technical data CHRYSLER VOYAGER 2000 Diagnostic Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 14 of 364

to non-emission codes, they will seem like an intermit-

tent. These codes require a set of parameters to be

performed (The DRBIIItpre-test screens will help

with this for MONITOR codes), this is called a ªTRIPº.

All EURO STAGE III OBD DTCs will be set after one

or in some cases two trip failures, and the MIL will be

turned on. These codes require three successful (no

failures) TRIPS to extinguish the MIL, followed by 40

warm-up cycles to erase the code.

3.3.2 INTERMITTENT CODE

A diagnostic trouble code that is not there every

time the PCM checks the circuit is an ªintermittentº

code. Most intermittent codes are caused by wiring

or connector problems. Defects that come and go

like this are the most difficult to diagnose; they

must be looked for under specific conditions that

cause them. The following checks may assist you in

identifying a possible intermittent problem:

²Visually inspect related wire harness connectors.

Look for broken, bent, pushed out, or corroded

terminals.

²Visually inspect the related harnesses. Look for

chafed, pierced, or partially broken wire.

²Refer to any Hotline Newsletters or technical

service bulletins that may apply.

²Use the DRBIIItdata recorder or co-pilot.

²Use the DRBIIItPEP module lab scope.

3.3.3 RESET COUNTER

The reset counter counts the number of times the

vehicle has been started since codes were last set,

erased, or the battery was disconnected. The reset

counter will count up to 255 start counts.

The number of starts helps determine when the

trouble code actually happened. This is recorded by

the PCM and can be viewed on the DRBIIItas

STARTS since set.

When there are no trouble codes stored in mem-

ory, the DRBIIItwill display ªNO DTC'S Detectedº

and the reset counter will show ªSTARTS since

clear = XXX.º

3.3.4 HANDLING NO TROUBLE CODE

PROBLEMS

Symptom checks cannot be used properly unless

the driveability problem characteristic actually

happens while the vehicle is being tested.

Select the symptom that most accurately de-

scribes the vehicle's driveability problem and then

perform the test routine that pertains to this symp-

tom. Perform each routine test in sequence until the

problem is found. For definitions, see Section 6.0

Glossary of Terms.SYMPTOM DIAGNOSTIC TEST

HARD START CHECKING THE 5-VOLT

SUPPLY CIRCUIT

CHECKING SECONDARY

IGNITION SYSTEM

CHECKING ENGINE VAC-

UUM

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING ENGINE ME-

CHANICAL SYSTEMS

CHECKING EVAP EMISSION

SYSTEM

CHECKING EGR SYSTEM

CHECKING IAT SENSOR

START AND

STALLCHECKING THE 5-VOLT

SUPPLY CIRCUIT

CHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

8

GENERAL INFORMATION

ProCarManuals.com

Page 151 of 364

TEST ACTION APPLICABILITY

8 Ignition On, Engine Not Running.

With the DRB, read codes.

With the DRB, actuate the Evap Purge Solenoid.

Wiggle Wiring Harness from the Solenoid to PCM.

Does the Evap Purge Solenoid Control Circuit code return?ALL

Ye s®Repair as necessary where wiggling caused problem to appear.

Perform Powertrain Verification Test VER-5A.

No®Go To 9

9 Ignition Off.

Using the Schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?ALL

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Go To 10

10 Check the freeze frame data to determine the conditions when code was set.

Attempt duplication of 'freeze frame' conditions for added diagnostics.

If there are no other possible causes remaining there is assumed to be an9intermit-

tent9problem with a Wiring Harness Connector or Wire.

View repair options.ALL

Repair

Visually inspect related Wire Harness Connectors and Harnesses.

Look for broken, bent, pushed out, or corroded terminals and for

chafed, pierced, or partiallly broken wire, respectively. Refer to

any hotlines or technical service bulletins that apply.

11 Ignition On, Engine Not Running.

With the DRB, actuate the Evap Purge Solenoid.

With the DRB, read codes.

Is the Global Good Trip displayed and equal to 0?ALL

Ye s®Go To 12

No®Go To 18

12 Ignition Off.

Disconnect Proportional Purge Solenoid Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance of the Proportional Purge Solenoid.

Is the resistance 14.2 ohms +/- 1.4?ALL

Ye s®Go To 13

No®Replace the open Proportional Purge Solenoid.

Perform Powertrain Verification Test VER-5A.

