automatic transmission fluid CHRYSLER VOYAGER 2001 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1602 of 4284

REAR DRIVELINE MODULE

TABLE OF CONTENTS

page page

REAR DRIVELINE MODULE

DESCRIPTION...........................26

OPERATION.............................26

DIAGNOSIS AND TESTING.................27

REAR DRIVELINE MODULE NOISE.........27

REAR DRIVELINE MODULE OPERATION....29

REMOVAL..............................29

DISASSEMBLY...........................30

ASSEMBLY.............................32

INSTALLATION...........................36

SPECIFICATIONS........................37

SPECIAL TOOLS.........................37

BI-DIRECTIONAL OVERRUNNING CLUTCH

DESCRIPTION...........................37

OPERATION.............................38

DIFFERENTIAL ASSEMBLY

DESCRIPTION...........................43

OPERATION.............................43FLUID - DIFFERENTIAL ASSEMBLY

STANDARD PROCEDURE..................44

DIFFERENTIAL ASSEMBLY FLUID CHANGE . . 44

FLUID

STANDARD PROCEDURE..................44

OVERRUNNING CLUTCH HOUSING FLUID

CHANGE..............................44

VISCOUS COUPLER

DESCRIPTION...........................45

OPERATION.............................45

TORQUE ARM

REMOVAL..............................47

INSTALLATION...........................47

INPUT FLANGE SEAL

REMOVAL..............................47

INSTALLATION...........................47

OUTPUT FLANGE SEAL

REMOVAL..............................49

INSTALLATION...........................50

REAR DRIVELINE MODULE

DESCRIPTION

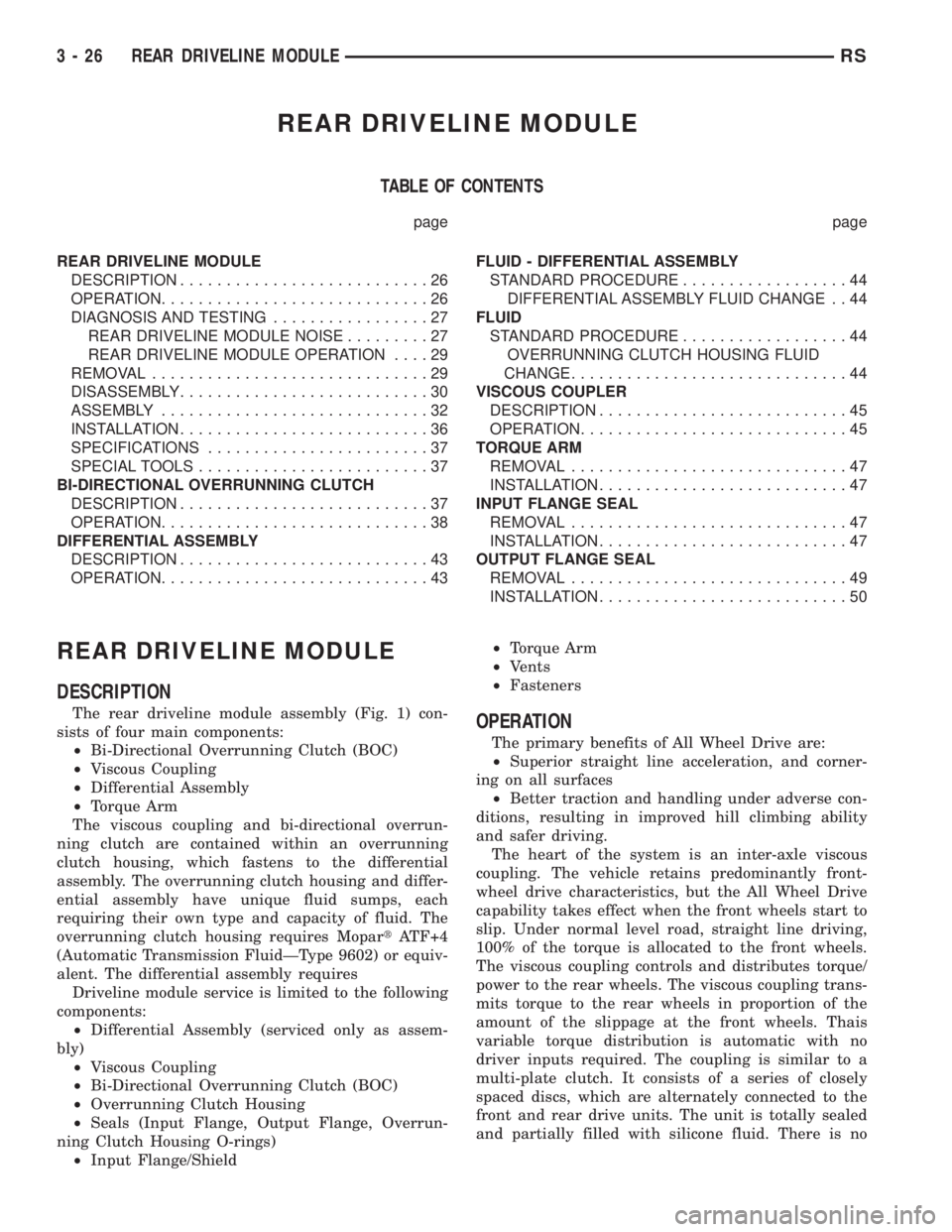

The rear driveline module assembly (Fig. 1) con-

sists of four main components:

²Bi-Directional Overrunning Clutch (BOC)

²Viscous Coupling

²Differential Assembly

²Torque Arm

The viscous coupling and bi-directional overrun-

ning clutch are contained within an overrunning

clutch housing, which fastens to the differential

assembly. The overrunning clutch housing and differ-

ential assembly have unique fluid sumps, each

requiring their own type and capacity of fluid. The

overrunning clutch housing requires MopartATF+4

(Automatic Transmission FluidÐType 9602) or equiv-

alent. The differential assembly requires

Driveline module service is limited to the following

components:

²Differential Assembly (serviced only as assem-

bly)

²Viscous Coupling

²Bi-Directional Overrunning Clutch (BOC)

²Overrunning Clutch Housing

²Seals (Input Flange, Output Flange, Overrun-

ning Clutch Housing O-rings)

²Input Flange/Shield²Torque Arm

²Vents

²FastenersOPERATION

The primary benefits of All Wheel Drive are:

²Superior straight line acceleration, and corner-

ing on all surfaces

²Better traction and handling under adverse con-

ditions, resulting in improved hill climbing ability

and safer driving.

The heart of the system is an inter-axle viscous

coupling. The vehicle retains predominantly front-

wheel drive characteristics, but the All Wheel Drive

capability takes effect when the front wheels start to

slip. Under normal level road, straight line driving,

100% of the torque is allocated to the front wheels.

