steering CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2051 of 4284

The components above must be replaced because

they cannot be reused. Replace any other driver air-

bag system components if damaged.

REMOVAL

DEPLOYED AIRBAG

The Driver Airbag and Driver Airbag Cover/Horn

Pad are serviced separately from each other.

(1) Clean powder residue from interior of vehicle,

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - STANDARD PROCEDURE ) Cleanup.

(2) Remove two screws attaching Driver Airbag to

steering wheel.

(3) Remove the driver airbag from steering wheel.

(4) Disconnect wire connectors from Airbag and

Clock Spring.

(5) Adjust the steering wheel so that the tires are

in a straight ahead position. Remove steering wheel,

(Refer to 19 - STEERING/COLUMN/STEERING

WHEEL - REMOVAL)

(6) Disconnect the 2-way and 4-way connectors

between the clock spring and the instrument panel

wiring harness.

(7) Remove upper and lower steering column

shrouds.

(8) Remove clock spring from the housing assem-

bly by depressing the 2 tabs on the clock spring.

UNDEPLOYED AIRBAG

(1) Remove screws attaching airbag/horn switch to

steering wheel.

(2) Remove Driver Airbag from steering wheel.

(3) Disconnect wire connectors from driver airbag

and clock spring.

INSTALLATION

DEPLOYED AIRBAG

(1) Perform cleanup procedure.(Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - STAN-

DARD PROCEDURE)

(2) Install a new steering column assembly and

lower steering column coupler. Refer to Steering, Col-

umn, Installation.

(3) Install the clock spring.

(4) Install the driver airbag and the two screws

retaining the airbag. Tighten screws to 10 N´m (90

in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEGA-

TIVE CABLE. REFER TO ELECTRICAL, RESTRAINTS,

DIAGNOSIS AND TESTING - AIRBAG SYSTEM FIRST.

UNDEPLOYED AIRBAG

(1) Position a new airbag into the airbag cavity.(2) Install the two screws retaining the airbag.

Tighten screws to 10 N´m (90 in. lbs.)

WARNING: DO NOT CONNECT THE BATTERY NEGA-

TIVE CABLE. REFER TO ELECTRICAL, RESTRAINTS,

DIAGNOSIS AND TESTING - AIRBAG SYSTEM FIRST.

OCCUPANT RESTRAINT

CONTROLLER

DESCRIPTION

The front driver and passenger airbag system is

designed to reduce the risk of fatality or serious

injury, caused by a frontal impact of the vehicle.

The Occupant Restraint Controller (ORC) contains

the impact sensor and energy reserve capacitor. It is

mounted on a bracket, under the instrument panel,

just forward of the storage bin. The ORC monitors

the system to determine the system readiness. The

ORC contains on-board diagnostics and will light the

AIRBAG warning lamp in the message center when a

problem occurs.

OPERATION

The impact sensor provides verification of the

direction and severity of the impact. One impact sen-

sor is used. It is located inside the Occupant

Restraint Controller (ORC). The impact sensor is an

accelerometer that senses deceleration. The decelera-

tion pulses are sent to a microprocessor which con-

tains a decision algorithm. When an impact is severe

enough to require airbag protection, the ORC micro-

processor sends a signal that completes the electrical

circuit to the driver and passenger airbags. The

impact sensor is calibrated for the specific vehicle

and reacts to the severity and direction of an impact.

REMOVAL

(1)Disconnect and isolate the battery negative cable.

(2) Remove storage bin from instrument panel.

Refer to Body, Instrument Panel, Storage Bin,

Removal.

(3) Remove three bolts holding ORC to floor

bracket.

(4) Disconnect the wire connector from ORC.

(5) Remove the ORC w/bracket assembly from

vehicle.

INSTALLATION

WARNING: DO NOT INSTALL ORC IF MOUNTING

LOCATION IS DEFORMED OR DAMAGED.

RSRESTRAINTS8O-5

DRIVER AIRBAG (Continued)

Page 2052 of 4284

CAUTION: Use correct screws when installing the

ORC.

(1) Install the ORC assembly into vehicle.

(2) Connect the wire connector to the ORC.

(3) Install three bolts holding ORC to floor

bracket. Torque bolts to 7.3 - 9.6 N´m (65 to 85 in.

lbs.)

