oil type CHRYSLER VOYAGER 2001 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1508 of 4284

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid check and fill locations (Fig. 1).

FLUID TYPES

DESCRIPTION - ENGINE OIL AND LUBRICANTS

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

When service is required, DaimlerChrysler Corpo-

ration recommends that only Mopartbrand parts,

lubricants and chemicals be used. Mopartprovides

the best engineered products for servicing

DaimlerChrysler Corporation vehicles.

Only lubricants bearing designations defined by

the following organization should be used.

²Society of Automotive Engineers (SAE)

²American Petroleum Institute (API)

²National Lubricating Grease Institute (NLGI)

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Certified. MOPARt

provides engine oils, meeting Material Standard

MS-6395, that meet or exceed this requirement.

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

Select an engine oil that is best suited to your par-

ticular temperature range and variation (Fig. 2).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. The designation of ENERGY CON-

SERVING is located on the label of an engine oil con-

tainer.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the front

label of engine oil plastic bottles and the top of

engine oil cans (Fig. 3).

This symbol means that the oil has been certified

by the American Petroleum Institute (API). Diamler-

Chrysler only recommend API Certified engine oils

that meet the requirements of Material Standard

MS-6395. Use Mopar or an equivalent oil meeting

the specification MS-6395.

GEAR LUBRICANTS

SAE ratings also apply to multigrade gear lubri-

cants. In addition, API classification defines the lubri-

cants usage. Such as API GL-5 and SAE 75W-90.

Fig. 1 International Symbols

Fig. 2 TEMPERATURE/ENGINE OIL VISCOSITY

Fig. 3 API Symbol

0a - 2 LUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESELRG

Page 1509 of 4284

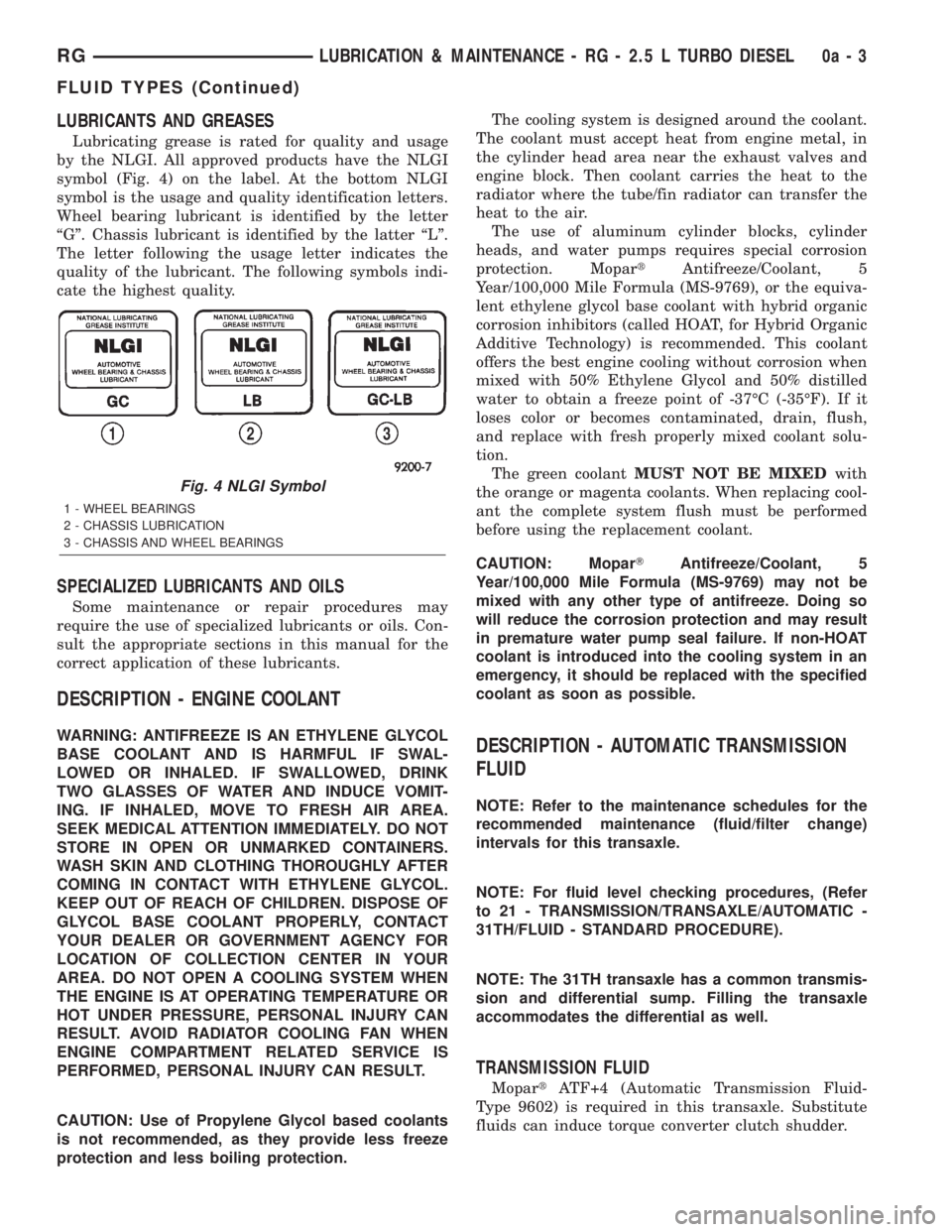

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 4) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

SPECIALIZED LUBRICANTS AND OILS

Some maintenance or repair procedures may

require the use of specialized lubricants or oils. Con-

sult the appropriate sections in this manual for the

correct application of these lubricants.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less boiling protection.The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with hybrid organic

corrosion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

The green coolantMUST NOT BE MIXEDwith

the orange or magenta coolants. When replacing cool-

ant the complete system flush must be performed

before using the replacement coolant.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Doing so

will reduce the corrosion protection and may result

in premature water pump seal failure. If non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.DESCRIPTION - AUTOMATIC TRANSMISSION

FLUID

NOTE: Refer to the maintenance schedules for the

recommended maintenance (fluid/filter change)

intervals for this transaxle.

