CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2981 of 4284

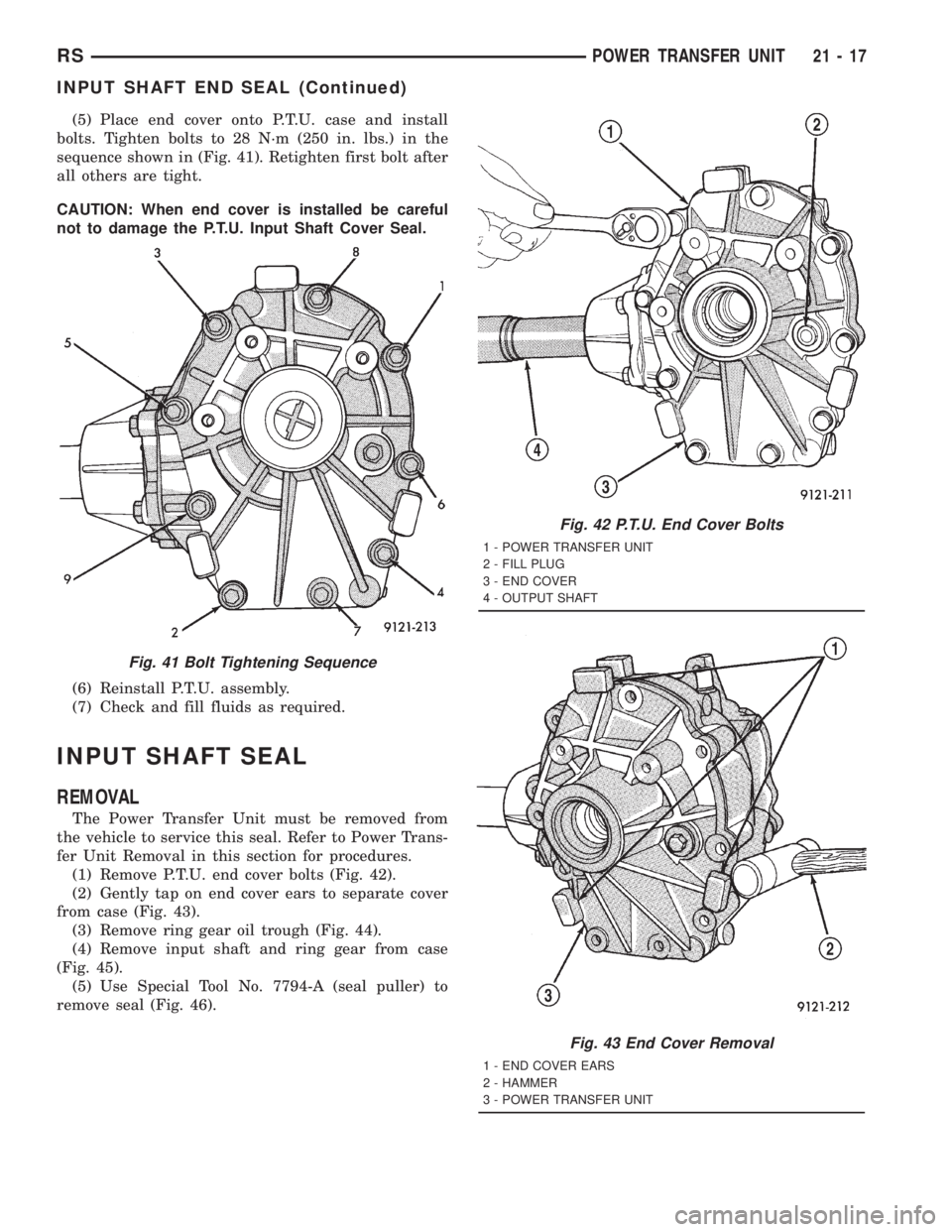

(5) Place end cover onto P.T.U. case and install

bolts. Tighten bolts to 28 N´m (250 in. lbs.) in the

sequence shown in (Fig. 41). Retighten first bolt after

all others are tight.

CAUTION: When end cover is installed be careful

not to damage the P.T.U. Input Shaft Cover Seal.

(6) Reinstall P.T.U. assembly.

(7) Check and fill fluids as required.

INPUT SHAFT SEAL

REMOVAL

The Power Transfer Unit must be removed from

the vehicle to service this seal. Refer to Power Trans-

fer Unit Removal in this section for procedures.

