traction control CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1045 of 4284

BODY CONTROL MODULE C4 - BLACK/GRAY 34 WAYCAV CIRCUIT FUNCTION

1 E18 20OR/LB (POWER

MIRRORS)PANEL LAMPS DRIVER (MIRROR SWITCH)

2 E12 20OR/GY PANEL LAMPS DRIVER (HVAC)

3 E19 20OR/BR PANEL LAMPS DRIVER (HEADLAMP SWITCH)

4 D9 20WT/GY RKE MODULE PROGRAM ENABLE

5 G150 20VT/BR INSTRUMENT CLUSTER WAKE UP SENSE

6 E17 20OR/YL (EXCEPT

BUILT-UP-EXPORT)PARADE MODE SIGNAL (RADIO)

7 P162 20LG/DG (BUILT-UP-

EXPORT)PASSENGER FOLDING MIRROR RELAY CONTROL

8 G69 20VT/WT (HIGH LINE) VTSS INDICATOR DRIVER

9 L161 20WT/LG LEFT TURN INDICATOR DRIVER

10 F504 20GY/PK IGNITION SWITCH OUTPUT (RUN)

11 E14 20OR/TN PANEL LAMPS DRIVER (RADIO)

12 E13 20OR/YL PANEL LAMPS DRIVER (INSTRUMENT CLUSTER)

13 X920 20GY/OR RADIO CONTROL MUX RETURN

14 G900 20VT/OR IGNITION SWITCH SENSE RETURN

15 - -

16 - -

17 L160 20WT/TN RIGHT TURN INDICATOR DRIVER

18 M26 20YL/DB HALO LAMP DRIVER

19 - -

20 - -

21 - -

22 G902 20VT/OR MULTI-FUNCTION SWITCH MUX RETURN

23 - -

24 - -

25 - -

26 M28 20YL/TN GLOVE BOX LAMP DRIVER

27 - -

28 - -

29 - -

30 - -

31 G96 20VT/DG REMOTE KEYLESS ENTRY INTERFACE

32 B27 20DG/WT TRACTION CONTROL SWITCH SENSE

33 P136 20TN/YL (BUILT-UP-

EXPORT)FOLDING MIRROR SWITCH SENSE

34 G26 20VT/OR CHIME DRIVER

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1016

CONNECTOR PINOUTS

Page 1156 of 4284

TABLE OF CONTENTS

1.0 INTRODUCTION.........................................................1

1.1SYSTEM COVERAGE...............................................1

1.2SIX-STEP TROUBLESHOOTING PROCEDURE..........................1

2.0 IDENTIFICATION OF SYSTEM.............................................1

3.0 SYSTEM DESCRIPTION AND FUNCTIONAL OPERATION......................1

3.1TEVES MARK 20 SYSTEM DESCRIPTION..............................1

3.2TRACTION CONTROL SYSTEM (TCS) DESCRIPTION....................1

3.3SYSTEM COMPONENTS.............................................2

3.3.1ABS AND BRAKE WARNING INDICATORS.......................2

3.3.2CONTROLLER ANTILOCK BRAKE (CAB)........................2

3.3.3HYDRAULIC CONTROL UNIT..................................3

3.3.4SWITCHES/SENSORS........................................3

3.3.5SYSTEM INITIALIZATION.....................................3

3.3.6DIAGNOSTIC MODE.........................................4

3.4DIAGNOSTIC TROUBLE CODES......................................4

3.5DRBIIITERROR MESSAGES AND BLANK SCREEN......................4

3.5.1DRBIIITDOES NOT POWER UP................................4

3.5.2DISPLAY IS NOT VISIBLE.....................................4

4.0 DISCLAIMERS, SAFETY, WARNINGS.......................................5

4.1DISCLAIMERS......................................................5

4.2SAFETY...........................................................5

4.2.1TECHNICIAN SAFETY INFORMATION...........................5

4.2.2VEHICLE PREPARATION FOR TESTING.........................5

4.2.3SERVICING SUB-ASSEMBLIES................................5

4.2.4DRBIIITSAFETY INFORMATION...............................5

4.3WARNINGS........................................................6

4.3.1VEHICLE DAMAGE WARNINGS................................6

4.3.2ROAD TESTING A COMPLAINT VEHICLE........................6

4.4DIAGNOSIS........................................................6

5.0 REQUIRED TOOLS AND EQUIPMENT......................................6

6.0 GLOSSARY OF TERMS...................................................7

7.0 DIAGNOSTIC INFORMATION AND PROCEDURES............................9

BRAKES (CAB)