The viscous coupling controls and distributes torque/

power to the rear wheels. The viscous coupling trans-

mits torque to the rear wheels in proportion of the

amount of the slippage at the front wheels. Thais

variable torque distribution is automatic with no

driver inputs required. The coupling is similar to a

multi-plate clutch. It consists of a series of closely

spaced discs, which are alternately connected to the

front and rear drive units. The unit is totally sealed

and partially filled with silicone fluid. There is no

3 - 26 REAR DRIVELINE MODULERS

Page 1603 of 4284

adjustment, maintenance or fluid checks required

during the life of the unit.

The overrunning clutch allows the rear wheels to

overrun the front wheels during a rapid front wheel

lock braking maneuver. The overrunning action pre-

vents any feed-back of front wheel braking torque to

the rear wheels. It also allows the braking system to

control the braking behavior as a two wheel drive

(2WD) vehicle.

The overrunning clutch housing has a separate oil

sump and is filled independently from the differen-

tial. The fill plug is located on the side of the over-

running clutch case. When filling the overrunning

clutch with lubricant use MopartATF+4 (Automatic

Transmission FluidÐType 9602) or equivalent.

The differential assembly contains a conventional

open differential with hypoid ring gear and pinion

gear set. The hypoid gears are lubricated by SAE

80W-90 gear lubricant.DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE NOISE

Different sources can be the cause of noise that the

rear driveline module assembly is suspected of mak-

ing. Refer to the following causes for noise diagnosis.

DRIVELINE MODULE ASSEMBLY NOISE

The most important part of driveline module ser-

vice is properly identifying the cause of failures and

noise complaints. The cause of most driveline module

failures is relatively easy to identify. The cause of

driveline module noise is more difficult to identify.

If vehicle noise becomes intolerable, an effort

should be made to isolate the noise. Many noises that

are reported as coming from the driveline module

may actually originate at other sources. For example:

Fig. 1 AWD Driveline Module Assembly

1 - TORQUE ARM

2 - INPUT FLANGE

3 - FLANGE NUT

4 - WASHER

5 - SHIELD

6 - VENT

7 - O-RING

8 - WASHER

9 - BI-DIRECTIONAL OVERRUNNING CLUTCH (BOC)

10 - VISCOUS COUPLER11 - SHIM (SELECT)

12 - O-RING

13 - DIFFERENTIAL ASSEMBLY

14 - PLUG-DIFFERENTIAL FILL

15 - PLUG-OVERRUNNING CLUTCH HOUSING DRAIN

16 - SNAP RING

17 - BEARING

18 - OVERRUNING CLUTCH HOUSING

19 - SEAL-INPUT FLANGE

RSREAR DRIVELINE MODULE3-27

REAR DRIVELINE MODULE (Continued)

Page 1621 of 4284

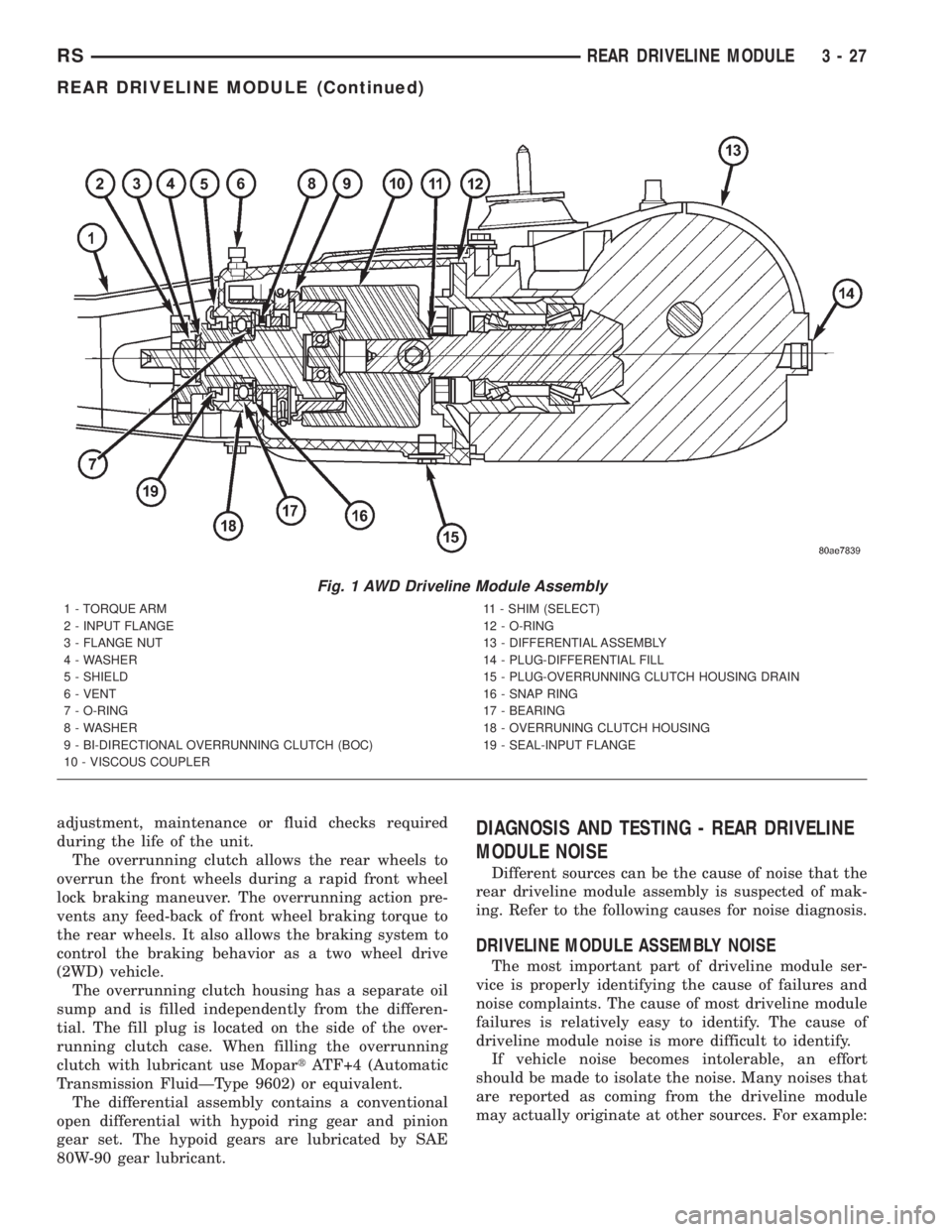

(3) Remove overrunning clutch housing drain plug

and drain fluid (Fig. 43).

