tire type CHRYSLER VOYAGER 1996 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 1996, Model line: VOYAGER, Model: CHRYSLER VOYAGER 1996Pages: 1938, PDF Size: 55.84 MB

Page 36 of 1938

CONDITION POSSIBLE CAUSES CORRECTION

Road Wander 1. Incorrect tire pressure 1. Inflate tires to recommended

pressure

2. Incorrect front or rear wheel toe 2. Check and reset wheel toe

3. Worn wheel bearings 3. Replace wheel bearing

4. Worn control arm bushings 4. Replace control arm bushing

5. Excessive friction in steering gear 5. Replace steering gear

6. Excessive friction in steering shaft

coupling6. Replace steering coupler

7. Excessive friction in strut upper

bearing7. Replace strut bearing

Lateral Pull 1. Unequal tire pressure 1. Inflate all tires to recommended

pressure

2. Radial tire lead 2. Perform lead correction procedure

3. Incorrect front wheel camber 3. Check and reset front wheel

camber

4. Power steering gear imbalance 4. Replace power steering gear

5. Wheel braking 5. Correct braking condition causing

lateral pull

Excessive Steering Free Play 1. Incorrect Steering Gear Adjustment 1. Adjust Or Replace Steering Gear

2. Worn or loose tie rod ends 2. Replace or tighten tie rod ends

3. Loose steering gear mounting bolts 3. Tighten steering gear bolts to

specified torque

4. Loose or worn steering shaft

coupler4. Replace steering shaft coupler

Excessive Steering Effort 1. Low tire pressure 1. Inflate all tires to recommended

pressure

2. Lack of lubricant in steering gear 2. Replace steering gear

3. Low power steering fluid level 3. Fill power steering fluid reservoir to

correct level

4. Loose power steering pump drive

belt4. Correctly adjust power steering

pump drive belt

5. Lack of lubricant in ball joints 5. Lubricate or replace ball joints

6. Steering gear malfunction 6. Replace steering gear

7. Lack of lubricant in steering

coupler7. Replace steering coupler

PRE-WHEEL ALIGNMENT INSPECTION

Before any attempt is made to change or correct

the wheel alignment factors. The following part

inspection and the necessary corrections should be

made to those parts which influence the steering of

the vehicle.

(1) Check and inflate all tires to recommended

pressure. All tires should be the same size and in

good condition and have approximately the same

wear. Note the type of tread wear which will aid in

diagnosing, see Wheels and Tires, Group 22.

(2) Check front wheel and tire assembly for radial

runout.

(3) Inspect lower ball joints and all steering link-

age for looseness.

(4) Check for broken or sagged front and rear

springs.(5) Check vehicle ride height to verify it is within

specifications.

(6) AlignmentMUSTonly be checked after the

vehicle has the following areas inspected and or

adjusted. Recommended tire pressures, full tank of

fuel, no passenger or luggage compartment load and

is on a level floor or a properly calibrated alignment

rack.

SERVICE PROCEDURES

WHEEL ALIGNMENT CHECK AND ADJUSTMENT

PROCEDURE

CASTER AND CAMBER

Front suspension Caster and Camber settings on

this vehicle are determined at the time the vehicle is

designed. This is done by determining the precise

2 - 4 SUSPENSIONNS

DIAGNOSIS AND TESTING (Continued)

Page 45 of 1938

instructions included with the thread insert for the

detailed procedure used for the installation of the

thread insert.

NOTE: The thread inserts for this application are

for the repair of M8x1.25 and M10x1.5 threads. Be

sure the correct tools are used for the required

thread insert size.

TOOL REQUIREMENT FOR M8x1.25 Thread

²8.3mm (5/16 in.) Drill Bit

²120É Countersink

²Heli-CoiltTap #4863-8

²Heli-CoiltGage #4624-8

²Heli-CoiltHand Inserting Tool 7751-8

²Needle Nose Pliers ± For Removal Of Thread

Insert Driving Tang

TOOL REQUIREMENT FOR M10x1.5 Thread

²10.5mm (25/64 in.) Drill Bit

²120É Countersink

²Heli-CoiltTap #4863-10

²Heli-CoiltGage #4624-10

²Heli-CoiltHand Inserting Tool 7751-10

²Needle Nose Pliers ± For Removal Of Thread

Insert Driving Tang

REMOVAL AND INSTALLATION

Mc PHERSON STRUT

REMOVAL

WARNING: DO NOT REMOVE THE NUT FROM THE

STRUT ROD WHILE STRUT ASSEMBLY IS

INSTALLED IN VEHICLE, OR BEFORE STRUT

ASSEMBLY SPRING IS COMPRESSED.

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this service man-

ual, for the required lifting procedure to be used for

this vehicle.

(2) Remove the wheel and tire assembly from loca-

tion on front of vehicle requiring strut removal.

(3) If both strut assemblies are to be removed,

mark the strut assemblies right or left according to

which side of the vehicle they were removed from.

