contain oxygen such as alcohol, MTBE

(Methyl Tertiary Butyl Ether) and ETBE (Ethyl Ter-

tiary Butyl Ether). Oxygenates are required in some

areas of the country during winter months to reduce

carbon monoxide emissions. The type and amount of

oxygenate used in the blend is important.

The following are generally used in gasoline

blends:

Ethanol- (Ethyl or Grain Alcohol) properly

blended, is used as a mixture of 10 percent ethanol

and 90 percent gasoline. Gasoline blended with etha-

nol may be used in your vehicle.

MTBE/ETBE- Gasoline and MTBE (Methyl Ter-

tiary Butyl Ether) blends are a mixture of unleaded

gasoline and up to 15 percent MTBE. Gasoline and

ETBE (Ethyl Tertiary Butyl Ether) are blends of gas-

oline and up to 17 percent ETBE. Gasoline blended

with MTBE or ETBE may be used in your vehicle.

Methanol- Methanol (Methyl or Wood Alcohol) is

used in a variety of concentrations blended with

unleaded gasoline. You may encounter fuels contain-

ing 3 percent or more methanol along with other

alcohols called cosolvents.

DO NOT USE GASOLINES CONTAINING

METHANOL.

Use of methanol/gasoline blends may result in

starting and driveability problems and damage criti-

cal fuel system components.

Problems that are the result of using methanol/

gasoline blends are not the responsibility of Chrysler

Corporation and may not be covered by the vehicle

warranty.

Reformulated Gasoline

Many areas of the country are requiring the use of

cleaner-burning fuel referred to asReformulated

Gasoline. Reformulated gasolines are specially

blended to reduce vehicle emissions and improve air

quality.

Chrysler Corporation strongly supports the use of

reformulated gasolines whenever available. Although

your vehicle was designed to provide optimum perfor-

mance and lowest emissions operating on high qual-

ity unleaded gasoline, it will perform equally well

and produce even lower emissions when operating on

reformulated gasoline.

Materials Added to Fuel

Indiscriminate use of fuel system cleaning agents

should be avoided. Many of these materials intended

for gum and varnish removal may contain active sol-

vents of similar ingredients that can be harmful to

fuel system gasket and diaphragm materials.

E-85 GENERAL INFORMATION

The information in this section is for Flexible Fuel

Vehicles (FFV) only. These vehicles can be identified

by the unique Fuel Filler Door Label that states

Ethanol (E-85) or Unleaded Gasoline Only. This sec-

tion only covers those subjects that are unique to

these vehicles. Please refer to the other sections of

this manual for information on features that are

common between Flexible Fuel and gasoline only

powered vehicles.

ETHANOL FUEL (E-85)

E-85 is a mixture of approximately 85% fuel etha-

nol and 15% unleaded gasoline.

WARNING: Ethanol vapors are extremely flammable

and could cause serious personal injury. Never

have any smoking materials lit in or near the vehi-

cle when removing the fuel filler tube cap (gas cap)

or filling the tank. Do not use E-85 as a cleaning

agent and never use it near an open flame.

FUEL REQUIREMENTS

Your vehicle will operate on both unleaded gasoline

with an octane rating of 87, or E-85 fuel, or any mix-

ture of these two.

For best results, a refueling pattern that alternates

between E-85 and unleaded gasoline should be

avoided. When you do switch fuels, it is recom-

mended that

²you do not switch when the fuel gauge indicates

less than 1/4 full

²you do not add less than 5 gallons when refuel-

ing

²you operate the vehicle immediately after refuel-

ing for a period of at least 5 minutes

Observing these precautions will avoid possible

hard starting and/or significant deterioration in driv-

ability during warm up.

NOTE: When the ambient temperature is above

90ÉF, you may experience hard starting and rough

idle following start up even if the above recommen-

dations are followed.

STARTING

The characteristics of E-85 fuel make it unsuitable

for use when ambient temperatures fall below 0ÉF. In

the range of 0ÉF to 32ÉF, you may experience an

increase in the time it takes for your engine to start,

and a deterioration in drivability (sags and/or hesita-

tions) until the engine is fully warmed up.

14 - 2 FUEL SYSTEMNS

GENERAL INFORMATION (Continued)

Page 1298 of 1938

FUEL DELIVERY SYSTEM

INDEX

page page

DESCRIPTION AND OPERATION

FUEL DELIVERY SYSTEM.................. 4

FUEL INJECTORS........................ 5

FUEL LEVEL SENSOR..................... 5

FUEL PRESSURE REGULATOR.............. 5

FUEL PUMP MODULE..................... 4

FUEL TANK............................. 5

PRESSURE-VACUUM FILLER CAP........... 6

QUICK-CONNECT FITTINGS................ 6

DIAGNOSIS AND TESTING

FUEL INJECTORS........................ 9

FUEL LEVEL SENSOR..................... 9

FUEL PUMP PRESSURE TEST 2.4/3.3/3.8L..... 6

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ2.4/3.3/3.8L............... 11

FUEL SYSTEM PRESSURE RELEASE

PROCEDUREÐ3.0L ENGINE............. 11

HOSES AND CLAMPS.................... 12QUICK-CONNECT FITTINGS............... 12

REMOVAL AND INSTALLATION

ACCELERATOR PEDAL................... 26

FUEL FILTER........................... 12

FUEL INJECTOR RAILÐ2.4L............... 18

FUEL INJECTOR RAILÐ3.0L............... 19

FUEL INJECTOR RAILÐ3.3/3.8L............ 21

FUEL INJECTORSÐ3.0L.................. 25

FUEL INJECTORÐ2.4L................... 24

FUEL INJECTORÐ3.3/3.8L................. 26

FUEL LEVEL SENSOR.................... 15

FUEL PRESSURE REGULATOR............. 14

FUEL PUMP INLET STRAINER............. 15

FUEL PUMP MODULE.................... 13

FUEL TANK............................ 17

THROTTLE CABLE...................... 27

SPECIFICATIONS

FUEL TANK CAPACITY................... 28

TORQUE.............................. 28

DESCRIPTION AND OPERATION

FUEL DELIVERY SYSTEM

The front wheel drive van uses a plastic fuel tank

located on the left side of the vehicle.

