manual transmission CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 27 of 4284

TABLE OF CONTENTS - Continued

RIGHT SLIDING DOOR CONTROL MODULE C1 (POWER SLIDING DOOR) - BLACK

8 WAY ..............................................................1082

RIGHT SLIDING DOOR CONTROL MODULE C2 (POWER SLIDING DOOR) -

BLACK/RED 20 WAY..................................................1082

RIGHT SLIDING DOOR LATCH SENSING SWITCH (POWER SLIDING DOOR) -

BLACK 6 WAY........................................................1082

RIGHT SLIDING DOOR LOCK MOTOR (POWER SLIDING DOOR) - BLACK 4

WAY................................................................1083

RIGHT SLIDING DOOR LOCK MOTOR/AJAR SWITCH (MANUAL SLIDING DOOR) -

BLACK 4 WAY........................................................1083

RIGHT SLIDING DOOR MOTOR (POWER SLIDING DOOR) - BLACK 8 WAY. . . .1083

SENTRY KEY IMMOBILIZER MODULE - BLACK 6 WAY.....................1083

SIREN (UNITED KINGDOM) - BLACK 4 WAY..............................1083

THATCHAM ALARM MODULE C1 (UNITED KINGDOM) - BLACK 16 WAY.......1084

THATCHAM ALARM MODULE C2 (UNITED KINGDOM) - WHITE 4 WAY........1084

TRANSMISSION CONTROL MODULE (EATX) - BLACK 60 WAY..............1085

TXV SOLENOID (ATC)-2WAY.........................................1086

10.0 SCHEMATIC DIAGRAMS...............................................1087

10.1AIRBAG SYSTEM................................................1087

10.2AUDIO SYSTEM.................................................1088

10.2.1PREMIUM.............................................1088

10.2.2BASE.................................................1089

10.2.3CD CHANGER.........................................1090

10.2.4REMOTE RADIO CONTROLS.............................1091

10.3CABIN HEATER.................................................1092

10.4AUTOMATIC TEMPERATURE CONTROL SYSTEM....................1093

10.4.1FRONT ATC............................................1093

10.4.2REAR ATC.............................................1094

10.5COMMUNICATION...............................................1095

10.5.1PCM COMMUNICATION.................................1096

10.5.2ECM & CABIN HEATER ASSIST COMMUNICATION - DIESEL

ONLY.................................................1096

10.6DOOR AJAR WITH POWER SLIDING DOORS........................1097

10.7DOOR AJAR WITHOUT POWER SLIDING DOORS....................1098

10.8EXTERIOR LIGHTING............................................1099

10.9IGNITION SWITCH...............................................1100

10.10INSTRUMENT CLUSTER Ð BASE..................................1101

10.11INSTRUMENT CLUSTER & MESSAGE CENTER......................1102

10.12INTELLIGENT POWER MODULE/BODY CONTROL MODULE POWER AND

GROUNDS......................................................1103

10.13INTERIOR LIGHTING.............................................1104

10.14MANUAL TEMPERATURE CONTROLS..............................1105

10.14.1BASE MANUAL TEMPERATURE CONTROL SYSTEM LHD.....1105

10.14.2BASE MANUAL TEMPERATURE CONTROL SYSTEM RHD....1106

10.14.3DUAL-ZONE MANUAL TEMPERATURE CONTROL SYSTEM

LHD ..................................................1107

10.14.4DUAL-ZONE MANUAL TEMPERATURE CONTROL SYSTEM

RHD..................................................1108

10.14.5BLOWER MOTOR.......................................1109

10.15MEMORY SYSTEM...............................................1110

10.16OVERHEAD CONSOLE...........................................1111

xxiv

Page 59 of 4284

WARNING: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED.

DURING THE TEST DRIVE, DO NOT TRY TO

READ THE DRBIIITSCREEN WHILE IN

MOTION. DO NOT HANG THE DRBIIITFROM

THE REAR VIEW MIRROR OR OPERATE IT

YOURSELF. HAVE AN ASSISTANT

AVAILABLE TO OPERATE THE DRBIIIT.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box)

Jumper wires

Ohmmeter

Voltmeter

Sentry Key Tester

Test Light

8310 Airbag System Load Tool

8443 SRS Airbag System Load Tool

Diagnostic Junction Port Tester 8339

6.0 GLOSSARY OF TERMS

ABSantilock brake system

ACMairbag control module

AECMairbag electronic control module

(ACM)

ASDMairbag system diagnostic module

(ACM)

AT Cautomatic temperature control

BCMbody control module

CABcontroller antilock brake

CMTCcompass/mini-trip computer

CPAconnector positive assurance

DABdriver airbag

DCHAdiesel cabin heater assist

(cabin heater)

DLCdata link connector

DTCdiagnostic trouble code

DRdriver

EBLelectric back lite (rear window de-

fogger)ECMEngine control module

EVICelectronic vehicle information center

FCMfront control module

GCCGulf Coast Countries

HVACheater ventilation, air conditioning

IPMintelligent power module

LDUlower drive unit

LHDLeft Hand Drive

MICmechanical instrument cluster

MTCmanual temperature control

MSMMmemory seat/mirror module

OBDon board diagnostics

ODOodometer

ORCoccupant restraint controller

PA Bpassenger airbag

PASSpassenger

PCIProgrammable Communication In-

terface (vehicle communication bus)