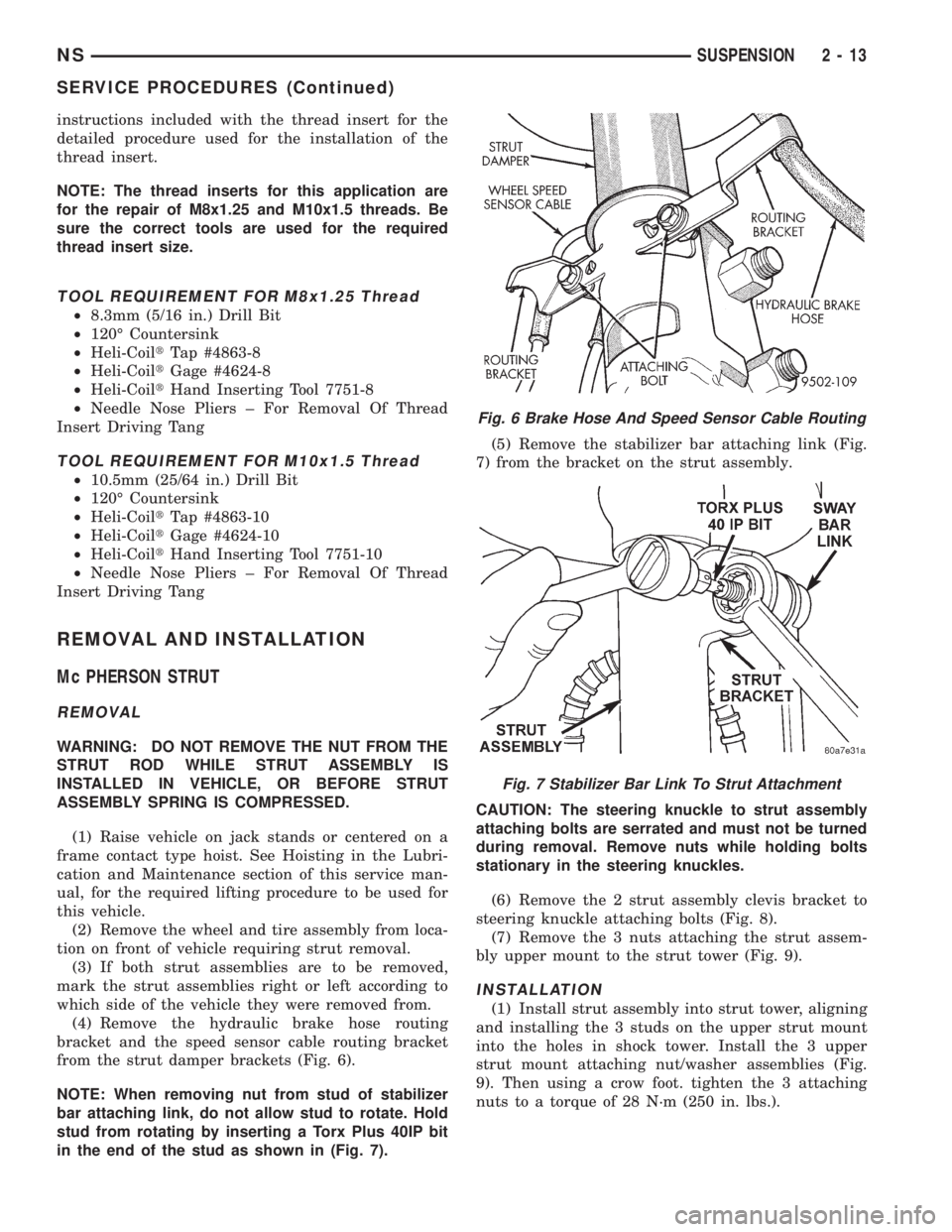

(4) Remove the hydraulic brake hose routing

bracket and the speed sensor cable routing bracket

from the strut damper brackets (Fig. 6).

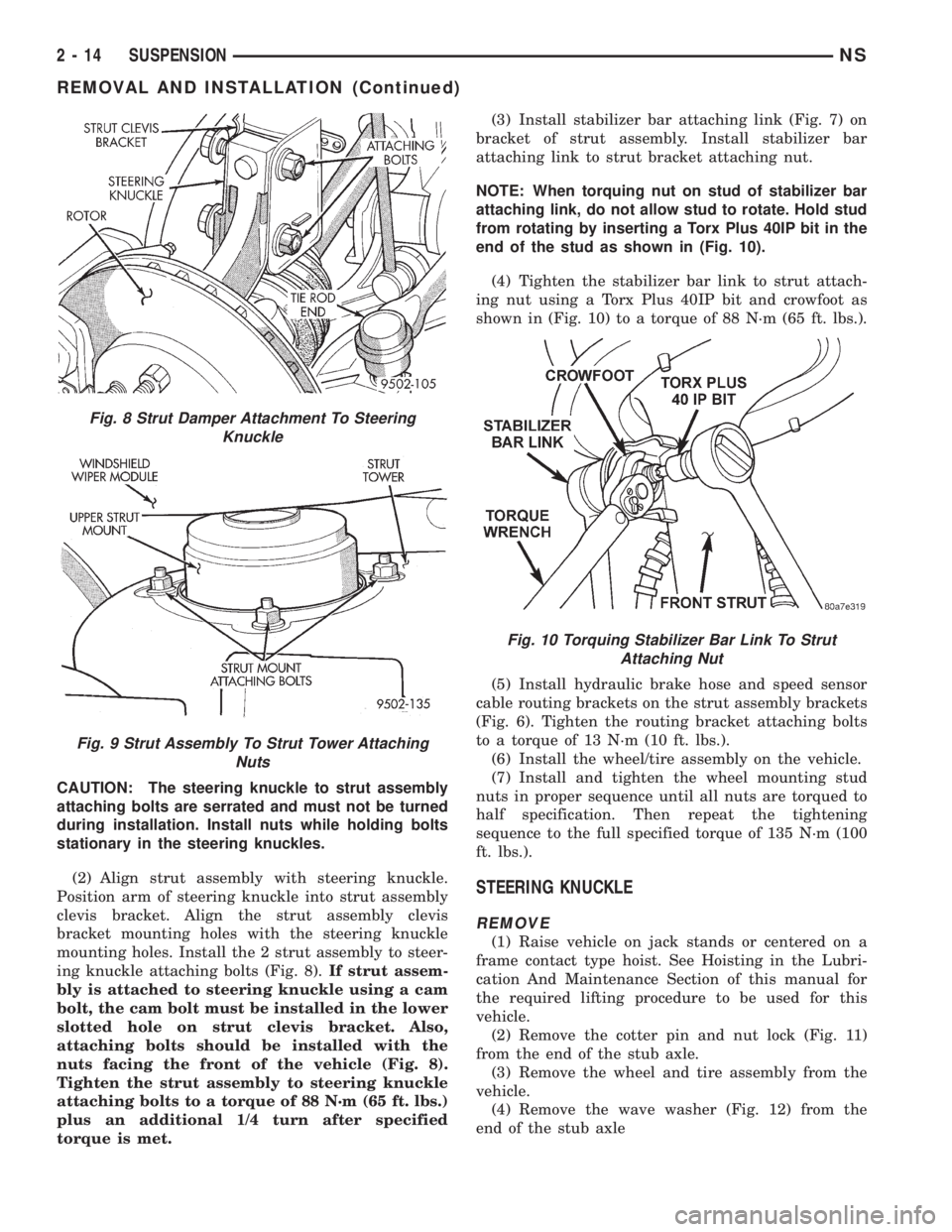

NOTE: When removing nut from stud of stabilizer

bar attaching link, do not allow stud to rotate. Hold

stud from rotating by inserting a Torx Plus 40IP bit

in the end of the stud as shown in (Fig. 7).(5) Remove the stabilizer bar attaching link (Fig.

7) from the bracket on the strut assembly.

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during removal. Remove nuts while holding bolts

stationary in the steering knuckles.

(6) Remove the 2 strut assembly clevis bracket to

steering knuckle attaching bolts (Fig. 8).

(7) Remove the 3 nuts attaching the strut assem-

bly upper mount to the strut tower (Fig. 9).

INSTALLATION

(1) Install strut assembly into strut tower, aligning

and installing the 3 studs on the upper strut mount

into the holes in shock tower. Install the 3 upper

strut mount attaching nut/washer assemblies (Fig.

9). Then using a crow foot. tighten the 3 attaching

nuts to a torque of 28 N´m (250 in. lbs.).

Fig. 6 Brake Hose And Speed Sensor Cable Routing

Fig. 7 Stabilizer Bar Link To Strut Attachment

NSSUSPENSION 2 - 13

SERVICE PROCEDURES (Continued)

Page 46 of 1938

CAUTION: The steering knuckle to strut assembly

attaching bolts are serrated and must not be turned

during installation. Install nuts while holding bolts

stationary in the steering knuckles.

(2) Align strut assembly with steering knuckle.

Position arm of steering knuckle into strut assembly

clevis bracket. Align the strut assembly clevis

bracket mounting holes with the steering knuckle

mounting holes. Install the 2 strut assembly to steer-

ing knuckle attaching bolts (Fig. 8).If strut assem-

bly is attached to steering knuckle using a cam

bolt, the cam bolt must be installed in the lower

slotted hole on strut clevis bracket. Also,

attaching bolts should be installed with the

nuts facing the front of the vehicle (Fig. 8).