The Fuel Delivery System consists of: the electric

fuel pump module, fuel filter, tubes/lines/hoses, fuel

rail, and fuel injectors.

The in-tank fuel pump module contains the fuel

pump and pressure regulator. The pump is serviced

as part of the fuel pump module. Refer to Fuel Pump

Module.

The fuel filter is a replaceable in-line filter. The fil-

ter attaches to a bracket mounted on top of the fuel

tank. Refer to the Maintenance Schedules in the

Introduction section of this manual for recommended

fuel filter replacement intervals.

A returnless fuel system is used on all vehicles.

Fuel is returned through the fuel pump module and

back to the fuel tank. A separate fuel return line

from the tank to the engine is no longer used.

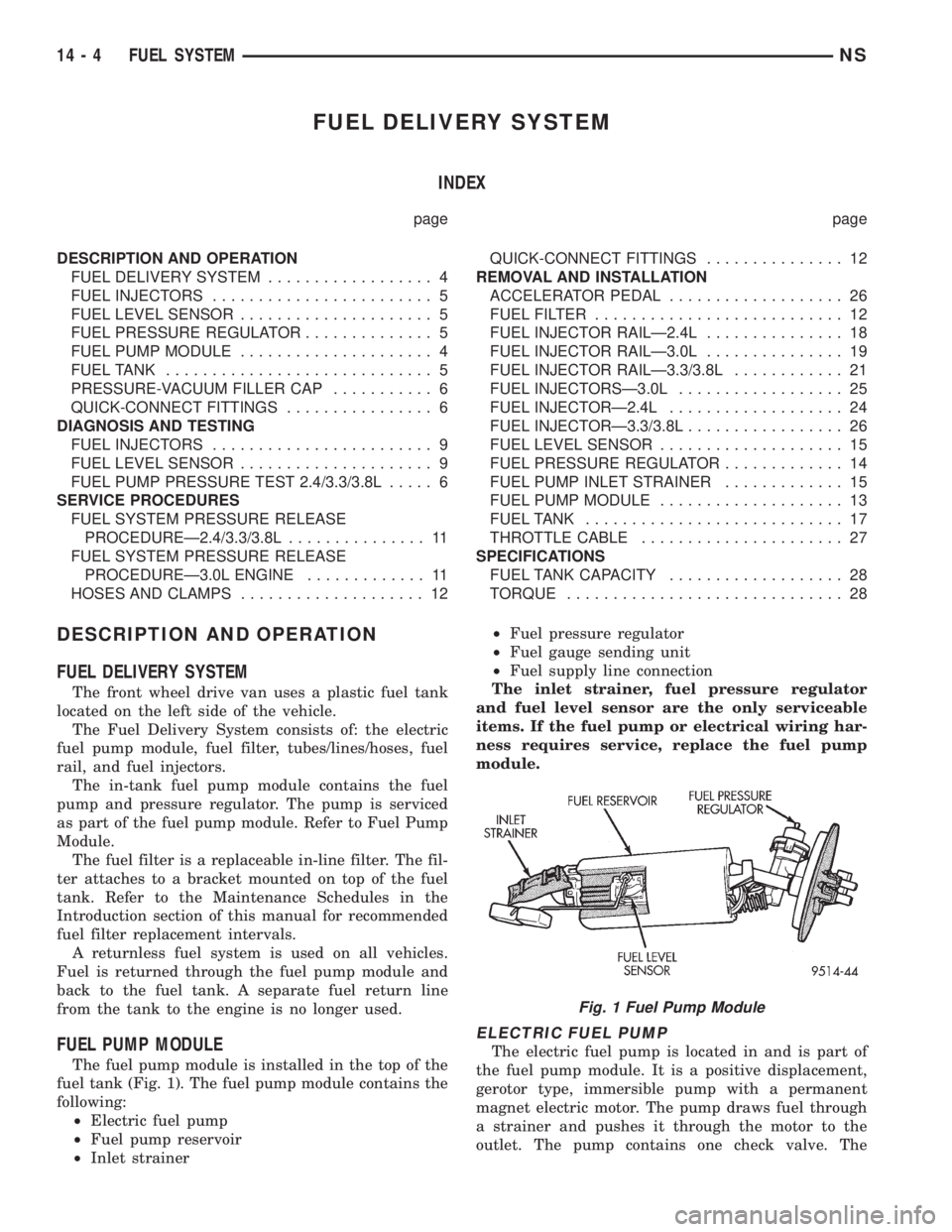

FUEL PUMP MODULE

The fuel pump module is installed in the top of the

fuel tank (Fig. 1). The fuel pump module contains the

following:

²Electric fuel pump

²Fuel pump reservoir

²Inlet strainer²Fuel pressure regulator

²Fuel gauge sending unit

²Fuel supply line connection

The inlet strainer, fuel pressure regulator

and fuel level sensor are the only serviceable

items. If the fuel pump or electrical wiring har-

ness requires service, replace the fuel pump

module.

