key CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2676 of 4284

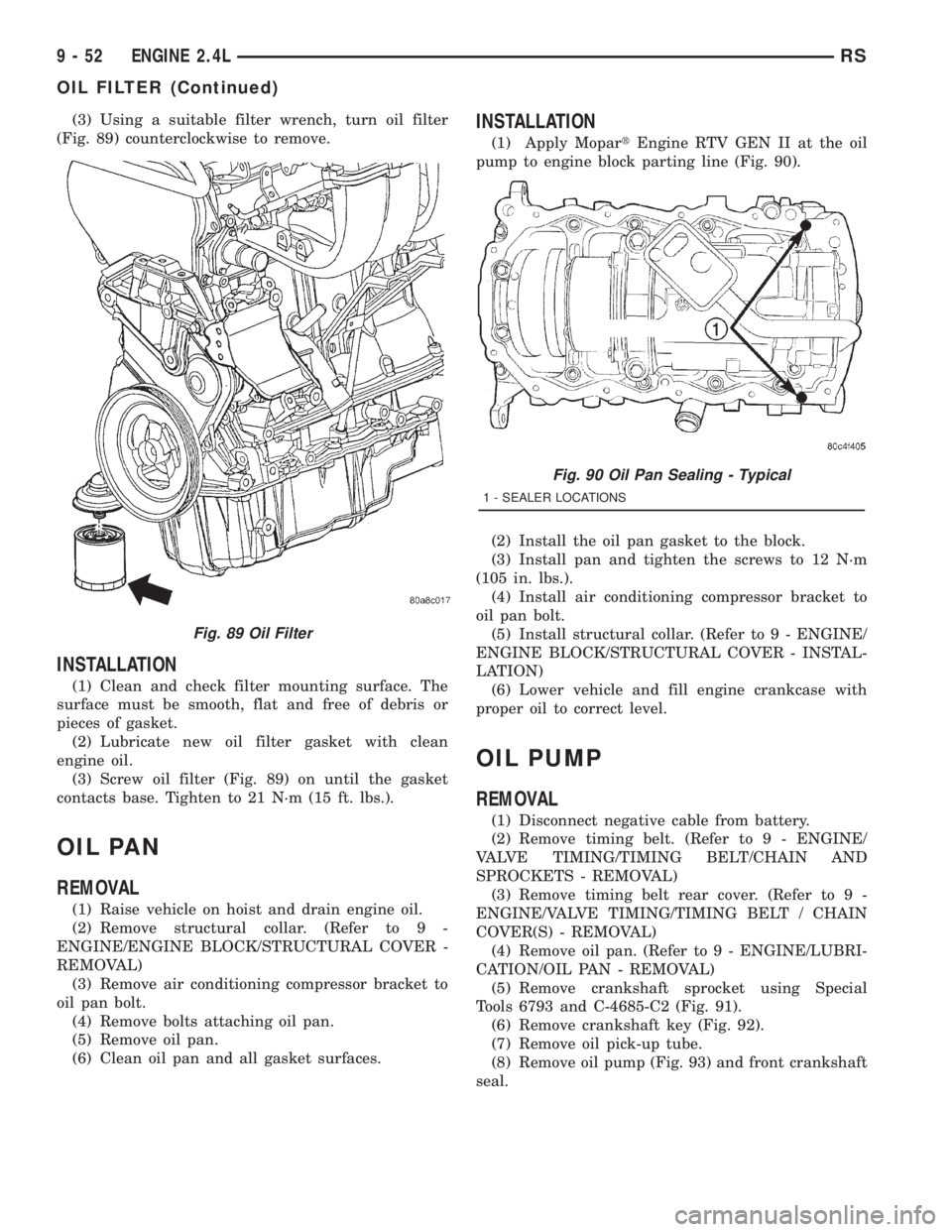

(3) Using a suitable filter wrench, turn oil filter

(Fig. 89) counterclockwise to remove.

INSTALLATION

(1) Clean and check filter mounting surface. The

surface must be smooth, flat and free of debris or

pieces of gasket.

(2) Lubricate new oil filter gasket with clean

engine oil.

