fuse CHRYSLER VOYAGER 2000 Diagnostic Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 5 of 364

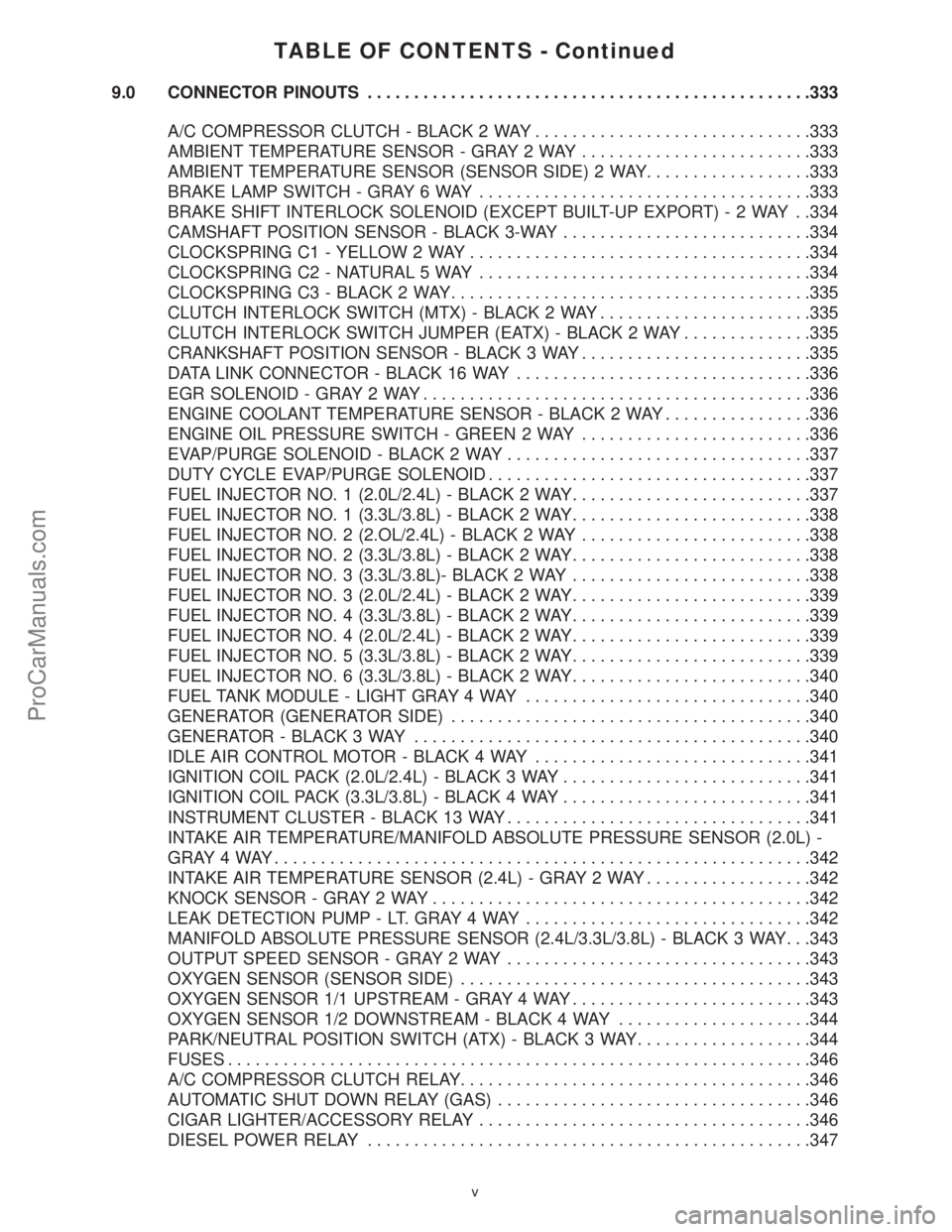

TABLE OF CONTENTS - Continued

9.0 CONNECTOR PINOUTS................................................333

A/C COMPRESSOR CLUTCH - BLACK 2 WAY..............................333

AMBIENT TEMPERATURE SENSOR - GRAY 2 WAY.........................333

AMBIENT TEMPERATURE SENSOR (SENSOR SIDE) 2 WAY..................333

BRAKE LAMP SWITCH - GRAY 6 WAY....................................333

BRAKE SHIFT INTERLOCK SOLENOID (EXCEPT BUILT-UP EXPORT)-2WAY ..334

CAMSHAFT POSITION SENSOR - BLACK 3-WAY...........................334

CLOCKSPRING C1 - YELLOW 2 WAY.....................................334

CLOCKSPRING C2 - NATURAL 5 WAY....................................334

CLOCKSPRING C3 - BLACK 2 WAY.......................................335

CLUTCH INTERLOCK SWITCH (MTX) - BLACK 2 WAY.......................335

CLUTCH INTERLOCK SWITCH JUMPER (EATX) - BLACK 2 WAY..............335

CRANKSHAFT POSITION SENSOR - BLACK 3 WAY.........................335

DATA LINK CONNECTOR - BLACK 16 WAY................................336

EGR SOLENOID - GRAY 2 WAY..........................................336

ENGINE COOLANT TEMPERATURE SENSOR - BLACK 2 WAY................336

ENGINE OIL PRESSURE SWITCH - GREEN 2 WAY.........................336

EVAP/PURGE SOLENOID - BLACK 2 WAY.................................337

DUTY CYCLE EVAP/PURGE SOLENOID...................................337

FUEL INJECTOR NO. 1 (2.0L/2.4L) - BLACK 2 WAY..........................337

FUEL INJECTOR NO. 1 (3.3L/3.8L) - BLACK 2 WAY..........................338

FUEL INJECTOR NO. 2 (2.OL/2.4L) - BLACK 2 WAY.........................338

FUEL INJECTOR NO. 2 (3.3L/3.8L) - BLACK 2 WAY..........................338

FUEL INJECTOR NO. 3 (3.3L/3.8L)- BLACK 2 WAY..........................338

FUEL INJECTOR NO. 3 (2.0L/2.4L) - BLACK 2 WAY..........................339

FUEL INJECTOR NO. 4 (3.3L/3.8L) - BLACK 2 WAY..........................339

FUEL INJECTOR NO. 4 (2.0L/2.4L) - BLACK 2 WAY..........................339

FUEL INJECTOR NO. 5 (3.3L/3.8L) - BLACK 2 WAY..........................339

FUEL INJECTOR NO. 6 (3.3L/3.8L) - BLACK 2 WAY..........................340

FUEL TANK MODULE - LIGHT GRAY 4 WAY...............................340

