washer fluid CHRYSLER VOYAGER 2001 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1605 of 4284

DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE OPERATION

Driveline module operation requires relatively

straight-forward diagnosis. Refer to the following

chart:

DRIVELINE MODULE DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

Rear wheels not

overrunning1) Bi-directional overrunning clutch

failure1) Replace overrunning clutch

components as required

No AWD in forward or

reverse directions, propeller

shaft turning1) Bi-directional overrunning clutch

failure1) Replace overrunning clutch

components as required

2) Viscous coupling failure 2) Replace viscous coupling

3) Rear differential failure 3) Replace the rear differential

assembly

No AWD in forward or

reverse directions, propeller

shaft not turning1) Power transfer unit failure. 1) Replace power transfer unit

components as necessary

Vibration at all speeds,

continuous torque transfer1) Mis-matched tires, worn tires on

front axle.1) Replace worn or incorrect

(mis-matched) tires with same

make and size

REMOVAL

(1) Raise vehicle on hoist.

(2) Drain fluid from overrunning clutch housing

and/or differential assembly if necessary.

(3) Remove propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT -

REMOVAL)

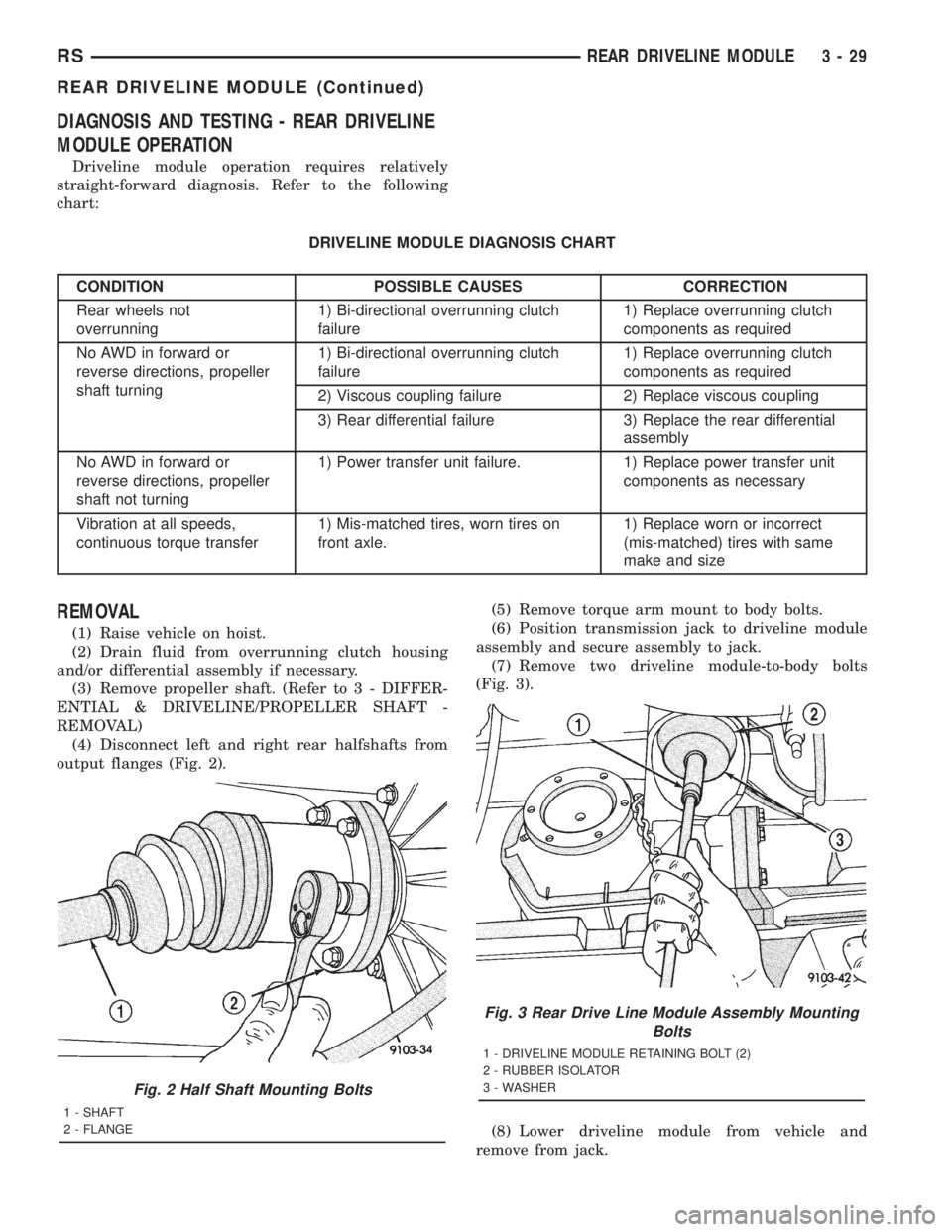

(4) Disconnect left and right rear halfshafts from

output flanges (Fig. 2).(5) Remove torque arm mount to body bolts.

(6) Position transmission jack to driveline module

assembly and secure assembly to jack.

(7) Remove two driveline module-to-body bolts

(Fig. 3).

(8) Lower driveline module from vehicle and

remove from jack.

Fig. 2 Half Shaft Mounting Bolts

1 - SHAFT

2 - FLANGE

Fig. 3 Rear Drive Line Module Assembly Mounting

Bolts

1 - DRIVELINE MODULE RETAINING BOLT (2)

2 - RUBBER ISOLATOR

3 - WASHER

RSREAR DRIVELINE MODULE3-29

REAR DRIVELINE MODULE (Continued)

Page 1623 of 4284

When a high speed difference (shear) occurs

because of loss of traction (one axle spinning faster

than the other), the silicone fluid expands as it heats

from this shearing. When the silicone expands to fill

the viscous coupler completely, this pressure differ-

ence is high enough to squeeze each pair of plates

together. The resulting hump torque is up to 8 times

higher than the shear torque. When the viscous cou-

pler is in the hump mode, it does not lock the axles

(undifferentiated 4-Wheel Drive). It controls the

amount of slippage while delivering maximum power

to the axle having greatest traction. Once the speed

difference equalizes the fluid and plates cool down

and the viscous coupler goes back to the shear mode.

