heating CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4037 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Turn the ignition on.

Measure the voltage of the A/C Pressure Sensor Signal circuit in the A/C Pressure

Sensor harness connector.

Is the voltage above 5.2 volts?All

Ye s®Repair the A/C Pressure Sensor Signal circuit for a short to

battery voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Go To 4

4 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Connect a jumper wire between the A/C Pressure Sensor Signal circuit and the

Sensor ground circuit.

With the DRBIIIt, monitor the A/C Pressure Sensor voltage.

Turn the ignition on.

Is the voltage below 1.0 volts?All

Ye s®Replace the A/C Pressure Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Go To 5

5 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the A/C Pressure Sensor Signal circuit between the A/C

Pressure Sensor harness connector and the PCM harness connector.

Is the resistance below 5 ohms?All

Ye s®Go To 6

No®Repair the A/C Pressure Sensor Signal circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

6 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Measure the resistance of the Sensor ground circuit in the A/C Pressure Sensor

harness connector to ground.

Is the resistance below 30 ohms?All

Ye s®Go To 7

No®Repair the Sensor ground circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

7 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module Module in

accordance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

243

HEATING & A/C

P1598-A/C PRESSURE SENSOR VOLTS TOO HIGH ÐContinued

Page 4038 of 4284

TEST ACTION APPLICABILITY

8NOTE: Ensure the A/C refrigerant System is properly charged per the

Service Information.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Test Complete.

244

HEATING & A/C

P1598-A/C PRESSURE SENSOR VOLTS TOO HIGH ÐContinued

Page 4039 of 4284

Symptom:

P1599-A/C PRESSURE SENSOR VOLTS TOO LOW

When Monitored and Set Condition:

P1599-A/C PRESSURE SENSOR VOLTS TOO LOW

When Monitored: Engine running. The A/C relay energized.

Set Condition: The A/C pressure sensor signal voltage at the PCM goes below 0.58 volts

for 2.6 seconds.

POSSIBLE CAUSES

INTERMITTENT CONDITION

5 VOLT SUPPLY CIRCUIT SHORTED TO GROUND

5 VOLT SUPPLY CIRCUIT OPEN

A/C PRESSURE SENSOR INTERNAL FAILURE

A/C PRESSURE SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

A/C PRESSURE SENSOR SIGNAL CIRCUIT SHORTED TO SENSOR GROUND CIRCUIT

PCM 5 VOLT SUPPLY CIRCUIT

PCM A/C PRESSURE SENSOR SIGNAL

TEST ACTION APPLICABILITY

1NOTE: Ensure the A/C refrigerant System is properly charged per the

Service Information.

Start the engine.

With the DRBIIIt, read the A/C Pressure Sensor voltage.

Is the voltage below 0.6 volts.All

Ye s®Go To 2

No®Go To 10

2 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Turn the ignition on.

Measure the voltage of the 5 Volt Supply circuit in the A/C Pressure Sensor harness

connector.

