check oil CHRYSLER VOYAGER 2001 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1512 of 4284

160 000 km (100 000 miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

²Flush and replace engine coolant. (3)

180 000 km (110 000 miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

IMPORTANT: Inspection and service should also

be performed any time a malfunction is observed or

suspected. Retain all receipts.

²Change oil every 12 months regardless of mile-

age.

²The fuel filter/water separator element should

be replaced once a year if the vehicle is driven less

than 40 000 km annually or if power loss from fuel

starvation is detected.

²

Flush and replace engine coolant every 60 months

even if the vehicle is driven less than 160 000 km.

SCHEDULE ªBº

Follow this schedule if the vehicle is operated

under one or more of the following conditions.

²Day or night temperatures are below 0É C

(32É F).

²Stop and go driving.

²Extensive engine idling.

²Driving in dusty conditions.

²Short trips of less than 16.2 km (10 miles).

²More than 50% of driving is at sustained high

speeds during hot weather, above 32É C (90É F).

²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

10 000 km (6 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element.

20 000 km (12 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

30 000 km (18 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element.

40 000 km (24 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

²Change manual transaxle fluid.

50 000 km (31 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element.

60 000 km (37 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

70 000 km (43 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element.

80 000 km (49 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

²Change manual transaxle fluid.

90 000 km (55 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element.

100 000 km (62 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

110 000 km (68 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

120 000 km (74 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Change manual transaxle fluid.

130 000 km (80 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

0a - 6 LUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESELRG

MAINTENANCE SCHEDULES (Continued)

Page 1513 of 4284

²Inspect air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

140 000 km (86 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

150 000 km (93 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

160 000 km (100 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Flush and replace engine coolant. (3)

²Change oil every 12 months regardless of mile-

age.

²The fuel filter/water separator element should

be replaced once a year if the vehicle is driven less

than 20 000 km annually or if power loss from fuel

starvation is detected.

²

Flush and replace engine coolant every 60 months

even if the vehicle is driven less than 160 000 km.

²Change manual transaxle fluid.

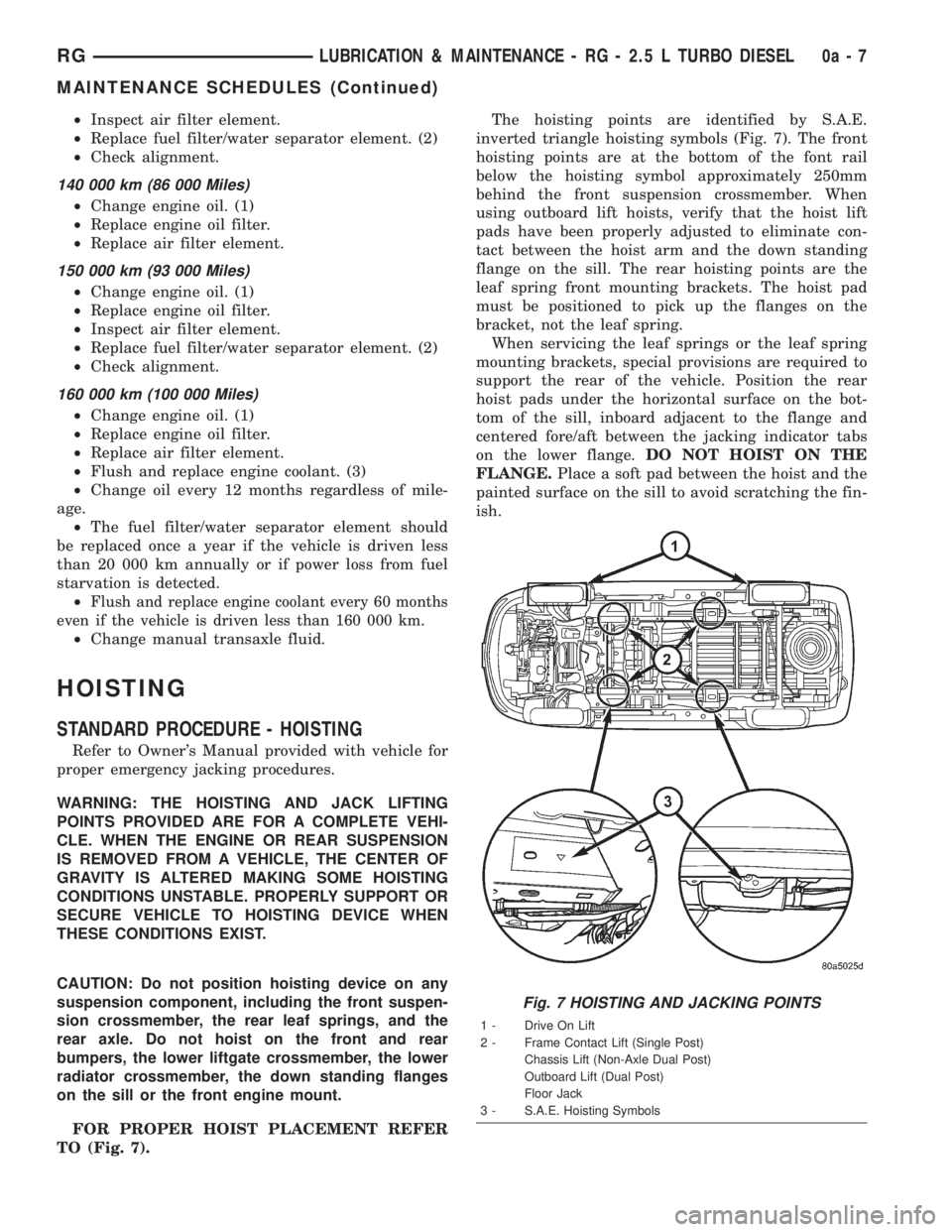

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

CAUTION: Do not position hoisting device on any

suspension component, including the front suspen-

sion crossmember, the rear leaf springs, and the

rear axle. Do not hoist on the front and rear

bumpers, the lower liftgate crossmember, the lower

radiator crossmember, the down standing flanges

on the sill or the front engine mount.