145

DRIVEABILITY

P-0443 EVAP PURGE SOLENOID CIRCUIT ÐContinued

ProCarManuals.com

Page 153 of 364

TEST ACTION APPLICABILITY

16 Ignition Off.

Disconnect Proportional Purge Solenoid Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the battery.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Powertrain Control Module.

Note: Check connectors - Clean/repair as necessary.

Using and Ohmmeter, measure the PWM Purge Sense Circuit PCM to Solenoid

Connector.

Is the resistance below 5.0 ohms?ALL

Ye s®Go To 17

No®Repair the open PWM Purge Sense Circuit.

Perform Powertrain Verification Test VER-5A.

17 If there are no potential causes remaining, the Powertrain Control Module is

assumed to be defective.

View repair options.ALL

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-5A.

18 Ignition On, Engine Not Running.

With the DRB, actuate the Evap Purge Solenoid.

With the DRB, read codes.

Wiggle Wiring Harness from the Solenoid to PCM.

Does the Evap Purge Solenoid Control Circuit code return?ALL

Ye s®Repair as necessary where wiggling caused problem to appear.

Perform Powertrain Verification Test VER-5A.

No®Go To 19

19 Ignition Off.

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?ALL

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Go To 20

20 Check the freeze frame data to determine the conditions when code was set.

Attempt duplication of 'freeze frame' conditions for added diagnostics.

If there are no other possible causes remaining there is assumed to be an9intermit-

tent9problem with a Wiring Harness Connector or Wire.

View repair options.ALL

Repair

Visually inspect related Wire Harness Connectors and Harnesses.

Look for broken, bent, pushed out, or corroded terminals and for

chafed, pierced, or partiallly broken wire, respectively. Refer to

any hotlines or technical service bulletins that apply.

147

DRIVEABILITY

P-0443 EVAP PURGE SOLENOID CIRCUIT ÐContinued

ProCarManuals.com

Page 216 of 364

TEST ACTION APPLICABILITY

4 Check the freeze frame data to determine the conditions when code was set.

Attempt duplication of 'freeze frame' conditions for added diagnostics.

If there are no other possible causes remaining there is assumed to be an9intermit-

tent9problem with a Wiring Harness Connector or Wire.

View repair options.All

Repair

Visually inspect related Wire Harness Connectors and Harnesses.

Look for broken, bent, pushed out, or corroded terminals and for

chafed, pierced, or partiallly broken wire, respectively. Refer to

any hotlines or technical service bulletins that apply.

5 Ignition Off

Disconnect the LDP Solenoid.

Note: Check connectors - Clean/repair as necessary.

Key on.

Using a Voltmeter, measure the voltage of the Fused Ignition Switch Output Circuit

at the Solenoid Connector.

Is the voltage above 10.0 volts?All

Ye s®Go To 6

No®Repair the open Fused Ignition Switch Output Circuit.

Perform Powertrain Verification Test VER-6A.

6 Ignition Off

Disconnect the LDP Solenoid.

Note: Check connectors - Clean/repair as necessary.

Disconnect the PCM.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance of the LDP Solenoid Control Circuit at

the PCM Connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the LDP Solenoid Circuit for a short to ground.

Perform Powertrain Verification Test VER-6A.

No®Go To 7

7 Ignition Off

Disconnect the LDP Solenoid.

Note: Check connectors - Clean/repair as necessary.

Disconnect the PCM.

Note: Check connectors - Clean/repair as necessary.

With an Ohmmeter, measure the resistance of the LDP Solenoid Control Circuit from

the PCM Connector to the LDP Connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 8

No®Repair the open LDP Solenoid Control Circuit.

Perform Powertrain Verification Test VER-6A.

210

DRIVEABILITY

P-1495 LEAK DETECTION PUMP SOLENOID CIRCUIT ÐContinued

ProCarManuals.com

Page 323 of 364

Verification Tests

VERIFICATION TEST VER-1A APPLICABILITY

No Start Verification

Use this test to verify that a No Start condition has been repaired and that the vehicle can be

returned to the customer.

Note: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and the Transponder (ignition key).

1. Inspect the vehicle to ensure that all components related to the repair are connected

properly.

2. Inspect the engine oil for fuel contamination. Replace the oil and filter as necessary

3. Attempt to start the engine.

4. If the No Start condition is still present, refer to the symptom list and perform diagnostic

testing as necessary. Refer to any Technical Service Bulletins that may apply.

5. Run the engine for one warm-up cycle to verify proper operation. With the DRBIIIt, confirm

that no DTC's are present and that all components are functioning properly.