Is the voltage between 4.5 to 5.2 volts?All

Ye s®Go To 3

No®Go To 7

245

HEATING & A/C

Page 4040 of 4284

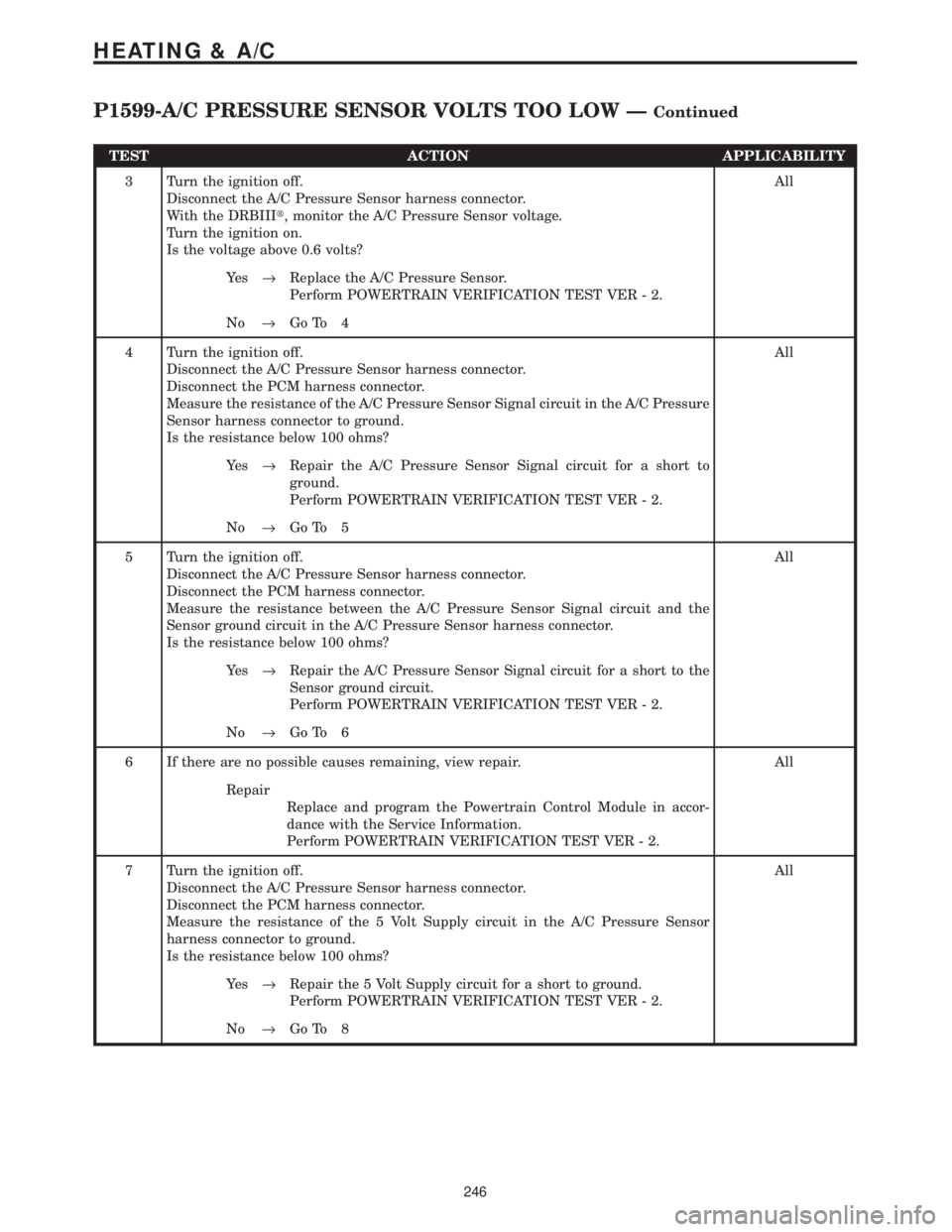

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

With the DRBIIIt, monitor the A/C Pressure Sensor voltage.

Turn the ignition on.

Is the voltage above 0.6 volts?All

Ye s®Replace the A/C Pressure Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Go To 4

4 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the A/C Pressure Sensor Signal circuit in the A/C Pressure

Sensor harness connector to ground.

Is the resistance below 100 ohms?All

Ye s®Repair the A/C Pressure Sensor Signal circuit for a short to

ground.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Go To 5

5 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance between the A/C Pressure Sensor Signal circuit and the

Sensor ground circuit in the A/C Pressure Sensor harness connector.

Is the resistance below 100 ohms?All

Ye s®Repair the A/C Pressure Sensor Signal circuit for a short to the

Sensor ground circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Go To 6

6 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

7 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the 5 Volt Supply circuit in the A/C Pressure Sensor

harness connector to ground.

Is the resistance below 100 ohms?All

Ye s®Repair the 5 Volt Supply circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Go To 8

246

HEATING & A/C

P1599-A/C PRESSURE SENSOR VOLTS TOO LOW ÐContinued

Page 4041 of 4284

TEST ACTION APPLICABILITY

8 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the 5 Volt Supply circuit between the A/C Pressure Sensor

harness connector and the PCM harness connector.

Is the resistance below 5 ohms?All

Ye s®Go To 9

No®Repair the 5 Volt Supply circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

9 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

10NOTE: Ensure the A/C refrigerant System is properly charges per the

Service Information.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Test Complete.