FOR PROPER HOIST PLACEMENT REFER

TO (Fig. 7).The hoisting points are identified by S.A.E.

inverted triangle hoisting symbols (Fig. 7). The front

hoisting points are at the bottom of the font rail

below the hoisting symbol approximately 250mm

behind the front suspension crossmember. When

using outboard lift hoists, verify that the hoist lift

pads have been properly adjusted to eliminate con-

tact between the hoist arm and the down standing

flange on the sill. The rear hoisting points are the

leaf spring front mounting brackets. The hoist pad

must be positioned to pick up the flanges on the

bracket, not the leaf spring.

When servicing the leaf springs or the leaf spring

mounting brackets, special provisions are required to

support the rear of the vehicle. Position the rear

hoist pads under the horizontal surface on the bot-

tom of the sill, inboard adjacent to the flange and

centered fore/aft between the jacking indicator tabs

on the lower flange.DO NOT HOIST ON THE

FLANGE.Place a soft pad between the hoist and the

painted surface on the sill to avoid scratching the fin-

ish.

Fig. 7 HOISTING AND JACKING POINTS

1 - Drive On Lift

2 - Frame Contact Lift (Single Post)

Chassis Lift (Non-Axle Dual Post)

Outboard Lift (Dual Post)

Floor Jack

3 - S.A.E. Hoisting Symbols

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-7

MAINTENANCE SCHEDULES (Continued)

Page 1538 of 4284

(1) Position the strut assembly in the strut coil

spring compressor following the manufacturers

instructions. Position the lower hooks on the coil

spring first. The strut clevis bracket should be posi-

tioned straight outward from the compressor.

(2) Turn the upper mount of the strut assembly

toward the inside of the compressor as shown to

allow positioning of the compressor upper hooks (Fig.

45). Position the upper hooks on top of the coil spring

upper seat approximately 1 inch from outside diame-

ter of seat (Fig. 48).Do not allow hooks to be

placed closer to edge.Place a clamp on the lower

end of the coil spring, so the strut is held in place

once the strut shaft nut is removed.

(3) Compress the coil spring until all coil spring

tension is removed from the upper mount.

(4) Install Strut Nut Socket, Special Tool 6864, on

the strut shaft retaining nut (Fig. 46). Next, install a

10 mm socket on the hex on the end of the strut

shaft. While holding the strut shaft from turning,

remove the nut from the strut shaft.

(5) Remove the upper mount from the strut shaft.

(6) If the pivot bearing needs to be serviced,

remove it from the top of the coil spring upper seat

by pulling it straight up.

(7) Remove the clamp from the bottom of the coil

spring and remove the strut out through the bottom

of the coil spring.

NOTE: If the coil spring or upper spring seat needs

to be serviced, proceed with the next step, other-

wise, proceed with step 10.(8) Release the tension from the coil spring by

backing off the compressor drive fully. Push back the

compressor upper hooks and remove the upper spring

seat.

(9) Remove the coil spring from the spring com-

pressor.

(10) Remove the dust shield and jounce bumper as

an assembly from the strut shaft by pulling both

straight up and off the strut shaft. The dust shield

cannot be separated from the jounce bumper until

after it is removed from strut shaft.

(11) Remove the jounce bumper from the dust

shield. The jounce bumper is removed from the dust

shield by collapsing the dust shield until the jounce

bumper can be pulled free from the dust boot.

(12) Remove the spring isolator from the lower

spring seat on the strut (Fig. 39).

(13) Inspect the strut assembly components (Fig.

39) for the following and replace as necessary:

²Inspect the strut for any condition of shaft bind-

ing over the full stroke of the shaft.

²Check the upper mount for cracks and distortion

and its retaining studs for any sign of damage.

²Check the upper seat for stress cracks and wear.

²Check the upper spring isolator for severe dete-

rioration.

²Check for binding of the strut assembly pivot

bearing.

²Inspect the dust shield for rips and deteriora-

tion.

²Inspect the jounce bumper for cracks and signs

of deterioration.

Fig. 45 MOUNT ROTATED AND HOOKS POSITIONED

1 - UPPER MOUNT TURNED TOWARD COMPRESSOR

2 - COMPRESSOR UPPER HOOKS

3 - UPPER SPRING SEAT

Fig. 46 Retaining Nut Removal/Installation (Typical)

1 - UPPER MOUNT

2 - SPECIAL TOOL 6864

2 - 22 FRONTRS

STRUT (Continued)