GENERATOR (GENERATOR SIDE).......................................340

GENERATOR - BLACK 3 WAY...........................................340

IDLE AIR CONTROL MOTOR - BLACK 4 WAY..............................341

IGNITION COIL PACK (2.0L/2.4L) - BLACK 3 WAY...........................341

IGNITION COIL PACK (3.3L/3.8L) - BLACK 4 WAY...........................341

INSTRUMENT CLUSTER - BLACK 13 WAY.................................341

INTAKE AIR TEMPERATURE/MANIFOLD ABSOLUTE PRESSURE SENSOR (2.0L) -

GRAY4 WAY..........................................................342

INTAKE AIR TEMPERATURE SENSOR (2.4L) - GRAY 2 WAY..................342

KNOCK SENSOR - GRAY 2 WAY.........................................342

LEAK DETECTION PUMP - LT. GRAY 4 WAY...............................342

MANIFOLD ABSOLUTE PRESSURE SENSOR (2.4L/3.3L/3.8L) - BLACK 3 WAY. . .343

OUTPUT SPEED SENSOR - GRAY 2 WAY.................................343

OXYGEN SENSOR (SENSOR SIDE)......................................343

OXYGEN SENSOR 1/1 UPSTREAM - GRAY 4 WAY..........................343

OXYGEN SENSOR 1/2 DOWNSTREAM - BLACK 4 WAY.....................344

PARK/NEUTRAL POSITION SWITCH (ATX) - BLACK 3 WAY...................344

FUSES...............................................................346

A/C COMPRESSOR CLUTCH RELAY......................................346

AUTOMATIC SHUT DOWN RELAY (GAS)..................................346

CIGAR LIGHTER/ACCESSORY RELAY....................................346

DIESEL POWER RELAY................................................347

v

ProCarManuals.com

Page 18 of 364

applicable. These procedures can be found in ser-

vice manual procedures. Following these proce-

dures is very important to the safety of individuals

performing diagnostic tests.

4.2.2 VEHICLE PREPARATION FOR

TESTING

Make sure the vehicle being tested has a fully

charged battery. If it does not, false diagnostic codes

or error messages may occur.

4.2.3 SERVICING SUB-ASSEMBLIES

Some components of the powertrain system are

intended to be serviced in assembly only. Attempt-

ing to remove or repair certain system sub-

components may result in personal injury and/or

improper system operation. Only those components

with approved repair and installation procedures in

the service manual should be serviced.

