fog light CHRYSLER VOYAGER 2001 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 477 of 4284

Symptom:

FRONT FOG LAMP SHORTED TO BATTERY

When Monitored and Set Condition:

FRONT FOG LAMP SHORTED TO BATTERY

When Monitored: Ignition On.

Set Condition: When a battery fault condition is present.

POSSIBLE CAUSES

INTERMITTENT CONDITION

FOG LAMP RELAY

FRONT CONTROL MODULE

INTELLIGENT POWER MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, clear all IPM DTC's.

Turn the Fog Lamps on.

With the DRBIIIt, read the DTC information.

Does the DRBIIItread: Front Fog Lamp Shorted To Battery?All

Ye s®Go To 2

No®The condition that caused the symptom is currently not present.

Inspect the related wiring for a possible intermittent condition.

Look for any chafed, pierced,pinched, or partially broken wires.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Remove and install a known good relay in place of the Fog Lamp Relay.

Do the Fog Lamps operate normally?All

Ye s®Replace the Fog Lamp Relay.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off.

Remove the Fog Lamp Relay from the IPM.

Remove the Front Control Module from the IPM.

Measure the voltage of the Fog Lamp Relay Control circuit and ground.

Is the voltage above 1.0 volts?All

Ye s®Replace the Intelligent Power Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

448

EXTERIOR LIGHTING

Page 543 of 4284

Symptom List:

A/C FAULT (STORED) - MANUAL A/C

BACKLIGHT DIMMING RX FAILURE (STORED) - MANUAL A/C

BLEND OVERCURRENT (STORED) - MANUAL A/C

CHECKSUM FAILURE (STORED) - MANUAL A/C

EVAPORATOR TEMPERATURE SENSOR CIRCUIT OPEN

(STORED) - MANUAL A/C

EVAPORATOR TEMPERATURE SENSOR CIRCUIT SHORT

(STORED) - MANUAL A/C

LOOPBACK FAILURE (STORED) - MANUAL A/C

LOOPBACK TEST FAILURE (STORED) - MANUAL A/C

MODE OVERCURRENT (STORED) - MANUAL A/C

NO BCM MESSAGE RECEIVED (STORED) - MANUAL A/C

NO PCM MESSAGE RECEIVED (STORED) - MANUAL A/C

PCM COMMUNICATION FAILURE (STORED) - MANUAL A/C

POWER FAULT (STORED) - MANUAL A/C

REAR BLEND OVERCURRENT (STORED) - MANUAL A/C

REAR BLEND POT CIRCUIT OPEN (STORED) - MANUAL A/C

REAR BLEND POT CIRCUIT SHORT (STORED) - MANUAL A/C

REAR DEFOG FAILURE (STORED) - MANUAL A/C

REAR MODE OVERCURRENT (STORED) - MANUAL A/C

RECIRC OVERCURRENT (STORED) - MANUAL A/C

RECIRCULATION FAULT (STORED) - MANUAL A/C

TX FAILURE (STORED) - MANUAL A/C

UNKNOWN FAULT DETECTED (STORED) - MANUAL A/C

VEHICLE ODOMETER FAILURE (STORED) - MANUAL A/C

ZONE OVERCURRENT (STORED) - MANUAL A/C

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be A/C FAULT (STORED) - MANUAL

A/C.

When Monitored and Set Condition:

A/C FAULT (STORED) - MANUAL A/C

When Monitored: With the ignition on.

Set Condition: This DTC will set if the A/C switch stays closed for 10 minutes.

BACKLIGHT DIMMING RX FAILURE (STORED) - MANUAL A/C

When Monitored: With the ignition on.

Set Condition: If the A/C - Heater Control Module does not receive the dimming function

message from the BCM for more than 5 seconds, then the A/C - Heater Control Module

LEDs will default to full brightness and the DTC will set.

514

HEATING & A/C

Page 596 of 4284

Symptom:

FRONT FOG LAMP INDICATOR OPEN

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

FRONT FOG LAMP INDICATOR CIRCUIT OPEN

FRONT FOG LAMP INDICATOR GROUND CIRCUIT OPEN

FRONT FOG LAMP INDICATOR CIRCUIT SHORT TO VOLTAGE

HEADLAMP SWITCH

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, record and erase Body Control Module DTC's.