TORQUE ARM

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove rear driveline module assembly. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/REAR DRIV-

ELINE MODULE - REMOVAL)

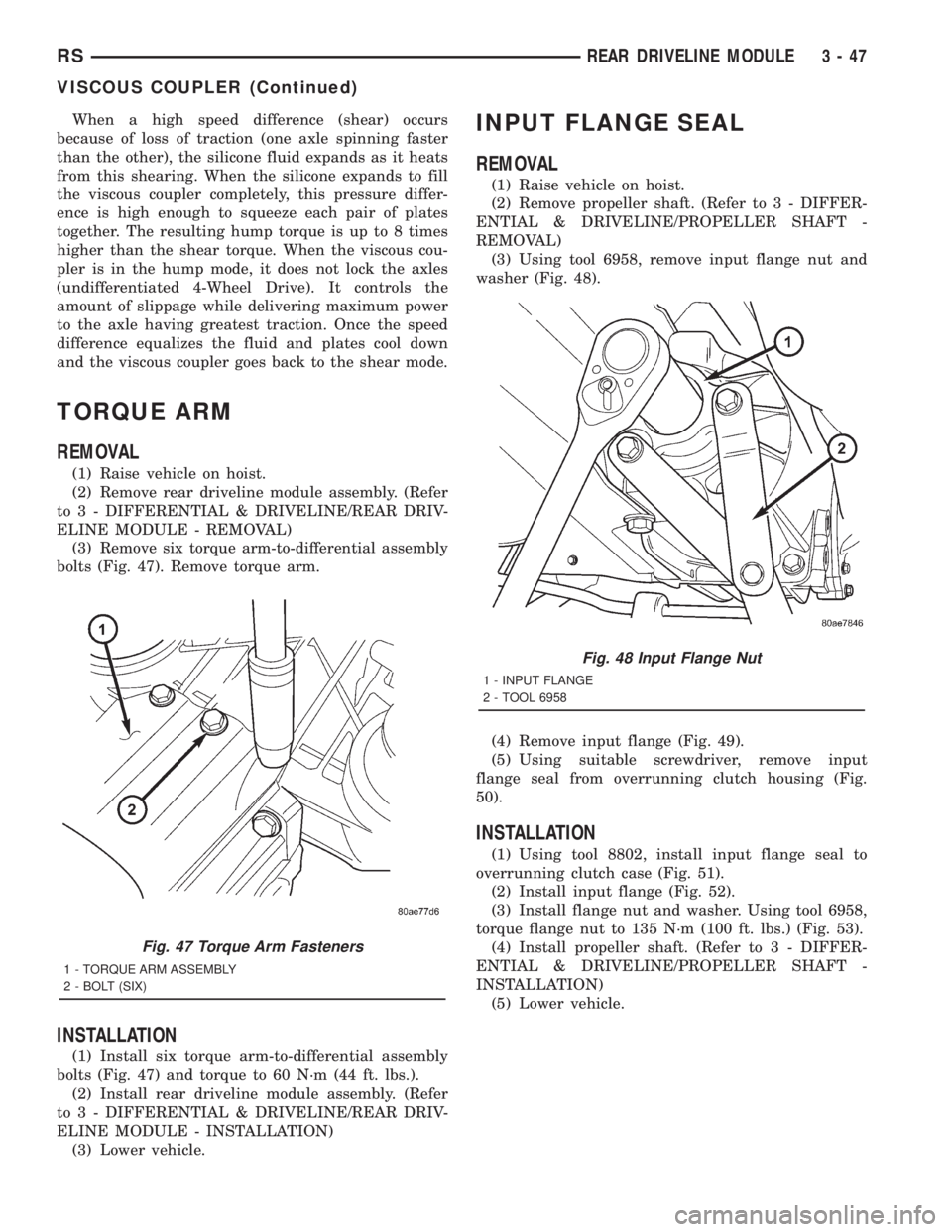

(3) Remove six torque arm-to-differential assembly

bolts (Fig. 47). Remove torque arm.

INSTALLATION

(1) Install six torque arm-to-differential assembly

bolts (Fig. 47) and torque to 60 N´m (44 ft. lbs.).

(2) Install rear driveline module assembly. (Refer

to 3 - DIFFERENTIAL & DRIVELINE/REAR DRIV-

ELINE MODULE - INSTALLATION)

(3) Lower vehicle.

INPUT FLANGE SEAL

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT -

REMOVAL)

(3) Using tool 6958, remove input flange nut and

washer (Fig. 48).

(4) Remove input flange (Fig. 49).

(5) Using suitable screwdriver, remove input

flange seal from overrunning clutch housing (Fig.

50).

INSTALLATION

(1) Using tool 8802, install input flange seal to

overrunning clutch case (Fig. 51).

(2) Install input flange (Fig. 52).

(3) Install flange nut and washer. Using tool 6958,

torque flange nut to 135 N´m (100 ft. lbs.) (Fig. 53).

(4) Install propeller shaft. (Refer to 3 - DIFFER-

ENTIAL & DRIVELINE/PROPELLER SHAFT -

INSTALLATION)

(5) Lower vehicle.

Fig. 47 Torque Arm Fasteners

1 - TORQUE ARM ASSEMBLY

2 - BOLT (SIX)

Fig. 48 Input Flange Nut

1 - INPUT FLANGE

2 - TOOL 6958

RSREAR DRIVELINE MODULE3-47

VISCOUS COUPLER (Continued)

Page 1648 of 4284

(20) Road test vehicle. The automatic adjuster will

continue the brake adjustment during the road test

of the vehicle.

ADJUSTMENT - REAR DRUM BRAKE SHOES

NOTE: Normally, self-adjusting drum brakes do not

require manual brake shoe adjustment. Although, in

the event of a brake shoe replacement, it is advis-

able to make the initial adjustment manually to

speed up the adjusting time.

NOTE: Before raising the vehicle, verify the parking

brake lever is fully released.

(1) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(2) Remove rubber plug from rear brake adjusting

hole in the rear brake support plate.

(3) Insert a thin screwdriver through the adjusting

hole in the support plate and against the star wheel

of the adjusting screw. Move handle of the tool

upward rotating the star wheel until a slight drag is

felt when tire and wheel assembly is rotated.

(4) Insert a second thin screwdriver or piece of

welding rod into brake adjusting hole and push the

adjusting lever out of engagement with the star

wheel.Care should be taken so as not to bend

adjusting lever or distort lever spring.

(5) While holding the adjusting lever out of

engagement, back off the star wheel just enough to

ensure a free wheel with no brake shoe drag.