BUS SYSTEM COMMUNICATION FAILURE.................................10

CAB INTERNAL FAILURE................................................11

CLUSTER LAMP FAILURE................................................12

LEFT FRONT SENSOR CIRCUIT FAILURE..................................14

LEFT REAR SENSOR CIRCUIT FAILURE...................................14

RIGHT FRONT SENSOR CIRCUIT FAILURE.................................14

RIGHT REAR SENSOR CIRCUIT FAILURE..................................14

LEFT FRONT WHEEL SPEED SIGNAL FAILURE.............................17

LEFT REAR WHEEL SPEED SIGNAL FAILURE..............................19

PUMP CIRCUIT FAILURE................................................21

RIGHT FRONT WHEEL SPEED SIGNAL FAILURE............................24

i

Page 1157 of 4284

TABLE OF CONTENTS - Continued

RIGHT REAR WHEEL SPEED SIGNAL FAILURE.............................26

SYSTEM OVERVOLTAGE................................................28

SYSTEM UNDERVOLTAGE...............................................30

VALVE POWER FEED FAILURE...........................................32

*BRAKE LAMP SWITCH..................................................35

*TRAC OFF INDICATOR NEVER/ALWAYS ON...............................36

*TRAC ON INDICATOR NEVER/ALWAYS ON................................39

VERIFICATION TESTS

VERIFICATION TESTS...................................................40

8.0 COMPONENT LOCATIONS...............................................41

8.1CONTROLLER ANTILOCK BRAKE (CAB)..............................41

8.2DATA LINK CONNECTOR...........................................41

8.3FUSES...........................................................42

8.4TRACTION CONTROL SWITCH......................................42

8.4.1TRACTION CONTROL INDICATORS...........................43

8.5WHEEL SPEED SENSORS..........................................43

8.5.1FRONT....................................................43

8.5.2REAR.....................................................44

8.5AWHEEL SPEED SENSOR CONNECTORS..............................44

8.5A.1FRONT....................................................44

8.5A.2REAR.....................................................45

8.6BRAKE LAMP SWITCH.............................................45

9.0 CONNECTOR PINOUTS.................................................47

CONTROLLER ANTILOCK BRAKE - BLACK 24 WAY..........................47

DATA LINK CONNECTOR - WHITE 16 WAY.................................47

DIAGNOSTIC JUNCTION PORT - BLACK 16 WAY............................48

INTELLIGENT POWER MODULE C4 - GRAY 10 WAY.........................48

LEFT FRONT WHEEL SPEED SENSOR - BLACK 2 WAY......................48

LEFT FRONT WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAY..49

LEFT REAR WHEEL SPEED SENSOR - BLACK 2 WAY........................49

LEFT REAR WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAY ...49

FUSES (IPM)...........................................................51

PUMP MOTOR CONNECTOR-2WAY.....................................52

RIGHT FRONT WHEEL SPEED SENSOR - GRAY 2 WAY......................52

RIGHT FRONT WHEEL SPEED SENSOR CONNECTOR

(SENSOR SIDE)-2WAY.................................................52

RIGHT REAR WHEEL SPEED SENSOR - BLACK 2 WAY......................52

RIGHT REAR WHEEL SPEED SENSOR CONNECTOR (SENSOR SIDE)-2WAY..53

TRACTION CONTROL SWITCH - BLACK 2 WAY.............................53

10.0 SCHEMATIC DIAGRAMS.................................................55

TEVES MARK 20 ANTILOCK BRAKE SYSTEM........................55

ii

Page 1158 of 4284

1.0 INTRODUCTION

The procedures contained in this manual include

all the specifications, instructions, and graphics

needed to diagnose Mark 20 Antilock Braking Sys-

tem (ABS) and Mark 20 Antilock Braking System

with Traction Control. The diagnostics in this man-

ual are based on the failure condition or symptom

being present at time of diagnosis.

