coolant CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3848 of 4284

Symptom:

P0117-ECT SENSOR VOLTAGE TOO LOW

When Monitored and Set Condition:

P0117-ECT SENSOR VOLTAGE TOO LOW

When Monitored: With the ignition on. Battery voltage greater than 10 volts.

Set Condition: The Engine Coolant Temperature (ECT) sensor circuit voltage at the PCM

is less than 0.8 volt for more than 2.6 seconds.

POSSIBLE CAUSES

INTERMITTENT CONDITION

ECT SENSOR INTERNAL FAILURE

ECT SENSOR SIGNAL SHORTED TO GROUND

ECT SENSOR SIGNAL SHORTED TO SENSOR GROUND CIRCUIT

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read the ECT voltage.

Is the voltage below 1.0 volt?All

Ye s®Go To 2

No®Go To 6

2 Turn the ignition off.

Disconnect the ECT harness connector.

Turn the ignition on.

With the DRBIIIt, read ECT voltage.

Is the voltage above 1.0 volt?All

Ye s®Replace the ECT Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

3 Turn the ignition off.

Disconnect the ECT Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the ECT Sensor Signal circuit in the ECT Sensor harness

connector to ground.

Is the resistance below 100 ohms?All

Ye s®Repair the ECT Sensor Signal circuit for a short to ground.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

54

DRIVEABILITY - GAS

Page 3850 of 4284

Symptom:

P0118-ECT SENSOR VOLTAGE TOO HIGH

When Monitored and Set Condition:

P0118-ECT SENSOR VOLTAGE TOO HIGH

When Monitored: With the ignition on. Battery voltage greater than 10 volts.

Set Condition: The Engine Coolant Temperature (ECT) sensor circuit voltage at the PCM

is greater than 4.96 volts for more than 2.6 seconds.

POSSIBLE CAUSES

INTERMITTENT CONDITION

ECT SENSOR SIGNAL CIRCUIT SHORTED TO BATTERY VOLTAGE

ECT SENSOR INTERNAL FAILURE

ECT SENSOR SIGNAL CIRCUIT OPEN

SENSOR GROUND CIRCUIT OPEN

PCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read the ECT voltage.

Is the voltage above 4.6 volts?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition off.

Disconnect the ECT Sensor harness connector.

Turn the ignition on.

Measure the voltage of the ECT Sensor Signal circuit in the ECT Sensor harness

connector.

Is the voltage above 5.2 volts?All

Ye s®Repair the ECT Sensor Signal circuit for a short to battery

voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

56

DRIVEABILITY - GAS

Page 3865 of 4284

Symptom:

P0125-CLOSED LOOP TEMP NOT REACHED

When Monitored and Set Condition:

P0125-CLOSED LOOP TEMP NOT REACHED

When Monitored: With battery voltage greater than 10.4 volts, after engine is started.

Set Condition: The engine temperature does not go above 60ÉF (15ÉC). F Time depen-

dants on start-up coolant temperature and ambient temperature. (i.e. 2 minutes for a start

temp of 10ÉC (50ÉF) or up to 10 mintues for a vehicle with a start-up temp of -28ÉC (20ÉF).

Two trips are required to set this DTC.

POSSIBLE CAUSES

LOW COOLANT LEVEL

THERMOSTAT OPERATION

ENGINE COOLANT TEMPERATURE SENSOR

TEST ACTION APPLICABILITY

1NOTE: If a ECT DTC set along with this code, diagnose the ECT DTC first.

NOTE: Inspect the ECT terminals and related PCM terminals. Ensure the

terminals are free from corrosion and damage.

NOTE: The best way to diagnose this DTC is to allow the vehicle to sit

overnight outside in order to have a totally cold soaked engine.

Note: Extremely cold outside ambient temperatures may have caused this

DTC to set.

WARNING: Never open the cooling system when the engine is hot. The

system is under pressure. Extreme burns or scalding may result. Allow the

engine to cool before opening the cooling system.

Check the coolant system to make sure that the coolant is in good condition and at

the proper level.

