window CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 6 of 4284

TABLE OF CONTENTS - Continued

3.18.3SYSTEM INHIBITORS.....................................26

3.19REAR WINDOW DEFOG/HEATED MIRROR/FRONT WIPER DE-ICE........26

3.20VEHICLE THEFT SECURITY SYSTEM.................................26

3.20.1BASE ALARM SYSTEM....................................26

3.20.2THATCHAM ALARM SYSTEM...............................27

3.21WIPER SYSTEM...................................................27

3.21.1FRONT WIPER...........................................27

3.21.2SPEED SENSITIVE INTERMITTENT WIPE MODE..............27

3.21.3PULSE WIPE.............................................27

3.21.4PARK AFTER IGNITION OFF................................27

3.21.5WIPE AFTER WASH.......................................27

3.21.6REAR WIPER............................................27

3.21.7SPEED SENSITIVE INTERMITTENT WIPE MODE..............27

3.21.8WIPE AFTER WASH.......................................28

3.22USING THE DRBIIIT.......................................28

3.22.1DRBIIITERROR MESSAGES...............................28

3.22.2DRBIIITDOES NOT POWER UP (BLANK SCREEN).............28

3.22.3DISPLAY IS NOT VISIBLE..................................28

4.0 DISCLAIMERS, SAFETY, WARNINGS......................................28

4.1DISCLAIMERS.....................................................28

4.2SAFETY..........................................................28

4.2.1TECHNICIAN SAFETY INFORMATION........................28

4.2.2VEHICLE PREPARATION FOR TESTING......................29

4.2.3SERVICING SUB-ASSEMBLIES.............................29

4.2.4DRBIIITSAFETY INFORMATION............................29

4.3WARNINGS.......................................................29

4.3.1VEHICLE DAMAGE WARNINGS.............................29

4.3.2ROAD TESTING A COMPLAINT VEHICLE.....................29

5.0 REQUIRED TOOLS AND EQUIPMENT.....................................30

6.0 GLOSSARY OF TERMS..................................................30

7.0 DIAGNOSTIC INFORMATION AND PROCEDURES...........................31

AIRBAG

FCM, ORC RUN ONLY DRIVER OPEN - ACTIVE.............................32

FCM, ORC RUN ONLY DRIVER OVER CURRENT - ACTIVE....................32

FCM, ORC RUN ONLY DRIVER OVER TEMP - ACTIVE.......................32

FCM, ORC RUN ONLY DRIVER OVER VOLT - ACTIVE........................32

FCM, ORC RUN ONLY DRIVER SHORT TO GROUND - ACTIVE................32

ORC, LOSS OF IGNITION RUN ONLY - ACTIVE..............................32

FCM, ORC RUN ONLY DRIVER OPEN - STORED............................37

FCM, ORC RUN ONLY DRIVER OVER CURRENT - STORED..................37

FCM, ORC RUN ONLY DRIVER OVER TEMP - STORED......................37

FCM, ORC RUN ONLY DRIVER OVER VOLT - STORED.......................37

FCM, ORC RUN ONLY DRIVER SHORT TO GROUND - STORED...............37

FCM, ORC RUN-START DRIVER OPEN - STORED...........................37

FCM, ORC RUN-START DRIVER OVER CURRENT - STORED.................37

FCM, ORC RUN-START DRIVER OVER TEMP - STORED.....................37

FCM, ORC RUN-START DRIVER OVER VOLT - STORED......................37

FCM, ORC RUN-START DRIVER SHORT TO GROUND - STORED..............37

iii

Page 30 of 4284

1.0 INTRODUCTION

The procedures contained in this manual include

all the specifications, instructions and graphics

needed to diagnose 2001 body system problems. The

diagnostics in this manual are based on the failure

condition or symptom being present at the time of

diagnosis.

Please follow the recommendations below when

choosing your diagnostic path.

1. First make sure the DRBIIItis communicating

with the appropriate modules; i.e., if the

DRBIIItdisplays a ªNo Responseº or a ªBus6

Signals Openº condition, you must diagnose that

first.

2. Read DTC's (diagnostic trouble codes) with the

DRBIIIt.

3. If no DTC's are present, identify the customer

complaint.

4. Once the DTC or customer complaint is identi-

fied, locate the matching test in the Table of

Contents and begin to diagnose the symptom.

All component location views are in Section 8.0. All

connector pinouts are in Section 9.0. All schematics

are in Section 10.0. All Charts and Graphs are in

Section 11.0.

An * placed before the symptom description indi-

cated a customer complaint.

When repairs are required, refer to the appropri-

ate service information for the proper removal and

repair procedure.

Diagnostic procedures change every year. New

diagnostic systems may be added: carryover systems

may be enhanced. READ THIS MANUAL BEFORE

TRYING TO DIAGNOSE A VEHICLE DIAGNOS-

TIC TROUBLE CODE. It is recommended that you

review the entire manual to become familiar with all

the new and changed diagnostic procedures.

