key CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4120 of 4284

since there is no power available to control the

transmission solenoids. However if power is re-

stored, the TCM will power-up and normal opera-

tion will be restored. This DTC identifies that

power to the TCM was restored when the gear

selector was in a9Drive9position while the vehicle

was moving at speeds above 32 Km/h (20 MPH). If

a person shifts to Neutral and cycles the ignition

key and quickly shifts to9Drive9while moving

before the TCM comes out of its START ROUTINE,

the DTC can be set. Therefore it is critical that this

DTC diagnosis repair procedure should only be used

if the vehicle is experiencing intermittent 2nd gear

operation and subsequently a return to normal

operation during normal driving.

Transmission Effects:No limp-in condition. The

DTC is for information only when trying to diagno-

sis intermittent 2nd gear operation and subse-

quently a return to normal operation.

Possible Causes:

± No Problem if vehicle is started in9neutral9at

speeds above 32 Km/h (20 MPH) and shifted

quickly to9Drive9before TCM comes out of the

START ROUTINE.

FOR INTERMITTENT 2ND GEAR OPER-

ATION AND THEN A SUBSEQUENT RE-

TURN TO NORMAL OPERATION WITH-

OUT CYCLING THE IGNITION KEY

± Intermittent Direct Battery connection be-

tween TCM (60-way pin 56) and battery.

± Intermittent Fused Ignition Switch Output

between TCM (60-way pin 11) and ignition

switch.

± Intermittent Ground to TCM (60 way pins 53

and 57).

Name of code:P1717(77) - No Communication

with Mechanical Instrument Cluster (MIC)

When monitored:Continuously with key on.

Set condition:If no PCI bus messages are received

from the Mechanical Instrument Cluster (MIC) for

25 seconds.

Theory of operation:The TCM communicates

with the MIC using the PCI bus. It relies on certain

information to function properly. The TCM contin-

uously monitors the PCI bus to check for messages

broadcast from the PCM.

Transmission Effects:Possible improper TCM

AutoStick configuration.

Possible causes:

> Open or shorted PCI bus circuit from MIC

> MIC

> TCM (If other communications codes are stored

in the TCM only)

Name of code:P0600(78) - Serial Communication

Link Malfunction

When monitored:Continuously with key on.

Set condition:If no PCI bus messages are received

by the Transmission Control Module (TCM) for 10

seconds.

Theory of operation:The TCM communicates

with the other modules in the vehicle using the PCI

bus. It relies on certain information to function

properly. The TCM continuously monitors the PCI

bus to check for messages broadcast from the cer-

tain modules.

Transmission Effects:Possible improper TCM

AutoStick configuration and delayed 3-4 shifts. No

EMCC and early 3-4 shifts for a few minutes after

engine is started.

Possible causes:

> Open or shorted PCI bus circuit from BCM

> TCM

Name of code:P1714(79) Low Battery Voltage

When monitored:Continuously with engine run-

ning and Transmission Relay energized.

Set condition:If the voltage sensed at the Trans-

mission Control Relay Output circuit (pins 16 and

17 at TCM) for 15 seconds.

Theory of operation:The Transmission system

requires sufficient battery voltage in order to ener-

gize the transmission solenoids. The TCM continu-

ously monitors the voltage available to the sole-

noids.

Transmission Effects:At speeds above 72 Km/h

(45 MPH) the transmission system will default to

neutral. Below 72 Km/h (45 MPH) the transmission

system will default to relay open limp-in mode.

Park, Reverse, and Neutral are still available.

Possible causes:

> Charging system problem

> Poor/High resistance connection between TCM

and Battery/Alternator

> TCM pin 16 and 17 high resistance or poor

connection

> TCM ground pins 53 and 57 high resistance or

poor connection

> High resistance in Transmission Control Relay

contacts

> TCM

3.3.8 QUICK LEARN

The Quick Learn function customizes adaptive

parameters of the TCM to the transmission charac-

teristics of a vehicle. This gives the customer im-

proved9as received9shift quality compared to the

initial parameters stored in the TCM.

Notes about Quick Learn Features

The nature of the Quick Learn function requires

that certain features must be taken into consider-

ation.