Is the coolant level and condition OK?All

Ye s®Go To 2

No®Inspect the vehicle for a coolant leak and add the necessary

amount of coolant.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

71

DRIVEABILITY - GAS

Page 3866 of 4284

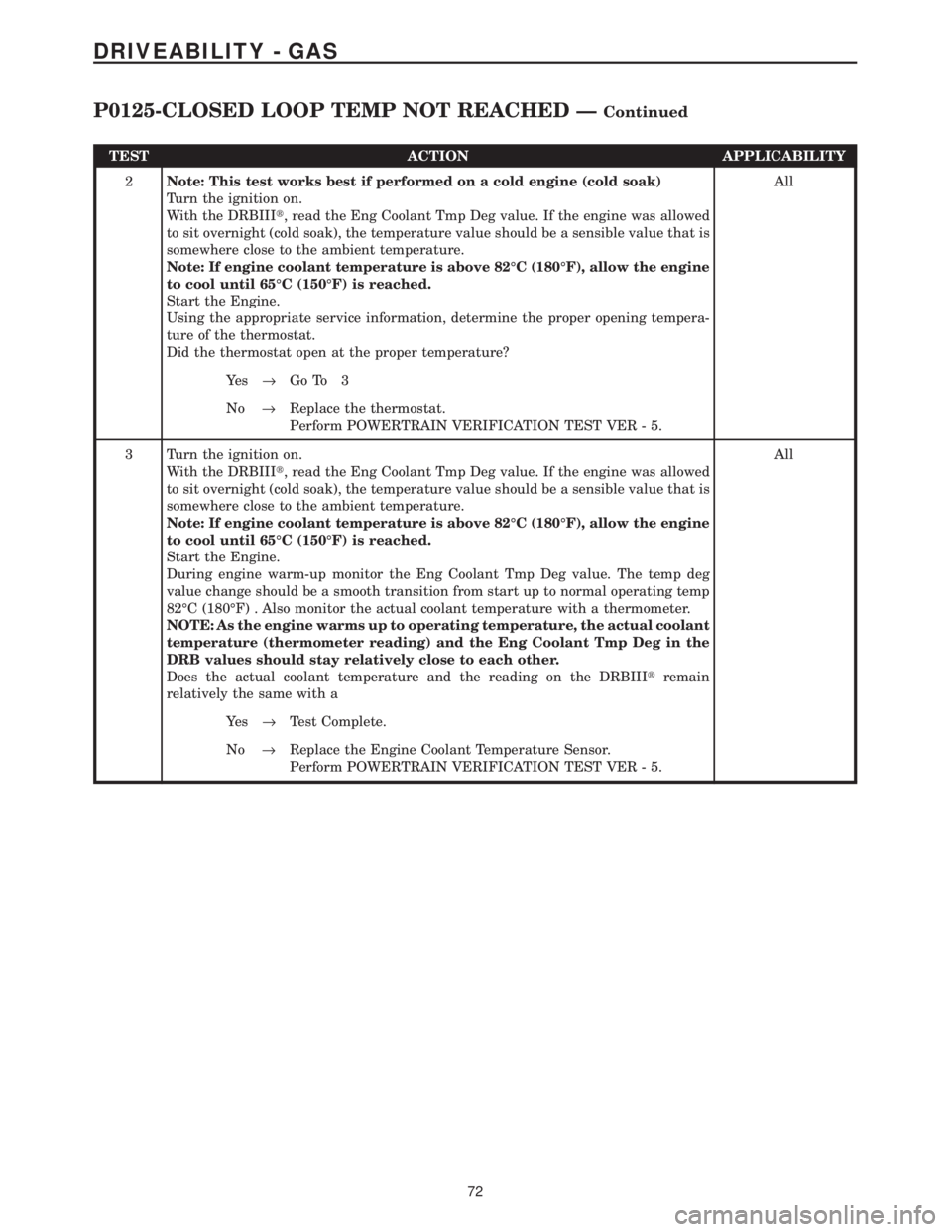

TEST ACTION APPLICABILITY

2Note: This test works best if performed on a cold engine (cold soak)

Turn the ignition on.

With the DRBIIIt, read the Eng Coolant Tmp Deg value. If the engine was allowed

to sit overnight (cold soak), the temperature value should be a sensible value that is

somewhere close to the ambient temperature.

Note: If engine coolant temperature is above 82ÉC (180ÉF), allow the engine

to cool until 65ÉC (150ÉF) is reached.