Page 1570 of 4284

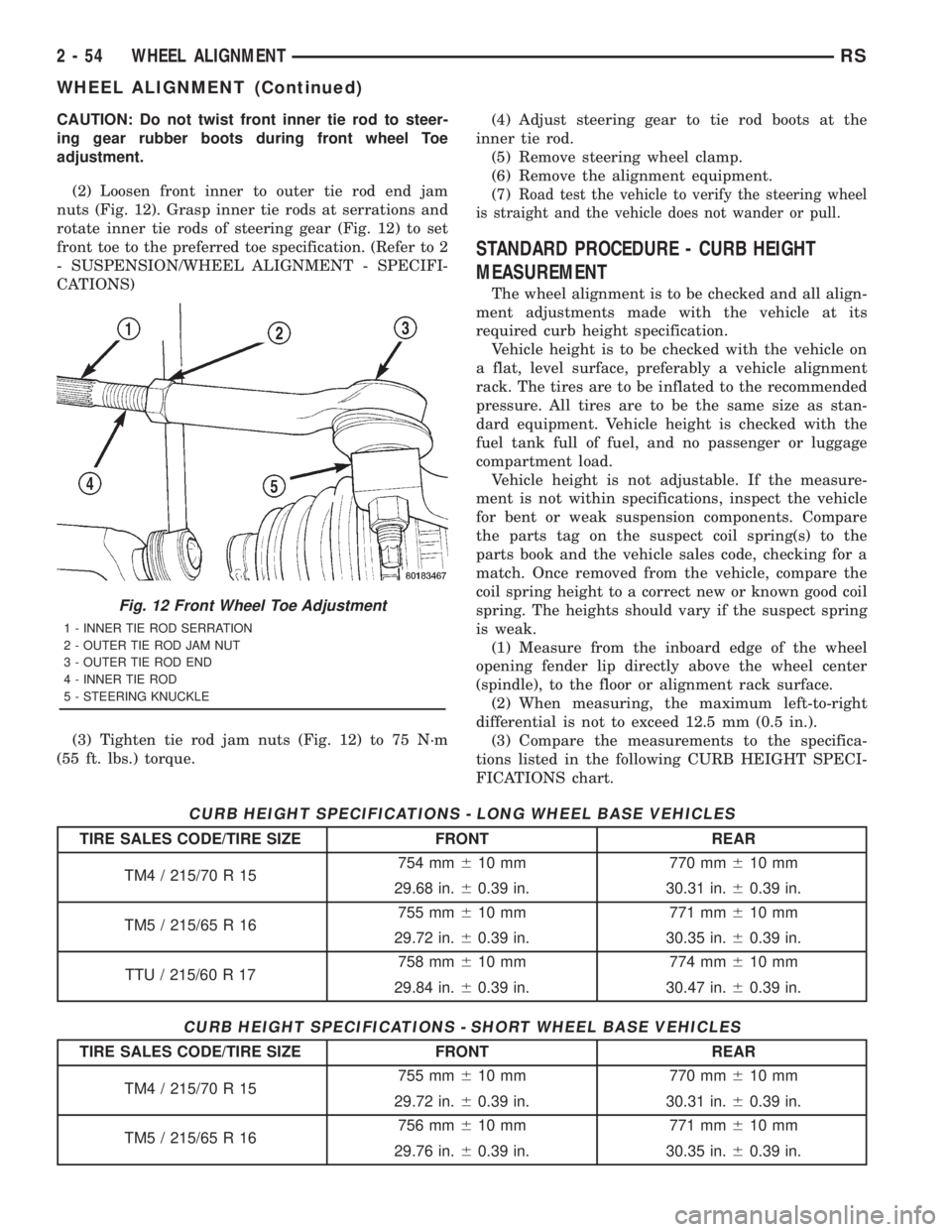

CAUTION: Do not twist front inner tie rod to steer-

ing gear rubber boots during front wheel Toe

adjustment.

(2) Loosen front inner to outer tie rod end jam

nuts (Fig. 12). Grasp inner tie rods at serrations and

rotate inner tie rods of steering gear (Fig. 12) to set

front toe to the preferred toe specification. (Refer to 2

- SUSPENSION/WHEEL ALIGNMENT - SPECIFI-

CATIONS)

(3) Tighten tie rod jam nuts (Fig. 12) to 75 N´m

(55 ft. lbs.) torque.(4) Adjust steering gear to tie rod boots at the

inner tie rod.

(5) Remove steering wheel clamp.

(6) Remove the alignment equipment.

(7)

Road test the vehicle to verify the steering wheel

is straight and the vehicle does not wander or pull.

STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT

The wheel alignment is to be checked and all align-

ment adjustments made with the vehicle at its

required curb height specification.

Vehicle height is to be checked with the vehicle on

a flat, level surface, preferably a vehicle alignment

rack. The tires are to be inflated to the recommended

pressure. All tires are to be the same size as stan-

dard equipment. Vehicle height is checked with the

fuel tank full of fuel, and no passenger or luggage

compartment load.

Vehicle height is not adjustable. If the measure-

ment is not within specifications, inspect the vehicle

for bent or weak suspension components. Compare

the parts tag on the suspect coil spring(s) to the

parts book and the vehicle sales code, checking for a

match. Once removed from the vehicle, compare the

coil spring height to a correct new or known good coil

spring. The heights should vary if the suspect spring

is weak.

(1) Measure from the inboard edge of the wheel

opening fender lip directly above the wheel center

(spindle), to the floor or alignment rack surface.

(2) When measuring, the maximum left-to-right

differential is not to exceed 12.5 mm (0.5 in.).

(3) Compare the measurements to the specifica-

tions listed in the following CURB HEIGHT SPECI-

FICATIONS chart.

CURB HEIGHT SPECIFICATIONS - LONG WHEEL BASE VEHICLES

TIRE SALES CODE/TIRE SIZE FRONT REAR

TM4 / 215/70 R 15754 mm610 mm 770 mm610 mm

29.68 in.60.39 in. 30.31 in.60.39 in.

TM5 / 215/65 R 16755 mm610 mm 771 mm610 mm

29.72 in.60.39 in. 30.35 in.60.39 in.

TTU / 215/60 R 17758 mm610 mm 774 mm610 mm

29.84 in.60.39 in. 30.47 in.60.39 in.

CURB HEIGHT SPECIFICATIONS - SHORT WHEEL BASE VEHICLES

TIRE SALES CODE/TIRE SIZE FRONT REAR

TM4 / 215/70 R 15755 mm610 mm 770 mm610 mm

29.72 in.60.39 in. 30.31 in.60.39 in.

TM5 / 215/65 R 16756 mm610 mm 771 mm610 mm

29.76 in.60.39 in. 30.35 in.60.39 in.