247

HEATING & A/C

P1599-A/C PRESSURE SENSOR VOLTS TOO LOW ÐContinued

Page 4124 of 4284

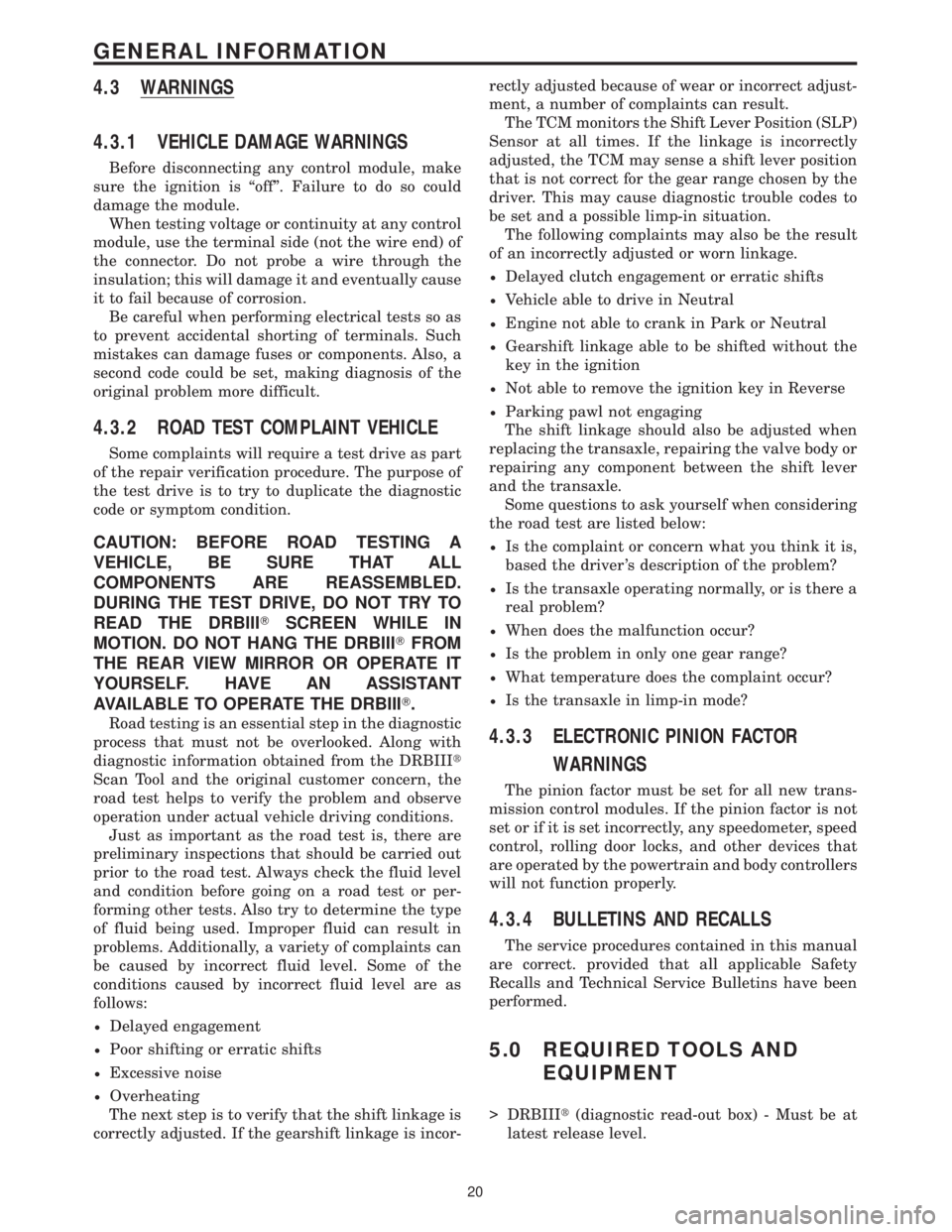

4.3 WARNINGS

4.3.1 VEHICLE DAMAGE WARNINGS

Before disconnecting any control module, make

sure the ignition is ªoffº. Failure to do so could

damage the module.

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

4.3.2 ROAD TEST COMPLAINT VEHICLE

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

CAUTION: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED.

DURING THE TEST DRIVE, DO NOT TRY TO

READ THE DRBIIITSCREEN WHILE IN

MOTION. DO NOT HANG THE DRBIIITFROM

THE REAR VIEW MIRROR OR OPERATE IT

YOURSELF. HAVE AN ASSISTANT

AVAILABLE TO OPERATE THE DRBIIIT.