Please follow the recommendations below when

choosing your diagnostic path.

1. First make sure the DRBIIItis communicating

with the CAB. If the DRBIIItdisplays a ªNo

Responseº condition, you must diagnose that

first.

2. Read DTC's (diagnostic trouble codes) with the

DRBIIIt.

3. If no DTC's are present, identify the customer

complaint.

4. Once the DTC or customer complaint is identi-

fied, locate the matching test in the Table of

Contents and begin to diagnose the symptom.

All component location views are in Section 8.0.

All connector pinouts are in Section 9.0. All sche-

matics are in Section 10.0.

An * placed before the symptom description indi-

cates a concern with no associated DTC.

When repairs are required, refer to the appropri-

ate service manual for the proper removal and

repair procedure.

Diagnostic procedures change every year. New

diagnostic systems may be added; carry over sys-

tems may be enhanced. READ THIS MANUAL

BEFORE TRYING TO DIAGNOSE A VEHICLE

CODE. It is recommended that you review the

entire manual to become familiar with all new and

changed diagnostic procedures.

After using this book, if you have any comments

or recommendations, please fill out the form at the

back of the book and mail it back to us.

1.1 SYSTEM COVERAGE

This diagnostic procedure manual covers the an-

tilock braking system (ABS) and traction control

system found on: 2001 Chrysler Town and Country,

Dodge Caravan and Grand Caravan.

1.2 SIX-STEP TROUBLESHOOTING

PROCEDURE

Diagnosis of the controller antilock brake module

is done in six basic steps:

²verification of complaint

²verification of any related symptoms

²symptom analysis

²problem isolation

²repair of isolated problem

²verification of proper operation

2.0 IDENTIFICATION OF

SYSTEM

Vehicles equipped with the Teves Mark 20 an-

tilock brake system can be identified by the pres-

ence of the controller antilock brake module located

beneath the master cylinder.

3.0 SYSTEM DESCRIPTION AND

FUNCTIONAL OPERATION

3.1 TEVES MARK 20 SYSTEM

DESCRIPTION

The controller antilock brake module is used to

monitor wheel speeds and to modulate (control)

hydraulic pressure in each brake channel. The

modulated hydraulic pressure is used to prevent

wheel lock-up during braking.

The Teves Mark 20 system uses a diagonal split

hydraulic brake system.

In the standard brake mode

the master cylinder primary circuit supplies pressure

to the right front and left rear wheel brakes, and the

secondary master cylinder circuit supplies pressure

to the left front and right rear wheel brakes.

3.2 TRACTION CONTROL SYSTEM (TCS)

DESCRIPTION

The main purpose of traction control is to reduce

wheel slip and maintain traction at the driven

wheels when road surfaces are slippery. The trac-

tion control system reduces wheel slip by braking

the wheel that is losing traction. The system is

designed to operate at speeds below 56 km/h (35

mph).

The Controller Antilock Brake (CAB) monitors

wheel speeds. If, during acceleration, the module

detects front (drive) wheel slip and the brakes are

not applied, the CAB will enter traction control

mode. Traction control works in the following order

when drive wheel slip is detected.

1. Close the (normally open) isolation valves.

2. Start pump/motor and supply volume/pressure

to front hydraulic circuits (pump runs continu-

ously during traction control).

3. Open and close build and decay valves to main-

tain minimum wheel slip and maximum trac-

tion.

1

GENERAL INFORMATION

Page 1159 of 4284

The cycling of the build and decay valves is

similar to the ABS except that they work to control

wheel spin by applying brakes. ABS function is to

control wheel skid by releasing brakes.

Two pressure relief valves allow excess fluid vol-

ume to return to the reservoir when not used by the

build/decay cycles. These are required because the

pump supplies more volume than the traction con-

trol system requires.

If at any time the brake pedal is applied during a

traction control cycle, the brake lamp switch will

trigger the CAB to switch off the traction control.