6. If DTC's are present, refer to the symptom list and perform diagnostic testing as necessary.ALL

VERIFICATION TEST VER-2A APPLICABILITY

Non-OBDII Verification

Use this test to verify that a non-OBDII symptom has been repaired and that the vehicle can

be returned to the customer. A non-OBDII symptom is a comprehensive component related

symptom that is not the result of a failed OBDII major monitor.

Note: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and the Transponder (ignition key).

1. Inspect the vehicle to ensure that all components related to the repair are connected

properly.

2. With the DRBIIIt, Clear DTC's and Reset Memory (all engine values).

3. Run the engine for one warm-up cycle to verify proper operation.

4. Road test the vehicle. Use all accessories that may be related to this repair.

With the DRBIIIt, confirm that no DTC's are present and that all components are functioning

properly.

6. If this test is being performed after a No Trouble Code test, verify that the symptom is no

longer present. If the symptom is still present, or any other symptom or DTC is present, refer

to the symptom list for further diagnostic testing procedures. Check for any Technical Service

Bulletins that may apply.

7. If there are no DTC's present and all components are functioning properly, repair is

complete.ALL

317

VERIFICATION TESTS

ProCarManuals.com

Page 324 of 364

VERIFICATION TEST VER-3A APPLICABILITY

Charging System Verification

Use this test to verify that the Charging System symptom has been repaired and that the

vehicle can be returned to the customer.

Note: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and the Transponder (ignition key).

1. Inspect the vehicle to ensure that all components related to the repair are connected

properly.

2. With the DRBIIIt, Clear DTC's.

3. Perform generator output test. Refer to the appropriate service information as necessary.

4. Start the engine and set engine speed to 2000 RPM for at least thirty seconds.

5. Turn the ignition OFF.

6. Turn the ignition ON, with the engine not running.

7. With the DRBIIIt, Read the DTC's. If the DTC returns, or any other symptom or DTC is

present, refer to the symptom list for further diagnostic testing procedures. Check for any

Technical Service Bulletins that may apply.

