coolant CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4001 of 4284

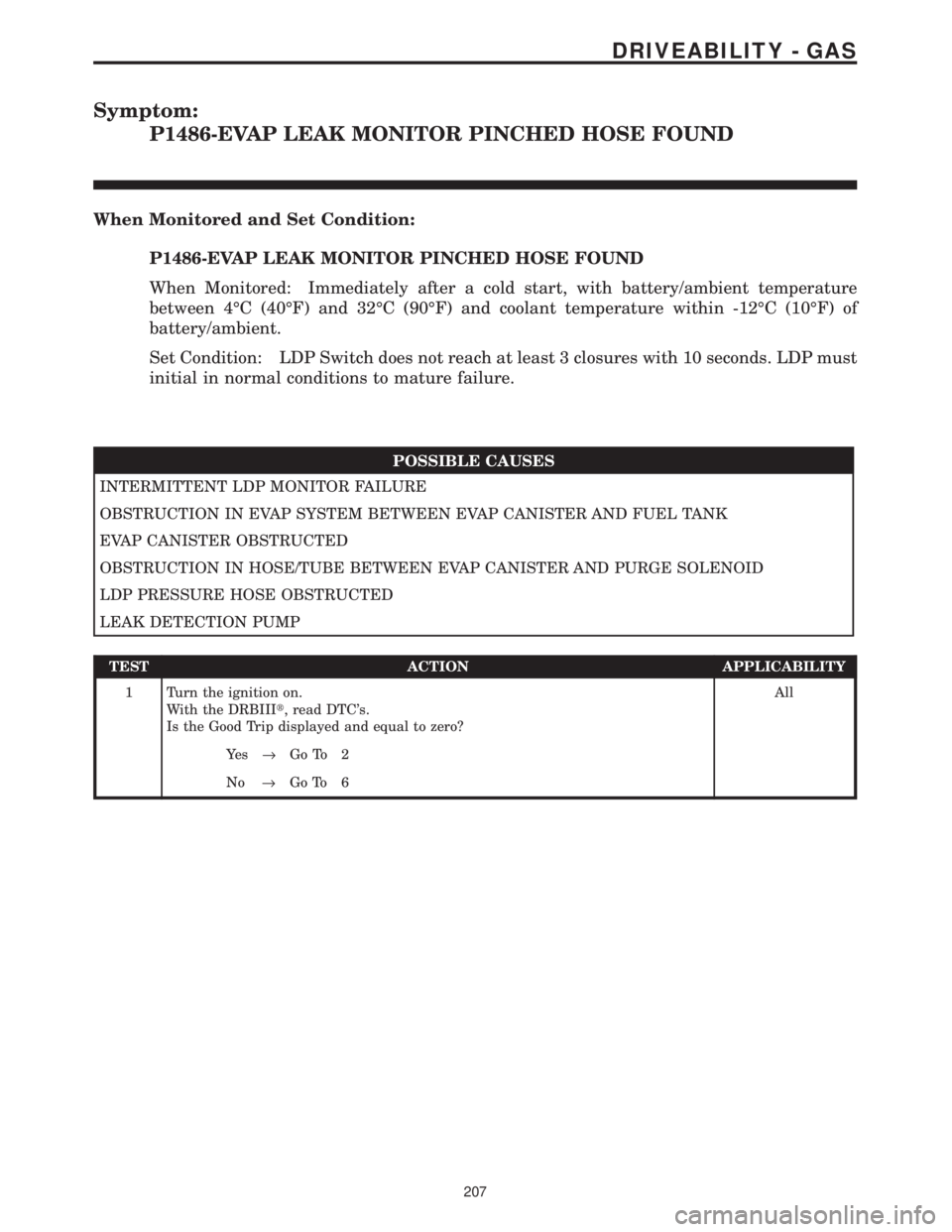

Symptom:

P1486-EVAP LEAK MONITOR PINCHED HOSE FOUND

When Monitored and Set Condition:

P1486-EVAP LEAK MONITOR PINCHED HOSE FOUND

When Monitored: Immediately after a cold start, with battery/ambient temperature

between 4ÉC (40ÉF) and 32ÉC (90ÉF) and coolant temperature within -12ÉC (10ÉF) of

battery/ambient.

Set Condition: LDP Switch does not reach at least 3 closures with 10 seconds. LDP must

initial in normal conditions to mature failure.