ELECTRIC FUEL PUMP

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor. The pump draws fuel through

a strainer and pushes it through the motor to the

outlet. The pump contains one check valve. The

Fig. 1 Fuel Pump Module

14 - 4 FUEL SYSTEMNS

Page 1300 of 1938

hydrocarbons. Vapors from the fuel tank are collected

in a charcoal filled canister. The vapors are held in

the canister until the engine is operating. When the

engine is running, the vapors are drawn through the

intake manifold into the combustion chambers.

PRESSURE-VACUUM FILLER CAP

The loss of any fuel or vapor out of the filler neck

is prevented by the use of a safety filler cap. The cap

will release pressure only under significant pressure

of 10.9 to 13.45 kPa (1.58 to 1.95 psi). The vacuum

release for all gas caps is between 0.97 and 2.0 kPa

(0.14 and 0.29 psi). The cap must be replaced by a

similar unit if replacement is necessary.

WARNING: REMOVE FILLER CAP TO RELIEVE

TANK PRESSURE BEFORE REMOVING OR REPAIR-

ING FUEL SYSTEM COMPONENTS.

QUICK-CONNECT FITTINGS

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type. Some are equipped with safety latch clips.

Refer to the Removal/Installation section for more

information.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

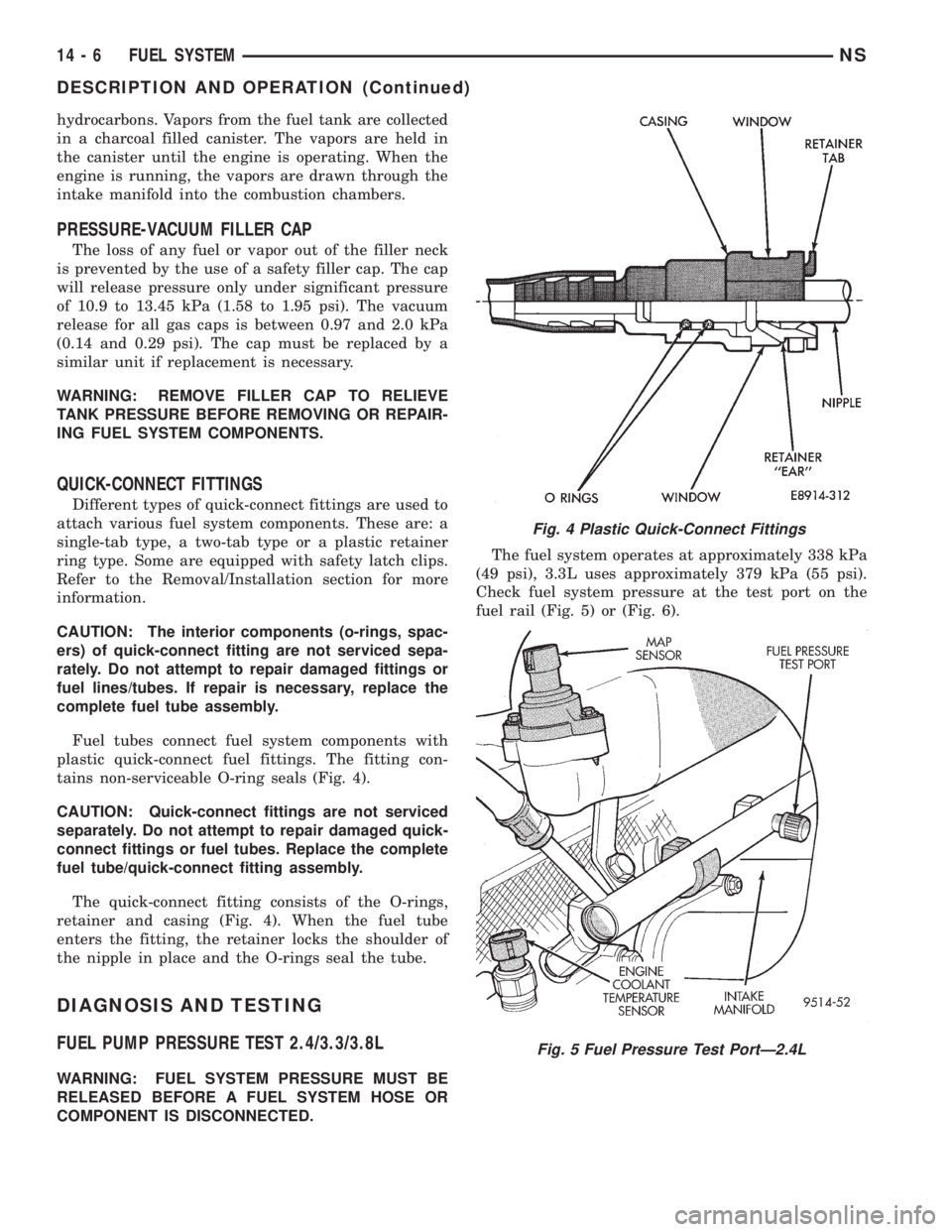

Fuel tubes connect fuel system components with

plastic quick-connect fuel fittings. The fitting con-

tains non-serviceable O-ring seals (Fig. 4).

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

The quick-connect fitting consists of the O-rings,

retainer and casing (Fig. 4). When the fuel tube

enters the fitting, the retainer locks the shoulder of

the nipple in place and the O-rings seal the tube.