(3) Screw oil filter (Fig. 89) on until the gasket

contacts base. Tighten to 21 N´m (15 ft. lbs.).

OIL PAN

REMOVAL

(1) Raise vehicle on hoist and drain engine oil.

(2) Remove structural collar. (Refer to 9 -

ENGINE/ENGINE BLOCK/STRUCTURAL COVER -

REMOVAL)

(3) Remove air conditioning compressor bracket to

oil pan bolt.

(4) Remove bolts attaching oil pan.

(5) Remove oil pan.

(6) Clean oil pan and all gasket surfaces.

INSTALLATION

(1) Apply MopartEngine RTV GEN II at the oil

pump to engine block parting line (Fig. 90).

(2) Install the oil pan gasket to the block.

(3) Install pan and tighten the screws to 12 N´m

(105 in. lbs.).

(4) Install air conditioning compressor bracket to

oil pan bolt.

(5) Install structural collar. (Refer to 9 - ENGINE/

ENGINE BLOCK/STRUCTURAL COVER - INSTAL-

LATION)

(6) Lower vehicle and fill engine crankcase with

proper oil to correct level.

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL)

(3) Remove timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL)

(4) Remove oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL)

(5) Remove crankshaft sprocket using Special

Tools 6793 and C-4685-C2 (Fig. 91).

(6) Remove crankshaft key (Fig. 92).

(7) Remove oil pick-up tube.

(8) Remove oil pump (Fig. 93) and front crankshaft

seal.

Fig. 89 Oil Filter

Fig. 90 Oil Pan Sealing - Typical

1 - SEALER LOCATIONS

9 - 52 ENGINE 2.4LRS

OIL FILTER (Continued)

Page 2677 of 4284

DISASSEMBLY

(1) To remove the relief valve, proceed as follows:

(a) Remove the threaded plug and gasket from

the oil pump (Fig. 94).

(b) Remove spring and relief valve (Fig. 94).

(2) Remove oil pump cover fasteners, and lift off

cover (Fig. 95).

(3) Remove pump rotors (Fig. 95).

(4) Wash all parts in a suitable solvent and

inspect carefully for damage or wear.

CLEANING

(1) Clean all parts thoroughly in a suitable sol-

vent.

INSPECTION

(1) Inspect the mating surface of the oil pump.

Surface should be smooth (Fig. 96). Replace pump

cover if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 97). If a 0.025 mm (0.001 in.) feeler gauge

Fig. 91 Crankshaft Sprocket - Removal

1 - SPECIAL TOOL 6793

2 - SPECIAL TOOL C-4685±C2

3 - CRANKSHAFT SPROCKET

Fig. 92 Crankshaft Key

1 - CRANKSHAFT KEY

Fig. 93 Oil Pump

1 - BOLTS

2 - BOLTS

3 - OIL PUMP

Fig. 94 Oil Pressure Relief Valve

1 - PLUG

2 - OIL PUMP BODY

3 - RELIEF VALVE

4 - SPRING

5 - SEAL

RSENGINE 2.4L9-53

OIL PUMP (Continued)

Page 2679 of 4284

ASSEMBLY

(1) Assemble pump, using new parts as required.

Install the inner rotor with chamfer facing the

cast iron oil pump cover.

(2) Prime oil pump before installation by filling

rotor cavity with engine oil.

(3) Install cover and tighten fasteners to 12 N´m

(105 in. lbs.) (Fig. 95).

CAUTION: Oil pump pressure relief valve must be

installed as shown in (Fig. 94) or serious engine

damage may occur.

(4) Install relief valve, spring, gasket and cap as

shown in (Fig. 94). Tighten cap to 41 N´m (30 ft.

lbs.).

INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.

(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 100). Install O-ring into oil pump body

discharge passage.

(3) Prime oil pump with engine oil before installa-

tion.

(4) Align oil pump rotor flats with flats on crank-

shaft. Install the oil pump to the block (Fig. 93).

CAUTION: To align, the front crankshaft seal MUST

be out of pump, or damage may result.

(5) Install new front crankshaft seal using Special

Tool 6780 (Fig. 101).(6) Install crankshaft key (Fig. 92).

