ignition CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4019 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Disconnect the PCM harness connector.

Disconnect the Transmission Range Sensor harness connector.

Measure the resistance of the P/N Position Switch Sense circuit.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the P/N Position Switch Sense circuit for an open.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

5 Turn the ignition off.

Disconnect the PCM harness connector.

Move the Gear selector through all gear positions, from Park to 1st and back.

While moving the gear selector through each gear, measure the resistance between

ground and the P/N Position Switch Sense circuit.

Did the resistance change from above 10.0 ohms to below 10.0 ohms?All

Ye s®Go To 6

No®Replace the Transmission Range Sensor.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Module in accordance with

the Service Information.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

7 At this time, the conditions required to set the DTC are not present.

NOTE: Use the Freeze Frame Data to help duplicate the conditions that set

the DTC. Pay particular attention to the DTC set conditions, such as, VSS,

MAP, ECT, and Load.

NOTE: Visually inspect the related wiring harness. Look for any chafed,

pierced, pinched, or partially broken wires.

NOTE: Visually inspect the related wiring harness connectors. Look for

broken, bent, pushed out, or corroded terminals.

NOTE: Refer to any technical service bulletins (TSB) that may apply.

Were any problems found?All

Ye s®Repair as necessary.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1..

No®Test Complete.

225

DRIVEABILITY - GAS

P1899-P/N SWITCH STUCK IN PARK OR IN GEAR (4SP AUTO TRNAS) Ð

Continued

Page 4020 of 4284

Symptom:

*CHECKING ECT SENSOR

POSSIBLE CAUSES

ECT SENSOR OPERATION

ECT SENSOR

TEST ACTION APPLICABILITY

1NOTE: The engine coolant temperature must be below 62ÉC (150ÉF).

Turn the ignition on.

With the DRBIIIt, monitor the ECT value.

Start the engine.

Does the ECT reach 82ÉC (180ÉF) and was it a smooth transition?All

Ye s®Engine Coolant Temperature sensor is operating normally.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Replace the Engine Coolant Temperature Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