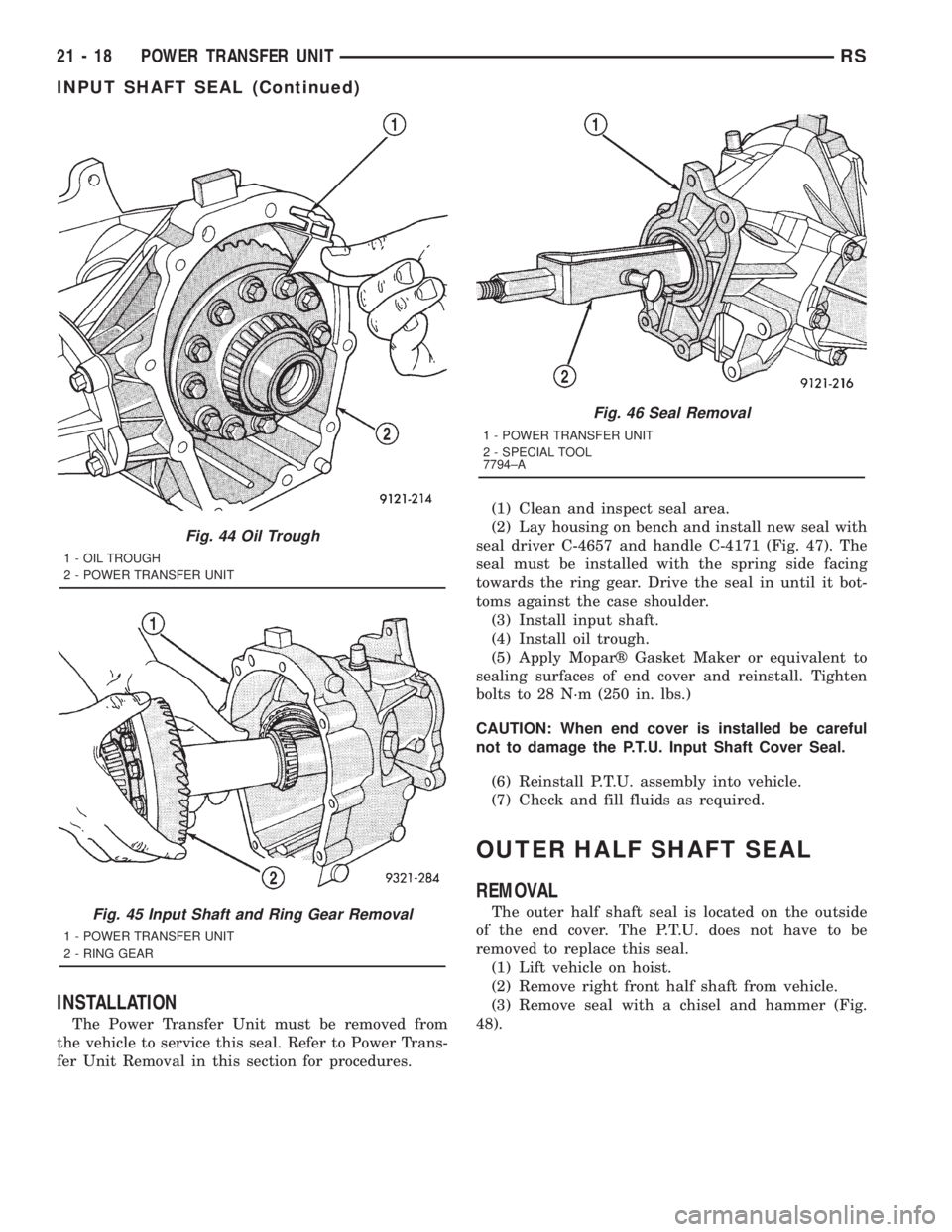

(1) Remove P.T.U. end cover bolts (Fig. 42).

(2) Gently tap on end cover ears to separate cover

from case (Fig. 43).

(3) Remove ring gear oil trough (Fig. 44).

(4) Remove input shaft and ring gear from case

(Fig. 45).

(5) Use Special Tool No. 7794-A (seal puller) to

remove seal (Fig. 46).

Fig. 41 Bolt Tightening Sequence

Fig. 42 P.T.U. End Cover Bolts

1 - POWER TRANSFER UNIT

2 - FILL PLUG

3 - END COVER

4 - OUTPUT SHAFT

Fig. 43 End Cover Removal

1 - END COVER EARS

2 - HAMMER

3 - POWER TRANSFER UNIT

RSPOWER TRANSFER UNIT21-17

INPUT SHAFT END SEAL (Continued)

Page 2982 of 4284

INSTALLATION

The Power Transfer Unit must be removed from

the vehicle to service this seal. Refer to Power Trans-

fer Unit Removal in this section for procedures.(1) Clean and inspect seal area.