POSSIBLE CAUSES

INTERMITTENT LDP MONITOR FAILURE

OBSTRUCTION IN EVAP SYSTEM BETWEEN EVAP CANISTER AND FUEL TANK

EVAP CANISTER OBSTRUCTED

OBSTRUCTION IN HOSE/TUBE BETWEEN EVAP CANISTER AND PURGE SOLENOID

LDP PRESSURE HOSE OBSTRUCTED

LEAK DETECTION PUMP

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 6

207

DRIVEABILITY - GAS

Page 4008 of 4284

Symptom:

P1494-LEAK DETECT PUMP SW OR MECHANICAL FAULT

When Monitored and Set Condition:

P1494-LEAK DETECT PUMP SW OR MECHANICAL FAULT

When Monitored: Immediately after a cold start, with battery/ambient temperature

between 4ÉC (40ÉF) and 32ÉC (90ÉF) and coolant temperature within -12ÉC (10ÉF) of

battery/ambient.

Set Condition: The state of the switch does not change when the solenoid is energized.

POSSIBLE CAUSES

LDP VACUUM SUPPLY

WIRING HARNESS INTERMITTENT

LEAK DETECTION PUMP

LDP SWITCH SENSE CIRCUIT SHORTED TO GROUND

LDP SWITCH SENSE CIRCUIT OPEN

POWERTRAIN CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition off.

Disconnect the vacuum supply hose at the Leak Detection Pump.

Connect a vacuum gauge to the disconnected vacuum supply hose at the Leak

Detection Pump.

Start the engine and read the vacuum gauge.

Does the vacuum gauge read at least 13 in/Hg?All

Ye s®Go To 3

No®Repair leak or obstruction in vacuum hose as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