16

GENERAL INFORMATION

Page 4121 of 4284

> Quick Learn should generally not be used as a

repair procedure unless directed by a repair or

diagnostic procedure. If the transmission system

is exhibiting a problem that you think is caused

by an invalid CVI, you should try to relearn the

value by performing the appropriate driving ma-

neuver. In most cases, if a quick learn makes a

vehicle shift better, the vehicle will return with

the same problem.

> Before performing Quick Learn, it is imperative

that the vehicle be shifted into OD with the

engine running and the oil level set to the correct

level. This step will purge air from the clutch

circuits to prevent erroneous clutch volume val-

ues which could cause poor initial shift quality.

> If an unused TCM is installed on a vehicle with a

HOT engine, Quick Learn will cause the TCM to

report a cold calculated oil temperature. This

requires monitoring the calculated oil tempera-

ture using the DRBIIIt. If the temperature is

below 15C (60É F), the transmission must be run

at idle or driven in gear until it goes above 15C

(60ÉF). If the temperature is above 93C (200ÉF),

the transmission must cool to below 93C (200ÉF).

> First gear is engaged in overdrive after Quick

Learn is completed. Place the vehicle in park

after performing Quick Learn.

The Quick Learn function should be performed:

± Upon installation of a new service TCM

± After replacement or rebuild of internal trans-

mission components or the torque converter

± If one or more of the clutch volumes indexes

(CVI's) contain skewed readings because of

abnormal conditions.

To perform the Quick Learn procedure, the fol-

lowing conditions must be met.

± It is imperative that the vehicle be shifted into

OD with the engine running and the oil level

set to the correct level. This step will purge the

air in the clutch circuits to prevent erroneous

clutch volume values, which could cause poor

initial shift quality.

± The brakes must be applied.

± The engine must be idling.

± The throttle angle (TP sensor) must be less

than 3 degrees.

± The shift lever position must stay in neutral

until prompted to shift into OD.

± The shift lever must stay in OD after the9Shift

to Overdrive9prompt until the DRBIIItindi-

cates the procedure is complete.

± The oil temperature must be between 15C

(60ÉF) and 93C (200ÉF).NOTE:The above conditions must be maintained

during the procedure to keep the procedure from

being aborted.

The Quick Learn procedure is performed with the

DRBIIItby selecting9Transmission9system then

9Miscellaneous9functions, then9Quick Learn9. Follow

the procedure instructions displayed on the DRBIIIt.

3.3.9 CLUTCH VOLUMES

The L-R clutch volume is updated when doing a

2-1 or 3-1 coast down shift. The transmission tem-

perature must be between 21-49C (70-120É F). The

clutch volume should be between 35 and 83.

The 2-4 clutch volume is updated when doing a

1-2 shift. The transmission temperature must be

above 43C (110ÉF). The clutch volume should be

between 20 and 77.

The OD clutch volume is updated when doing a

2-3 shift. The transmission temperature must be

above 43C (110ÉF). The clutch volume should be

between 40 and 150.

The UD clutch volume is updated when doing a

4-3 or 4-2 shift. The transmission temperature must

be above 43C (110ÉF). The clutch volume should be

between 24 and 70.

3.3.10 ELECTRONIC PINION FACTOR

The transmission output speed signal supplies

distance pulses to the powertrain control module

(PCM), which are used to calculate speed and

mileage. A pinion factor is stored in the transmis-

sion control module (TCM) in order to provide the

appropriate distance pulses for the vehicle. The

pinion factor is programmed into the TCM at the

assembly plant.

Using the following steps, the pinion factor can be

checked and/or reset using the DRBIIIt:

1. Select Transmission system, then Miscellaneous

functions, then Pinion Factor. The DRBIIItwill

display the current tire size.

2. If the tire size is incorrect, depress the Enter key

and then select the correct size.

3. Depress the Page Back key to exit the reset

procedure.

Notes About Electronic Pinion Factor Features

The nature of the electronic pinion factor requires that

certain features must be taken into consideration.

> If no pinion factor is stored in an installed TCM,

the vehicle speedometer will not operate, engine

speed will be limited to 2300 RPM, and catalyst

damage may occur.