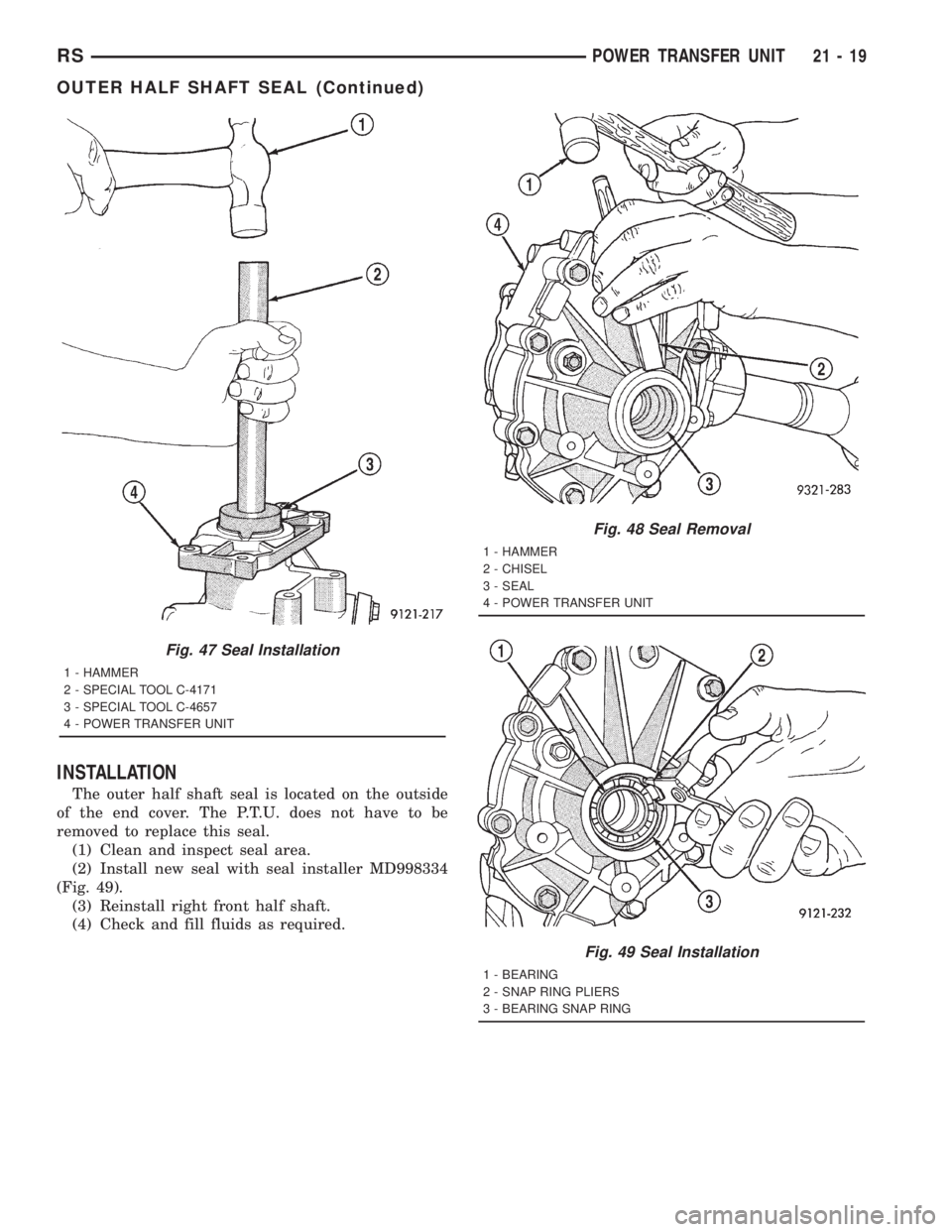

(2) Lay housing on bench and install new seal with

seal driver C-4657 and handle C-4171 (Fig. 47). The

seal must be installed with the spring side facing

towards the ring gear. Drive the seal in until it bot-

toms against the case shoulder.

(3) Install input shaft.

(4) Install oil trough.

(5) Apply Moparž Gasket Maker or equivalent to

sealing surfaces of end cover and reinstall. Tighten

bolts to 28 N´m (250 in. lbs.)

CAUTION: When end cover is installed be careful

not to damage the P.T.U. Input Shaft Cover Seal.

(6) Reinstall P.T.U. assembly into vehicle.

(7) Check and fill fluids as required.

OUTER HALF SHAFT SEAL

REMOVAL

The outer half shaft seal is located on the outside

of the end cover. The P.T.U. does not have to be

removed to replace this seal.

(1) Lift vehicle on hoist.

(2) Remove right front half shaft from vehicle.

(3) Remove seal with a chisel and hammer (Fig.

48).

Fig. 44 Oil Trough

1 - OIL TROUGH

2 - POWER TRANSFER UNIT

Fig. 45 Input Shaft and Ring Gear Removal

1 - POWER TRANSFER UNIT

2 - RING GEAR

Fig. 46 Seal Removal

1 - POWER TRANSFER UNIT

2 - SPECIAL TOOL

7794±A

21 - 18 POWER TRANSFER UNITRS

INPUT SHAFT SEAL (Continued)

Page 2983 of 4284

INSTALLATION

The outer half shaft seal is located on the outside

of the end cover. The P.T.U. does not have to be

removed to replace this seal.

(1) Clean and inspect seal area.

(2) Install new seal with seal installer MD998334

(Fig. 49).

(3) Reinstall right front half shaft.

(4) Check and fill fluids as required.

Fig. 47 Seal Installation

1 - HAMMER

2 - SPECIAL TOOL C-4171

3 - SPECIAL TOOL C-4657

4 - POWER TRANSFER UNIT

Fig. 48 Seal Removal

1 - HAMMER

2 - CHISEL

3 - SEAL

4 - POWER TRANSFER UNIT

Fig. 49 Seal Installation

1 - BEARING

2 - SNAP RING PLIERS

3 - BEARING SNAP RING

RSPOWER TRANSFER UNIT21-19

OUTER HALF SHAFT SEAL (Continued)