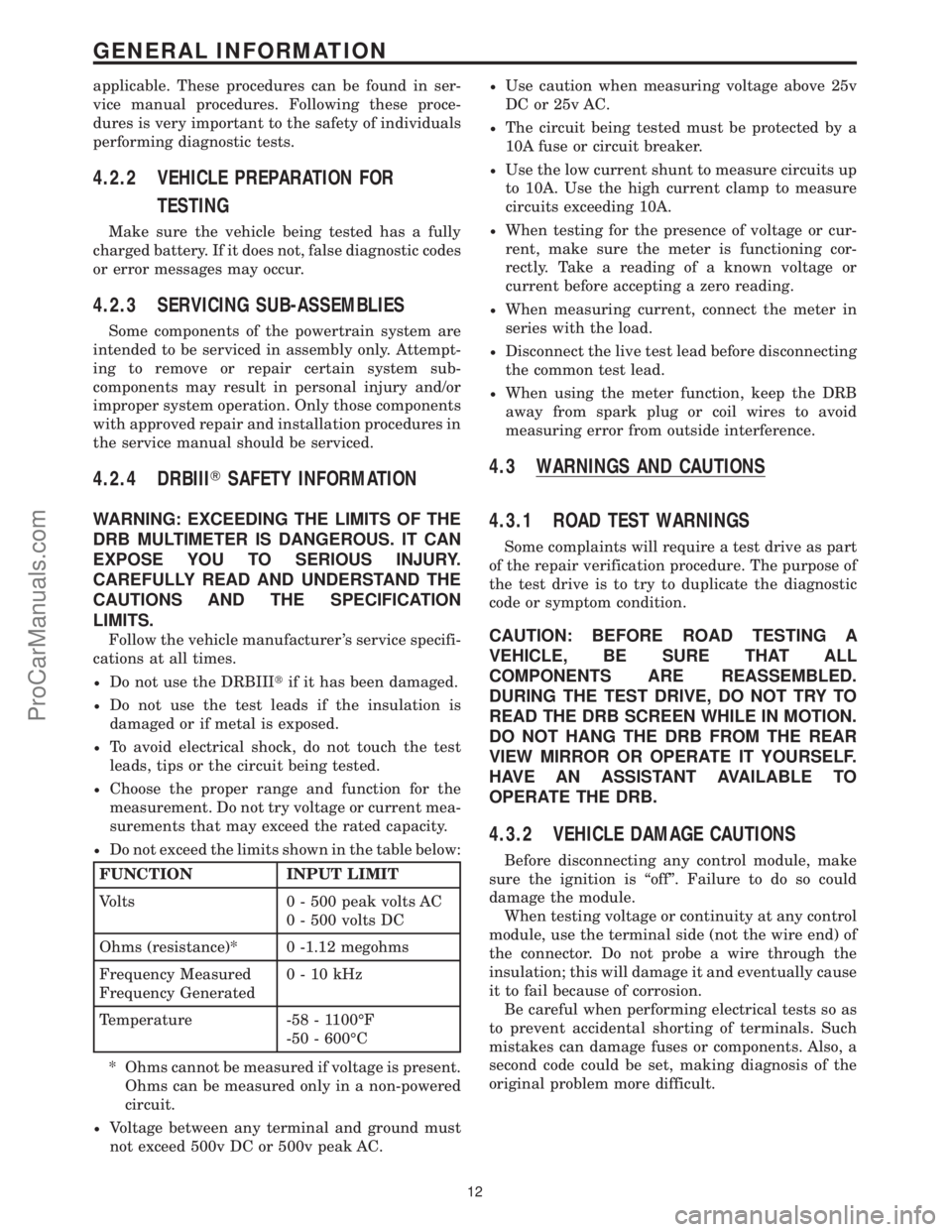

4.2.4 DRBIIITSAFETY INFORMATION

WARNING: EXCEEDING THE LIMITS OF THE

DRB MULTIMETER IS DANGEROUS. IT CAN

EXPOSE YOU TO SERIOUS INJURY.

CAREFULLY READ AND UNDERSTAND THE

CAUTIONS AND THE SPECIFICATION

LIMITS.

Follow the vehicle manufacturer 's service specifi-

cations at all times.

²Do not use the DRBIIItif it has been damaged.

²Do not use the test leads if the insulation is

damaged or if metal is exposed.

²To avoid electrical shock, do not touch the test

leads, tips or the circuit being tested.

²Choose the proper range and function for the

measurement. Do not try voltage or current mea-

surements that may exceed the rated capacity.