> Selecting a wrong tire size will cause the speed-

ometer to be inaccurate and will also cause any

speed related features to operate improperly.

Note: After replacing the TCM, you must

reprogram pinion factor

17

GENERAL INFORMATION

Page 4122 of 4284

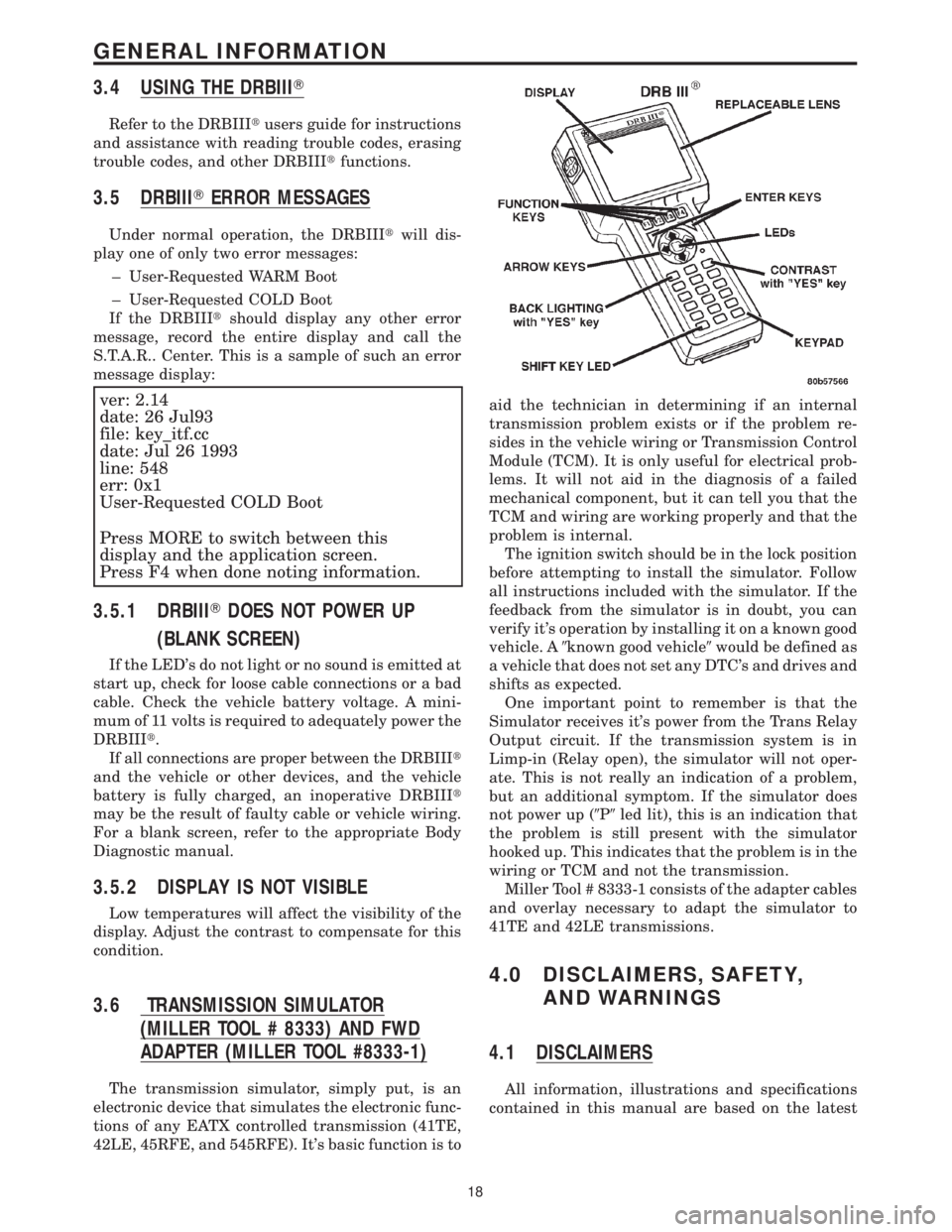

3.4 USING THE DRBIIIT

Refer to the DRBIIItusers guide for instructions

and assistance with reading trouble codes, erasing

trouble codes, and other DRBIIItfunctions.