(4) Install the drain plug and torque to 30 N´m (22

ft. lbs.).

(5) Re-position the drain pan under the overrun-

ning clutch housing fill plug.

(6) Remove fill plug (Fig. 44).

(7) Using a suction gun (Fig. 45), add 0.58 L (1.22

pts.) of MopartATF+4 (Automatic Transmission Flu-

idÐType 9602).

(8)

Install fill plug and torque to 30 N´m (22 ft. lbs.).

VISCOUS COUPLER

DESCRIPTION

The heart of the all-wheel drive system is the inter-

axle viscous coupling and bi-directional overrunning

clutch. Under normal driving the vehicle retains pre-

dominantly front wheel drive characteristics. The all-

wheel drive takes effect when the front wheels start to

slip. Under normal level road, straight line driving,

100% of the torque is allocated to the front wheels.

The viscous coupler allows more torque to the rear

wheels in accordance with the amount of slippage at

the front wheels. The variable torque distribution is

automatic with no driver inputs required.

OPERATION

The viscous coupler (Fig. 46) is a housing nearly

filled with a high viscosity silicone liquid and thin

metal plates alternately splined to an inner and

outer drum. The viscous coupler provides torque in

the following modes:

²Shear mode (normal operation)

²Hump mode (locked mode)

The inner plates are slotted around the radius and

the outer plates have holes in them. In the shear

mode (normal operation), the plates are evenly

spaced and the torque is created by the shearing of

the plates through the fluid and 90-100% of the

torque is applied to the rear axle. During the shear

mode, a fluid flow pattern is created from this design

(holes and slots). This fluid flow causes high pressure

on each side of each pair of plates and low pressure

between each pair of plates.

Fig. 43 Overrunning Clutch Case Drain Plug

1 - OVERRUNNING CLUTCH HOUSING DRAIN PLUG

Fig. 44 Overrunning Clutch Housing Fill Plug

1 - OVERRUNNING CLUTCH HOUSING FILL PLUG

2 - FUEL TANK

Fig. 45 Filling Overrunning Clutch Case

1 - OVERRUNNING CLUTCH HOUSING FILL HOLE

2 - SUCTION GUN

RSREAR DRIVELINE MODULE3-45

FLUID (Continued)

Page 1771 of 4284

- 31TH/OIL PUMP - STANDARD PROCEDURE)

(Refer to 21 - TRANSMISSION/TRANSAXLE/AU-

TOMATIC - 41TE/OIL PUMP - STANDARD PRO-

CEDURE)

(b) If oil pump volume is within specification, a

possible restriction in the cooler lines or cooler has

occurred.

(c) If oil pump volume is not within specification,

possible internal transmission restrictions, compo-

nent wear or damage has occurred. (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH - DIAGNOSIS AND TESTING) (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC -

41TE - DIAGNOSIS AND TESTING)

(d) If an oil cooler restriction is suspected, per-

form further inspections and flow meter testing by

isolating components (i.e. lines, coolers).

(e) After a restriction is isolated, perform cooler

flush procedure. (Refer to 7 - COOLING/TRANS-

MISSION - STANDARD PROCEDURE)

(f) Re-test cooler flow. If cooler flow does not

exceed minimum specification, replace compo-

nent(s) as necessary.

STANDARD PROCEDURE - FLUSHING

COOLERS AND TUBES

The recommended procedure for cooler flushing is

to use Tool 6906 Cooler Flusher.

WARNING:

WEAR PROTECTIVE EYEWEAR THAT MEETS THE

REQUIREMENTS OF OSHA AND ANSI Z87.1±1968.

WEAR STANDARD INDUSTRIAL RUBBER GLOVES.

KEEP LIGHTED CIGARETTES, SPARKS, FLAMES,

AND OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

(1) Remove cover plate filler plug on Tool 6906.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Use MopartTransmission Cooler Flush (MS-552) or

equivalent solution conforming to MS-552. Flushing

solvents are petroleum based solutions generally

used to clean automatic transmission components.

DO NOTuse solvents containing acids, water, gaso-

line, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

(4) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(5) Connect the CLEAR return line to the INLET

(To) cooler line

(6) Turn pump ON for two to three minutes to

flush cooler and lines.

(7) Turn pump OFF.

(8) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(9) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(10) Place CLEAR suction line into a one quart

container of MopartATF+4 (Automatic Transmission

FluidÐType 9602).

(11) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(12) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

RSTRANSMISSION7-37

TRANSMISSION (Continued)