NOTE: For fluid level checking procedures, (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/FLUID - STANDARD PROCEDURE).

NOTE: The 31TH transaxle has a common transmis-

sion and differential sump. Filling the transaxle

accommodates the differential as well.

TRANSMISSION FLUID

MopartATF+4 (Automatic Transmission Fluid-

Type 9602) is required in this transaxle. Substitute

fluids can induce torque converter clutch shudder.

Fig. 4 NLGI Symbol

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-3

FLUID TYPES (Continued)

Page 1510 of 4284

MopartATF+4 (Automatic Transmission Fluid-

Type 9602) when new is red in color. The ATF is dyed

red so it can be identified from other fluids used in

the vehicle such as engine oil or antifreeze. The red

color is not permanent and is not an indicator of fluid

condition. As the vehicle is driven, the ATF will begin

to look darker in color and may eventually become

brown.This is normal.A dark brown/black fluid

accompanied with a burnt odor and/or deterioration

in shift quality may indicate fluid deterioration or

transmission component failure.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and these

additivesmust not be used.

The use of transmission

ªsealersº should also be avoided, since they may

adversely affect the integrity of transmission seals.

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE

WARNING: DO NOT USE ALCOHOL OR GASOLINE

AS A FUEL BLENDING AGENT. THEY CAN BE

UNSTABLE UNDER CERTAIN CONDITIONS AND

HAZARDOUS OR EXPLOSIVE WHEN MIXED WITH

DIESEL FUEL.

Use good quality diesel fuel from a reputable sup-

plier. For most year-round service, number 2 diesel

fuel meeting ASTM specification D-975 will provide

good performance. If the vehicle is exposed to

extreme cold (below -18ÉC/0ÉF) or is required to oper-

ate at colder than normal conditions for prolonged

periods, use climatize No. 2 diesel fuel or dilute the

No. 2 diesel fuel with 50% No. 1 diesel fuel. This will

provide better protection from fuel gelling or wax

plugging of the fuel filters.

Diesel fuel is seldom completely free of water. To

prevent fuel system trouble, including fuel line freez-

ing in winter, drain the accumulated water from the

fuel/water separator using the fuel/water separator

drain provided. If you buy good quality fuel and follow

the cold weather advice above, fuel conditioners should

not be required in your vehicle. If available in your

area, a high cetane ªpremiumº diesel fuel may offer

improved cold starting and warm up performance.

