ignition CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1427 of 4284

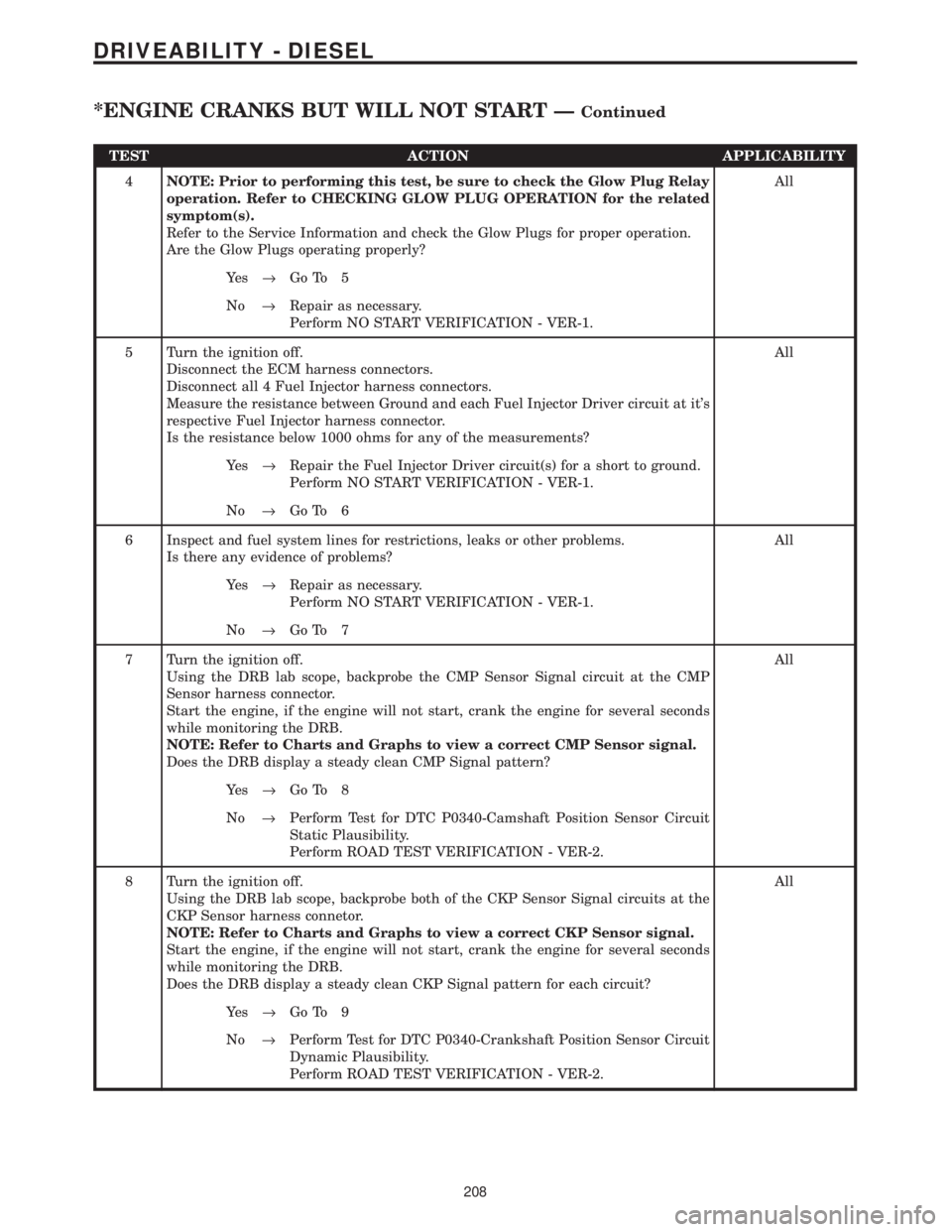

TEST ACTION APPLICABILITY

4NOTE: Prior to performing this test, be sure to check the Glow Plug Relay

operation. Refer to CHECKING GLOW PLUG OPERATION for the related

symptom(s).

Refer to the Service Information and check the Glow Plugs for proper operation.

Are the Glow Plugs operating properly?All

Ye s®Go To 5

No®Repair as necessary.

Perform NO START VERIFICATION - VER-1.