Page 2984 of 4284

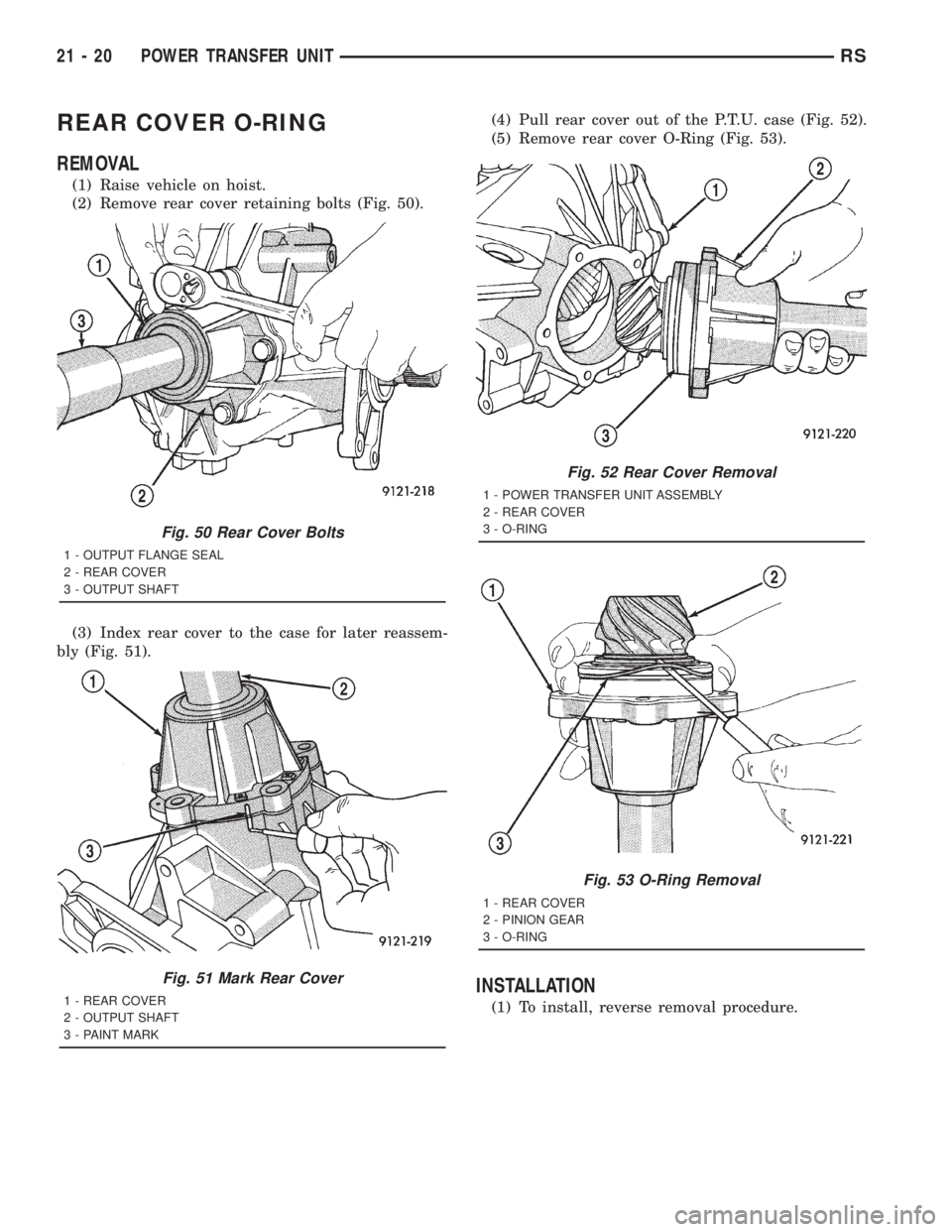

REAR COVER O-RING

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove rear cover retaining bolts (Fig. 50).

(3) Index rear cover to the case for later reassem-

bly (Fig. 51).(4) Pull rear cover out of the P.T.U. case (Fig. 52).

(5) Remove rear cover O-Ring (Fig. 53).

INSTALLATION

(1) To install, reverse removal procedure.

