wiring CHRYSLER VOYAGER 2000 Diagnostic Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2000Pages: 364, PDF Size: 2.17 MB

Page 14 of 364

to non-emission codes, they will seem like an intermit-

tent. These codes require a set of parameters to be

performed (The DRBIIItpre-test screens will help

with this for MONITOR codes), this is called a ªTRIPº.

All EURO STAGE III OBD DTCs will be set after one

or in some cases two trip failures, and the MIL will be

turned on. These codes require three successful (no

failures) TRIPS to extinguish the MIL, followed by 40

warm-up cycles to erase the code.

3.3.2 INTERMITTENT CODE

A diagnostic trouble code that is not there every

time the PCM checks the circuit is an ªintermittentº

code. Most intermittent codes are caused by wiring

or connector problems. Defects that come and go

like this are the most difficult to diagnose; they

must be looked for under specific conditions that

cause them. The following checks may assist you in

identifying a possible intermittent problem:

²Visually inspect related wire harness connectors.

Look for broken, bent, pushed out, or corroded

terminals.

²Visually inspect the related harnesses. Look for

chafed, pierced, or partially broken wire.

²Refer to any Hotline Newsletters or technical

service bulletins that may apply.

²Use the DRBIIItdata recorder or co-pilot.

²Use the DRBIIItPEP module lab scope.

3.3.3 RESET COUNTER

The reset counter counts the number of times the

vehicle has been started since codes were last set,

erased, or the battery was disconnected. The reset

counter will count up to 255 start counts.

The number of starts helps determine when the

trouble code actually happened. This is recorded by

the PCM and can be viewed on the DRBIIItas

STARTS since set.

When there are no trouble codes stored in mem-

ory, the DRBIIItwill display ªNO DTC'S Detectedº

and the reset counter will show ªSTARTS since

clear = XXX.º

3.3.4 HANDLING NO TROUBLE CODE

PROBLEMS

Symptom checks cannot be used properly unless

the driveability problem characteristic actually

happens while the vehicle is being tested.

Select the symptom that most accurately de-

scribes the vehicle's driveability problem and then

perform the test routine that pertains to this symp-

tom. Perform each routine test in sequence until the

problem is found. For definitions, see Section 6.0

Glossary of Terms.SYMPTOM DIAGNOSTIC TEST

HARD START CHECKING THE 5-VOLT

SUPPLY CIRCUIT

CHECKING SECONDARY

IGNITION SYSTEM

CHECKING ENGINE VAC-

UUM

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING ENGINE ME-

CHANICAL SYSTEMS

CHECKING EVAP EMISSION

SYSTEM

CHECKING EGR SYSTEM

CHECKING IAT SENSOR

START AND

STALLCHECKING THE 5-VOLT

SUPPLY CIRCUIT

CHECKING SECONDARY

IGNITION SYSTEM

CHECKING PCM POWER

AND GND CKT

CHECKING THE FUEL

PRESSURE

CHECKING COOLANT SEN-

SOR CALIBRATION

CHECKING THROTTLE PO-

SITION SENSOR CALIBRA-

TION

CHECKING MAP SENSOR

CALIBRATION

CHECKING THE MINIMUM

IDLE AIR FLOW

8

GENERAL INFORMATION

ProCarManuals.com

Page 17 of 364

CHECKING FOR OXYGEN

SENSOR SWITCHING

CHECKING O2S HEATER

CHECKING IDLE AIR CON-

TROL MOTOR OPERATION

CHECKING ENGINE ME-

CHANICAL SYSTEMS

CHECKING EVAP EMISSION

SYSTEM

CHECKING EGR SYSTEM

CHECKING IAT SENSOR

CHECKING PNP SWITCH

3.4 USING THE DRBIIIT

Refer to the DRBIIItuser 's guide for instructions

and assistance with reading trouble codes, erasing

trouble codes, and other DRBIIItfunctions.