CAUTION: The crankshaft sprocket is set to a pre-

determined depth from the factory for correct tim-

ing belt tracking. If removed, use of Special Tool

6792 is required to set the sprocket to original

installation depth. An incorrectly installed sprocket

will result in timing belt and engine damage.

(7) Install crankshaft sprocket using Special Tool

6792 (Fig. 102).

(8) Install oil pump pick-up tube.

(9) Install oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION)

(10) Install timing belt rear cover. (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION)

(11) Install timing belt. (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION)

Fig. 100 Oil Pump Sealing

1 - O-RING

2 - SEALER LOCATION

Fig. 101 Front Crankshaft Seal - Installation

1 - PROTECTOR

2 - SEAL

3 - SPECIAL TOOL 6780

RSENGINE 2.4L9-55

OIL PUMP (Continued)

Page 2691 of 4284

chain sprocket. Sprocket will hang in lower chain

loop.

(3) Remove carrier to crankcase attaching bolts to

remove carrier.

BALANCE SHAFT TIMING

BALANCE SHAFT INSTALLATION

Balance shaft and carrier assembly installation is

the reverse of the removal procedure.During instal-

lation crankshaft-to-balance shaft timing must

be established. Refer to Timing procedure in

this section.

(1) With balance shafts installed in carrier (Fig.

131) position carrier on crankcase and install four

attaching bolts and tighten to 54 N´m (40 ft. lbs.).

(2) Turn balance shafts until both shaft key ways

are up, parallel to vertical centerline of engine.

Install short hub drive gear on sprocket driven shaft

and long hub gear on gear driven shaft. After instal-

lation gear and balance shaft keyways must be up

with gear timing marks meshed as shown in (Fig.

132).

Fig. 128 Chain Cover, Guide and Tensioner

1 - STUD

2 - TENSIONER (ADJUSTER)

3 - GEAR COVER

4 - ADJUST SCREW

5 - PIVOT SCREW

6 - CHAIN COVER (CUTAWAY)

7 - GUIDE

Fig. 129 Drive Chain and Sprockets

1 - NICKEL PLATED LINK AND MARK

2 - GEAR/SPROCKET SCREWS

3 - NICKEL PLATED LINK AND DOT

Fig. 130 Gear Cover and Gears

1 - STUD (DOUBLE ENDED)

2 - DRIVE GEAR

3 - DRIVEN GEAR

4 - CARRIER DOWEL

5 - GEAR(S)

6 - GEAR COVER

RSENGINE 2.4L9-67

BALANCE SHAFT (Continued)

Page 2692 of 4284

(3) Install gear cover and tighten double ended

stud/washer fastener to 12 N´m (105 in. lbs.).

(4) Align flat on balance shaft drive sprocket to the

flat on crankshaft (Fig. 133).

(5) Install balance shaft drive sprocket on crank-

shaft using Special Tool 6052 (Fig. 134).