PCMpowertrain control module

PDCpower distribution center

PLGpower liftgate

PLGMpower liftgate module

PSDpower sliding door

PSDMpower sliding door module

PWMpulse width modulated

RHDRight Hand Drive

RKEremote keyless entry

SABseat airbag

SBTseat belt tensioner

SIACMside impact airbag control module

SKIMsentry key immobilizer module

SKISsentry key immobilizer system

SQUIBalso called initiator (located inside

airbag)

SRSsupplemental restraint system

TCMtransmission control module

VFDvacuum fluorescent display

VTSSvehicle theft security system

30

GENERAL INFORMATION

Page 547 of 4284

POSSIBLE CAUSES

CHECK FOR ACTIVE HVAC DTCS, & COOLDOWN TEST & DOOR RECALIBRATION MESSAGES

STORED CODE(S) TEST COMPLETE

TEST ACTION APPLICABILITY

1NOTE: Active codes must be resolved before diagnosing stored codes.

NOTE: Anytime a code becomes active during this test, proceed to the

conclusion question.

Turn the ignition on.

With the DRBIIIt, record and erase stored HVAC DTC's.

Cycle the ignition switch.

Start the engine.

Monitor the DRBIIItfor active HVAC DTCs while performing the following test

steps.

Manually press the A/C - Heater Control power switch on.

Turn the front blower motor control switch knob to the low position.

If equipped, turn the rear blower motor control switch knob to the low position.

Set the passenger blend control switch to the full cold position.

If equipped, set the zone/driver blend control switch to the full cold position.

Turn the mode select switch knob to the panel position.

Manually press the recirculation mode switch on, wait 30 seconds then press it off.

Manually press the A/C mode switch on, wait 30 seconds then press it off.

Manually press the rear window defogger switch on, wait 30 seconds then press it off.

Manually sweep the passenger blend control switch from full cold to full hot then

back to full cold.

If equipped, manually sweep the zone/driver blend control switch from full cold to full

hot then back to full cold.

Manually sweep the front blower motor control switch knob through all positions.

If equipped, manually sweep the rear blower motor control switch knob through all

positions.

If equipped, turn the rear blower motor control switch knob to the rear position.

If equipped, on the Rear Blower Rear Control, manually sweep the rear blower motor

control switch knob through all positions.

If equipped, on the Rear Blower Rear Control, manually sweep the rear blend/mode

control switch knob from full cold to full hot then back to full cold.

With the DRBIIIt, actuate the AC Cooldown Test.

With the DRBIIIt, actuate the HVAC Door Recalibration Test.

Place the vehicle on a hoist, and raise the wheels off the floor.

WARNING: Be sure to keep hands and feet clear of rotating wheels. Keep

clear of the engine's moving parts

Start the engine. Place the transmission in drive. Brake off.

Does the DRBIIItdisplay any active HVAC DTC(s), Cooldown Test or Door Recali-

bration message(s)?All

Ye s®Return to the symptom list and choose the symptom(s).

Perform BODY VERIFICATION TEST - VER 1.

No®No problem found at this time.

Perform BODY VERIFICATION TEST - VER 1.