5 Turn the ignition off.

Disconnect the ECM harness connectors.

Disconnect all 4 Fuel Injector harness connectors.

Measure the resistance between Ground and each Fuel Injector Driver circuit at it's

respective Fuel Injector harness connector.

Is the resistance below 1000 ohms for any of the measurements?All

Ye s®Repair the Fuel Injector Driver circuit(s) for a short to ground.

Perform NO START VERIFICATION - VER-1.

No®Go To 6

6 Inspect and fuel system lines for restrictions, leaks or other problems.

Is there any evidence of problems?All

Ye s®Repair as necessary.

Perform NO START VERIFICATION - VER-1.

No®Go To 7

7 Turn the ignition off.

Using the DRB lab scope, backprobe the CMP Sensor Signal circuit at the CMP

Sensor harness connector.

Start the engine, if the engine will not start, crank the engine for several seconds

while monitoring the DRB.

NOTE: Refer to Charts and Graphs to view a correct CMP Sensor signal.

Does the DRB display a steady clean CMP Signal pattern?All

Ye s®Go To 8

No®Perform Test for DTC P0340-Camshaft Position Sensor Circuit

Static Plausibility.

Perform ROAD TEST VERIFICATION - VER-2.

8 Turn the ignition off.

Using the DRB lab scope, backprobe both of the CKP Sensor Signal circuits at the

CKP Sensor harness connetor.

NOTE: Refer to Charts and Graphs to view a correct CKP Sensor signal.

Start the engine, if the engine will not start, crank the engine for several seconds

while monitoring the DRB.

Does the DRB display a steady clean CKP Signal pattern for each circuit?All

Ye s®Go To 9

No®Perform Test for DTC P0340-Crankshaft Position Sensor Circuit

Dynamic Plausibility.

Perform ROAD TEST VERIFICATION - VER-2.

208

DRIVEABILITY - DIESEL

*ENGINE CRANKS BUT WILL NOT START ÐContinued

Page 1428 of 4284

TEST ACTION APPLICABILITY

9 Refer to the Service Information and perform the fuel pressure test.

Is the fuel pressure within specification?All

Ye s®Go To 10

No®Repair as necessary.

Perform NO START VERIFICATION - VER-1.

10 Refer to the Service Information and perform the fuel pressure test. Note the test

results.

Using the DRB, read the Fuel Pressure PSI and compare the two readings.

Are the two readings within 500 psi of each other?All

Ye s®Go To 11

No®Go To 12

11 Refer to the Service Information to ensure the Engine Drive Belt is installed correctly

and the camshaft and crankshaft gears are timed correctly.

Were any problems found?All

Ye s®Repair as necessary.

Perform NO START VERIFICATION - VER-1.

No®Check the fuel supply for contamination.

Perform NO START VERIFICATION - VER-1.

12 Turn the ignition off.

Disconnect the Fuel Pressure Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Fuel Pressure Sensor Signal circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 13

No®Repair the Fuel Pressure Sensor Signal circuit for an open.

Perform NO START VERIFICATION - VER-1.

13 Turn the ignition off.

Disconnect the Fuel Pressure Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Fuel Pressure Sensor 5-volt Supply circuit.

Is the resistance below 10.0 ohms?All

Ye s®Go To 14

No®Repair the Fuel Pressure Sensor 5-volt Supply circuit for an open.

Perform NO START VERIFICATION - VER-1.

14 Turn the ignition off.

Disconnect the Fuel Pressure Sensor harness connector.

Disconnect the ECM harness connectors.

Measure the resistance of the Sensor Ground circuit.

Is the resistance below 10.0 ohms?All

Ye s®Replace the Fuel Pressure Sensor in accordance with the Service

Information.

Perform NO START VERIFICATION - VER-1.

No®Repair the Sensor Ground circuit for an open.

Perform NO START VERIFICATION - VER-1.