The traction control system will be enabled at

each ignition cycle. It may be turned off by depress-

ing the Traction Control Switch. The traction con-

trol system function lamp will illuminate ªTRAC

OFFº immediately upon depressing the traction

control switch button. Only the ªTRACº portion of

the ªTRAC OFFº indicator will illuminate during a

traction control event. If the CAB calculates that

the brake temperatures are high, the traction con-

trol system will become inoperative until a time-out

period has elapsed. When in this thermal protection

mode, the traction control ªTRAC OFFº lamp will

illuminate; however, a fault will not be registered.

3.3 SYSTEM COMPONENTS

²controller antilock brake (CAB)

²vacuum booster

²master cylinder

²ABS integrated electronic control module/

hydraulic control unit (HCU), valve block assem-

bly: 8 valve solenoids (4 inlet valves, 4 outlet

valves, 2 accumulators) 1 motor, 2 pump

²ABS integrated electronic control module with

traction control same as above but has 10 valve

solenoids.

²4 wheel speed sensor/tone wheel assemblies

²ABS warning indicator

²fuses and wiring harness

²fluid reservoir

²TRAC/TRAC OFF indicator

3.3.1 ABS AND BRAKE WARNING

INDICATORS

The amber ABS warning indicator is located in

the instrument cluster. It is used to inform the

driver that the antilock function has been turned

off. The ABS warning indicator is controlled by the

CAB. The CAB controls the lamp with a command

over the PCI bus.

The ABS Warning Indicator will remain lit during

every key cycle until a circuit or component fault is

repaired and the CAB no longer detects the fault.After repair of a sensor signal fault or a pump motor

fault, the CAB must sense all four wheels at 25

km/h (15 mph) before it will extinguish the ABS and

TRAC OFF Indicators.

The Instrument Cluster will illuminate the ABS

Warning Indicator if it loses communication with

the CAB.

The red BRAKE warning indicator is also located

in the instrument cluster. It can be activated in

several ways. Application of the parking brake or a

low fluid signal from the fluid level switch located in

the master cylinder reservoir will cause the indica-

tor to come on.

3.3.2 CONTROLLER ANTILOCK BRAKE

(CAB)

The Controller Antilock Brake (CAB) is a

microprocessor-based device that monitors wheel

speeds and controls the antilock functions. The

CAB contains two microprocessors that receive

identical sensor signals and then independently

process the information. The results are then com-

pared to make sure that they agree. Otherwise, the

CAB will turn off the antilock and turn on the ABS

amber warning indicator.

The primary functions of the CAB are to:

²detect wheel locking tendencies

²control fluid pressure modulation to the brakes

during antilock stop

²monitor the system for proper operation

²manage traction control functions

²provide communication to the DRBIIItwhile in

diagnostic mode

²store diagnostic information in non-volatile memory

The CAB continuously monitors the speed of each

wheel. When a wheel locking tendency is detected,

the CAB will command the appropriate valve to

modulate brake fluid pressure in its hydraulic unit.

Brake pedal position is maintained during an an-

tilock stop by being a closed system with the use of

2 accumulators. The CAB continues to control pres-

sure in individual hydraulic circuits until a wheel

locking tendency is no longer present. The CAB

turns on the pump motor during an antilock stop.

The antilock brake system is constantly moni-

tored by the CAB for proper operation. If the CAB

detects a system malfunction, it can disable the

antilock system and turn on the ABS warning

indicator. If the antilock function is disabled, the

system will revert to standard base brake system

operation.

The CAB inputs include the following:

²diagnostic communication

²four wheel speed sensors

2

GENERAL INFORMATION

Page 1160 of 4284

²three power feeds: valves, pump and microproces-

sor

²brake switch

²traction control switch

The CAB outputs include the following:

²ABS warning indicator actuation

²12 volts power to wheel speed sensors

²eight valves

²ten valves with traction control

²diagnostic communication

²PCI bus communication

²traction control lamp illumination

3.3.3 HYDRAULIC CONTROL UNIT

The hydraulic control unit (HCU) contains the

valve block assembly, two accumulators, and pump/

motor assembly. The HCU is attached to the CAB.