3.5 DRBIIITERROR MESSAGES

Under normal operation, the DRBIIItwill dis-

play one of only two error messages:

± User-Requested WARM Boot

± User-Requested COLD Boot

If the DRBIIItshould display any other error

message, record the entire display and call the

S.T.A.R.. Center. This is a sample of such an error

message display:

ver: 2.14

date: 26 Jul93

file: key_itf.cc

date: Jul 26 1993

line: 548

err: 0x1

User-Requested COLD Boot

Press MORE to switch between this

display and the application screen.

Press F4 when done noting information.

3.5.1 DRBIIITDOES NOT POWER UP

(BLANK SCREEN)

If the LED's do not light or no sound is emitted at

start up, check for loose cable connections or a bad

cable. Check the vehicle battery voltage. A mini-

mum of 11 volts is required to adequately power the

DRBIIIt.

If all connections are proper between the DRBIIIt

and the vehicle or other devices, and the vehicle

battery is fully charged, an inoperative DRBIIIt

may be the result of faulty cable or vehicle wiring.

For a blank screen, refer to the appropriate Body

Diagnostic manual.

3.5.2 DISPLAY IS NOT VISIBLE

Low temperatures will affect the visibility of the

display. Adjust the contrast to compensate for this

condition.

3.6 TRANSMISSION SIMULATOR

(MILLER TOOL # 8333) AND FWD

ADAPTER (MILLER TOOL #8333-1)

The transmission simulator, simply put, is an

electronic device that simulates the electronic func-

tions of any EATX controlled transmission (41TE,

42LE, 45RFE, and 545RFE). It's basic function is toaid the technician in determining if an internal

transmission problem exists or if the problem re-

sides in the vehicle wiring or Transmission Control

Module (TCM). It is only useful for electrical prob-

lems. It will not aid in the diagnosis of a failed

mechanical component, but it can tell you that the

TCM and wiring are working properly and that the

problem is internal.

The ignition switch should be in the lock position

before attempting to install the simulator. Follow

all instructions included with the simulator. If the

feedback from the simulator is in doubt, you can

verify it's operation by installing it on a known good

vehicle. A9known good vehicle9would be defined as

a vehicle that does not set any DTC's and drives and

shifts as expected.

One important point to remember is that the

Simulator receives it's power from the Trans Relay

Output circuit. If the transmission system is in

Limp-in (Relay open), the simulator will not oper-

ate. This is not really an indication of a problem,

but an additional symptom. If the simulator does

not power up (9P9led lit), this is an indication that

the problem is still present with the simulator

hooked up. This indicates that the problem is in the

wiring or TCM and not the transmission.

Miller Tool # 8333-1 consists of the adapter cables

and overlay necessary to adapt the simulator to

41TE and 42LE transmissions.

4.0 DISCLAIMERS, SAFETY,

AND WARNINGS

4.1 DISCLAIMERS

All information, illustrations and specifications

contained in this manual are based on the latest

18

GENERAL INFORMATION

Page 4124 of 4284

4.3 WARNINGS

4.3.1 VEHICLE DAMAGE WARNINGS

Before disconnecting any control module, make

sure the ignition is ªoffº. Failure to do so could

damage the module.

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

4.3.2 ROAD TEST COMPLAINT VEHICLE

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

CAUTION: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED.

DURING THE TEST DRIVE, DO NOT TRY TO

READ THE DRBIIITSCREEN WHILE IN

MOTION. DO NOT HANG THE DRBIIITFROM

THE REAR VIEW MIRROR OR OPERATE IT

YOURSELF. HAVE AN ASSISTANT

AVAILABLE TO OPERATE THE DRBIIIT.

Road testing is an essential step in the diagnostic

process that must not be overlooked. Along with

diagnostic information obtained from the DRBIIIt

Scan Tool and the original customer concern, the

road test helps to verify the problem and observe

operation under actual vehicle driving conditions.