DESCRIPTION - DIESEL ENGINE OIL

API SERVICE GRADE CERTIFIED

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-

MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

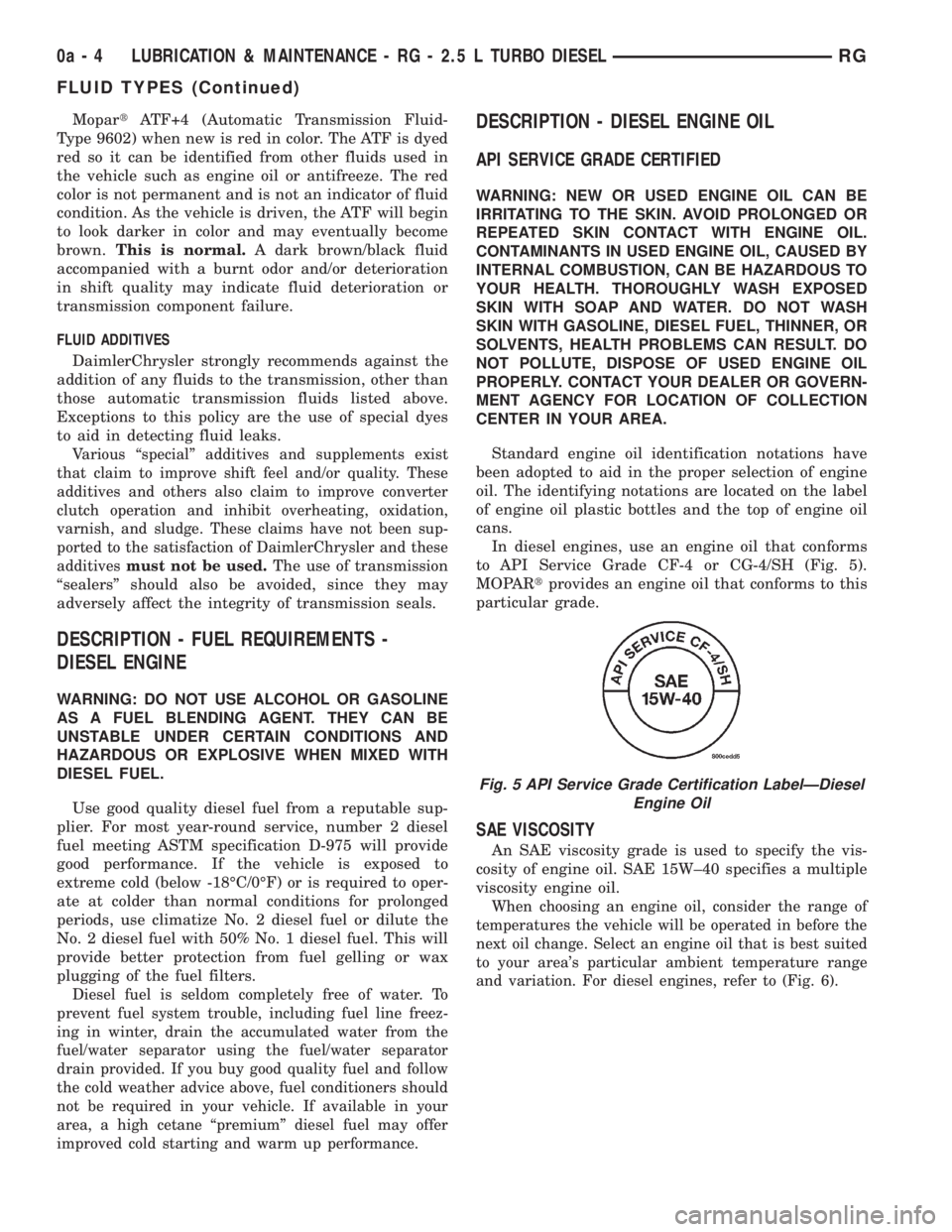

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans.

In diesel engines, use an engine oil that conforms

to API Service Grade CF-4 or CG-4/SH (Fig. 5).

MOPARtprovides an engine oil that conforms to this

particular grade.

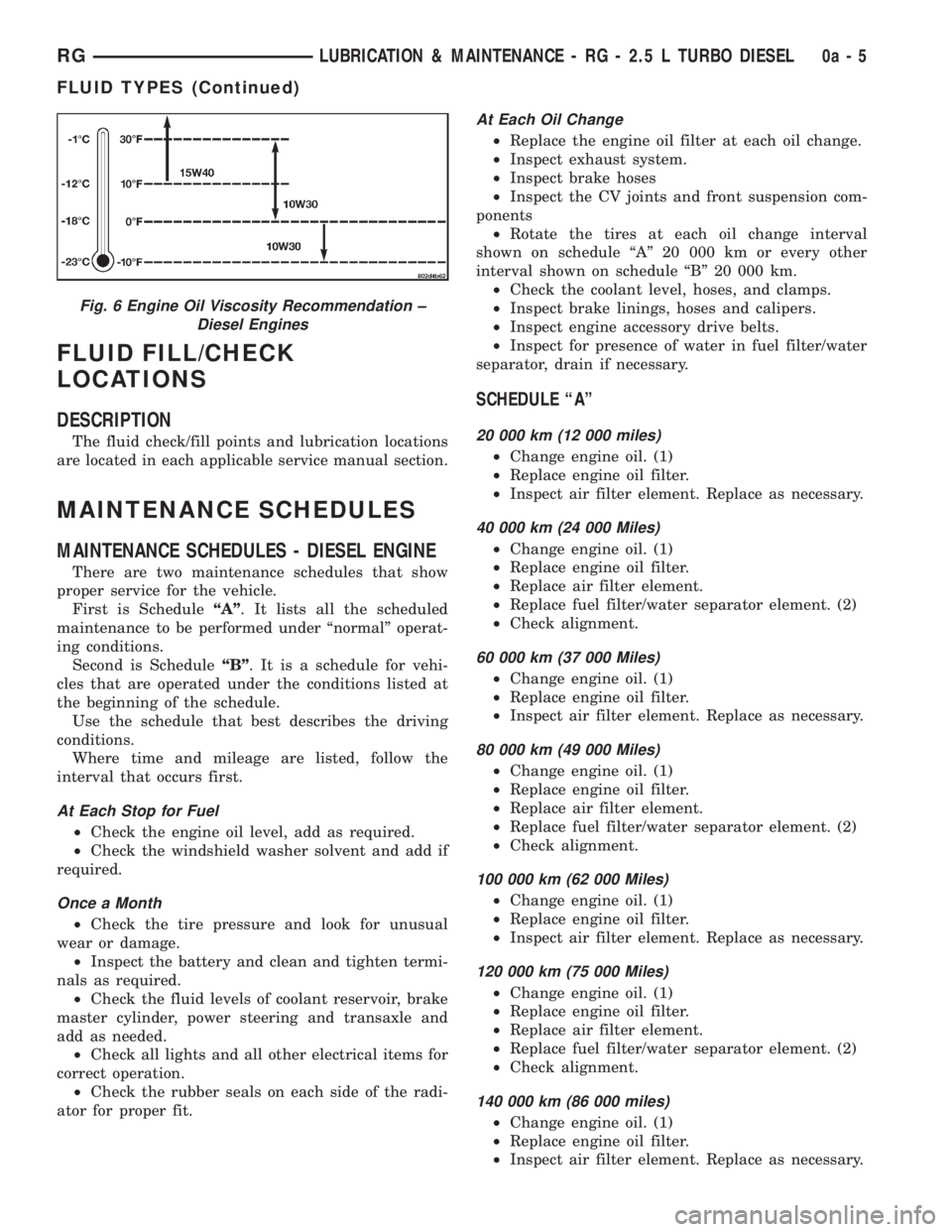

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. SAE 15W±40 specifies a multiple

viscosity engine oil.