Fig. 50 Rear Cover Bolts

1 - OUTPUT FLANGE SEAL

2 - REAR COVER

3 - OUTPUT SHAFT

Fig. 51 Mark Rear Cover

1 - REAR COVER

2 - OUTPUT SHAFT

3 - PAINT MARK

Fig. 52 Rear Cover Removal

1 - POWER TRANSFER UNIT ASSEMBLY

2 - REAR COVER

3 - O-RING

Fig. 53 O-Ring Removal

1 - REAR COVER

2 - PINION GEAR

3 - O-RING

21 - 20 POWER TRANSFER UNITRS

Page 2985 of 4284

AUTOMATIC - 31TH

TABLE OF CONTENTS

page page

AUTOMATIC - 31TH

DESCRIPTION...........................22

OPERATION.............................24

DIAGNOSIS AND TESTING.................24

PRELIMINARY DIAGNOSIS...............24

ROAD TEST...........................31

HYDRAULIC PRESSURE TESTS...........32

TORQUE CONVERTER HOUSING FLUID

LEAKAGE.............................34

CLUTCH AND SERVO AIR PRESSURE

TESTS...............................35

STANDARD PROCEDURE..................36

ALUMINUM THREAD REPAIR.............36

REMOVAL..............................36

DISASSEMBLY...........................39

ASSEMBLY.............................50

INSTALLATION...........................59

SCHEMATICS AND DIAGRAMS..............63

SPECIFICATIONS........................71

SPECIAL TOOLS.........................74

ACCUMULATOR

DESCRIPTION...........................78

OPERATION.............................78

BANDS

DESCRIPTION...........................79

OPERATION.............................79

ADJUSTMENTS..........................79

CLUTCH - FRONT

DESCRIPTION...........................80

OPERATION.............................81

DISASSEMBLY...........................81

ASSEMBLY.............................84

CLUTCH - REAR

DESCRIPTION...........................85

OPERATION.............................85

DISASSEMBLY...........................86

ASSEMBLY.............................89

FINAL DRIVE

DISASSEMBLY...........................90

ASSEMBLY.............................94

ADJUSTMENTS..........................96

FLUID

STANDARD PROCEDURE..................98

FLUID LEVEL AND CONDITION CHECK......98

FLUID AND FILTER CHANGE..............98

GEAR SHIFT CABLE

REMOVAL.............................100

INSTALLATION..........................101

ADJUSTMENTS.........................103GOVERNOR

DESCRIPTION..........................103

OPERATION............................103

CLEANING.............................104

INSPECTION...........................104

OIL PUMP

DESCRIPTION..........................104

OPERATION............................104

STANDARD PROCEDURE.................105

OIL PUMP VOLUME CHECK..............105

DISASSEMBLY..........................105

CLEANING.............................105

INSPECTION...........................105

ASSEMBLY............................105

PARK/NEUTRAL POSITION SWITCH

DIAGNOSIS AND TESTING................106

PARK/NEUTRAL POSITION SWITCH.......106

REMOVAL.............................106

INSTALLATION..........................107

PLANETARY GEARTRAIN

DISASSEMBLY..........................107

ASSEMBLY............................107

SEAL - OIL PUMP

REMOVAL.............................109

INSTALLATION..........................109

SERVO - KICKDOWN

DESCRIPTION..........................109

OPERATION............................109

DISASSEMBLY..........................110

CLEANING.............................111

INSPECTION...........................111

ASSEMBLY.............................112

SERVO - LOW/REVERSE

DESCRIPTION..........................112

OPERATION............................112

DISASSEMBLY..........................112

CLEANING.............................113

ASSEMBLY.............................113

SHIFT INTERLOCK SOLENOID

DESCRIPTION..........................113

OPERATION............................114

DIAGNOSIS AND TESTING................115

BRAKE/TRANSMISSION SHIFT INTERLOCK

SOLENOID...........................115

REMOVAL.............................115

INSTALLATION..........................116

SOLENOID - TCC

DESCRIPTION..........................117

OPERATION............................117

RSAUTOMATIC - 31TH21-21

Page 2986 of 4284

REMOVAL.............................118

INSTALLATION..........................118

THROTTLE VALVE CABLE

REMOVAL.............................118

INSTALLATION..........................118

ADJUSTMENTS.........................120

TORQUE CONVERTER

DESCRIPTION..........................120

OPERATION............................123

REMOVAL.............................125

INSTALLATION..........................125

TRANSFER SYSTEM - OUTPUT SHAFT/GEAR/

BEARING

REMOVAL.............................126

INSTALLATION..........................129

ADJUSTMENTS.........................132TRANSFER SYSTEM - TRANSFER SHAFT/

GEAR/BEARING

REMOVAL.............................134

INSTALLATION..........................137

ADJUSTMENTS.........................142

VALVE BODY

REMOVAL.............................142

DISASSEMBLY..........................145

CLEANING.............................151

INSPECTION...........................152

ASSEMBLY............................152

INSTALLATION..........................155

ADJUSTMENTS.........................157

VEHICLE SPEED SENSOR/PINION GEAR

REMOVAL.............................157

INSTALLATION..........................157

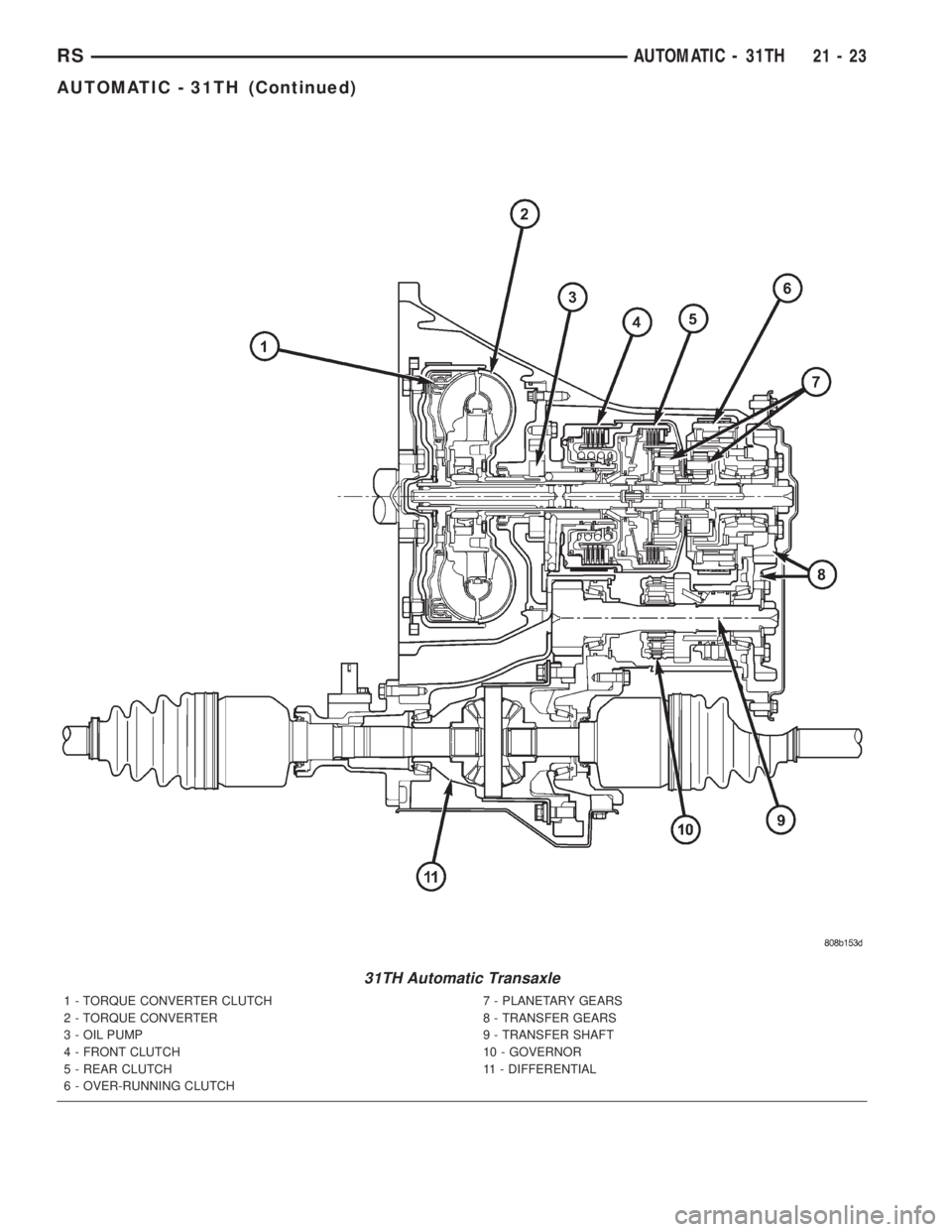

AUTOMATIC - 31TH

DESCRIPTION

This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

Center distances between the main rotating parts

in these three areas are held precise to maintain a

low noise level.

The torque converter, transaxle area, and differen-

tial are housed in an integral aluminum die casting.

The differential oil sump is common with the

transaxle sump. Separate filling of the differen-

tial is NOT necessary.

The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through a remote cooler. There are two types of

coolers used. An oil-to-water type cooler located in

the radiator side tank and/or an oil-to-air heat

exchanger. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assembly.Engine torque is transmitted to the torque con-

verter and then through the input shaft to multiple-

disc clutches in the transaxle. The power flow

depends on the application of the clutches and bands.

Refer to Elements in Use Chart in Diagnosis and

Tests section.

The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands

²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The driving shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor in the

transaxle final drive (axle) ratio. The shaft also car-

ries the governor and parking sprag. An integral heli-

cal gear on the transfer shaft drives the differential

ring gear.