214

DRIVEABILITY - GAS

Page 4010 of 4284

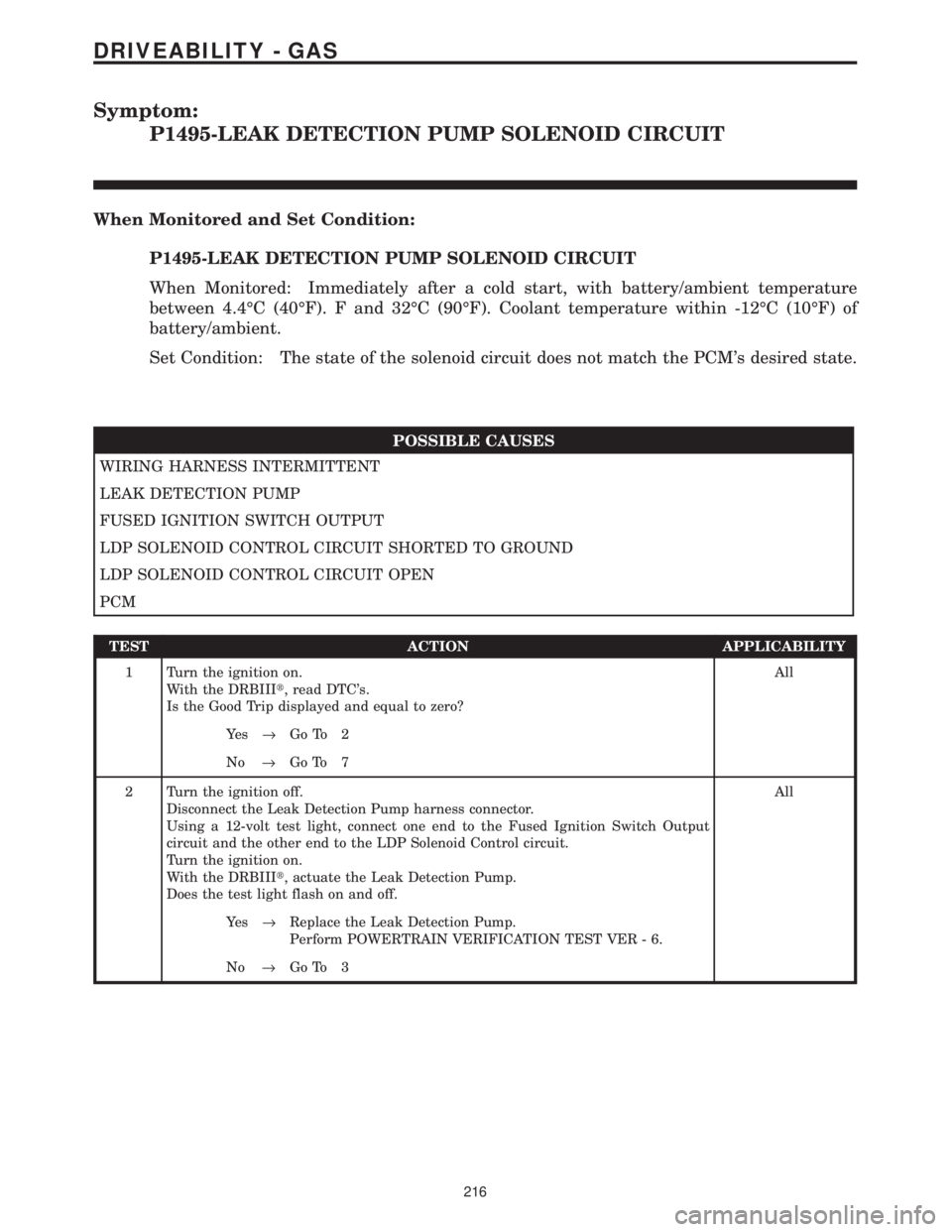

Symptom:

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT

When Monitored and Set Condition:

P1495-LEAK DETECTION PUMP SOLENOID CIRCUIT

When Monitored: Immediately after a cold start, with battery/ambient temperature

between 4.4ÉC (40ÉF). F and 32ÉC (90ÉF). Coolant temperature within -12ÉC (10ÉF) of

battery/ambient.

Set Condition: The state of the solenoid circuit does not match the PCM's desired state.

POSSIBLE CAUSES

WIRING HARNESS INTERMITTENT

LEAK DETECTION PUMP

FUSED IGNITION SWITCH OUTPUT

LDP SOLENOID CONTROL CIRCUIT SHORTED TO GROUND

LDP SOLENOID CONTROL CIRCUIT OPEN

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition off.

Disconnect the Leak Detection Pump harness connector.

Using a 12-volt test light, connect one end to the Fused Ignition Switch Output

circuit and the other end to the LDP Solenoid Control circuit.

Turn the ignition on.

With the DRBIIIt, actuate the Leak Detection Pump.

Does the test light flash on and off.All

Ye s®Replace the Leak Detection Pump.

Perform POWERTRAIN VERIFICATION TEST VER - 6.

No®Go To 3

216

DRIVEABILITY - GAS

Page 4020 of 4284

Symptom:

*CHECKING ECT SENSOR

POSSIBLE CAUSES

ECT SENSOR OPERATION

ECT SENSOR

TEST ACTION APPLICABILITY

1NOTE: The engine coolant temperature must be below 62ÉC (150ÉF).

Turn the ignition on.

With the DRBIIIt, monitor the ECT value.

Start the engine.

Does the ECT reach 82ÉC (180ÉF) and was it a smooth transition?All

Ye s®Engine Coolant Temperature sensor is operating normally.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

No®Replace the Engine Coolant Temperature Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 2.

226

DRIVEABILITY - GAS

Page 4050 of 4284

TEST ACTION APPLICABILITY

8 The following items need to be checked as a possible cause for a no start condition.

Refer to any Technical Service Bulletins that may apply to the symptom.

The spark plugs must be free from fuel, oil, coolant and/or any foreign material or

deposits.

The fuel must be free from contamination.

The exhaust may be free from restrictions.

The engine compression must be within specifications.

The engine valve timing must be within specifications.

The engine must be free from vacuum leaks.

Were any of the above conditions found?All

Ye s®Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Test Complete.

9 Turn the ignition off.

Disconnect the fuel pump module harness connector.

Turn the ignition on.

With the DRBIIIt, actuate the ASD Fuel System test.

Using a 12 volt test light connected to ground, probe the Fuel Pump Relay Output

circuit at the Fuel Pump Module harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 10

No®Go To 12

Caution: Stop All Actuations.

10 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Note: Check connectors - It is critical that the connector is free from any

signs of corrosion or deformities - Clean/repair as necessary.

Using a test light connected to battery voltage, probe the Fuel Pump ground circuit

at the Fuel Pump Module harness connector.

Does the test light illuminate brightly?All

Ye s®Go To 11

No®Repair the open/high resistance in the fuel pump ground circuit.

Perform POWERTRAIN VERIFICATION TEST VER-1.

11 If there are no possible causes remaining, view repair. All

Repair

Replace the Fuel Pump Module.

Perform POWERTRAIN VERIFICATION TEST VER-1.

12 Turn the ignition off.

Remove the Fuel Pump Relay from the IPM.