This book reflects many suggested changes from

readers of past issues. After using this book, if you

have any comments or suggestions, please fill out

the form in the back of this book and mail it back to

us.

1.1 SYSTEM COVERAGE

This diagnostic procedures manual covers all

2001 Chrysler Voyager and Caravan vehicles. This

diagnostic procedures manual also covers both left

hand drive (LHD) and right hand drive (RHD)

vehicles. There may be some slight differences in

the location views of components. If the location

views shown are on a LHD vehicle, a RHD vehicle

will be symmetrically opposite.

1.2 SIX-STEP TROUBLESHOOTING

PROCEDURE

Diagnosis of the body system is done in six basic

steps:

²verification of complaint

²verification of any related symptoms

²symptom analysis

²problem isolation

²repair of isolated problem

²verification of proper operation

2.0 IDENTIFICATION OF

SYSTEM

The vehicle systems that are part of the ªbodyº

system are:

²Airbag

²Audio

²Cabin Heater

²Chime

²Communication

²Door Ajar System

²Electrically heated system

²Exterior lighting

²Heating and A/C

²Instrument Cluster

²Interior Lighting

²Manual Temperature Control

²Memory Seat

²Overhead Console

²Power Door Lock/RKE

²Power Folding Mirrors

²Power Sliding Doors

²Power Liftgate

²Power windows

²Vehicle Theft Security System (VTSS)

²Windshield Wiper and Washer

3.0 SYSTEM DESCRIPTION AND

FUNCTIONAL OPERATION

The body system on the 2001 RG consists of a

combination of modules that communicate over the

PCI bus (Programmable Communication Interface

multiplex system). Through the PCI bus, informa-

tion about the operation of vehicle components and

circuits is relayed quickly to the appropriate mod-

ule(s). All modules receive all the information trans-

1

GENERAL INFORMATION

Page 43 of 4284

EATX power

The electronic automatic 4 speed transmission

module is powered when the ignition switch is in

the UNLOCK, RUN or START positions. This cir-

cuit is electronically controlled and continuously

monitored for malfunctions. Power is supplied

through pin 27 of the FCM connector.

Front washer motor

The front washer switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it of a request to wash. The front

washer motor is then powered through low side

control inside the FCM. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. In addition, the FCM electronically protects

the washer motor from system voltages higher than

16 volts by automatically switching off the low side

circuit. The low side circuit is connected to pin 45 in

the FCM connector.

Rear washer motor

The rear washer switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it of a request to wash. The rear

washer motor is then powered through low side

control inside the FCM. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. In addition, the FCM electronically protects

the washer motor from system voltages higher than

16 volts by automatically switching off the low side

circuit. The low side circuit is connected to pin 46 in

the FCM connector.

Brake shift interlock system

The brake shift interlock solenoid receives power

from both high side and low side controls inside the

FCM. The high side control is on the same circuit as

the EATX module power, and the low side control

comes through pin 47 of the FCM connector. The

solenoid is controlled by the low side driver when

the brake pedal is pressed. Both circuits are contin-

uously monitored for malfunctions.

3.8.2 RELAY CONTROLS

Fog lamp relay

The fog lamp switch is a direct input to the BCM.

The BCM sends a PCI Bus message to the FCM

informing it to turn on the fog lamp relay. The fog

lamp relay is then powered through low side control

on pin 33 of the FCM. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. Fog lamp functionality is not equipped on all

vehicles. The FCM ªlearnsº that the vehicle is

equipped with fog lamps by reading the BCM PCI

Bus message.

Park lamp relay

The park lamp switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it to turn on the park lamp relay.

The park lamp relay is then powered through lowside control on pin 13 of the FCM. This circuit is

electronically controlled and continuously moni-

tored for malfunctions.

Front wiper on relay

The front wiper switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it to turn on the front wiper on

relay. The front wiper on relay is then powered

through low side control on pin 14 of the FCM. This

circuit is electronically controlled and continuously

monitored for malfunctions.

Front wiper high/low relay

The front wiper switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it to turn on the front wiper high/

low relay. The relay switches power between the low

speed and high speed windings of the wiper motor.

The front wiper high/low relay is powered through

low side control on pin 34 of the FCM. This circuit is

electronically controlled and continuously moni-

tored for malfunctions.

Accessory relay

The accessory relay works in conjunction with the

FCM's power accessory delay feature to control the

operation of the radio, power windows, washer

motors, wiper motors and power outlet. The acces-

sory relay is turned on through low side control on

pin 35 of the FCM. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. Depending on the ignition switch position,

the accessory relay will remain on or will time-out

and turn off. The accessory relay remains on in the

RUN and ACCY positions of the ignition switch. In

the UNLK and OFF positions, the relay will remain

energized for 45 seconds then turn off. During this

time-out period, if the driver or passenger doors are

opened, the relay will turn off immediately. While

the ignition switch is in the START position, the

relay will also drop-out, then resume operation.

Accessory relay operation is most noticeable by

observing the operation of the radio or blower

functions.