Turn the ignition off, wait 15 seconds, then turn the ignition on.

Turn on the Front Fog Lamps.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay FRONT FOG LAMP INDICATOR OPEN?All

Ye s®Go To 2

No®Go To 8

2 Turn the ignition off to the lock position.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Turn ON the Front Fog Lamps.

Using a 12-volt test light connected to ground, back probe the Front Fog Lamp

Indicator circuit in the Headlamp Switch harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Go To 6

3 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Headlamp Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Front Fog Lamp Indicator Ground circuit from the

Body Control Module harness connector to the Headlamp Switch harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Front Fog Lamp Indicator Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

567

INSTRUMENT CLUSTER

Page 598 of 4284

Symptom:

FRONT FOG LAMP INDICATOR SHORT TO GROUND

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

FRONT FOG LAMP INDICATOR CIRCUIT SHORT TO GROUND

HEADLAMP SWITCH

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, record and erase Body Control Module DTC's.

Turn the ignition off, wait 15 seconds, then turn the ignition on.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay FRONT FOG LAMP INDICATOR SHORT TO GROUND?All

Ye s®Go To 2

No®Go To 6

2 Turn the ignition off to the lock position.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Turn ON the Front Fog Lamps.

Using a 12-volt test light connected to ground, back probe the Rear Fog Lamp

Indicator circuit in the Headlamp Switch harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Go To 4

3 If there are no possible causes remaining, view repair. All

Repair

Replace the Headlamp Switch.

Perform BODY VERIFICATION TEST - VER 1.

4 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Headlamp Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between ground and the Front Fog Lamp Indicator circuit.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Front Fog Lamp Indicator circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 If there are no possible causes remaining, view repair. All

Repair

Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

569

INSTRUMENT CLUSTER

Page 629 of 4284

Symptom:

REAR FOG INDICATOR OUTPUT OPEN

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

REAR FOG LAMP INDICATOR CIRCUIT OPEN

REAR FOG LAMP INDICATOR GROUND CIRCUIT OPEN

REAR FOG LAMP INDICATOR CIRCUIT SHORT TO VOLTAGE

HEADLAMP SWITCH

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, record and erase Body Control Module DTC's.

Turn the ignition off, wait 15 seconds, then turn the ignition on.

Turn on the Rear Fog Lamps.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay REAR FOG LAMP INDICATOR OPEN?All

Ye s®Go To 2

No®Go To 8

2 Turn the ignition off to the lock position.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Turn ON the Rear Fog Lamps.

Using a 12-volt test light connected to ground, back probe the Rear Fog Lamp

Indicator circuit in the Headlamp Switch harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Go To 6

3 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Headlamp Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Rear Fog Lamp Indicator Ground circuit from the Body

Control Module harness connector to the Headlamp Switch harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Rear Fog Lamp Indicator Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

600

INSTRUMENT CLUSTER

Page 631 of 4284

Symptom:

REAR FOG INDICATOR OUTPUT SHORT

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

REAR FOG LAMP INDICATOR CIRCUIT SHORT TO GROUND

HEADLAMP SWITCH

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, record and erase Body Control Module DTC's.

Turn the ignition off, wait 15 seconds, then turn the ignition on.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay REAR FOG LAMP INDICATOR SHORT TO GROUND?All

Ye s®Go To 2

No®Go To 6

2 Turn the ignition off to the lock position.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Turn ON the Rear Fog Lamps.

Using a 12-volt test light connected to ground, back probe the Rear Fog Lamp

Indicator circuit in the Headlamp Switch harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Go To 4

3 If there are no possible causes remaining, view repair. All

Repair

Replace the Headlamp Switch.

Perform BODY VERIFICATION TEST - VER 1.