Start the Engine.

Using the appropriate service information, determine the proper opening tempera-

ture of the thermostat.

Did the thermostat open at the proper temperature?All

Ye s®Go To 3

No®Replace the thermostat.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

3 Turn the ignition on.

With the DRBIIIt, read the Eng Coolant Tmp Deg value. If the engine was allowed

to sit overnight (cold soak), the temperature value should be a sensible value that is

somewhere close to the ambient temperature.

Note: If engine coolant temperature is above 82ÉC (180ÉF), allow the engine

to cool until 65ÉC (150ÉF) is reached.

Start the Engine.

During engine warm-up monitor the Eng Coolant Tmp Deg value. The temp deg

value change should be a smooth transition from start up to normal operating temp

82ÉC (180ÉF) . Also monitor the actual coolant temperature with a thermometer.

NOTE: As the engine warms up to operating temperature, the actual coolant

temperature (thermometer reading) and the Eng Coolant Tmp Deg in the

DRB values should stay relatively close to each other.

Does the actual coolant temperature and the reading on the DRBIIItremain

relatively the same with aAll

Ye s®Test Complete.

No®Replace the Engine Coolant Temperature Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

72

DRIVEABILITY - GAS

P0125-CLOSED LOOP TEMP NOT REACHED ÐContinued

Page 3867 of 4284

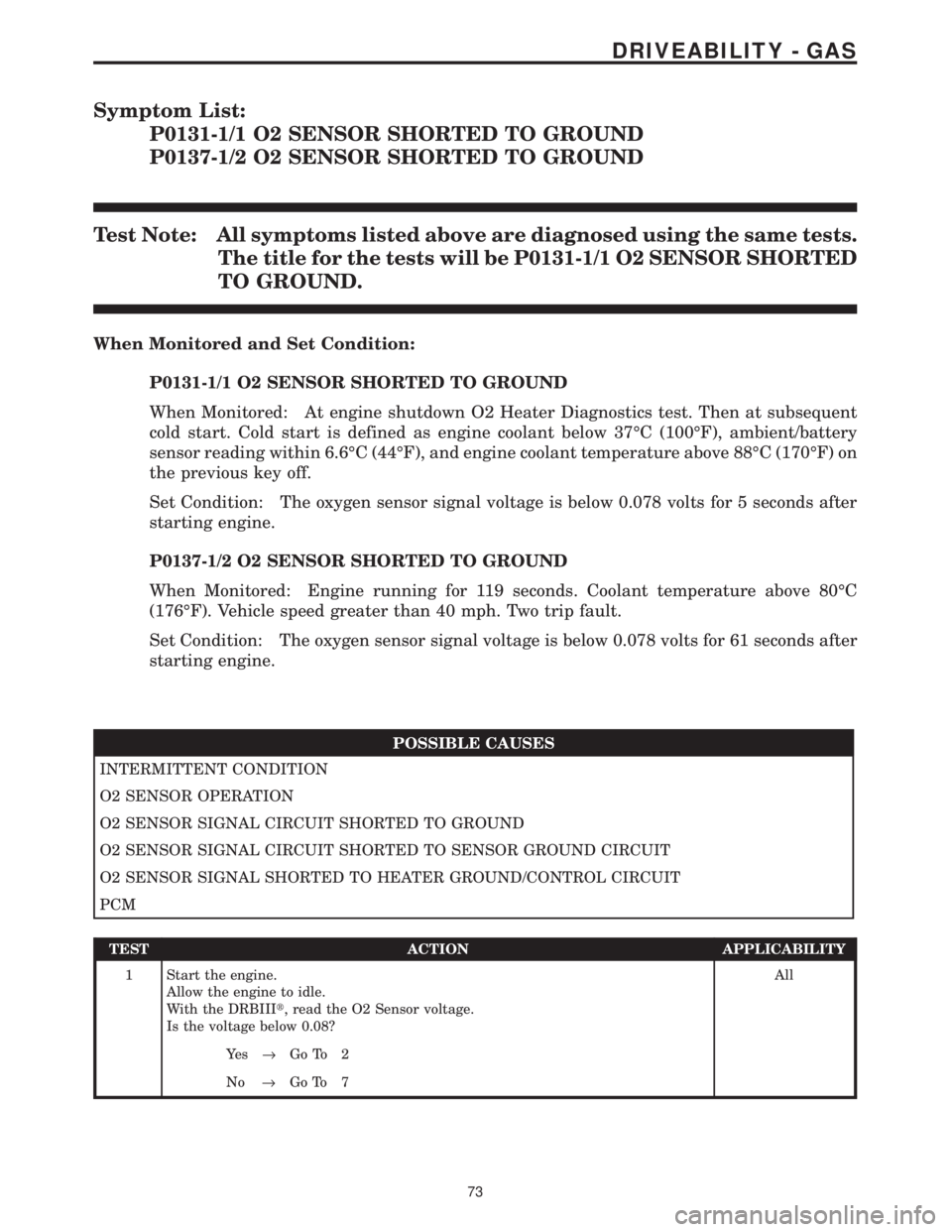

Symptom List:

P0131-1/1 O2 SENSOR SHORTED TO GROUND

P0137-1/2 O2 SENSOR SHORTED TO GROUND

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0131-1/1 O2 SENSOR SHORTED

TO GROUND.

When Monitored and Set Condition:

P0131-1/1 O2 SENSOR SHORTED TO GROUND

When Monitored: At engine shutdown O2 Heater Diagnostics test. Then at subsequent

cold start. Cold start is defined as engine coolant below 37ÉC (100ÉF), ambient/battery

sensor reading within 6.6ÉC (44ÉF), and engine coolant temperature above 88ÉC (170ÉF) on

the previous key off.

Set Condition: The oxygen sensor signal voltage is below 0.078 volts for 5 seconds after

starting engine.

P0137-1/2 O2 SENSOR SHORTED TO GROUND

When Monitored: Engine running for 119 seconds. Coolant temperature above 80ÉC

(176ÉF). Vehicle speed greater than 40 mph. Two trip fault.

Set Condition: The oxygen sensor signal voltage is below 0.078 volts for 61 seconds after

starting engine.

POSSIBLE CAUSES

INTERMITTENT CONDITION

O2 SENSOR OPERATION

O2 SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

O2 SENSOR SIGNAL CIRCUIT SHORTED TO SENSOR GROUND CIRCUIT

O2 SENSOR SIGNAL SHORTED TO HEATER GROUND/CONTROL CIRCUIT

PCM

TEST ACTION APPLICABILITY

1 Start the engine.

Allow the engine to idle.

With the DRBIIIt, read the O2 Sensor voltage.