209

DRIVEABILITY - DIESEL

*ENGINE CRANKS BUT WILL NOT START ÐContinued

Page 1429 of 4284

Symptom:

*ENGINE WILL NOT CRANK

POSSIBLE CAUSES

BATTERY CABLE HIGH RESISTANCE

CHECKING FOR SKIM CODES

CLUTCH INTERLOCK SWITCH

CLUTCH INTERLOCK SWITCH OUTPUT CIRCUIT

ECM

IGNITION SWITCH START OUTPUT CIRCUIT OPEN

IGNITION SWITCH START OUTPUT CIRCUIT OPEN

INSPECT BATTERY CABLES

MECHANICAL PROBLEM

OPEN FUSED BATTERY (+) CIRCUIT

STARTER MOTOR

STARTER RELAY

STARTER RELAY CONTROL CIRCUIT OPEN

STARTER RELAY CONTROL CIRCUIT SHORTED TO VOLTAGE

STARTER RELAY OUTPUT CIRCUIT OPEN

TEST ACTION APPLICABILITY

1 Turn the ignition off.

NOTE: The battery must be fully charged before diagnosing a no crank

condition.

Inspect the battery cables for corrosion, looseness or other problems.

Is there evidence of problems?All

Ye s®Repair as necessary.

Perform NO START VERIFICATION - VER-1.

No®Go To 2

2 Turn the ignition on.

With the DRBIIIt, read the SKIM DTCs.

Does the DRBIIItdisplay any SKIM DTCs?All

Ye s®Refer to symptom list for problems related to SKIM.

Perform NO START VERIFICATION - VER-1.

No®Go To 3

210

DRIVEABILITY - DIESEL

Page 1430 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Remove the Starter Relay from the PDC.

WARNING: THE TRANSMISSION MUST BE IN NEUTRAL AND THE PARK

BRAKE MUST BE SET FOR THIS TEST.

WARNING: THE ENGINE MAY CRANK IN THE NEXT STEP. WHEN THE

ENGINE IS CRANKING, DO NOT STAND IN A DIRECT LINE WITH THE

FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN.

DO NOT WEAR LOOSE CLOTHING.

Momentarily jumper Starter Relay connector cavities 30 and 87 in the IPM

connector.

Did the engine crank?All

Ye s®Go To 4

No®Go To 11

4 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit while fully depressing the clutch pedal and turning the ignition switch

to the START position.

Does the test light illuminate with the ignition switch in the START position?All

Ye s®Go To 5

No®Go To 9

5 Turn the ignition off.

Remove the Starter Relay From the PDC.

Install a substitute relay in place of the Starter Relay.

Attempt to start the engine.

Does the engine crank?All

Ye s®Replace the Starter Relay.

Perform NO START VERIFICATION - VER-1.

No®Go To 6

6 Turn the ignition off.

Disconnect the ECM harness connectors.

Using a 12-volt test light connected to ground, probe ECM harness connector cavity

49 while fully depressing the clutch pedal and turning the ignition switch to the

START position.

Does the test light illuminate while the ignition is in the Start position.All

Ye s®Go To 7

No®Repair the Ignition Switch Start Output circuit to the ECM.

Perform NO START VERIFICATION - VER-1.

211

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1431 of 4284

TEST ACTION APPLICABILITY

7 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Remove the ECM/PCM Relay from the IPM.

Using a jumper wire, connect ECM/PCM relay connector cavities 30 and 87 in the

IPM.

Turn the ignition on.

Measure the voltage of the Starter Relay Control circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the Starter Relay Control circuit for a short to voltage.

Perform NO START VERIFICATION - VER-1.

No®Go To 8

8 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Turn the ignition on.

Measure the resistance of the Starter Relay Control circuit.

Is the resistance below 10.0 ohms?All

Ye s®Replace and program the ECM in accordance with the Service

Information.

Perform NO START VERIFICATION - VER-1.

No®Repair the Starter Relay Control circuit for an open.

Perform NO START VERIFICATION - VER-1.

9 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the Clutch Interlock Switch harness connector.

Connect a jumper wire across the Clutch Interlock Switch harness connector.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit at the Starter Relay connector in the PDC and turning the ignition

switch to the crank position.

Does the test light illuminate with the ignition switch in the crank position?All

Ye s®Replace the Clutch Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Go To 10

10 Turn the ignition off.

Disconnect the Clutch Interlock Switch harness connector.

Remove the Starter Relay from the PDC.

Measure the resistance of the Clutch Interlock Switch Output circuit between the

PDC and the Clutch Interlock Switch harness connector.