Fig. 12 Front Wheel Toe Adjustment

1 - INNER TIE ROD SERRATION

2 - OUTER TIE ROD JAM NUT

3 - OUTER TIE ROD END

4 - INNER TIE ROD

5 - STEERING KNUCKLE

2 - 54 WHEEL ALIGNMENTRS

WHEEL ALIGNMENT (Continued)

Page 1575 of 4284

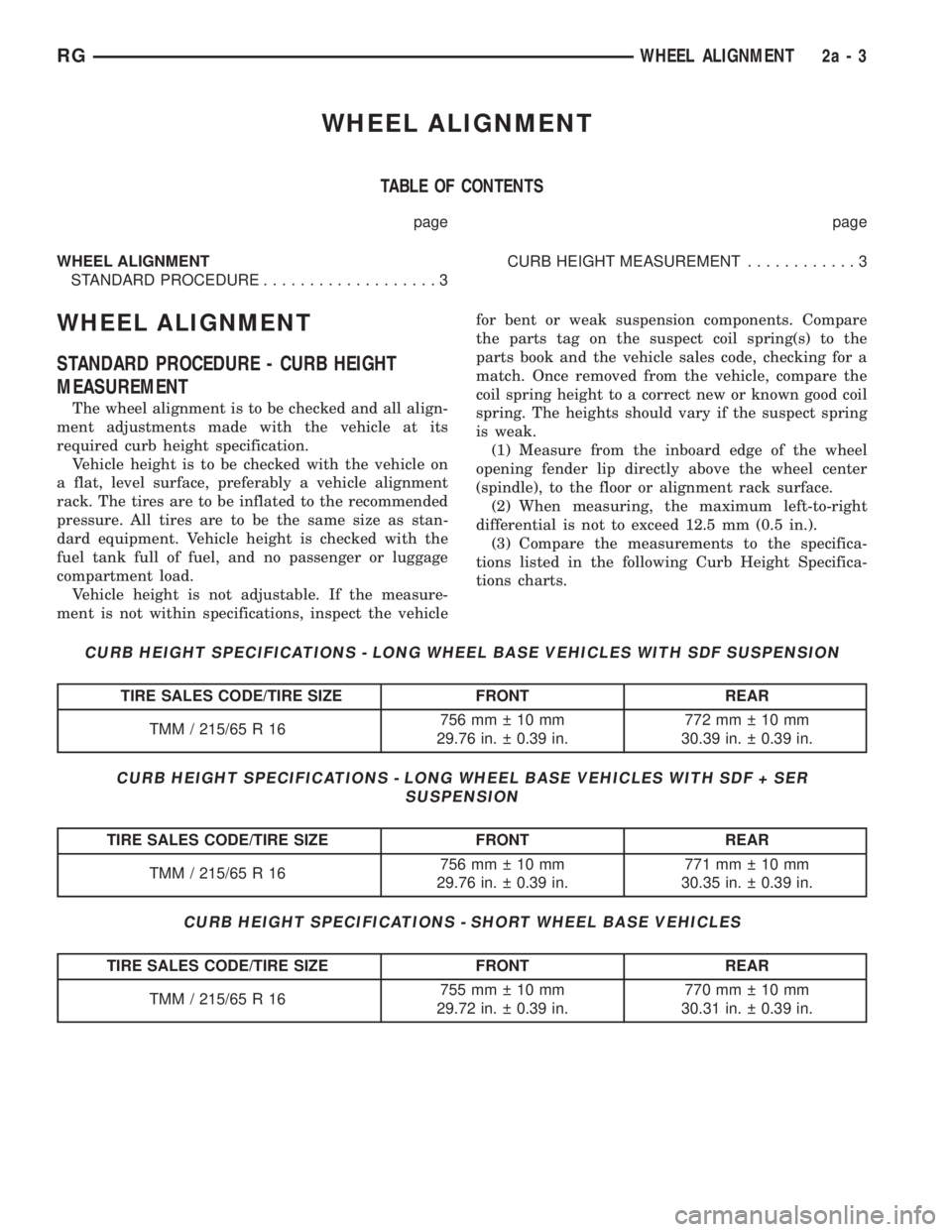

WHEEL ALIGNMENT

TABLE OF CONTENTS

page page

WHEEL ALIGNMENT

STANDARD PROCEDURE...................3CURB HEIGHT MEASUREMENT............3

WHEEL ALIGNMENT

STANDARD PROCEDURE - CURB HEIGHT

MEASUREMENT

The wheel alignment is to be checked and all align-

ment adjustments made with the vehicle at its

required curb height specification.

Vehicle height is to be checked with the vehicle on

a flat, level surface, preferably a vehicle alignment

rack. The tires are to be inflated to the recommended

pressure. All tires are to be the same size as stan-

dard equipment. Vehicle height is checked with the

fuel tank full of fuel, and no passenger or luggage

compartment load.

Vehicle height is not adjustable. If the measure-

ment is not within specifications, inspect the vehiclefor bent or weak suspension components. Compare

the parts tag on the suspect coil spring(s) to the

parts book and the vehicle sales code, checking for a

match. Once removed from the vehicle, compare the

coil spring height to a correct new or known good coil

spring. The heights should vary if the suspect spring

is weak.

(1) Measure from the inboard edge of the wheel

opening fender lip directly above the wheel center

(spindle), to the floor or alignment rack surface.

(2) When measuring, the maximum left-to-right

differential is not to exceed 12.5 mm (0.5 in.).

(3) Compare the measurements to the specifica-

tions listed in the following Curb Height Specifica-

tions charts.

CURB HEIGHT SPECIFICATIONS - LONG WHEEL BASE VEHICLES WITH SDF SUSPENSION

TIRE SALES CODE/TIRE SIZE FRONT REAR

TMM / 215/65 R 16756mm 10mm

29.76 in. 0.39 in.772mm 10mm

30.39 in. 0.39 in.

CURB HEIGHT SPECIFICATIONS - LONG WHEEL BASE VEHICLES WITH SDF + SER

SUSPENSION

TIRE SALES CODE/TIRE SIZE FRONT REAR

TMM / 215/65 R 16756mm 10mm

29.76 in. 0.39 in.771mm 10mm

30.35 in. 0.39 in.

CURB HEIGHT SPECIFICATIONS - SHORT WHEEL BASE VEHICLES

TIRE SALES CODE/TIRE SIZE FRONT REAR

TMM / 215/65 R 16755mm 10mm

29.72 in. 0.39 in.770mm 10mm

30.31 in. 0.39 in.