Page 2099 of 4284

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch Relay........... 8Wa-42

A/C Compressor Clutch................ 8Wa-42

A/C-Heater Control................... 8Wa-42

A/C Pressure Sensor.................. 8Wa-42

Accelerator Pedal Position Sensor........ 8Wa-30

Accessory Relay...................... 8Wa-10

Airbags............................. 8Wa-43

Ambient Temp Sensor................. 8Wa-49

Antenna............................ 8Wa-47

ATC Remote Sensor................... 8Wa-42

Auto Shut Down Relay................. 8Wa-30

Auto Temp Control.................... 8Wa-42

Automatic Day/Night Mirror............ 8Wa-49

Autostick Switch..................... 8Wa-31

Back-Up Lamp Switch................. 8Wa-51

Battery Temperature Sensor............ 8Wa-20

Battery............................. 8Wa-20

Blend Door Actuators.................. 8Wa-42

Blower Motor Resistor................. 8Wa-42

Body Control Module.................. 8Wa-45

Boost Pressure Sensor................. 8Wa-30

B-Pillar Switches..................... 8Wa-61

Brake Fluid Level Switch............... 8Wa-40

Brake Lamp Switch................... 8Wa-51

Brake Transmission Shift Interlock

Solenoid.......................... 8Wa-31

Cabin Heater Assist................... 8Wa-30

Camshaft Position Sensor.............. 8Wa-30

CD Changer......................... 8Wa-47

Center High Mounted Stop Lamp........ 8Wa-51

Cinch/Release Motors.................. 8Wa-61

Clockspring................. 8Wa-33, 41, 43, 47

Clutch Pedal Interlock Switch Jumper..... 8Wa-10

Clutch Pedal Interlock Switch........... 8Wa-10

Clutch Pedal Upstop Switch............. 8Wa-30

Combination Relays................... 8Wa-54

Controller Antilock Brake.............. 8Wa-35

Crank Case Ventilation Heater.......... 8Wa-30

Crankshaft Position Sensor............. 8Wa-30

Cylinder Lock Switches................ 8Wa-39

Data Link Connector.................. 8Wa-18

Defogger Relay....................... 8Wa-48

Diagnostic Junction Port............... 8Wa-18

Dome Lamps........................ 8Wa-44

Door Ajar Switches.................... 8Wa-39

Door Courtesy Lamps.................. 8Wa-44

Door Lock Motor/Ajar Switches.......... 8Wa-61

Door Lock Switches................... 8Wa-61

Dosing Pump........................ 8Wa-30

Driver Heated Seat Module............. 8Wa-63

ECM/PCM Relay..................... 8Wa-30

EGR Solenoid........................ 8Wa-30Component Page

Electric Wiper De-Icer................. 8Wa-48

Engine Control Module................ 8Wa-30

Engine Coolant Temp Sensor............ 8Wa-30

Engine Oil Pressure Sensor............. 8Wa-30

Engine Oil Pressure Switch............. 8Wa-30

Engine Oil Temperature Sensor.......... 8Wa-30

EVAP/Purge Solenoid.................. 8Wa-30

Evaporator Temperature Sensor......... 8Wa-42

Floor Console Lamp................... 8Wa-44

Floor Console Power Outlet............. 8Wa-41

Fog Lamps.......................... 8Wa-50

Front Blower Module.................. 8Wa-42

Front Blower Motor Relay.............. 8Wa-42

Front Blower Motor................... 8Wa-42

Front Cigar Lighter................... 8Wa-41

Front Control Module.................. 8Wa-10

Front Fog Lamp Relay................. 8Wa-50

Front Intrusion Sensor................. 8Wa-39

Front Reading Lamps/Switch............ 8Wa-44

Front Washer Pump Motor.............. 8Wa-53

Front Wiper Hi/Low Relay.............. 8Wa-53

Front Wiper On/Off Relay.............. 8Wa-53

Fuel Heater Relay.................... 8Wa-10

Fuel Heater......................... 8Wa-30

Fuel Injectors........................ 8Wa-30

Fuel Pressure Sensor.................. 8Wa-30

Fuel Pressure Solenoid................. 8Wa-30

Fuel Pump Module.................... 8Wa-30

Fuel Pump Relay..................... 8Wa-30

Full Open Switches................... 8Wa-61

Fuselink............................ 8Wa-10

Fuses (IPM)......................... 8Wa-10

Generator........................... 8Wa-20

Glove Box Lamp...................... 8Wa-44

Glow Plug Relay...................... 8Wa-30

Glow Plugs.......................... 8Wa-30

Grounds............................ 8Wa-15

Halo Lamp.......................... 8Wa-44

Headlamp Leveling Motors............. 8Wa-50

Headlamp Switch..................... 8Wa-50

Headlamp Washer Pump Motor.......... 8Wa-53

Headlamp Washer Relay............... 8Wa-53

Headlamps.......................... 8Wa-50

Heated Seat Backs.................... 8Wa-63

Heated Seat Cushions................. 8Wa-63

High Beam Lamps.................... 8Wa-50