(6) Repeat the above adjustment at the other rear

wheel.

(7) Install the adjusting hole rubber plugs back in

the rear brake support plates.

(8) Lower the vehicle.

DISC BRAKE CALIPERS -

FRONT

REMOVAL - FRONT DISC BRAKE CALIPER

(DISC/DISC BRAKES)

(1) Depress the brake pedal past its first inch of

travel and hold it in this position using a brake pedal

depressor (holding) tool. This is done to isolate the

master cylinder from the brake hydraulic system dis-

allowing the brake fluid to completely drain out of

the brake fluid reservoir.

(2) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(3) Remove front wheel and tire assembly.(4) Remove the banjo bolt connecting the brake

hose to the brake caliper. There are two washers (one

on each side of the brake hose fitting) that will come

off with the banjo bolt. Discard these washers.

(5) Remove the 2 caliper guide pin bolts.

(6) Remove the brake caliper from the adapter.

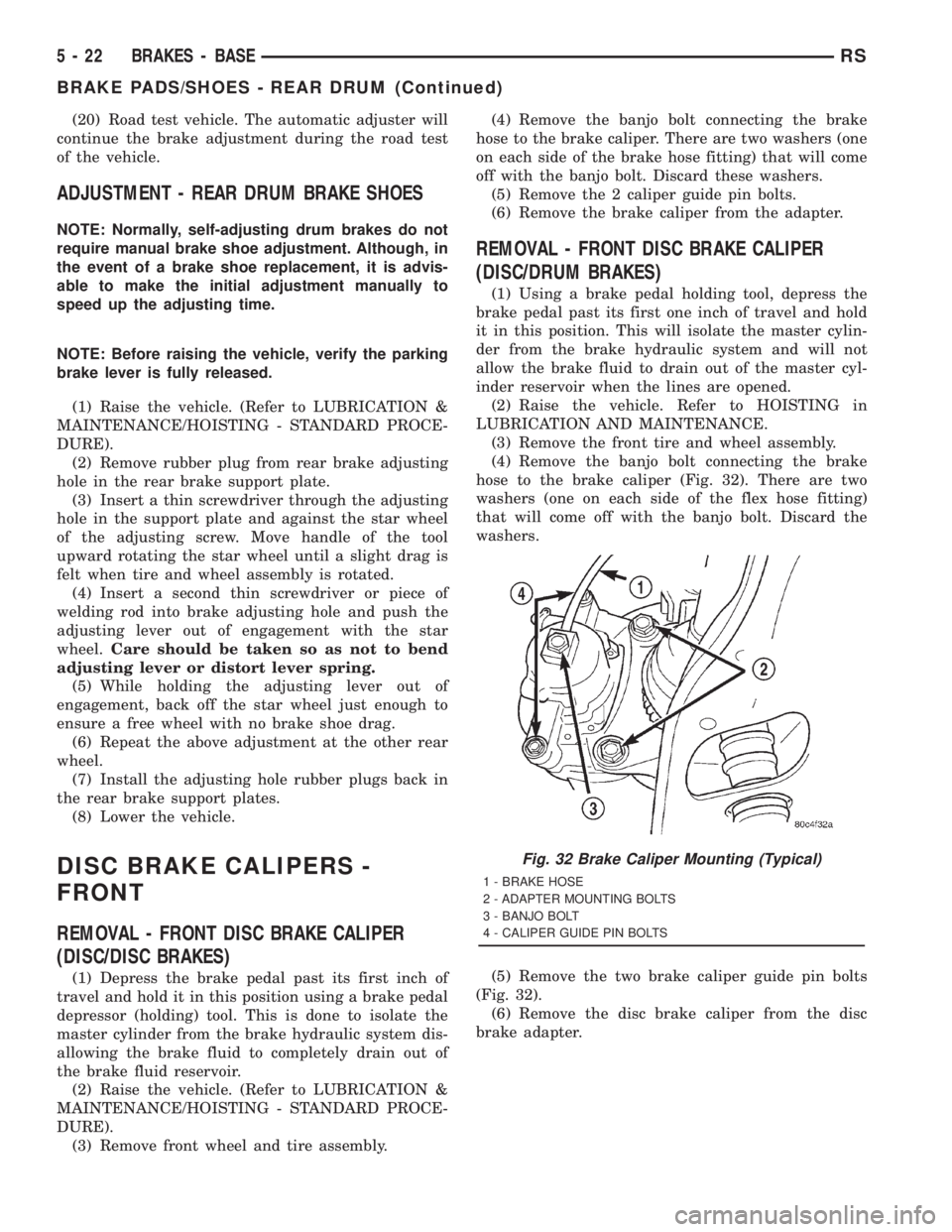

REMOVAL - FRONT DISC BRAKE CALIPER

(DISC/DRUM BRAKES)

(1) Using a brake pedal holding tool, depress the

brake pedal past its first one inch of travel and hold

it in this position. This will isolate the master cylin-

der from the brake hydraulic system and will not

allow the brake fluid to drain out of the master cyl-

inder reservoir when the lines are opened.

(2) Raise the vehicle. Refer to HOISTING in

LUBRICATION AND MAINTENANCE.

(3) Remove the front tire and wheel assembly.

(4) Remove the banjo bolt connecting the brake

hose to the brake caliper (Fig. 32). There are two

washers (one on each side of the flex hose fitting)

that will come off with the banjo bolt. Discard the

washers.

(5) Remove the two brake caliper guide pin bolts

(Fig. 32).

(6) Remove the disc brake caliper from the disc

brake adapter.

Fig. 32 Brake Caliper Mounting (Typical)

1 - BRAKE HOSE

2 - ADAPTER MOUNTING BOLTS

3 - BANJO BOLT

4 - CALIPER GUIDE PIN BOLTS

5 - 22 BRAKES - BASERS

BRAKE PADS/SHOES - REAR DRUM (Continued)

Page 1652 of 4284

(10) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoe linings.

INSTALLATION - FRONT DISC BRAKE CALIPER

(DISC/DRUM BRAKES)

CAUTION: TRW and Continental Teves brake cali-

pers are not interchangeable. Each caliper is specif-

ically designed for the unique brake system (TRW -

disc/drum brake combination and Continental Teves

- disc/disc brake combination). If calipers are inter-

changed, improper performance, noise and

increased stopping distance can occur.