3.5 DRB ERROR MESSAGES AND BLANK

SCREEN

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

± User-Requested WARM Boot or User-

Requested COLD Boot.

This is a sample of such an error message display:

ver: 2.14

date: 26 Jul93

file: key_itf.cc

date: Jul 26 1993

line: 548

err: 0x1

User-Requested COLD Boot

Press MORE to switch between this display

and the application screen.

Press F4 when done noting information.

3.5.1 DRB IIITDOES NOT POWER UP

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage (data link

connector cavity 16). A minimum of 11 volts is

required to adequately power the DRBIIIt.

If all connections are proper between the

DRBIIItand vehicle or other devices, and the

vehicle battery is fully charged, an inoperative

DRBIIItmay be the result of a faulty cable or

vehicle wiring. For a blank screen, refer to the

appropriate body diagnostics manual.

3.5.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

4.0 DISCLAIMERS, SAFETY,

WARNINGS

4.1 DISCLAIMERS

All information, illustrations, and specifications

contained in this manual are based on the latest

information available at the time of publication.

The right is reserved to make changes at any time

without notice.

4.2 SAFETY

4.2.1 TECHNICIAN SAFETY INFORMATION

WARNING: ENGINES PRODUCE CARBON

MONOXIDE THAT IS ODORLESS, CAUSES

SLOWER REACTION TIME, AND CAN LEAD

TO SERIOUS INJURY. WHEN THE ENGINE IS

OPERATING, KEEP SERVICE AREAS WELL

VENTILATED OR ATTACH THE VEHICLE

EXHAUST SYSTEM TO THE SHOP EXHAUST

REMOVAL SYSTEM.

Set the parking brake and block the wheels before

testing or repairing the vehicle. It is especially impor-

tant to block the wheels on front-wheel drive vehicles;

the parking brake does not hold the drive wheels.

When servicing a vehicle, always wear eye pro-

tection, and remove any metal jewelry such as

watchbands or bracelets that might make an inad-

vertent electrical contact.

When diagnosing a powertrain system problem,

it is important to follow approved procedures where

11

GENERAL INFORMATION

ProCarManuals.com

Page 22 of 364

Symptom:

P-0622 GENERATOR FIELD NOT SWITCHING PROPERLY

When Monitored and Set Condition:

P-0622 GENERATOR FIELD NOT SWITCHING PROPERLY

When Monitored: With the ignition key on and the engine not running.

Set Condition: This trouble code sets when the PCM tries to regulate the generator field

with no result during monitoring.

POSSIBLE CAUSES

GENERATOR FIELD RESISTANCE > = 5.0 OHMS

ASD WIRING HARNESS INTERMITTENT DEFECT

ASD WIRING HARNESS OBSERVABLE DEFECT

GENERATOR FIELD DRIVE CIRCUIT SHORT TO GROUND

GENERATOR FIELD DRIVER CIRCUIT OPEN

PCM DEFECTIVE (GENERATOR)

ASD RELAY OUTPUT CIRCUIT OPEN

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running.

With the DRB, actuate the Generator Field Driver Circuit.

Backprobe the ASD Relay Output Circuit at the back of the Generator.

Is the voltage above 10.0 volts?All

Ye s®Go To 2

No®Repair the open ASD Relay Output Circuit, Generator to Harness

Splice.

2 Engine Running

With the DRB, actuate the Generator Field Driver Circuit.

Backprobe the Generator Field Driver Circuit at the back of the Generator.

Does the voltage shift from low to high?All

Ye s®Go To 3

No®Go To 5

3 Ignition On, Engine Not Running.

With the DRB, actuate the Generator Field Driver Circuit.

With the DRB, read codes.

Wiggle Wiring Harness from the Generator to PCM.

Does the Generator Field Driver Circuit code return?All

Ye s®Repair as necessary where wiggling caused problem to appear.

Perform Powertrain Verification Test VER-3A.

