fuse diagram CHRYSLER VOYAGER 2001 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1904 of 4284

²Remote Keyless Entry Module (RKE)- Refer

toRemote Keyless Entry Modulein Power Locks

for more information.

²Electronic Vehicle Information Center

(EVIC)- Refer toElectronic Vehicle Information

Centerin Overhead Console for more information.

²Heated Seat Module (HSM)- Refer toHeated

Seat Modulein Electronic Control Modules for more

information.

²Memory Heated Seat Module (MHSM)-If

the vehicle is equipped with the Memory System,

refer toMemory Seat Mirror Module (MSMM)in

Electronic Control Modules for more information.

Refer toWiring Diagramsfor complete circuit

diagrams. Following are general descriptions of the

major components in the heated seat system.

OPERATION

The heated seat system will only operate when the

ignition switch is in the On position, and the surface

temperature at the front seat heating element sen-

sors is below the designed temperature set points of

the system. The heated seat system will not operate

in ambient temperatures greater than about 41É C

(105É F). The front seat heating elements and sensors

are hard wired to the Heated Seat Module (HSM) or

the Memory Heated Seat Module (MHSM).

The heated seat switches are hard wired to the

Body Control Module (BCM). The BCM monitors the

heated seat switch inputs, then sends heated seat

switch status messages to the HSM or MHSM over

the Programmable Communications Interface J1850

(PCI) data bus. The HSM or MHSM contains the con-

trol logic for the heated seat system. The HSM or

MHSM responds to the heated seat switch status

messages, ignition switch status messages, and the

front seat heating element sensor inputs by control-

ling the output to the front seat heating elements

through integral solid-state relays.

When a seat heater is turned on, the sensor

located on the seat cushion electric heater element

provides the HSM or MHSM with an input indicating

the surface temperature of the seat cushion. If the

surface temperature input is below the temperature

set point for the selected Low or High heated seat

switch position, the HSM or MHSM energizes the

integral solid-state relay, which supplies battery cur-

rent to the heating elements in the seat cushion and

back. When the sensor input indicates the correct

temperature set point has been achieved, the HSM or

MHSM de-energizes the solid-state relay. The HSM

or MHSM will continue to cycle the solid-state relay

as needed to maintain the temperature set point.

The HSM or MHSM and the seat heater elements

operate on non-switched battery current supplied

through the power seat fuse in the intelligent powermodule. However, the HSM or MHSM will automati-

cally turn off the heating elements if it detects an

open in the sensor circuit, a short in the heating ele-

ment circuit causing an excessive current draw, or

when the ignition switch is turned to the Off posi-

tion.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the heated seat system.