Hood Ajar Switch..................... 8Wa-39

Horn Relay.......................... 8Wa-41

Horn Switch......................... 8Wa-41

Horns.............................. 8Wa-41

Idle Air Control Motor................. 8Wa-30

Ignition Coil......................... 8Wa-30

RG8W-02 COMPONENT INDEX8Wa-02-1

Page 2165 of 4284

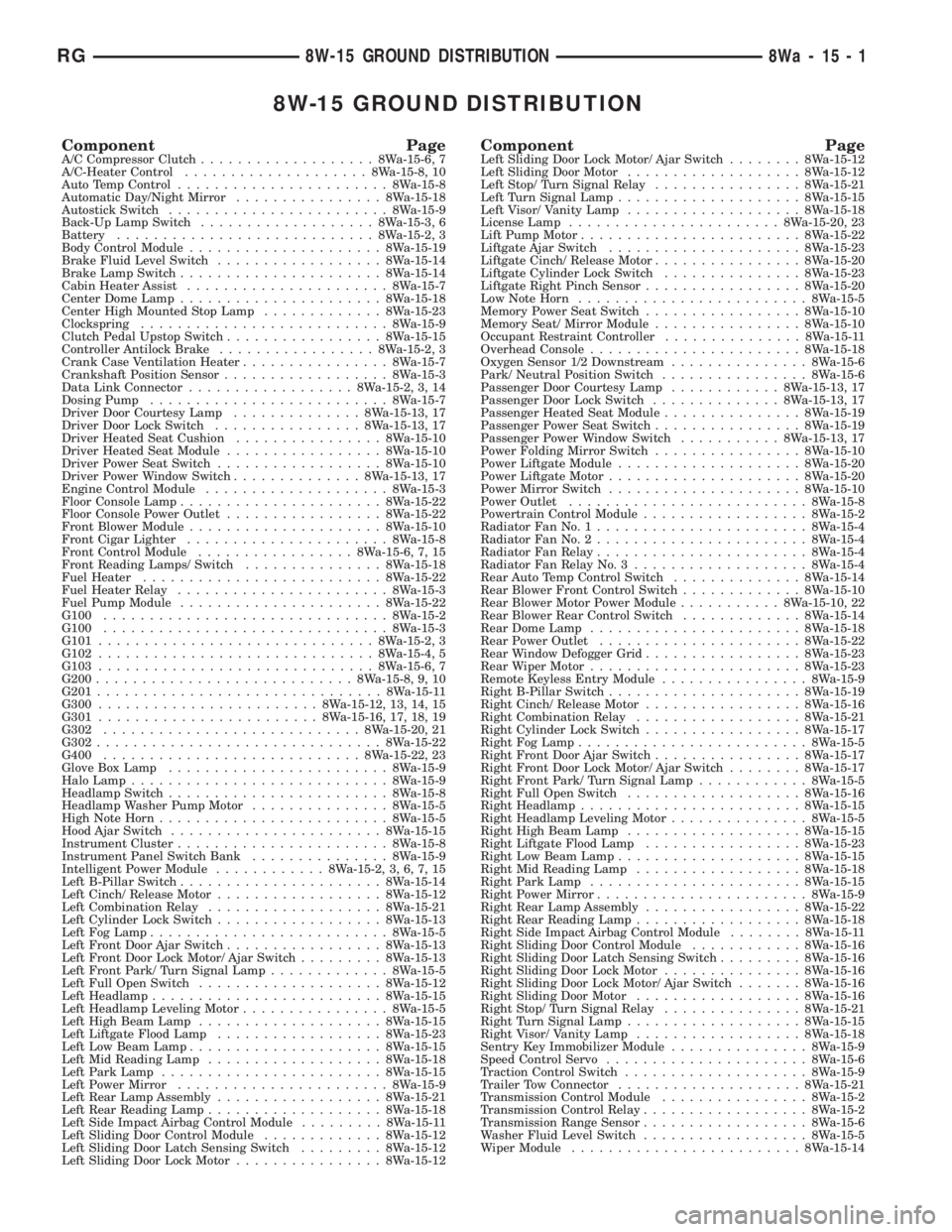

8W-15 GROUND DISTRIBUTION

Component PageA/C Compressor Clutch...................8Wa-15-6, 7

A/C-Heater Control....................8Wa-15-8, 10

Auto Temp Control.......................8Wa-15-8

Automatic Day/Night Mirror................8Wa-15-18

Autostick Switch........................8Wa-15-9

Back-Up Lamp Switch...................8Wa-15-3, 6

Battery............................8Wa-15-2, 3

Body Control Module.....................8Wa-15-19

Brake Fluid Level Switch..................8Wa-15-14

Brake Lamp Switch......................8Wa-15-14

Cabin Heater Assist......................8Wa-15-7

Center Dome Lamp......................8Wa-15-18

Center High Mounted Stop Lamp.............8Wa-15-23

Clockspring...........................8Wa-15-9

Clutch Pedal Upstop Switch.................8Wa-15-15

Controller Antilock Brake.................8Wa-15-2, 3

Crank Case Ventilation Heater................8Wa-15-7

Crankshaft Position Sensor..................8Wa-15-3

Data Link Connector..................8Wa-15-2, 3, 14

Dosing Pump..........................8Wa-15-7

Driver Door Courtesy Lamp..............8Wa-15-13, 17

Driver Door Lock Switch................8Wa-15-13, 17

Driver Heated Seat Cushion................8Wa-15-10

Driver Heated Seat Module.................8Wa-15-10

Driver Power Seat Switch..................8Wa-15-10

Driver Power Window Switch..............8Wa-15-13, 17

Engine Control Module....................8Wa-15-3

Floor Console Lamp......................8Wa-15-22

Floor Console Power Outlet.................8Wa-15-22

Front Blower Module.....................8Wa-15-10

Front Cigar Lighter......................8Wa-15-8

Front Control Module.................8Wa-15-6, 7, 15

Front Reading Lamps/ Switch...............8Wa-15-18

Fuel Heater..........................8Wa-15-22

Fuel Heater Relay.......................8Wa-15-3

Fuel Pump Module......................8Wa-15-22

G100...............................8Wa-15-2

G100...............................8Wa-15-3

G101..............................8Wa-15-2, 3

G102..............................8Wa-15-4, 5

G103..............................8Wa-15-6, 7

G200............................8Wa-15-8, 9, 10

G201...............................8Wa-15-11

G300........................8Wa-15-12, 13, 14, 15

G301........................8Wa-15-16, 17, 18, 19

G302............................8Wa-15-20, 21

G302...............................8Wa-15-22

G400............................8Wa-15-22, 23

Glove Box Lamp........................8Wa-15-9

Halo Lamp............................8Wa-15-9

Headlamp Switch........................8Wa-15-8

Headlamp Washer Pump Motor...............8Wa-15-5

High Note Horn.........................8Wa-15-5

Hood Ajar Switch.......................8Wa-15-15

Instrument Cluster.......................8Wa-15-8

Instrument Panel Switch Bank...............8Wa-15-9

Intelligent Power Module............8Wa-15-2, 3, 6, 7, 15

Left B-Pillar Switch......................8Wa-15-14

Left Cinch/ Release Motor..................8Wa-15-12

Left Combination Relay...................8Wa-15-21

Left Cylinder Lock Switch..................8Wa-15-13

Left Fog Lamp..........................8Wa-15-5

Left Front Door Ajar Switch.................8Wa-15-13

Left Front Door Lock Motor/ Ajar Switch.........8Wa-15-13

Left Front Park/ Turn Signal Lamp.............8Wa-15-5

Left Full Open Switch....................8Wa-15-12

Left Headlamp.........................8Wa-15-15

Left Headlamp Leveling Motor................8Wa-15-5

Left High Beam Lamp....................8Wa-15-15

Left Liftgate Flood Lamp..................8Wa-15-23

Left Low Beam Lamp.....................8Wa-15-15

Left Mid Reading Lamp...................8Wa-15-18

Left Park Lamp........................8Wa-15-15

Left Power Mirror.......................8Wa-15-9

Left Rear Lamp Assembly..................8Wa-15-21

Left Rear Reading Lamp...................8Wa-15-18

Left Side Impact Airbag Control Module.........8Wa-15-11

Left Sliding Door Control Module.............8Wa-15-12

Left Sliding Door Latch Sensing Switch.........8Wa-15-12

Left Sliding Door Lock Motor................8Wa-15-12Component PageLeft Sliding Door Lock Motor/ Ajar Switch........8Wa-15-12