No®Go To 4

16

CHARGING

ProCarManuals.com

Page 23 of 364

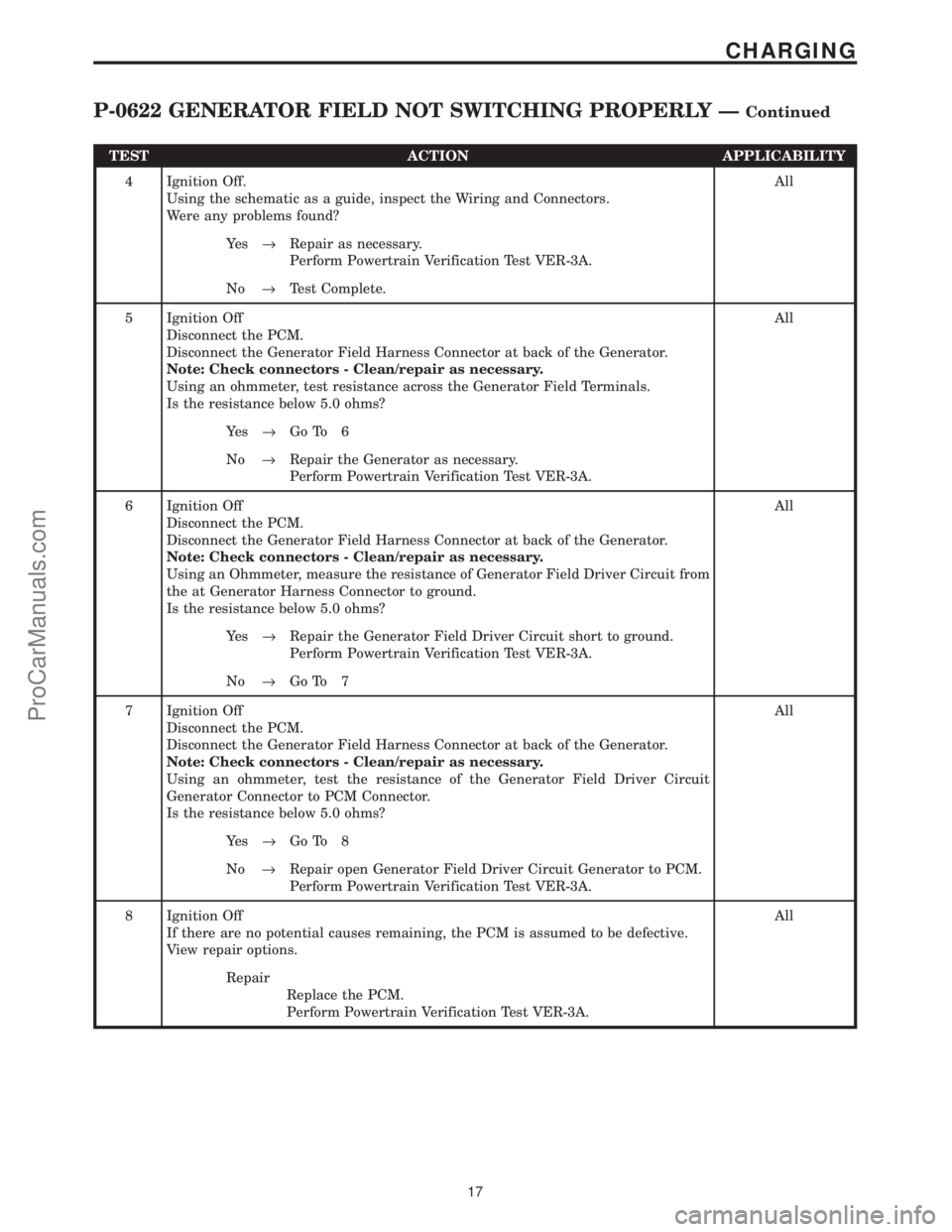

TEST ACTION APPLICABILITY

4 Ignition Off.

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-3A.

No®Test Complete.