DRIVER HEATED SEAT

SWITCH

DESCRIPTION

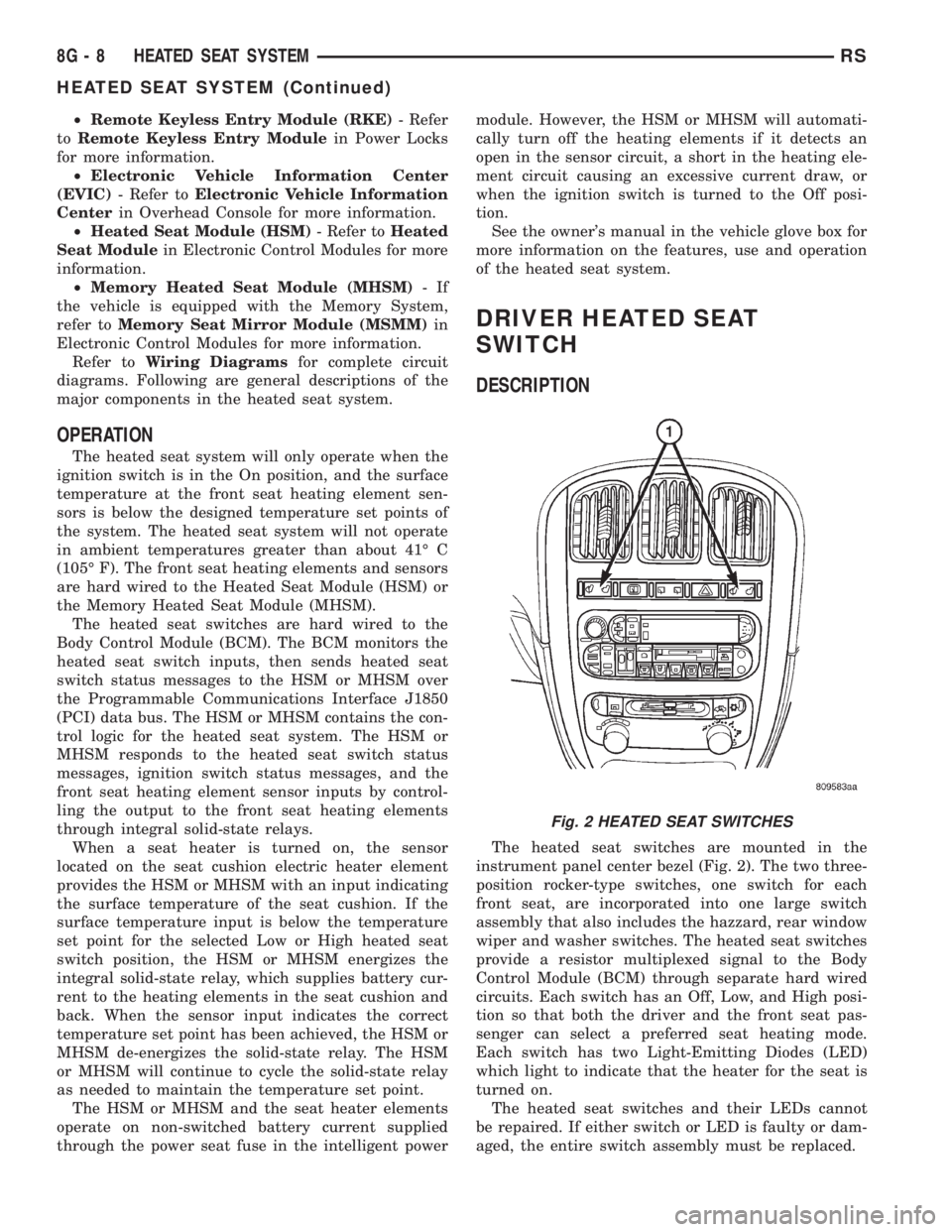

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 2). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switch

assembly that also includes the hazzard, rear window

wiper and washer switches. The heated seat switches

provide a resistor multiplexed signal to the Body

Control Module (BCM) through separate hard wired

circuits. Each switch has an Off, Low, and High posi-

tion so that both the driver and the front seat pas-

senger can select a preferred seat heating mode.

Each switch has two Light-Emitting Diodes (LED)

which light to indicate that the heater for the seat is

turned on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

Fig. 2 HEATED SEAT SWITCHES

8G - 8 HEATED SEAT SYSTEMRS

HEATED SEAT SYSTEM (Continued)

Page 1905 of 4284

OPERATION

There are three positions that can be selected with

each of the heated seat switches: Off, Low, or High.

When the left side of the switch rocker is fully

depressed, the Low position is selected and the high

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the low position LED indica-

tor illuminates. When the switch rocker is moved to

its neutral position (middle), Off is selected and both

LED indicators are extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the BCM to indicate the

selected switch position. The BCM monitors the

switch inputs and sends heated seat switch status

messages to the Heated Seat Module (HSM) or the

Memory Heated Seat Module (MHSM) over the Pro-

grammable Communications Interface (PCI) data

bus. The HSM or MHSM responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS & TESTING - HEATED SEAT

SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused ignition switch output (run)

fuse in the intelligent power module. If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the intelligent power module. If

OK, go to Step 3. If not OK, repair the open fused

ignition switch output (run) circuit to the ignition

switch as required.

(3) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel and disconnect the instrument panel wire har-

ness connectors from the heated seat switch connec-

tor receptacle. Check for continuity between the

ground circuit cavity of the instrument panel wireharness connector for the inoperative heated seat

switch(es) and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel wire harness con-

nector for the inoperative heated seat switch(es). If

OK, turn the ignition switch to the Off position, dis-

connect and isolate the battery negative cable, and go

to Step 5. If not OK, repair the open fused ignition

switch output (run) circuit to the intelligent power

module fuse as required.