Just as important as the road test is, there are

preliminary inspections that should be carried out

prior to the road test. Always check the fluid level

and condition before going on a road test or per-

forming other tests. Also try to determine the type

of fluid being used. Improper fluid can result in

problems. Additionally, a variety of complaints can

be caused by incorrect fluid level. Some of the

conditions caused by incorrect fluid level are as

follows:

²Delayed engagement

²Poor shifting or erratic shifts

²Excessive noise

²Overheating

The next step is to verify that the shift linkage is

correctly adjusted. If the gearshift linkage is incor-rectly adjusted because of wear or incorrect adjust-

ment, a number of complaints can result.

The TCM monitors the Shift Lever Position (SLP)

Sensor at all times. If the linkage is incorrectly

adjusted, the TCM may sense a shift lever position

that is not correct for the gear range chosen by the

driver. This may cause diagnostic trouble codes to

be set and a possible limp-in situation.

The following complaints may also be the result

of an incorrectly adjusted or worn linkage.

²Delayed clutch engagement or erratic shifts

²Vehicle able to drive in Neutral

²Engine not able to crank in Park or Neutral

²Gearshift linkage able to be shifted without the

key in the ignition

²Not able to remove the ignition key in Reverse

²Parking pawl not engaging

The shift linkage should also be adjusted when

replacing the transaxle, repairing the valve body or

repairing any component between the shift lever

and the transaxle.

Some questions to ask yourself when considering

the road test are listed below:

²Is the complaint or concern what you think it is,

based the driver 's description of the problem?

²Is the transaxle operating normally, or is there a

real problem?

²When does the malfunction occur?

²Is the problem in only one gear range?

²What temperature does the complaint occur?

²Is the transaxle in limp-in mode?

4.3.3 ELECTRONIC PINION FACTOR

WARNINGS

The pinion factor must be set for all new trans-

mission control modules. If the pinion factor is not

set or if it is set incorrectly, any speedometer, speed

control, rolling door locks, and other devices that

are operated by the powertrain and body controllers

will not function properly.

4.3.4 BULLETINS AND RECALLS

The service procedures contained in this manual

are correct. provided that all applicable Safety

Recalls and Technical Service Bulletins have been

performed.

5.0 REQUIRED TOOLS AND

EQUIPMENT

> DRBIIIt(diagnostic read-out box) - Must be at

latest release level.

20

GENERAL INFORMATION

Page 4125 of 4284

> Transmission Simulator (Miller # 8333)

> Transmission Simulator (Miller # 8333-1)

Adapter harness kit and panel overlay for FWD

vehicles.

> Jumper wires

> Test Light (minimum of 25 ohms of resistance)

> Ohmmeter

> Voltmeter

> Pressure gauge (0-300 PSI)

6.0 GLOSSARY OF TERMS

6.1 ACRONYMS

BCMBody Control Module

CKTCircuit

CVIClutch Volume Index

DLCData Link Connector

DRBIIItDiagnostic Readout Box

DTCDiagnostic Trouble Code

EATXElectronic Automatic Transaxle

EMCCElectronically Modulated Converter

Clutch

FCMFront Control Module (part of the

IPM system)

IODIgnition off-draw

IPMIntelligent Power Module

IRTIntelligent Recovery Timer

ISSInput Speed Sensor

LEDLight Emitting Diode

LRLow/reverse Clutch or Pressure

Switch

LULockupMICMechanical Instrument Cluster

MILMalfunction Indicator Lamp

OBDIIOn Board Diagnostics

ODOverdrive Clutch or Pressure

Switch

OSSOutput Speed Sensor

PCMPowertrain Control Module

PEMCCPartial Electronically Modulated

Converter Clutch

PLUPartial Lockup

REVReverse Clutch

SLPKSolenoid Pack

SSVSolenoid Switch Valve

SWSwitch

TCCTorque Converter Clutch

TCMTransmission Control Module

TPThrottle Position

TRDTorque Reduction

TRSTransmission Range Sensor

UDUnderdrive Clutch

2-42nd and 4th gear Clutch or Pres-

sure Switch

6.2 DEFINITIONS

OBDII (EURO STAGE III OBD) Trip - A vehicle

start and drive cycle such that all once per trip

diagnostic monitors have run.