8. If there are no DTC's present and all components are functioning properly, the repair is

complete.All

318

VERIFICATION TESTS

Verification Tests ÐContinued

ProCarManuals.com

Page 325 of 364

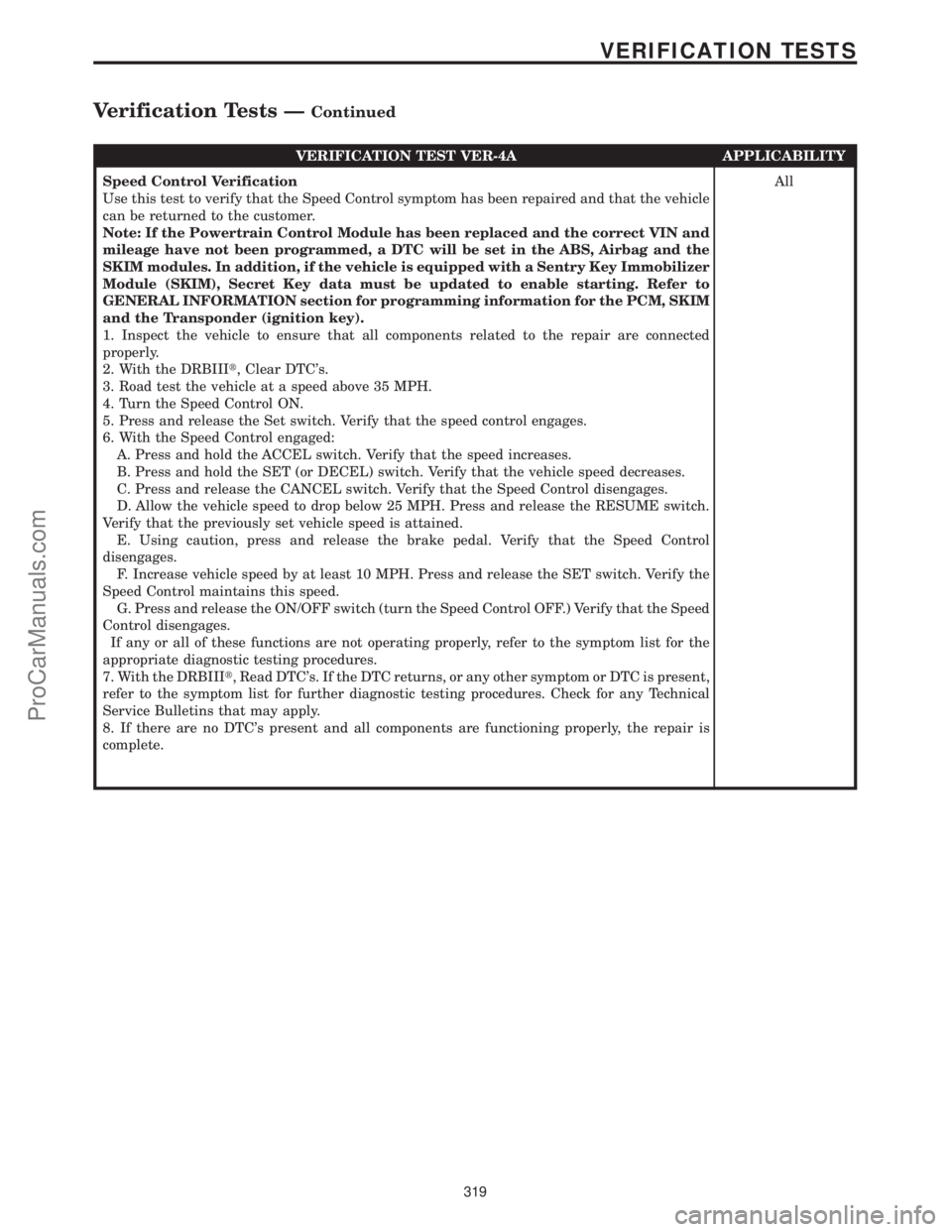

VERIFICATION TEST VER-4A APPLICABILITY

Speed Control Verification

Use this test to verify that the Speed Control symptom has been repaired and that the vehicle

can be returned to the customer.

Note: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and the Transponder (ignition key).

1. Inspect the vehicle to ensure that all components related to the repair are connected

properly.

2. With the DRBIIIt, Clear DTC's.

3. Road test the vehicle at a speed above 35 MPH.

4. Turn the Speed Control ON.

5. Press and release the Set switch. Verify that the speed control engages.

6. With the Speed Control engaged:

A. Press and hold the ACCEL switch. Verify that the speed increases.

B. Press and hold the SET (or DECEL) switch. Verify that the vehicle speed decreases.

C. Press and release the CANCEL switch. Verify that the Speed Control disengages.

D. Allow the vehicle speed to drop below 25 MPH. Press and release the RESUME switch.

Verify that the previously set vehicle speed is attained.

E. Using caution, press and release the brake pedal. Verify that the Speed Control

disengages.

F. Increase vehicle speed by at least 10 MPH. Press and release the SET switch. Verify the

Speed Control maintains this speed.

G. Press and release the ON/OFF switch (turn the Speed Control OFF.) Verify that the Speed

Control disengages.

If any or all of these functions are not operating properly, refer to the symptom list for the

appropriate diagnostic testing procedures.

7. With the DRBIIIt, Read DTC's. If the DTC returns, or any other symptom or DTC is present,

refer to the symptom list for further diagnostic testing procedures. Check for any Technical

Service Bulletins that may apply.

8. If there are no DTC's present and all components are functioning properly, the repair is

complete.All

319

VERIFICATION TESTS

Verification Tests ÐContinued

ProCarManuals.com

Page 326 of 364

VERIFICATION TEST VER-5A APPLICABILITY

OBDII Road Test Verification

Use this test to verify that the OBDII symptom has been repaired and that the vehicle can be

returned to the customer. The proper way to verify that an OBDII DTC has been repaired is to

allow the PCM to run and pass the appropriate OBDII monitor(s).

Note: If the Powertrain Control Module has been changed and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and the Transponder (ignition key).

1. Inspect the vehicle to ensure that all components related to the repair are connected

properly.

2. If any other DTC is present, refer to the symptom list for further diagnostic testing

procedures.

3. With the DRBIIIt, Clear DTC's.

4. In order for an OBDII monitor to run, certain pre-test conditions must be met. Refer to the

applicable OBDII monitor pre-test screen on the DRBIIItfor monitor enabling conditions.

5. Operate the vehicle within the enabling conditions and allow the applicable monitor to run.

While the monitor is running, the OBDII monitor screen on the DRBIIItwill display ªIN

PROGRESSº and the DRBIIItwill beep. After the monitor is complete, view the results. Refer

to the appropriate service information as necessary. A monitor may have to fail more than once

in order to set a DTC.

If the monitor fails, or the DTC returns, or any other symptom or DTC is present, refer to the

symptom list for further diagnostic testing procedures. Check for any Technical Service

Bulletins that may apply.