Horn relay

The horn relay operates through a direct wire

input to the FCM from the horn switch (FCM pin

17) , or a PCI Bus message from the BCM. The relay

responds to the horn switch, remote door lock and

VTA alarm functions. The horn relay is powered

through low side control on pin 10 of the FCM.

Under normal operating conditions, if the horn is

pressed for longer than 30 seconds, the FCM will

automatically deactivate the horn to prevent dam-

age to it. The FCM will re-activate control of the

relay after a 25 second cool-down period. This

circuit is electronically controlled and continuously

monitored for malfunctions.

14

GENERAL INFORMATION

Page 44 of 4284

Front and rear blower relay

The blower control switch is part of the Automatic

Temperature Control (ATC) or A/C-Heater Control

Module, (Manual Temp). When the blower switch is

turned on, the ATC or A/C-Heater Control Module

sends a PCI Bus message to the FCM. The front and

rear blower relay is then powered through low side

control on pin 30 of the FCM. The relay provides the

high side to the blower motor, and the blower speed

is governed through low side control in the ATC or

A/C-Heater Control Module. This circuit is electron-

ically controlled and continuously monitored for

malfunctions.

Name Brand Speakers (NBS) relay

The NBS relay operates through the vehicle bus

interface between the radio and the FCM. When the

radio is turned on, the radio sends a PCI Bus

message to the FCM. The NBS relay is then pow-

ered on through low side control on pin 11 of the

FCM. The relay supplies power to the amplified

speaker, and ground is supplied through the radio.

This circuit is electronically controlled and contin-

uously monitored for malfunctions.

Electronic Back Light (EBL) relay

The rear defrost switch is part of the Automatic

Temperature Control or A/C-Heater Control Module

(Manual Temp). When the ignition switch is in the

RUN position and the rear defrost switch is turned

on, the ATC or A/C-Heater Control Module sends a

PCI Bus message to the FCM. The EBL run only

relay is then powered through low side control on

pin 31 of the FCM. The relay provides the high side

to the rear window defrost grid, and ground is

attached to the vehicle body. The FCM will only

allow the rear defrost to operate in the RUN posi-

tion. This circuit is electronically controlled and

continuously monitored for malfunctions.

Cabin Heater Relay

When the ignition is in Run, the FCM monitors

the PCI bus for the Cabin Heater Activation re-

quest. The A/C ± Heater Control Module initiates

this request only when all conditions for Cabin

Heater activation are favorable. The request carries

the status bit that the FCM requires to activate its

Cabin Heater Assist Control output. This output is

a low side driver (coming from FCM pin 15) which

supplies a ground signal to the Cabin Heater (pin

5). When the Cabin Heater receives this ground

signal input, it interprets this as an activation

signal. The FCM low side driver is also capable of

diagnostic sensing. The driver will sense an open

circuit when the driver is off, and will sense a short

to voltage when the driver is on. The FCM will set

DTCs for both of these types of faults. For addi-

tional information, refer to Cabin Heater under

General Information and Diagnostic Procedures in

the manual.3.8.3 ELECTRICAL INPUTS

Headlamp battery supplies1&2Ð12 volt

input on pins 1 and 2. Battery supply voltage for

switching headlamp circuits only.

Module battery supply Ð12 volt input on pin 9.

Battery supply voltage for all other FCM opera-

tions.

Power ground ÐGround source on pin 8 for all

FCM operations.

Ignition switch RUN or START position status

Ð12 volt input on pin 37. Allows the FCM to

determine the ignition switch status for related

FCM operations.

Ignition switch START only status Ð12 volt

input on pin 19. Allows the FCM to discriminate

between RUN/START input and START for related

FCM operations.

PCI Bus ÐApproximately 7.5 volt input on pin 22.

Allows the FCM to communicate with other mod-

ules on the vehicle bus.

Stop lamp Switch status Ð12 volt input on pin

44. Provides for brake shift interlock function.

Horn Switch ÐGround input on pin 17. Primary

means for engaging the horn.

Back-up switch ÐGround input on pin 39. Input

is converted to a PCI Bus status message for use by

other modules.

Wiper park switch ÐGround input on pin 16.

Used to determine park placement of wipers. Also

used as feedback to FCM to determine correct

operating mode of wipers.

Washer fluid level switch ÐGround input to

pull-up on pin 18. Ground is switched into the

circuit when washer bottle fluid level is low.

Brake fluid level switch ÐGround input to

pull-up on pin 36. Ground is switched into the

circuit when brake fluid level is low.

Ambient temperature sensor ÐResistive input

to pull-up on pin 25. Corresponding voltage level is

converted to a PCI Bus message for use by other

modules on the bus.

Right park lamp outage Ð12 volt input on pin

21. Used to determine if right park lamp circuit is

operating properly.

Left park lamp outage Ð12 volt input on pin 41.

Used to determine if left park lamp circuit is

operating properly.

Battery IOD Ð12 volt input on pin 20. The FCM

enters a low power consumption mode when the

ignition is turned OFF. This low current draw

battery supply keeps the microprocessor function-

ing in the low power mode.