When choosing an engine oil, consider the range of

temperatures the vehicle will be operated in before the

next oil change. Select an engine oil that is best suited

to your area's particular ambient temperature range

and variation. For diesel engines, refer to (Fig. 6).

Fig. 5 API Service Grade Certification LabelÐDiesel

Engine Oil

0a - 4 LUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESELRG

FLUID TYPES (Continued)

Page 1511 of 4284

FLUID FILL/CHECK

LOCATIONS

DESCRIPTION

The fluid check/fill points and lubrication locations

are located in each applicable service manual section.

MAINTENANCE SCHEDULES

MAINTENANCE SCHEDULES - DIESEL ENGINE

There are two maintenance schedules that show

proper service for the vehicle.

First is ScheduleªAº. It lists all the scheduled

maintenance to be performed under ªnormalº operat-

ing conditions.

Second is ScheduleªBº. It is a schedule for vehi-

cles that are operated under the conditions listed at

the beginning of the schedule.

Use the schedule that best describes the driving

conditions.

Where time and mileage are listed, follow the

interval that occurs first.

At Each Stop for Fuel

²Check the engine oil level, add as required.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check the tire pressure and look for unusual

wear or damage.

²Inspect the battery and clean and tighten termi-

nals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check the rubber seals on each side of the radi-

ator for proper fit.

At Each Oil Change

²Replace the engine oil filter at each oil change.

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on schedule ªAº 20 000 km or every other

interval shown on schedule ªBº 20 000 km.

²Check the coolant level, hoses, and clamps.

²Inspect brake linings, hoses and calipers.

²Inspect engine accessory drive belts.

²Inspect for presence of water in fuel filter/water

separator, drain if necessary.

SCHEDULE ªAº

20 000 km (12 000 miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

40 000 km (24 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

60 000 km (37 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

80 000 km (49 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

100 000 km (62 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

120 000 km (75 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

140 000 km (86 000 miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

Fig. 6 Engine Oil Viscosity Recommendation ±

Diesel Engines

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-5

FLUID TYPES (Continued)

Page 1535 of 4284

(6) Tighten the stabilizer bar bushing retainer to

cradle attaching bolts (Fig. 35) to 68 N´m (50 ft. lbs.)

torque.

(7) Install the reinforcement on the front suspen-

sion cradle crossmember and install the bolts attach-

ing the reinforcement to the cradle crossmember

(Fig. 33). Tighten the M-14 size bolts to a torque of

163 N´m (120 ft. lbs.). Tighten the M-12 size bolts to

a torque of 108 N´m (80 ft. lbs.).

(8) Install the lower control arm rear bushing

retainer bolts through reinforcement on each side of

each lower control arm rear bushing. Tighten bolts to

a torque of 61 N´m (45 ft. lbs.).

(9) Install the two bolts and bushings attaching

the reinforcement and rear of cradle crossmember to

body of vehicle (Fig. 33). Tighten bolts to a torque of

163 N´m (120 ft. lbs.).

(10) Install the power steering cooler (Fig. 32).

Tighten bolts to a torque of 11 N´m (100 in. lbs.).

(11) Lower the vehicle.STRUT

DESCRIPTION - STRUT ASSEMBLY

A Macpherson type strut assembly is used in place

of a conventional front suspension's upper control

arm and upper ball joint. The bottom of the strut

mounts directly to the steering knuckle using two

bolts and nuts going through the strut clevis bracket

and steering knuckle. The top of the strut mounts

directly to the strut tower of the vehicle using the

threaded studs on the strut assemblies upper mount.

The strut assembly includes the components listed

in the figure (Fig. 39).

Each component is serviced by removing the strut

assembly from the vehicle and disassembling it.

The coil springs are side-oriented. Springs on the

left side of the vehicle have a left-hand wind top-to-

bottom while springs on the right side have a right-

hand wind top-to-bottom. This helps provide better

vehicle stability during jounce and rebound maneu-

vers of the front suspension. Left and right springs

must not be interchanged. Coil springs are rated sep-

Fig. 39 STRUT ASSEMBLY

1 - NUT

2 - UPPER MOUNT

3 - PIVOT BEARING

4 - UPPER SPRING SEAT

5 - UPPER SPRING ISOLATOR

6 - COIL SPRING7 - DUST SHIELD

8 - JOUNCE BUMPER

9 - LOWER SPRING ISOLATOR

10 - STRUT (DAMPER)

RSFRONT2-19

STABILIZER BAR (Continued)

Page 1536 of 4284

arately for each corner or side of the vehicle depend-

ing on optional equipment and type of vehicle

service. If the coil springs require replacement, be

sure that the springs are replaced with springs meet-

ing the correct load rating and spring rate for the

vehicle and its specific options.

OPERATION - STRUT ASSEMBLY

The strut assembly cushions the ride of the vehicle,

controlling vibration, along with jounce and rebound

of the suspension.

The coil spring controls ride quality and maintains

proper ride height.

The spring isolators isolate the coil spring at the

top and bottom from coming into metal-to-metal con-

tact with the upper seat and strut.

The jounce bumper limits suspension travel and

metal-to-metal contact under full jounce condition.

The strut dampens jounce and rebound motions of

the coil spring and suspension.

During steering maneuvers, the strut assembly

(through a pivot bearing in the upper strut mount)

and steering knuckle (through the lower ball joint)

turn as an assembly.