518

HEATING & A/C

A/C FAULT (STORED) - MANUAL A/C ÐContinued

Page 1468 of 4284

GROUP TAB LOCATOR

INIntroduction

INaIntroduction

0Lubrication & Maintenance

0aLubrication & Maintenance

2Suspension

2aSuspension

3Differential & Driveline

5Brakes

5aBrakes

6aClutch

7Cooling

7aCooling

8AAudio

8AaAudio

8BChime/Buzzer

8BaChime/Buzzer

8EElectronic Control Modules

8FEngine Systems

8FaEngine Systems

8GHeated Systems

8HHorn

8IIgnition Control

8JInstrument Cluster

8JaInstrument Cluster

8LLamps

8LaLamps

8MMessage Systems

8NPower Systems

8NaPower Systems

8ORestraints

8PSpeed Control

8QVehicle Theft Security

8RWipers/Washers

8WaWiring

9Engine

9aEngine

11Exhaust System

11aExhaust System

13Frame & Bumpers

14Fuel System

14aFuel System

19Steering

19aSteering

21Transmission/Transaxle

21aTransmission/Transaxle

22Tires/Wheels

23Body

24Heating & Air Conditioning

24aHeating & Air Conditioning

25Emissions Control

25aEmissions Control

Service Manual Comment Forms

Page 1504 of 4284

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

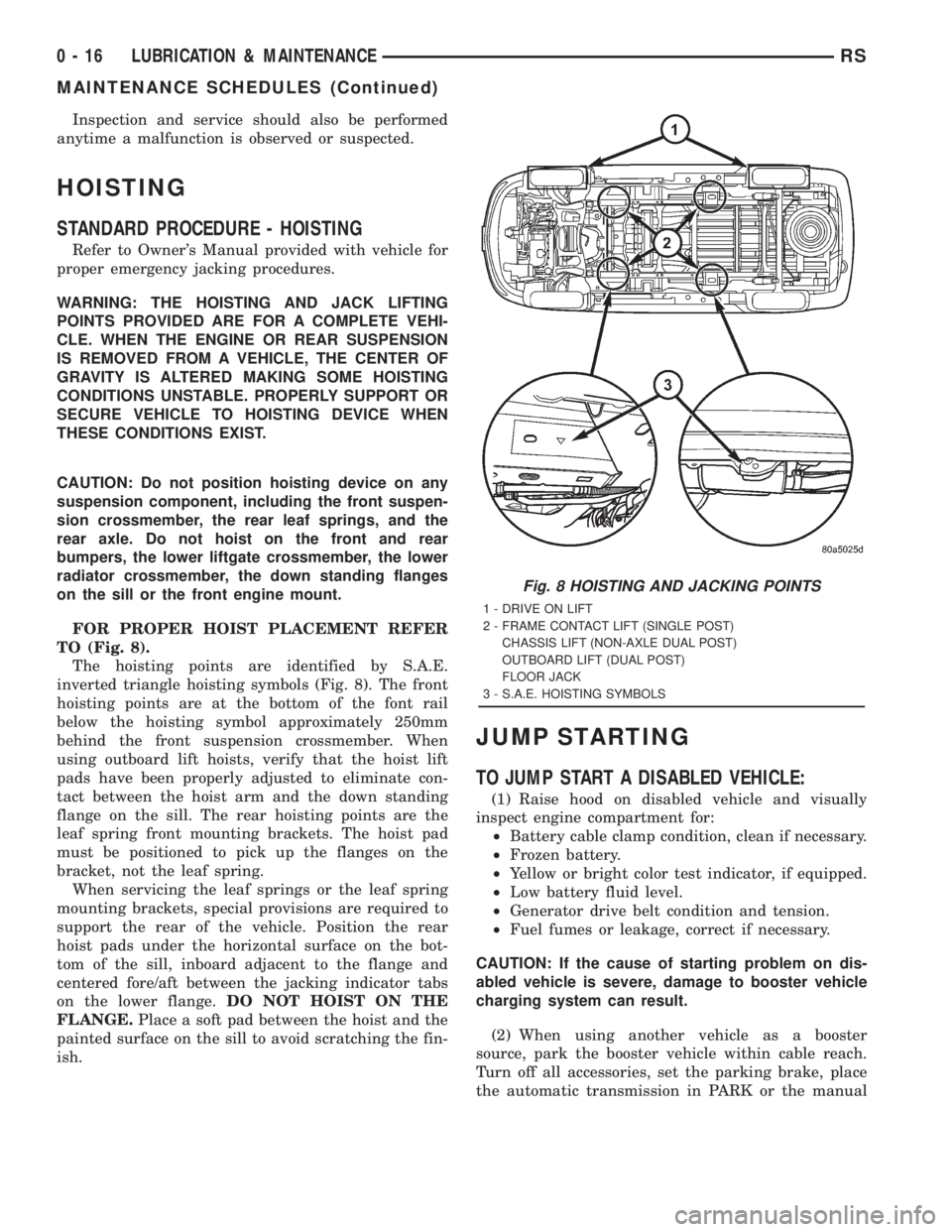

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

CAUTION: Do not position hoisting device on any

suspension component, including the front suspen-

sion crossmember, the rear leaf springs, and the

rear axle. Do not hoist on the front and rear

bumpers, the lower liftgate crossmember, the lower

radiator crossmember, the down standing flanges

on the sill or the front engine mount.

FOR PROPER HOIST PLACEMENT REFER

TO (Fig. 8).

The hoisting points are identified by S.A.E.

inverted triangle hoisting symbols (Fig. 8). The front

hoisting points are at the bottom of the font rail

below the hoisting symbol approximately 250mm

behind the front suspension crossmember. When

using outboard lift hoists, verify that the hoist lift

pads have been properly adjusted to eliminate con-

tact between the hoist arm and the down standing

flange on the sill. The rear hoisting points are the

leaf spring front mounting brackets. The hoist pad

must be positioned to pick up the flanges on the

bracket, not the leaf spring.

When servicing the leaf springs or the leaf spring

mounting brackets, special provisions are required to

support the rear of the vehicle. Position the rear

hoist pads under the horizontal surface on the bot-

tom of the sill, inboard adjacent to the flange and

centered fore/aft between the jacking indicator tabs

on the lower flange.DO NOT HOIST ON THE

FLANGE.Place a soft pad between the hoist and the

painted surface on the sill to avoid scratching the fin-

ish.