Battery (+) connection detection Ð12 volt

input on pin 38. The battery connection on the PDC

incorporates the use of an internal switch to deter-

mine if the connector is properly mated and the

Connector Positive Assurance (CPA) is engaged. If

15

GENERAL INFORMATION

Page 46 of 4284

± Evap Temp Sensor Shorted

± Evap Temp Sensor Open

± A/C Pressure Too Low

± A/C Pressure Too High

± Invalid Conditions for Cooldown Test, Evap

Temperature Too Low

If a message other than Cooldown Test Passed

occurs, refer to the appropriate symptom for diag-

nosis.

3.9.1.7 ACTIVE AND STORED TROUBLE

CODES

The Automatic Temperature Control (ATC) is

capable of storing Active and Stored trouble codes.

Active codes indicate a current fault in the system.

Stored codes indicate that a problem has occurred

in the system, however is not currently present.

Active codes cannot be erased until the problem

causing the code has been repaired. At this time the

Active code is converted to a Stored code, which can

be erased using the DRBIIIt.

3.9.2 MANUAL TEMPERATURE CONTROL

3.9.2.1 SYSTEM AVAILABILITY

Depending on the model, either a Single-Zone Air

Conditioning System or a Dual-Zone Air Condition-

ing System is currently available in these vehicles.

3.9.2.2 CABIN HEATER

For Vehicles equipped with a diesel engine, a

Cabin Heater is used in conjunction with the HVAC

system. The Cabin Heater is designed to supply the

vehicle's occupants with heat prior to the engine

reaching operating temperature. For additional in-

formation on this system, refer to Cabin Heater

under General Information and Diagnostic Proce-

dures in this manual.

3.9.2.3 ZONE CONTROL ± SINGLE-ZONE

The Single-Zone Air Conditioning System main-

tains incoming air temperature, airflow, fan speed,

and fresh air intake for the entire vehicle from the

instrument panel mounted A/C ± Heater Control

Module. The full range of temperature that the

system can produce in any mode for the entire

vehicle is available by positioning the blend control

to the desired range.

3.9.2.4 ZONE CONTROL ± DUAL-ZONE

The Dual-Zone Air Conditioning System main-

tains incoming air temperature, airflow, fan speed,

and fresh air intake for the entire vehicle from the

instrument panel mounted A/C ± Heater ControlModule. In addition, this system provides com-

pletely independent side-to-side control of incoming

air temperature. The full range of temperature that

the system can produce in any mode is available on

either side of the vehicle by positioning the inde-

pendent driver and passenger blend controls to the

desired range.

3.9.2.5 AIR DISTRIBUTION

The HVAC unit has five fully adjustable instru-

ment panel outlets. Side-window demister outlets

in the instrument panel eliminate door ducts and

door-to-instrument panel seals. A single, central

mounted outlet delivers air for defrosting the wind-

shield. Air exhausters allow air entering at the

front of the vehicle to flow out the back to the rear

occupants. Mid-cabin comfort control directs only

cooling air flow to the intermediate seat occupants

through outlets at the rear of each front door trim

panel. Air is supplied to these outlets from the

instrument panel through ducts in the doors that

use molded seals at the instrument panel to prevent

air leakage. Wide outlets under the front seats with

directional dividers distribute heated air across the

floor to the intermediate seat occupants. Ducts in

the center of the vehicle under the carpet deliver air

from the HVAC unit to these outlets. Models

equipped with Dual-Zone A/C systems also include

a dust and odor air filter installed in the HAVC

housing.

3.9.2.6 DOOR ACTUATORS

The electric door actuators are a two-wire design.

Each door actuator uses a similar connector wired

directly to the A/C ± Heater Control Module. Single-

Zone systems have one blend door actuator, one

mode door actuator, and one recirculation door

actuator. Dual-Zone systems have two blend door

actuators, one mode door actuator, and one recircu-

lation door actuator. All of the door actuators are

accessible from the vehicle's interior.

3.9.2.7 DOOR ACTUATOR CONTROL

The A/C ± Heater Control Module knows the

number of operating actuator revolutions required

for full door travel as well as the number of actuator

commutator pulses per revolution. Using these pa-

rameters, the A/C ± Heater Control Module runs

the actuator for the number of commutator pulses

that correspond to the desired door position. To

maintain accuracy, the system recalibrates itself

periodically at known zero and full travel condi-

tions.

17

GENERAL INFORMATION

Page 47 of 4284

3.9.2.8 HVAC SYSTEM RELAYS

The Integrated Power Module (IPM) houses and

provides power to the A/C Clutch Relay and Front

Blower Motor Relay.

3.9.2.9 EVAPORATOR TEMPERATURE

SENSOR

An evaporator temperature sensor, located on the

A/C expansion valve under the hood, replaces the

previously used fin sensor.

3.9.2.10 A/C ± HEATER CONTROL

MODULE, SWITCH OPERATION

Power Switch

The Power Switch is a momentary contact switch.

The switch LED illuminates when the switch is on.