Left Sliding Door Motor...................8Wa-15-12

Left Stop/ Turn Signal Relay................8Wa-15-21

Left Turn Signal Lamp....................8Wa-15-15

Left Visor/ Vanity Lamp...................8Wa-15-18

License Lamp.......................8Wa-15-20, 23

Lift Pump Motor........................8Wa-15-22

Liftgate Ajar Switch.....................8Wa-15-23

Liftgate Cinch/ Release Motor................8Wa-15-20

Liftgate Cylinder Lock Switch...............8Wa-15-23

Liftgate Right Pinch Sensor.................8Wa-15-20

Low Note Horn.........................8Wa-15-5

Memory Power Seat Switch.................8Wa-15-10

Memory Seat/ Mirror Module................8Wa-15-10

Occupant Restraint Controller...............8Wa-15-11

Overhead Console.......................8Wa-15-18

Oxygen Sensor 1/2 Downstream...............8Wa-15-6

Park/ Neutral Position Switch................8Wa-15-6

Passenger Door Courtesy Lamp............8Wa-15-13, 17

Passenger Door Lock Switch..............8Wa-15-13, 17

Passenger Heated Seat Module...............8Wa-15-19

Passenger Power Seat Switch................8Wa-15-19

Passenger Power Window Switch...........8Wa-15-13, 17

Power Folding Mirror Switch................8Wa-15-10

Power Liftgate Module....................8Wa-15-20

Power Liftgate Motor.....................8Wa-15-20

Power Mirror Switch.....................8Wa-15-10

Power Outlet..........................8Wa-15-8

Powertrain Control Module..................8Wa-15-2

Radiator Fan No. 1.......................8Wa-15-4

Radiator Fan No. 2.......................8Wa-15-4

Radiator Fan Relay.......................8Wa-15-4

Radiator Fan Relay No. 3...................8Wa-15-4

Rear Auto Temp Control Switch..............8Wa-15-14

Rear Blower Front Control Switch.............8Wa-15-10

Rear Blower Motor Power Module...........8Wa-15-10, 22

Rear Blower Rear Control Switch.............8Wa-15-14

Rear Dome Lamp.......................8Wa-15-18

Rear Power Outlet......................8Wa-15-22

Rear Window Defogger Grid.................8Wa-15-23

Rear Wiper Motor.......................8Wa-15-23

Remote Keyless Entry Module................8Wa-15-9

Right B-Pillar Switch.....................8Wa-15-19

Right Cinch/ Release Motor.................8Wa-15-16

Right Combination Relay..................8Wa-15-21

Right Cylinder Lock Switch.................8Wa-15-17

Right Fog Lamp.........................8Wa-15-5

Right Front Door Ajar Switch................8Wa-15-17

Right Front Door Lock Motor/ Ajar Switch........8Wa-15-17

Right Front Park/ Turn Signal Lamp............8Wa-15-5

Right Full Open Switch...................8Wa-15-16

Right Headlamp........................8Wa-15-15

Right Headlamp Leveling Motor...............8Wa-15-5

Right High Beam Lamp...................8Wa-15-15

Right Liftgate Flood Lamp.................8Wa-15-23

Right Low Beam Lamp....................8Wa-15-15

Right Mid Reading Lamp..................8Wa-15-18

Right Park Lamp.......................8Wa-15-15

Right Power Mirror.......................8Wa-15-9

Right Rear Lamp Assembly.................8Wa-15-22

Right Rear Reading Lamp..................8Wa-15-18

Right Side Impact Airbag Control Module........8Wa-15-11

Right Sliding Door Control Module............8Wa-15-16

Right Sliding Door Latch Sensing Switch.........8Wa-15-16

Right Sliding Door Lock Motor...............8Wa-15-16

Right Sliding Door Lock Motor/ Ajar Switch.......8Wa-15-16

Right Sliding Door Motor..................8Wa-15-16

Right Stop/ Turn Signal Relay...............8Wa-15-21

Right Turn Signal Lamp...................8Wa-15-15

Right Visor/ Vanity Lamp..................8Wa-15-18

Sentry Key Immobilizer Module...............8Wa-15-9

Speed Control Servo......................8Wa-15-6

Traction Control Switch....................8Wa-15-9

Trailer Tow Connector....................8Wa-15-21

Transmission Control Module................8Wa-15-2

Transmission Control Relay..................8Wa-15-2

Transmission Range Sensor..................8Wa-15-6

Washer Fluid Level Switch..................8Wa-15-5

Wiper Module.........................8Wa-15-14

RG8W-15 GROUND DISTRIBUTION8Wa-15-1

Page 2441 of 4284

8W-80 CONNECTOR PIN-OUTS

Component Page

A/C Compressor Clutch................ 8W-80-6

A/C-Heater Control C1 (MTC)........... 8W-80-6

A/C-Heater Control C2 (MTC)........... 8W-80-6

A/C Pressure Sensor.................. 8W-80-7

Accelerator Pedal Position Sensor (Diesel) . 8W-80-7

Ambient Temp Sensor (Except Base)..... 8W-80-7

ATC Remote Sensor (ATC)............. 8W-80-7

Automatic Day/Night Mirror

(Premium/Luxury)................. 8W-80-8

Autostick Switch (Except Built-Up-Export) . 8W-80-8

Auto Temp Control C1................ 8W-80-8

Auto Temp Control C2................ 8W-80-9

Auto Temp Control C3................ 8W-80-9

Back-Up Lamp Switch (MTX)........... 8W-80-9

Battery Temperature Sensor (Diesel)..... 8W-80-9

Blower Motor Resistor C1 (MTC)....... 8W-80-10

Blower Motor Resistor C2 (MTC)....... 8W-80-10

Body Control Module C1.............. 8W-80-10

Body Control Module C2.............. 8W-80-11

Body Control Module C3.............. 8W-80-12

Body Control Module C4.............. 8W-80-13

Body Control Module C5.............. 8W-80-14

Boost Pressure Sensor (Diesel)......... 8W-80-14

Brake Fluid Level Switch............. 8W-80-15

Brake Lamp Switch................. 8W-80-15

Brake Transmission Shift Interlock Solenoid

(EATX) ......................... 8W-80-15

C100............................. 8W-80-15

C100............................. 8W-80-16