(1) Completely retract the caliper piston back into

the bore of the caliper. Use a C-clamp to retract the

piston if necessary. Place a wood block over the pis-

ton before installing the C-clamp to avoid damaging

the piston.

CAUTION: Use care when installing the caliper onto

the disc brake adapter to avoid damaging the boots

on the caliper guide pins.

(2) Install the disc brake caliper over the brake

shoes on the brake caliper adapter.

(3) Align the caliper guide pin bolt holes with the

guide pins. Install the caliper guide pin bolts and

tighten them to a torque of 35 N´m (26 ft. lbs.) (Fig.

32).

(4) Install the banjo bolt connecting the brake hose

to the brake caliper (Fig. 32). Install NEW copper

washers on each side of the hose fitting as the banjo

bolt is guided through the fitting. Thread the banjo

bolt into the caliper and tighten it to a torque of 47

N´m (35 ft. lbs.).

(5) Install the tire and wheel assembly. Tighten

the wheel mounting nuts to a torque of 135 N´m (100

ft. lbs.).

(6) Lower the vehicle.

(7) Remove the brake pedal holding tool.

(8) Bleed the caliper as necessary. (Refer to 5 -

BRAKES - BASE - STANDARD PROCEDURE).

(9) Road test the vehicle and make several stops to

wear off any foreign material on the brakes and to

seat the brake shoes.

DISC BRAKE CALIPERS -

REAR

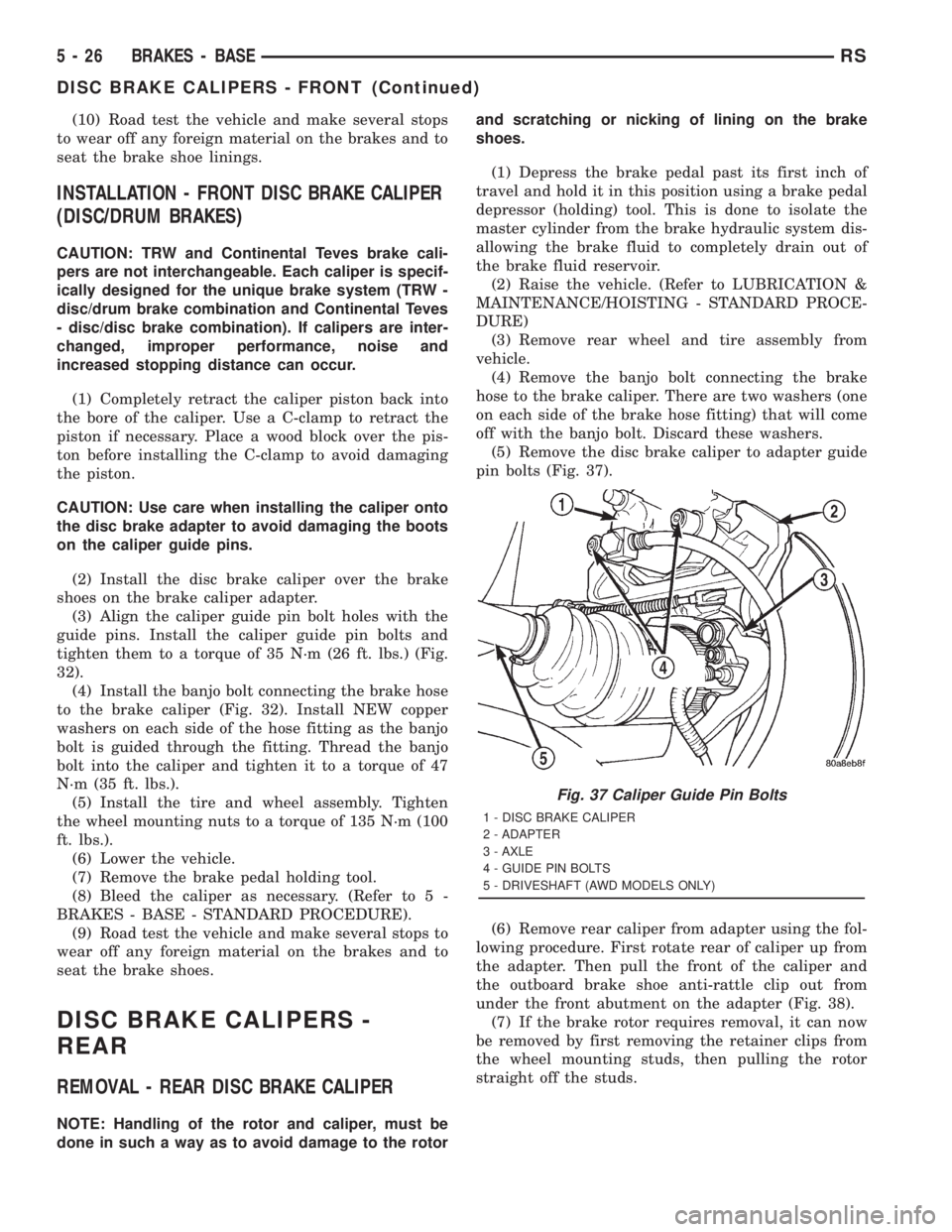

REMOVAL - REAR DISC BRAKE CALIPER

NOTE: Handling of the rotor and caliper, must be

done in such a way as to avoid damage to the rotorand scratching or nicking of lining on the brake

shoes.

(1) Depress the brake pedal past its first inch of

travel and hold it in this position using a brake pedal

depressor (holding) tool. This is done to isolate the

master cylinder from the brake hydraulic system dis-

allowing the brake fluid to completely drain out of

the brake fluid reservoir.

(2) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(3) Remove rear wheel and tire assembly from

vehicle.

(4) Remove the banjo bolt connecting the brake

hose to the brake caliper. There are two washers (one

on each side of the brake hose fitting) that will come

off with the banjo bolt. Discard these washers.

(5) Remove the disc brake caliper to adapter guide

pin bolts (Fig. 37).

(6) Remove rear caliper from adapter using the fol-

lowing procedure. First rotate rear of caliper up from

the adapter. Then pull the front of the caliper and

the outboard brake shoe anti-rattle clip out from

under the front abutment on the adapter (Fig. 38).

(7) If the brake rotor requires removal, it can now

be removed by first removing the retainer clips from

the wheel mounting studs, then pulling the rotor

straight off the studs.