²Do not exceed the limits shown in the table below:

FUNCTION INPUT LIMIT

Volts 0 - 500 peak volts AC

0 - 500 volts DC

Ohms (resistance)* 0 -1.12 megohms

Frequency Measured

Frequency Generated0-10kHz

Temperature -58 - 1100ÉF

-50 - 600ÉC

* Ohms cannot be measured if voltage is present.

Ohms can be measured only in a non-powered

circuit.

²Voltage between any terminal and ground must

not exceed 500v DC or 500v peak AC.

²Use caution when measuring voltage above 25v

DC or 25v AC.

²The circuit being tested must be protected by a

10A fuse or circuit breaker.

²Use the low current shunt to measure circuits up

to 10A. Use the high current clamp to measure

circuits exceeding 10A.

²When testing for the presence of voltage or cur-

rent, make sure the meter is functioning cor-

rectly. Take a reading of a known voltage or

current before accepting a zero reading.

²When measuring current, connect the meter in

series with the load.

²Disconnect the live test lead before disconnecting

the common test lead.

²When using the meter function, keep the DRB

away from spark plug or coil wires to avoid

measuring error from outside interference.

4.3 WARNINGS AND CAUTIONS

4.3.1 ROAD TEST WARNINGS

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

CAUTION: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED.

DURING THE TEST DRIVE, DO NOT TRY TO

READ THE DRB SCREEN WHILE IN MOTION.

DO NOT HANG THE DRB FROM THE REAR

VIEW MIRROR OR OPERATE IT YOURSELF.

HAVE AN ASSISTANT AVAILABLE TO

OPERATE THE DRB.

4.3.2 VEHICLE DAMAGE CAUTIONS

Before disconnecting any control module, make

sure the ignition is ªoffº. Failure to do so could

damage the module.

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

12

GENERAL INFORMATION

ProCarManuals.com

Page 31 of 364

TEST ACTION APPLICABILITY

4 Engine Running

With the DRB, read trouble codes.

Are there any Charging System trouble codes?All

Ye s®Refer to Symptom List for problems related to Charging.

Perform Powertrain Verification Test VER-3A.

No®Go To 5

5 Ignition Off

Using a Voltmeter, measure the voltage between the Generator Case and Battery (-)

side.

Caution: Ensure all Wires are clear of the engine's moving parts.

Start the engine.

Is the voltage above 0.4 volt?All

Ye s®Repair Generator Ground high resistance Generator Case to

Battery (-) side.

Perform Powertrain Verification Test VER-3A.

No®Go To 6

6 Ignition Off

Connect Voltmeter between the Generator (12V) B+ Terminal and the Battery (+)

side.

Caution: Ensure all Wires are clear of the engine's moving parts.

Start the engine.

Is the voltage above 0.4 volt?All

Ye s®Repair the B(+) Circuit for high resistance between the Generator

and Battery.

Perform Powertrain Verification Test VER-3A.

No®Go To 7

7 Turn engine off, ignition key on.

With the DRB, read Battery voltage and record.

Using a Voltmeter, measure Battery voltage B(+) to B(-) Terminal.

Record second voltage reading.

Compare the two voltage readings.

Is the voltage difference less than one volt?All

Ye s®Test Complete.

Perform Powertrain Verification Test VER-3A.

No®Go To 8

8 Ignition Off

Disconnect the PCM Connector.

Note: Check connectors - Clean/repair as necessary.

Using a voltmeter, measure the fused B(+) at PCM.

Is the voltage within one volt of the DRB recorded reading?All

Ye s®Repair the B(+) Circuit for high resistance between the PCM and

the Battery.

Perform Powertrain Verification Test VER-3A.

No®Go To 9

25

CHARGING

* CHECKING CHARGING SYSTEM OPERATION WITH NO DTC'S Ð

Continued

ProCarManuals.com

Page 139 of 364

Symptom:

P-0403 EGR SOLENOID CIRCUIT

When Monitored and Set Condition:

P-0403 EGR SOLENOID CIRCUIT

When Monitored: With the ignition key on and engine running and battery voltage > 10

volts.

Set Condition: The EGR solenoid control circuit is not in the expected state when

requested to operate by the PCM.

POSSIBLE CAUSES

EGR SOLENOID DEFECTIVE

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

EGR SOLENOID CIRCUIT WIRING HARNESS INTER DEFECT

EGR SOLENOID CIRCUIT WIRING HARNESS OBSERVABLE DEF

EGR SOLENOID CONTROL CIRCUIT OPEN

EGR SOLENOID CONTROL CIRCUIT SHORT TO GROUND

PCM DEFECTIVE (EGR SOL CKT)

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

With the DRB, read the codes.

Is the Global Good Trip displayed and equal to 0?All

Ye s®Go To 2

No®Go To 7

2 Ignition Off

Disconnect the EGR Solenoid Connector.