Key Start - A vehicle start and run cycle of at least

20 seconds.

Warm-up Cycle - A vehicle start and run cycle

such that the engine coolant must rise to at least

71C (160ÉF) and must rise by at least 4.4C (40ÉF)

from initial start up. To count as a warm-up cycle,

no DTC may occur during the cycle.

21

GENERAL INFORMATION

Page 4135 of 4284

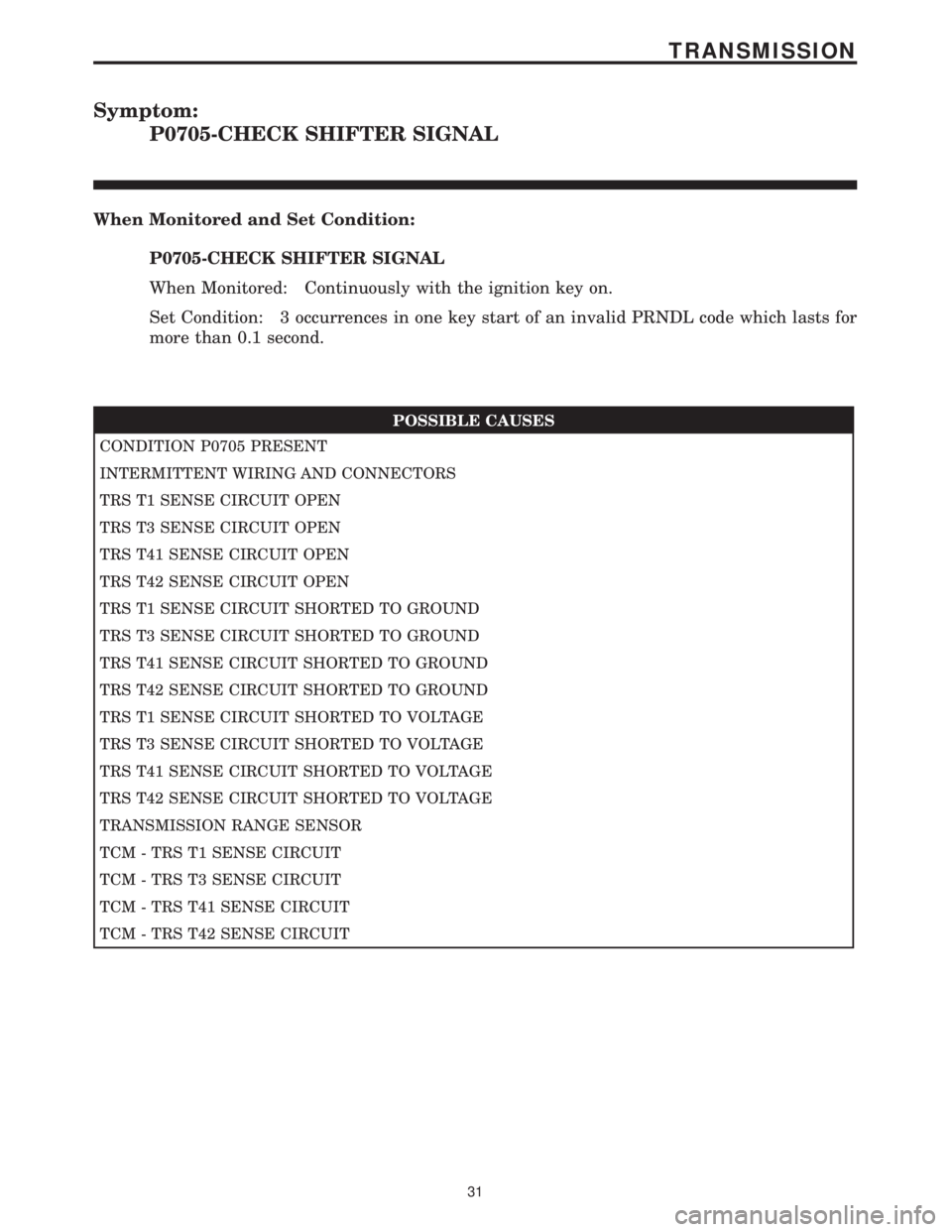

Symptom:

P0705-CHECK SHIFTER SIGNAL

When Monitored and Set Condition:

P0705-CHECK SHIFTER SIGNAL

When Monitored: Continuously with the ignition key on.