21 - 22 AUTOMATIC - 31THRS

Page 2987 of 4284

31TH Automatic Transaxle

1 - TORQUE CONVERTER CLUTCH

2 - TORQUE CONVERTER

3 - OIL PUMP

4 - FRONT CLUTCH

5 - REAR CLUTCH

6 - OVER-RUNNING CLUTCH7 - PLANETARY GEARS

8 - TRANSFER GEARS

9 - TRANSFER SHAFT

10 - GOVERNOR

11 - DIFFERENTIAL

RSAUTOMATIC - 31TH21-23

AUTOMATIC - 31TH (Continued)

Page 2988 of 4284

OPERATION

Transmission output is directed to an integral dif-

ferential by a transfer gear system in the following

input-to-output ratios:

FIRST 2.69:1

SECOND 1.55:1

THIRD 1.00:1

REVERSE 2.10:1

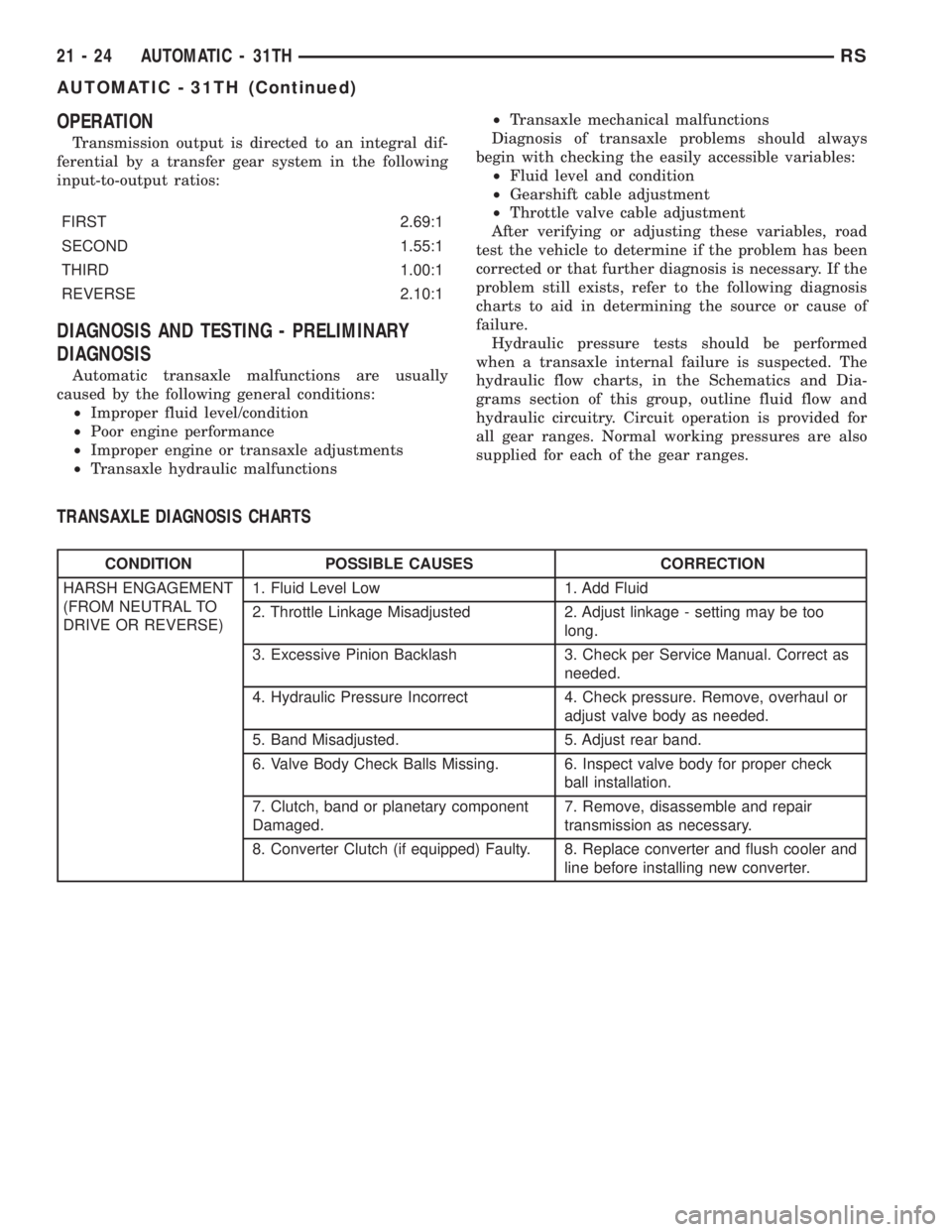

DIAGNOSIS AND TESTING - PRELIMINARY

DIAGNOSIS

Automatic transaxle malfunctions are usually

caused by the following general conditions:

²Improper fluid level/condition

²Poor engine performance

²Improper engine or transaxle adjustments

²Transaxle hydraulic malfunctions²Transaxle mechanical malfunctions

Diagnosis of transaxle problems should always

begin with checking the easily accessible variables:

²Fluid level and condition

²Gearshift cable adjustment

²Throttle valve cable adjustment

After verifying or adjusting these variables, road

test the vehicle to determine if the problem has been

corrected or that further diagnosis is necessary. If the

problem still exists, refer to the following diagnosis

charts to aid in determining the source or cause of

failure.

Hydraulic pressure tests should be performed

when a transaxle internal failure is suspected. The

hydraulic flow charts, in the Schematics and Dia-

grams section of this group, outline fluid flow and

hydraulic circuitry. Circuit operation is provided for

all gear ranges. Normal working pressures are also

supplied for each of the gear ranges.