226

DRIVEABILITY - GAS

Page 4021 of 4284

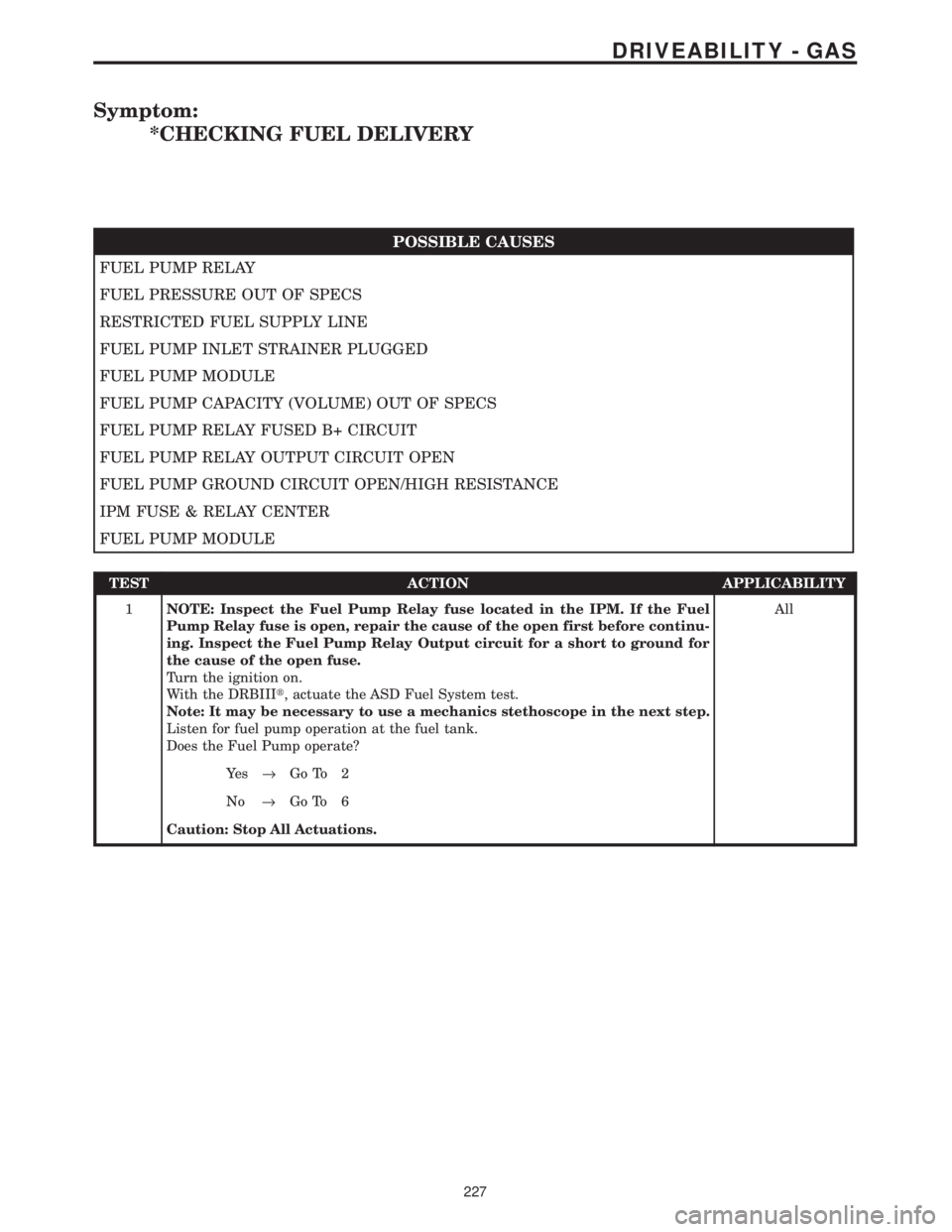

Symptom:

*CHECKING FUEL DELIVERY

POSSIBLE CAUSES

FUEL PUMP RELAY

FUEL PRESSURE OUT OF SPECS

RESTRICTED FUEL SUPPLY LINE

FUEL PUMP INLET STRAINER PLUGGED

FUEL PUMP MODULE

FUEL PUMP CAPACITY (VOLUME) OUT OF SPECS

FUEL PUMP RELAY FUSED B+ CIRCUIT

FUEL PUMP RELAY OUTPUT CIRCUIT OPEN

FUEL PUMP GROUND CIRCUIT OPEN/HIGH RESISTANCE

IPM FUSE & RELAY CENTER

FUEL PUMP MODULE

TEST ACTION APPLICABILITY

1NOTE: Inspect the Fuel Pump Relay fuse located in the IPM. If the Fuel

Pump Relay fuse is open, repair the cause of the open first before continu-

ing. Inspect the Fuel Pump Relay Output circuit for a short to ground for

the cause of the open fuse.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test.

Note: It may be necessary to use a mechanics stethoscope in the next step.

Listen for fuel pump operation at the fuel tank.

Does the Fuel Pump operate?All

Ye s®Go To 2

No®Go To 6

Caution: Stop All Actuations.

227

DRIVEABILITY - GAS

Page 4022 of 4284

TEST ACTION APPLICABILITY

2 Turn the ignition off.

WARNING: The fuel system is under a constant pressure even with the

engine off. Before testing or servicing any fuel system hose, fitting or line,

the fuel system pressure must be released.

Install a fuel pressure gauge to the fuel rail test port.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test and observe the fuel pressure

gauge.

NOTE: Fuel pressure specification is 400 KPa +/- 34 KPa (58 psi +/- 5 psi).

Choose a conclusion that best matches your fuel pressure reading.All

Below Specification

Go To 3

Within Specification

Go To 5

Above Specification

Replace the fuel filter/fuel pressure regulator.