JUMP STARTING

TO JUMP START A DISABLED VEHICLE:

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

Fig. 8 HOISTING AND JACKING POINTS

1 - DRIVE ON LIFT

2 - FRAME CONTACT LIFT (SINGLE POST)

CHASSIS LIFT (NON-AXLE DUAL POST)

OUTBOARD LIFT (DUAL POST)

FLOOR JACK

3 - S.A.E. HOISTING SYMBOLS

0 - 16 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

Page 1509 of 4284

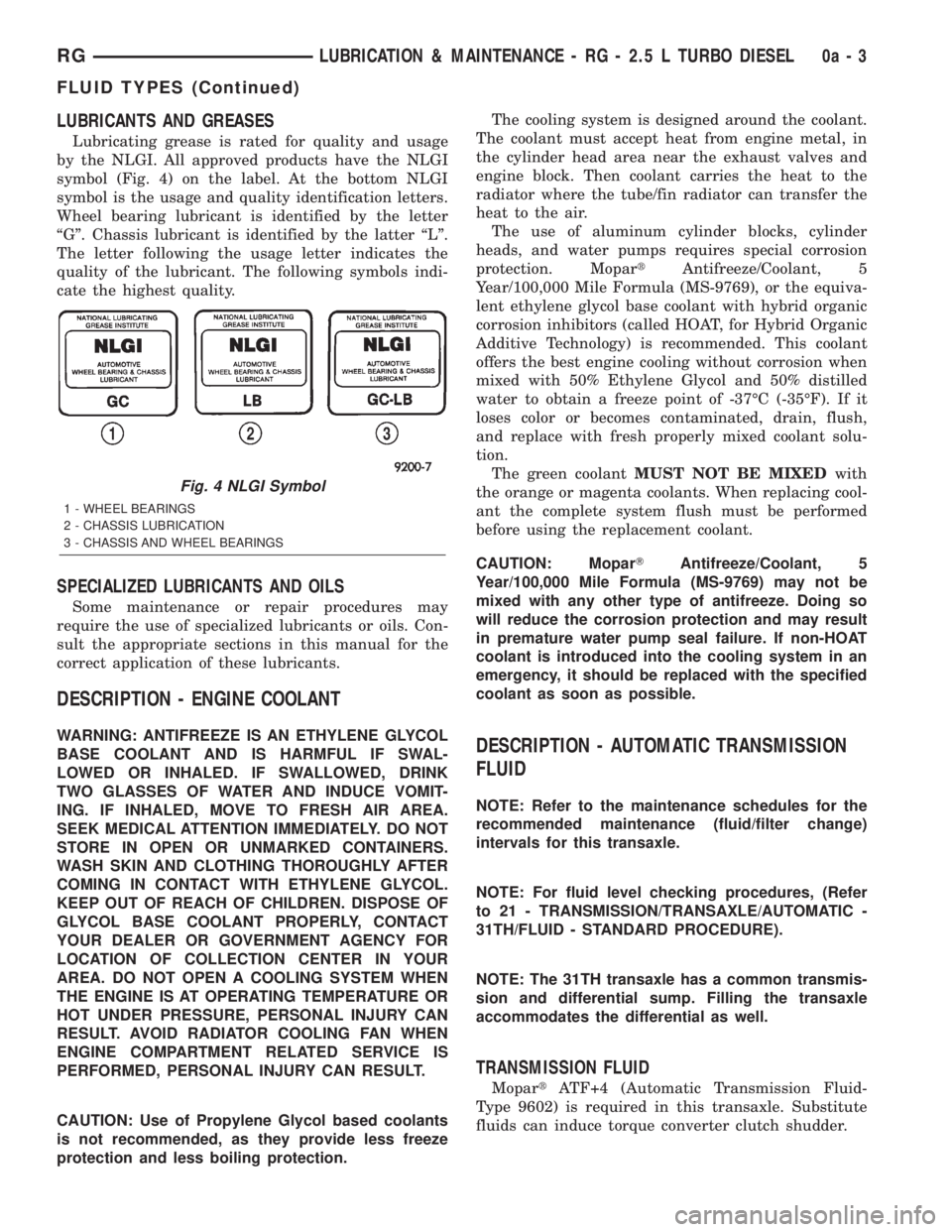

LUBRICANTS AND GREASES

Lubricating grease is rated for quality and usage

by the NLGI. All approved products have the NLGI

symbol (Fig. 4) on the label. At the bottom NLGI

symbol is the usage and quality identification letters.

Wheel bearing lubricant is identified by the letter

ªGº. Chassis lubricant is identified by the latter ªLº.

The letter following the usage letter indicates the

quality of the lubricant. The following symbols indi-

cate the highest quality.

SPECIALIZED LUBRICANTS AND OILS

Some maintenance or repair procedures may

require the use of specialized lubricants or oils. Con-

sult the appropriate sections in this manual for the

correct application of these lubricants.

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less boiling protection.The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with hybrid organic

corrosion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

The green coolantMUST NOT BE MIXEDwith

the orange or magenta coolants. When replacing cool-

ant the complete system flush must be performed

before using the replacement coolant.

CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Doing so

will reduce the corrosion protection and may result

in premature water pump seal failure. If non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.DESCRIPTION - AUTOMATIC TRANSMISSION

FLUID

NOTE: Refer to the maintenance schedules for the

recommended maintenance (fluid/filter change)

intervals for this transaxle.

NOTE: For fluid level checking procedures, (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC -

31TH/FLUID - STANDARD PROCEDURE).

NOTE: The 31TH transaxle has a common transmis-

sion and differential sump. Filling the transaxle

accommodates the differential as well.

TRANSMISSION FLUID

MopartATF+4 (Automatic Transmission Fluid-

Type 9602) is required in this transaxle. Substitute

fluids can induce torque converter clutch shudder.