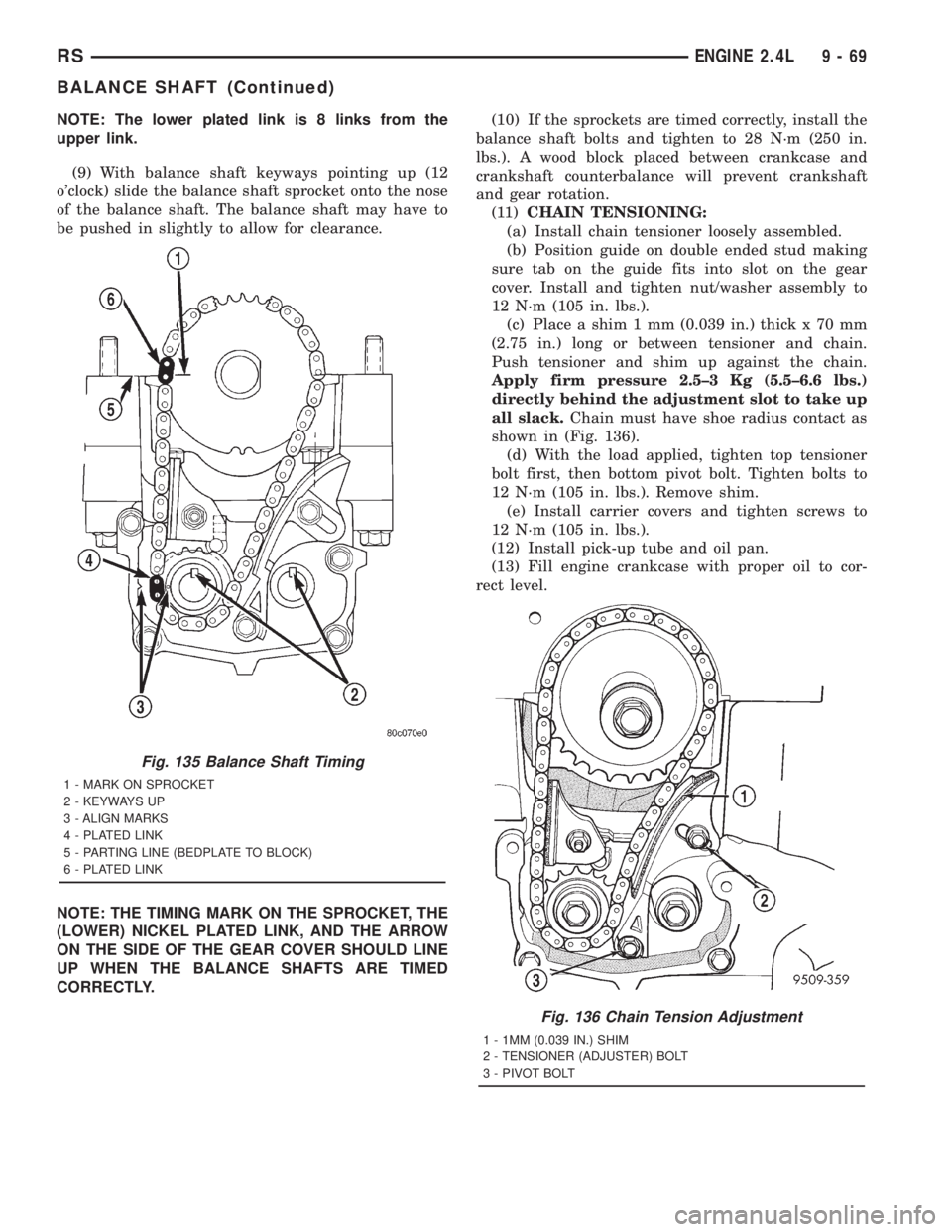

(6) Turn crankshaft until number 1 cylinder is at

top dead center (TDC). The timing marks on the

chain sprocket should line up with the parting line

on the left side of number one main bearing cap.

(Fig. 135).(7) Place chain over crankshaft sprocket so that

the plated link of the chain is over the number 1 cyl-

inder timing mark on the balance shaft crankshaft

sprocket (Fig. 135).

(8) Place balance shaft sprocket into the timing

chain (Fig. 135) and align the timing mark on the

sprocket (dot) with the (lower) plated link on the

chain.

Fig. 131 Balance Shaft - Removal/Installation

1 - REAR COVER

2 - CARRIER

3 - BALANCE SHAFT

Fig. 132 Gear Timing

1 - KEY WAYS UP

2 - GEAR ALIGNMENT DOTS

Fig. 133 Balance Shaft Sprocket Alignment to

Crankshaft

1 - ALIGN FLATS

Fig. 134 Balance Shaft Drive

1 - SPROCKET

2 - SPECIAL TOOL 6052

9 - 68 ENGINE 2.4LRS

BALANCE SHAFT (Continued)

Page 2693 of 4284

NOTE: The lower plated link is 8 links from the

upper link.

(9) With balance shaft keyways pointing up (12

o'clock) slide the balance shaft sprocket onto the nose

of the balance shaft. The balance shaft may have to

be pushed in slightly to allow for clearance.