The Power Switch setting is remembered during

power down.

Rear Window Defogger Switch

The Rear Window Defogger Switch is a momen-

tary contact switch. Toggling the switch results in

the A/C ± Heater Control Module sending a change

of state message to the FCM to provide rear window

defogger activation or deactivation respectively.

The switch LED illuminates when the switch is on.

Recirculation Switch

The Recirculation Switch is a momentary contact

switch. Toggling the switch on results in the A/C ±

Heater Control Module signaling the actuator to

close the fresh-air door. Toggling the switch off

results in the A/C ± Heater Control Module signal-

ing the actuator to open the fresh-air door. The

switch LED illuminates when the switch is on.

When the Power Switch is off, the A/C ± Heater

Control Module closes the fresh-air door to prevent

outside air from entering the passenger compart-

ment. The recirculation mode will cancel whenever

defrost is requested. Pressing the Recirculation

Switch while in defrost mode will illuminate the

Recirculation Switch LED, but only while the but-

ton is pressed. Under this circumstance, the recir-

culation request will be denied and the fresh-air

door will remain in the fresh position. All door

positions are determined relative to the number of

commutator pulses required to provide full travel of

the door. On command, the A/C ± Heater Control

Module runs the actuator for the number of pulses

corresponding to the desired door position.

A/C Switch

The A/C Switch is a momentary contact switch.

Toggling the switch results in the A/C ± Heater

Control Module sending a change of state message

to the Powertrain Control Module (PCM ± gasoline)or Engine Control Module (ECM ± diesel) to provide

A/C compressor clutch activation or deactivation

respectively. The A/C ± Heater Control Module will

only provide this request if EVAP function is found

acceptable. The Power Switch must be on to make

the A/C switch active. The switch LED illuminates

when the switch is on. The A/C Switch setting is

remembered during power down.

Blower Switch

The rotary Blower Switch has five positions, Low,

M1, M2, M3, and High. The Power Switch must be

on to make the Blower Switch active. Toggling the

Power Switch results in the A/C ± Heater Control

Module sending a request to the FCM to provide

blower motor activation or deactivation respec-

tively.

Blend Switch ± Single Zone

The single rotary Blend Switch has multiple

detents to control the full range of temperature that

the system can produce in any mode. Rotating the

switch results in the A/C ± Heater Control Module

signaling the actuator to move the blend door. All

door positions are determined relative to the num-

ber of commutator pulses required to provide full

travel of the door. On command, the A/C ± Heater

Control Module runs the actuator for the number of

pulses corresponding to the desired door position.

Blend Switch ± Dual Zone

The dual sliding Blend Switches have multiple

detents to control the full range of temperature that

the system can produce an any mode. The upper

slide pot controls the driver-side blend door, while

the lower slide pot controls the passenger-side

blend door. Sliding the switch results in the A/C ±

Heater Control Module signaling the actuator to

move the blend door. All door positions are deter-

mined relative to the number of commutator pulses

required to provide full travel of the door. On

command, the A/C ± Heater Control Module runs

the actuator for the number of pulses corresponding

to the desired door position.

Mode Switch

The single rotary Mode Switch has 13 detents to

either direct airflow to the panel outlets, a mix of

floor and panel outlets, floor outlets, a mix of floor

and defrost outlets, or defrost outlets. Rotating the

switch results in the A/C ± Heater Control Module

signaling the actuator to move the mode door. All

door positions are determined relative to the num-

ber of commutator pulses required to provide full

travel of the door. On command, the A/C ± Heater

Control Module runs the actuator for the number of

pulses corresponding to the desired door position.

18

GENERAL INFORMATION

Page 55 of 4284

manual sliding door. When the child lock out switch

is on, the B pillar switches are disabled.

There is only one part number for the power

sliding door module (PSDM). The driver sliding

door harness has an additional ground circuit which

will identify it as the driver side. This eliminates

the need for a left and a right side module.

3.18.2 DIAGNOSTIC FEATURES

The PSDM can be flashed on vehicle via PCI bus

with a DRBIIItdiagnostic tool. The DRBIIItcan

read all inputs, actuate all outputs, read module

information, and read diagnostic trouble codes. As a

reminder, some DTC's can be set during normal

PSD operation.

3.18.3 SYSTEM INHIBITORS

1. Battery voltage too high or too low (above 16V,

below 9.5V)

2. Vehicle in gear

3. Vehicle speed > 0 mph/km/h

4. Child locks enabled inhibit the B pillar switch

operation

5. O/H console lockout will inhibit the B pillar

switches

6. Doors locked will inhibit all interior switches

from opening (Overhead Console, B Pillar). A

locked sliding door can be power closed.

3.19 REAR WINDOW DEFOG/HEATED

MIRROR/FRONT WIPER DE-ICE

The defroster button located on the HVAC control

controls the rear window defogger, heated side view

mirrors and front wiper de-icer grid. In addition the

front wiper de-ice function is turned on when front

defog/defrost mode is selected.