(4) Install the storage bin onto the instrument

panel. Refer to Body, Instrument Panel, Storage Bin,

Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

PASSENGER AIRBAG

DESCRIPTION

WARNING: NEVER DISASSEMBLE THE PASSEN-

GER AIRBAG, THE PASSENGER AIRBAG HAS NO

SERVICEABLE PARTS.

The Passenger Airbag is located beneath the

instrument panel and pad assembly. The airbag is

mounted to the back side of the instrument panel

reinforcement.

The instrument panel top pad is the most visible

part of the passenger airbag system. Located under

the instrument panel top pad are the airbag door, the

passenger airbag cushion and the airbag cushion

supporting components.

The passenger airbag includes a magnesium hous-

ing within which the cushion and inflator are

mounted and sealed.

Following a passenger airbag deployment, the pas-

senger airbag and the instrument panel must be

replaced. The passenger airbag cannot be repaired,

and must be replaced if deployed or damaged in any

way.

OPERATION

The passenger airbag is equipped with two infla-

tors, each with three levels of pressure output. The

inflators seal the hole in the airbag cushion so it can

discharge the gas it produces directly into the cush-

ion when supplied with the proper electrical signal.

Following an airbag deployment, the airbag cushion

quickly deflates by venting this gas through the

cushion material towards the instrument panel.

The passenger airbag is secured with screws to the

instrument panel beneath the instrument panel top

pad and above the glove box opening. The instrumentpanel top pad above the glove box opening conceals

the airbag door and a predetermined hinge line

beneath its decorative cover. Upon airbag deploy-

ment, the top pad will bend at the hinge line and the

door will fold back out of the way onto the top of the

instrument panel.

WHEN THE FRONT AIRBAG SYSTEM IS

DEPLOYED BECAUSE OF A COLLISION, THE

FOLLOWING MUST BE REPLACED:

²COMPLETE STEERING COLUMN ASSEMBLY

²LOWER STEERING COUPLER

²STEERING WHEEL

²STEERING COLUMN CLOCK SPRING

²DRIVER AIRBAG COVER/HORN SWITCH

²DRIVER AIRBAG

²PASSENGER AIRBAG

²UPPER INSTRUMENT PANEL WITH PAD

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

STANDARD PROCEDURE - DEPLOYED

PASSENGER AIRBAG CLEAN UP

Roll or fold the passenger airbag towards the

instrument panel surface and close the door over the

folded bag. Then tape the door shut.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well. If

HVAC was in RECIRC mode at time of airbag

deployment, operate HVAC blower on low speed/heat

and vacuum powder residue expelled from the heat

outlets. Multiple vacuum cleaning may be necessary

to decontaminate the interior of the vehicle.

SERVICE OF DEPLOYED AIRBAG

If a Passenger Airbag has been deployed, but not

due to a collision, replace the following:

²Passenger Airbag

²Upper instrument panel with pad

The component above must be replaced because

they cannot be reused. Inspect the heat duct near the

passenger airbag for any damage replace as neces-

sary. Replace any other passenger airbag system

components if damaged.

8O - 6 RESTRAINTSRS

OCCUPANT RESTRAINT CONTROLLER (Continued)