DIAGNOSIS AND TESTING

FUEL PUMP PRESSURE TEST 2.4/3.3/3.8L

WARNING: FUEL SYSTEM PRESSURE MUST BE

RELEASED BEFORE A FUEL SYSTEM HOSE OR

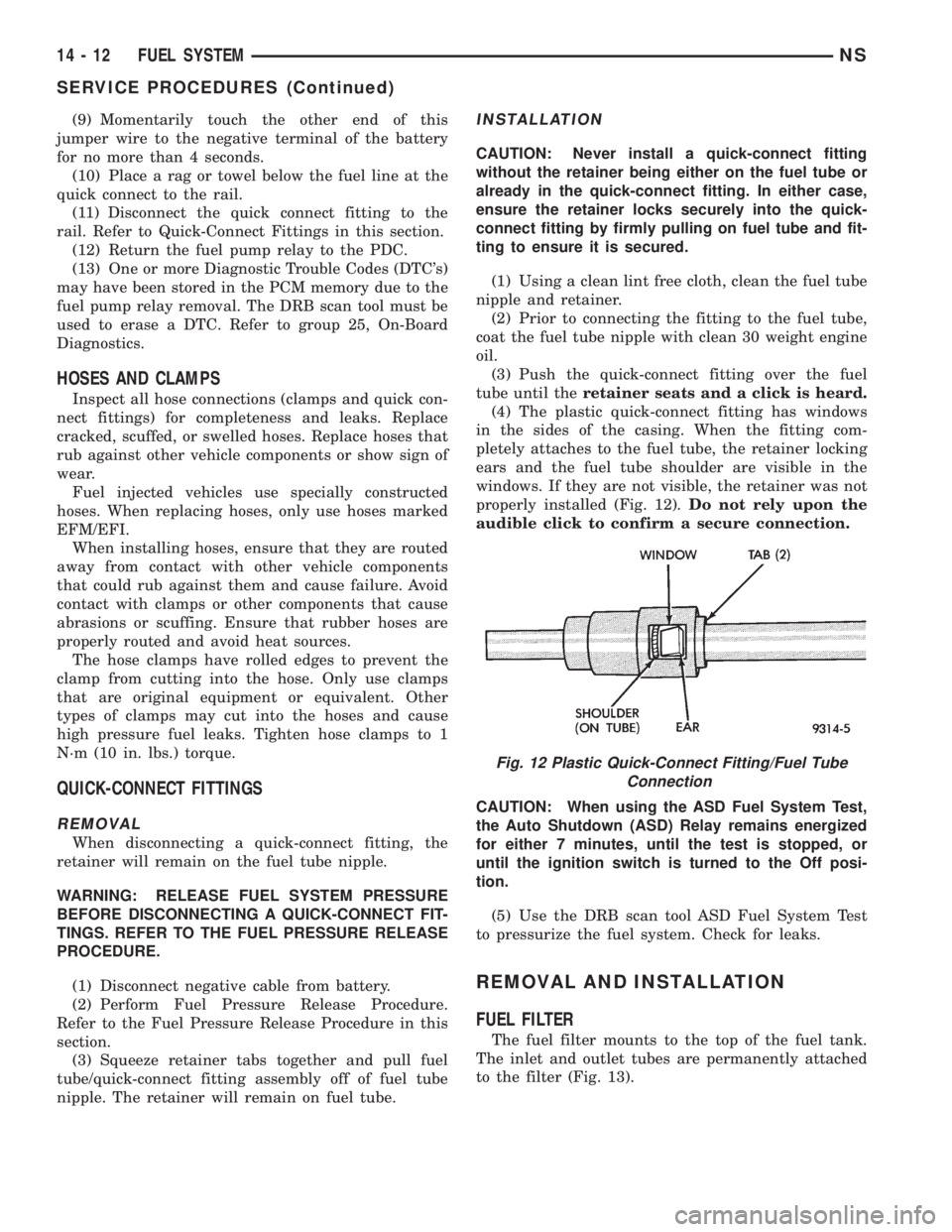

COMPONENT IS DISCONNECTED.The fuel system operates at approximately 338 kPa

(49 psi), 3.3L uses approximately 379 kPa (55 psi).

Check fuel system pressure at the test port on the

fuel rail (Fig. 5) or (Fig. 6).

Fig. 4 Plastic Quick-Connect Fittings

Fig. 5 Fuel Pressure Test PortÐ2.4L

14 - 6 FUEL SYSTEMNS

DESCRIPTION AND OPERATION (Continued)

Page 1306 of 1938

(9) Momentarily touch the other end of this

jumper wire to the negative terminal of the battery

for no more than 4 seconds.

(10) Place a rag or towel below the fuel line at the

quick connect to the rail.

(11) Disconnect the quick connect fitting to the

rail. Refer to Quick-Connect Fittings in this section.

(12) Return the fuel pump relay to the PDC.

(13) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in the PCM memory due to the

fuel pump relay removal. The DRB scan tool must be

used to erase a DTC. Refer to group 25, On-Board

Diagnostics.