Is the voltage below 0.08?All

Ye s®Go To 2

No®Go To 7

73

DRIVEABILITY - GAS

Page 3870 of 4284

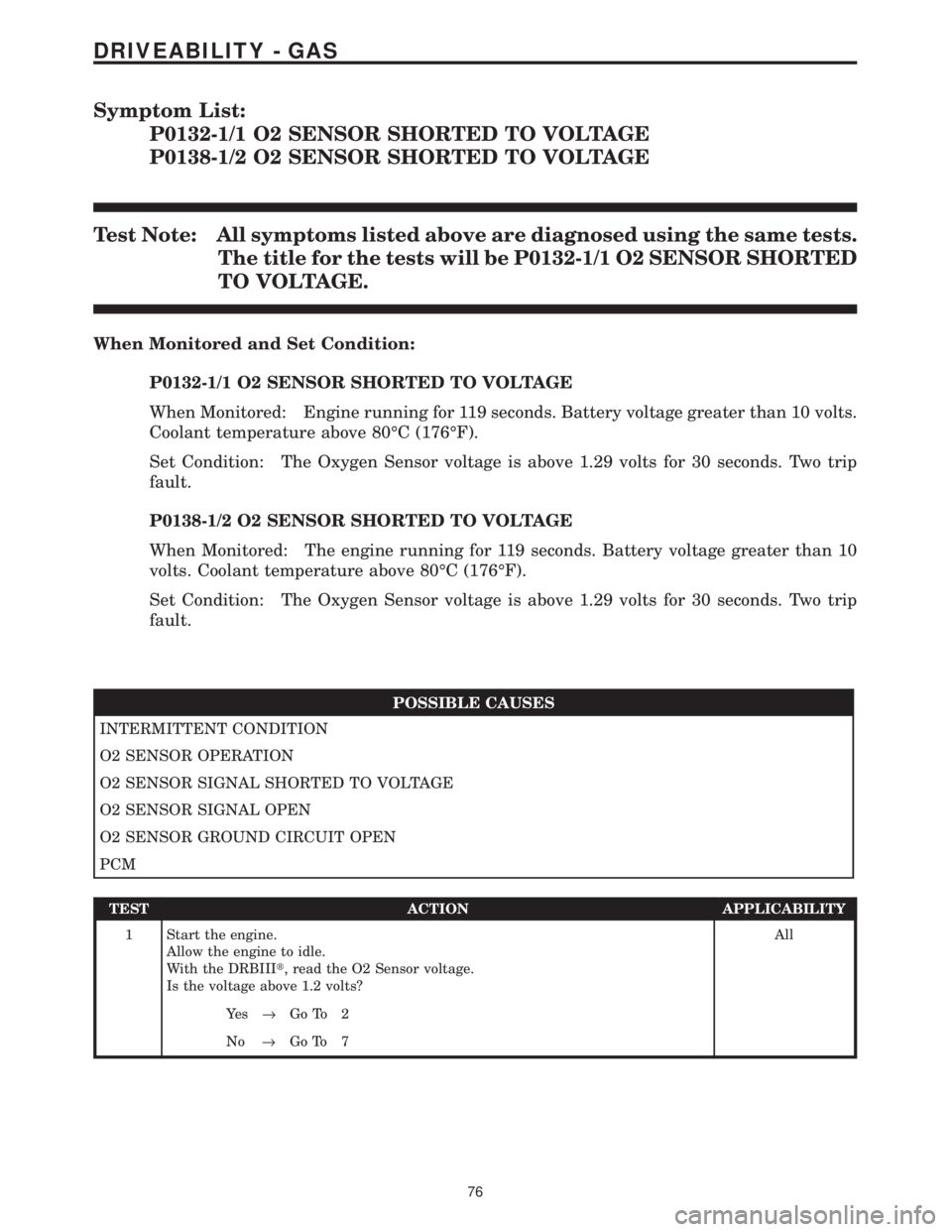

Symptom List:

P0132-1/1 O2 SENSOR SHORTED TO VOLTAGE

P0138-1/2 O2 SENSOR SHORTED TO VOLTAGE

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0132-1/1 O2 SENSOR SHORTED

TO VOLTAGE.

When Monitored and Set Condition:

P0132-1/1 O2 SENSOR SHORTED TO VOLTAGE

When Monitored: Engine running for 119 seconds. Battery voltage greater than 10 volts.

Coolant temperature above 80ÉC (176ÉF).

Set Condition: The Oxygen Sensor voltage is above 1.29 volts for 30 seconds. Two trip

fault.

P0138-1/2 O2 SENSOR SHORTED TO VOLTAGE

When Monitored: The engine running for 119 seconds. Battery voltage greater than 10

volts. Coolant temperature above 80ÉC (176ÉF).

Set Condition: The Oxygen Sensor voltage is above 1.29 volts for 30 seconds. Two trip

fault.

POSSIBLE CAUSES

INTERMITTENT CONDITION

O2 SENSOR OPERATION

O2 SENSOR SIGNAL SHORTED TO VOLTAGE

O2 SENSOR SIGNAL OPEN

O2 SENSOR GROUND CIRCUIT OPEN

PCM

TEST ACTION APPLICABILITY

1 Start the engine.

Allow the engine to idle.

With the DRBIIIt, read the O2 Sensor voltage.

Is the voltage above 1.2 volts?All

Ye s®Go To 2

No®Go To 7

76

DRIVEABILITY - GAS

Page 3873 of 4284

Symptom List:

P0133-1/1 O2 SENSOR SLOW RESPONSE

P0139-1/2 O2 SENSOR SLOW RESPONSE

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0133-1/1 O2 SENSOR SLOW

RESPONSE.

When Monitored and Set Condition:

P0133-1/1 O2 SENSOR SLOW RESPONSE

When Monitored: Start and drive vehicle greater than 10 MPH with throttle open for a

minimum 200 seconds. Coolant greater than 70ÉC (158ÉF). EVAP Purge is active. Test

performs in idle drive.