4 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Headlamp Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between ground and the Rear Fog Lamp Indicator circuit.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Rear Fog Lamp Indicator circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 If there are no possible causes remaining, view repair. All

Repair

Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

602

INSTRUMENT CLUSTER

Page 1473 of 4284

FASTENER IDENTIFICATION

DESCRIPTION

The SAE bolt strength grades range from grade 2

to grade 8. The higher the grade number, the greater

the bolt strength. Identification is determined by the

line marks on the top of each bolt head. The actual

bolt strength grade corresponds to the number of line

marks plus 2. The most commonly used metric bolt

strength classes are 9.8 and 10.9. The metric

strength class identification number is imprinted on

the head of the bolt. The higher the class number,

the greater the bolt strength. Some metric nuts are

imprinted with a single-digit strength class on the

nut face. Refer to the Fastener Identification and

Fastener Strength Charts.

FASTENER USAGE

DESCRIPTION - FASTENER USAGE

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

International Symbols

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RSINTRODUCTION5

INTERNATIONAL SYMBOLS (Continued)

Page 1483 of 4284

FASTENER USAGE

DESCRIPTION

WARNING: USE OF AN INCORRECT FASTENER

MAY RESULT IN COMPONENT DAMAGE OR PER-

SONAL INJURY.

Figure art, specifications and torque references in

this Service Manual are identified in metric and SAE

format.

During any maintenance or repair procedures, it is

important to salvage all fasteners (nuts, bolts, etc.)

for reassembly. If the fastener is not salvageable, a

fastener of equivalent specification must be used.

THREADED HOLE REPAIR

DESCRIPTION

Most stripped threaded holes can be repaired using

a Helicoilt. Follow the vehicle or Helicoiltrecommen-

dations for application and repair procedures.

INTERNATIONAL VEHICLE

CONTROL & DISPLAY

SYMBOLS

DESCRIPTION

The graphic symbols illustrated in the following

International Control and Display Symbols Chart

(Fig. 4) are used to identify various instrument con-

trols. The symbols correspond to the controls and dis-

plays that are located on the instrument panel.

Fig. 4 INTERNATIONAL CONTROL AND DISPLAY SYMBOLS

1 High Beam 13 Rear Window Washer

2 Fog Lamps 14 Fuel

3 Headlamp, Parking Lamps, Panel Lamps 15 Engine Coolant Temperature

4 Turn Warning 16 Battery Charging Condition

5 Hazard Warning 17 Engine Oil

6 Windshield Washer 18 Seat Belt

7 Windshield Wiper 19 Brake Failure

8 Windshield Wiper and Washer 20 Parking Brake

9 Windscreen Demisting and Defrosting 21 Front Hood

10 Ventilating Fan 22 Rear hood (Decklid)

11 Rear Window Defogger 23 Horn

12 Rear Window Wiper 24 Lighter

RGINTRODUCTION5a

Page 1830 of 4284

²Front Fog Lamp Relay Actuation

²Front and Rear Blower Motor Relay Actuation

²Accessory Relay Actuation

²Electronic Back Light (EBL) Rear Defogger

²Horn Relay Actuation

²Park Lamp Relay Actuation

²Name Brand Speaker (NBS) Relay Actuation

²Headlamp Washer Relay Actuation

²Diesel Cabin Heater (Diesel Engine Vehicles)

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection

²Ambient Temperature Sensing

²Right/Left Park Lamp Outage

²Ignition Switch Start Only

²Ignition Switch Run and Start Only

²Washer Fluid Level

²Windshield Wiper Park

²Brake Fluid Level

²Back-Up switch

²Stop Lamp Sense

²Engine Crank Signal (Diesel Engine Vehicles)

²Horn Input

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Remove the battery from the vehicle. Refer to

the procedure in Battery Systems.(3) Using a long flat-pladed screwdriver, gently

twist the Intelligent Power Module (IPM) retaining

clip outboard to free the intelligent power module

from its mounting bracket (Fig. 6). Rotate intelligent

power module upward to access the Front Control

Module (FCM) retaining screws.

(4) Remove the front control module retaining

screws.

(5) Using both hands, pull the front control module

straight from the intelligent power module assembly

to disconnect the 49-way electrical connector (Fig. 7)

and remove the front control module from the vehi-

cle.