Fig. 4 NLGI Symbol

1 - WHEEL BEARINGS

2 - CHASSIS LUBRICATION

3 - CHASSIS AND WHEEL BEARINGS

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-3

FLUID TYPES (Continued)

Page 1514 of 4284

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3)

On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accessories.

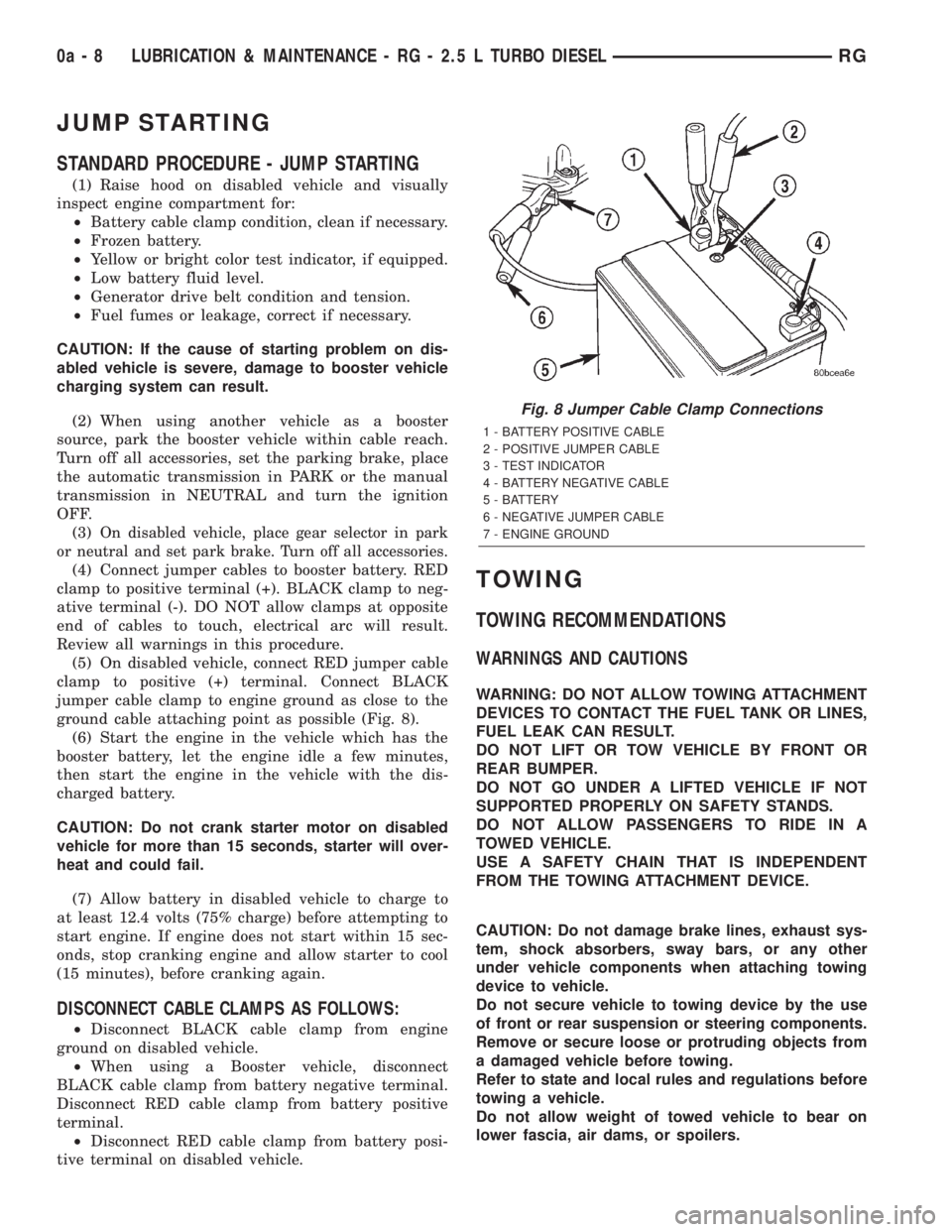

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 8).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 minutes), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