Perform POWERTRAIN VERIFICATION TEST VER-1.

Caution: Stop All Actuations.

3 Turn the ignition off.

WARNING: The fuel system is under a constant pressure even with the

engine off. Before testing or servicing any fuel system hose, fitting or line,

the fuel system pressure must be released.

Raise vehicle on hoist, and disconnect the fuel pressure line at the fuel pump module.

Install special 5/169fuel line adapter tool #6539 between disconnected fuel line and

the fuel pump module.

Attach a fuel pressure test gauge to the9T9fitting on tool #6539.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test and observe the fuel pressure

gauge.

NOTE: Fuel pressure specification is 400 KPa +/- 34 KPa (58 psi +/- 5 psi).

Is the fuel pressure within specification now?All

Ye s®Repair/replace fuel supply line as necessary.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Go To 4

Caution: Stop All Actuations.

4 Turn the ignition off.

WARNING: The fuel system is under a constant pressure even with the

engine off. Before testing or servicing any fuel system hose,fitting or line,

the fuel system pressure must be released.

Remove the Fuel Pump Module and inspect the Fuel Inlet Strainer.

Is the Fuel Inlet Strainer plugged?All

Ye s®Replace the Fuel Pump Inlet Strainer.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Replace the Fuel Pump Module.

Perform POWERTRAIN VERIFICATION TEST VER-1.