When the defroster button is pushed, the HVAC

control sends a bus message over the PCI bus to the

Front Control Module (FCM) which controls the

Rear Window Defogger relay. The defroster LED

will illuminate when the defroster function is on.

The defroster will function for 10 minutes or can be

cycled off sooner by pressing the defroster button

again. The front wiper de-icer grid receives its 12

volts from the accessory relay through fuse 11 and

the HVAC control module supplies the grid ground.

3.20 VEHICLE THEFT SECURITY SYSTEM

3.20.1 BASE ALARM SYSTEM

The Vehicle Theft Security System (VTSS) is part

of the Body Control Module (BCM). The BCM

monitors the vehicle doors, liftgate, hood, and theignition for unauthorized operation. The alarm ac-

tivates by sounding the horn, flashing the head-

lamps and the VTSS indicator lamp. The VTSS does

not prevent engine operation, this is done with the

Sentry Key Immobilizer Module (SKIM). Passive

arming occurs in one of two ways. Upon normal

vehicle exit by removing the ignition key, opening

the driver door, locking the doors with the power

lock, and closing the driver door, or by removing the

ignition key, opening the driver door, closing the

driver door, and locking the doors with the Remote

Keyless Entry (RKE) transmitter. The VTSS indi-

cator lamp will flash for approximately 15 seconds

during the arming process. If there is no interrup-

tion during the arming process, upon completion

the VTSS indicator lamp will flash at a slower rate.

When the BCM receives an input to trigger the

alarm, the BCM will control the outputs of the

headlamps, horn, and VTSS lamp for approxi-

mately 18 minutes.

Arming (Active and Passive)

Active arming occurs when the RKE transmitter

is used to lock the vehicle doors, whether the doors

are open or closed. The arming process is complete

only after all doors are closed.

Passive arming occurs when the ignition key is

removed, the driver door is opened, and the doors

are locked with the power door lock switch, and the

door is closed.

Disarming (Active and Passive)

Active disarming occurs when the RKE transmit-

ter is used to unlock the vehicle doors. This disarm-

ing will also halt the alarm once it has been acti-

vated.

Passive disarming occurs upon normal vehicle

entry (unlocking driver door with the key). This

disarming will also halt the alarm once it has been

activated.

Tamper Alert

The VTSS tamper alert will sound the horn three

times upon disarming to indicate a tamper condi-

tion has occurred.

Manual Override

The system will not arm if the doors are locked

using the manual lock control or if the locks are

actuated by an inside occupant after the doors are

closed.

Diagnosis

For complaints about the Vehicle Theft Alarm

triggering on its own, use the DRBIIItand read the

Last VTSS Cause status.

26

GENERAL INFORMATION

Page 59 of 4284

WARNING: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED.

DURING THE TEST DRIVE, DO NOT TRY TO

READ THE DRBIIITSCREEN WHILE IN

MOTION. DO NOT HANG THE DRBIIITFROM

THE REAR VIEW MIRROR OR OPERATE IT

YOURSELF. HAVE AN ASSISTANT

AVAILABLE TO OPERATE THE DRBIIIT.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box)

Jumper wires

Ohmmeter

Voltmeter

Sentry Key Tester

Test Light

8310 Airbag System Load Tool

8443 SRS Airbag System Load Tool

Diagnostic Junction Port Tester 8339

6.0 GLOSSARY OF TERMS

ABSantilock brake system

ACMairbag control module

AECMairbag electronic control module

(ACM)

ASDMairbag system diagnostic module

(ACM)

AT Cautomatic temperature control

BCMbody control module

CABcontroller antilock brake

CMTCcompass/mini-trip computer

CPAconnector positive assurance

DABdriver airbag

DCHAdiesel cabin heater assist

(cabin heater)

DLCdata link connector

DTCdiagnostic trouble code

DRdriver

EBLelectric back lite (rear window de-

fogger)ECMEngine control module

EVICelectronic vehicle information center

FCMfront control module

GCCGulf Coast Countries

HVACheater ventilation, air conditioning

IPMintelligent power module

LDUlower drive unit

LHDLeft Hand Drive

MICmechanical instrument cluster

MTCmanual temperature control

MSMMmemory seat/mirror module

OBDon board diagnostics

ODOodometer

ORCoccupant restraint controller

PA Bpassenger airbag

PASSpassenger

PCIProgrammable Communication In-

terface (vehicle communication bus)

PCMpowertrain control module

PDCpower distribution center

PLGpower liftgate

PLGMpower liftgate module

PSDpower sliding door

PSDMpower sliding door module

PWMpulse width modulated

RHDRight Hand Drive

RKEremote keyless entry

SABseat airbag

SBTseat belt tensioner

SIACMside impact airbag control module

SKIMsentry key immobilizer module

SKISsentry key immobilizer system

SQUIBalso called initiator (located inside

airbag)