NOTE: THE TIMING MARK ON THE SPROCKET, THE

(LOWER) NICKEL PLATED LINK, AND THE ARROW

ON THE SIDE OF THE GEAR COVER SHOULD LINE

UP WHEN THE BALANCE SHAFTS ARE TIMED

CORRECTLY.(10) If the sprockets are timed correctly, install the

balance shaft bolts and tighten to 28 N´m (250 in.

lbs.). A wood block placed between crankcase and

crankshaft counterbalance will prevent crankshaft

and gear rotation.

(11)CHAIN TENSIONING:

(a) Install chain tensioner loosely assembled.

(b) Position guide on double ended stud making

sure tab on the guide fits into slot on the gear

cover. Install and tighten nut/washer assembly to

12 N´m (105 in. lbs.).

(c) Place a shim 1 mm (0.039 in.) thick x 70 mm

(2.75 in.) long or between tensioner and chain.

Push tensioner and shim up against the chain.

Apply firm pressure 2.5±3 Kg (5.5±6.6 lbs.)

directly behind the adjustment slot to take up

all slack.Chain must have shoe radius contact as

shown in (Fig. 136).

(d) With the load applied, tighten top tensioner

bolt first, then bottom pivot bolt. Tighten bolts to

12 N´m (105 in. lbs.). Remove shim.

(e) Install carrier covers and tighten screws to

12 N´m (105 in. lbs.).

(12) Install pick-up tube and oil pan.

(13) Fill engine crankcase with proper oil to cor-

rect level.

Fig. 135 Balance Shaft Timing

1 - MARK ON SPROCKET

2 - KEYWAYS UP

3 - ALIGN MARKS

4 - PLATED LINK

5 - PARTING LINE (BEDPLATE TO BLOCK)

6 - PLATED LINK

Fig. 136 Chain Tension Adjustment

1 - 1MM (0.039 IN.) SHIM

2 - TENSIONER (ADJUSTER) BOLT

3 - PIVOT BOLT

RSENGINE 2.4L9-69

BALANCE SHAFT (Continued)

Page 2874 of 4284

The fuel filter is replaceable, it is mounted on the

outside and on top of the fuel tank. Refer to the

Maintenance Schedules in the Introduction section of

this manual for recommended fuel filter replacement

intervals.

FFV REPLACEMENT PARTS

Many components in a Flexible Fuel Vehicle (FFV)

are designed to be compatible with ethanol. Always

be sure that the vehicle is serviced with correct etha-

nol compatible parts.

CAUTION: Replacing fuel system components with

non-ethanol compatible components can damage

your vehicle and may void the warranty.

OPERATION

The fuel system is provided fuel pressure by an in-

tank pump module. The PCM controls the operation

of the fuel system by providing battery voltage to the

fuel pump through the fuel pump relay. The PCM

requires only three inputs and a good ground to oper-

ate the fuel pump relay. The three inputs are:

²Ignition voltage

²Crankshaft Position (CKP) sensor

²Camshaft Position (CMP) sensor

DIAGNOSIS AND TESTING - FUEL DELIVERY

SYSTEM

(Refer to Appropriate Diagnositic Information)

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE PROCEDURE

(1) Remove Fuel Pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.(2) Start and run engine until it stalls.

(3) Attempt restarting engine until it will no

longer run.

(4) Turn ignition key to OFF position.

(5) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(6) Return fuel pump relay to PDC.

(7) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRB IIItscan tool must be

used to erase a DTC.

STANDARD PROCEDURE - DRAINING FUEL

TANK

(1) Release fuel system pressure, refer to the Fuel

System Release Procedure in this section.

(2) Insert a 1/4 inch siphon (max. O. D. 5/16) hose

from a portable fuel siphoning tank through the fuel

filler neck opening into the fuel tank. Hose most

have a 30 degree angle cut on the end to bypass the

check valve in the end of the filler neck. Refer to the

siphoning tank's Manufacturing Instructions.

(3) Drain fuel from fuel tank into siphoning tank.