Tighten the strut assembly to steering knuckle

attaching bolts to a torque of 88 N´m (65 ft. lbs.)

plus an additional 1/4 turn after specified

torque is met.(3) Install stabilizer bar attaching link (Fig. 7) on

bracket of strut assembly. Install stabilizer bar

attaching link to strut bracket attaching nut.

NOTE: When torquing nut on stud of stabilizer bar

attaching link, do not allow stud to rotate. Hold stud

from rotating by inserting a Torx Plus 40IP bit in the

end of the stud as shown in (Fig. 10).

(4) Tighten the stabilizer bar link to strut attach-

ing nut using a Torx Plus 40IP bit and crowfoot as

shown in (Fig. 10) to a torque of 88 N´m (65 ft. lbs.).

(5) Install hydraulic brake hose and speed sensor

cable routing brackets on the strut assembly brackets

(Fig. 6). Tighten the routing bracket attaching bolts

to a torque of 13 N´m (10 ft. lbs.).

(6) Install the wheel/tire assembly on the vehicle.

(7) Install and tighten the wheel mounting stud

nuts in proper sequence until all nuts are torqued to

half specification. Then repeat the tightening

sequence to the full specified torque of 135 N´m (100

ft. lbs.).

STEERING KNUCKLE

REMOVE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation And Maintenance Section of this manual for

the required lifting procedure to be used for this

vehicle.

(2) Remove the cotter pin and nut lock (Fig. 11)

from the end of the stub axle.

(3) Remove the wheel and tire assembly from the

vehicle.

(4) Remove the wave washer (Fig. 12) from the

end of the stub axle

Fig. 8 Strut Damper Attachment To Steering

Knuckle

Fig. 9 Strut Assembly To Strut Tower Attaching

Nuts

Fig. 10 Torquing Stabilizer Bar Link To Strut

Attaching Nut

2 - 14 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 51 of 1938

LOWER CONTROL ARM

REMOVE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove wheel and tire assembly from the side

of vehicle requiring service to the lower control arm.

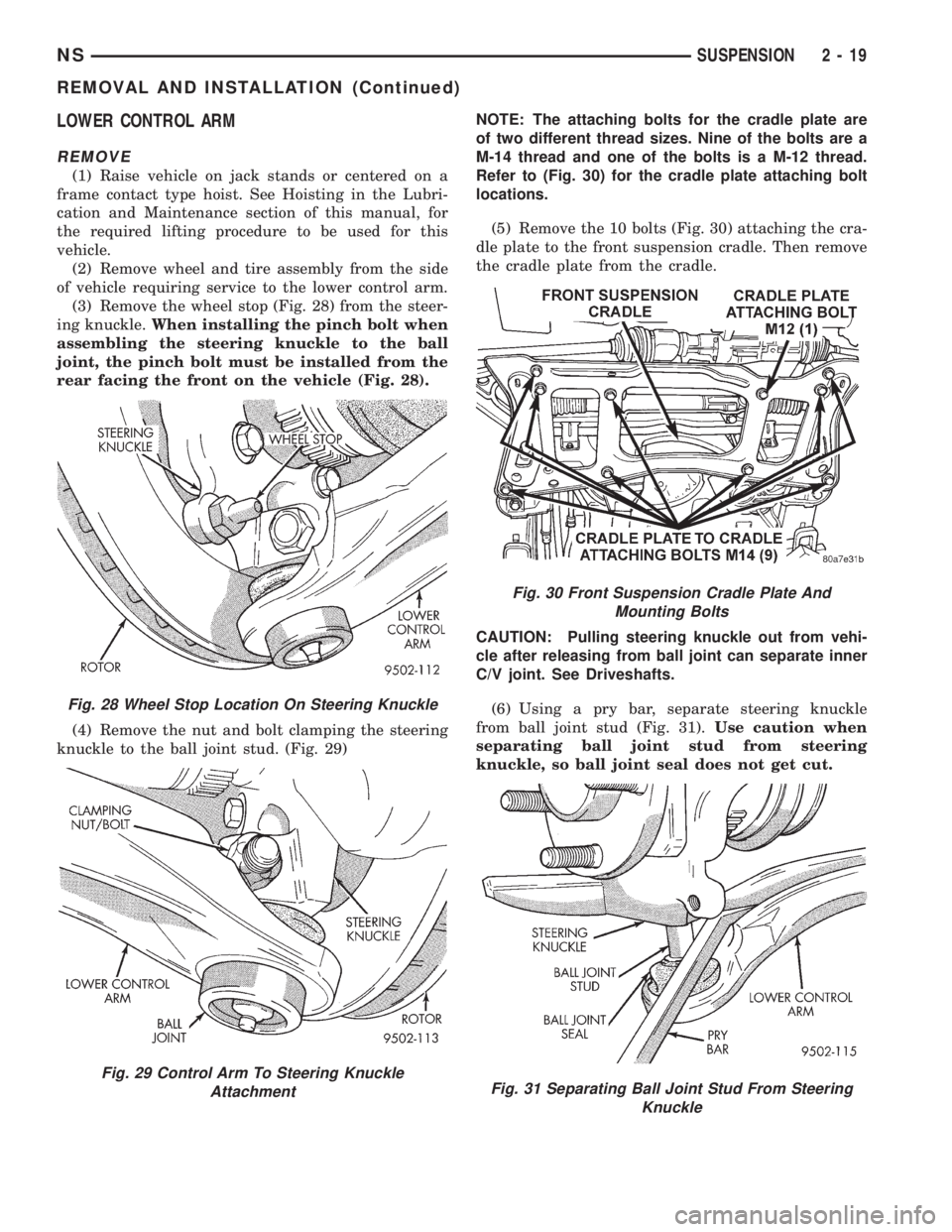

(3) Remove the wheel stop (Fig. 28) from the steer-

ing knuckle.When installing the pinch bolt when

assembling the steering knuckle to the ball

joint, the pinch bolt must be installed from the

rear facing the front on the vehicle (Fig. 28).

(4) Remove the nut and bolt clamping the steering

knuckle to the ball joint stud. (Fig. 29)NOTE: The attaching bolts for the cradle plate are

of two different thread sizes. Nine of the bolts are a

M-14 thread and one of the bolts is a M-12 thread.

Refer to (Fig. 30) for the cradle plate attaching bolt

locations.

(5) Remove the 10 bolts (Fig. 30) attaching the cra-

dle plate to the front suspension cradle. Then remove

the cradle plate from the cradle.

CAUTION: Pulling steering knuckle out from vehi-

cle after releasing from ball joint can separate inner

C/V joint. See Driveshafts.

(6) Using a pry bar, separate steering knuckle

from ball joint stud (Fig. 31).Use caution when

separating ball joint stud from steering

knuckle, so ball joint seal does not get cut.

Fig. 28 Wheel Stop Location On Steering Knuckle

Fig. 29 Control Arm To Steering Knuckle

Attachment

Fig. 30 Front Suspension Cradle Plate And

Mounting Bolts

Fig. 31 Separating Ball Joint Stud From Steering

Knuckle

NSSUSPENSION 2 - 19

REMOVAL AND INSTALLATION (Continued)

Page 58 of 1938

CAUTION: Wheel bearing damage will result if

after loosening hub nut, vehicle is rolled on the

ground or the weight of the vehicle is allowed to be

supported by the tires.