Page 2063 of 4284

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................3

ROAD TEST............................3

SPECIFICATIONS.........................3

CABLE

DESCRIPTION............................3

OPERATION.............................3

REMOVAL...............................3

INSTALLATION............................4

SERVO

DESCRIPTION............................4OPERATION.............................4

REMOVAL...............................4

INSTALLATION............................4

SWITCH

DESCRIPTION............................5

OPERATION.............................5

REMOVAL...............................5

INSTALLATION............................5

VACUUM RESERVOIR

DESCRIPTION............................6

OPERATION.............................6

REMOVAL...............................6

INSTALLATION............................6

SPEED CONTROL

DESCRIPTION

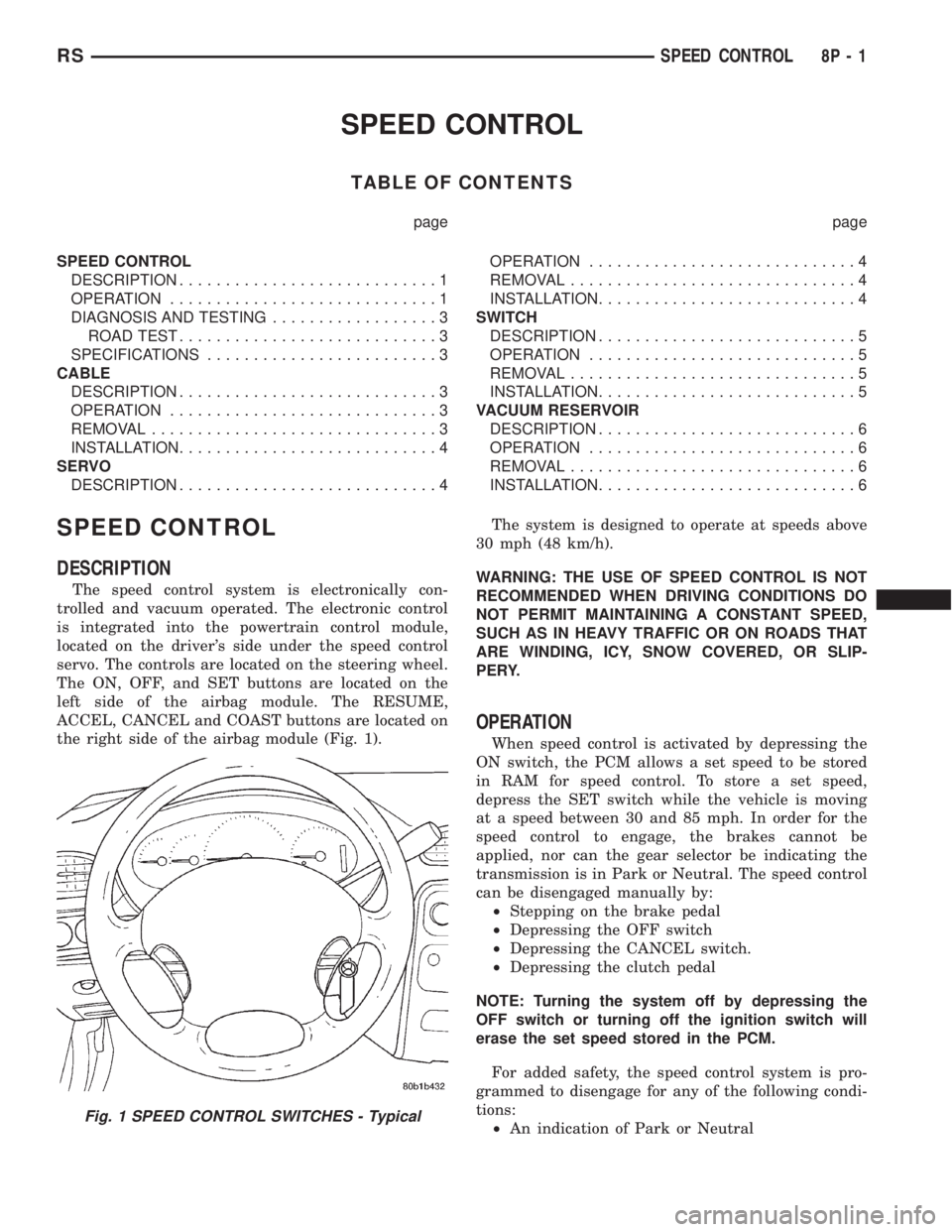

The speed control system is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the powertrain control module,

located on the driver's side under the speed control

servo. The controls are located on the steering wheel.

The ON, OFF, and SET buttons are located on the

left side of the airbag module. The RESUME,

ACCEL, CANCEL and COAST buttons are located on

the right side of the airbag module (Fig. 1).The system is designed to operate at speeds above

30 mph (48 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

When speed control is activated by depressing the

ON switch, the PCM allows a set speed to be stored

in RAM for speed control. To store a set speed,

depress the SET switch while the vehicle is moving

at a speed between 30 and 85 mph. In order for the

speed control to engage, the brakes cannot be

applied, nor can the gear selector be indicating the

transmission is in Park or Neutral. The speed control

can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal

NOTE: Turning the system off by depressing the

OFF switch or turning off the ignition switch will

erase the set speed stored in the PCM.

For added safety, the speed control system is pro-

grammed to disengage for any of the following condi-

tions:

²An indication of Park or Neutral

Fig. 1 SPEED CONTROL SWITCHES - Typical

RSSPEED CONTROL8P-1

Page 2067 of 4284

(4) Connect vacuum line to speed control servo

that leads to the battery tray/vacuum reservoir.