Is the resistance below 10.0 ohms?All

Ye s®Repair the Ignition Switch Start Output circuit to the Clutch

Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Repair the Clutch Interlock Switch Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

212

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1432 of 4284

TEST ACTION APPLICABILITY

11 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Fused B+ circuit.

Is the test light on?All

Ye s®Go To 12

No®Repair the Fused B(+) circuit for an open.

Perform NO START VERIFICATION - VER-1.

12 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the Starter Relay Output wire from the Starter Solenoid.

Connect the Starter Relay Output wire (at the Starter) to ground.

Using a 12-volt test light connected to 12-volts, check the Starter Relay Output

circuit at the Starter Relay connector in the IPM.

Does the test light illuminate brightly?All

Ye s®Go To 13

No®Repair the Starter Relay Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

13 Using the Service Information, check the battery cables for high resistance.

Did either battery cable have a voltage drop greater than 0.2 volts?All

Ye s®Replace the battery cable(s).

Perform NO START VERIFICATION - VER-1.

No®Go To 14

14 Turn the ignition off.

Attempt to manually rotate the crankshaft 360É.

Is the crankshaft able to rotate 360É?All

Ye s®Replace the Starter Motor.

Perform NO START VERIFICATION - VER-1.

No®Repair the engine mechanical problem.

Perform NO START VERIFICATION - VER-1.