Valve Block Assembly:The valve block assem-

bly contains valves with four inlet valves and four

outlet valves. The inlet valves are spring-loaded in

the open position and the outlet valves are spring

loaded in the closed position. During an antilock

stop, these valves are cycled to maintain the proper

slip ratio for each wheel. If a wheel detects slip, the

inlet valve is closed to prevent and further pressure

increase. Then the outlet valve is opened to release

the pressure to the accumulators until the wheel is

no longer slipping. Once the wheel is no longer

slipping, the outlet valve is closed and the inlet

valve is opened to reapply pressure. If the wheel is

decelerating within its predetermined limits (prop-

er slip ratio), the inlet valve will close to hold the

pressure constant. On vehicles which are equipped

with a traction control system, there are two addi-

tional valves that isolate the master cylinder and

rear wheels. During a traction control event the

brakes are applied to reduce wheel slippage.

Pump Motor Assembly:The pump motor as-

sembly provides the extra amount of fluid needed

during antilock braking. The pump is supplied fluid

that is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

is also used to drain the accumulator circuits after

the antilock stop is complete. The pump is operated

by an integral electric motor. This DC-type motor is

controlled by the CAB. The CAB may turn on the

pump motor when an antilock stop is detected. The

pump continues to run during the antilock stop and

is turned off after the stop is complete. Under some

conditions, the pump motor will run to drain the

accumulators during the next drive off. The CAB

monitors the pump motor operation internally.

Accumulators:The accumulators provide tem-

porary fluid storage during an antilock stop and are

drained by the pump motor.

3.3.4 SWITCHES/SENSORS

Master Cylinder:The master cylinder is a stan-

dard tandem compensating port design for ABS and

non ABS systems. Traction control vehicles use a

dual center port master cylinder. For proper trac-

tion control operation the standard master cylinder

must not be used.

A fluid level switch is located in the master

cylinder fluid reservoir. The switch closes when a

low fluid level is detected. The fluid level switch

turns on the brake warning indicator by grounding

the indicator circuit. This switch does not disable

the ABS system.

Wheel Speed Sensors and Tone Wheels:One

active wheel speed sensor (WSS) is located at each

wheel and sends a small signal to the control

module (CAB). This signal is generated when a

toothed sensor ring (tone wheel) passes by a station-

ary wheel speed sensor. The CAB converts the

signals into digital signals for each wheel.

Because of internal circuitry, correct wheel speed

sensor function cannot be determined by a continu-

ity or resistance check through the sensor.

The front wheel speed sensor is attached to a boss

in the steering knuckle. The tone wheel is an

integral part of the front axle shaft. The rear speed

sensor is mounted though the bearing cover and the

rear tone wheel is an integral part of the rear

bearing hub. The wheel speed sensor air gap is not

adjustable. Refer to the service manual for wheel

speed sensor air gap and resistance specifications.

The four wheel speed sensors are serviced indi-

vidually. The front tone wheels are serviced as an

assembly with the outer constant velocity (C.V.)

joint housing. The rear tone wheels are serviced as

an assembly.

Correct antilock system operation is dependent

on tone wheel speed signals from the wheel speed

sensors. The vehicle's wheels and tires should all be

the same size and type to generate accurate signals.

In addition, the tires should be inflated to the

recommended pressure for optimum system opera-

tion. Variation in wheel and tire size or significant

variations in inflation pressure can produce inaccu-

rate wheel speed signals; however, the system will

continue to function when using the mini-spare.

3.3.5 SYSTEM INITIALIZATION

System initialization starts when the key is

turned to ªrunº. At this point, the CAB performs a

complete self-check of all electrical components in

the antilock systems.

Between 8-17 km/h (5-10 mph), a dynamic test is

performed. This will momentarily cycle the inlet

and outlet valves, check wheel speed sensor cir-

cuitry, and run the pump motor at 25 km/h (15

mph). The CAB will try to test the pump motor. If

3

GENERAL INFORMATION

Page 1163 of 4284

4.3 WARNINGS

4.3.1 VEHICLE DAMAGE WARNINGS

Before disconnecting any control module, make

sure the ignition is ``off ''. Failure to do so could

damage the module.

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation, this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

4.3.2 ROAD TESTING A COMPLAINT

VEHICLE

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

WARNING: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED.

DURING THE TEST DRIVE, DO NOT TRY TO

READ THE DRB SCREEN WHILE IN MOTION.