5 Ignition Off

Disconnect the PCM.

Disconnect the Generator Field Harness Connector at back of the Generator.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, test resistance across the Generator Field Terminals.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the Generator as necessary.

Perform Powertrain Verification Test VER-3A.

6 Ignition Off

Disconnect the PCM.

Disconnect the Generator Field Harness Connector at back of the Generator.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance of Generator Field Driver Circuit from

the at Generator Harness Connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Generator Field Driver Circuit short to ground.

Perform Powertrain Verification Test VER-3A.

No®Go To 7

7 Ignition Off

Disconnect the PCM.

Disconnect the Generator Field Harness Connector at back of the Generator.

Note: Check connectors - Clean/repair as necessary.

Using an ohmmeter, test the resistance of the Generator Field Driver Circuit

Generator Connector to PCM Connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 8

No®Repair open Generator Field Driver Circuit Generator to PCM.

Perform Powertrain Verification Test VER-3A.

8 Ignition Off

If there are no potential causes remaining, the PCM is assumed to be defective.

View repair options.All

Repair

Replace the PCM.

Perform Powertrain Verification Test VER-3A.

17

CHARGING

P-0622 GENERATOR FIELD NOT SWITCHING PROPERLY ÐContinued

ProCarManuals.com

Page 33 of 364

Symptom:

P-0106 BAROMETRIC PRESSURE OUT OF RANGE

When Monitored and Set Condition:

P-0106 BAROMETRIC PRESSURE OUT OF RANGE

When Monitored: With the ignition key on at less than 350 milliseconds and engine speed

at less than 255 RPM.

Set Condition: The PCM senses the voltage from the MAP sensor to be less than 2.196

volts but above 0.019 volt for 300 milliseconds

POSSIBLE CAUSES

MAP SENSOR 5V SUPPLY CIRCUIT OPEN

MAP SENSOR 5V SUPPLY CIRCUIT SHORT TO GROUND

MAP SENSOR SIGNAL CIRCUIT OPEN

MAP SENSOR SIGNAL CIRCUIT PARTIAL SHORT TO GROUND

MAP SENSOR WIRING HARNESS INTERMITTENT DEFECT

MAP SENSOR WIRING HARNESS OBSERVABLE DEFECT

MAP SENSOR DEFECTIVE

PCM DEFECTIVE (VOLTAGE HIGH)

PCM DEFECTIVE (VOLTAGE LOW)

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

With the DRB, read the MAP Sensor voltage.

Is the voltage below 2.2 volts?All

Ye s®Go To 2

No®Go To 11

2 Ignition Off

Disconnect the MAP Sensor Electrical Connector.

Turn the ignition on, engine not running.

Note: Check connectors - Clean/repair as necessary.

Using a Voltmeter, measure voltage of the 5-Volt Supply Circuit at the Map Sensor

Connector.

Is the voltage above 4.5 volts?All

Ye s®Go To 3

No®Go To 7

27

DRIVEABILITY

ProCarManuals.com

Page 35 of 364

TEST ACTION APPLICABILITY

8 Ignition Off

Disconnect the MAP Sensor Electrical Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the Powertrain Control Module Connector.

Note: Check connectors - Clean/repair as necessary.

With an Ohmmeter, measure the 5-Volt Supply Circuit to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the 5-Volt Supply Circuit for a short to ground.

Perform Powertrain Verification Test VER-2A.

No®Go To 9

9 Ignition Off

Disconnect the MAP Sensor Electrical Connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, with engine not running.

With the DRB, read the MAP Sensor voltage.

Is the voltage above 2.2 volts?All

Ye s®Repair the MAP Sensor Signal Circuit for a partial short to

ground.

Perform Powertrain Verification Test VER-2A.

No®Go To 10

10 If there are no potential causes remaining, the PCM is assumed to be defective.

View repair options.All

Repair

Replace the PCM.

Perform Powertrain Verification Test VER-2A.