With a 12 volt test light connected to ground, probe the Fuel Pump Relay Fused B+

circuit in the IPM.

Does the test light illuminate?All

Ye s®Go To 13

No®Check for an open Fuel Pump fuse, repair cause of open. If OK,

replace the IPM Fuse & Relay Center.

Perform POWERTRAIN VERIFICATION TEST VER-1.

256

STARTING

*ENGINE CRANKS DOES NOT START ÐContinued

Page 4059 of 4284

TEST ACTION APPLICABILITY

9Note: For this test to be valid, the thermostat must be operating correctly.

Note: This test works best if performed on a cold engine (cold soaked).

NOTE: If the vehicle was allow to sit over night with no engine start, coolant

temperature should be near ambient temperatures.

Turn the ignition on.

With the DRBIIIt, read the Engine Coolant Temperature value.

Note: If engine coolant temperature is above 82É C (180É F), allow the engine

to cool until 65É C (150É F) is reached.

Start the engine.

During engine warm-up, monitor the Engine Coolant Temperature value. The

temperature value change should be a smooth transition from start up to normal

operating temp 82É C (180É F). The value should reach at least 82É C (180É F).

Did the Engine Temperature value increase smoothly and did it reach at least 82É C

(180É F)?All

Ye s®Go To 10

No®Replace the Engine Coolant Temperature Sensor.

Perform POWERTRAIN VERIFICATION TEST VER-1.

10 The following additional items should be checked as a possible cause for a start and

stall condition.

Refer to any Technical Service Bulletins (TSB's) that may apply to the symptom.

Fuel must be free of contamination.

The exhaust system must be free of any restrictions.

The engine compression must be within specifications.

The engine valve timing must be within specifications.

The engine must be free from vacuum leaks.

The throttle body must be free of carbon buildup and dirt.

Do any of the above conditions exist?All

Ye s®Repair as necessary.

Perform POWERTRAIN VERIFICATION TEST VER-1.

No®Test Complete.