TOWING RECOMMENDATIONS

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

Fig. 8 Jumper Cable Clamp Connections

1 - BATTERY POSITIVE CABLE

2 - POSITIVE JUMPER CABLE

3 - TEST INDICATOR

4 - BATTERY NEGATIVE CABLE

5 - BATTERY

6 - NEGATIVE JUMPER CABLE

7 - ENGINE GROUND

0a - 8 LUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESELRG

Page 1729 of 4284

CLUTCH RELEASE LEVER AND

BEARING

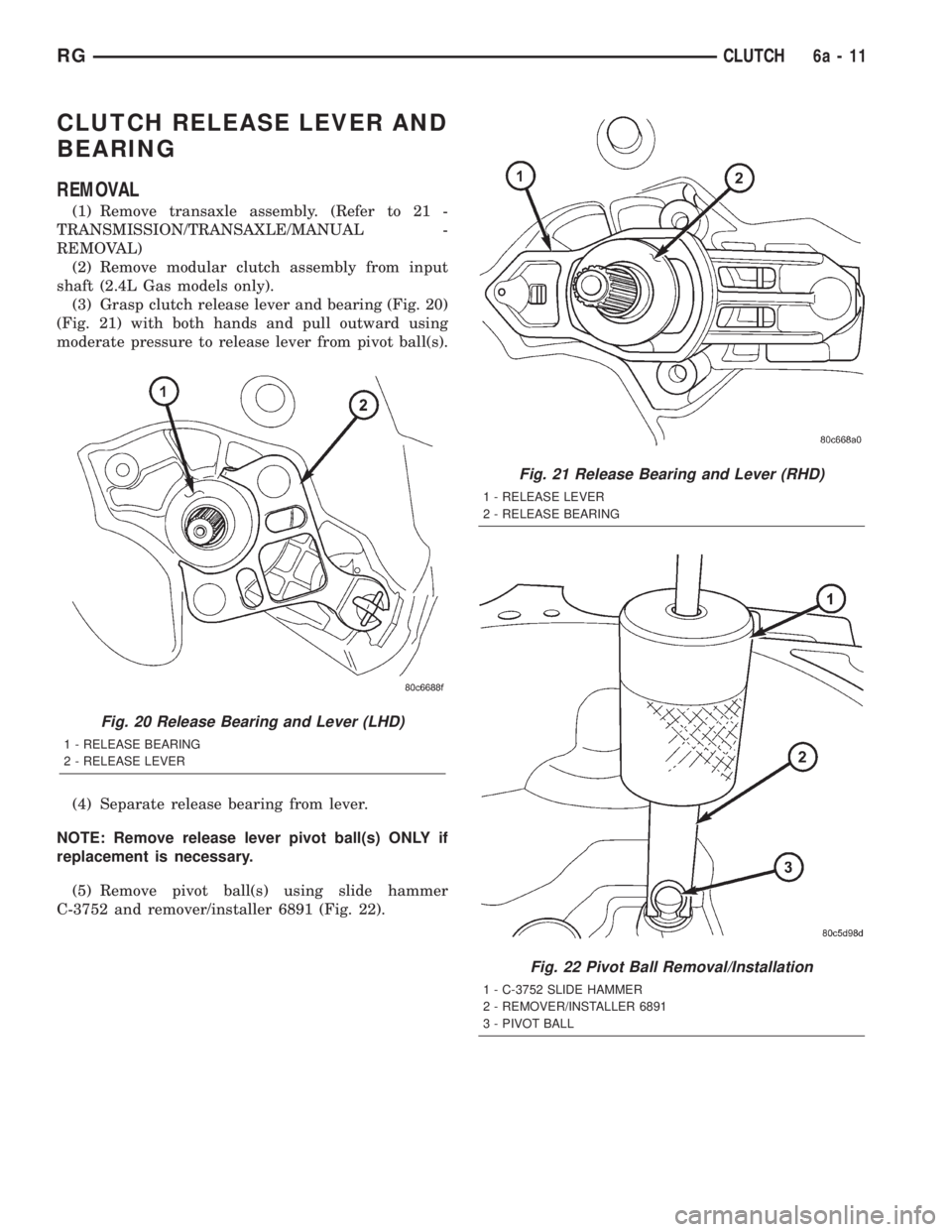

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove modular clutch assembly from input

shaft (2.4L Gas models only).

(3) Grasp clutch release lever and bearing (Fig. 20)

(Fig. 21) with both hands and pull outward using

moderate pressure to release lever from pivot ball(s).

(4) Separate release bearing from lever.

NOTE: Remove release lever pivot ball(s) ONLY if

replacement is necessary.

(5) Remove pivot ball(s) using slide hammer

C-3752 and remover/installer 6891 (Fig. 22).

Fig. 20 Release Bearing and Lever (LHD)

1 - RELEASE BEARING

2 - RELEASE LEVER

Fig. 21 Release Bearing and Lever (RHD)