TRANSAXLE DIAGNOSIS CHARTS

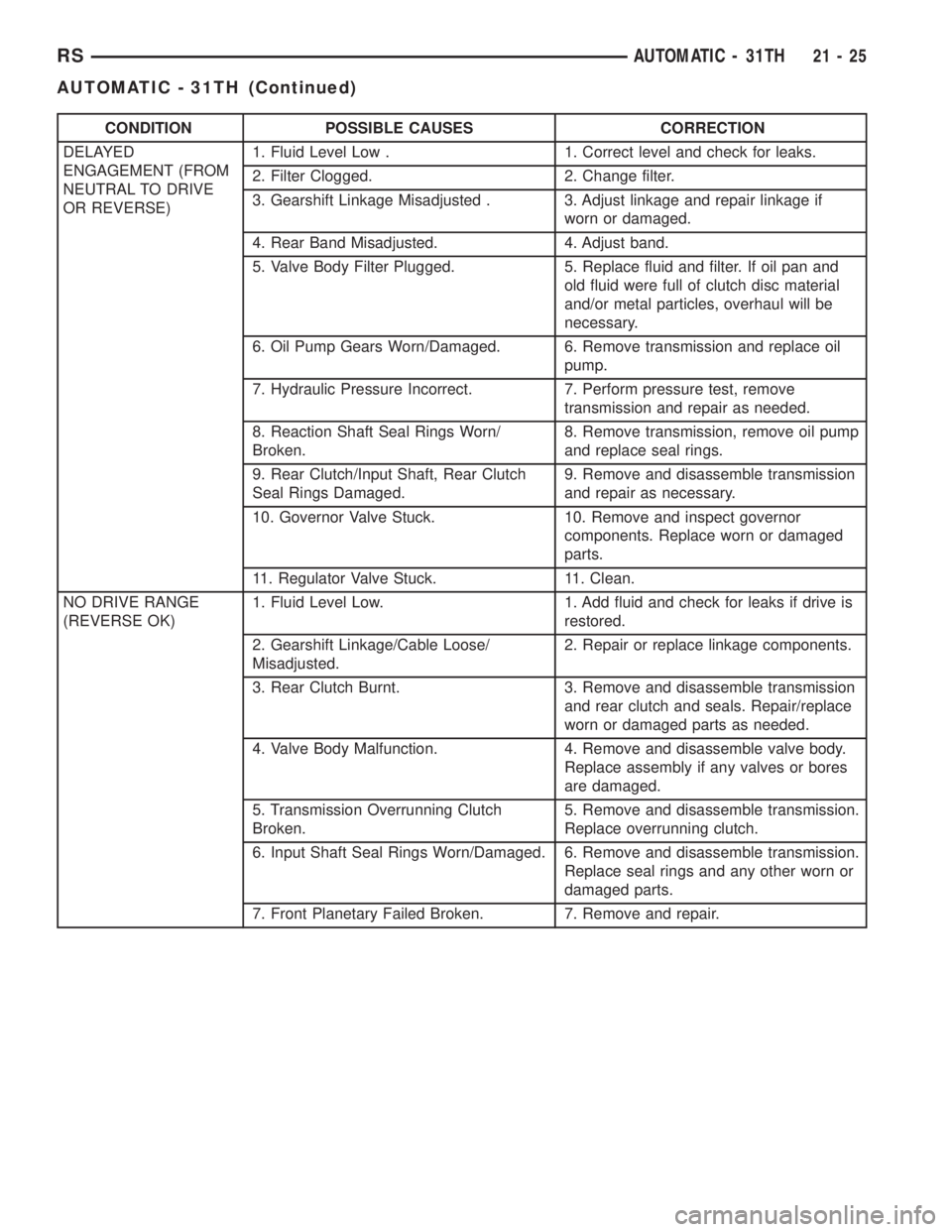

CONDITION POSSIBLE CAUSES CORRECTION

HARSH ENGAGEMENT

(FROM NEUTRAL TO

DRIVE OR REVERSE)1. Fluid Level Low 1. Add Fluid

2. Throttle Linkage Misadjusted 2. Adjust linkage - setting may be too

long.

3. Excessive Pinion Backlash 3. Check per Service Manual. Correct as

needed.

4. Hydraulic Pressure Incorrect 4. Check pressure. Remove, overhaul or

adjust valve body as needed.

5. Band Misadjusted. 5. Adjust rear band.

6. Valve Body Check Balls Missing. 6. Inspect valve body for proper check

ball installation.

7. Clutch, band or planetary component

Damaged.7. Remove, disassemble and repair

transmission as necessary.

8. Converter Clutch (if equipped) Faulty. 8. Replace converter and flush cooler and

line before installing new converter.

21 - 24 AUTOMATIC - 31THRS

AUTOMATIC - 31TH (Continued)

Page 2989 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

DELAYED

ENGAGEMENT (FROM

NEUTRAL TO DRIVE

OR REVERSE)1. Fluid Level Low . 1. Correct level and check for leaks.

2. Filter Clogged. 2. Change filter.

3. Gearshift Linkage Misadjusted . 3. Adjust linkage and repair linkage if

worn or damaged.

4. Rear Band Misadjusted. 4. Adjust band.

5. Valve Body Filter Plugged. 5. Replace fluid and filter. If oil pan and

old fluid were full of clutch disc material

and/or metal particles, overhaul will be

necessary.

6. Oil Pump Gears Worn/Damaged. 6. Remove transmission and replace oil

pump.

7. Hydraulic Pressure Incorrect. 7. Perform pressure test, remove

transmission and repair as needed.

8. Reaction Shaft Seal Rings Worn/

Broken.8. Remove transmission, remove oil pump

and replace seal rings.

9. Rear Clutch/Input Shaft, Rear Clutch

Seal Rings Damaged.9. Remove and disassemble transmission

and repair as necessary.

10. Governor Valve Stuck. 10. Remove and inspect governor

components. Replace worn or damaged

parts.

11. Regulator Valve Stuck. 11. Clean.

NO DRIVE RANGE

(REVERSE OK)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable Loose/

Misadjusted.2. Repair or replace linkage components.

3. Rear Clutch Burnt. 3. Remove and disassemble transmission

and rear clutch and seals. Repair/replace

worn or damaged parts as needed.

4. Valve Body Malfunction. 4. Remove and disassemble valve body.

Replace assembly if any valves or bores

are damaged.

5. Transmission Overrunning Clutch

Broken.5. Remove and disassemble transmission.

Replace overrunning clutch.

6. Input Shaft Seal Rings Worn/Damaged. 6. Remove and disassemble transmission.

Replace seal rings and any other worn or

damaged parts.