Set Condition: 3 occurrences in one key start of an invalid PRNDL code which lasts for

more than 0.1 second.

POSSIBLE CAUSES

CONDITION P0705 PRESENT

INTERMITTENT WIRING AND CONNECTORS

TRS T1 SENSE CIRCUIT OPEN

TRS T3 SENSE CIRCUIT OPEN

TRS T41 SENSE CIRCUIT OPEN

TRS T42 SENSE CIRCUIT OPEN

TRS T1 SENSE CIRCUIT SHORTED TO GROUND

TRS T3 SENSE CIRCUIT SHORTED TO GROUND

TRS T41 SENSE CIRCUIT SHORTED TO GROUND

TRS T42 SENSE CIRCUIT SHORTED TO GROUND

TRS T1 SENSE CIRCUIT SHORTED TO VOLTAGE

TRS T3 SENSE CIRCUIT SHORTED TO VOLTAGE

TRS T41 SENSE CIRCUIT SHORTED TO VOLTAGE

TRS T42 SENSE CIRCUIT SHORTED TO VOLTAGE

TRANSMISSION RANGE SENSOR

TCM - TRS T1 SENSE CIRCUIT

TCM - TRS T3 SENSE CIRCUIT

TCM - TRS T41 SENSE CIRCUIT

TCM - TRS T42 SENSE CIRCUIT

31

TRANSMISSION

Page 4183 of 4284

Symptom:

P1716-BUS COMMUNICATION WITH PCM

When Monitored and Set Condition:

P1716-BUS COMMUNICATION WITH PCM

When Monitored: Continuously with ignition key on.

Set Condition: If no bus messages are received from the Powertrain Control Module for

10 seconds.

POSSIBLE CAUSES

NO COMMUNICATION WITH PCM

OTHER BUS PROBLEMS PRESENT

INTERMITTENT WIRING AND CONNECTORS

TCM - BUS COMMUNICATION

TEST ACTION APPLICABILITY

1 With the DRBIIIt, Check the STARTS SINCE SET counter.

Note: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter equal to zero?All

Ye s®Go To 2

No®Go To 5

2 Ignition on, engine not running.

With the DRBIIIt, attempt to communicate with the Powertrain Control Module

(PCM).

Can the DRBIIItcommunicate with the PCM?All

Ye s®Go To 3

No®Refer to symptom list for problems related to No Response From

PCM.

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

3 With the DRBIIIt, check all of the other modules on the vehicle for evidence of a

vehicle bus problem.

Bus related DTC's in other modules point to an overall vehicle bus problem. Other

symptoms such as a customer complaint of intermittent operation of bus controlled

features also indicate a bus problem.

Does the PRNDL display indicate9No Bus9or is there any evidence of an overall

vehicle bus problem?All

Ye s®Refer to the Communications category for the related symp-

tom(s).

Perform 41TE TRANSMISSION VERIFICATION TEST - VER 1.

No®Go To 4

79

TRANSMISSION

Page 4190 of 4284

Symptom:

P1765-SWITCHED BATTERY

When Monitored and Set Condition:

P1765-SWITCHED BATTERY

When Monitored: Ignition key is turned from the OFF position to RUN position and/or

ignition key is turned from the CRANK position to RUN position.

Set Condition: This DTC is set if the Transmission Control Module senses voltage on any

of the Pressure Switch Inputs prior to the TCM energizing the Transmission Control Relay.

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

2-4 PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

L/R PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

OD PRESSURE SWITCH SENSE CIRCUIT SHORT TO VOLTAGE

TCM - SWITCHED BATTERY

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many Transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the Service Information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTC's. Check and repair all engine DTC's prior

to performing Transmission Symptom Diagnostics.

With the DRBIIIt, read Transmission DTC's. Record all DTC's and 1 Trip Failures.

NOTE: Diagnose 1 Trip Failures as a fully matured DTC.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Perform the Shift Lever Position Test. If the test does not pass, refer to Symptom test

for P0705 Check Shifter Signal.