265

STARTING

*START AND STALL CONDITION ÐContinued

Page 4088 of 4284

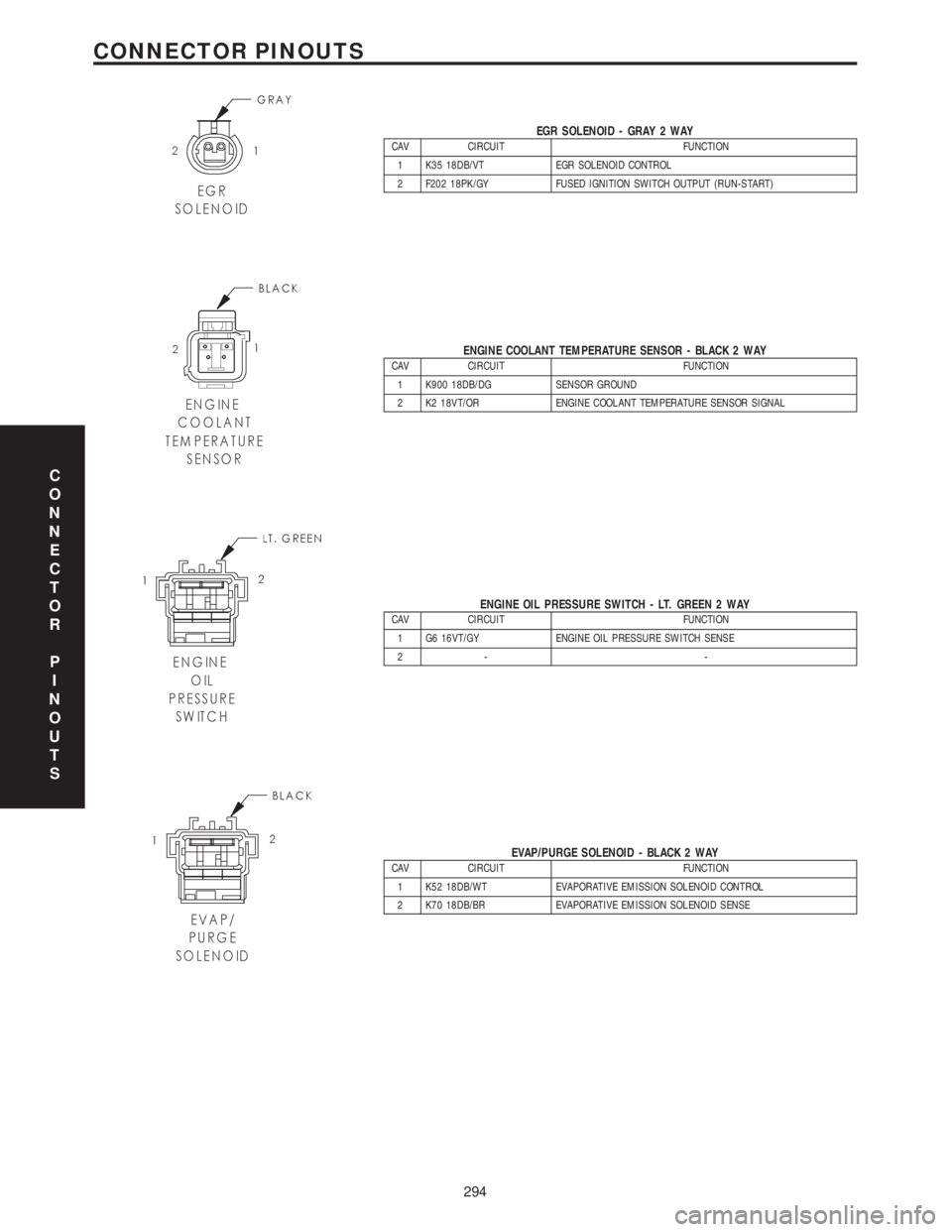

EGR SOLENOID - GRAY 2 WAYCAV CIRCUIT FUNCTION

1 K35 18DB/VT EGR SOLENOID CONTROL

2 F202 18PK/GY FUSED IGNITION SWITCH OUTPUT (RUN-START)

ENGINE COOLANT TEMPERATURE SENSOR - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K900 18DB/DG SENSOR GROUND

2 K2 18VT/OR ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

ENGINE OIL PRESSURE SWITCH - LT. GREEN 2 WAYCAV CIRCUIT FUNCTION

1 G6 16VT/GY ENGINE OIL PRESSURE SWITCH SENSE

2- -

EVAP/PURGE SOLENOID - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 K52 18DB/WT EVAPORATIVE EMISSION SOLENOID CONTROL