RGWHEEL ALIGNMENT2a-3

Page 1603 of 4284

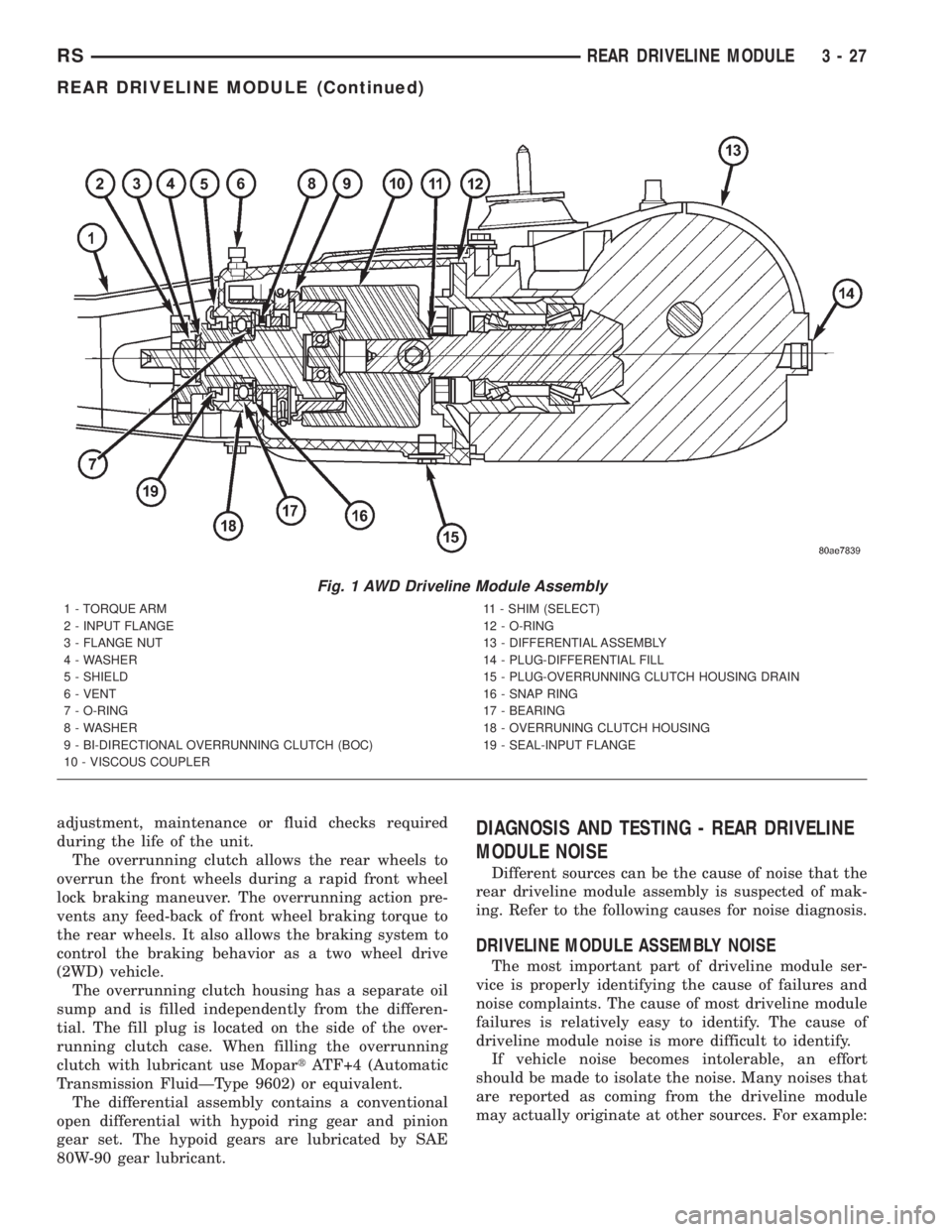

adjustment, maintenance or fluid checks required

during the life of the unit.

The overrunning clutch allows the rear wheels to

overrun the front wheels during a rapid front wheel

lock braking maneuver. The overrunning action pre-

vents any feed-back of front wheel braking torque to

the rear wheels. It also allows the braking system to

control the braking behavior as a two wheel drive

(2WD) vehicle.

The overrunning clutch housing has a separate oil

sump and is filled independently from the differen-

tial. The fill plug is located on the side of the over-

running clutch case. When filling the overrunning

clutch with lubricant use MopartATF+4 (Automatic

Transmission FluidÐType 9602) or equivalent.

The differential assembly contains a conventional

open differential with hypoid ring gear and pinion

gear set. The hypoid gears are lubricated by SAE

80W-90 gear lubricant.DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE NOISE

Different sources can be the cause of noise that the

rear driveline module assembly is suspected of mak-

ing. Refer to the following causes for noise diagnosis.

DRIVELINE MODULE ASSEMBLY NOISE

The most important part of driveline module ser-

vice is properly identifying the cause of failures and

noise complaints. The cause of most driveline module

failures is relatively easy to identify. The cause of

driveline module noise is more difficult to identify.

If vehicle noise becomes intolerable, an effort

should be made to isolate the noise. Many noises that

are reported as coming from the driveline module

may actually originate at other sources. For example:

Fig. 1 AWD Driveline Module Assembly

1 - TORQUE ARM

2 - INPUT FLANGE

3 - FLANGE NUT

4 - WASHER

5 - SHIELD

6 - VENT

7 - O-RING

8 - WASHER

9 - BI-DIRECTIONAL OVERRUNNING CLUTCH (BOC)

10 - VISCOUS COUPLER11 - SHIM (SELECT)

12 - O-RING

13 - DIFFERENTIAL ASSEMBLY

14 - PLUG-DIFFERENTIAL FILL

15 - PLUG-OVERRUNNING CLUTCH HOUSING DRAIN

16 - SNAP RING

17 - BEARING

18 - OVERRUNING CLUTCH HOUSING

19 - SEAL-INPUT FLANGE

RSREAR DRIVELINE MODULE3-27

REAR DRIVELINE MODULE (Continued)

Page 1658 of 4284

STANDARD PROCEDURE - BRAKE FLUID

LEVEL CHECKING

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

Fluid reservoirs are marked with the words FULL

and ADD to indicate proper brake fluid fill level of

the master cylinder.

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.

Use only Mopartbrake fluid or equivalent from a

sealed container. Brake fluid must conform to DOT 3

specifications (DOT 4 or DOT 4+ are acceptable).