SRSsupplemental restraint system

TCMtransmission control module

VFDvacuum fluorescent display

VTSSvehicle theft security system

30

GENERAL INFORMATION

Page 469 of 4284

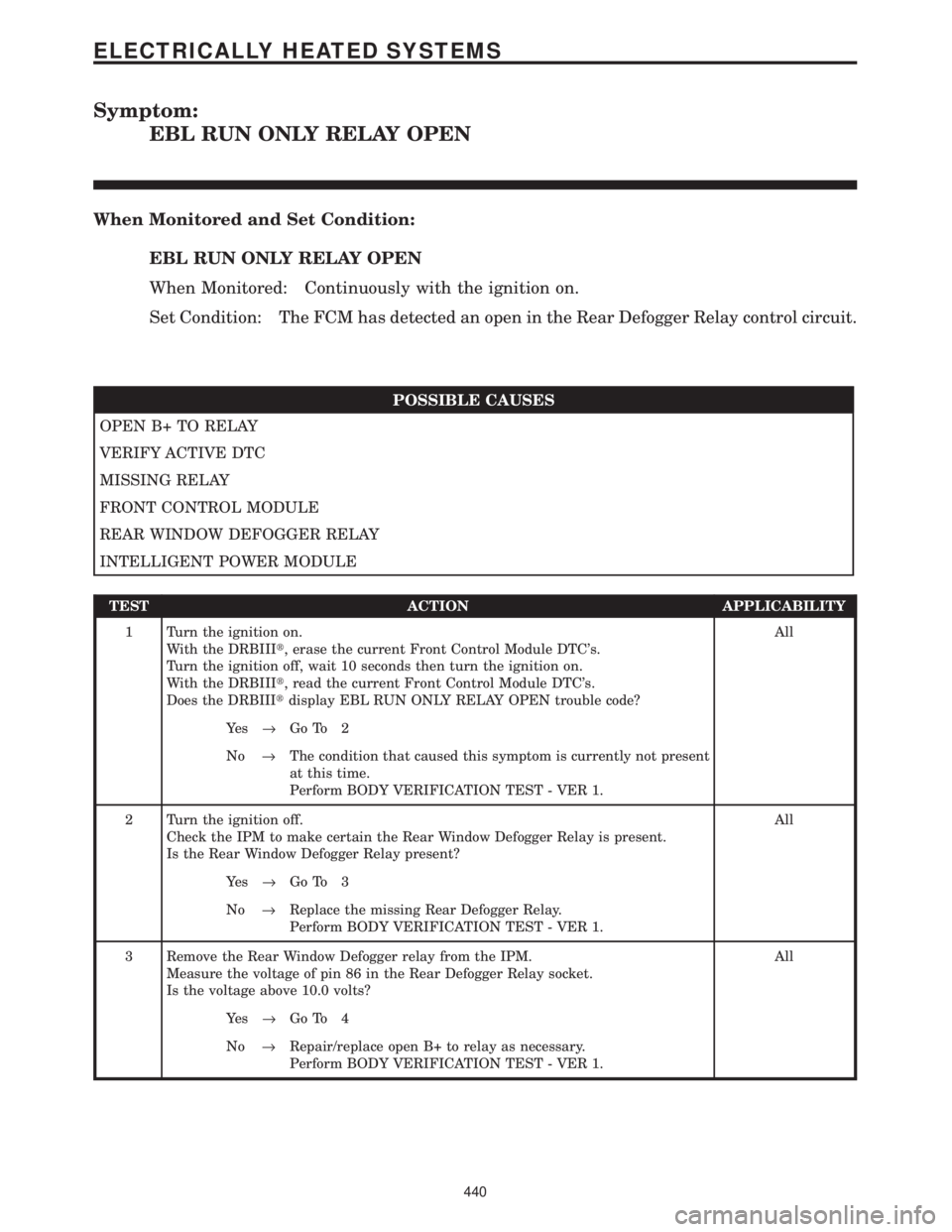

Symptom:

EBL RUN ONLY RELAY OPEN

When Monitored and Set Condition:

EBL RUN ONLY RELAY OPEN

When Monitored: Continuously with the ignition on.

Set Condition: The FCM has detected an open in the Rear Defogger Relay control circuit.

POSSIBLE CAUSES

OPEN B+ TO RELAY

VERIFY ACTIVE DTC

MISSING RELAY

FRONT CONTROL MODULE

REAR WINDOW DEFOGGER RELAY

INTELLIGENT POWER MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, erase the current Front Control Module DTC's.

Turn the ignition off, wait 10 seconds then turn the ignition on.

With the DRBIIIt, read the current Front Control Module DTC's.

Does the DRBIIItdisplay EBL RUN ONLY RELAY OPEN trouble code?All

Ye s®Go To 2

No®The condition that caused this symptom is currently not present

at this time.

Perform BODY VERIFICATION TEST - VER 1.

2 Turn the ignition off.

Check the IPM to make certain the Rear Window Defogger Relay is present.

Is the Rear Window Defogger Relay present?All

Ye s®Go To 3

No®Replace the missing Rear Defogger Relay.

Perform BODY VERIFICATION TEST - VER 1.