DIAGNOSIS AND TESTING - STRUT ASSEMBLY

(FRONT)

(1) Inspect for damaged or broken coil springs

(Fig. 39).

(2) Inspect for torn or damaged strut assembly

dust boots (Fig. 39).

(3) Inspect the coil spring isolator on the lower

spring seat for any signs of damage or deterioration.

(4) Lift dust boot (Fig. 40) and inspect strut

assembly for evidence of fluid running from the

upper end of fluid reservoir. (Actual leakage will be a

stream of fluid running down the side and dripping

off lower end of unit). A slight amount of seepage

between the strut rod and strut shaft seal is not

unusual and does not affect performance of the strut

assembly (Fig. 40). Also inspect jounce bumpers for

signs of damage or deterioration.

REMOVAL - STRUT ASSEMBLY

WARNING: DO NOT REMOVE THE NUT FROM THE

STRUT ROD WHILE STRUT ASSEMBLY IS

INSTALLED IN VEHICLE, OR BEFORE STRUT

ASSEMBLY SPRING IS COMPRESSED.

(1) Raise the vehicle. See Hoisting in Lubrication

and Maintenance.

(2) Remove the wheel and tire assembly from loca-

tion on front of vehicle requiring strut removal.(3) If both strut assemblies are to be removed,

mark the strut assemblies right or left according to

which side of the vehicle they were removed from.

(4) Remove the hydraulic brake hose routing

bracket and the speed sensor cable routing bracket

from the strut damper brackets (Fig. 41).

Fig. 40 Strut Assembly Leakage Inspection (Typical)

1 - DUST BOOT

2 - STRUT SHAFT

3 - STRUT FLUID RESERVOIR

4 - INSPECT THIS AREA FOR EVIDENCE OF EXCESSIVE FLUID

LEAKAGE

Fig. 41 Brake Hose And Speed Sensor Cable

Routing

1 - STRUT DAMPER

2 - WHEEL SPEED SENSOR CABLE

3 - ROUTING BRACKET

4 - HYDRAULIC BRAKE HOSE

5 - ATTACHING BOLT

6 - ROUTING BRACKET

2 - 20 FRONTRS

STRUT (Continued)

Page 1603 of 4284

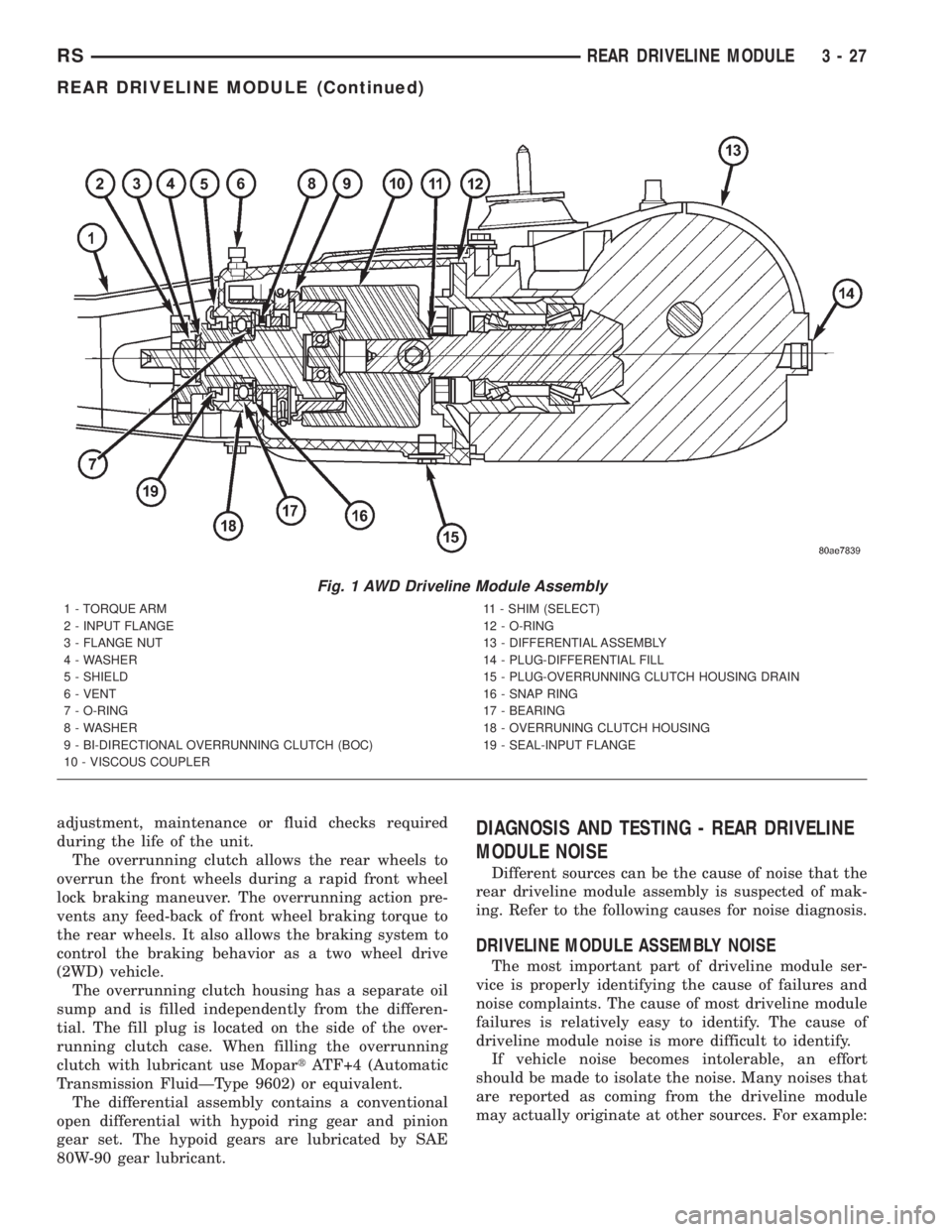

adjustment, maintenance or fluid checks required

during the life of the unit.