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

Use only brake fluid that was stored in a tightly-

sealed container.

DO NOTuse petroleum-based fluid because seal

damage will result. Petroleum based fluids would be

items such as engine oil, transmission fluid, power

steering fluid etc.

SPECIFICATIONS

BRAKE FLUID

The brake fluid used in this vehicle must conform

to DOT 3 specifications (DOT 4 and DOT 4+ are

acceptable) and SAE J1703 standards. No other type

of brake fluid is recommended or approved for usage

in the vehicle brake system. Use only MopartBrake

Fluid or equivalent from a tightly sealed container.

CAUTION: Never use reclaimed brake fluid or fluid

from an container which has been left open. An

open container of brake fluid will absorb moisture

from the air and contaminate the fluid.

CAUTION: Never use any type of a petroleum-based

fluid in the brake hydraulic system. Use of such

type fluids will result in seal damage of the vehicle

brake hydraulic system causing a failure of the

vehicle brake system. Petroleum based fluids would

be items such as engine oil, transmission fluid,

power steering fluid, etc.

JUNCTION BLOCK

DESCRIPTION - NON-ABS JUNCTION BLOCK

A junction block is used on vehicles that are not

equipped with antilock brakes (ABS). The junction

block mounts in the same location as the integrated

control unit (ICU) does on vehicles equipped withABS. This allows for use of the same brake tube con-

figuration on all vehicles. The junction block is

located on the driver's side of the front suspension

cradle/crossmember below the master cylinder (Fig.

46).

It has six threaded ports to which the brake tubes

connect. Two are for the primary and secondary

brake tubes coming from the master cylinder. The

remaining four are for the chassis brake tubes going

to each brake assembly.

OPERATION - NON-ABS JUNCTION BLOCK

The junction block distributes the brake fluid com-

ing from the master cylinder primary and secondary

ports to the four chassis brake tubes leading to the

brakes at each wheel. Since the junction block

mounts in the same location as the ABS integrated

control unit (ICU), it allows for the common use of

brake tubes going to the brakes whether the vehicle

is equipped with or without ABS.

NOTE: Although the brake tubes coming from the

master cylinder to the junction block or ABS ICU

may appear to be the same, they are not. They are

unique to each brake system application.

REMOVAL - NON-ABS JUNCTION BLOCK

(1) Using a brake pedal depressor, move and lock

the brake pedal to a position past its first 1 inch of

travel. This will prevent brake fluid from draining

out of the master cylinder when the brake tubes are

removed from the junction block.

(2) Disconnect the battery negative cable.

(3) If the vehicle is equipped with speed control,

perform the following:

(a) Disconnect the battery positive cable.

(b) Remove the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - REMOVAL).

(c) Disconnect the vacuum hose connector at the

tank built into the battery tray.

(d) Remove the screw securing the coolant filler

neck to the battery tray.

(e) Remove the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - REMOVAL).

(f) Remove the fasteners and move the speed

control servo off to the side, out of the way.

CAUTION: Before removing the brake tubes from

the junction block, the junction block and the brake

tubes must be thoroughly cleaned. This is required

to prevent contamination from entering the brake

hydraulic system.

5 - 32 BRAKES - BASERS

FLUID (Continued)

Page 1705 of 4284

BRAKES

TABLE OF CONTENTS

page page

BRAKES - BASE........................... 1BRAKES - ABS........................... 10

BRAKES - BASE

TABLE OF CONTENTS

page page

BRAKES - BASE

DESCRIPTION............................1

HYDRAULIC/MECHANICAL

DESCRIPTION............................1

FLUID

STANDARD PROCEDURE...................1

BRAKE FLUID LEVEL CHECKING...........1

MASTER CYLINDER - RHD

DESCRIPTION............................2

REMOVAL...............................2

INSTALLATION............................3

PEDAL TORQUE SHAFT

REMOVAL...............................3

INSTALLATION............................4POWER BRAKE BOOSTER - RHD

REMOVAL...............................4

INSTALLATION............................6

ROTORS

SPECIFICATIONS.........................8

PARKING BRAKE

DESCRIPTION............................8

CABLES - PARKING BRAKE

REMOVAL...............................8

INSTALLATION............................8

LEVER - PARKING BRAKE

REMOVAL...............................8

INSTALLATION............................9

BRAKES - BASE

DESCRIPTION - BASE BRAKES

Four-Wheel Disc Antilock Brakes are standard on

all models.

HYDRAULIC/MECHANICAL

DESCRIPTION - DISC BRAKES

All vehicles are equipped with Four-Wheel-Disc

brakes. Both 15º (BRE) and 16º (BR3) disc/disc brake

systems are available. The disc brakes are manufac-

tured by Continental Teves. The BR3 system is stan-

dard equipment on all-wheel drive and all right-hand

drive models. It is optional on other models.

The BR3 system features larger, externally vented

front brake rotors.

Although there are different disc/disc systems, they

are serviced using the same service procedures. Some

specifications differ.

FLUID

STANDARD PROCEDURE - BRAKE FLUID

LEVEL CHECKING

Right hand drive vehicles feature a brake fluid res-

ervoir with the same markings as left hand drive res-

ervoirs.

Check master cylinder reservoir fluid level a mini-

mum of twice annually.

Fluid reservoirs are marked with the words FULL

and ADD to indicate proper brake fluid fill level of

the master cylinder.

If necessary, add brake fluid to bring the level to

the bottom of the FULL mark on the side of the mas-

ter cylinder fluid reservoir.

Use only Mopartbrake fluid or equivalent from a

sealed container. Brake fluid must conform to DOT 3

specifications (DOT 4 or DOT 4+ are acceptable).

DO NOTuse brake fluid with a lower boiling

point, as brake failure could result during prolonged

hard braking.