3 Remove the Rear Window Defogger relay from the IPM.

Measure the voltage of pin 86 in the Rear Defogger Relay socket.

Is the voltage above 10.0 volts?All

Ye s®Go To 4

No®Repair/replace open B+ to relay as necessary.

Perform BODY VERIFICATION TEST - VER 1.

440

ELECTRICALLY HEATED SYSTEMS

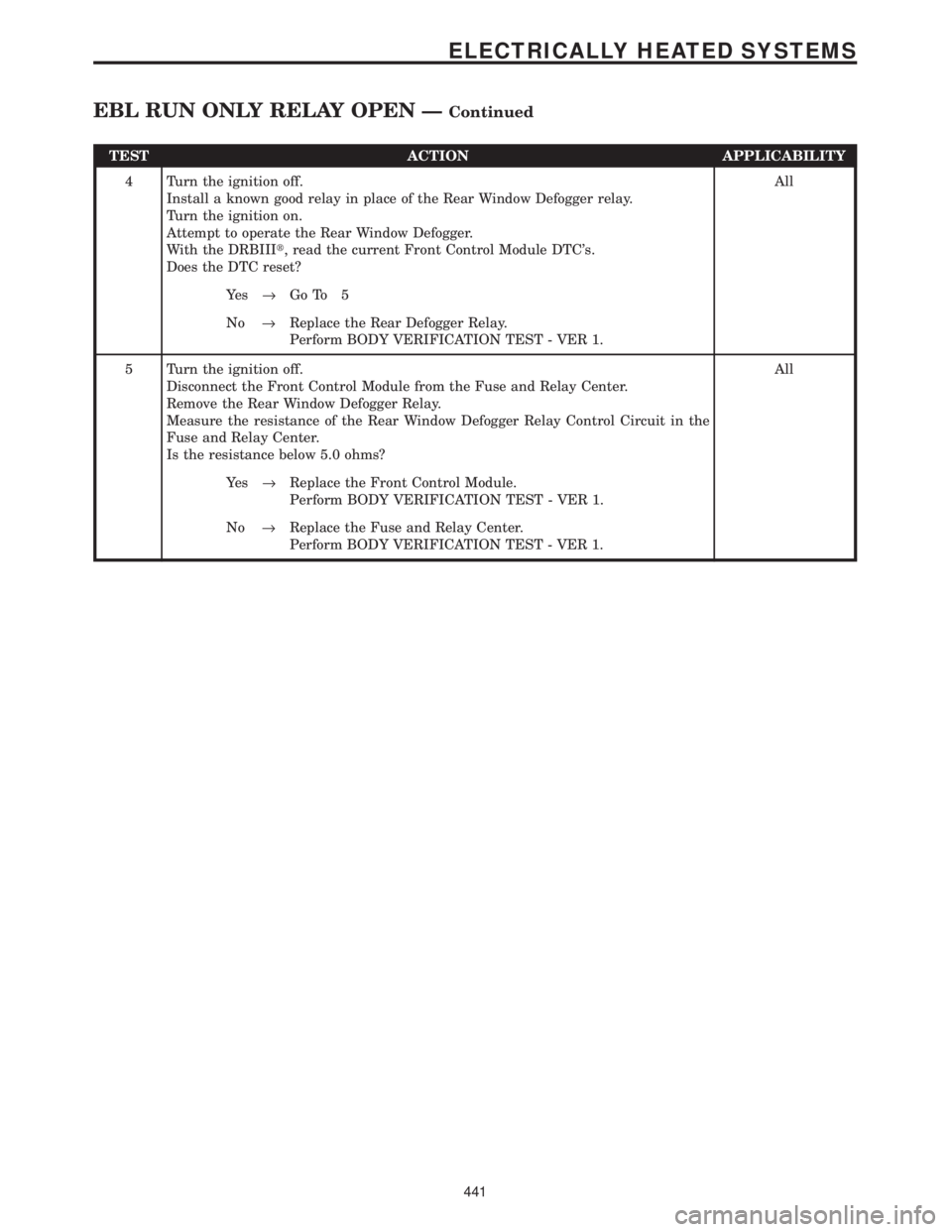

Page 470 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off.

Install a known good relay in place of the Rear Window Defogger relay.

Turn the ignition on.

Attempt to operate the Rear Window Defogger.

With the DRBIIIt, read the current Front Control Module DTC's.

Does the DTC reset?All

Ye s®Go To 5

No®Replace the Rear Defogger Relay.

Perform BODY VERIFICATION TEST - VER 1.

5 Turn the ignition off.

Disconnect the Front Control Module from the Fuse and Relay Center.

Remove the Rear Window Defogger Relay.

Measure the resistance of the Rear Window Defogger Relay Control Circuit in the

Fuse and Relay Center.

Is the resistance below 5.0 ohms?All

Ye s®Replace the Front Control Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Fuse and Relay Center.

Perform BODY VERIFICATION TEST - VER 1.

441

ELECTRICALLY HEATED SYSTEMS

EBL RUN ONLY RELAY OPEN ÐContinued