HOSES AND CLAMPS

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

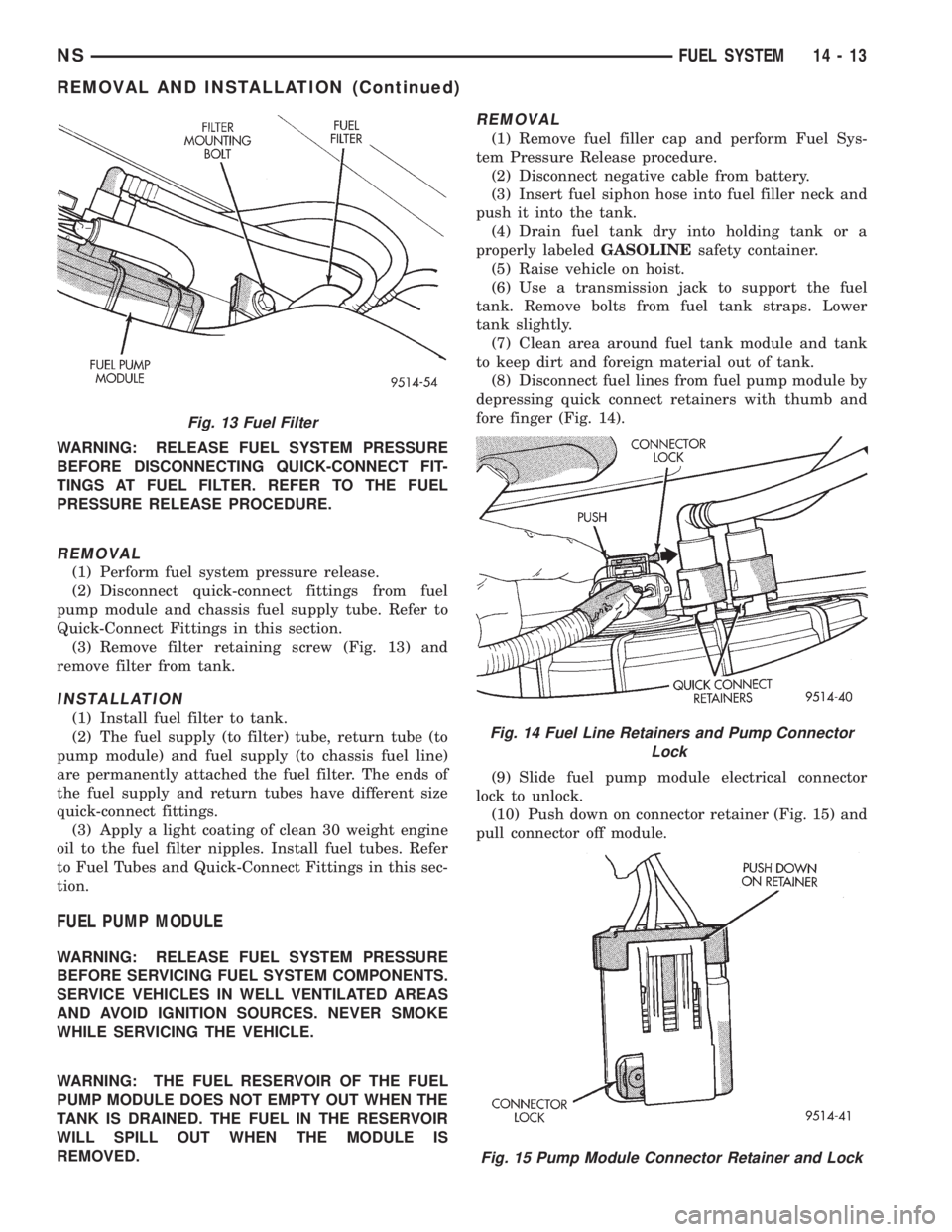

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 12).Do not rely upon the

audible click to confirm a secure connection.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(5) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