RGBRAKES5a-1

Page 1722 of 4284

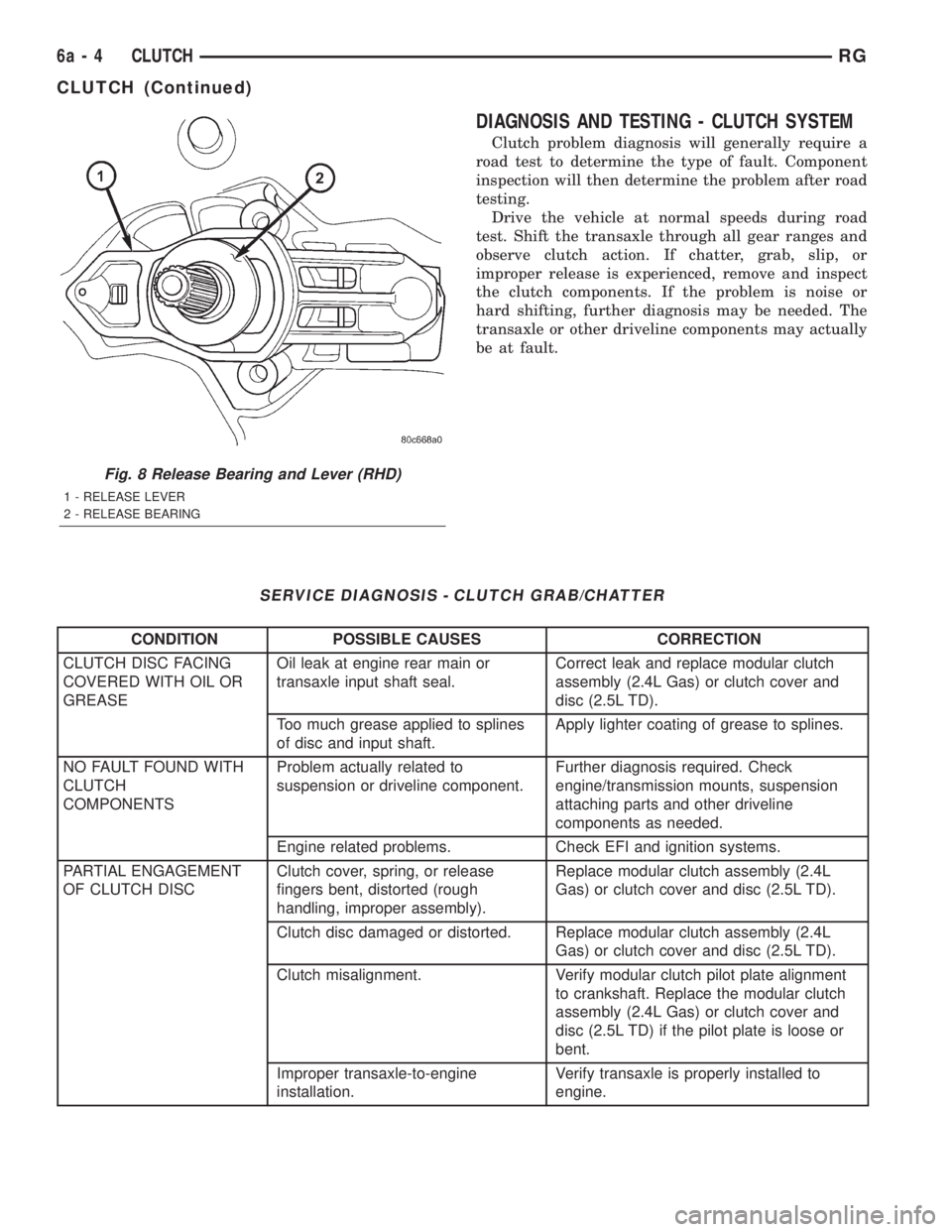

DIAGNOSIS AND TESTING - CLUTCH SYSTEM

Clutch problem diagnosis will generally require a

road test to determine the type of fault. Component

inspection will then determine the problem after road

testing.

Drive the vehicle at normal speeds during road

test. Shift the transaxle through all gear ranges and

observe clutch action. If chatter, grab, slip, or

improper release is experienced, remove and inspect

the clutch components. If the problem is noise or

hard shifting, further diagnosis may be needed. The

transaxle or other driveline components may actually

be at fault.

SERVICE DIAGNOSIS - CLUTCH GRAB/CHATTER

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC FACING

COVERED WITH OIL OR

GREASEOil leak at engine rear main or

transaxle input shaft seal.Correct leak and replace modular clutch

assembly (2.4L Gas) or clutch cover and

disc (2.5L TD).

Too much grease applied to splines

of disc and input shaft.Apply lighter coating of grease to splines.

NO FAULT FOUND WITH

CLUTCH

COMPONENTSProblem actually related to

suspension or driveline component.Further diagnosis required. Check

engine/transmission mounts, suspension

attaching parts and other driveline

components as needed.

Engine related problems. Check EFI and ignition systems.

PARTIAL ENGAGEMENT

OF CLUTCH DISCClutch cover, spring, or release

fingers bent, distorted (rough

handling, improper assembly).Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Clutch disc damaged or distorted. Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Clutch misalignment. Verify modular clutch pilot plate alignment

to crankshaft. Replace the modular clutch

assembly (2.4L Gas) or clutch cover and

disc (2.5L TD) if the pilot plate is loose or

bent.

Improper transaxle-to-engine

installation.Verify transaxle is properly installed to

engine.

Fig. 8 Release Bearing and Lever (RHD)

1 - RELEASE LEVER

2 - RELEASE BEARING

6a - 4 CLUTCHRG

CLUTCH (Continued)

Page 1725 of 4284

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT

Common causes of misalignment are:

²Heat warping

²Mounting drive plate on a dirty crankshaft

flange

²Incorrect bolt tightening

²Improper seating on the crankshaft shoulder

²Loose crankshaft bolts

Clean the crankshaft flange before mounting the

drive plate. Dirt and grease on the flange surface

may misalign the flywheel, causing excessive runout.

Use new bolts when mounting drive plate to crank-

shaft. Tighten drive plate bolts to specified torque

only. Over-tightening can distort the drive plate hub

causing excessive runout.