11 Ignition On, Engine Not Running

Wiggle the Wiring Harness from the MAP Sensor to the Powertrain Control Module.

Monitor the MAP Sensor voltage with the DRB, while wiggling the Wiring Harness.

Did the voltage go below 2.2 volts?All

Ye s®Repair Wiring as necessary where wiggling caused voltage drop.

Perform Powertrain Verification Test VER-2A.

No®Go To 12

12 Ignition Off

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-2A.

No®Test Complete.

29

DRIVEABILITY

P-0106 BAROMETRIC PRESSURE OUT OF RANGE ÐContinued

ProCarManuals.com

Page 36 of 364

Symptom:

P-0107 MAP SENSOR VOLTAGE TOO LOW

When Monitored and Set Condition:

P-0107 MAP SENSOR VOLTAGE TOO LOW

When Monitored: With engine rpm above 400 but less than 1500 and the TP Sensor

voltage less than 1.0 volt.

Set Condition: The MAP Sensor Signal voltage is below 1.2 volts at start, or below .02 volt

for 1.76 seconds with engine running.

POSSIBLE CAUSES

MAP SENSOR CONN/WIRING HARNESS INTERMITTENT DEF

MAP SENSOR CONN/WIRING HARNESS OBSERVABLE DEFECT

MAP SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

MANIFOLD ABSOLUTE PRESSURE SENSOR DEFECTIVE

POWERTRAIN CONTROL MODULE DEFECTIVE

MAP SENSOR SIGNAL CIRCUIT OPEN

MAP SENSOR SIGNAL CKT SHORTED TO SENSOR GROUND CKT

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

With the DRB, read the MAP Sensor voltage.

Is the MAP Sensor voltage below 1.2 volts?All

Ye s®Go To 2

No®Go To 6

2 Ignition Off

Disconnect the MAP Sensor Electrical Connector.

Ignition on, engine not running.

Note: Check connectors - Clean/repair as necessary.

Use the DRB to read MAP Sensor voltage.

Is the MAP Sensor voltage above 4.0 volts?All

Ye s®Replace the MAP Sensor.

Perform Powertrain Verification Test VER-5A.

No®Go To 3

30

DRIVEABILITY

ProCarManuals.com

Page 37 of 364

TEST ACTION APPLICABILITY

3 Ignition Off

Disconnect the MAP Sensor Electrical Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance of the MAP Sensor Signal Circuit to

ground.

Is resistance below 5.0 ohms?All

Ye s®Repair MAP Sensor Signal Circuit shorted to ground.

Perform Powertrain Verification Test VER-5A.

No®Go To 4

4 Ignition Off

Disconnect the MAP Sensor Electrical Connector.

Note: Check connectors - Clean/repair as necessary.

Using an Ohmmeter, measure the resistance of the MAP Sensor Signal Circuit to

Sensor Ground at MAP Sensor Connector.

Is resistance below 5.0 ohms?All

Ye s®Repair MAP Sensor Signal Circuit shorted to Sensor Ground

Circuit.

Perform Powertrain Verification Test VER-5A.

No®Go To 5

5 If there are no potential causes remaining, the PCM is assumed to be defective.

View repair options.All

Repair

Replace the Powertrain Control Module.

Perform Powertrain Verification Test VER-5A.

6 Ignition On, Engine Not Running

Wiggle MAP Sensor Connector & Harness.

Monitor the DRB display.

Was there any MAP Sensor voltage change?All

Ye s®Repair the Harness or Connector that caused the voltage change.

Perform Powertrain Verification Test VER-5A.

No®Go To 7

7 Ignition Off

Using the schematic as a guide, inspect the Wiring and Connectors.

Were any problems found?All

Ye s®Repair as necessary.

Perform Powertrain Verification Test VER-5A.

No®Test Complete.