SPECIFICATIONS

FUEL SYSTEM PRESSURE

400 kpa634 kpa (58 psi65 psi)

TORQUE

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Fuel Rail 2.4L 22 200

Fuel Rail 3.3/3.8L 11.8 105

Fuel Tank Strap 54 40

Fuel Tank T Strap 28.2 250

Fuel Filter Bolt 4.5 40

14 - 2 FUEL DELIVERYRS

FUEL DELIVERY (Continued)

Page 2889 of 4284

the PCM must calculate a different injector pulse

width and ignition timing for idle than it does for

Wide Open Throttle (WOT). There are several differ-

ent modes of operation that determine how the PCM

responds to the various input signals.

There are two different areas of operation, OPEN

LOOP and CLOSED LOOP.

During OPEN LOOP modes the PCM receives

input signals and responds according to preset PCM

programming. Inputs from the upstream and down-

stream heated oxygen sensors are not monitored dur-

ing OPEN LOOP modes, except for heated oxygen

sensor diagnostics (they are checked for shorted con-

ditions at all times).

During CLOSED LOOP modes the PCM monitors

the inputs from the upstream and downstream

heated oxygen sensors. The upstream heated oxygen

sensor input tells the PCM if the calculated injector

pulse width resulted in the ideal air-fuel ratio of 14.7

to one. By monitoring the exhaust oxygen content

through the upstream heated oxygen sensor, the

PCM can fine tune injector pulse width. Fine tuning

injector pulse width allows the PCM to achieve opti-

mum fuel economy combined with low emissions.

For the PCM to enter CLOSED LOOP operation,

the following must occur:

(1) Engine coolant temperature must be over 35ÉF.

²If the coolant is over 35É the PCM will wait 44

seconds.

²If the coolant is over 50ÉF the PCM will wait 38

seconds.

²If the coolant is over 167ÉF the PCM will wait

11 seconds.

(2) For other temperatures the PCM will interpo-

late the correct waiting time.

(3) O2 sensor must read either greater than 0.745

volts or less than 0.1 volt.

(4) The multi-port fuel injection systems has the

following modes of operation:

²Ignition switch ON (Zero RPM)

²Engine start-up

²Engine warm-up

²Cruise

²Idle

²Acceleration

²Deceleration

²Wide Open Throttle

²Ignition switch OFF

(5) The engine start-up (crank), engine warm-up,

deceleration with fuel shutoff and wide open throttle

modes are OPEN LOOP modes. Under most operat-

ing conditions, the acceleration, deceleration (with

A/C on), idle and cruise modes,with the engine at

operating temperatureare CLOSED LOOP modes.IGNITION SWITCH ON (ZERO RPM) MODE

When the ignition switch activates the fuel injec-

tion system, the following actions occur:

²The PCM monitors the engine coolant tempera-

ture sensor and throttle position sensor input. The

PCM determines basic fuel injector pulse width from

this input.

²The PCM determines atmospheric air pressure

from the MAP sensor input to modify injector pulse

width.

When the key is in the ON position and the engine

is not running (zero rpm), the Auto Shutdown (ASD)

and fuel pump relays de-energize after approximately

1 second. Therefore, battery voltage is not supplied to

the fuel pump, ignition coil, fuel injectors and heated

oxygen sensors.

ENGINE START-UP MODE

This is an OPEN LOOP mode. If the vehicle is in

park or neutral (automatic transaxles) or the clutch

pedal is depressed (manual transaxles) the ignition

switch energizes the starter relay. The following

actions occur when the starter motor is engaged.

²If the PCM receives the camshaft position sensor

and crankshaft position sensor signals, it energizes

the Auto Shutdown (ASD) relay and fuel pump relay.

If the PCM does not receive both signals within

approximately one second, it will not energize the

ASD relay and fuel pump relay. The ASD and fuel

pump relays supply battery voltage to the fuel pump,

fuel injectors, ignition coil and heated oxygen sen-

sors.

²The PCM energizes the injectors (on the 69É

degree falling edge) for a calculated pulse width until

it determines crankshaft position from the camshaft

position sensor and crankshaft position sensor sig-

nals. The PCM determines crankshaft position within

1 engine revolution.

²After determining crankshaft position, the PCM

begins energizing the injectors in sequence. It adjusts

injector pulse width and controls injector synchroni-

zation by turning the individual ground paths to the

injectors On and Off.