213

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1433 of 4284

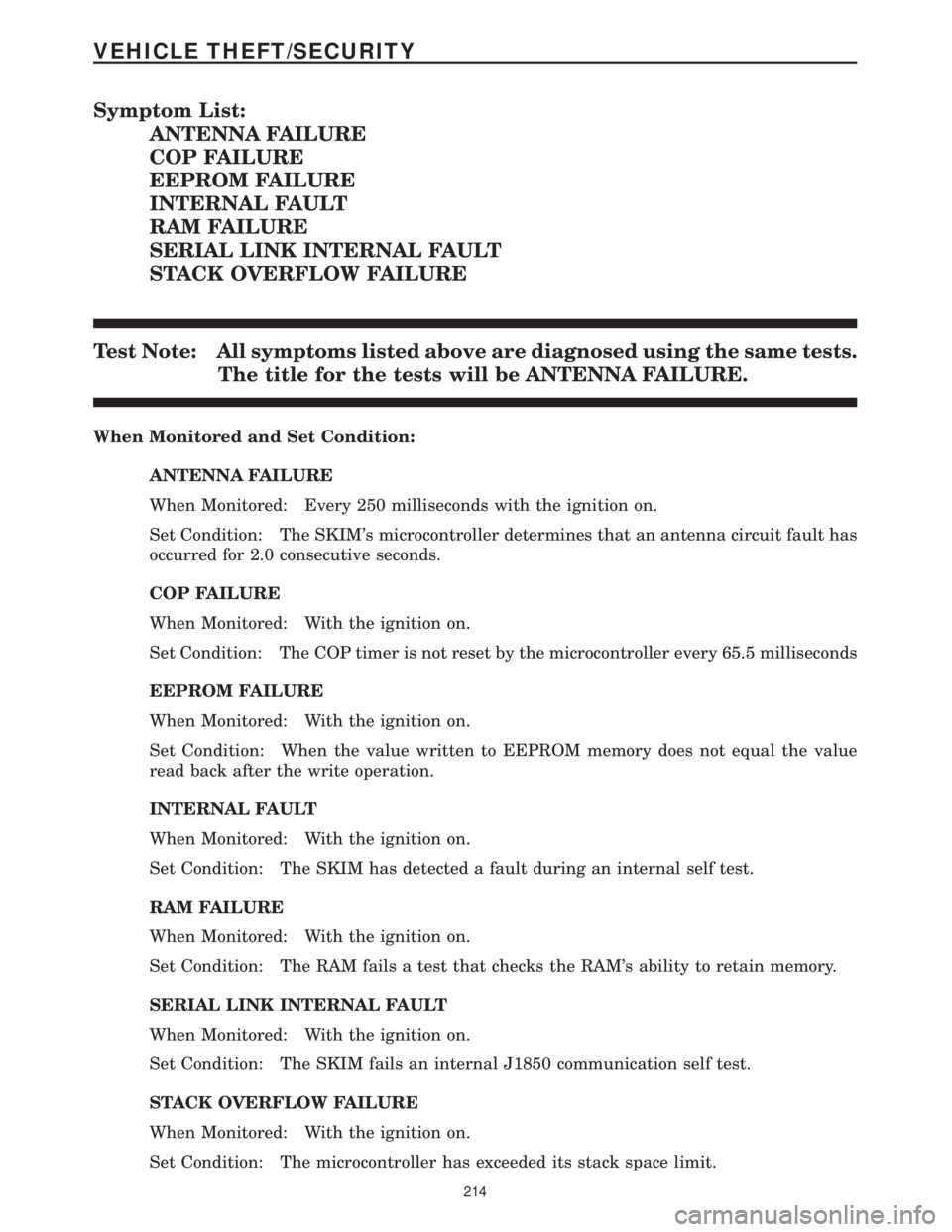

Symptom List:

ANTENNA FAILURE

COP FAILURE

EEPROM FAILURE

INTERNAL FAULT

RAM FAILURE

SERIAL LINK INTERNAL FAULT

STACK OVERFLOW FAILURE

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be ANTENNA FAILURE.

When Monitored and Set Condition:

ANTENNA FAILURE

When Monitored: Every 250 milliseconds with the ignition on.

Set Condition: The SKIM's microcontroller determines that an antenna circuit fault has

occurred for 2.0 consecutive seconds.

COP FAILURE

When Monitored: With the ignition on.

Set Condition: The COP timer is not reset by the microcontroller every 65.5 milliseconds

EEPROM FAILURE

When Monitored: With the ignition on.

Set Condition: When the value written to EEPROM memory does not equal the value

read back after the write operation.

INTERNAL FAULT

When Monitored: With the ignition on.

Set Condition: The SKIM has detected a fault during an internal self test.

RAM FAILURE

When Monitored: With the ignition on.

Set Condition: The RAM fails a test that checks the RAM's ability to retain memory.

SERIAL LINK INTERNAL FAULT

When Monitored: With the ignition on.

Set Condition: The SKIM fails an internal J1850 communication self test.

STACK OVERFLOW FAILURE

When Monitored: With the ignition on.

Set Condition: The microcontroller has exceeded its stack space limit.