(3) With the aid of a helper applying the brakes to

keep the front hub from turning,loosen but do not

removethe hub nut.The hub and driveshaft are

splined together through the knuckle (bearing)

and retained by the hub nut.

(4) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(5) Remove wheel lug nuts, and front tire and

wheel assembly.

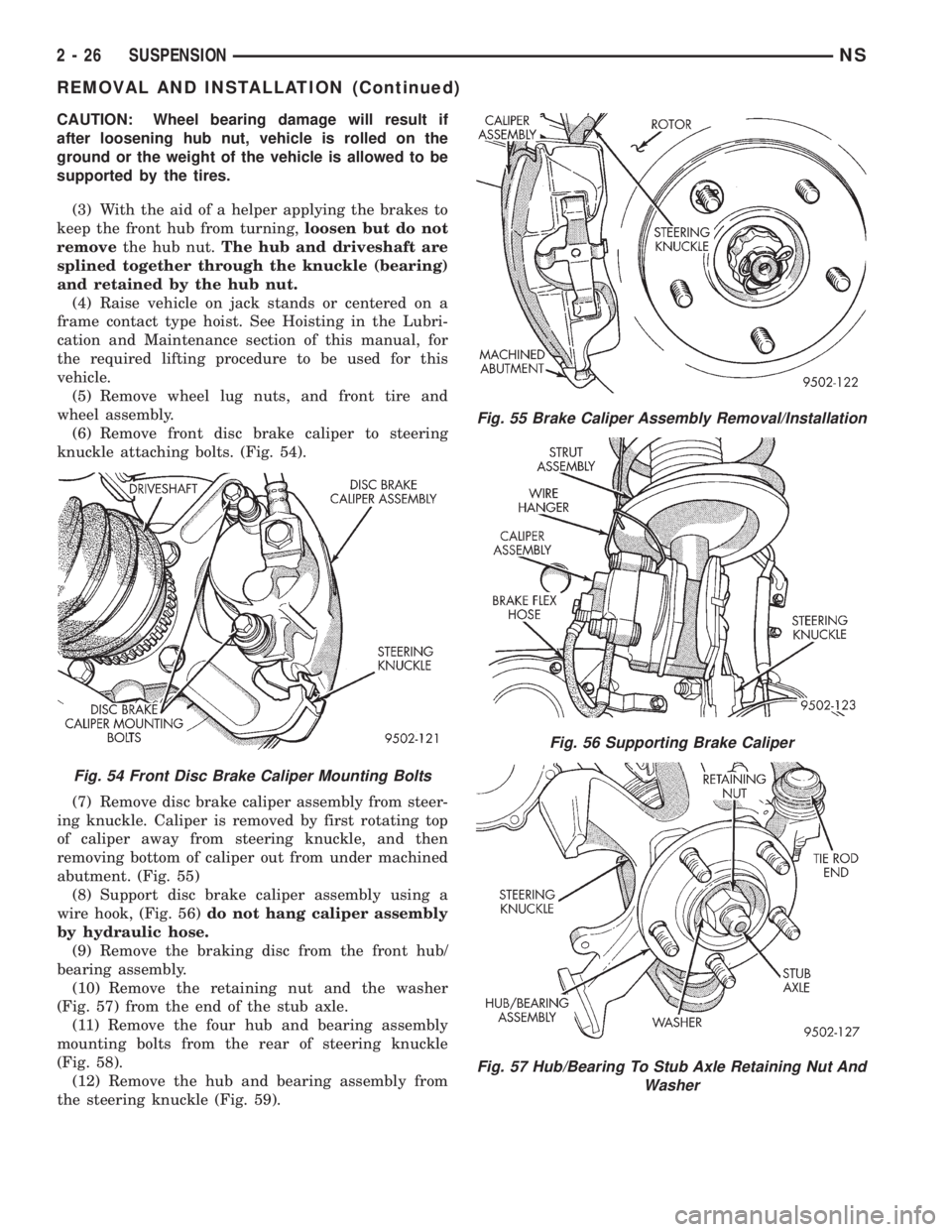

(6) Remove front disc brake caliper to steering

knuckle attaching bolts. (Fig. 54).

(7) Remove disc brake caliper assembly from steer-

ing knuckle. Caliper is removed by first rotating top

of caliper away from steering knuckle, and then

removing bottom of caliper out from under machined

abutment. (Fig. 55)

(8) Support disc brake caliper assembly using a

wire hook, (Fig. 56)do not hang caliper assembly

by hydraulic hose.

(9) Remove the braking disc from the front hub/

bearing assembly.

(10) Remove the retaining nut and the washer

(Fig. 57) from the end of the stub axle.

(11) Remove the four hub and bearing assembly

mounting bolts from the rear of steering knuckle

(Fig. 58).

(12) Remove the hub and bearing assembly from

the steering knuckle (Fig. 59).

Fig. 54 Front Disc Brake Caliper Mounting Bolts

Fig. 55 Brake Caliper Assembly Removal/Installation

Fig. 56 Supporting Brake Caliper

Fig. 57 Hub/Bearing To Stub Axle Retaining Nut And

Washer

2 - 26 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 60 of 1938

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N´m (95 ft. lbs.).

(7) Lower vehicle to the ground.

CAUTION: When tightening hub/bearing assembly

to stub shaft retaining nut, do not exceed the max-

imum torque of 244 N´m (180 ft. lbs.).

(8) With vehicle brakes applied to keep vehicle

from moving, torque stub shaft to hub/bearing assem-

bly retaining nut to 244 N´m (180 ft. lbs.).

(9) Check the Toe setting on the vehicle and reset

if not within specifications.