(5) Install speed control servo and bracket.

(6) Install battery tray/vacuum reservoir, refer to

the Battery section for more information.

(7) Install speed control and throttle cable casing

to cable mount bracket.

(8) Connect the throttle and speed control cable

ends to throttle body.

(9) Connect the negative battery cable.

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system and are located on the

steering wheel.

OPERATION

The speed control system has five separate resis-

tive switches that provide a single multiplexed

(MUX) voltage inputs to the PCM.The switch names

are: ON, OFF, SET, COAST, RESUME, ACCEL, TAP-

UP, COAST, and CANCEL. Based on conditions when

the buttons are pushed (and released), the five volt-

ages ranges provided to the PCM result in the follow-

ing functions: ON, OFF, SET, COAST, RESUME,

ACCEL, TAP-UP, COAST, and CANCEL. Refer to the

Speed Control Section for more information

Also the PCM receives an input from the brake

switch to sense whether the brake pedal has been

depressed. When the PCM receives the brake

depressed input, it turns off power to the speed con-

trol servo and disengages speed control.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

REMOVAL

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Remove the negative battery cable.

(2) Turn off ignition.

(3) Remove the air bag, refer to the restraint sec-

tion for more information.

(4) Remove two screws from side of the switch.

(5) Remove switch from steering wheel.

(6) Disconnect two-way electrical connector.

(7) Repeat for the other switch.

INSTALLATION

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Connect two-way electrical connector.

(2) Install switch.

Fig. 3 BATTERY TRAY/VACUUM RESERVOIR

Fig. 4 SPEED CONTROL SERVO

RSSPEED CONTROL8P-5

SERVO (Continued)

Page 2069 of 4284

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................2

SENTRY KEY IMMOBILIZER SYSTEM........2

VEHICLE THEFT SECURITY SYSTEM........3

HOOD AJAR SWITCH

REMOVAL...............................3

INSTALLATION............................3TRANSPONDER KEY

DESCRIPTION............................3

OPERATION.............................4

STANDARD PROCEDURE...................4

TRANSPONDER PROGRAMMING...........4

VTSS/SKIS INDICATOR LAMP

DESCRIPTION............................5

OPERATION.............................5

VEHICLE THEFT SECURITY

DESCRIPTION

VEHICLE THEFT SECURITY SYSTEM

The Vehicle Theft Security System (VTSS) is

designed to protect against whole vehicle theft. The

system monitors vehicle doors, hood, liftgate, and

ignition action for unauthorized operation. The alarm

activates:

²Sounding of the horn

²Flashing of the park and tail lamps

²Flashing of the headlamps

²An engine kill feature (without SKIS)

SENTRY KEY IMMOBILIZER SYSTEM

The Sentry Key Immobilizer System (SKIS) is

available as a factory-installed option on this vehicle.

It is designed to provide passive protection against

unauthorized vehicle use by disabling the engine,

after two (2) seconds of running, whenever an invalid

key is used to start the vehicle. The SKIS is active

whenever the ignition is on and does not require any

customer intervention. The primary components of

the system are the Sentry Key Immobilizer Module

(SKIM), Sentry Key (ignition key w/ a transponder

molded into the head), indicator light, Body Control

Module (BCM), and the Powertrain Control Module

(PCM). The SKIM is mounted to the steering column

with the molded, integral antenna mounted on the

light halo surrounding the ignition lock cylinder. The

indicator light, is located in the message center.

OPERATION

VEHICLE THEFT SECURITY SYSTEM

Upon failure of proper SKIM communication to the

PCM, the PCM will shut off fuel after two seconds ofrun time. The engine will not re-crank on the key

cycle that the failure occurred, a full key down

sequence must be performed for the engine to crank

again. After six consecutive fuel shut-offs, the engine

will no longer crank on subsequent key cycles. The

failure must be corrected and a valid communication

process between the SKIM and the PCM must occur

for the engine to crank and start again.

The electronics for the VTSS are part of the Body

Control Module (BCM). The system is armed when

the vehicle is locked using the:

²Power door lock switches (with any door ajar)

²Remote Keyless Entry transmitter.

²Door Cylinder Lock Switches.

For vehicles equipped with SKIS, the doors do not

have to be locked to enable the fuel shut off feature.