Fig. 37 Caliper Guide Pin Bolts

1 - DISC BRAKE CALIPER

2 - ADAPTER

3 - AXLE

4 - GUIDE PIN BOLTS

5 - DRIVESHAFT (AWD MODELS ONLY)

5 - 26 BRAKES - BASERS

DISC BRAKE CALIPERS - FRONT (Continued)

Page 1664 of 4284

DIAGNOSIS AND TESTING - POWER BRAKE

BOOSTER

BASIC TEST

(1) With engine off, depress and release the brake

pedal several times to purge all vacuum from the

power brake booster.

(2) Depress and hold the pedal with light effort (15

to 25 lbs. pressure), then start the engine.

The pedal should fall slightly, then hold. Less effort

should be needed to apply the pedal at this time. If

the pedal fell as indicated, perform the VACUUM

LEAK TEST listed after the BASIC TEST. If the

pedal did not fall, continue on with this BASIC TEST.

(3) Disconnect the vacuum hose on the vacuum

check valve, then place a vacuum gauge in line

between the vacuum hose and the valve.

(4) Start the engine.

(5) When the engine is at warm operating temper-

ature, allow it to idle and check the vacuum at the

gauge.

If the vacuum supply is 12 inches Hg (40.5 kPa) or

more, the power brake booster is defective and must

be replaced. If the vacuum supply is below 12 inches

Hg, continue on with this BASIC TEST.

(6) Shut off the engine.

(7) Connect the vacuum gauge to the vacuum ref-

erence port on the engine intake manifold.

(8) Start the engine and observe the vacuum

gauge.

If the vacuum is still low, check the engine tune

and repair as necessary. If the vacuum is above 12

inches Hg, the hose or check valve to the booster has

a restriction or leak.

Once an adequate vacuum supply is obtained,

repeat the BASIC TEST.

VACUUM LEAK TEST

(1) Disconnect the vacuum hose on the vacuum

check valve, then place a vacuum gauge in line

between the vacuum hose and the valve.

(2) Start the engine.

(3) Allow the engine to warm up to normal operat-

ing temperature and engine idle.

(4) Using vacuum line pliers, close off the vacuum

supply hose near the booster, but before the vacuum

gauge, then observe the vacuum gauge.

If the vacuum drop exceeds 1.0 inch Hg (3.3 kPa)

in one minute, repeat the above steps to confirm the

reading. The vacuum loss should be less than 1.0

inch Hg in one minute time span. If the loss is more

than 1.0 inch Hg, replace the power brake booster. If

it is not, continue on with this test.

(5) Remove the pliers from the hose temporarily.

(6) Apply light effort (approximately 15 lbs. of

force) to the brake pedal and hold the pedal steady.Do not move the pedal once the pressure is applied

or the test results may vary.

(7) Have an assistant reattach the vacuum line

pliers to the vacuum supply hose.

(8) Allow 5 seconds for stabilization, then observe

the vacuum gauge.

If the vacuum drop exceeds 3.0 inches Hg (10 kPa)

in 15 seconds, repeat the above steps to confirm the

reading. The vacuum loss should be less than 3.0

inches Hg in 15 seconds time span. If the loss is

more than 3.0 inches Hg, replace the power brake

booster. If it is not, the booster is not defective.

(9) Remove the pliers and vacuum gauge.

REMOVAL - POWER BRAKE BOOSTER

CAUTION: Reserve vacuum in power brake booster

must be pumped down (removed) before removing

master cylinder from booster. This is necessary to

prevent booster from sucking in any contamination

as master cylinder is removed. This can be done

simply by pumping the brake pedal, with the vehi-

cle's engine not running, until a firm feeling brake

pedal is achieved.

(1) With engine not running, pump the brake

pedal until a firm pedal is achieved (4-5 strokes).

(2) Remove negative battery cable terminal from

battery.

(3) Remove positive battery cable terminal from

battery.

(4) Remove battery thermal guard shield.

(5) Remove battery clamp, nut and battery from

the battery tray.

(6) Remove screw securing engine coolant filler

tube to battery tray.

(7) If the vehicle is equipped with speed control,

disconnect the vacuum hose at the vacuum tank built

into the battery tray.

(8) Remove the two nuts and one bolt securing bat-

tery tray in place. Remove battery tray.

(9) If vehicle is equipped with speed control:

(a) Disconnect wiring harness connector from

the speed control servo.

(b) Remove the two servo mounting nuts.

(c) Lay speed control servo off to the side, out of

the way.

(10) Remove the wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL)

(11) Disconnect wiring harness connector from

brake fluid level switch in master cylinder fluid res-

ervoir (Fig. 54).

5 - 38 BRAKES - BASERS

POWER BRAKE BOOSTER (Continued)

Page 1667 of 4284

CAUTION: The master cylinder (and its rear seal) is

used to create the seal for holding vacuum in the

vacuum booster. The vacuum seal on the master

cylinder MUST be replaced with a NEW seal when-

ever the master cylinder is removed from the vac-

uum booster.

CAUTION: When removing the vacuum seal from

the master cylinder do not use a sharp tool.

(8) Using a soft tool such as a trim stick, remove

the vacuum seal from the master cylinder mounting

flange.

(9) Install a NEW vacuum seal on rear mounting

flange of the master cylinder (Fig. 60).

(10) Position master cylinder on studs of booster,

aligning push rod on booster with master cylinder

piston.

(11) Install the two nuts mounting the master cyl-

inder to the booster (Fig. 55). Tighten both mounting

nuts to a torque of 25 N´m (225 in. lbs.).

(12) Connect wiring harness connector to brake

fluid level switch in the master cylinder fluid reser-

voir (Fig. 54).

(13) Connect primary and secondary brake tubes

to ABS ICU or non-ABS junction block (Fig. 55).

Tighten the tube nuts to 17 N´m (145 in lbs.).

(14) Install wiper module (unit). (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION)

(15) If equipped with speed control, install speed

control servo and connect wiring connector. Tighten

the mounting nuts to a torque of 14 N´m (124 in.

lbs.).(16) Install the battery tray. Install the two nuts

and one bolt attaching the battery tray to the vehicle.

Tighten the bolt and nuts to a torque of 14 N´m (124

in. lbs.).

(17) If vehicle is equipped with speed control, con-

nect the servo vacuum hose to the vacuum tank on

the battery tray.

(18) Install the air inlet resonator and hoses as an

assembly on the throttle body and air cleaner hous-

ing. Securely tighten hose clamp at air cleaner hous-

ing and throttle body.