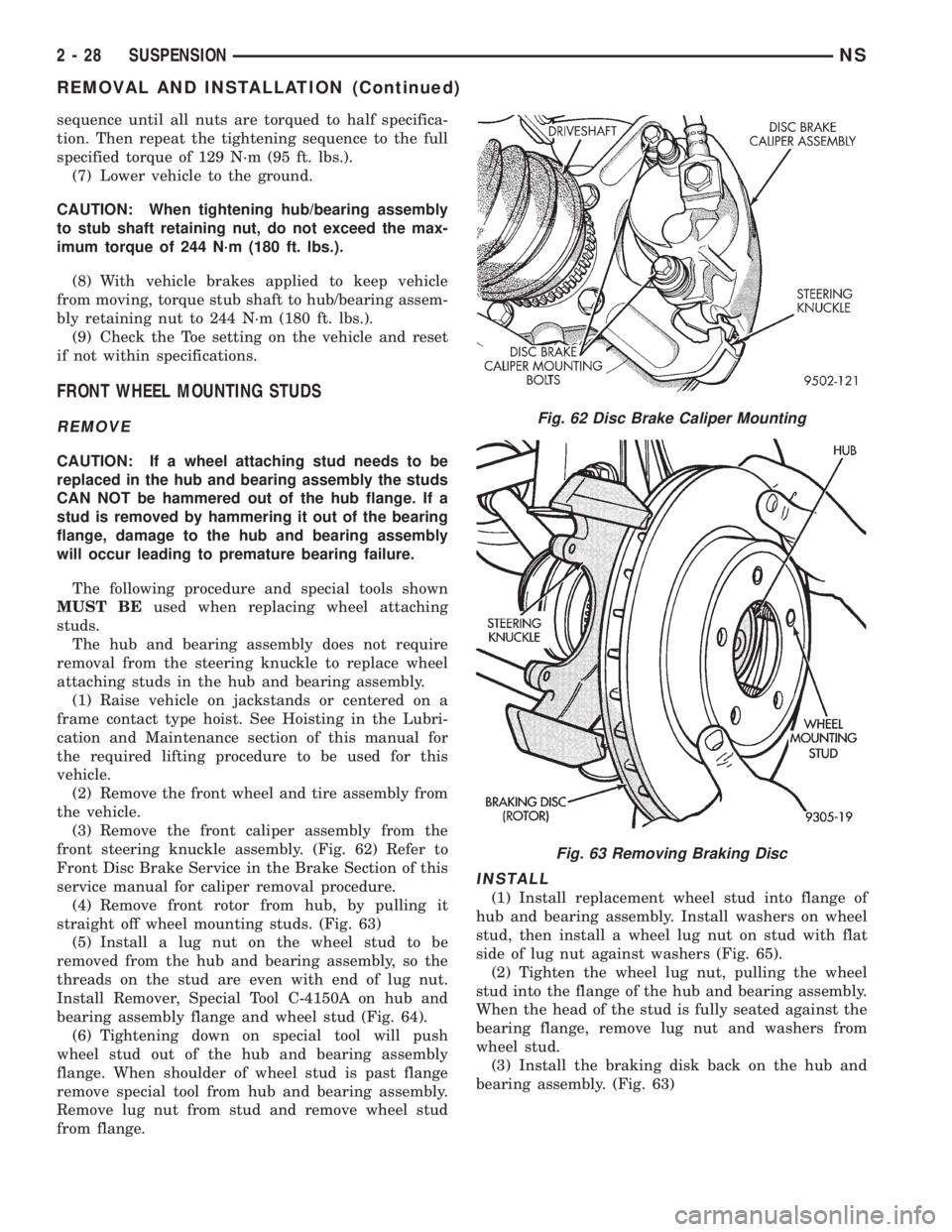

FRONT WHEEL MOUNTING STUDS

REMOVE

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

CAN NOT be hammered out of the hub flange. If a

stud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature bearing failure.

The following procedure and special tools shown

MUST BEused when replacing wheel attaching

studs.

The hub and bearing assembly does not require

removal from the steering knuckle to replace wheel

attaching studs in the hub and bearing assembly.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual for

the required lifting procedure to be used for this

vehicle.

(2) Remove the front wheel and tire assembly from

the vehicle.

(3) Remove the front caliper assembly from the

front steering knuckle assembly. (Fig. 62) Refer to

Front Disc Brake Service in the Brake Section of this

service manual for caliper removal procedure.

(4) Remove front rotor from hub, by pulling it

straight off wheel mounting studs. (Fig. 63)

(5) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly, so the

threads on the stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 64).

(6) Tightening down on special tool will push

wheel stud out of the hub and bearing assembly

flange. When shoulder of wheel stud is past flange

remove special tool from hub and bearing assembly.

Remove lug nut from stud and remove wheel stud

from flange.

INSTALL

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheel

stud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 65).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

(3) Install the braking disk back on the hub and

bearing assembly. (Fig. 63)

Fig. 62 Disc Brake Caliper Mounting

Fig. 63 Removing Braking Disc

2 - 28 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 61 of 1938

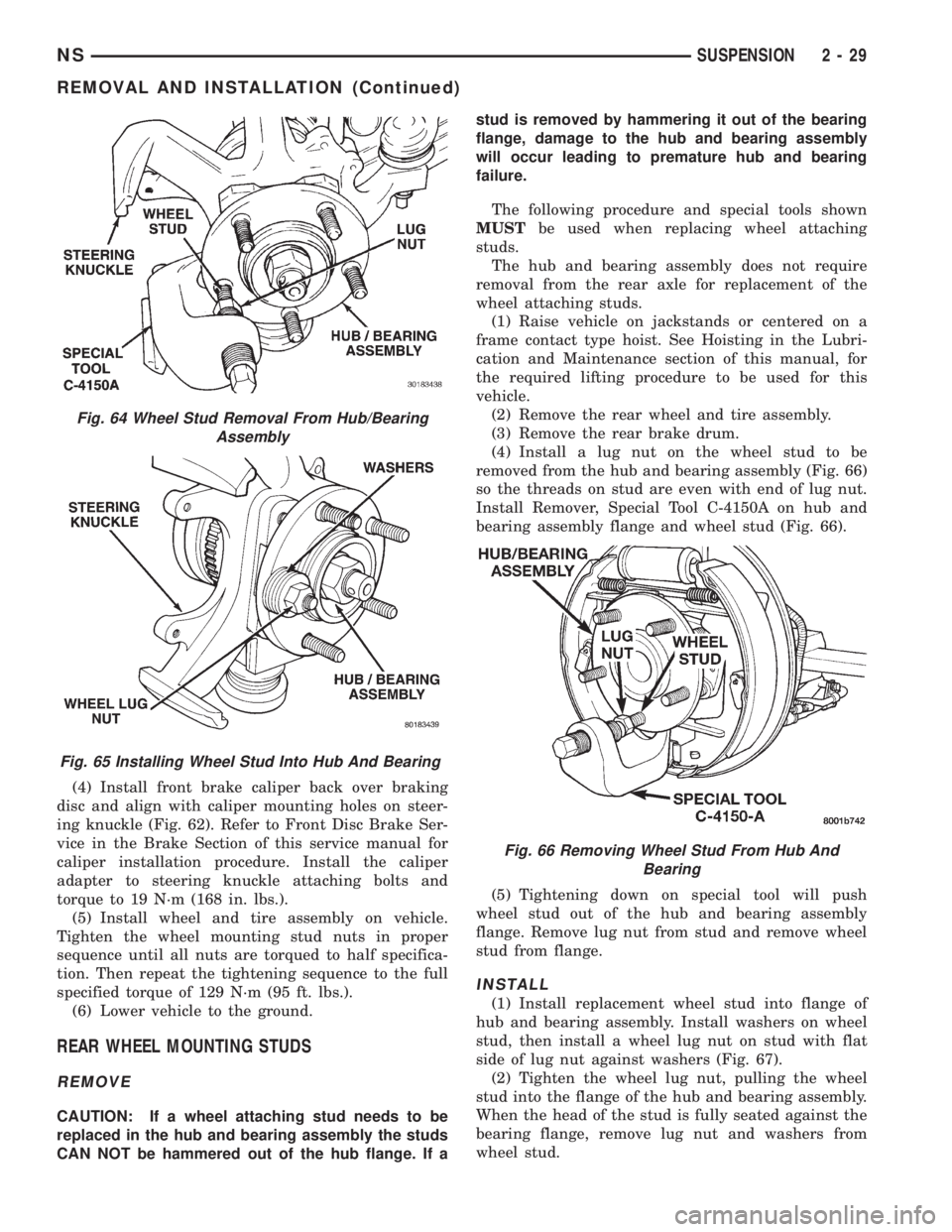

(4) Install front brake caliper back over braking

disc and align with caliper mounting holes on steer-

ing knuckle (Fig. 62). Refer to Front Disc Brake Ser-

vice in the Brake Section of this service manual for

caliper installation procedure. Install the caliper

adapter to steering knuckle attaching bolts and

torque to 19 N´m (168 in. lbs.).