REMOVAL AND INSTALLATION

FUEL FILTER

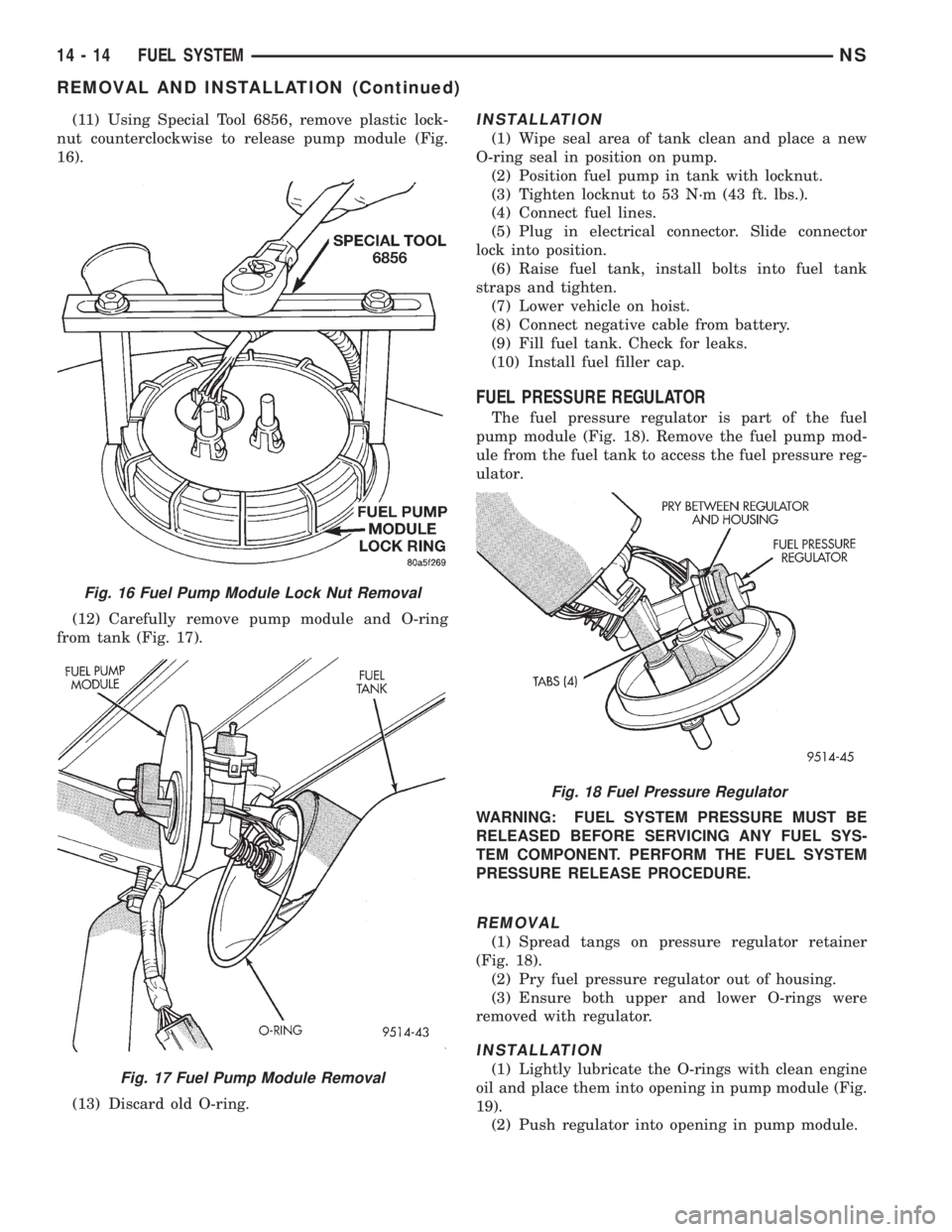

The fuel filter mounts to the top of the fuel tank.

The inlet and outlet tubes are permanently attached

to the filter (Fig. 13).

Fig. 12 Plastic Quick-Connect Fitting/Fuel Tube

Connection

14 - 12 FUEL SYSTEMNS

SERVICE PROCEDURES (Continued)

Page 1307 of 1938

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING QUICK-CONNECT FIT-

TINGS AT FUEL FILTER. REFER TO THE FUEL

PRESSURE RELEASE PROCEDURE.

REMOVAL

(1) Perform fuel system pressure release.

(2) Disconnect quick-connect fittings from fuel

pump module and chassis fuel supply tube. Refer to

Quick-Connect Fittings in this section.

(3) Remove filter retaining screw (Fig. 13) and

remove filter from tank.

INSTALLATION

(1) Install fuel filter to tank.

(2) The fuel supply (to filter) tube, return tube (to

pump module) and fuel supply (to chassis fuel line)

are permanently attached the fuel filter. The ends of

the fuel supply and return tubes have different size

quick-connect fittings.

(3) Apply a light coating of clean 30 weight engine

oil to the fuel filter nipples. Install fuel tubes. Refer

to Fuel Tubes and Quick-Connect Fittings in this sec-

tion.

FUEL PUMP MODULE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

WARNING: THE FUEL RESERVOIR OF THE FUEL

PUMP MODULE DOES NOT EMPTY OUT WHEN THE

TANK IS DRAINED. THE FUEL IN THE RESERVOIR

WILL SPILL OUT WHEN THE MODULE IS

REMOVED.

REMOVAL

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure.

(2) Disconnect negative cable from battery.

(3) Insert fuel siphon hose into fuel filler neck and

push it into the tank.

(4) Drain fuel tank dry into holding tank or a

properly labeledGASOLINEsafety container.

(5) Raise vehicle on hoist.

(6) Use a transmission jack to support the fuel

tank. Remove bolts from fuel tank straps. Lower

tank slightly.

(7) Clean area around fuel tank module and tank

to keep dirt and foreign material out of tank.

(8) Disconnect fuel lines from fuel pump module by

depressing quick connect retainers with thumb and

fore finger (Fig. 14).

(9) Slide fuel pump module electrical connector

lock to unlock.

(10) Push down on connector retainer (Fig. 15) and

pull connector off module.

Fig. 13 Fuel Filter

Fig. 14 Fuel Line Retainers and Pump Connector

Lock

Fig. 15 Pump Module Connector Retainer and Lock

NSFUEL SYSTEM 14 - 13

REMOVAL AND INSTALLATION (Continued)

Page 1308 of 1938

(11) Using Special Tool 6856, remove plastic lock-

nut counterclockwise to release pump module (Fig.

16).

(12) Carefully remove pump module and O-ring

from tank (Fig. 17).

(13) Discard old O-ring.INSTALLATION

(1) Wipe seal area of tank clean and place a new

O-ring seal in position on pump.

(2) Position fuel pump in tank with locknut.

(3) Tighten locknut to 53 N´m (43 ft. lbs.).

(4) Connect fuel lines.

(5) Plug in electrical connector. Slide connector

lock into position.

(6) Raise fuel tank, install bolts into fuel tank

straps and tighten.

(7) Lower vehicle on hoist.

(8) Connect negative cable from battery.

(9) Fill fuel tank. Check for leaks.

(10) Install fuel filler cap.

FUEL PRESSURE REGULATOR

The fuel pressure regulator is part of the fuel

pump module (Fig. 18). Remove the fuel pump mod-

ule from the fuel tank to access the fuel pressure reg-

ulator.

WARNING: FUEL SYSTEM PRESSURE MUST BE

RELEASED BEFORE SERVICING ANY FUEL SYS-

TEM COMPONENT. PERFORM THE FUEL SYSTEM

PRESSURE RELEASE PROCEDURE.

REMOVAL

(1) Spread tangs on pressure regulator retainer

(Fig. 18).

(2) Pry fuel pressure regulator out of housing.

(3) Ensure both upper and lower O-rings were

removed with regulator.