The overrunning clutch allows the rear wheels to

overrun the front wheels during a rapid front wheel

lock braking maneuver. The overrunning action pre-

vents any feed-back of front wheel braking torque to

the rear wheels. It also allows the braking system to

control the braking behavior as a two wheel drive

(2WD) vehicle.

The overrunning clutch housing has a separate oil

sump and is filled independently from the differen-

tial. The fill plug is located on the side of the over-

running clutch case. When filling the overrunning

clutch with lubricant use MopartATF+4 (Automatic

Transmission FluidÐType 9602) or equivalent.

The differential assembly contains a conventional

open differential with hypoid ring gear and pinion

gear set. The hypoid gears are lubricated by SAE

80W-90 gear lubricant.DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE NOISE

Different sources can be the cause of noise that the

rear driveline module assembly is suspected of mak-

ing. Refer to the following causes for noise diagnosis.

DRIVELINE MODULE ASSEMBLY NOISE

The most important part of driveline module ser-

vice is properly identifying the cause of failures and

noise complaints. The cause of most driveline module

failures is relatively easy to identify. The cause of

driveline module noise is more difficult to identify.

If vehicle noise becomes intolerable, an effort

should be made to isolate the noise. Many noises that

are reported as coming from the driveline module

may actually originate at other sources. For example:

Fig. 1 AWD Driveline Module Assembly

1 - TORQUE ARM

2 - INPUT FLANGE

3 - FLANGE NUT

4 - WASHER

5 - SHIELD

6 - VENT

7 - O-RING

8 - WASHER

9 - BI-DIRECTIONAL OVERRUNNING CLUTCH (BOC)

10 - VISCOUS COUPLER11 - SHIM (SELECT)

12 - O-RING

13 - DIFFERENTIAL ASSEMBLY

14 - PLUG-DIFFERENTIAL FILL

15 - PLUG-OVERRUNNING CLUTCH HOUSING DRAIN

16 - SNAP RING

17 - BEARING

18 - OVERRUNING CLUTCH HOUSING

19 - SEAL-INPUT FLANGE

RSREAR DRIVELINE MODULE3-27

REAR DRIVELINE MODULE (Continued)

Page 1658 of 4284

STANDARD PROCEDURE - BRAKE FLUID

LEVEL CHECKING

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

Fluid reservoirs are marked with the words FULL

and ADD to indicate proper brake fluid fill level of

the master cylinder.

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.

Use only Mopartbrake fluid or equivalent from a

sealed container. Brake fluid must conform to DOT 3

specifications (DOT 4 or DOT 4+ are acceptable).

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid etc.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications (DOT 4 and DOT 4+ are

acceptable) and SAE J1703 standards. No other type

of brake fluid is recommended or approved for usage

in the vehicle brake system. Use only MopartBrake

Fluid or equivalent from a tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

JUNCTION BLOCK

DESCRIPTION - NON-ABS JUNCTION BLOCK

A junction block is used on vehicles that are not

equipped with antilock brakes (ABS). The junction

block mounts in the same location as the integrated

control unit (ICU) does on vehicles equipped withABS. This allows for use of the same brake tube con-

figuration on all vehicles. The junction block is

located on the driver's side of the front suspension

cradle/crossmember below the master cylinder (Fig.

46).

It has six threaded ports to which the brake tubes

connect. Two are for the primary and secondary

brake tubes coming from the master cylinder. The

remaining four are for the chassis brake tubes going

to each brake assembly.

OPERATION - NON-ABS JUNCTION BLOCK

The junction block distributes the brake fluid com-

ing from the master cylinder primary and secondary

ports to the four chassis brake tubes leading to the

brakes at each wheel. Since the junction block

mounts in the same location as the ABS integrated

control unit (ICU), it allows for the common use of

brake tubes going to the brakes whether the vehicle

is equipped with or without ABS.

NOTE: Although the brake tubes coming from the

master cylinder to the junction block or ABS ICU

may appear to be the same, they are not. They are

unique to each brake system application.

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block.

(2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following:

(a) Disconnect the battery positive cable.

(b) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(c) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(d) Remove the screw securing the coolant filler

neck to the battery tray.

(e) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system.