Note: Check connectors - Clean/repair as necessary.

Turn ignition on with engine not running.

Using the DRB, actuate the EGR Solenoid.

Using a Voltmeter, probe the Fused Ignition Switch Output Circuit at the EGR

Solenoid Connector.

Is the voltage above 10.0 volts?All

Ye s®Go To 3

No®Repair the open Fused Ignition Switch Output Circuit.

Perform Powertrain Verification Test VER-2A.

133

DRIVEABILITY

ProCarManuals.com

Page 149 of 364

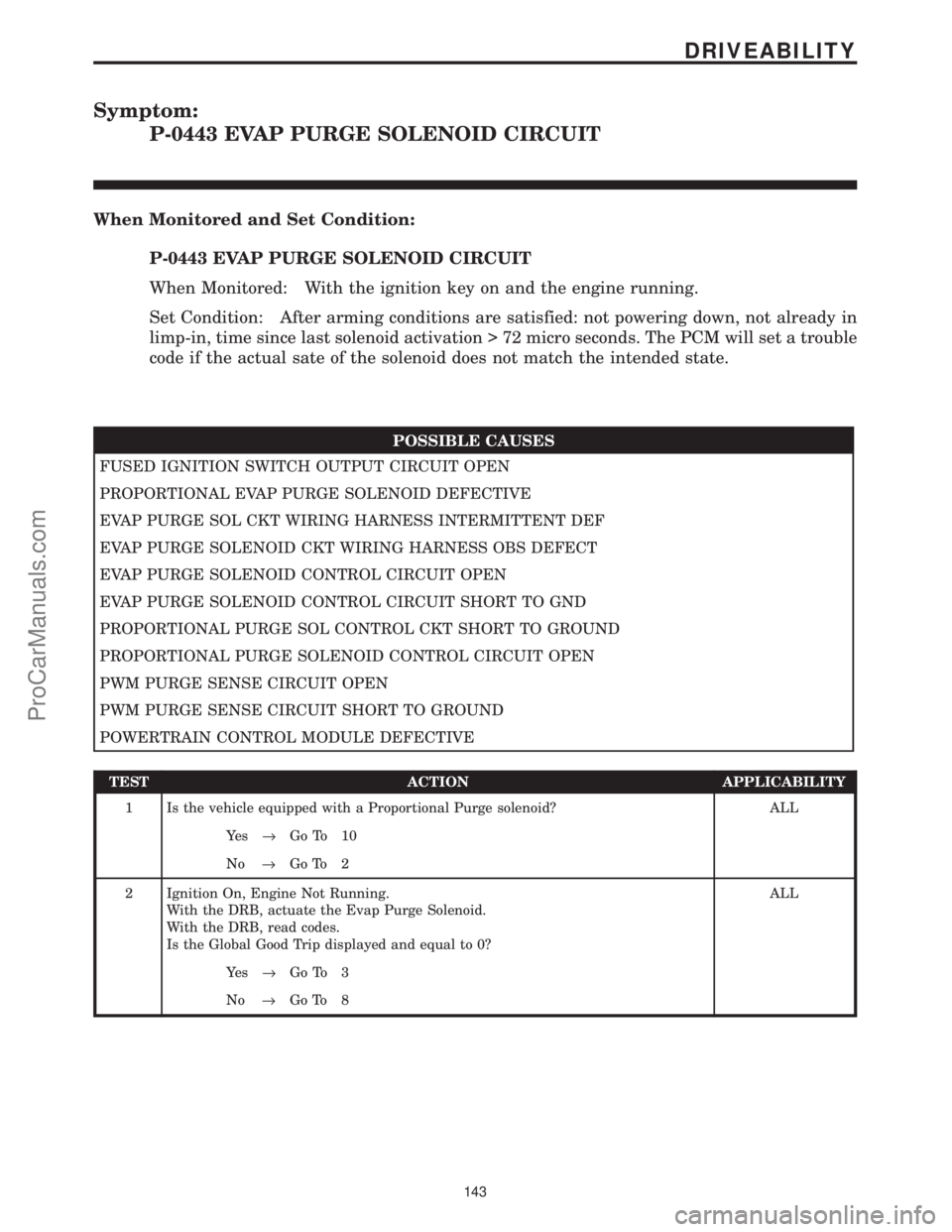

Symptom:

P-0443 EVAP PURGE SOLENOID CIRCUIT

When Monitored and Set Condition:

P-0443 EVAP PURGE SOLENOID CIRCUIT

When Monitored: With the ignition key on and the engine running.