214

VEHICLE THEFT/SECURITY

Page 1434 of 4284

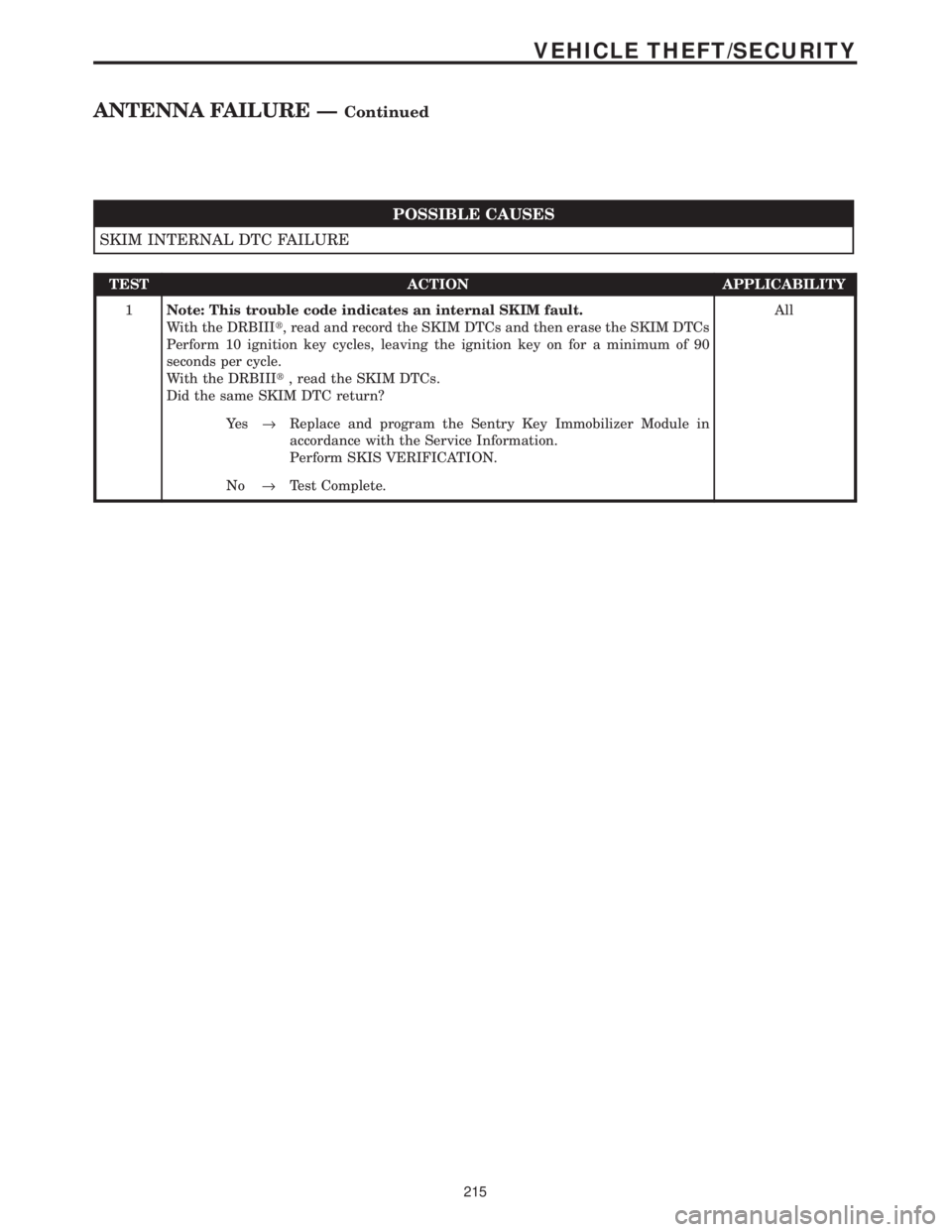

POSSIBLE CAUSES

SKIM INTERNAL DTC FAILURE

TEST ACTION APPLICABILITY

1Note: This trouble code indicates an internal SKIM fault.

With the DRBIIIt, read and record the SKIM DTCs and then erase the SKIM DTCs

Perform 10 ignition key cycles, leaving the ignition key on for a minimum of 90

seconds per cycle.

With the DRBIIIt, read the SKIM DTCs.

Did the same SKIM DTC return?All

Ye s®Replace and program the Sentry Key Immobilizer Module in

accordance with the Service Information.

Perform SKIS VERIFICATION.

No®Test Complete.