After the vehicle is locked and the last door is

closed, the set LED indicator in the top cover will

flash quickly for 16 seconds, indicating that arming

is in progress. If no monitored systems are activated

during this period, the system will arm. The LED

will extinguish unless the liftgate is open. If the lift-

gate is open, the LED will flash at a slower rate.

This indicates that the system is armed. If fault is

detected on any key cylinder input, the indicator

LED will remain solid during the arming process,

although the system will still arm. If the indicator

LED does not illuminate at all upon door closing it

indicates that the system is not arming.

Passive disarming occurs upon normal vehicle

entry by unlocking either door with the ignition key/

remote transmitter. This disarming will also halt the

alarm once it has been activated.

A tamper alert exists to notify the driver that the

VTSS had been activated. This alert consists of 3

horn pulses when the vehicle is disarmed.

RSVEHICLE THEFT SECURITY8Q-1

Page 2564 of 4284

Component/Ground Color Location Fig.

Boost Pressure Sensor (Diesel) BK Top Left of Engine N/S

Brake Fuid Level Switch BK On Master Cylinder 7

Brake Lamp Switch BK At Top Of Brake Pedal 31, 32

Brake Transmission Shift

Interlock Solenoid (EATX)BK Near Steering Column 16, 17, 18,

26

C100 BK Left Fender Shield 6

C101 LTGY Left Fender Shield 6

C102 (2.4L) BK Top Front of Engine 11

C102 (3.3/3.8L) BK At Fuel Rail 14