DIAGNOSIS AND TESTING - CLUTCH COVER

AND DISC RUNOUT

Check condition of the clutch cover before installa-

tion. A warped cover or diaphragm spring will cause

grab and/or incomplete release or engagement. Use

care when handling the clutch assembly. Impact can

distort the cover, diaphragm spring, and release fin-

gers.

DIAGNOSIS AND TESTING - CLUTCH CHATTER

COMPLAINTS

For all clutch chatter complaints, perform the fol-

lowing:

(1) Check for loose, misaligned, or broken engine

and transmission mounts. If present, they should be

corrected at this time. Test vehicle for chatter. If

chatter is gone, there is no need to go any further.

(2) If chatter persists, check hydraulic clutch

release system is functioning properly.

(3) Check for loose connections in drivetrain. Cor-

rect any problems and determine if clutch chatter

complaints have been satisfied. If not:

(a) Remove transaxle.

(b) Check to see if the release bearing is sticky

or binding. Replace bearing, if needed.

(c) Check linkage for excessive wear on the pivot

stud and fork fingers. Replace all worn parts.

(d) Check clutch assembly for contamination

(dirt, oil). Replace clutch assembly, if required.

(e) Check to see if the clutch disc hub splines

are damaged. Replace with new clutch assembly, if

necessary.

(f) Check input shaft splines for damage.

Replace, if necessary.

(g) Check for uneven wear on clutch fingers.

(h) Check for broken clutch cover diaphragm

spring fingers. Replace with new clutch assembly,

if necessary.

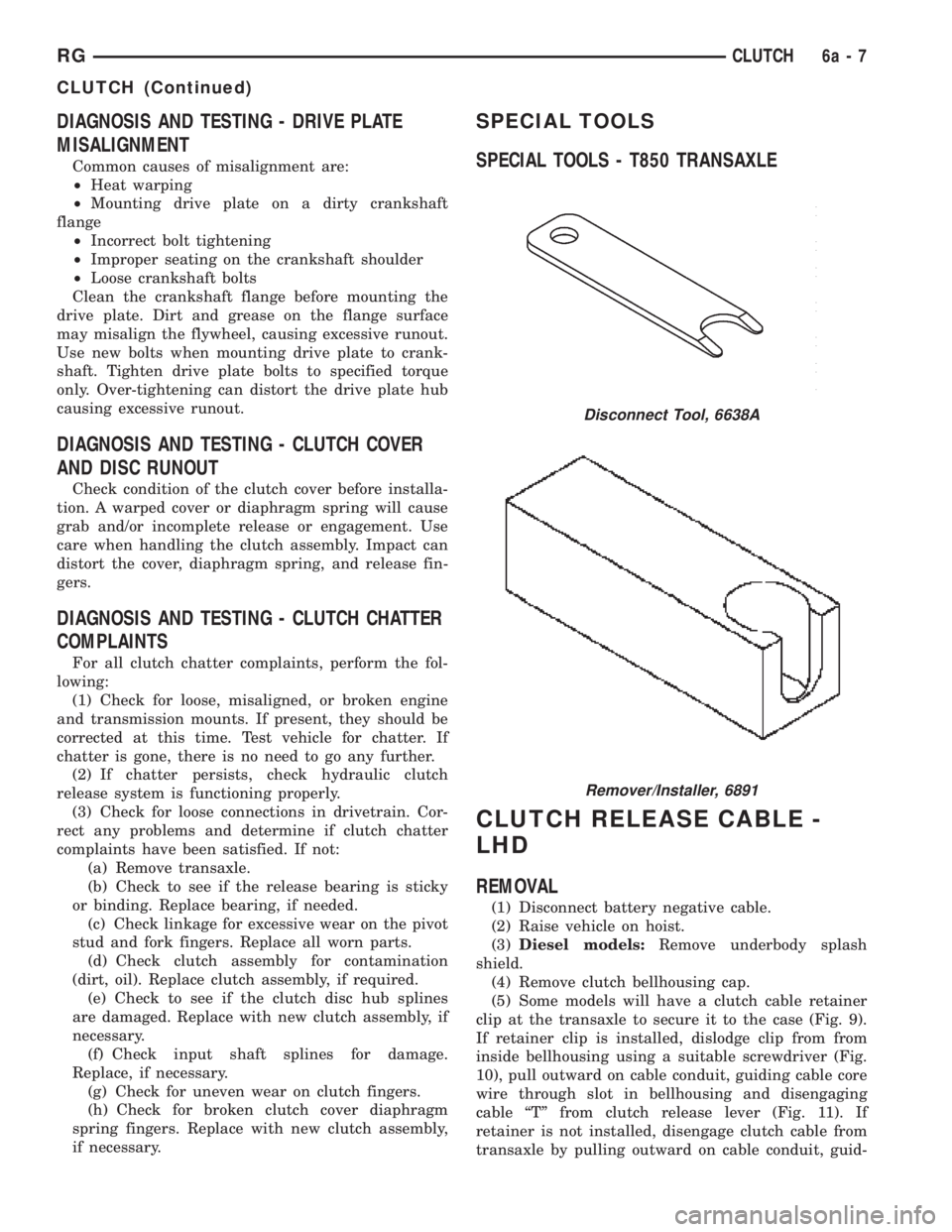

SPECIAL TOOLS

SPECIAL TOOLS - T850 TRANSAXLE

CLUTCH RELEASE CABLE -

LHD

REMOVAL

(1) Disconnect battery negative cable.

(2) Raise vehicle on hoist.

(3)Diesel models:Remove underbody splash

shield.

(4) Remove clutch bellhousing cap.

(5) Some models will have a clutch cable retainer

clip at the transaxle to secure it to the case (Fig. 9).

If retainer clip is installed, dislodge clip from from

inside bellhousing using a suitable screwdriver (Fig.

10), pull outward on cable conduit, guiding cable core

wire through slot in bellhousing and disengaging

cable ªTº from clutch release lever (Fig. 11). If

retainer is not installed, disengage clutch cable from

transaxle by pulling outward on cable conduit, guid-

Disconnect Tool, 6638A

Remover/Installer, 6891

RGCLUTCH6a-7

CLUTCH (Continued)