215

VEHICLE THEFT/SECURITY

ANTENNA FAILURE ÐContinued

Page 1435 of 4284

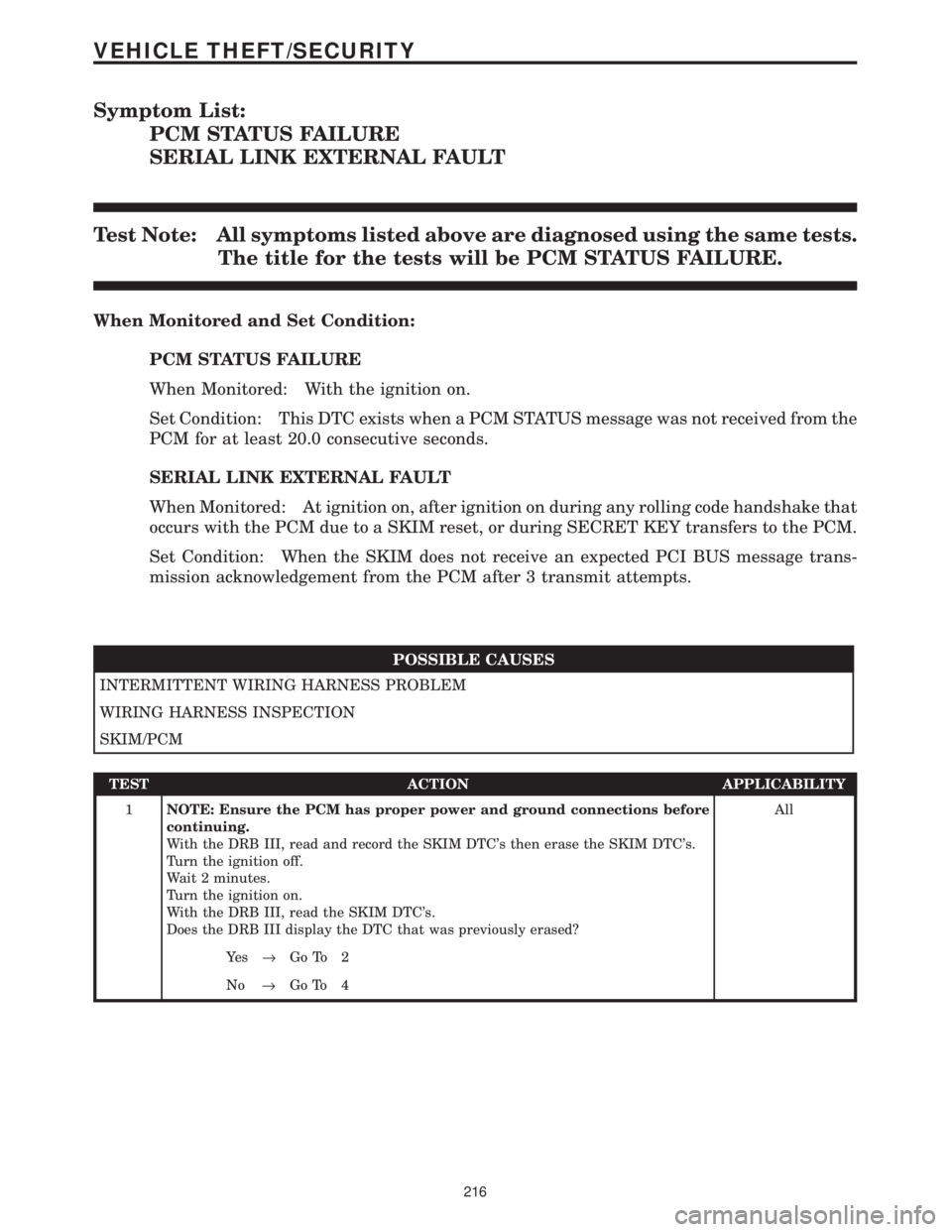

Symptom List:

PCM STATUS FAILURE

SERIAL LINK EXTERNAL FAULT

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be PCM STATUS FAILURE.

When Monitored and Set Condition:

PCM STATUS FAILURE

When Monitored: With the ignition on.

Set Condition: This DTC exists when a PCM STATUS message was not received from the

PCM for at least 20.0 consecutive seconds.

SERIAL LINK EXTERNAL FAULT

When Monitored: At ignition on, after ignition on during any rolling code handshake that

occurs with the PCM due to a SKIM reset, or during SECRET KEY transfers to the PCM.

Set Condition: When the SKIM does not receive an expected PCI BUS message trans-

mission acknowledgement from the PCM after 3 transmit attempts.

POSSIBLE CAUSES

INTERMITTENT WIRING HARNESS PROBLEM

WIRING HARNESS INSPECTION

SKIM/PCM

TEST ACTION APPLICABILITY

1NOTE: Ensure the PCM has proper power and ground connections before

continuing.

With the DRB III, read and record the SKIM DTC's then erase the SKIM DTC's.

Turn the ignition off.

Wait 2 minutes.

Turn the ignition on.

With the DRB III, read the SKIM DTC's.