INSTALLATION

(1) Install the front control module in the intelli-

gent power module assembly by pushing the 49-way

electrical connector straight in (Fig. 7).

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Rotate the intelligent power module assembly

downward to secure in mounting bracket.

(4) Install the battery in the vehicle. Refer to the

procedure in Battery Systems.

(5) Connect the positive and negative battery

cables.

NOTE: If the vehicle is not equipped with Name

Brand Speakers (NBS, Infinity) or Headlamp Wash-

ers the DRB IIITmust be used to Disable the appro-

priate relays in the Intelligent Power Module

Assembly.

Fig. 6 REMOVING INTELLIGENT POWER MODULE

8E - 6 ELECTRONIC CONTROL MODULESRS

FRONT CONTROL MODULE (Continued)

Page 1899 of 4284

WINDSHIELD GRID

DIAGNOSIS AND TESTING - SYSTEM TEST

Electrically heated rear window defogger or the

heated windshield wiper deicer operation can be

checked on the vehicle in the following manner:

(1) Turn the ignition switch to the ON position.

(2) Using a ammeter on the battery, turn the rear

defogger control switch to the ON position, a distinct

increase in amperage draw should be noted.

(3) The rear window defogger or the heated wind-

shield wiper deicer operation can be checked by feel-

ing the glass. A distinct difference in temperature

between the grid lines and adjacent clear glass can

be detected in 3 to 4 minutes of operation.