Set Condition: After arming conditions are satisfied: not powering down, not already in

limp-in, time since last solenoid activation > 72 micro seconds. The PCM will set a trouble

code if the actual sate of the solenoid does not match the intended state.

POSSIBLE CAUSES

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

PROPORTIONAL EVAP PURGE SOLENOID DEFECTIVE

EVAP PURGE SOL CKT WIRING HARNESS INTERMITTENT DEF

EVAP PURGE SOLENOID CKT WIRING HARNESS OBS DEFECT

EVAP PURGE SOLENOID CONTROL CIRCUIT OPEN

EVAP PURGE SOLENOID CONTROL CIRCUIT SHORT TO GND

PROPORTIONAL PURGE SOL CONTROL CKT SHORT TO GROUND

PROPORTIONAL PURGE SOLENOID CONTROL CIRCUIT OPEN

PWM PURGE SENSE CIRCUIT OPEN

PWM PURGE SENSE CIRCUIT SHORT TO GROUND

POWERTRAIN CONTROL MODULE DEFECTIVE

TEST ACTION APPLICABILITY

1 Is the vehicle equipped with a Proportional Purge solenoid? ALL

Ye s®Go To 10

No®Go To 2

2 Ignition On, Engine Not Running.

With the DRB, actuate the Evap Purge Solenoid.

With the DRB, read codes.