228

DRIVEABILITY - GAS

*CHECKING FUEL DELIVERY ÐContinued

Page 4023 of 4284

TEST ACTION APPLICABILITY

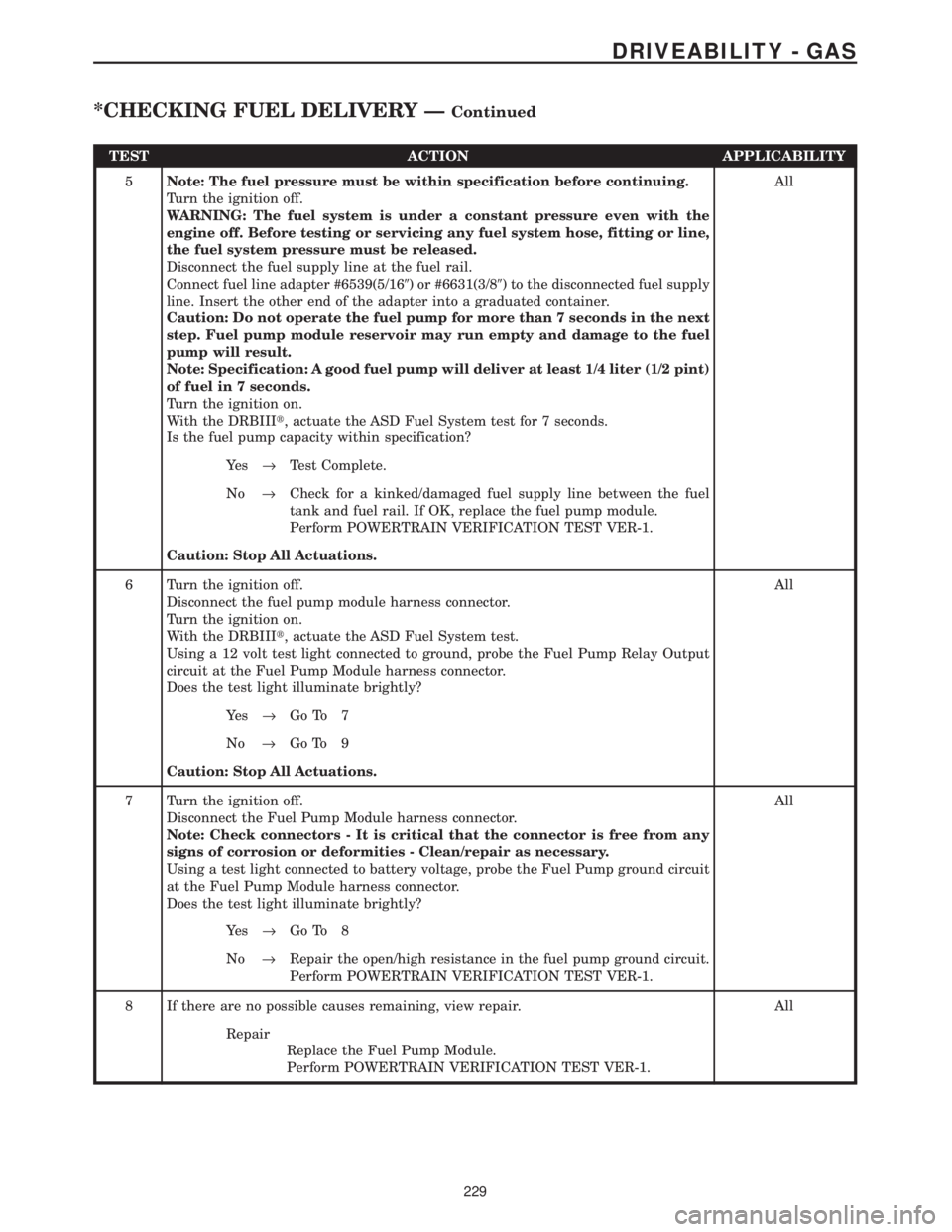

5Note: The fuel pressure must be within specification before continuing.

Turn the ignition off.

WARNING: The fuel system is under a constant pressure even with the

engine off. Before testing or servicing any fuel system hose, fitting or line,

the fuel system pressure must be released.

Disconnect the fuel supply line at the fuel rail.

Connect fuel line adapter #6539(5/169) or #6631(3/89) to the disconnected fuel supply

line. Insert the other end of the adapter into a graduated container.

Caution: Do not operate the fuel pump for more than 7 seconds in the next

step. Fuel pump module reservoir may run empty and damage to the fuel

pump will result.

Note: Specification: A good fuel pump will deliver at least 1/4 liter (1/2 pint)

of fuel in 7 seconds.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test for 7 seconds.

Is the fuel pump capacity within specification?All

Ye s®Test Complete.

No®Check for a kinked/damaged fuel supply line between the fuel

tank and fuel rail. If OK, replace the fuel pump module.

Perform POWERTRAIN VERIFICATION TEST VER-1.

Caution: Stop All Actuations.

6 Turn the ignition off.

Disconnect the fuel pump module harness connector.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test.

Using a 12 volt test light connected to ground, probe the Fuel Pump Relay Output

circuit at the Fuel Pump Module harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 7

No®Go To 9

Caution: Stop All Actuations.

7 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Note: Check connectors - It is critical that the connector is free from any

signs of corrosion or deformities - Clean/repair as necessary.

Using a test light connected to battery voltage, probe the Fuel Pump ground circuit

at the Fuel Pump Module harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 8

No®Repair the open/high resistance in the fuel pump ground circuit.

Perform POWERTRAIN VERIFICATION TEST VER-1.

8 If there are no possible causes remaining, view repair. All

Repair

Replace the Fuel Pump Module.

Perform POWERTRAIN VERIFICATION TEST VER-1.