C103 (Diesel) BK Left Side Engine Compartment N/S

C106 (BUX) BK Near Left Headlamp Leveling Motor N/S

C107 (BUX) BK Near Right Headlamp Leveling Motor N/S

C200 GY Left Side Instrument Panel 16, 17, 25,

31, 32

C201 YL Left Side Instrument Panel 16, 17, 25,

31, 32

C202 GY Right Side Instrument Panel A/C Heatrer Unit 16, 20, 25

C203 (United Kingdom) WT Right Side of Instrument Panel N/S

C300 BK Left Front Door Lower N/S

C301 LTGY Left Front Door Upper N/S

C302 LTGY Right Front Door Upper 9, 29, 33

C303 BK Right Front Door Lower 9, 29, 33

C304 YL Left Wire Track Seat to Body 27

C305 GY Left Wire Track Seat to Body 27

C306 YL Right Wire Track Seat to Body 28

C307 GY Right Wire Track Seat to Body 28

C308 BL Left Rear Sliding Door 30

C309 GN Right Rear Sliding Door 27, 28, 29

C310 BK At Front Console N/S

C311 GY Rear A/C Switch N/S

C312 GY At Dome Lamp 28, 29

C313 BK At Rear Console N/S

C314 BK Left Side Liftgate 38

C315 BK Right Side Liftgate 38

C316 BK Wire Track to Sliding Door N/S

C317 BK Right Sliding Door 27, 34

C318 (Trailer Tow) BK Left Quarter N/S

C319 (Except Built-up Export) Left Side Liftgate N/S

C320 DKGY Driver Power Seat on Seat Harness N/S

C321 DKGY Under Passenger Seat N/S

C322 BK On Seat Harness to Body 27

C324 BK Left Sliding Door N/S

C325 BK Right Sliding Door 27

8Wa - 90 - 2 8W-90 CONNECTOR/GROUND LOCATIONS BUXRG

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 2565 of 4284

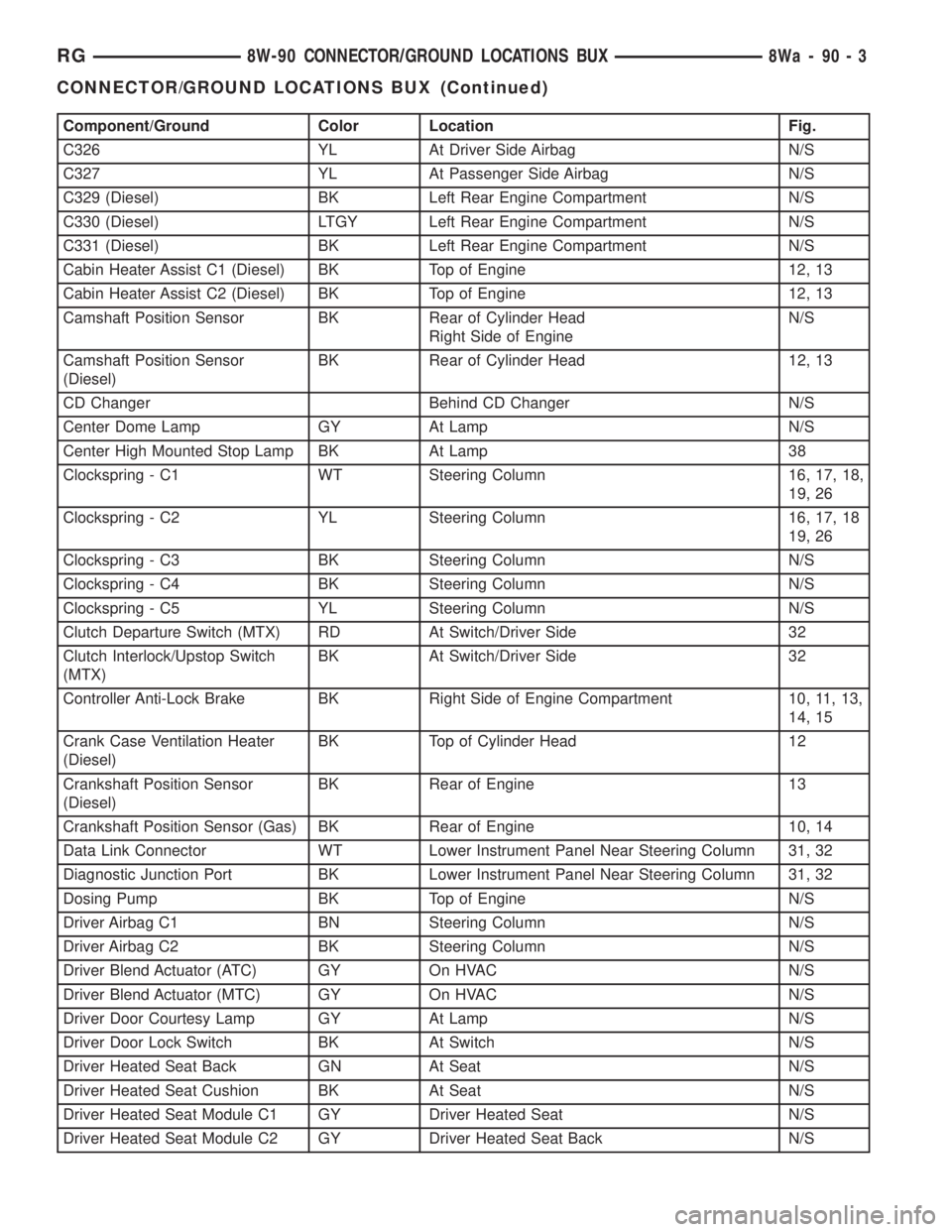

Component/Ground Color Location Fig.