Is the Global Good Trip displayed and equal to 0?ALL

Ye s®Go To 3

No®Go To 8

143

DRIVEABILITY

ProCarManuals.com

Page 150 of 364

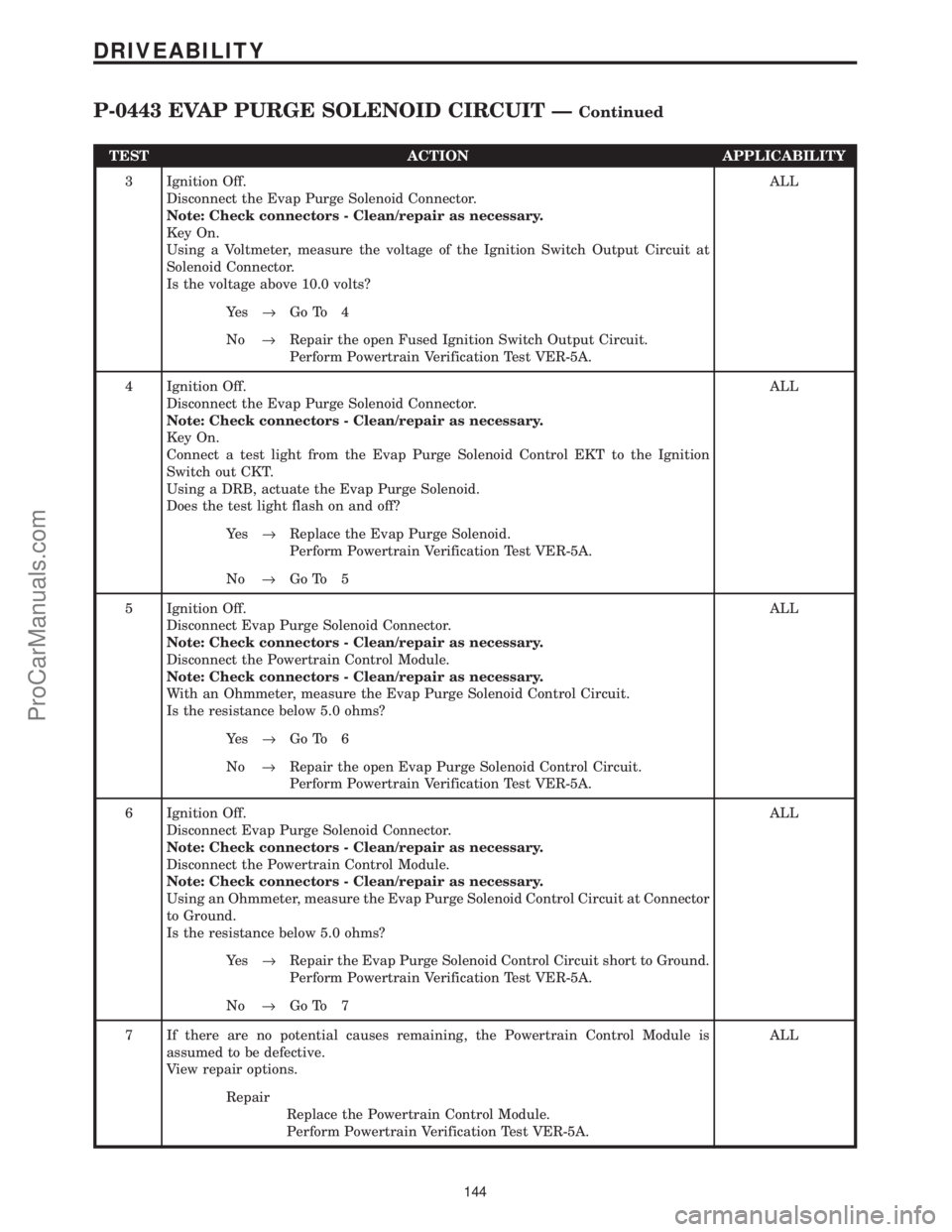

TEST ACTION APPLICABILITY

3 Ignition Off.

Disconnect the Evap Purge Solenoid Connector.

Note: Check connectors - Clean/repair as necessary.

Key On.

Using a Voltmeter, measure the voltage of the Ignition Switch Output Circuit at

Solenoid Connector.

Is the voltage above 10.0 volts?ALL

Ye s®Go To 4

No®Repair the open Fused Ignition Switch Output Circuit.

Perform Powertrain Verification Test VER-5A.

4 Ignition Off.

Disconnect the Evap Purge Solenoid Connector.

Note: Check connectors - Clean/repair as necessary.

Key On.

Connect a test light from the Evap Purge Solenoid Control EKT to the Ignition

Switch out CKT.

Using a DRB, actuate the Evap Purge Solenoid.

Does the test light flash on and off?ALL

Ye s®Replace the Evap Purge Solenoid.

Perform Powertrain Verification Test VER-5A.

No®Go To 5

5 Ignition Off.

Disconnect Evap Purge Solenoid Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

With an Ohmmeter, measure the Evap Purge Solenoid Control Circuit.

Is the resistance below 5.0 ohms?ALL

Ye s®Go To 6

No®Repair the open Evap Purge Solenoid Control Circuit.

Perform Powertrain Verification Test VER-5A.

6 Ignition Off.

Disconnect Evap Purge Solenoid Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the Evap Purge Solenoid Control Circuit at Connector

to Ground.

Is the resistance below 5.0 ohms?ALL

Ye s®Repair the Evap Purge Solenoid Control Circuit short to Ground.

Perform Powertrain Verification Test VER-5A.

No®Go To 7

7 If there are no potential causes remaining, the Powertrain Control Module is

assumed to be defective.

View repair options.ALL

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-5A.

144

DRIVEABILITY

P-0443 EVAP PURGE SOLENOID CIRCUIT ÐContinued

ProCarManuals.com

Page 176 of 364

Symptom:

P-0645 A/C CLUTCH RELAY CIRCUIT

When Monitored and Set Condition:

P-0645 A/C CLUTCH RELAY CIRCUIT

When Monitored: With the ignition key on and battery voltage greater than 10 volts.

Set Condition: An open or shorted condition is detected in the A/C clutch relay control

circuit.

POSSIBLE CAUSES

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

AIR CONDITIONING CLUTCH RELAY DEFECTIVE

A/C CLUTCH RELAY CIRCUIT WITHOUT INTER DEFECT

A/C CLUTCH RELAY CIRCUIT WITHOUT OBSER DEFECT

A/C CLUTCH RELAY CONTROL CIRCUIT SHORT TO GROUND

AIR CONDITIONING CLUTCH RELAY CONTROL CIRCUIT OPEN

PCM DEF (A/C CLUTCH RELAY)

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

Actuate the Air Conditioning Clutch Relay.

Is the Air Conditioning Clutch Relay clicking?All

Ye s®Go To 2

No®Go To 4

2 Ignition On, Engine Not Running

Actuate the Air Conditioning Clutch Relay.

Wiggle the Wiring Harness from the Relay to the PCM.

Did the wiggling interrupt the clicking?All

Ye s®Repair as necessary where wiggling caused the clicking to be

interrupted.

Perform Powertrain Verification Test VER-2A.

No®Go To 3

3 Ignition Off

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-2A.

No®Test Complete.

170

DRIVEABILITY

ProCarManuals.com

Page 177 of 364

TEST ACTION APPLICABILITY

4 Ignition Off

Remove the Air Conditioning Clutch Relay.

Note: Check connectors - Clean/repair as necessary.

Using a Voltmeter, measure the Fused Ignition Switch Output Circuit.

Is the voltage above 10.0 volts?All

Ye s®Go To 5

No®Repair the open Fused Ignition Switch Output Circuit.

Perform Powertrain Verification Test VER-2A.