²When the engine idles within664 RPM of its

target RPM, the PCM compares current MAP sensor

value with the atmospheric pressure value received

during the Ignition Switch On (zero RPM) mode.

Once the ASD and fuel pump relays have been

energized, the PCM determines injector pulse width

based on the following:

²Battery voltage

²Engine coolant temperature

²Engine RPM

²Inlet/Intake air temperature (IAT)

²MAP

²Throttle position

RSFUEL INJECTION14-17

FUEL INJECTION (Continued)

Page 2901 of 4284

PCM to vary the battery charging rate. System volt-

age will be higher at colder temperatures and is

gradually reduced at warmer temperatures.

The battery temperature information is also used

for OBD II diagnostics. Certain faults and OBD II

monitors are either enabled or disabled depending

upon the battery temperature sensor input (example:

disable purge, enable LDP). Most OBD II monitors

are disabled below 20ÉF.

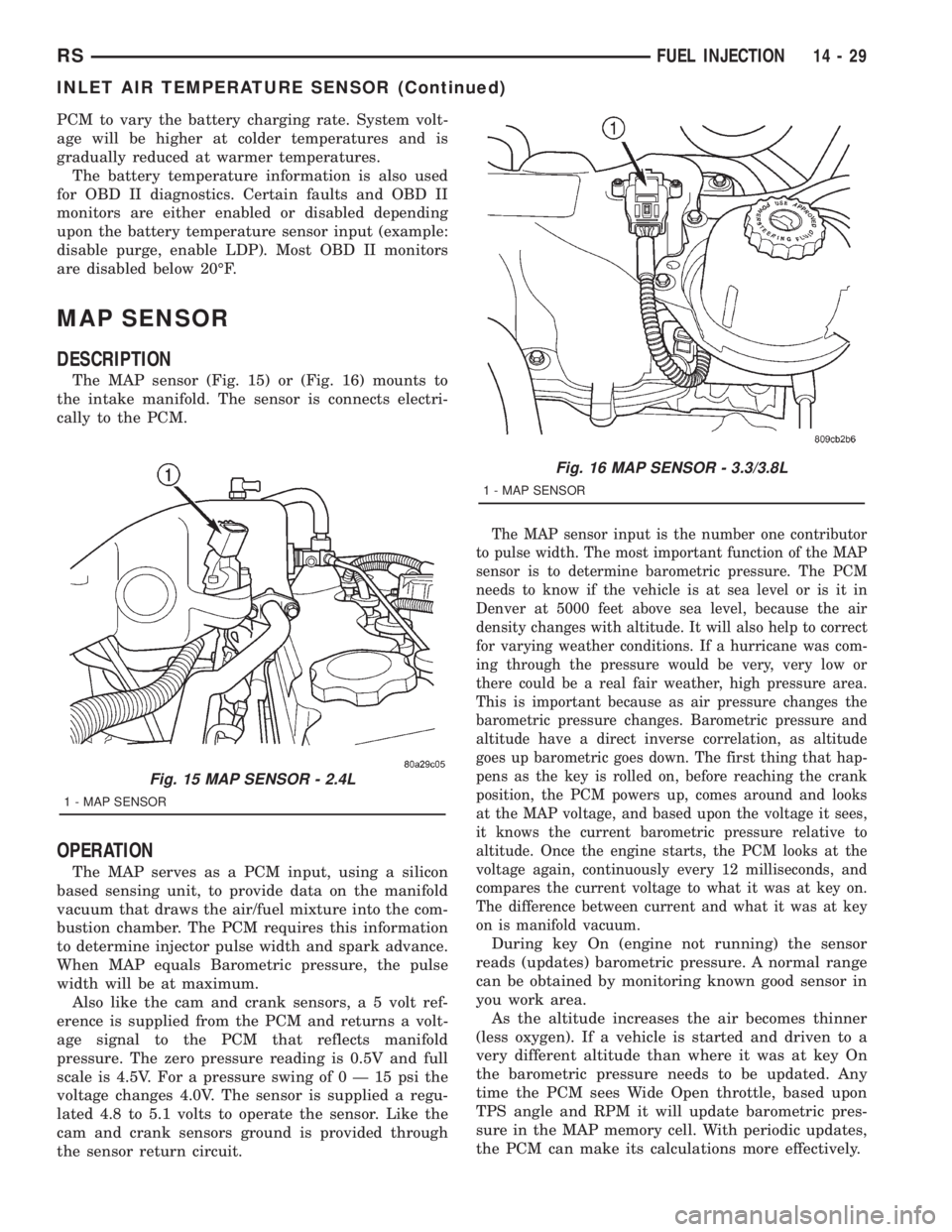

MAP SENSOR

DESCRIPTION

The MAP sensor (Fig. 15) or (Fig. 16) mounts to

the intake manifold. The sensor is connects electri-

cally to the PCM.

OPERATION

The MAP serves as a PCM input, using a silicon

based sensing unit, to provide data on the manifold

vacuum that draws the air/fuel mixture into the com-

bustion chamber. The PCM requires this information

to determine injector pulse width and spark advance.

When MAP equals Barometric pressure, the pulse

width will be at maximum.

Also like the cam and crank sensors, a 5 volt ref-

erence is supplied from the PCM and returns a volt-

age signal to the PCM that reflects manifold

pressure. The zero pressure reading is 0.5V and full

scale is 4.5V. For a pressure swing of0Ð15psithe

voltage changes 4.0V. The sensor is supplied a regu-

lated 4.8 to 5.1 volts to operate the sensor. Like the

cam and crank sensors ground is provided through

the sensor return circuit.

The MAP sensor input is the number one contributor

to pulse width. The most important function of the MAP

sensor is to determine barometric pressure. The PCM

needs to know if the vehicle is at sea level or is it in

Denver at 5000 feet above sea level, because the air

density changes with altitude. It will also help to correct

for varying weather conditions. If a hurricane was com-

ing through the pressure would be very, very low or

there could be a real fair weather, high pressure area.