(5) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 129 N´m (95 ft. lbs.).

(6) Lower vehicle to the ground.

REAR WHEEL MOUNTING STUDS

REMOVE

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

CAN NOT be hammered out of the hub flange. If astud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature hub and bearing

failure.

The following procedure and special tools shown

MUSTbe used when replacing wheel attaching

studs.

The hub and bearing assembly does not require

removal from the rear axle for replacement of the

wheel attaching studs.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the rear wheel and tire assembly.

(3) Remove the rear brake drum.

(4) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly (Fig. 66)

so the threads on stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 66).

(5) Tightening down on special tool will push

wheel stud out of the hub and bearing assembly

flange. Remove lug nut from stud and remove wheel

stud from flange.

INSTALL

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheel

stud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 67).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

Fig. 64 Wheel Stud Removal From Hub/Bearing

Assembly

Fig. 65 Installing Wheel Stud Into Hub And Bearing

Fig. 66 Removing Wheel Stud From Hub And

Bearing

NSSUSPENSION 2 - 29

REMOVAL AND INSTALLATION (Continued)

Page 78 of 1938

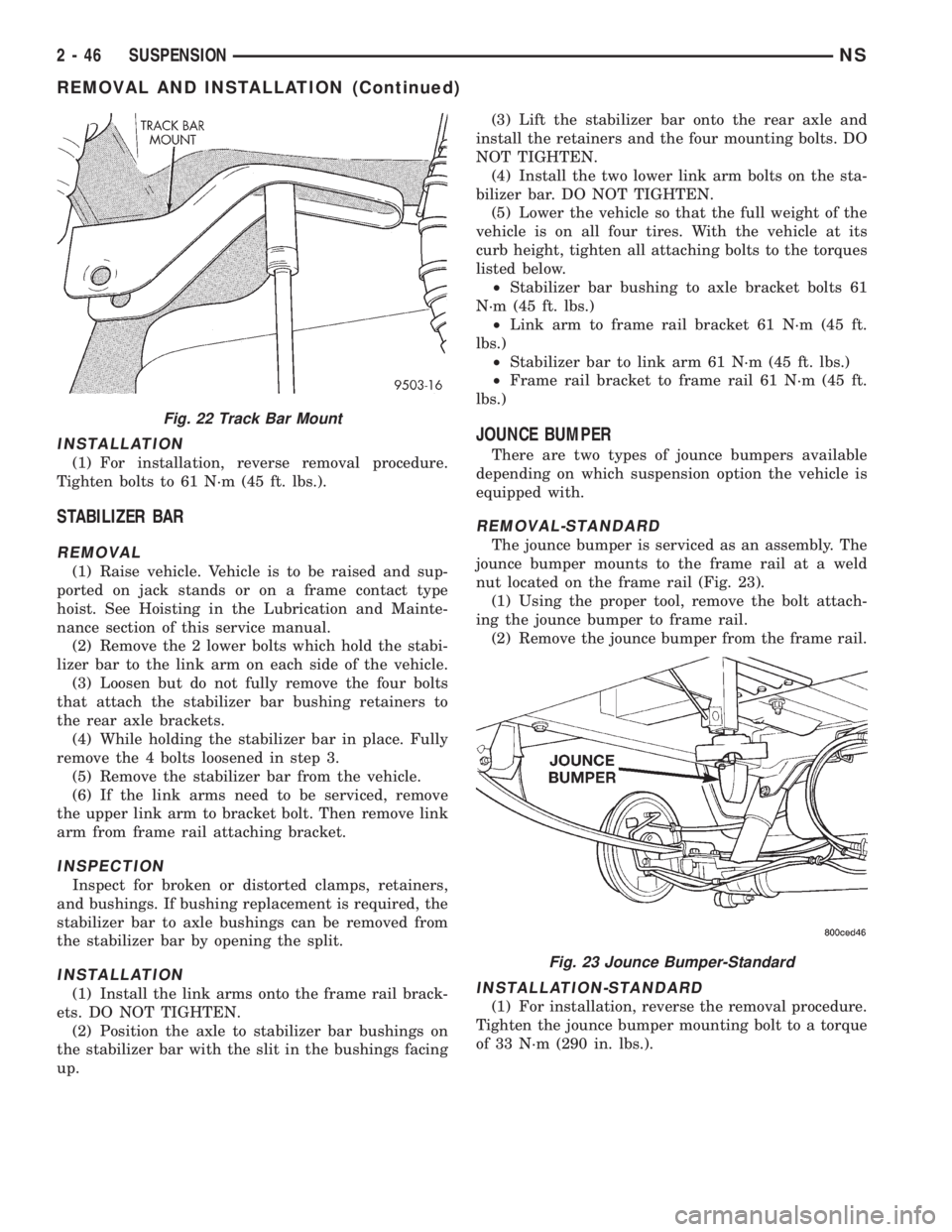

INSTALLATION

(1) For installation, reverse removal procedure.

Tighten bolts to 61 N´m (45 ft. lbs.).

STABILIZER BAR

REMOVAL

(1) Raise vehicle. Vehicle is to be raised and sup-

ported on jack stands or on a frame contact type

hoist. See Hoisting in the Lubrication and Mainte-

nance section of this service manual.

(2) Remove the 2 lower bolts which hold the stabi-

lizer bar to the link arm on each side of the vehicle.

(3) Loosen but do not fully remove the four bolts

that attach the stabilizer bar bushing retainers to

the rear axle brackets.

(4) While holding the stabilizer bar in place. Fully

remove the 4 bolts loosened in step 3.

(5) Remove the stabilizer bar from the vehicle.

(6) If the link arms need to be serviced, remove

the upper link arm to bracket bolt. Then remove link

arm from frame rail attaching bracket.

INSPECTION

Inspect for broken or distorted clamps, retainers,

and bushings. If bushing replacement is required, the

stabilizer bar to axle bushings can be removed from

the stabilizer bar by opening the split.

INSTALLATION

(1) Install the link arms onto the frame rail brack-

ets. DO NOT TIGHTEN.

(2) Position the axle to stabilizer bar bushings on

the stabilizer bar with the slit in the bushings facing

up.(3) Lift the stabilizer bar onto the rear axle and

install the retainers and the four mounting bolts. DO

NOT TIGHTEN.

(4) Install the two lower link arm bolts on the sta-

bilizer bar. DO NOT TIGHTEN.

(5) Lower the vehicle so that the full weight of the

vehicle is on all four tires. With the vehicle at its

curb height, tighten all attaching bolts to the torques

listed below.

²Stabilizer bar bushing to axle bracket bolts 61

N´m (45 ft. lbs.)

²Link arm to frame rail bracket 61 N´m (45 ft.

lbs.)

²Stabilizer bar to link arm 61 N´m (45 ft. lbs.)

²Frame rail bracket to frame rail 61 N´m (45 ft.

lbs.)