5 - 32 BRAKES - BASERS

FLUID (Continued)

Page 1722 of 4284

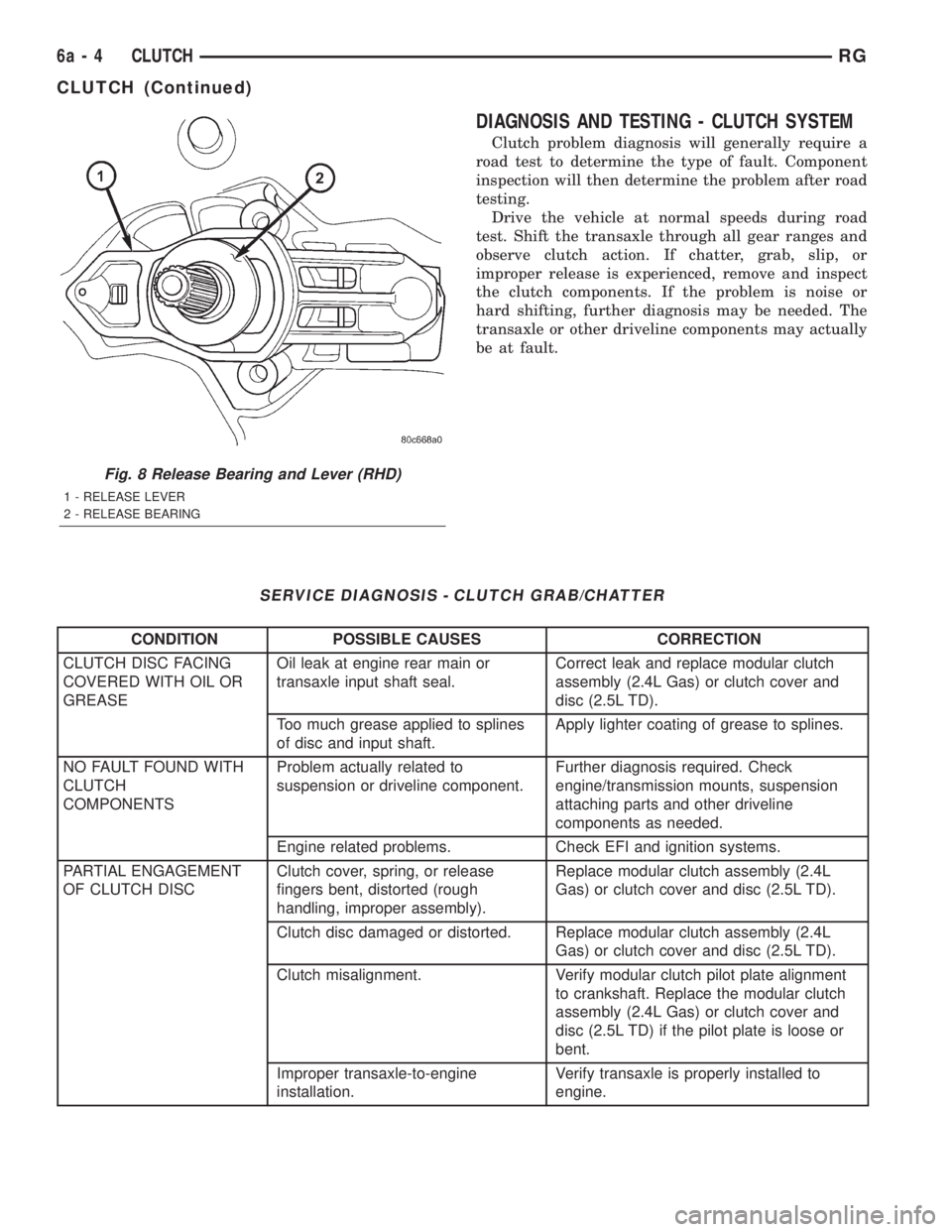

DIAGNOSIS AND TESTING - CLUTCH SYSTEM

Clutch problem diagnosis will generally require a

road test to determine the type of fault. Component

inspection will then determine the problem after road

testing.

Drive the vehicle at normal speeds during road

test. Shift the transaxle through all gear ranges and

observe clutch action. If chatter, grab, slip, or

improper release is experienced, remove and inspect

the clutch components. If the problem is noise or

hard shifting, further diagnosis may be needed. The

transaxle or other driveline components may actually

be at fault.

SERVICE DIAGNOSIS - CLUTCH GRAB/CHATTER

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC FACING

COVERED WITH OIL OR

GREASEOil leak at engine rear main or

transaxle input shaft seal.Correct leak and replace modular clutch

assembly (2.4L Gas) or clutch cover and

disc (2.5L TD).

Too much grease applied to splines

of disc and input shaft.Apply lighter coating of grease to splines.

NO FAULT FOUND WITH

CLUTCH

COMPONENTSProblem actually related to

suspension or driveline component.Further diagnosis required. Check

engine/transmission mounts, suspension

attaching parts and other driveline

components as needed.

Engine related problems. Check EFI and ignition systems.

PARTIAL ENGAGEMENT

OF CLUTCH DISCClutch cover, spring, or release

fingers bent, distorted (rough

handling, improper assembly).Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Clutch disc damaged or distorted. Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Clutch misalignment. Verify modular clutch pilot plate alignment

to crankshaft. Replace the modular clutch

assembly (2.4L Gas) or clutch cover and

disc (2.5L TD) if the pilot plate is loose or

bent.

Improper transaxle-to-engine

installation.Verify transaxle is properly installed to

engine.