This is important because as air pressure changes the

barometric pressure changes. Barometric pressure and

altitude have a direct inverse correlation, as altitude

goes up barometric goes down. The first thing that hap-

pens as the key is rolled on, before reaching the crank

position, the PCM powers up, comes around and looks

at the MAP voltage, and based upon the voltage it sees,

it knows the current barometric pressure relative to

altitude. Once the engine starts, the PCM looks at the

voltage again, continuously every 12 milliseconds, and

compares the current voltage to what it was at key on.

The difference between current and what it was at key

on is manifold vacuum.

During key On (engine not running) the sensor

reads (updates) barometric pressure. A normal range

can be obtained by monitoring known good sensor in

you work area.

As the altitude increases the air becomes thinner

(less oxygen). If a vehicle is started and driven to a

very different altitude than where it was at key On

the barometric pressure needs to be updated. Any

time the PCM sees Wide Open throttle, based upon

TPS angle and RPM it will update barometric pres-

sure in the MAP memory cell. With periodic updates,

the PCM can make its calculations more effectively.

Fig. 15 MAP SENSOR - 2.4L

1 - MAP SENSOR

Fig. 16 MAP SENSOR - 3.3/3.8L

1 - MAP SENSOR

RSFUEL INJECTION14-29

INLET AIR TEMPERATURE SENSOR (Continued)

Page 2917 of 4284

(12) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(14) Install air cleaner housing assembly.

(15) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(16) Connect negative battery cable.

WATER IN FUEL SENSOR

DESCRIPTION

The WIF sensor is located in the bowl assembly of

the fuel filter/water separator.

OPERATION

The sensor sends an input to the Engine Control

Module (ECM) when it senses water in the fuel filter/

water separator. As the water level in the filter/sep-

arator increases, the resistance across the WIF

sensor decreases. This decrease in resistance is sent

as a signal to the ECM and compared to a high

water standard value. Once the value reaches 30 to

40 kilohms, the ECM will activate the water-in-fuel

warning lamp through CCD bus circuits. This all

takes place when the ignition key is initially put in

the ON position. The ECM continues to monitor the

input at the end of the intake manifold air heater

post-heat cycle.

RGFUEL DELIVERY14a-9

FUEL INJECTION PUMP (Continued)