INSTALLATION

(1) Lightly lubricate the O-rings with clean engine

oil and place them into opening in pump module (Fig.

19).

(2) Push regulator into opening in pump module.

Fig. 16 Fuel Pump Module Lock Nut Removal

Fig. 17 Fuel Pump Module Removal

Fig. 18 Fuel Pressure Regulator

14 - 14 FUEL SYSTEMNS

REMOVAL AND INSTALLATION (Continued)

Page 1309 of 1938

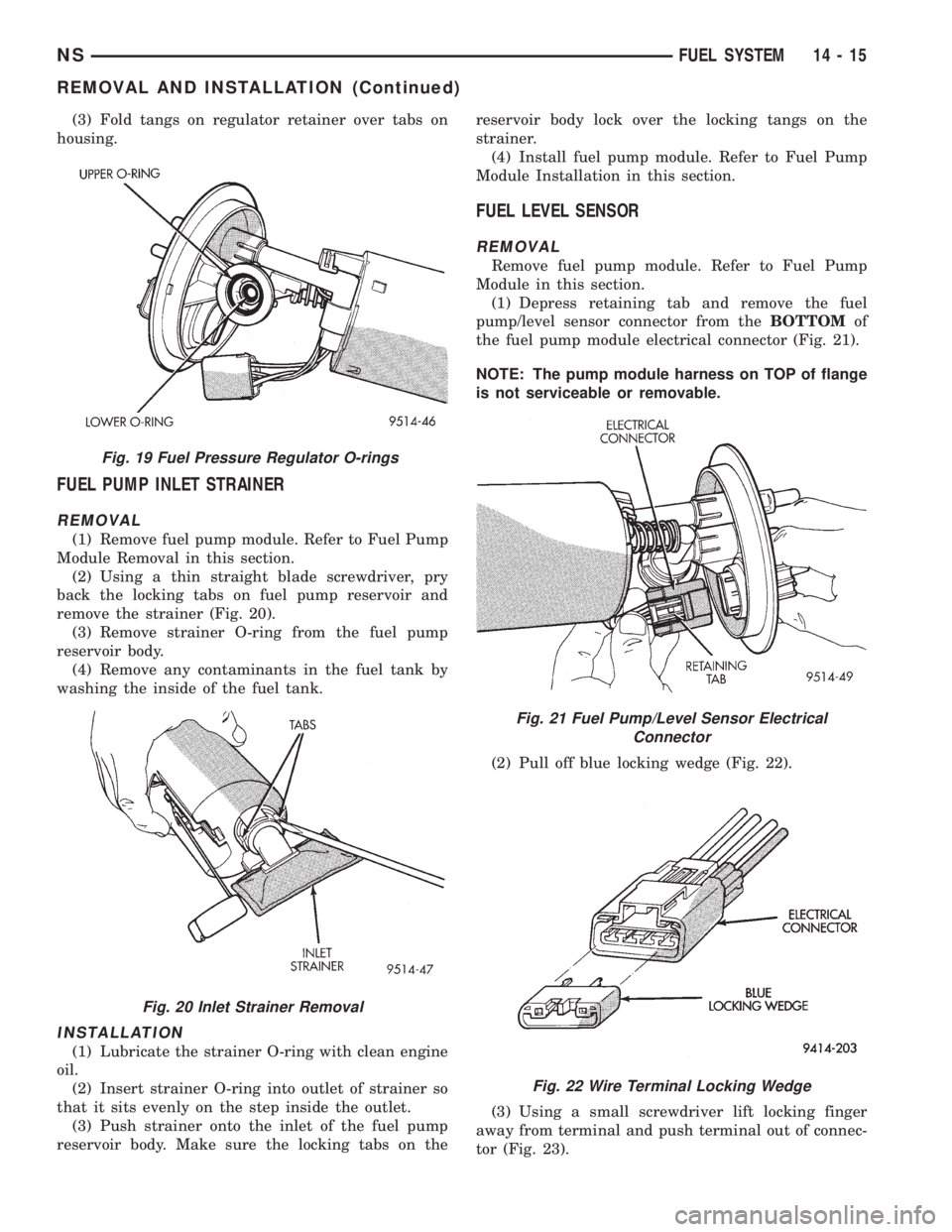

(3) Fold tangs on regulator retainer over tabs on

housing.

FUEL PUMP INLET STRAINER

REMOVAL

(1) Remove fuel pump module. Refer to Fuel Pump

Module Removal in this section.

(2) Using a thin straight blade screwdriver, pry

back the locking tabs on fuel pump reservoir and

remove the strainer (Fig. 20).

(3) Remove strainer O-ring from the fuel pump

reservoir body.

(4) Remove any contaminants in the fuel tank by

washing the inside of the fuel tank.

INSTALLATION

(1) Lubricate the strainer O-ring with clean engine

oil.

(2) Insert strainer O-ring into outlet of strainer so

that it sits evenly on the step inside the outlet.

(3) Push strainer onto the inlet of the fuel pump

reservoir body. Make sure the locking tabs on thereservoir body lock over the locking tangs on the

strainer.

(4) Install fuel pump module. Refer to Fuel Pump

Module Installation in this section.

FUEL LEVEL SENSOR

REMOVAL

Remove fuel pump module. Refer to Fuel Pump

Module in this section.

(1) Depress retaining tab and remove the fuel

pump/level sensor connector from theBOTTOMof

the fuel pump module electrical connector (Fig. 21).

NOTE: The pump module harness on TOP of flange

is not serviceable or removable.

(2) Pull off blue locking wedge (Fig. 22).