C326 YL At Driver Side Airbag N/S

C327 YL At Passenger Side Airbag N/S

C329 (Diesel) BK Left Rear Engine Compartment N/S

C330 (Diesel) LTGY Left Rear Engine Compartment N/S

C331 (Diesel) BK Left Rear Engine Compartment N/S

Cabin Heater Assist C1 (Diesel) BK Top of Engine 12, 13

Cabin Heater Assist C2 (Diesel) BK Top of Engine 12, 13

Camshaft Position Sensor BK Rear of Cylinder Head

Right Side of EngineN/S

Camshaft Position Sensor

(Diesel)BK Rear of Cylinder Head 12, 13

CD Changer Behind CD Changer N/S

Center Dome Lamp GY At Lamp N/S

Center High Mounted Stop Lamp BK At Lamp 38

Clockspring - C1 WT Steering Column 16, 17, 18,

19, 26

Clockspring - C2 YL Steering Column 16, 17, 18

19, 26

Clockspring - C3 BK Steering Column N/S

Clockspring - C4 BK Steering Column N/S

Clockspring - C5 YL Steering Column N/S

Clutch Departure Switch (MTX) RD At Switch/Driver Side 32

Clutch Interlock/Upstop Switch

(MTX)BK At Switch/Driver Side 32

Controller Anti-Lock Brake BK Right Side of Engine Compartment 10, 11, 13,

14, 15

Crank Case Ventilation Heater

(Diesel)BK Top of Cylinder Head 12

Crankshaft Position Sensor

(Diesel)BK Rear of Engine 13

Crankshaft Position Sensor (Gas) BK Rear of Engine 10, 14

Data Link Connector WT Lower Instrument Panel Near Steering Column 31, 32

Diagnostic Junction Port BK Lower Instrument Panel Near Steering Column 31, 32

Dosing Pump BK Top of Engine N/S

Driver Airbag C1 BN Steering Column N/S

Driver Airbag C2 BK Steering Column N/S

Driver Blend Actuator (ATC) GY On HVAC N/S

Driver Blend Actuator (MTC) GY On HVAC N/S

Driver Door Courtesy Lamp GY At Lamp N/S

Driver Door Lock Switch BK At Switch N/S

Driver Heated Seat Back GN At Seat N/S

Driver Heated Seat Cushion BK At Seat N/S

Driver Heated Seat Module C1 GY Driver Heated Seat N/S

Driver Heated Seat Module C2 GY Driver Heated Seat Back N/S

RG8W-90 CONNECTOR/GROUND LOCATIONS BUX8Wa-90-3

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 2567 of 4284

Component/Ground Color Location Fig.

Fuel Injector No.1 (Diesel) BK At Fuel Injector 12

Fuel Injector No.2 BK At Fuel Injector N/S

Fuel Injector No.2 (Diesel) BK 12

Fuel Injector No.3 BK At Fuel Injector N/S

Fuel Injector No.3 (Diesel) BK 12

Fuel Injector No.4 BK At Fuel Injector N/S

Fuel Injector No.4 (Diesel) BK 12

Fuel Injector No.5 BK At Fuel Injector N/S

Fuel Injector No.6 BK At Fuel Injector N/S

Fuel Tank Module LTGY Side of Fuel Tank N/S

Fuel Rail Pressure Sensor

(Diesel)BK Top Left of Engine 12

G100 Body Ground Near Powertrain Control Module N/S

G101 Above Starter 11

G102 Left Headlamp Area N/S

G103 Above Starter 11

G200 Right Side of Instrument Panel 16, 20, 25

G201 Right Side of Instrument Panel 16, 20, 25

G300 Left B Pillar 27

G301 Right B Pillar 28, 29

G302 Left Rear Quarter N/S

G400 Liftgate Ground 38

Generator BK Rear of Generator 11, 12, 14,

15

Glove Box Lamp BL Rear of Glove Box 19, 25

Glow Plug Relay (Diesel) BK At Relay N/S

Halo Lamp WT Steering Column 16, 17, 18,

19, 26

Headlamp Switch BK Rear of Switch 16, 17, 25

Headlamp Washer Pump Motor At Motor

High Note Horn BK Left Frame Rail 6

High Pressure Fuel Pump

(Diesel)Rear of Pump

Hood Ajar Switch BK Left Fender 7

Idle Air Control Motor (2.4L) BK On Throttle Body 10

Idle Air Control Motor (3.3/3.8L) BK On Throttle Body 14

Ignition Coil Pack 2.4L BK Top of Valve Cover 10, 11

Ignition Coil Pack 3.3L, 3.8L DKGY Top of Engine 15

Ignition Switch BK Rear of Switch at Steering Column 16, 17 18,

19, 26

Inlet Air Temperature Sensor BK Top Left of Engine 14

Instrument Cluster BK Rear of Cluster 16, 17, 23

Instrument Panel Switch Bank BK Right Center of Instrument Panel 16, 19, 21

RG8W-90 CONNECTOR/GROUND LOCATIONS BUX8Wa-90-5

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 2569 of 4284

Component/Ground Color Location Fig.