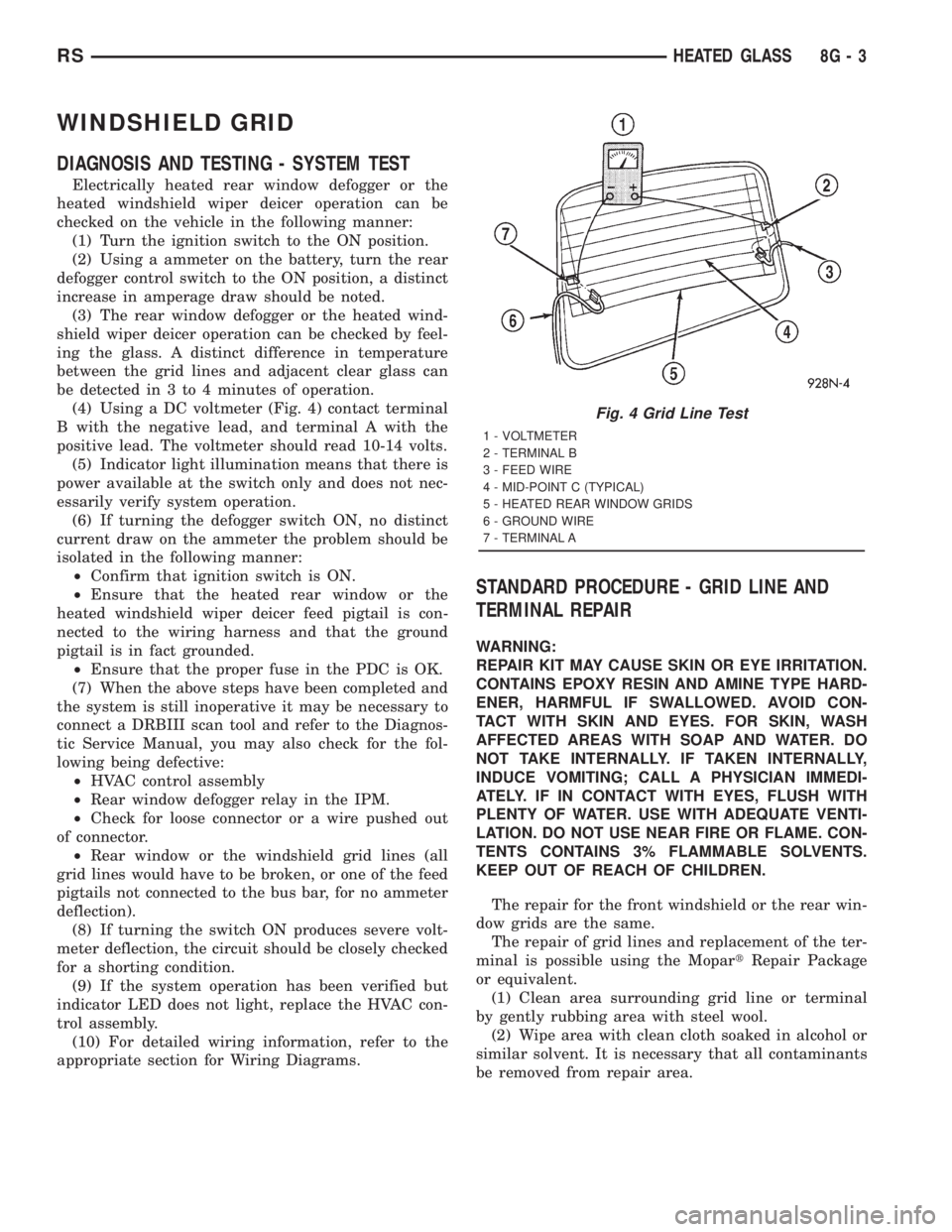

(4) Using a DC voltmeter (Fig. 4) contact terminal

B with the negative lead, and terminal A with the

positive lead. The voltmeter should read 10-14 volts.

(5) Indicator light illumination means that there is

power available at the switch only and does not nec-

essarily verify system operation.

(6) If turning the defogger switch ON, no distinct

current draw on the ammeter the problem should be

isolated in the following manner:

²Confirm that ignition switch is ON.

²Ensure that the heated rear window or the

heated windshield wiper deicer feed pigtail is con-

nected to the wiring harness and that the ground

pigtail is in fact grounded.

²Ensure that the proper fuse in the PDC is OK.

(7) When the above steps have been completed and

the system is still inoperative it may be necessary to

connect a DRBIII scan tool and refer to the Diagnos-

tic Service Manual, you may also check for the fol-

lowing being defective:

²HVAC control assembly

²Rear window defogger relay in the IPM.

²Check for loose connector or a wire pushed out

of connector.

²Rear window or the windshield grid lines (all

grid lines would have to be broken, or one of the feed

pigtails not connected to the bus bar, for no ammeter

deflection).

(8) If turning the switch ON produces severe volt-

meter deflection, the circuit should be closely checked

for a shorting condition.

(9) If the system operation has been verified but

indicator LED does not light, replace the HVAC con-

trol assembly.

(10) For detailed wiring information, refer to the

appropriate section for Wiring Diagrams.

STANDARD PROCEDURE - GRID LINE AND

TERMINAL REPAIR

WARNING:

REPAIR KIT MAY CAUSE SKIN OR EYE IRRITATION.

CONTAINS EPOXY RESIN AND AMINE TYPE HARD-

ENER, HARMFUL IF SWALLOWED. AVOID CON-

TACT WITH SKIN AND EYES. FOR SKIN, WASH

AFFECTED AREAS WITH SOAP AND WATER. DO

NOT TAKE INTERNALLY. IF TAKEN INTERNALLY,

INDUCE VOMITING; CALL A PHYSICIAN IMMEDI-

ATELY. IF IN CONTACT WITH EYES, FLUSH WITH

PLENTY OF WATER. USE WITH ADEQUATE VENTI-

LATION. DO NOT USE NEAR FIRE OR FLAME. CON-

TENTS CONTAINS 3% FLAMMABLE SOLVENTS.

KEEP OUT OF REACH OF CHILDREN.

The repair for the front windshield or the rear win-

dow grids are the same.

The repair of grid lines and replacement of the ter-

minal is possible using the MopartRepair Package

or equivalent.

(1) Clean area surrounding grid line or terminal

by gently rubbing area with steel wool.

(2) Wipe area with clean cloth soaked in alcohol or

similar solvent. It is necessary that all contaminants

be removed from repair area.

Fig. 4 Grid Line Test

1 - VOLTMETER

2 - TERMINAL B

3 - FEED WIRE

4 - MID-POINT C (TYPICAL)

5 - HEATED REAR WINDOW GRIDS

6 - GROUND WIRE

7 - TERMINAL A

RSHEATED GLASS8G-3