Does the DRB III display the DTC that was previously erased?All

Ye s®Go To 2

No®Go To 4

216

VEHICLE THEFT/SECURITY

Page 1436 of 4284

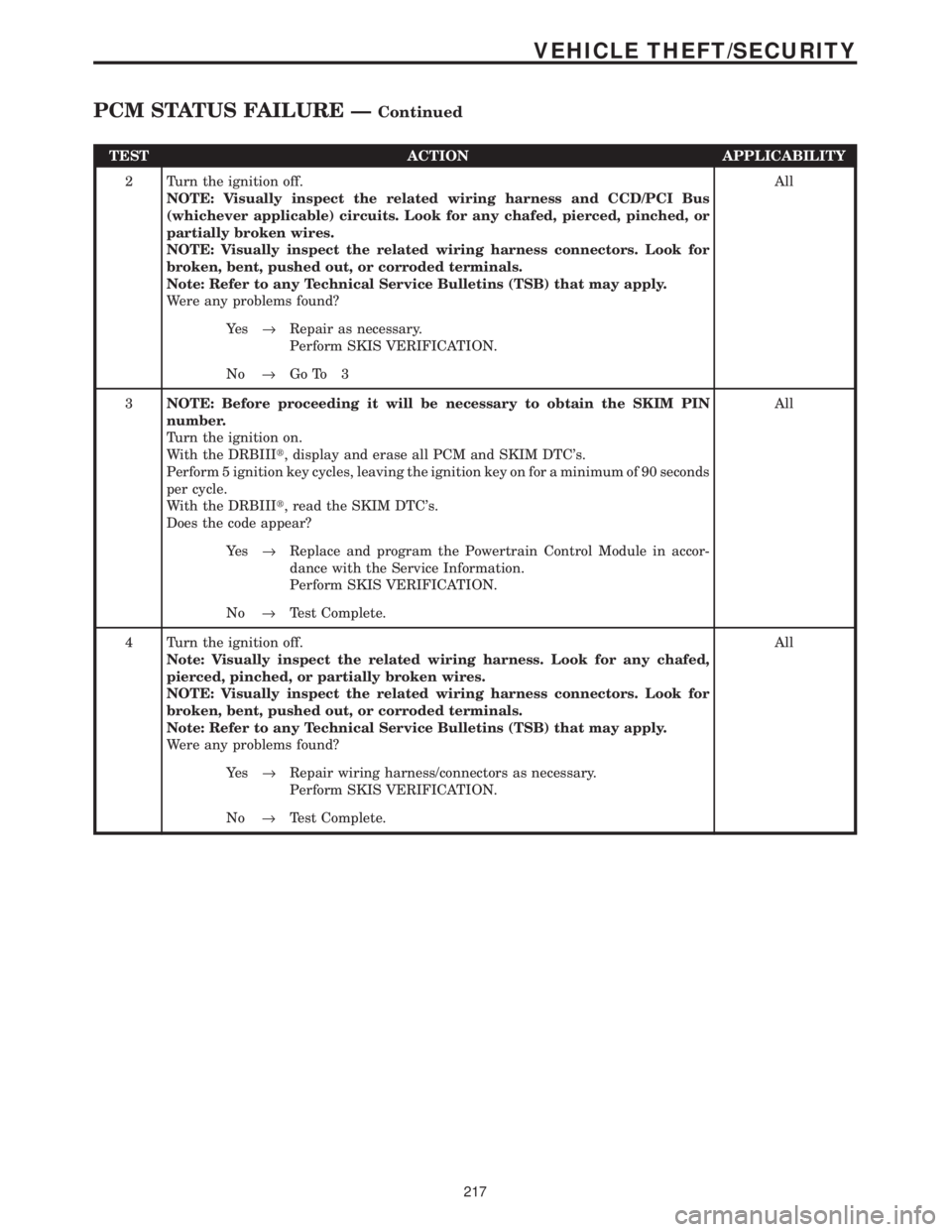

TEST ACTION APPLICABILITY

2 Turn the ignition off.

NOTE: Visually inspect the related wiring harness and CCD/PCI Bus

(whichever applicable) circuits. Look for any chafed, pierced, pinched, or

partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform SKIS VERIFICATION.

No®Go To 3

3NOTE: Before proceeding it will be necessary to obtain the SKIM PIN

number.

Turn the ignition on.

With the DRBIIIt, display and erase all PCM and SKIM DTC's.

Perform 5 ignition key cycles, leaving the ignition key on for a minimum of 90 seconds

per cycle.

With the DRBIIIt, read the SKIM DTC's.

Does the code appear?All

Ye s®Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform SKIS VERIFICATION.

No®Test Complete.

4 Turn the ignition off.

Note: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

Note: Refer to any Technical Service Bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair wiring harness/connectors as necessary.

Perform SKIS VERIFICATION.

No®Test Complete.

217

VEHICLE THEFT/SECURITY

PCM STATUS FAILURE ÐContinued