Left Remote Radio Switch Steering Wheel N/S

Left Repeater Lamp GY Left Front Fender 5

Left Seat Airbag YL Left Seat N/S

Left Side Impact Airbag Control

ModuleYL Left B Pillar 30

Left Sliding Door Control Module

C1BK Left Sliding Door N/S

Left Sliding Door Control Module

C2BK/RD Left Sliding Door N/S

Left Sliding Door Latch Sensing

SwitchBK Left Sliding Door N/S

Left Sliding Door Lock Motor BK Left Sliding Door N/S

Left Sliding Door Lock Motor/Ajar

SwitchBK Left Sliding Door N/S

Left Sliding Door Motor BK Left Sliding Door N/S

Left Speed Control Switch BK Steering Wheel N/S

Left Stop/Turn Signal Relay BK Left Quarter Panel N/S

Left Turn Signal Lamp BK AT Lamp N/S

Left Visor/Vanity Lamp BK At Lamp N/S

License Lamp DKGY At Lamp 38

Lift Pump Motor BK Left Rear Engine Compartment N/S

Liftgate Ajar Switch (Manual

Release)BK At Latch 38

Liftgate Ajar Switch (Power

Release)BK Lower Liftgate 38

Liftgate Cinch/Release Motor BL Liftgate N/S

Liftgate Cylinder Lock Switch BK At Switch 38

Liftgate Left Pinch Sensor BK Left Side of Liftgate N/S

Liftgate Right Pinch Sensor BK Right Side of Liftgate N/S

Low Note Horn BK Left Frame Rail 6

Manifold Absolute Pressure

SensorBK On Intake 11

Mass Air Flow Sensor (Diesel) OR Top of Engine 12, 13

Memory Power Seat Switch GN On Seat N/S

Memory Seat/Mirror Module C1 GY Under Driver Seat N/S

Memory Seat/Mirror Module C2 GY Under Driver Seat N/S

Memory Seat/Mirror Module C3 GY Under Driver Seat N/S

Memory Seat/Mirror Module C4 WT Under Driver Seat N/S

Memory Seat Front Vertical Motor RD Under Seat N/S

Memory Seat Front Vertical

Position SensorBK Under Seat N/S

Memory Seat Horizontal Motor BK Under Seat N/S

Memory Seat Horizontal Position

SensorBK Under Seat N/S

RG8W-90 CONNECTOR/GROUND LOCATIONS BUX8Wa-90-7

CONNECTOR/GROUND LOCATIONS BUX (Continued)

Page 2570 of 4284

Component/Ground Color Location Fig.

Memory Seat Rear Vertical Motor RD Under Seat N/S

Memory Seat Rear Vertical

Position SensorBK Under Seat N/S

Memory Seat Recliner Motor GN Under Seat N/S

Memory Seat Recliner Position

SensorBK Under Seat N/S

Memory Seat Switch BK At Switch Driver Door N/S

Message Center WT Rear of Message Center 16, 17, 23

Mode Door Actuator BK Left Side of HVAC N/S

Multi Function Switch BK At Steering Column 16, 17, 18,

19, 26

Occupant Restraint Controller YL/RD Right Side of Instrument Panel 16, 20, 21

Output Speed Sensor GY Front of Transmission 15

Overhead Console BK Front of Console N/S

Oxygen Sensor 1/1 Upstream GY Rear of Engine 10, 11, 15

Oxygen Sensor 1/2 Downstream BK Rear of Engine 10, 11, 15

Park/Neutral Positon Switch BK Front of Transmission 11

Passenger Airbag YL Passenger Side of Instrument Panel 16, 19, 20,

25

Passenger Blend Door Actuator On HVAC N/S

Passenger Door Courtesy Lamp BK At Lamp 33

Passenger Door Lock Switch BK At Switch 33

Passenger Folding Mirror Relay BL Right Kick Panel N/S

Passenger Heated Seat Back GN At Seat N/S

Passenger Heated Seat Cushion BK At Seat N/S

Passenger Heated Seat Module

C1GY At Heated Seat N/S

Passenger Heated Seat Module

C2GY At Heated Seat Back N/S

Passenger Heated Seat Module

C3GN At Heated Seat N/S

Passenger Power Seat Front

Riser MotorRD Under Seat N/S

Passenger Power Seat Horizontal

MotorBK Under Seat N/S

Passenger Power Seat Rear

Riser MotorRD Under Seat N/S

Passenger Power Seat Recliner

MotorGN Under Seat N/S

Passenger Power Seat Switch GN At Switch N/S

Passenger Power Window Motor RD At Motor 33

Passenger Power Window Switch BK At Switch 33

Passenger Seatbelt Switch On Seat Harness N/S

Passenger Seatbelt Tensioner On Seat Harness N/S

Power Folding Mirror Switch BK Near Steering Column 26

8Wa - 90 - 8 8W-90 CONNECTOR/GROUND LOCATIONS BUXRG

CONNECTOR/GROUND LOCATIONS BUX (Continued)