(19) Secure the engine coolant filler neck to the

battery tray with its mounting screw.

(20) Install the battery, clamp and mounting nut.

(21) Install the positive battery cable on the bat-

tery.

(22) Install the negative battery cable on the bat-

tery.

(23) Install the battery thermal guard shield.

(24) Bleed the base brakes as necessary. (Refer to

5 - BRAKES - STANDARD PROCEDURE)

(25) Road test vehicle to ensure operation of the

brakes.

PROPORTIONING VALVE

DESCRIPTION - PROPORTIONING VALVE

(HEIGHT SENSING)

NOTE: Only vehicles without antilock brakes (ABS)

have a proportioning valve. Vehicles with ABS uti-

lize electronic brake distribution which is controlled

through the ABS integrated control unit.

Vehicles not equipped with ABS use a height sens-

ing proportioning valve. It is mounted to the body of

the vehicle above the rear axle (Fig. 61). It has an

actuator lever that attaches to the rear axle and

moves with the axle to help the valve sense the vehi-

cle height.

CAUTION: The height sensing proportioning valve

is not adjustable. No attempt should be made to

adjust it. It is replaced as a complete assembly.

CAUTION: The use of after-market load leveling or

load capacity increasing devices on this vehicle are

prohibited. Using air shock absorbers or helper

springs on this vehicle will cause the height sens-

ing proportioning valve to inappropriately reduce

the hydraulic pressure to the rear brakes. This inap-

propriate reduction in hydraulic pressure potentially

could result in increased stopping distance of the

vehicle.

Fig. 60 Vacuum Seal (Typical)

1 - MASTER CYLINDER ASSEMBLY

2 - VACUUM SEAL

RSBRAKES - BASE5-41

POWER BRAKE BOOSTER (Continued)

Page 1830 of 4284

²Front Fog Lamp Relay Actuation

²Front and Rear Blower Motor Relay Actuation

²Accessory Relay Actuation

²Electronic Back Light (EBL) Rear Defogger

²Horn Relay Actuation

²Park Lamp Relay Actuation

²Name Brand Speaker (NBS) Relay Actuation

²Headlamp Washer Relay Actuation

²Diesel Cabin Heater (Diesel Engine Vehicles)

The following inputs areReceived/Monitoredby

the Front Control Module:

²B+ Connection Detection

²Ambient Temperature Sensing

²Right/Left Park Lamp Outage

²Ignition Switch Start Only

²Ignition Switch Run and Start Only

²Washer Fluid Level

²Windshield Wiper Park

²Brake Fluid Level

²Back-Up switch

²Stop Lamp Sense

²Engine Crank Signal (Diesel Engine Vehicles)

²Horn Input

DIAGNOSIS AND TESTING - FRONT CONTROL

MODULE

The front control module is a printed circuit board

based module with a on-board micro-processor. The

front control module interfaces with other electronic

modules in the vehicle via the Programmable Com-

munications Interface (PCI) data bus (J1850). In

order to obtain conclusive testing the Programmable

Communications Interface (PCI) data bus network

and all of the electronic modules that provide inputs

to, or receive outputs from the front control module

must be checked. All PCI (J1850) communication

faults must be resolved prior to further diagnosing

any front control module related issues.

The front control module was designed to be diag-

nosed with an appropriate diagnostic scan tool, such

as the DRB IIIt. The most reliable, efficient, and

accurate means to diagnose the front control module

requires the use of a DRB IIItscan tool and the

proper Body Diagnostic Procedures manual.

Before any testing of the front control module is

attempted, the battery should be fully charged and

all wire harness and ground connections inspected

around the affected areas on the vehicle.

REMOVAL

(1) Disconnect the positive and negative battery

cables from the battery.

(2) Remove the battery from the vehicle. Refer to

the procedure in Battery Systems.(3) Using a long flat-pladed screwdriver, gently

twist the Intelligent Power Module (IPM) retaining

clip outboard to free the intelligent power module

from its mounting bracket (Fig. 6). Rotate intelligent

power module upward to access the Front Control

Module (FCM) retaining screws.

(4) Remove the front control module retaining

screws.

(5) Using both hands, pull the front control module

straight from the intelligent power module assembly

to disconnect the 49-way electrical connector (Fig. 7)

and remove the front control module from the vehi-

cle.

INSTALLATION

(1) Install the front control module in the intelli-

gent power module assembly by pushing the 49-way

electrical connector straight in (Fig. 7).

(2) Install the front control module retaining

screws. Torque the screws to 7 in. lbs.

(3) Rotate the intelligent power module assembly

downward to secure in mounting bracket.

(4) Install the battery in the vehicle. Refer to the

procedure in Battery Systems.

(5) Connect the positive and negative battery

cables.

NOTE: If the vehicle is not equipped with Name

Brand Speakers (NBS, Infinity) or Headlamp Wash-

ers the DRB IIITmust be used to Disable the appro-

priate relays in the Intelligent Power Module

Assembly.

Fig. 6 REMOVING INTELLIGENT POWER MODULE

8E - 6 ELECTRONIC CONTROL MODULESRS

FRONT CONTROL MODULE (Continued)