5 Ignition Off

Remove the Air Conditioning Clutch Relay.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, measure the resistance between terminals C (85) and A (86) of

the Air Conditioning Clutch Relay.

Is the resistance below between 50 to 90 ohms?All

Ye s®Go To 6

No®Replace the Air Conditioning Clutch Relay.

Perform Powertrain Verification Test VER-2A.

6 Ignition Off

Disconnect the PCM grey connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the A/C Clutch Control Circuit from the PCM

connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Air Conditioning Clutch Relay Control Circuit for a

short to ground.

Perform Powertrain Verification Test VER-2A.

No®Go To 7

7 Ignition Off

Disconnect the PCM grey connector.

Remove the Air Conditioning Clutch Relay.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, measure the resistance of the Air Conditioning Clutch Relay

Control Circuit from the relay to the PCM.

Is the resistance below 5.0 ohms?All

Ye s®Go To 8

No®Repair open Air Conditioning Clutch Relay Control Circuit.

Perform Powertrain Verification Test VER-2A.

8 Ignition Off

If there are no potential causes remaining, the PCM is assumed to be defective.

View repair options.All

Repair

Replace the PCM.

Perform Powertrain Verification Test VER-2A.

171

DRIVEABILITY

P-0645 A/C CLUTCH RELAY CIRCUIT ÐContinued

ProCarManuals.com

Page 184 of 364

Symptom:

P1282 FUEL PUMP RELAY CONTROL CIRCUIT

When Monitored and Set Condition:

P±1282 FUEL PUMP RELAY CONTROL CIRCUIT

When Monitored: With the ignition key on and battery voltage greater than 10 volts.

Set Condition: An open or shorted condition is detected in the fuel pump relay control

circuit.

POSSIBLE CAUSES

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

FUEL PUMP RELAY DEFECTIVE

FUEL PUMP RELAY CONTROL CIRCUIT OPEN

FUEL PUMP RELAY CONTROL CIRCUIT SHORT TO GROUND

FUEL PUMP RELAY WIRING HARNESS INTER DEF

FUEL PUMP RELAY WIRING HARNESS OBS DEF

PCM DEFECTIVE

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

With the DRB, actuate the Fuel Pump Relay.

Is the Fuel Pump Relay clicking?All

Ye s®Go To 2

No®Go To 4

2 Ignition On, Engine Not Running

With the DRB actuate the Fuel Pump Relay.

Wiggle the Wiring Harness from the Relay to the PCM.

Did the Fuel Pump Relay clicking stop or become erratic while wiggling the wires?All

Ye s®Repair Circuit as necessary where wiggling caused the clicking to

become erratic.

Perform Powertrain Verification Test VER-2A.

No®Go To 3

3 Ignition Off

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-2A.

No®Test Complete.

178

DRIVEABILITY

ProCarManuals.com

Page 185 of 364

TEST ACTION APPLICABILITY

4 Ignition Off

Disconnect the Fuel Pump Relay.

Note: Check connectors - Clean/repair as necessary.

Ignition On, Engine Not Running

Using a Voltmeter, measure the Fused Ignition Switch Output Circuit.

Is the voltage above 10.0 volts?All

Ye s®Go To 5

No®Repair the open Fused Ignition Switch Output Circuit.

Perform Powertrain Verification Test VER-2A.

5 Ignition Off

Disconnect the Fuel Pump Relay.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure across Terminals 85 and 86 of the Fuel Pump Relay for

resistance.

Is the resistance between 50 and 90 ohms?All

Ye s®Go To 6

No®Replace Fuel Pump Relay.

Perform Powertrain Verification Test VER-2A.

6 Ignition Off

Disconnect the Powertrain Control Module Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Fuel Pump Relay.

Note: Check connectors - Clean/repair as necessary

Using an Ohmmeter, measure the Fuel Pump Relay Control Circuit for resistance.

Is the resistance below 5.0 ohms?All

Ye s®Go To 7

No®Repair the open Fuel Pump Relay Control Circuit.

Perform Powertrain Verification Test VER-2A.

7 Ignition Off

Disconnect the PCM Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Fuel Pump Relay.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the Fuel Pump Relay Control Circuit to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Fuel Pump Relay Control Circuit for a short to ground.

Perform Powertrain Verification Test VER-2A.

No®Go To 8

8 Ignition off.

If there are no potential causes remaining, the PCM is assumed to be defective.

View repair options.All

Repair

Replace the PCM.

Perform Powertrain Verification Test VER-2A.

179

DRIVEABILITY

P1282 FUEL PUMP RELAY CONTROL CIRCUIT ÐContinued

ProCarManuals.com