229

DRIVEABILITY - GAS

*CHECKING FUEL DELIVERY ÐContinued

Page 4024 of 4284

TEST ACTION APPLICABILITY

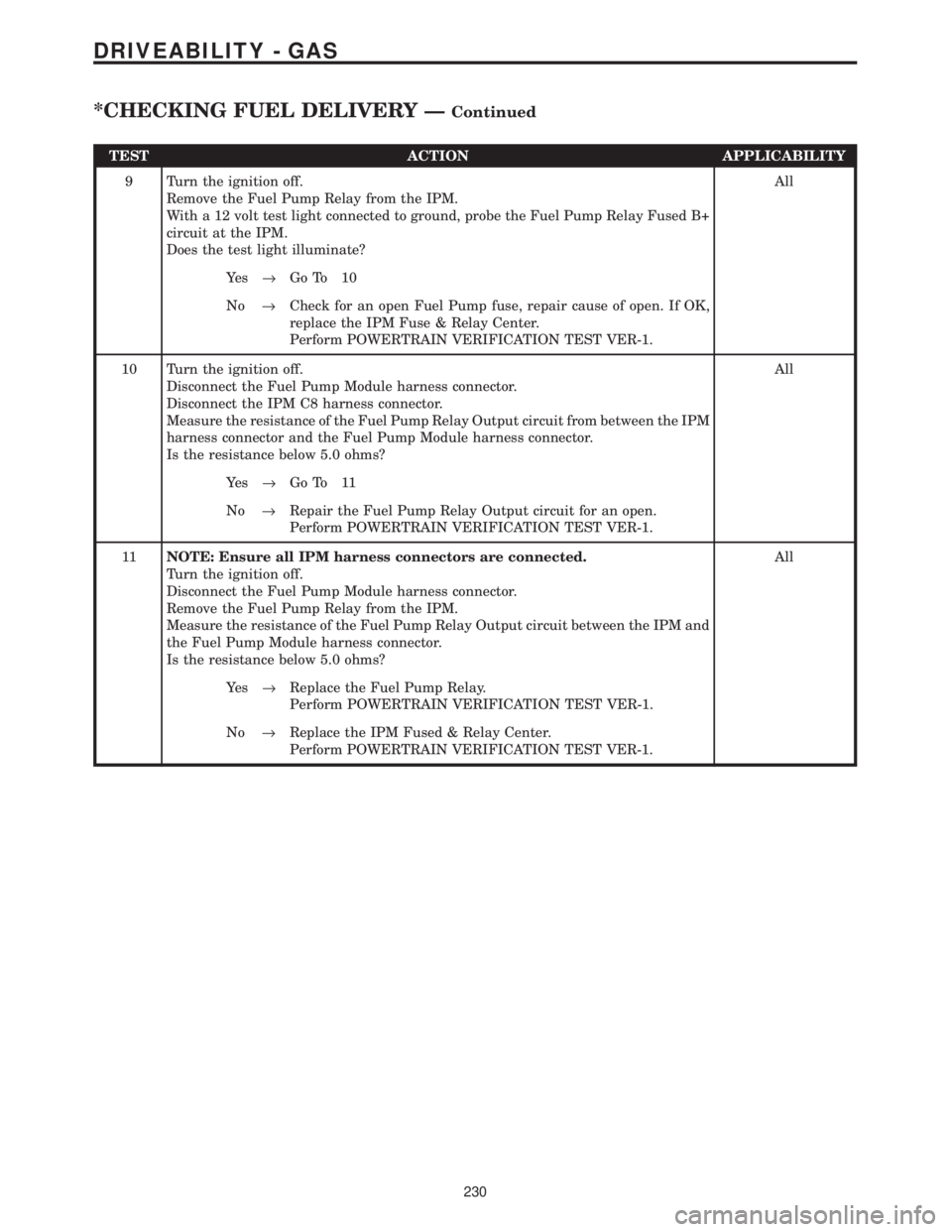

9 Turn the ignition off.

Remove the Fuel Pump Relay from the IPM.

With a 12 volt test light connected to ground, probe the Fuel Pump Relay Fused B+

circuit at the IPM.

Does the test light illuminate?All

Ye s®Go To 10

No®Check for an open Fuel Pump fuse, repair cause of open. If OK,

replace the IPM Fuse & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER-1.

10 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Disconnect the IPM C8 harness connector.