2 K70 18DB/BR EVAPORATIVE EMISSION SOLENOID SENSE

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

294

CONNECTOR PINOUTS

Page 4095 of 4284

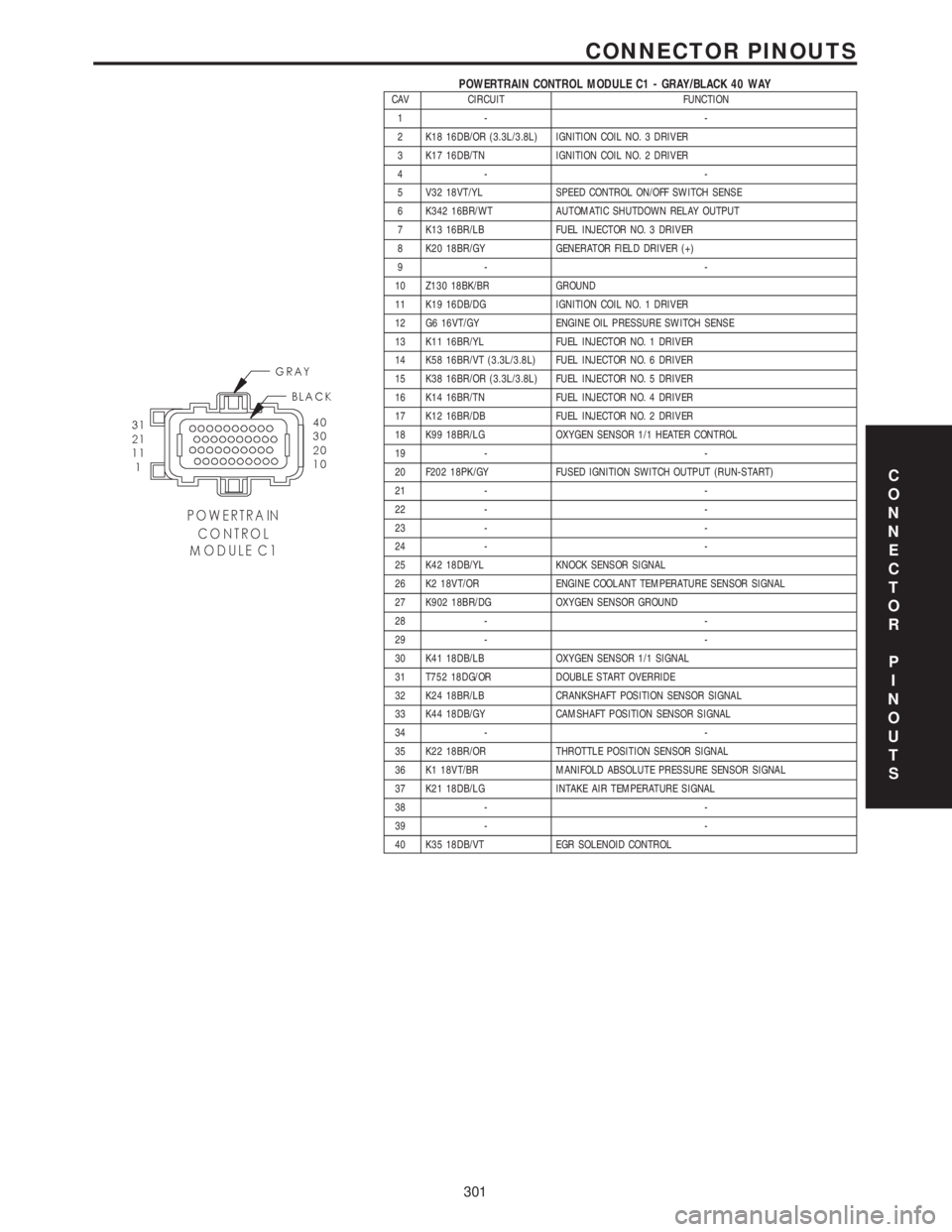

POWERTRAIN CONTROL MODULE C1 - GRAY/BLACK 40 WAYCAV CIRCUIT FUNCTION

1- -

2 K18 16DB/OR (3.3L/3.8L) IGNITION COIL NO. 3 DRIVER

3 K17 16DB/TN IGNITION COIL NO. 2 DRIVER

4- -

5 V32 18VT/YL SPEED CONTROL ON/OFF SWITCH SENSE

6 K342 16BR/WT AUTOMATIC SHUTDOWN RELAY OUTPUT

7 K13 16BR/LB FUEL INJECTOR NO. 3 DRIVER

8 K20 18BR/GY GENERATOR FIELD DRIVER (+)

9- -

10 Z130 18BK/BR GROUND

11 K19 16DB/DG IGNITION COIL NO. 1 DRIVER

12 G6 16VT/GY ENGINE OIL PRESSURE SWITCH SENSE

13 K11 16BR/YL FUEL INJECTOR NO. 1 DRIVER

14 K58 16BR/VT (3.3L/3.8L) FUEL INJECTOR NO. 6 DRIVER

15 K38 16BR/OR (3.3L/3.8L) FUEL INJECTOR NO. 5 DRIVER

16 K14 16BR/TN FUEL INJECTOR NO. 4 DRIVER

17 K12 16BR/DB FUEL INJECTOR NO. 2 DRIVER

18 K99 18BR/LG OXYGEN SENSOR 1/1 HEATER CONTROL

19 - -

20 F202 18PK/GY FUSED IGNITION SWITCH OUTPUT (RUN-START)

21 - -

22 - -

23 - -

24 - -

25 K42 18DB/YL KNOCK SENSOR SIGNAL

26 K2 18VT/OR ENGINE COOLANT TEMPERATURE SENSOR SIGNAL

27 K902 18BR/DG OXYGEN SENSOR GROUND

28 - -

29 - -

30 K41 18DB/LB OXYGEN SENSOR 1/1 SIGNAL

31 T752 18DG/OR DOUBLE START OVERRIDE

32 K24 18BR/LB CRANKSHAFT POSITION SENSOR SIGNAL

33 K44 18DB/GY CAMSHAFT POSITION SENSOR SIGNAL

34 - -

35 K22 18BR/OR THROTTLE POSITION SENSOR SIGNAL

36 K1 18VT/BR MANIFOLD ABSOLUTE PRESSURE SENSOR SIGNAL

37 K21 18DB/LG INTAKE AIR TEMPERATURE SIGNAL

38 - -

39 - -

40 K35 18DB/VT EGR SOLENOID CONTROL

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

301

CONNECTOR PINOUTS

Page 4106 of 4284

3.2.2 TRANSMISSION OPERATION AND

SHIFT SCHEDULING AT VARIOUS

OIL TEMPERATURES.