C101............................. 8W-80-16

C101............................. 8W-80-16

C102 (2.4L)........................ 8W-80-17

C102 (2.4L)........................ 8W-80-17

C102 (3.3L/3.8L).................... 8W-80-17

C102 (3.3L/3.8L).................... 8W-80-18

C103 (Diesel)....................... 8W-80-18

C103 (Diesel)....................... 8W-80-18

C106 (Built-Up-Export)............... 8W-80-18

C106 (Built-Up-Export)............... 8W-80-19

C107 (Built-Up-Export)............... 8W-80-19

C107 (Built-Up-Export)............... 8W-80-19

C200............................. 8W-80-20

C200............................. 8W-80-22

C201............................. 8W-80-23

C201............................. 8W-80-24

C202............................. 8W-80-24

C202............................. 8W-80-24

C203 (United Kingdom).............. 8W-80-25

C203 (United Kingdom).............. 8W-80-25

C300 (LHD)........................ 8W-80-25

C300 (LHD)........................ 8W-80-25

C300 (RHD)....................... 8W-80-26Component Page

C300 (RHD)....................... 8W-80-26

C301............................. 8W-80-26

C301............................. 8W-80-27

C302............................. 8W-80-27

C302............................. 8W-80-27

C303 (LHD)........................ 8W-80-28

C303 (LHD)........................ 8W-80-28

C303 (RHD)....................... 8W-80-28

C303 (RHD)....................... 8W-80-29

C304............................. 8W-80-29

C304............................. 8W-80-29

C305............................. 8W-80-29

C305............................. 8W-80-30

C306............................. 8W-80-30

C306............................. 8W-80-30

C307............................. 8W-80-30

C307............................. 8W-80-31

C308............................. 8W-80-31

C308............................. 8W-80-31

C309............................. 8W-80-32

C309............................. 8W-80-32

C310 (Front Console)................ 8W-80-32

C310 (Front Console)................ 8W-80-33

C311 ............................. 8W-80-33

C311 ............................. 8W-80-33

C312............................. 8W-80-34

C312............................. 8W-80-34

C313 (Rear Console)................. 8W-80-35

C313 (Rear Console)................. 8W-80-35

C314 (High Line)................... 8W-80-35

C314 (High Line)................... 8W-80-35

C315 (High Line)................... 8W-80-36

C315 (High Line)................... 8W-80-36

C316 (Power Sliding Door)............ 8W-80-36

C316 (Power Sliding Door)............ 8W-80-37

C317 (Power Sliding Door)............ 8W-80-37

C317 (Power Sliding Door)............ 8W-80-37

C318 (Trailer Tow).................. 8W-80-38

C318 (Trailer Tow).................. 8W-80-38

C319 (Except Built-Up-Export/Low Line) . 8W-80-38

C319 (Except Built-Up-Export/Low Line) . 8W-80-38

C320............................. 8W-80-39

C320............................. 8W-80-39

C321............................. 8W-80-39

C321............................. 8W-80-39

C322 (Memory)..................... 8W-80-39

C322 (Memory)..................... 8W-80-40

C324 (Manual Sliding Door)........... 8W-80-40

C324 (Manual Sliding Door)........... 8W-80-40

C325 (Manual Sliding Door)........... 8W-80-40

C325 (Manual Sliding Door)........... 8W-80-41

C326............................. 8W-80-41

RG8W-80 CONNECTOR PIN-OUTS8Wa-80-1

Page 2634 of 4284

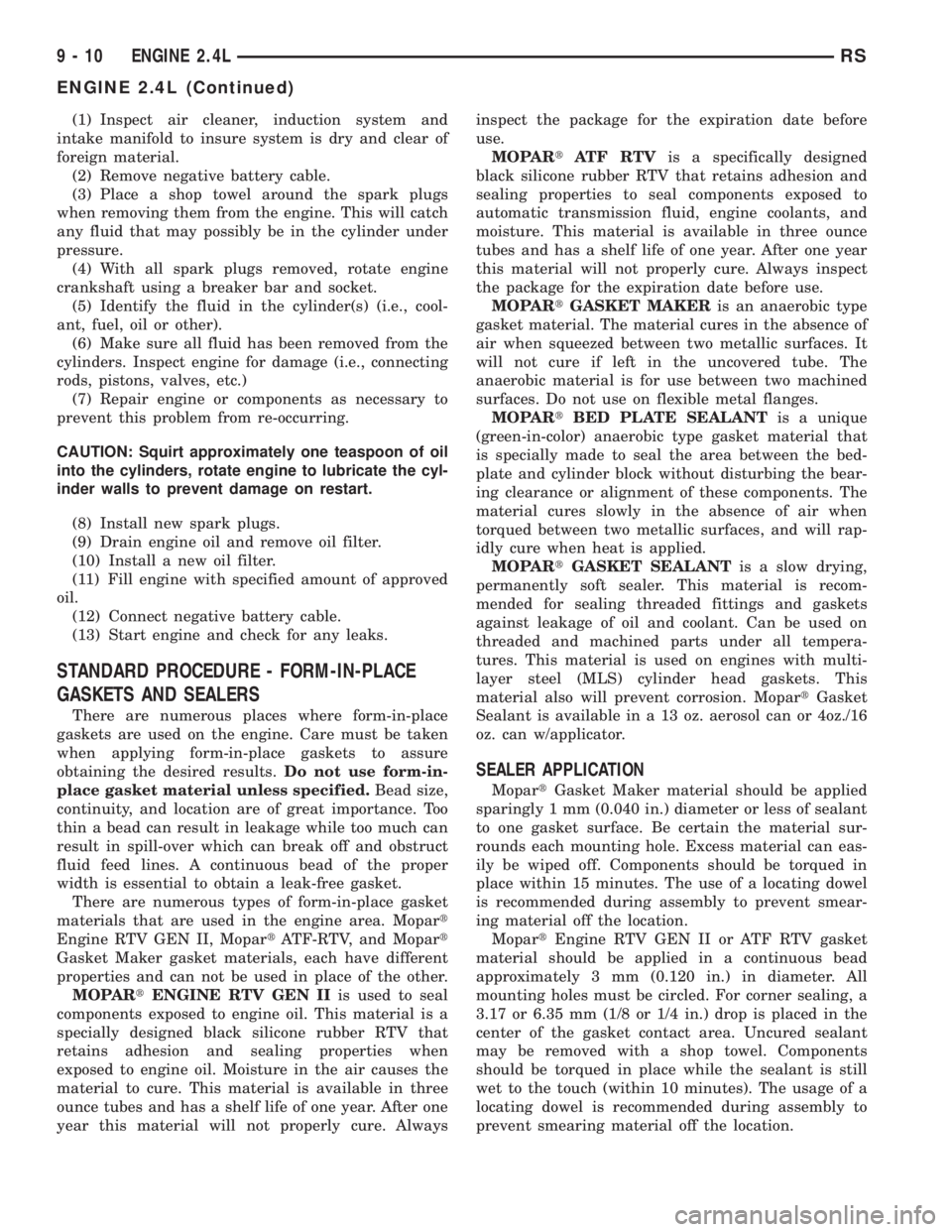

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.)

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Install a new oil filter.

(11) Fill engine with specified amount of approved

oil.

(12) Connect negative battery cable.

(13) Start engine and check for any leaks.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Alwaysinspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

anaerobic material is for use between two machined

surfaces. Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANTis a unique

(green-in-color) anaerobic type gasket material that

is specially made to seal the area between the bed-

plate and cylinder block without disturbing the bear-

ing clearance or alignment of these components. The

material cures slowly in the absence of air when

torqued between two metallic surfaces, and will rap-

idly cure when heat is applied.

MOPARtGASKET SEALANTis a slow drying,

permanently soft sealer. This material is recom-

mended for sealing threaded fittings and gaskets

against leakage of oil and coolant. Can be used on

threaded and machined parts under all tempera-

tures. This material is used on engines with multi-

layer steel (MLS) cylinder head gaskets. This

material also will prevent corrosion. MopartGasket

Sealant is available in a 13 oz. aerosol can or 4oz./16

oz. can w/applicator.

SEALER APPLICATION

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

9 - 10 ENGINE 2.4LRS

ENGINE 2.4L (Continued)

Page 2704 of 4284

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

anaerobic material is for use between two machined

surfaces. Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANTis a unique

(green-in-color) anaerobic type gasket material that

is specially made to seal the area between the bed-

plate and cylinder block without disturbing the bear-

ing clearance or alignment of these components. The

material cures slowly in the absence of air when

torqued between two metallic surfaces, and will rap-

idly cure when heat is applied.