Page 1927 of 4284

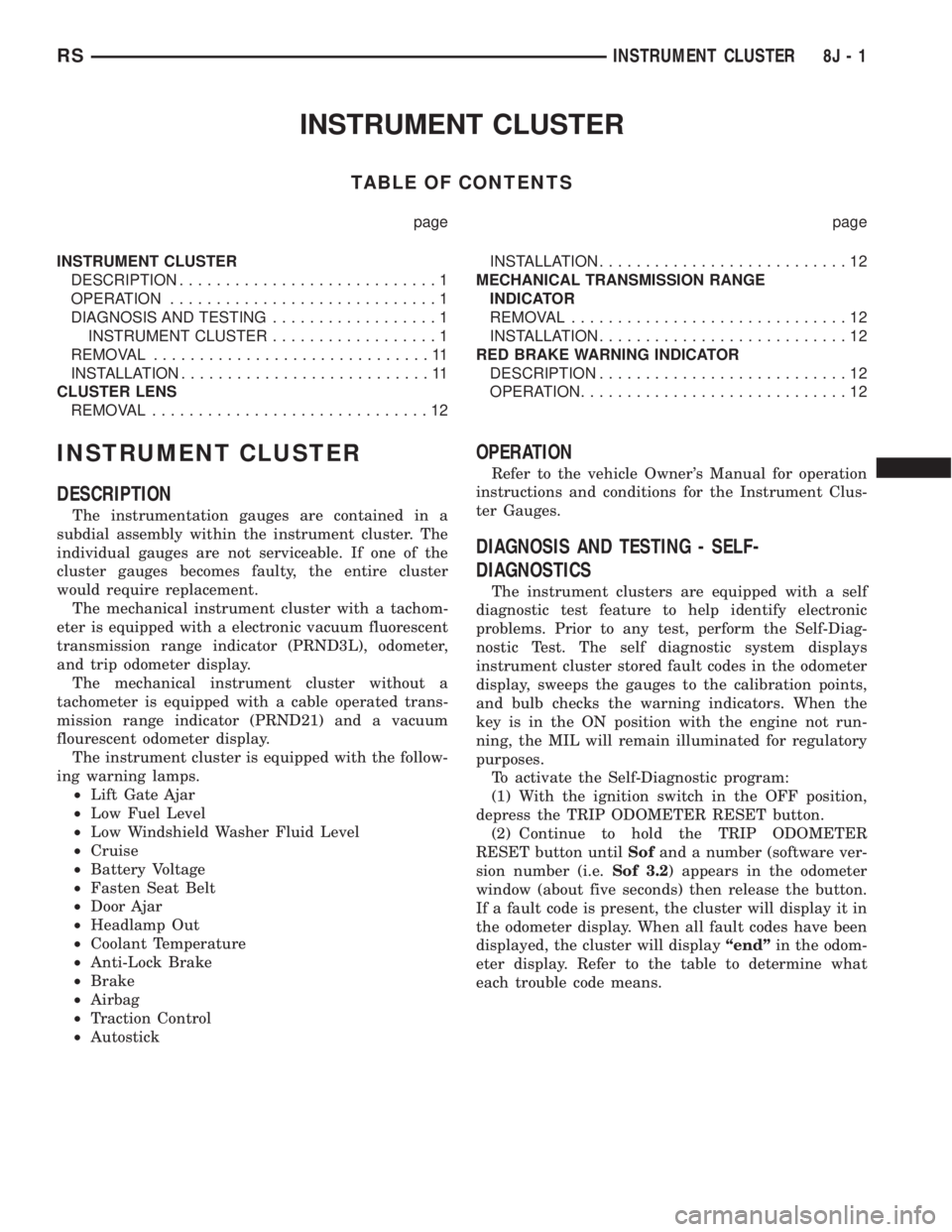

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................1

INSTRUMENT CLUSTER..................1

REMOVAL..............................11

INSTALLATION...........................11

CLUSTER LENS

REMOVAL..............................12INSTALLATION...........................12

MECHANICAL TRANSMISSION RANGE

INDICATOR

REMOVAL..............................12

INSTALLATION...........................12

RED BRAKE WARNING INDICATOR

DESCRIPTION...........................12

OPERATION.............................12

INSTRUMENT CLUSTER

DESCRIPTION

The instrumentation gauges are contained in a

subdial assembly within the instrument cluster. The

individual gauges are not serviceable. If one of the

cluster gauges becomes faulty, the entire cluster

would require replacement.

The mechanical instrument cluster with a tachom-

eter is equipped with a electronic vacuum fluorescent

transmission range indicator (PRND3L), odometer,

and trip odometer display.

The mechanical instrument cluster without a

tachometer is equipped with a cable operated trans-

mission range indicator (PRND21) and a vacuum

flourescent odometer display.

The instrument cluster is equipped with the follow-

ing warning lamps.

²Lift Gate Ajar

²Low Fuel Level

²Low Windshield Washer Fluid Level

²Cruise

²Battery Voltage

²Fasten Seat Belt

²Door Ajar

²Headlamp Out

²Coolant Temperature

²Anti-Lock Brake

²Brake

²Airbag

²Traction Control

²Autostick

OPERATION

Refer to the vehicle Owner's Manual for operation

instructions and conditions for the Instrument Clus-

ter Gauges.

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic

problems. Prior to any test, perform the Self-Diag-

nostic Test. The self diagnostic system displays

instrument cluster stored fault codes in the odometer

display, sweeps the gauges to the calibration points,

and bulb checks the warning indicators. When the

key is in the ON position with the engine not run-

ning, the MIL will remain illuminated for regulatory

purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window (about five seconds) then release the button.

If a fault code is present, the cluster will display it in

the odometer display. When all fault codes have been

displayed, the cluster will displayªendºin the odom-

eter display. Refer to the table to determine what

each trouble code means.