Measure the resistance of the Fuel Pump Relay Output circuit from between the IPM

harness connector and the Fuel Pump Module harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 11

No®Repair the Fuel Pump Relay Output circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER-1.

11NOTE: Ensure all IPM harness connectors are connected.

Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Remove the Fuel Pump Relay from the IPM.

Measure the resistance of the Fuel Pump Relay Output circuit between the IPM and

the Fuel Pump Module harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Replace the Fuel Pump Relay.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Replace the IPM Fused & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER-1.

230

DRIVEABILITY - GAS

*CHECKING FUEL DELIVERY ÐContinued

Page 4025 of 4284

Symptom:

*CHECKING IAC MOTOR (2.4L)

POSSIBLE CAUSES

IAC MOTOR OPERATION

IAC DRIVER CIRCUITS OPEN

IAC MOTOR

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, monitor engine RPM.

With the DRBIIIt, set the engine speed to 1400 RPM.

Does the engine speed reach 1400 rpm?All

Ye s®The IAC Motor is operation normally

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Go To 2

2 Turn the ignition off.

Disconnect IAC Motor harness connector.

Disconnect the PCM harness connector.

Repeat each measurement for each IAC Driver circuit.

Measure the resistance of each IAC Driver circuit between the IAC Motor harness

connector and the PCM harness connector.

Is the resistance below 5.0 ohms at all IAC Driver circuits?All

Ye s®Replace the Idle Air Control Motor.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Repair the IAC Driver circuit(s) for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