Road testing is an essential step in the diagnostic

process that must not be overlooked. Along with

diagnostic information obtained from the DRBIIIt

Scan Tool and the original customer concern, the

road test helps to verify the problem and observe

operation under actual vehicle driving conditions.

Just as important as the road test is, there are

preliminary inspections that should be carried out

prior to the road test. Always check the fluid level

and condition before going on a road test or per-

forming other tests. Also try to determine the type

of fluid being used. Improper fluid can result in

problems. Additionally, a variety of complaints can

be caused by incorrect fluid level. Some of the

conditions caused by incorrect fluid level are as

follows:

²Delayed engagement

²Poor shifting or erratic shifts

²Excessive noise

²Overheating

The next step is to verify that the shift linkage is

correctly adjusted. If the gearshift linkage is incor-rectly adjusted because of wear or incorrect adjust-

ment, a number of complaints can result.

The TCM monitors the Shift Lever Position (SLP)

Sensor at all times. If the linkage is incorrectly

adjusted, the TCM may sense a shift lever position

that is not correct for the gear range chosen by the

driver. This may cause diagnostic trouble codes to

be set and a possible limp-in situation.

The following complaints may also be the result

of an incorrectly adjusted or worn linkage.

²Delayed clutch engagement or erratic shifts

²Vehicle able to drive in Neutral

²Engine not able to crank in Park or Neutral

²Gearshift linkage able to be shifted without the

key in the ignition

²Not able to remove the ignition key in Reverse

²Parking pawl not engaging

The shift linkage should also be adjusted when

replacing the transaxle, repairing the valve body or

repairing any component between the shift lever

and the transaxle.

Some questions to ask yourself when considering

the road test are listed below:

²Is the complaint or concern what you think it is,

based the driver 's description of the problem?

²Is the transaxle operating normally, or is there a

real problem?

²When does the malfunction occur?

²Is the problem in only one gear range?

²What temperature does the complaint occur?

²Is the transaxle in limp-in mode?

4.3.3 ELECTRONIC PINION FACTOR

WARNINGS

The pinion factor must be set for all new trans-

mission control modules. If the pinion factor is not

set or if it is set incorrectly, any speedometer, speed

control, rolling door locks, and other devices that

are operated by the powertrain and body controllers

will not function properly.

4.3.4 BULLETINS AND RECALLS

The service procedures contained in this manual

are correct. provided that all applicable Safety

Recalls and Technical Service Bulletins have been

performed.

5.0 REQUIRED TOOLS AND

EQUIPMENT

> DRBIIIt(diagnostic read-out box) - Must be at

latest release level.

20

GENERAL INFORMATION

Page 4187 of 4284

Symptom:

P1738-HIGH TEMPERATURE OPERATION ACTIVATED

When Monitored and Set Condition:

P1738-HIGH TEMPERATURE OPERATION ACTIVATED

When Monitored: Whenever the engine is running.

Set Condition: Immediately when the Overheat shift schedule is activated (240 degrees

Trans oil temp).

POSSIBLE CAUSES

ENGINE COOLING SYSTEM MALFUNCTION

INCORRECT FLUID LEVEL

TRANSMISSION OIL COOLER PLUGGED

HIGH TEMPERATURE OPERATIONS ACTIVATED

TEST ACTION APPLICABILITY

1 Perform Engine Cooling System diagnostics per Service Information

Is the engine cooling system functioning properly?All

Ye s®Go To 2

No®Repair cause of engine overheating. Refer to Service Information

for additional repair information.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

2 Check the Transmission Fluid level per the Service Information.

Is the Transmission Fluid Level at the proper level?All

Ye s®Go To 3

No®Repair any Transmission Fluid leak as necessary and adjust the

Transmission Fluid Level in accordance with the Service Infor-

mation.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

3 Perform Cooler Flow Check per Service Information.

Did the cooler flow test pass?All

Ye s®Go To 4

No®Repair cause of plugged Transmission Oil Cooler. Flush or replace

Transmission Oil Cooler(s) as necessary per Service Information.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