DO NOT HANG THE DRBIIITFROM THE

REAR VIEW MIRROR OR OPERATE IT

YOURSELF. HAVE AN ASSISTANT

AVAILABLE TO OPERATE THE DRBIIIT.

4.4 DIAGNOSIS

1. Your diagnostic test procedure must begin with a

thorough visual inspection of the ABS system for

damaged components or disconnected connec-

tors. The brake lamps must be operational, and

if they are not, repair them prior to continuing.

2. Connect the DRBIIItto the data link connector,

which is located under the dash to the left of the

steering column. If the DRBIIItdoes not power

up, check the power and ground supplies to the

connector.

3. Turn the ignition on. Select ªAntilock Brakesº. If

the DRBIIItdisplays ªNo Responseº condition

you must diagnose that first.

4. Read and record all ABS diagnostic trouble

codes. If the ªCAB Power Feed Circuitº diagnos-

tic trouble code is present, it must be repaired

prior to addressing any other DTC's. If any

additional DTC's are present, proceed to theappropriate test by locating the matching test in

the Table of Contents and begin to diagnose the

symptom.

5. If there are no diagnostic trouble codes present,

identify the customer complaint. Select ªInputs/

Outputsº and read the brake switch input as you

press and release the brake pedal. If the display

does not match the state of the pedal, perform

the proper test by locating the matching test in

the Table of Contents and begin to diagnose the

symptom. If a problem exists with the yellow

ªABSº warning indicator or the red ªBrakeº

indicator exists, refer to the proper tests by

locating the matching test in the Table of Con-

tents and begin to diagnose the symptom. Read

the traction control switch input as you press

and release the switch. If the display does not

match the state of the indicator perform the

proper test by locating the matching test in the

Table of Contents and begin to diagnose the

symptom.

6. If no other problems are found, it will be neces-

sary to road test the vehicle. Perform several

antilock stops from above 50 Km/h (30 mph) and

then repeat step 4. If any diagnostic trouble

codes are present, proceed to the appropriate test.

7. The following conditions should be considered

ªNORMALº operation, and no repairs should be

attempted to correct them.

± Brake pedal feedback during an ABS stop

(clicking, vibrating).

± Clicking, groaning or buzzing at 25 Km/h (15

mph) or 40 Km/h (24 mph) (drive off self test).

± Groaning noise during an ABS stop.

± Slight brake pedal drop and pop noise when

ignition is initially turned on.

± Brake pedal ratcheting down at the end of an

ABS stop.

8. If the complaint is ABS ªcyclingº at the end of a

stop at low speeds, it may be caused by a

marginal wheel speed sensor signal. The sensor

air gap, tone wheel condition, and/or brakes

hanging up are possible causes of this condition.

9. After a road test in which no problems were

found, refer to any Technical Service Bulletins

that may apply.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box)

jumper wires

ohmmeter

voltmeter

test light

6

GENERAL INFORMATION

Page 1196 of 4284

Symptom:

*TRAC ON INDICATOR NEVER/ALWAYS ON

POSSIBLE CAUSES

CAB -- INTERNAL FAULT

CHECK TRACTION CONTROL SYSTEM

CLUSTER FAILS SELF TEST

CAB - NO TRAC MESSAGE

TEST ACTION APPLICABILITY

1NOTE: The DRBIIItmust be able to communicate with the CAB prior to

performing this test.

NOTE: Note: If any CAB DTC's are present, they must be repaired prior to

performing this test.

Perform the KEY-ON bulb test.

Did the TRAC Indicator illuminate and then go out?All

Ye s®Go To 2

No®Go To 3

2 Make sure the Traction Control system has not been deactivated with the TRAC OFF

switch.

NOTE: The purpose of this test is to determine if the Traction Control

system is operating.

With the DRBIIItin Inputs/Outputs, read the ABS Pump Motor voltage state.

Accelerate sufficient to cause drive wheel slip.

Does the TRAC Indicator illuminate and the DRBIIItdisplay approximately 9 volts?All

Ye s®The traction control system is functioning normally.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

3NOTE: The purpose of this test is to perform the Instrument Cluster self

test.

Depress and hold the Odometer Reset Button.

Turn the Key from OFF to ON and then back to OFF.

Release the Odometer Reset Button.