231

DRIVEABILITY - GAS

Page 4026 of 4284

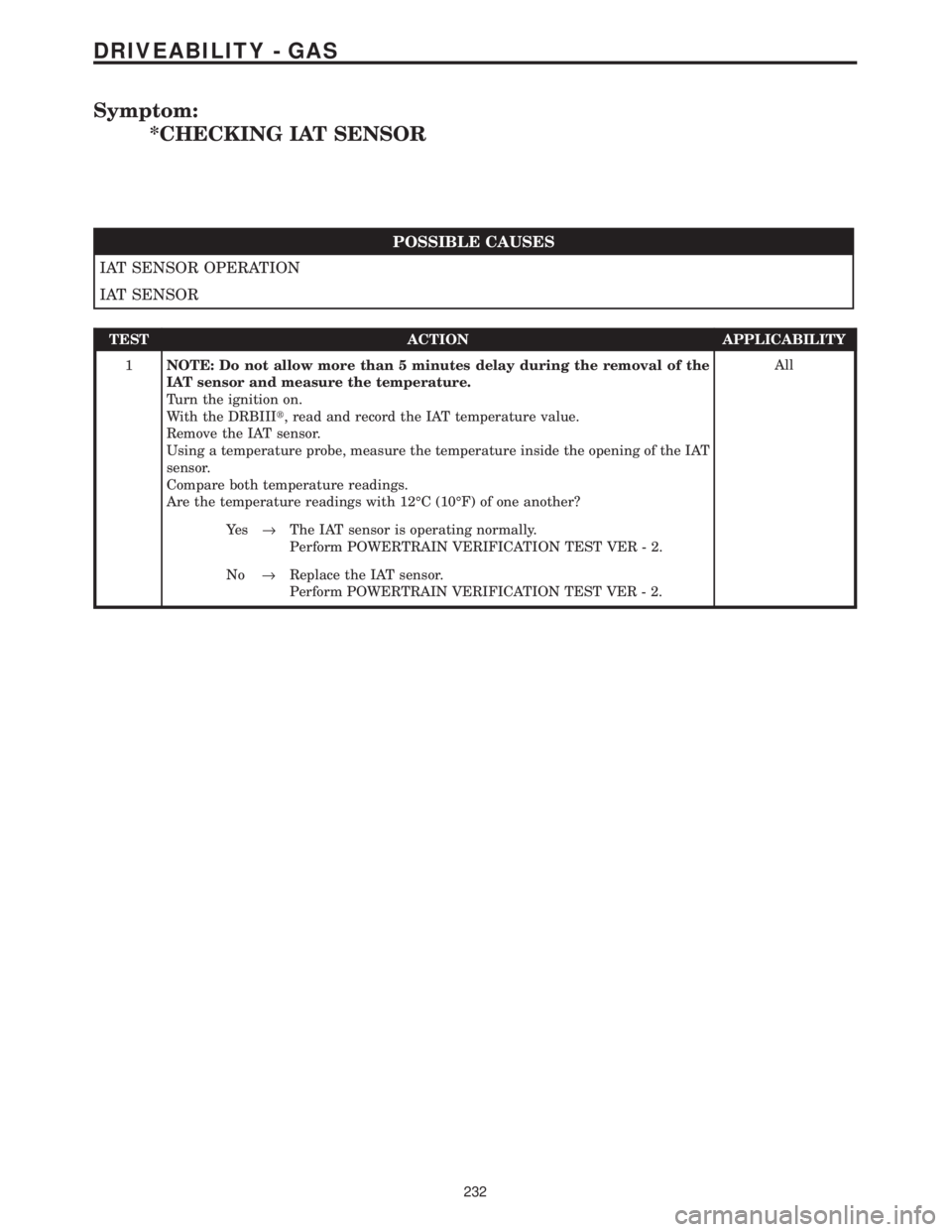

Symptom:

*CHECKING IAT SENSOR

POSSIBLE CAUSES

IAT SENSOR OPERATION

IAT SENSOR

TEST ACTION APPLICABILITY

1NOTE: Do not allow more than 5 minutes delay during the removal of the

IAT sensor and measure the temperature.

Turn the ignition on.

With the DRBIIIt, read and record the IAT temperature value.

Remove the IAT sensor.

Using a temperature probe, measure the temperature inside the opening of the IAT

sensor.

Compare both temperature readings.

Are the temperature readings with 12ÉC (10ÉF) of one another?All

Ye s®The IAT sensor is operating normally.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Replace the IAT sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

232

DRIVEABILITY - GAS

Page 4027 of 4284

Symptom:

*CHECKING MAP SENSOR

POSSIBLE CAUSES

MAP SENSOR OPERATION

MAP SENSOR

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Attach a vacuum gauge to a manifold vacuum source.

NOTE: If the engine will not idle, maintain a constant engine speed above

idle.

Allow the engine to idle.

With the DRBIIIt, monitor the MAP sensor vacuum.

Compare the MAP vacuum value on the DRBIIItand the vacuum reading on the

vacuum gauge.

Are the vacuum readings within 1 inch of vacuum of each other?All

Ye s®The MAP sensor is operating normally.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Replace the MAP sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