83

TRANSMISSION

Page 4188 of 4284

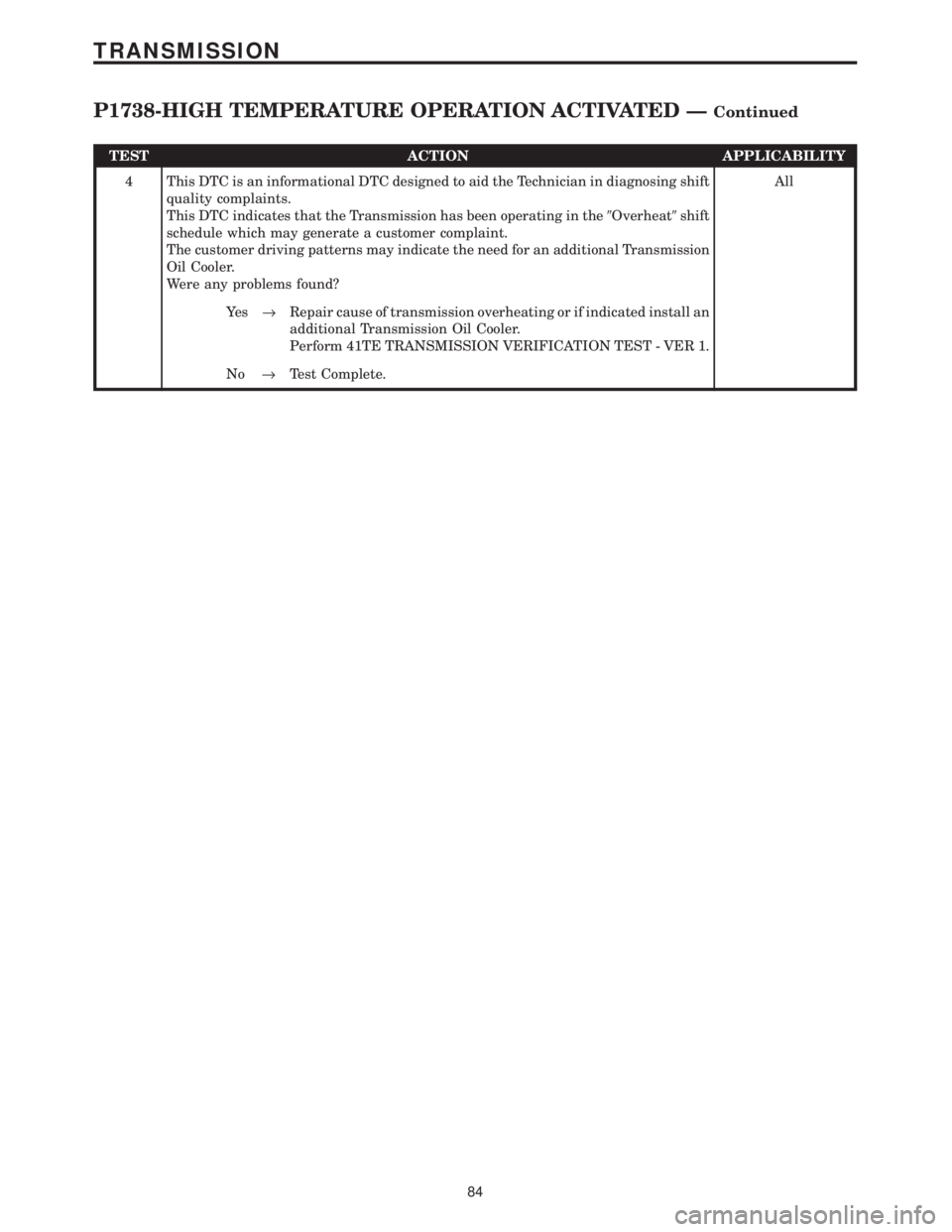

TEST ACTION APPLICABILITY

4 This DTC is an informational DTC designed to aid the Technician in diagnosing shift

quality complaints.

This DTC indicates that the Transmission has been operating in the9Overheat9shift

schedule which may generate a customer complaint.

The customer driving patterns may indicate the need for an additional Transmission

Oil Cooler.

Were any problems found?All

Ye s®Repair cause of transmission overheating or if indicated install an

additional Transmission Oil Cooler.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

No®Test Complete.

84

TRANSMISSION

P1738-HIGH TEMPERATURE OPERATION ACTIVATED ÐContinued