MOPARtGASKET SEALANTis a slow drying,

permanently soft sealer. This material is recom-

mended for sealing threaded fittings and gaskets

against leakage of oil and coolant. Can be used on

threaded and machined parts under all tempera-

tures. This material is used on engines with multi-

layer steel (MLS) cylinder head gaskets. This

material also will prevent corrosion. MopartGasket

Sealant is available in a 13 oz. aerosol can or 4oz./16

oz. can w/applicator.SEALER APPLICATION

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURES - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 4)

NOTE: Multi-Layer Steel (MLS) head gaskets require

a scratch free sealing surface.

Only use the following for cleaning gasket surfaces:

²Solvent or a commercially available gasket

remover

²Plastic or wood scraper (Fig. 4)

²Drill motor with 3M RolocyBristle Disc (white

or yellow) (Fig. 4)

9 - 80 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

Page 2965 of 4284

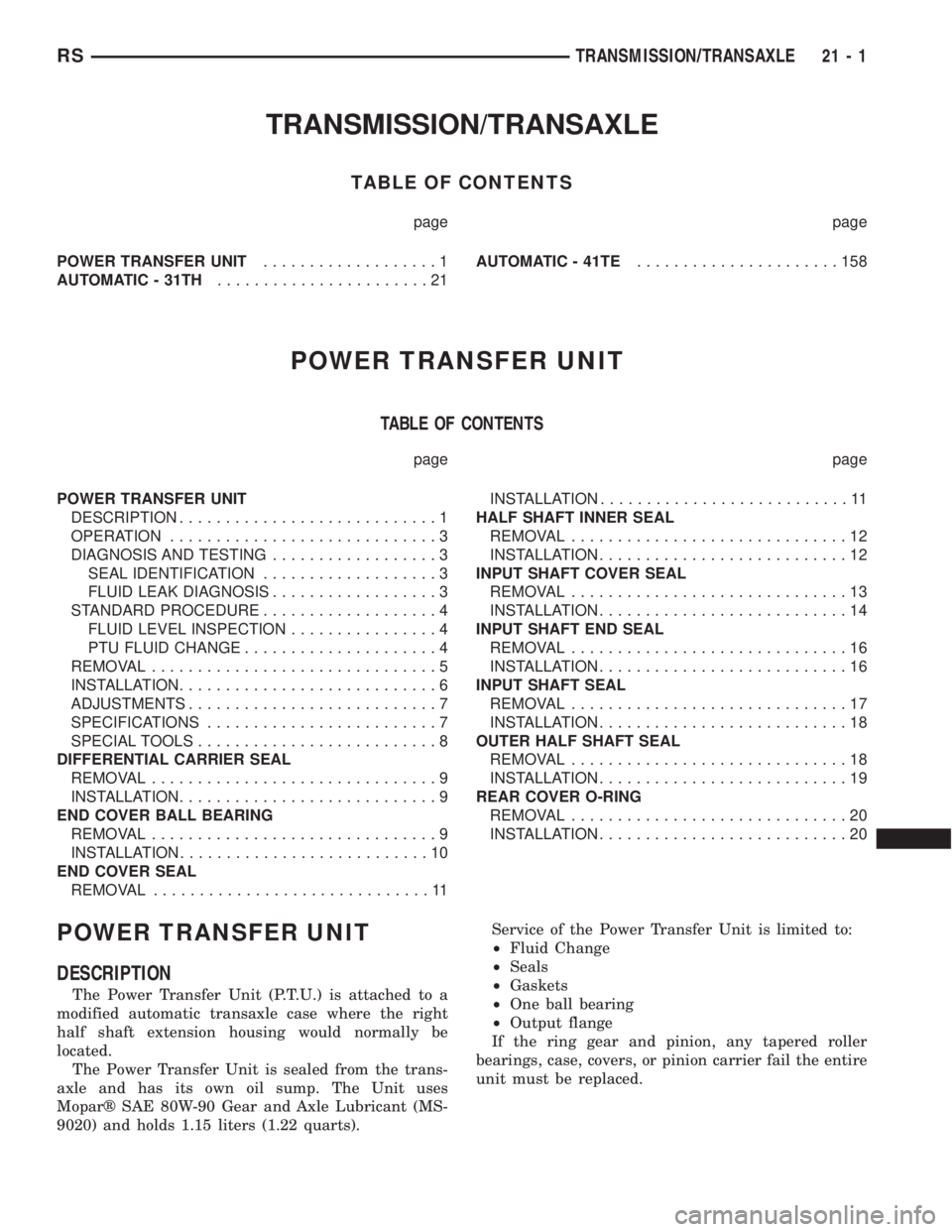

TRANSMISSION/TRANSAXLE

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT...................1

AUTOMATIC - 31TH.......................21AUTOMATIC - 41TE......................158

POWER TRANSFER UNIT

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT

DESCRIPTION............................1

OPERATION.............................3

DIAGNOSIS AND TESTING..................3

SEAL IDENTIFICATION...................3

FLUID LEAK DIAGNOSIS..................3

STANDARD PROCEDURE...................4

FLUID LEVEL INSPECTION................4

PTU FLUID CHANGE.....................4

REMOVAL...............................5

INSTALLATION............................6

ADJUSTMENTS...........................7

SPECIFICATIONS.........................7

SPECIAL TOOLS..........................8

DIFFERENTIAL CARRIER SEAL

REMOVAL...............................9

INSTALLATION............................9

END COVER BALL BEARING

REMOVAL...............................9

INSTALLATION...........................10

END COVER SEAL

REMOVAL..............................11INSTALLATION...........................11

HALF SHAFT INNER SEAL

REMOVAL..............................12

INSTALLATION...........................12

INPUT SHAFT COVER SEAL

REMOVAL..............................13

INSTALLATION...........................14

INPUT SHAFT END SEAL

REMOVAL..............................16

INSTALLATION...........................16

INPUT SHAFT SEAL

REMOVAL..............................17

INSTALLATION...........................18

OUTER HALF SHAFT SEAL

REMOVAL..............................18

INSTALLATION...........................19

REAR COVER O-RING

REMOVAL..............................20

INSTALLATION...........................20

POWER TRANSFER UNIT

DESCRIPTION

The Power Transfer Unit (P.T.U.) is attached to a

modified automatic transaxle case where the right

half shaft extension housing would normally be

located.

The Power Transfer Unit is sealed from the trans-

axle and has its own oil sump. The Unit uses

Moparž SAE 80W-90 Gear and Axle Lubricant (MS-

9020) and holds 1.15 liters (1.22 quarts).Service of the Power Transfer Unit is limited to:

²Fluid Change

²Seals

²Gaskets

²One ball bearing

²Output flange

If the ring gear and pinion, any tapered roller

bearings, case, covers, or pinion carrier fail the entire

unit must be replaced.

RSTRANSMISSION/TRANSAXLE21-1