7. Front Planetary Failed Broken. 7. Remove and repair.

RSAUTOMATIC - 31TH21-25

AUTOMATIC - 31TH (Continued)

Page 2990 of 4284

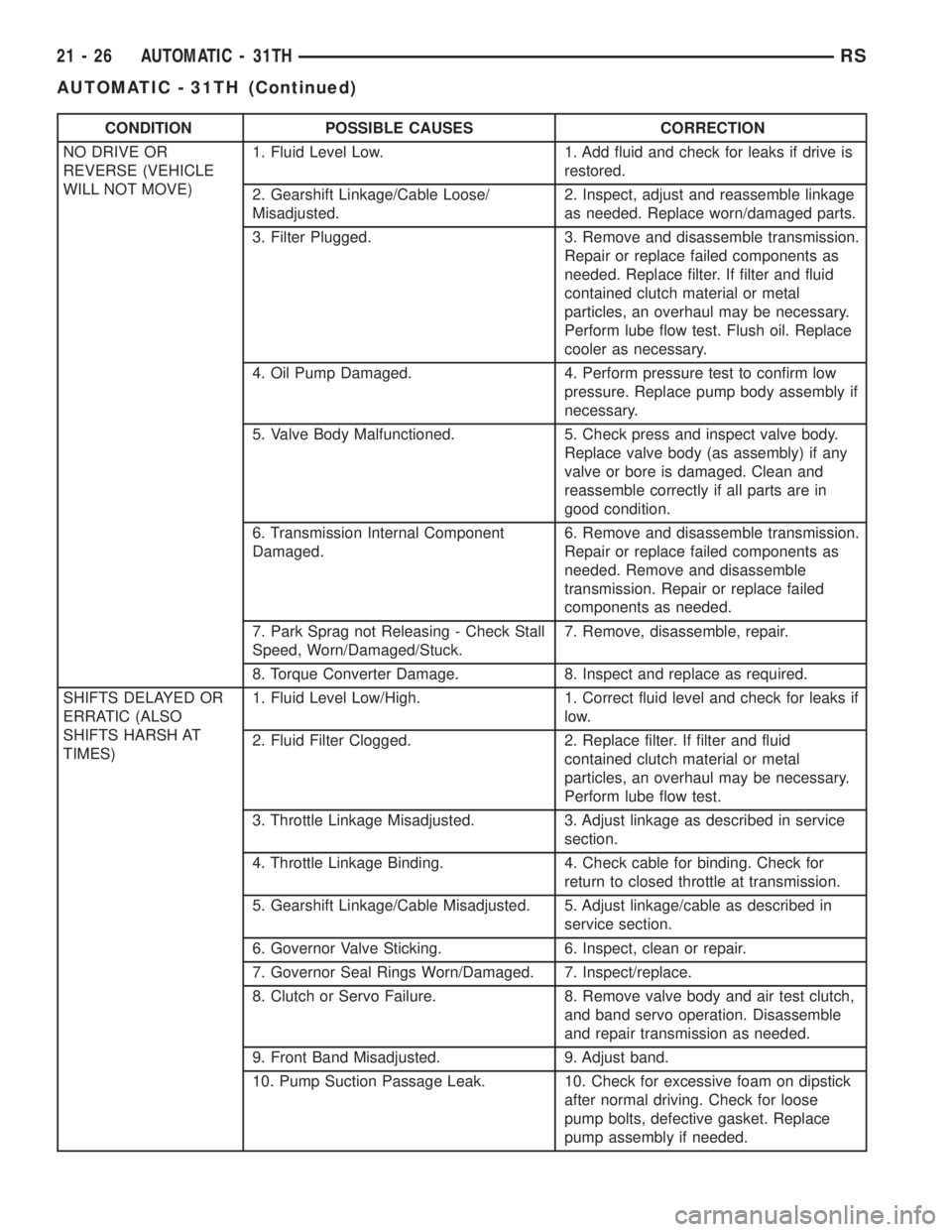

CONDITION POSSIBLE CAUSES CORRECTION

NO DRIVE OR

REVERSE (VEHICLE

WILL NOT MOVE)1. Fluid Level Low. 1. Add fluid and check for leaks if drive is

restored.

2. Gearshift Linkage/Cable Loose/

Misadjusted.2. Inspect, adjust and reassemble linkage

as needed. Replace worn/damaged parts.

3. Filter Plugged. 3. Remove and disassemble transmission.

Repair or replace failed components as

needed. Replace filter. If filter and fluid

contained clutch material or metal

particles, an overhaul may be necessary.

Perform lube flow test. Flush oil. Replace

cooler as necessary.

4. Oil Pump Damaged. 4. Perform pressure test to confirm low

pressure. Replace pump body assembly if

necessary.

5. Valve Body Malfunctioned. 5. Check press and inspect valve body.

Replace valve body (as assembly) if any

valve or bore is damaged. Clean and

reassemble correctly if all parts are in

good condition.

6. Transmission Internal Component

Damaged.6. Remove and disassemble transmission.

Repair or replace failed components as

needed. Remove and disassemble

transmission. Repair or replace failed

components as needed.

7. Park Sprag not Releasing - Check Stall

Speed, Worn/Damaged/Stuck.7. Remove, disassemble, repair.

8. Torque Converter Damage. 8. Inspect and replace as required.

SHIFTS DELAYED OR

ERRATIC (ALSO

SHIFTS HARSH AT

TIMES)1. Fluid Level Low/High. 1. Correct fluid level and check for leaks if

low.

2. Fluid Filter Clogged. 2. Replace filter. If filter and fluid

contained clutch material or metal

particles, an overhaul may be necessary.

Perform lube flow test.

3. Throttle Linkage Misadjusted. 3. Adjust linkage as described in service

section.

4. Throttle Linkage Binding. 4. Check cable for binding. Check for

return to closed throttle at transmission.

5. Gearshift Linkage/Cable Misadjusted. 5. Adjust linkage/cable as described in

service section.

6. Governor Valve Sticking. 6. Inspect, clean or repair.

7. Governor Seal Rings Worn/Damaged. 7. Inspect/replace.

8. Clutch or Servo Failure. 8. Remove valve body and air test clutch,

and band servo operation. Disassemble

and repair transmission as needed.

9. Front Band Misadjusted. 9. Adjust band.

10. Pump Suction Passage Leak. 10. Check for excessive foam on dipstick

after normal driving. Check for loose

pump bolts, defective gasket. Replace

pump assembly if needed.

21 - 26 AUTOMATIC - 31THRS

AUTOMATIC - 31TH (Continued)