31

DRIVEABILITY

P-0107 MAP SENSOR VOLTAGE TOO LOW ÐContinued

ProCarManuals.com

Page 38 of 364

Symptom:

P-0108 MAP SENSOR VOLTAGE TOO HIGH

When Monitored and Set Condition:

P-0108 MAP SENSOR VOLTAGE TOO HIGH

When Monitored: With engine rpm above 400 but less than 1500 and closed throttle.

Set Condition: The MAP Sensor Signal voltage is greater than 4.6.

POSSIBLE CAUSES

MAP SENSOR GROUND CIRCUIT OPEN

MAP SENSOR SIGNAL CIRCUIT OPEN

MAP SENSOR DEFECTIVE

MAP SENSOR WIRING HARN AND CONN INTERMITTENT DEF

MAP SENSOR WIRING HARNESS AND CONN OBSERVABLE DEF

PCM DEFECTIVE (MAP SENSOR VOLTAGE TOO HIGH)

TEST ACTION APPLICABILITY

1 Start the engine.

With the DRB, read the MAP Sensor voltage.

Is the MAP Sensor voltage above 4.6 volts?All

Ye s®Go To 2

No®Go To 6

2 Ignition Off

Disconnect the MAP Sensor Electrical Connector.

Note: Check connectors - Clean/repair as necessary.

Connect a jumper wire between the Sensor Signal and Sensor Ground Circuits.

Turn ignition on, use the DRB to read the MAP Sensor voltage.

Is the voltage below 1.0 volt?All

Ye s®Replace the MAP Sensor.

Perform Powertrain Verification Test VER-5A.

No®Go To 3

3 Ignition Off

Disconnect the MAP Sensor Electrical Connector.

Note: Check connectors - Clean/repair as necessary.

Connect a jumper wire between the Sensor Signal Circuit and an engine ground.

Ignition On.

Read the MAP Sensor voltage.

Is the MAP Sensor voltage below 1.0 volt?All

Ye s®Repair the open MAP Sensor Ground Circuit.

Perform Powertrain Verification Test VER-5A.

No®Go To 4

32

DRIVEABILITY

ProCarManuals.com

Page 40 of 364

Symptom:

P-0112 INTAKE AIR TEMP SENSOR VOLTAGE LOW

When Monitored and Set Condition:

P-0112 INTAKE AIR TEMP SENSOR VOLTAGE LOW

When Monitored: With the ignition on and the engine running.

Set Condition: The intake air sensor circuit voltage at PCM cavity 37 goes below .51 volt.

POSSIBLE CAUSES

IAT SEN WIRING HARNESS INTERMITTENT DEFECT

IAT SEN WRING HARNESS OBSERVABLE DEFECT

SENSOR SIGNAL CIRCUIT SHORT TO GROUND

SENSOR SIGNAL CIRCUIT SHORT TO SENSOR GND CIRCUIT

IAT SENSOR VOLTAGE GREATER THAN 4.0 VOLTS

PCM DEFECTIVE (IAT SENSOR)

TEST ACTION APPLICABILITY

1 Ignition On, Engine Not Running

With the DRB, read the IAT Sensor voltage.

Is the IAT Sensor voltage below 0.5 volt?All

Ye s®Go To 2

No®Go To 6

2 Ignition Off

Disconnect the IAT Sensor Connector.

Note: Check connectors - Clean/repair as necessary.

Ignition On, Engine Not Running

With the DRB, read the IAT Sensor voltage.

Is the IAT Sensor voltage above 4.0 volts?All

Ye s®Replace the IAT Sensor.

Perform Powertrain Verification Test VER-5A.

No®Go To 3

3 Ignition Off

Disconnect the IAT Sensor Connector.

Note: Check connectors - Clean/repair as necessary.

Disconnect the PCM Connector.

Check connectors - Clean/repair as necessary.

Using an ohmmeter, measure the Sensor Signal Circuit to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Sensor Signal Circuit for a short to ground.

Perform Powertrain Verification Test VER-5A.

No®Go To 4

34

DRIVEABILITY

ProCarManuals.com