Fig. 8 Release Bearing and Lever (RHD)

1 - RELEASE LEVER

2 - RELEASE BEARING

6a - 4 CLUTCHRG

CLUTCH (Continued)

Page 1735 of 4284

COOLING

TABLE OF CONTENTS

page page

COOLING

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................3

COOLING SYSTEM LEAK TEST.............3

COOLING SYSTEM FLOW CHECK..........3

COOLING SYSTEM AERATION.............3

COOLING SYSTEM DEAERATION...........3

STANDARD PROCEDURE...................4COOLING SYSTEM - DRAINING............4

COOLING SYSTEM - REFILLING............4

COOLANT - ADDING ADDITIONAL...........4

COOLANT LEVEL CHECK - ROUTINE........5

SPECIFICATIONS.........................6

SPECIAL TOOLS..........................6

ACCESSORY DRIVE.......................7

ENGINE................................13

TRANSMISSION.........................36

COOLING

DESCRIPTION - COOLING SYSTEM

The cooling system components consist of a radia-

tor, electric fan motors, shroud, pressure cap, thermo-

stat, transmission oil cooler, water pump, hoses,

clamps, coolant, and a coolant reserve system to com-

plete the circuit.

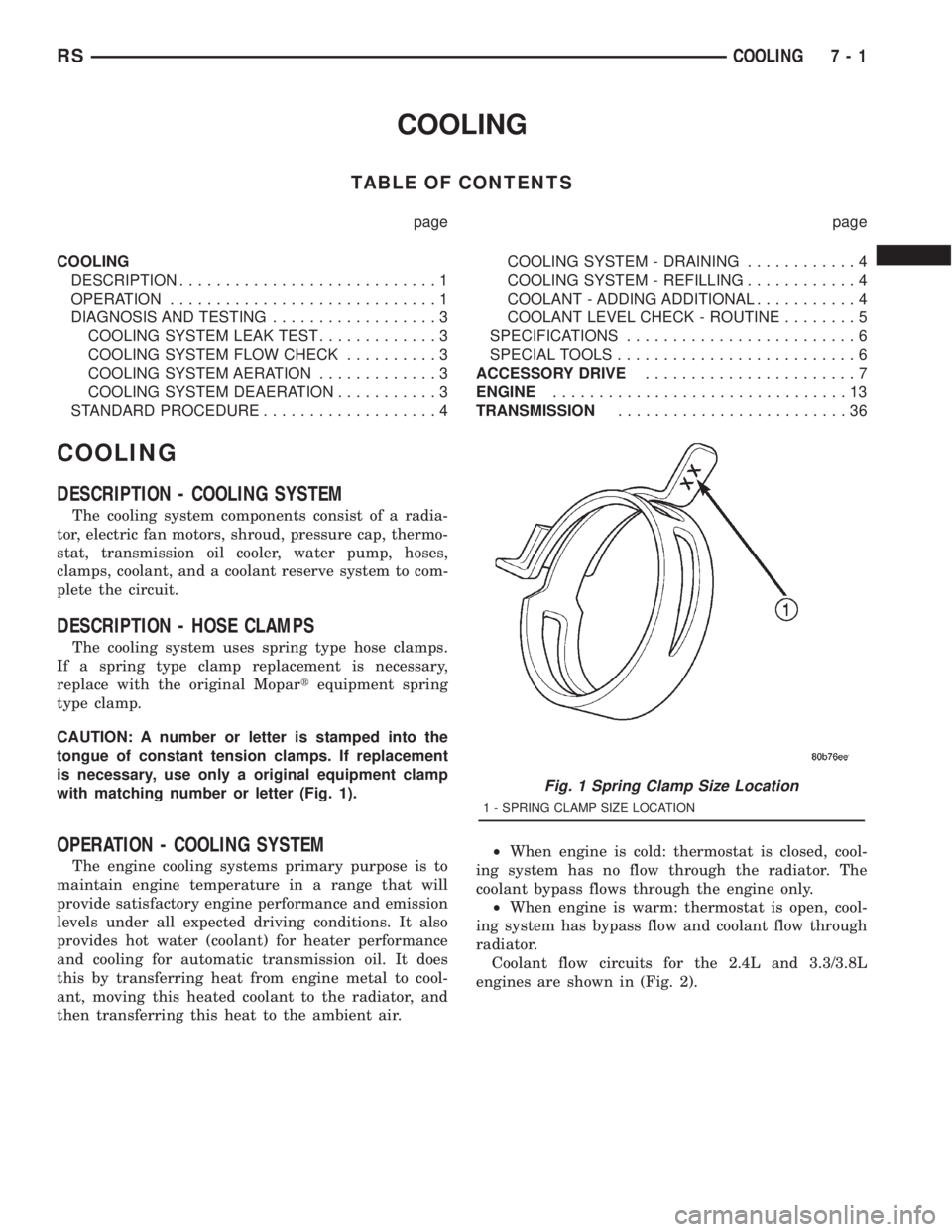

DESCRIPTION - HOSE CLAMPS

The cooling system uses spring type hose clamps.

If a spring type clamp replacement is necessary,

replace with the original Mopartequipment spring

type clamp.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter (Fig. 1).

OPERATION - COOLING SYSTEM

The engine cooling systems primary purpose is to

maintain engine temperature in a range that will

provide satisfactory engine performance and emission

levels under all expected driving conditions. It also

provides hot water (coolant) for heater performance

and cooling for automatic transmission oil. It does

this by transferring heat from engine metal to cool-

ant, moving this heated coolant to the radiator, and

then transferring this heat to the ambient air.²When engine is cold: thermostat is closed, cool-

ing system has no flow through the radiator. The

coolant bypass flows through the engine only.

²When engine is warm: thermostat is open, cool-

ing system has bypass flow and coolant flow through

radiator.

Coolant flow circuits for the 2.4L and 3.3/3.8L

engines are shown in (Fig. 2).

Fig. 1 Spring Clamp Size Location

1 - SPRING CLAMP SIZE LOCATION

RSCOOLING7-1