JOUNCE BUMPER

There are two types of jounce bumpers available

depending on which suspension option the vehicle is

equipped with.

REMOVAL-STANDARD

The jounce bumper is serviced as an assembly. The

jounce bumper mounts to the frame rail at a weld

nut located on the frame rail (Fig. 23).

(1) Using the proper tool, remove the bolt attach-

ing the jounce bumper to frame rail.

(2) Remove the jounce bumper from the frame rail.

INSTALLATION-STANDARD

(1) For installation, reverse the removal procedure.

Tighten the jounce bumper mounting bolt to a torque

of 33 N´m (290 in. lbs.).

Fig. 22 Track Bar Mount

Fig. 23 Jounce Bumper-Standard

2 - 46 SUSPENSIONNS

REMOVAL AND INSTALLATION (Continued)

Page 99 of 1938

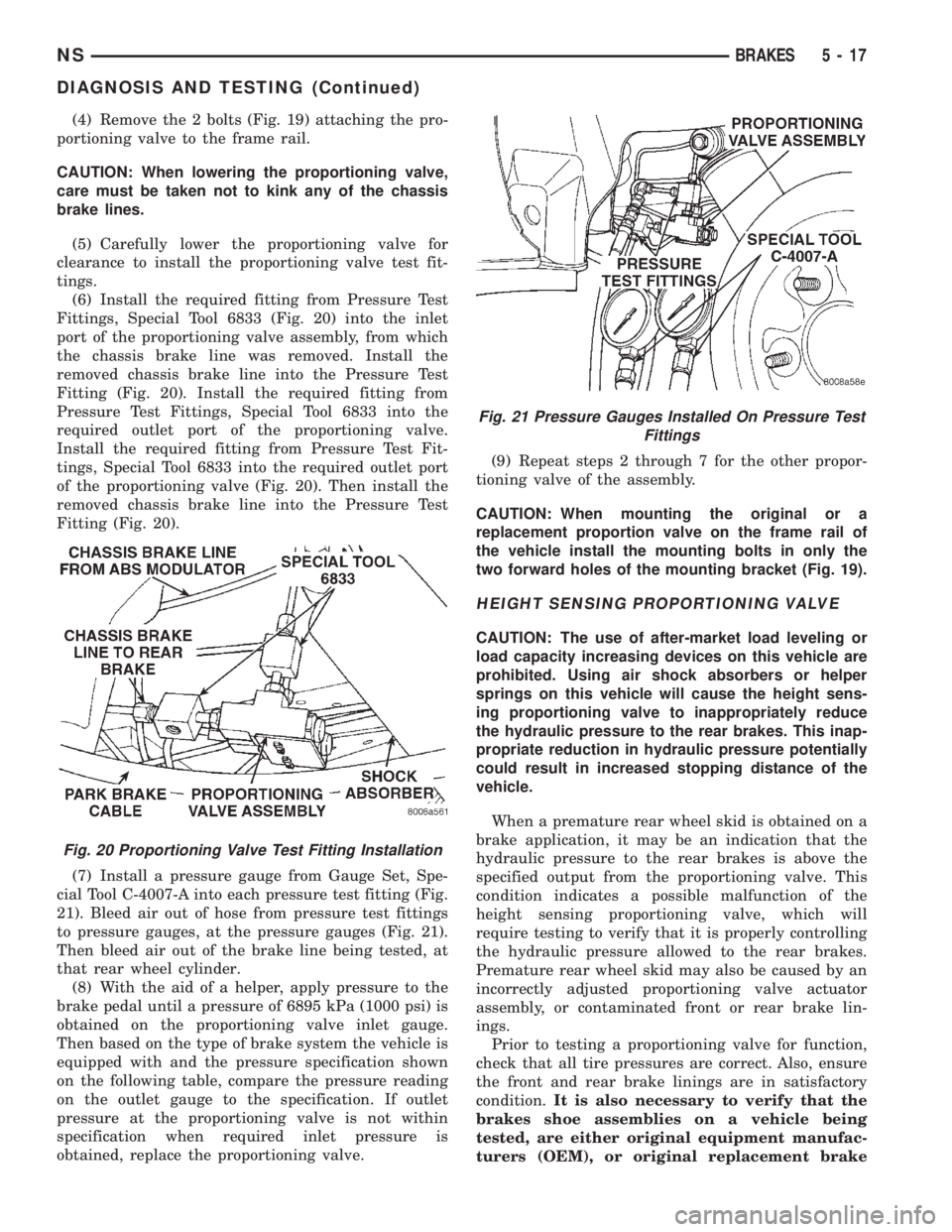

(4) Remove the 2 bolts (Fig. 19) attaching the pro-

portioning valve to the frame rail.

CAUTION: When lowering the proportioning valve,

care must be taken not to kink any of the chassis

brake lines.

(5) Carefully lower the proportioning valve for

clearance to install the proportioning valve test fit-

tings.

(6) Install the required fitting from Pressure Test

Fittings, Special Tool 6833 (Fig. 20) into the inlet

port of the proportioning valve assembly, from which

the chassis brake line was removed. Install the

removed chassis brake line into the Pressure Test

Fitting (Fig. 20). Install the required fitting from

Pressure Test Fittings, Special Tool 6833 into the

required outlet port of the proportioning valve.

Install the required fitting from Pressure Test Fit-

tings, Special Tool 6833 into the required outlet port

of the proportioning valve (Fig. 20). Then install the

removed chassis brake line into the Pressure Test

Fitting (Fig. 20).

(7) Install a pressure gauge from Gauge Set, Spe-

cial Tool C-4007-A into each pressure test fitting (Fig.

21). Bleed air out of hose from pressure test fittings

to pressure gauges, at the pressure gauges (Fig. 21).

Then bleed air out of the brake line being tested, at

that rear wheel cylinder.

(8) With the aid of a helper, apply pressure to the

brake pedal until a pressure of 6895 kPa (1000 psi) is

obtained on the proportioning valve inlet gauge.

Then based on the type of brake system the vehicle is

equipped with and the pressure specification shown

on the following table, compare the pressure reading

on the outlet gauge to the specification. If outlet

pressure at the proportioning valve is not within

specification when required inlet pressure is

obtained, replace the proportioning valve.(9) Repeat steps 2 through 7 for the other propor-

tioning valve of the assembly.

CAUTION: When mounting the original or a

replacement proportion valve on the frame rail of

the vehicle install the mounting bolts in only the

two forward holes of the mounting bracket (Fig. 19).

HEIGHT SENSING PROPORTIONING VALVE

CAUTION: The use of after-market load leveling or

load capacity increasing devices on this vehicle are

prohibited. Using air shock absorbers or helper

springs on this vehicle will cause the height sens-

ing proportioning valve to inappropriately reduce

the hydraulic pressure to the rear brakes. This inap-

propriate reduction in hydraulic pressure potentially

could result in increased stopping distance of the

vehicle.

When a premature rear wheel skid is obtained on a

brake application, it may be an indication that the

hydraulic pressure to the rear brakes is above the

specified output from the proportioning valve. This

condition indicates a possible malfunction of the

height sensing proportioning valve, which will

require testing to verify that it is properly controlling

the hydraulic pressure allowed to the rear brakes.