If there are no DTC's present and all components are functioning properly, the repair is

complete.ALL

Powertrain Verification Test VER-5A2 APPLICABILITY

Fuel System Lean/Rich or Misfire Verification

Use this test to verify that the Fuel System Lean, Fuel System Rich, or Misfire symptom has

been repaired and that the vehicle can be returned to the customer.

NOTE: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret KEY data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and the Transponder (ignition key).

1. Inspect the vehicle to ensure that all components related to the repair are connected

properly.

2. If any other DTC is present, refer to the symptom list for further diagnostic testing

procedures.

3. With the DRBIIIt, monitor the Similar Conditions Window and attempt to duplicate the

conditions that the vehicle was operating at when the DTC was set. If the conditions can be

duplicated, the Good Trip counter will change to one or more.

4. If the DTC resets, or the OBDII monitor fails after running, or if any other symptom or DTC

is present, return to the symptom list and perform the appropriate diagnostic testing

procedures. Check for any Technical Service Bulletins that may apply.

5. If the monitor runs and the Good Trip Counter changes to one or more, the condition is no

longer present. If there are no DTCs and all components are functioning properly, the repair is

complete.ALL

320

VERIFICATION TESTS

Verification Tests ÐContinued

ProCarManuals.com

Page 327 of 364

Powertrain Verification Test VER-5A3 APPLICABILITY

OBDII Monitor Verification

Use this test to verify that the OBDII monitor symptom has been repaired and that the vehicle

can be returned to the customer.

NOTE: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and the Transponder (ignition key).

1. Inspect the vehicle to ensure that all components related to the repair are connected

properly.

2. If any other DTC is present, refer to the symptom list for further diagnostic testing

procedures.

3. With the DRBIIIt, monitor the pre-test enabling conditions. Operate the vehicle within the

enabling conditions and allow the applicable monitor to run.

4. If the DTC resets, or the OBDII monitor fails after running, or if any other symptom or DTC

is present, return to the symptom list and perform the appropriate diagnostic testing

procedurs. Refer to any Technical Service Bulletins that may apply.

5. If the monitor runs and the Good Trip Counter changes to one or more, the condition is no

longer present.

6. If there are no DTCs and all components are functioning properly, the repair is complete.All

Powertrain Verification Test VER-6A APPLICABILITY

LDP Monitor Verification

Use this test to verify that the LDP monitor symptom has been repaired and that the vehicle

can be returned to the customer.

NOTE: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and the

SKIM modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programming information for the PCM, SKIM

and Transponder (ignition key).

1. Inspect the vehicle to ensure that all components are related to the repair are connected

properly.

2. If any other DTC is present, refer to the symptom list for futher diagnostic testing

procedures.

3. With the DRBIIIt, perform the LDP Monitor Test. Follow the instructions on the DRBIIIt

screen.

4. If the DTC resets, or the OBDII monitor fails after running, or if any other symptom or DTC

is present, return to the symptom list and perform the appropriate diagnostic testing

procedures. Refer to any Technical Service Bulletins that mat apply.

5. If the monitor runs and test does not fail, the condition is no longer present.

6. If there are no DTCs and all components are functioning properly, the repair is complete.All

321

VERIFICATION TESTS

Verification Tests ÐContinued

ProCarManuals.com

Page 328 of 364

Powertrain Verification Test VER-7A APPLICABILITY

SKIS Verfication

Use this test to verify that SKIM system symptom has been repaired and that the vehicle can

be returned to the customer.

Note: If the Powertrain Control Module has been replaced and the correct VIN and

mileage have not been programmed, a DTC will be set in the ABS, Airbag and SKIM

modules. In addition, if the vehicle is equipped with a Sentry Key Immobilizer

Module (SKIM), Secret Key data must be updated to enable starting. Refer to

GENERAL INFORMATION section for programmig information for the PCM, SKIM

and the Transponder (ignition key).

1.Inspect the vehicle to ensure that all components related to the repair are connected properly.

2. Inspect the engine oil for fuel contamination. Replace the oil and filter as necessary.

3. Start the engine.

4. Run the engine for one warm-up cycle to verify proper operation. With the DRBIIIt, confirm

that no DTCs are present and that all components are functioning properly. If the DTC is still

present refer to any Technical Service Bulletins that may apply.

5. If a different DTC(s) is present, refer to the symtom list and perform diagnostic testing as

necessary. If there are no DTCs present and all components are functioning correctly, repair is

now complete.All

322

VERIFICATION TESTS

Verification Tests ÐContinued

ProCarManuals.com