For Gear Ratio DTC's, check and record all CVI's.

Most DTC's set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

NOTE: Verify flash level of Transmission Control Module. Some problems

are corrected by software upgrades to the Transmission Control Module.

NOTE: Check for applicable TSB's related to the symptom.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

2 With the DRBIIIt, Check the STARTS SINCE SET counter.

Note: This counter only applies to the last DTC set.

Is the STARTS SINCE SET counter for P1765 set at 0?All

Ye s®Go To 3

No®Go To 7

86

TRANSMISSION

Page 4193 of 4284

Symptom:

P1767-TRANSMISSION RELAY ALWAYS ON

When Monitored and Set Condition:

P1767-TRANSMISSION RELAY ALWAYS ON

When Monitored: When ignition key is turned from the OFF position to the RUN position

and/or ignition is turned from the CRANK position to RUN position.

Set Condition: This DTC is set if the Transmission Control Module senses greater than

3 volts at the Transmission Control Relay Output terminal of the TCM prior to the TCM

energizing the relay.

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

TRANSMISSION CONTROL RELAY STUCK CLOSED

TRANSMISSION CONTROL RELAY OUTPUT CIRCUIT SHORT TO VOLTAGE

TRANSMISSION RELAY CONTROL CIRCUIT SHORT TO VOLTAGE

TCM - TRANSMISSION RELAY ALWAYS ON

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many Transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the Service Information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTC's. Check and repair all engine DTC's prior

to performing Transmission Symptom Diagnostics.

With the DRBIIIt, read Transmission DTC's. Record all DTC's and 1 Trip Failures.

NOTE: Diagnose 1 Trip Failures as a fully matured DTC.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Perform the Shift Lever Position Test. If the test does not pass, refer to Symptom test

for P0705 Check Shifter Signal.

For Gear Ratio DTC's, check and record all CVI's.

Most DTC's set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

NOTE: Verify flash level of Transmission Control Module. Some problems

are corrected by software upgrades to the Transmission Control Module.

NOTE: Check for applicable TSB's related to the symptom.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

89

TRANSMISSION

Page 4231 of 4284

Symptom:

P1792-BATTERY WAS DISCONNECTED

When Monitored and Set Condition:

P1792-BATTERY WAS DISCONNECTED

When Monitored: Whenever the key is in the Run/Start position.

Set Condition: This code is set whenever Transmission Control Module (TCM) is

disconnected from battery power B+ or ground. It will also be set during the DRBIIIt

Quick Battery Disconnect procedure.

POSSIBLE CAUSES

QUICK LEARN WAS PERFORMED

RECENT BATTERY DISCONNECTION

TCM WAS REPLACED OR DISCONNECTED

INTERMITTENT WIRING AND CONNECTORS

FUSED B+ CIRCUIT TO TCM OPEN

GROUND CIRCUIT OPEN

TEST ACTION APPLICABILITY

1NOTE: Low fluid level can be the cause of many Transmission problems. If

the fluid level is low locate and repair the leak then check and adjust the

fluid level per the Service Information.

NOTE: Always perform diagnostics with a fully charged battery to avoid

false symptoms.

With the DRBIIIt, read the engine DTC's. Check and repair all engine DTC's prior

to performing Transmission Symptom Diagnostics.

With the DRBIIIt, read Transmission DTC's. Record all DTC's and 1 Trip Failures.

NOTE: Diagnose 1 Trip Failures as a fully matured DTC.

Using the wiring diagram/schematic as a guide, inspect the wiring and connectors.

Repair as necessary.

Perform the Shift Lever Position Test. If the test does not pass, refer to Symptom test

for P0705 Check Shifter Signal.

For Gear Ratio DTC's, check and record all CVI's.

Most DTC's set on start up but some must be set by driving the vehicle such that all

diagnostic monitors have run.

NOTE: Verify flash level of Transmission Control Module. Some problems

are corrected by software upgrades to the Transmission Control Module.

NOTE: Check for applicable TSB's related to the symptom.

Perform this procedure prior to Symptom diagnosis.All

Continue

Go To 2

127

TRANSMISSION