Do the Instrument Cluster Indicators and Gauges activate and deactivate?All

Ye s®Replace the Controller Antilock Brake in accordance with the

Service Information.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Instrument Cluster in accordance with the Service

Information.

Perform ABS VERIFICATION TEST - VER 1.

39

BRAKES (CAB)

Page 1199 of 4284

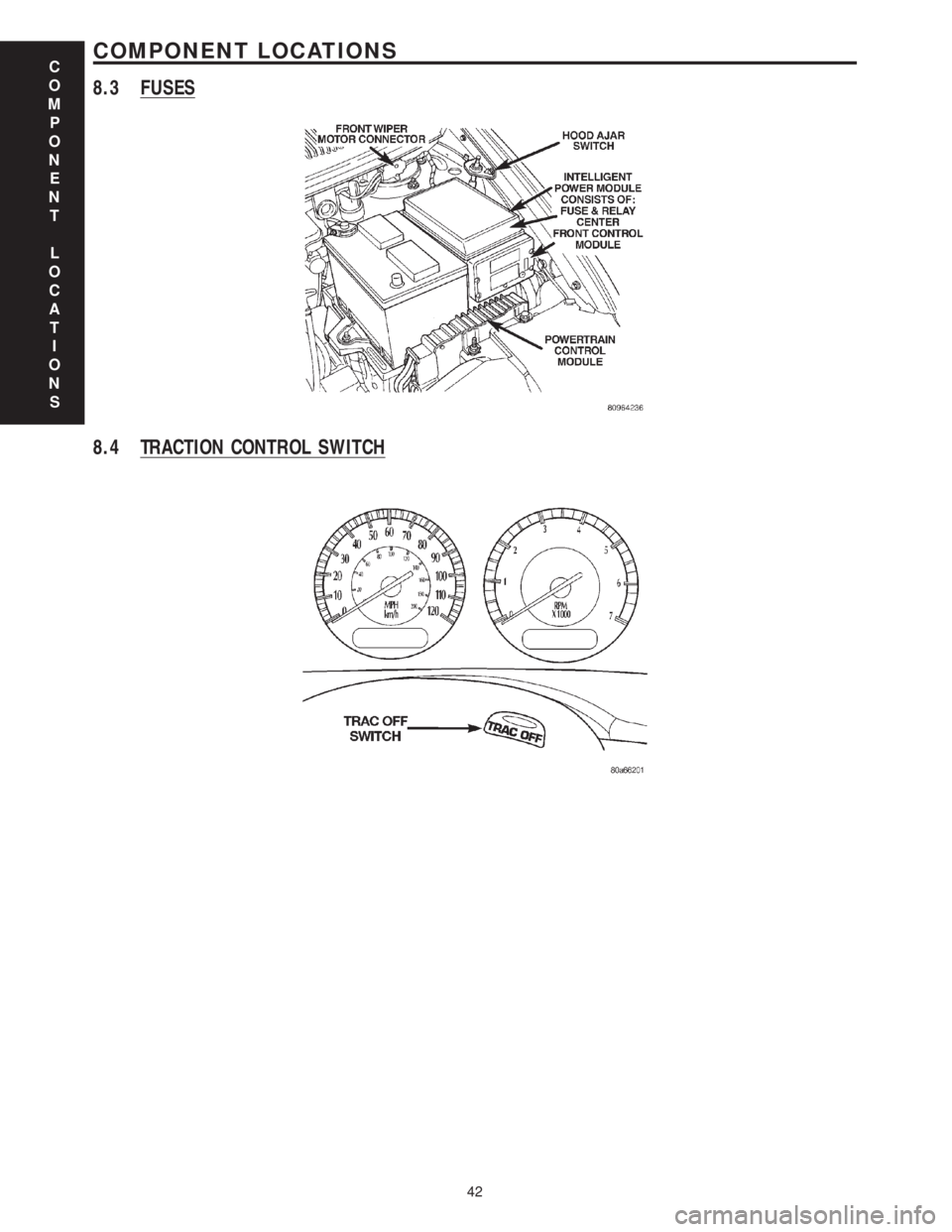

8.3 FUSES

8.4 TRACTION CONTROL SWITCH

C

O

M

P

O

N

E

N

T

L

O

C

A

T

I

O

N

S

42

COMPONENT LOCATIONS

Page 1200 of 4284

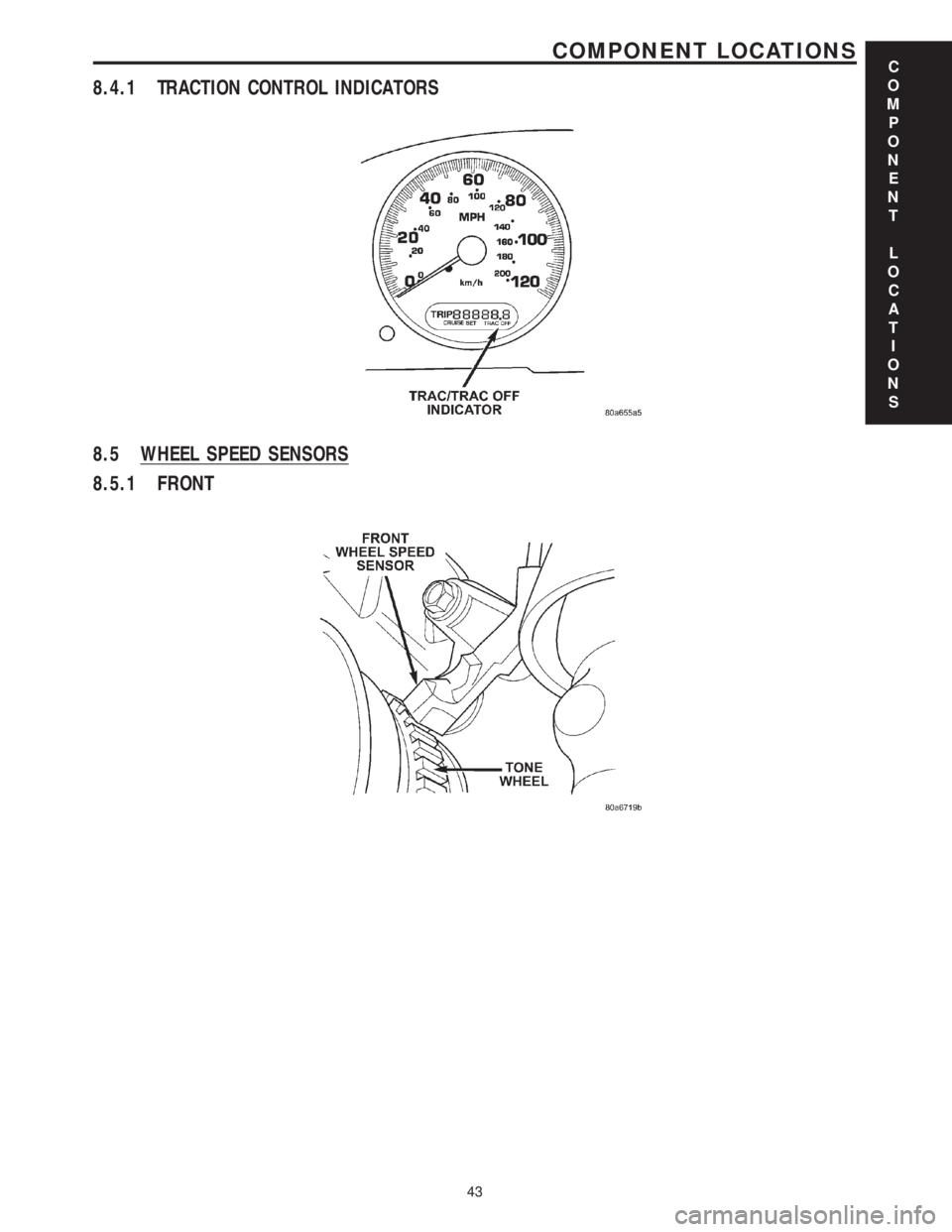

8.4.1 TRACTION CONTROL INDICATORS

8.5 WHEEL SPEED SENSORS

8.5.1 FRONT

C

O

M

P

O

N

E

N

T

L

O

C

A

T

I

O

N

S

43

COMPONENT LOCATIONS