RSINSTRUMENT CLUSTER8J-1

Page 1957 of 4284

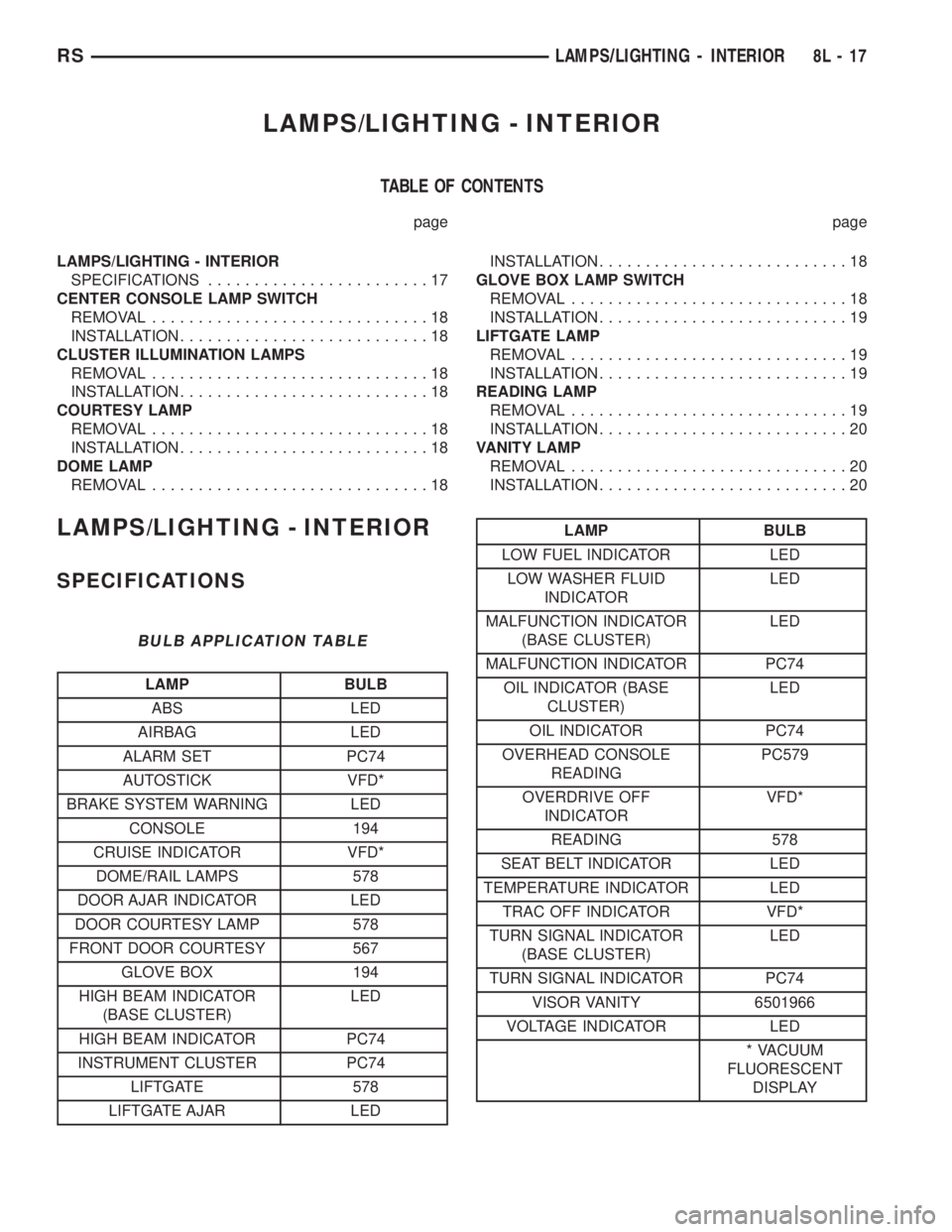

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS........................17

CENTER CONSOLE LAMP SWITCH

REMOVAL..............................18

INSTALLATION...........................18

CLUSTER ILLUMINATION LAMPS

REMOVAL..............................18

INSTALLATION...........................18

COURTESY LAMP

REMOVAL..............................18

INSTALLATION...........................18

DOME LAMP

REMOVAL..............................18INSTALLATION...........................18

GLOVE BOX LAMP SWITCH

REMOVAL..............................18

INSTALLATION...........................19

LIFTGATE LAMP

REMOVAL..............................19

INSTALLATION...........................19

READING LAMP

REMOVAL..............................19

INSTALLATION...........................20

VANITY LAMP

REMOVAL..............................20

INSTALLATION...........................20

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

BULB APPLICATION TABLE

LAMP BULB

ABS LED

AIRBAG LED

ALARM SET PC74

AUTOSTICK VFD*

BRAKE SYSTEM WARNING LED

CONSOLE 194

CRUISE INDICATOR VFD*

DOME/RAIL LAMPS 578

DOOR AJAR INDICATOR LED

DOOR COURTESY LAMP 578

FRONT DOOR COURTESY 567

GLOVE BOX 194

HIGH BEAM INDICATOR

(BASE CLUSTER)LED

HIGH BEAM INDICATOR PC74

INSTRUMENT CLUSTER PC74

LIFTGATE 578

LIFTGATE AJAR LED

LAMP BULB

LOW FUEL INDICATOR LED

LOW WASHER FLUID

INDICATORLED

MALFUNCTION INDICATOR

(BASE CLUSTER)LED

MALFUNCTION INDICATOR PC74

OIL INDICATOR (BASE

CLUSTER)LED

OIL INDICATOR PC74

OVERHEAD CONSOLE

READINGPC579

OVERDRIVE OFF

INDICATORVFD*

READING 578

SEAT BELT INDICATOR LED

TEMPERATURE INDICATOR LED

TRAC OFF INDICATOR VFD*

TURN SIGNAL INDICATOR

(BASE CLUSTER)LED

TURN SIGNAL INDICATOR PC74

VISOR VANITY 6501966

VOLTAGE INDICATOR LED

* VACUUM

FLUORESCENT

DISPLAY

RSLAMPS/LIGHTING - INTERIOR8L-17

Page 2082 of 4284

INSTALLATION

(1) Install rear window wiper motor. (Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/REAR WIPER

MOTOR - INSTALLATION).

(2) Peel wiper pivot seal grommet from rear glass.

(3) Install grommets from (Fig. 11).

WASHER RESERVOIR

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Hoist and support vehicle on safety stands.

(3) Remove the right front wheel (Refer to 22 -

TIRES/WHEELS - REMOVAL).

(4) Remove front wheelhouse splash shield.

(5) Disconnect connectors from the front wind-

shield and rear window washer pumps, the fluid

level sensor, and the rear washer hose (Fig. 12).

(6) If washer bottle has fluid in it place a suitable

drain pan under the hose connections.

(7) Disconnect the front washer hose at the front

wiper unit in the engine compartment (Fig. 13). The

front hose will be removed with the bottle.

(8) Allow the washer bottle to drain.

(9) Remove the screws holding the washer bottle to

the front fender support and remove the bottle.

INSTALLATION

(1) Place the washer bottle in position and attach

to the front fender support using proper screws.

(2) Connect the front washer hose at the front

wiper unit in the engine compartment (Fig. 13).

(3) Connect the front windshield and the rear win-

dow washer pumps, fluid level sensor and the rear

washer hose (Fig. 12).

(4) Install the front wheelhouse splashshield.

(5) Install the right front wheel (Refer to 22 -

TIRES/WHEELS - INSTALLATION).

(6) Lower the vehicle.

Fig. 11 REAR GLASS RUBBER GROMMET

1 - WIPER MOTOR PIVOT GROMMET

Fig. 12 WINDSHIELD WASHER BOTTLE - TYPICAL

1 - INNER FENDER

2 - FRONT FASCIA

3 - REAR PUMP

4 - FRONT PUMP

5 - WINDSHIELD AND REAR WINDOW WASHER BOTTLE

Fig. 13 (TYPICAL) Front Washer Hose

1 - WINDSHIELD WASHER BOTTLE

2 - FRONT WINDSHIELD WASHER HOSE

8R - 8 WIPERS/WASHERSRS

WASHER HOSES (Continued)