(3) Using a small screwdriver lift locking finger

away from terminal and push terminal out of connec-

tor (Fig. 23).

Fig. 19 Fuel Pressure Regulator O-rings

Fig. 20 Inlet Strainer Removal

Fig. 21 Fuel Pump/Level Sensor Electrical

Connector

Fig. 22 Wire Terminal Locking Wedge

NSFUEL SYSTEM 14 - 15

REMOVAL AND INSTALLATION (Continued)

Page 1311 of 1938

(7) Install fuel pump module. Refer to Fuel Pump

Module in this section.

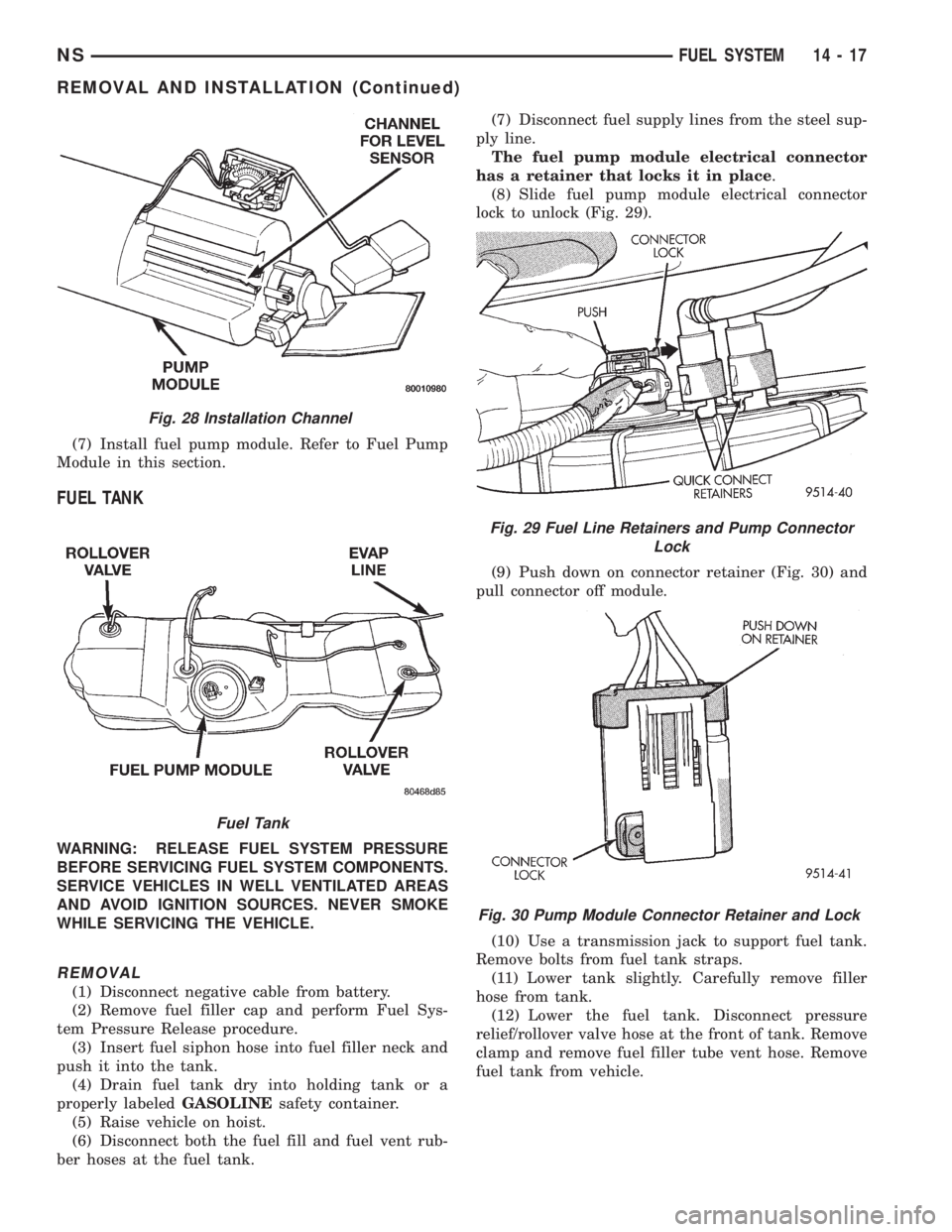

FUEL TANK

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure.

(3) Insert fuel siphon hose into fuel filler neck and

push it into the tank.

(4) Drain fuel tank dry into holding tank or a

properly labeledGASOLINEsafety container.

(5) Raise vehicle on hoist.

(6) Disconnect both the fuel fill and fuel vent rub-

ber hoses at the fuel tank.(7) Disconnect fuel supply lines from the steel sup-

ply line.

The fuel pump module electrical connector

has a retainer that locks it in place.

(8) Slide fuel pump module electrical connector

lock to unlock (Fig. 29).

(9) Push down on connector retainer (Fig. 30) and

pull connector off module.

(10) Use a transmission jack to support fuel tank.

Remove bolts from fuel tank straps.

(11) Lower tank slightly. Carefully remove filler

hose from tank.

(12) Lower the fuel tank. Disconnect pressure

relief/rollover valve hose at the front of tank. Remove

clamp and remove fuel filler tube vent hose. Remove

fuel tank from vehicle.

Fig. 28 Installation Channel

Fuel Tank

Fig. 29 Fuel Line Retainers and Pump Connector

Lock

Fig. 30 Pump Module Connector Retainer and Lock

NSFUEL SYSTEM 14 - 17

REMOVAL AND INSTALLATION (Continued)