1 - RELEASE LEVER

2 - RELEASE BEARING

Fig. 22 Pivot Ball Removal/Installation

1 - C-3752 SLIDE HAMMER

2 - REMOVER/INSTALLER 6891

3 - PIVOT BALL

RGCLUTCH6a-11

Page 1732 of 4284

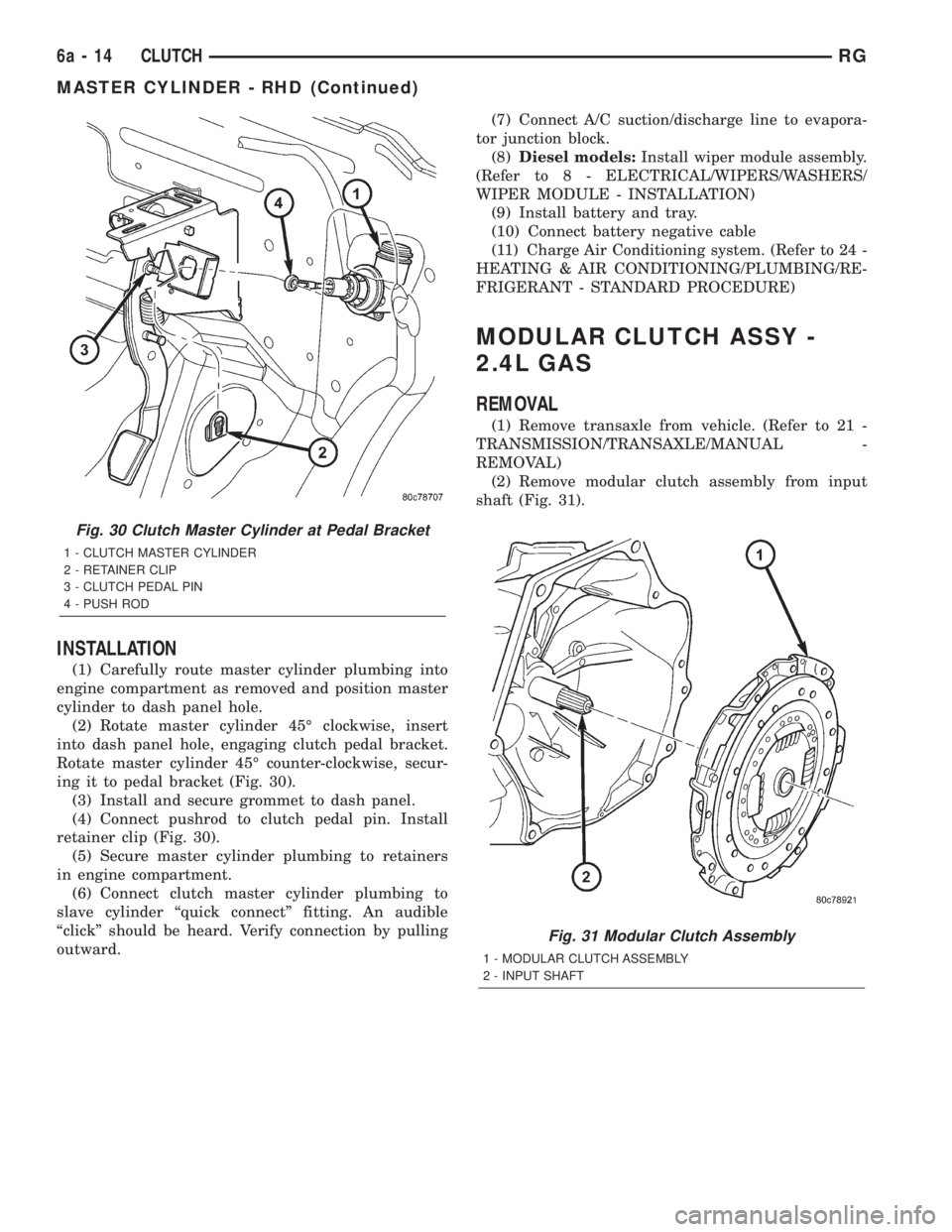

INSTALLATION

(1) Carefully route master cylinder plumbing into

engine compartment as removed and position master

cylinder to dash panel hole.

(2) Rotate master cylinder 45É clockwise, insert

into dash panel hole, engaging clutch pedal bracket.

Rotate master cylinder 45É counter-clockwise, secur-

ing it to pedal bracket (Fig. 30).

(3) Install and secure grommet to dash panel.

(4) Connect pushrod to clutch pedal pin. Install

retainer clip (Fig. 30).

(5) Secure master cylinder plumbing to retainers

in engine compartment.

(6) Connect clutch master cylinder plumbing to

slave cylinder ªquick connectº fitting. An audible

ªclickº should be heard. Verify connection by pulling

outward.(7) Connect A/C suction/discharge line to evapora-

tor junction block.

(8)Diesel models:Install wiper module assembly.

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - INSTALLATION)

(9) Install battery and tray.

(10) Connect battery negative cable

(11) Charge Air Conditioning system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/RE-

FRIGERANT - STANDARD PROCEDURE)

MODULAR CLUTCH ASSY -

2.4L GAS

REMOVAL

(1) Remove transaxle from vehicle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove modular clutch assembly from input

shaft (Fig. 31).

Fig. 30 Clutch Master Cylinder at Pedal Bracket

1 - CLUTCH MASTER CYLINDER

2 - RETAINER CLIP

3 - CLUTCH PEDAL PIN

4 - PUSH ROD

Fig. 31 Modular Clutch Assembly

1 - MODULAR CLUTCH ASSEMBLY

2 - INPUT SHAFT

6a - 14 CLUTCHRG

MASTER CYLINDER - RHD (Continued)

Page 1733 of 4284

INSTALLATION

(1) Install modular clutch assembly to transaxle

input shaft (Fig. 31).