Premature rear wheel skid may also be caused by an

incorrectly adjusted proportioning valve actuator

assembly, or contaminated front or rear brake lin-

ings.

Prior to testing a proportioning valve for function,

check that all tire pressures are correct. Also, ensure

the front and rear brake linings are in satisfactory

condition.It is also necessary to verify that the

brakes shoe assemblies on a vehicle being

tested, are either original equipment manufac-

turers (OEM), or original replacement brake

Fig. 20 Proportioning Valve Test Fitting Installation

Fig. 21 Pressure Gauges Installed On Pressure Test

Fittings

NSBRAKES 5 - 17

DIAGNOSIS AND TESTING (Continued)

Page 119 of 1938

CAUTION: When installing the tension clip on the

automatic adjuster, it must be located on only the

threaded area of the adjuster assembly (Fig. 66). If

it is located on a non-threaded area of the adjuster,

the function of the automatic adjuster will be

affected.

(7) Install the tension clip (Fig. 66) attaching the

upper return spring to the automatic adjuster assem-

bly.

(8) Install the brake shoe to brake shoe lower

return springs on the brake shoes (Fig. 64) and (Fig.

65).

(9) Install automatic adjustment lever on the lead-

ing brake shoe of the rear brake assembly (Fig. 63).

(10) Install the actuating spring on the automatic

adjustment lever and leading brake shoe assembly

(Fig. 62).

(11) Verify that the automatic adjuster lever has

positive contact with the star wheel on the automatic

adjuster assembly.

(12) When all components of both rear brake

assemblies are correctly and fully installed, remove

the locking pliers from the front park brake cable.

(13) Adjust brake shoes assemblies so as not to

interfere with brake drum installation.

(14) Install the rear brake drums on the hubs.

(15) Adjust rear brake shoes per Adjusting Rear

Brakes procedure in the service adjustments section

of the service manual.

(16) Install the wheel and tire assembly.

(17) Push the park brake pedal to the floor once

and release pedal. This will automatically remove the

slack from and correctly adjust the park brake

cables.

(18) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 130 N´m (95 ft. lbs.).

(19) Road test vehicle. The automatic adjuster will

continue the brake adjustment during the road test

of the vehicle.

BRAKE SUPPORT PLATE (REAR DRUM BRAKES)

REMOVE

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this service man-

ual for required lifting procedure.

(2) Remove wheel and tire.

(3) Remove brake drum from hub/bearing.

(4) Remove brake shoes from brake support plate.

Refer to Rear Brake Shoe Removal in the removal

and installation section in this group of the service

manual for the required procedure.(5) Disconnect the park brake cable from the park

brake actuation lever.

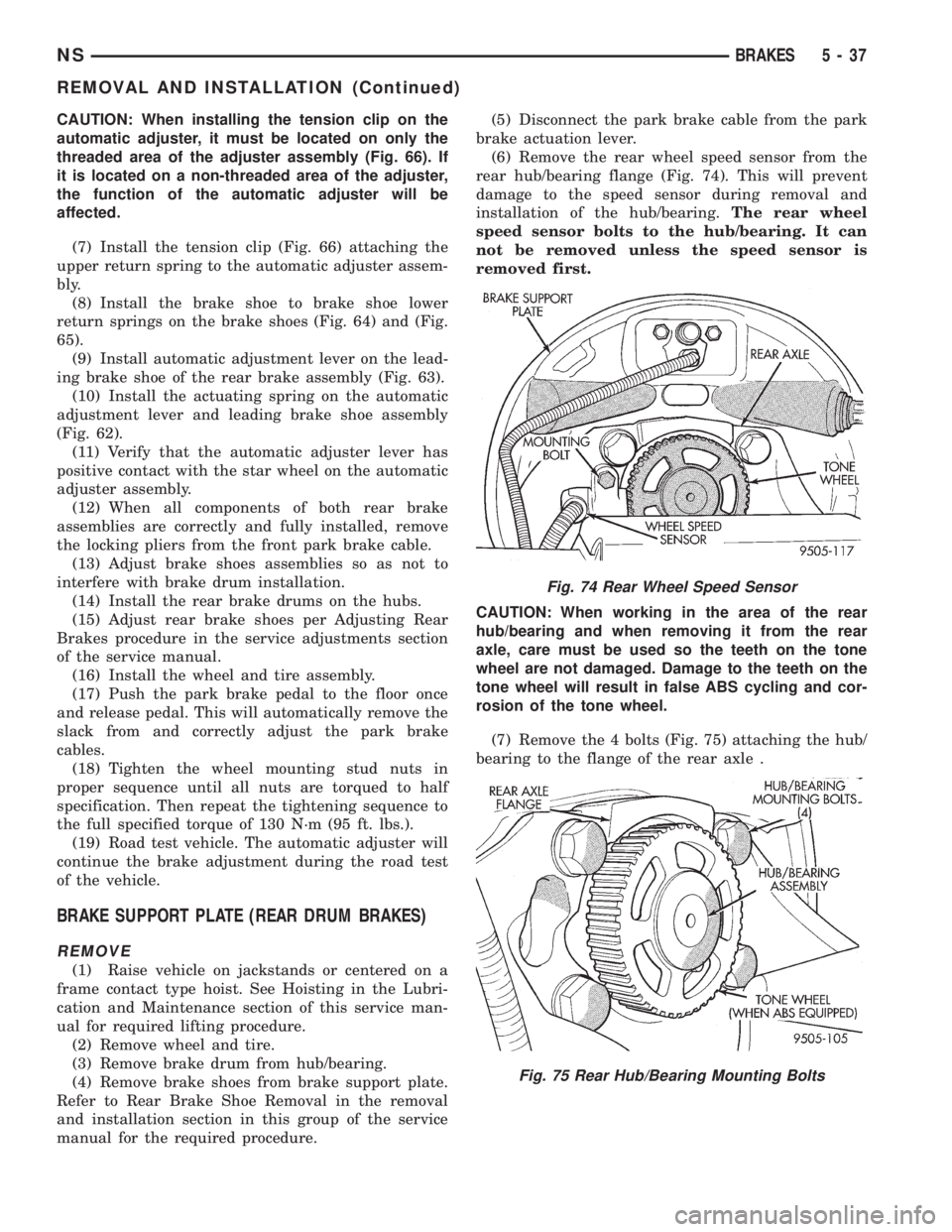

(6) Remove the rear wheel speed sensor from the

rear hub/bearing flange (Fig. 74). This will prevent

damage to the speed sensor during removal and

installation of the hub/bearing.The rear wheel

speed sensor bolts to the hub/bearing. It can

not be removed unless the speed sensor is

removed first.

CAUTION: When working in the area of the rear

hub/bearing and when removing it from the rear

axle, care must be used so the teeth on the tone

wheel are not damaged. Damage to the teeth on the

tone wheel will result in false ABS cycling and cor-

rosion of the tone wheel.

(7) Remove the 4 bolts (Fig. 75) attaching the hub/

bearing to the flange of the rear axle .

Fig. 74 Rear Wheel Speed Sensor

Fig. 75 Rear Hub/Bearing Mounting Bolts

NSBRAKES 5 - 37

REMOVAL AND INSTALLATION (Continued)