Set Condition: The oxygen sensor signal voltage is switching from below 0.39 volts to

above 0.58 volts and back fewer times than required in 60 seconds. Two trip fault..

P0139-1/2 O2 SENSOR SLOW RESPONSE

When Monitored: Start engine. Allow engine to idle. For 1st part of test, if limits are

exceeded, test passes. If not, 2nd part of test runs. Engine running for grater than 295

seconds. amb/batt temp >44ÉF, Baro >22.139HG, MAP >13.8 & <21.69HG, RPM >1400 &

<2500 (4cylinder) RPM > 1120 & <1950(6 cylinder) and vss >22 and < 60 MPH.

Set Condition: The oxygen sensor signal voltage is has not switched below 0.35 volts to

above 0.53 volts in 411 seconds of engine run. Two trip fault.

POSSIBLE CAUSES

INTERMITTENT CONDITION

EXHAUST LEAK

O2 SENSOR SIGNAL CIRCUIT VOLTAGE DROP

O2 SENSOR GROUND CIRCUIT VOLTAGE DROP

O2 SENSOR

TEST ACTION APPLICABILITY

1NOTE: Check for contaminates that may have damaged the O2 Sensor:

contaminated fuel, unapproved silicone, oil and coolant.

Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 6

79

DRIVEABILITY - GAS

Page 3875 of 4284

TEST ACTION APPLICABILITY

6NOTE: Check for contaminates that may have damaged the O2 Sensor:

contaminated fuel, unapproved silicone, oil and coolant.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

81

DRIVEABILITY - GAS

P0133-1/1 O2 SENSOR SLOW RESPONSE ÐContinued

Page 3876 of 4284

Symptom List:

P0134-1/1 O2 SENSOR STAYS AT CENTER

P0140-1/2 O2 SENSOR STAYS AT CENTER

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0134-1/1 O2 SENSOR STAYS AT

CENTER.

When Monitored and Set Condition:

P0134-1/1 O2 SENSOR STAYS AT CENTER

When Monitored: Engine running for greater than 121 second. Coolant Temperature

greater than 66ÉC (150.8ÉF). Engine in closed loop fuel control mode.

Set Condition: O2 signal voltage is between .35 volt and .58 volt for a total of 30 seconds

and than O2 signal volt is 1.5 volts for 60 seconds. One trip fault.

P0140-1/2 O2 SENSOR STAYS AT CENTER

When Monitored: Engine running for greater than 121 second. Coolant Temperature

greater than 66ÉC (150.8ÉF). Engine in closed loop fuel control mode. Vehicle Speed greater

than 40 MPH.

Set Condition: O2 signal voltage is between .35 volt and .58 volt for a total of 30 seconds

and than O2 signal volt is 1.5 volts for 60 seconds. Two trip fault.

POSSIBLE CAUSES

INTERMITTENT CONDITION

O2 SENSOR OPERATION

O2 SENSOR GROUND CIRCUIT OPEN

O2 SENSOR SIGNAL OPEN

O2 SENSOR GROUND CIRCUIT VOLTAGE DROP

O2 SENSOR SIGNAL CIRCUIT VOLTAGE DROP

PCM

TEST ACTION APPLICABILITY

1NOTE: Check for contaminates that may have damaged the O2 Sensor:

contaminated fuel, unapproved silicone, oil and coolant.

Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 8

82

DRIVEABILITY - GAS

Page 3878 of 4284

TEST ACTION APPLICABILITY

6NOTE: Ensure the voltmeter leads meet the terminals in the connector and

that there is good terminal to wire connection.

NOTE: Ensure the voltmeter leads are connected for positive polarity

Perform a voltage drop test backprobe between the O2 Sensor Signal circuit at the O2

Sensor harness connector and PCM harness connector.

Start the engine.

Allow the engine to idle.

Is the voltage below 0.10 volt?All

Ye s®Go To 7

No®Repair the high resistance on the O2 Sensor Signal circuit.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

7 If there are no possible causes remaining, view repair. All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

8NOTE: Check for contaminates that may have damaged the O2 Sensor:

contaminated fuel, unapproved silicone, oil and coolant.

WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

84

DRIVEABILITY - GAS

P0134-1/1 O2 SENSOR STAYS AT CENTER ÐContinued