233

DRIVEABILITY - GAS

Page 4028 of 4284

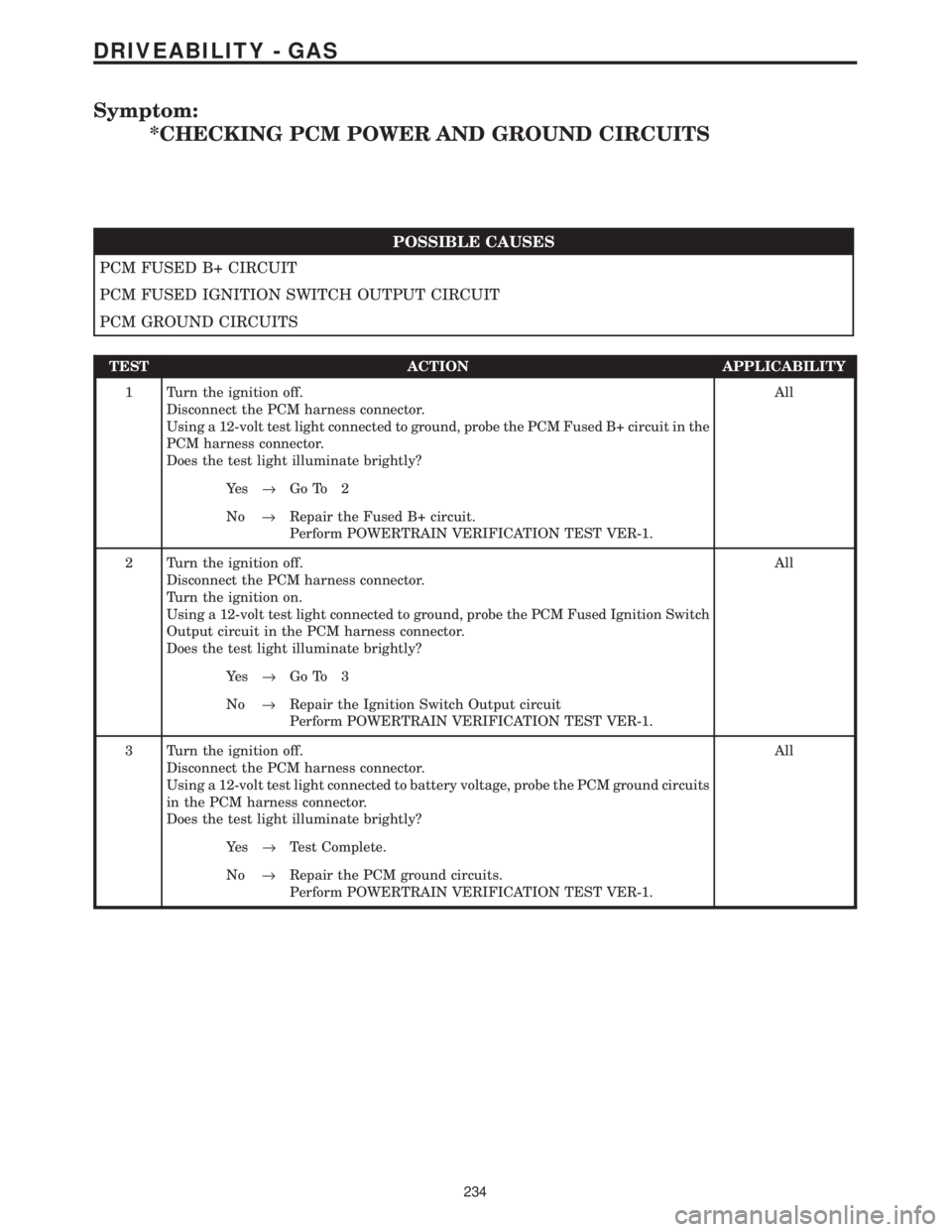

Symptom:

*CHECKING PCM POWER AND GROUND CIRCUITS

POSSIBLE CAUSES

PCM FUSED B+ CIRCUIT

PCM FUSED IGNITION SWITCH OUTPUT CIRCUIT

PCM GROUND CIRCUITS

TEST ACTION APPLICABILITY

1 Turn the ignition off.

Disconnect the PCM harness connector.

Using a 12-volt test light connected to ground, probe the PCM Fused B+ circuit in the

PCM harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 2

No®Repair the Fused B+ circuit.

Perform POWERTRAIN VERIFICATION TEST VER-1.

2 Turn the ignition off.

Disconnect the PCM harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the PCM Fused Ignition Switch

Output circuit in the PCM harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the Ignition Switch Output circuit

Perform POWERTRAIN VERIFICATION TEST VER-1.

3 Turn the ignition off.

Disconnect the PCM harness connector.

Using a 12-volt test light connected to battery voltage, probe the PCM ground circuits

in the PCM harness connector.

Does the test light illuminate brightly?All

Ye s®Test Complete.

No®Repair the PCM ground circuits.

Perform POWERTRAIN VERIFICATION TEST VER-1.

234

DRIVEABILITY - GAS