The transmission covered in this manual has

unique shift schedules depending on the tempera-

ture of the transmission oil. The shift schedule is

modified to extend the life of the transmission while

operating under extreme conditions.

The oil temperature is measured with a Temper-

ature Sensor on the 41TE/AE transmission. The

Temperature Sensor is an integral component of the

Transmission Range Sensor (TRS). If the Tempera-

ture Sensor is faulty, (DTC P1799(74)) the trans-

mission will default to a calculated oil temperature.

Oil temperature will then be calculated through a

complex heat transfer equation which uses engine

coolant temperature, battery/ambient temperature,

and engine off time from the Body Control Module

(BCM). These inputs are received from the PCI bus

periodically and used to initialize the oil tempera-

ture at start up. Once the engine is started, the

TCM updates the transmission oil temperature

based on torque converter slip speed, vehicle speed,

gear, and engine coolant temperature to determine

an estimated oil temperature during vehicle opera-

tion. Vehicles using a calculated oil temperature

track oil temperature reasonably accurate during

normal operation. However, if a transmission is

overfilled, a transmission oil cooler becomes re-

stricted, or if a customer drives aggressively in low

gear, the calculated oil temperature will be inaccu-

rate. Consequently the shift schedule selected may

be inappropriate for the current conditions. The key

highlights of the various shift schedules are as

follows:

Extreme Cold:Oil temperature at start up below

-26.6C (-16ÉF)

> Goes to a Cold schedule above -24C (-12ÉF) oil

temperature

> Park, Reverse, Neutral and 2nd gear only (pre-

vents shifting which may fail a clutch with fre-

quent shifts)

Cold:Oil temperature at start up above -24C

(-12ÉF) and below 2.2C (36ÉF)

> Goes to a Warm schedule above 4.4C (40ÉF) oil

temperature

> Delayed 2-3 upshift approximately 35-50 Km/h

(22-31 MPH)

> Delayed 3-4 upshift 72-85 Km/h (45-53 MPH)

> Early 4-3 coastdown shift approximately 48

Km/h (30 MPH)

> Early 3-2 coastdown shift approximately 27

Km/h (17 MPH)> High speed 4-2, 3-2, 2-1 kickdown shifts are

prevented

> No EMCC

Warm:Oil temperature at start up above 2.2C

(36ÉF) and below 27C (80ÉF)

> Goes to a Hot schedule above 27C (80ÉF) oil

temperature

> Normal operation (upshifts, kickdowns, and

coastdowns)

> No EMCC

Hot:Oil temperature at start up above 27C (80ÉF)

> Goes to a Overheat schedule above 115C (240ÉF)

oil temperature

> Normal operation (upshifts, kickdowns, and

coastdowns)

> Full EMCC, No PEMCC except to engage

FEMCC

(Except at closed throttle at speeds above 113-133

Km/h (70 - 83 MPH)

Overheat:Oil temperature above 115C (240ÉF) or

engine coolant temperature above 118C (244ÉF)

> Goes to a Hot below 110C (230ÉF) oil temperature

or a Super Overheat above 115C (240ÉF) oil

temperature

> Delayed 2-3 upshift 40-51 Km/h (25-32 MPH)

> Delayed 3-4 upshift 66-77 Km/h (41-48 MPH)

> 3rd gear FEMCC from 48-77 Km/h (30-48 MPH)

> 3rd gear PEMCC from 43-50 Km/h (27-31 MPH)

Super Overheat:Oil temperature above 127C

(260ÉF)

> Goes back to a Overheat below 115C (240ÉF) oil

temperature

> All a Overheat shift schedules features apply

> 2nd gear PEMCC above 35 Km/h (22 MPH)

> Above 35 Km/h (22 MPH) the torque converter

will not unlock unless the throttle is closed (i.e. at

80 Km/h (50 MPH) a 4th FEMCC to 3rd FEMCC

shift will be made during a part throttle kick-

down or a 4th FEMCC to 2nd PEMCC shift will

be made at wide open throttle) or if a wide open

throttle 2nd PEMCC to 1 kickdown is made.

Causes for operation in the wrong tempera-

ture shift schedule:

Extreme Cold or Cold shift schedule at start up:

> Temperature Sensor circuit.

Overheat or Super Overheat shift schedule after

extended operation:

> Operation in city traffic or stop and go traffic

> Engine idle speed too high

> Aggressive driving in low gear

2

GENERAL INFORMATION

Page 4107 of 4284

> Trailer towing in OD gear position (use 3 position

(or A/S 3rd) if frequent shifting occurs)

> Cooling system failure causing engine to operate

over 110C (230ÉF)

> Engine coolant temperature stays low too long -

If engine coolant temperature drops below 65C

(150ÉF), the transmission will disengage EMCC.