(2) Install transaxle to vehicle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL - INSTAL-

LATION)

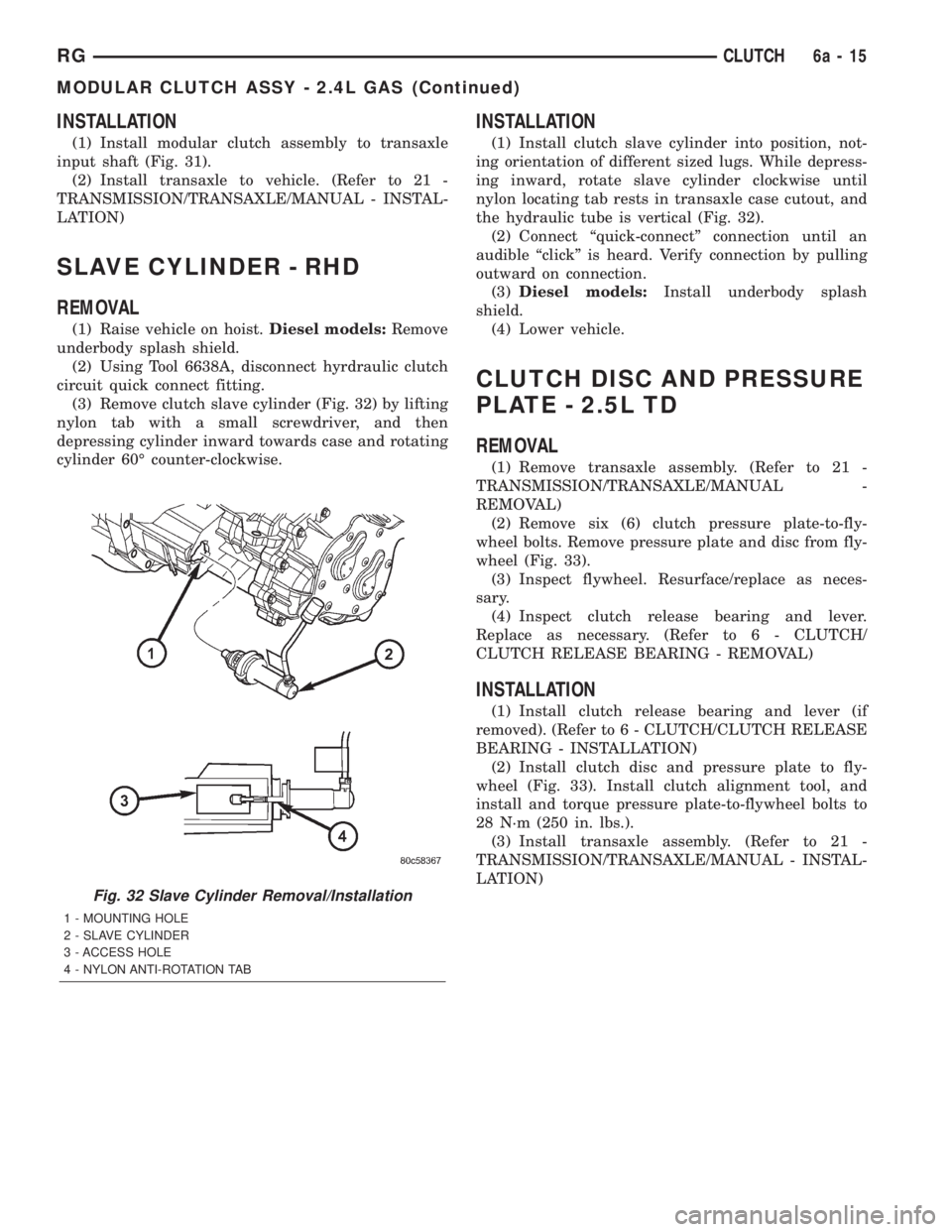

SLAVE CYLINDER - RHD

REMOVAL

(1) Raise vehicle on hoist.Diesel models:Remove

underbody splash shield.

(2) Using Tool 6638A, disconnect hyrdraulic clutch

circuit quick connect fitting.

(3) Remove clutch slave cylinder (Fig. 32) by lifting

nylon tab with a small screwdriver, and then

depressing cylinder inward towards case and rotating

cylinder 60É counter-clockwise.

INSTALLATION

(1) Install clutch slave cylinder into position, not-

ing orientation of different sized lugs. While depress-

ing inward, rotate slave cylinder clockwise until

nylon locating tab rests in transaxle case cutout, and

the hydraulic tube is vertical (Fig. 32).

(2) Connect ªquick-connectº connection until an

audible ªclickº is heard. Verify connection by pulling

outward on connection.

(3)Diesel models:Install underbody splash

shield.

(4) Lower vehicle.

CLUTCH DISC AND PRESSURE

PLATE - 2.5L TD

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove six (6) clutch pressure plate-to-fly-

wheel bolts. Remove pressure plate and disc from fly-

wheel (Fig. 33).

(3) Inspect flywheel. Resurface/replace as neces-

sary.

(4) Inspect clutch release bearing and lever.

Replace as necessary. (Refer to 6 - CLUTCH/

CLUTCH RELEASE BEARING - REMOVAL)

INSTALLATION

(1) Install clutch release bearing and lever (if

removed). (Refer to 6 - CLUTCH/CLUTCH RELEASE

BEARING - INSTALLATION)

(2) Install clutch disc and pressure plate to fly-

wheel (Fig. 33). Install clutch alignment tool, and

install and torque pressure plate-to-flywheel bolts to

28 N´m (250 in. lbs.).

(3) Install transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL - INSTAL-

LATION)

Fig. 32 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

RGCLUTCH6a-15

MODULAR CLUTCH ASSY - 2.4L GAS (Continued)