Extended operation with the EMCC disengaged

will cause the transmission to overheat.

> A brake switch issue will cause the EMCC to

disengage. Extended operation with the EMCC

disengaged will cause the transmission to over-

heat.

> Transmission fluid overfilled

> Transmission cooler or cooler lines restricted

> Transmission Temperature Sensor circuit

3.3 DIAGNOSTIC TROUBLE CODES

Diagnostic trouble codes (DTC's) are codes stored

by the Transmission Control Module (TCM) that

help us diagnose Transmission problems. They are

viewed using the DRBIIItscan tool.

Always begin by performing a visual inspection of

the wiring, connectors, cooler lines and the trans-

mission. Any obvious wiring problems or leaks

should be repaired prior to performing any diagnos-

tic test procedures. Some engine driveability prob-

lems can be misinterpreted as a transmission prob-

lem. Ensure that the engine is running properly

and that no PCM DTC's are present that could

cause a transmission complaint.

If there is a communication bus problem, trouble

codes will not be accessible until the problem is

fixed. The DRBIIItwill display an appropriate

message. The following is a possible list of causes

for a bus problem:

± open or short to ground/battery in PCI bus

circuit (pin 43).

± internal failure of any module or component on

the bus

Each diagnostic trouble code is diagnosed by

following a specific testing sequence. The diagnostic

test procedures contain step-by-step instructions

for determining the cause of a transmission diag-

nostic trouble code. Possible sources of the code are

checked and eliminated one by one. It is not neces-

sary to perform all of the tests in this book to

diagnose an individual code. These tests are based

on the problem being present at the time that the

test is run.All testing should be done with a

fully charged battery.

If the TCM records a DTC that will adversely

affect vehicle emissions, it will request (via the

communication bus) that the PCM illuminate the

Malfunction Indicator Lamp (MIL). Although theseDTC's will be stored in the TCM immediately as a 1

trip failure, it may take up to five minutes of

accumulated trouble confirmation set the DTC and

illuminate the MIL. Three consecutive successful

OBDII (EURO STAGE III OBD) trips or clearing

the DTC's with a diagnostic tool (DRBIIItor equiv-

alent) is required to extinguish the MIL. When the

TCM requests that the PCM illuminate the MIL,

the PCM sets a DTC P0700(89) to alert the techni-

cian that there are DTC's in the TCM. This must

also be erased in the PCM in order to extinguish the

MIL.

3.3.1 HARD CODE

Any Diagnostic Trouble Code (DTC) that is set

whenever the system or component is monitored is

a HARD code. This means that the problem is there

every time the TCM checks that system or compo-

nent. Some codes will set immediately at start up

and others will require a road test under specific

conditions. It must be determined if a code is

repeatable (Hard) or intermittent before attempt-

ing diagnosis.

3.3.2 ONE TRIP FAILURES

A One Trip Failure, when read from the TCM, is

a hard OBDII (EURO STAGE III OBD) code that

has not matured for the full 5 minutes. This applies

to codes that will only set after 5 minutes of

substituted gear operation.

3.3.3 INTERMITTENT CODE

A diagnostic trouble code that is not there every

time the TCM checks the circuit or function is an a

intermittent code. Some intermittent codes, such as

codes P1792(12), P1767(14), P1768(15), P0725(18),

P1716(19), P1781(21), P1782(22), P1724(24),

P0705(28), P0120(29), P0750(41), P0755(42),

P0760(43), P0765(44), P1793(48), P0715(56),

P0720(57), P1794(58), P1796(70), P1799(74),

P1739(76), P1717(77), and P0600(78) are caused by

wiring or connector problems. However intermit-

tent codes 50 - 54 are usually caused by intermit-

tent hydraulic seal leakage in the clutch and/or

accumulator circuits. Problems that come and go

like this are the most difficult to diagnose, they

must be looked for under the specific conditions

that cause them.

3.3.4 STARTS SINCE SET COUNTER

For the most recent code (Code 1), the Starts

Since Set counter counts the number of times the

vehicle has started since it was last set. The counter

will count up to 255 starts. Note that this code only

applies to the last code set.

When there are no diagnostic trouble codes stored

in memory, the DRBIIItwill display ``NO DTC'S

3

GENERAL INFORMATION