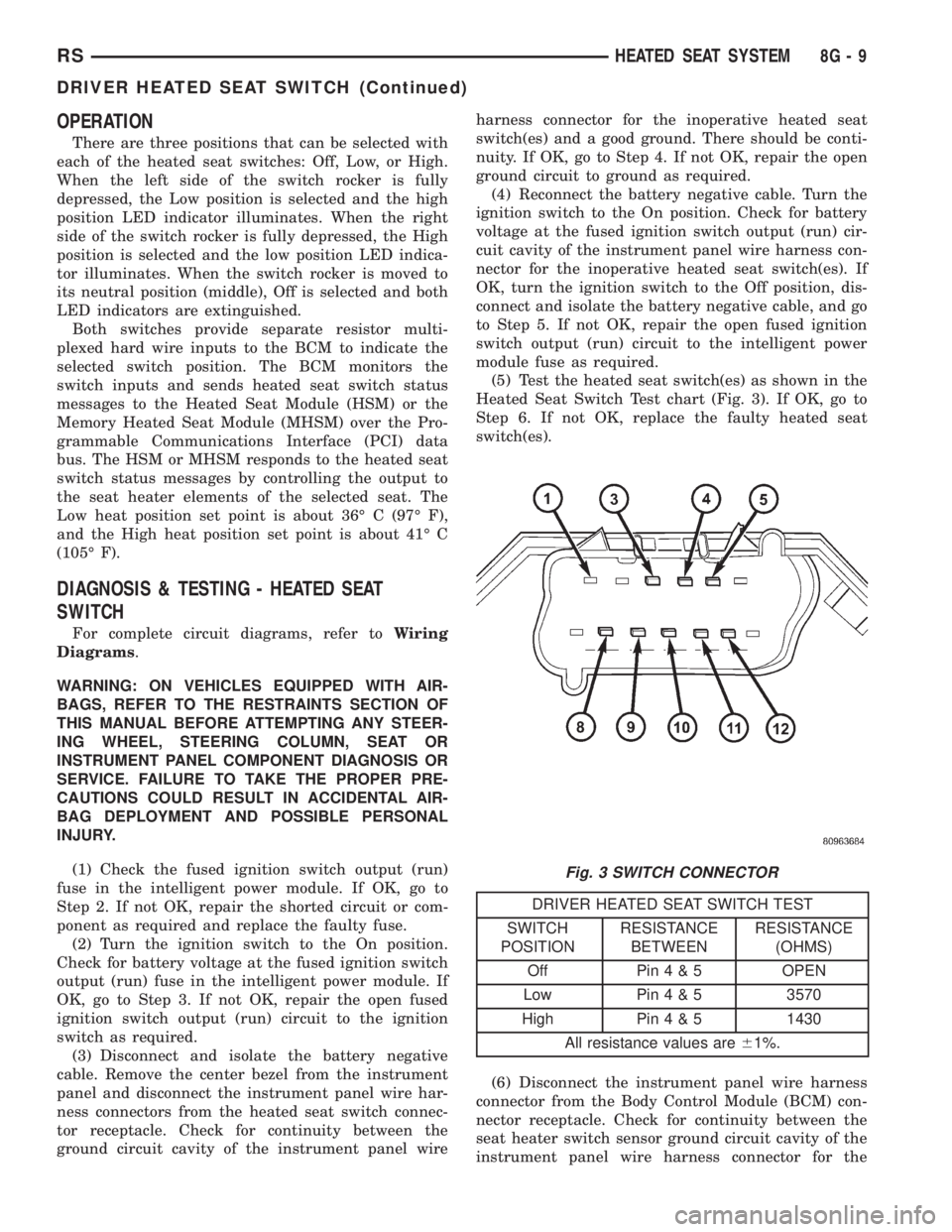

(5) Test the heated seat switch(es) as shown in the

Heated Seat Switch Test chart (Fig. 3). If OK, go to

Step 6. If not OK, replace the faulty heated seat

switch(es).

DRIVER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin4&5OPEN

Low Pin4&53570

High Pin4&51430

All resistance values are61%.

(6) Disconnect the instrument panel wire harness

connector from the Body Control Module (BCM) con-

nector receptacle. Check for continuity between the

seat heater switch sensor ground circuit cavity of the

instrument panel wire harness connector for the

Fig. 3 SWITCH CONNECTOR

RSHEATED SEAT SYSTEM8G-9

DRIVER HEATED SEAT SWITCH (Continued)

Page 1908 of 4284

depressed, the Low position is selected and the high

position LED indicator illuminates. When the right

side of the switch rocker is fully depressed, the High

position is selected and the low position LED indica-

tor illuminates. When the switch rocker is moved to

its neutral position (middle), Off is selected and both

LED indicators are extinguished.

Both switches provide separate resistor multi-

plexed hard wire inputs to the BCM to indicate the

selected switch position. The BCM monitors the

switch inputs and sends heated seat switch status

messages to the Heated Seat Module (HSM) or the

Memory Heated Seat Module (MHSM) over the Pro-

grammable Communications Interface (PCI) data

bus. The HSM or MHSM responds to the heated seat

switch status messages by controlling the output to

the seat heater elements of the selected seat. The

Low heat position set point is about 36É C (97É F),

and the High heat position set point is about 41É C

(105É F).

DIAGNOSIS & TESTING - HEATED SEAT

SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE RESTRAINTS SECTION OF

THIS MANUAL BEFORE ATTEMPTING ANY STEER-

ING WHEEL, STEERING COLUMN, SEAT OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Check the fused ignition switch output (run)

fuse in the intelligent power module. If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

(2) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run) fuse in the intelligent power module. If

OK, go to Step 3. If not OK, repair the open fused

ignition switch output (run) circuit to the ignition

switch as required.

(3) Disconnect and isolate the battery negative

cable. Remove the center bezel from the instrument

panel and disconnect the instrument panel wire har-

ness connectors from the heated seat switch connec-

tor receptacle. Check for continuity between the

ground circuit cavity of the instrument panel wire

harness connector for the inoperative heated seat

switch(es) and a good ground. There should be conti-

nuity. If OK, go to Step 4. If not OK, repair the open

ground circuit to ground as required.

(4) Reconnect the battery negative cable. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (run) cir-

cuit cavity of the instrument panel wire harness con-

nector for the inoperative heated seat switch(es). If

OK, turn the ignition switch to the Off position, dis-

connect and isolate the battery negative cable, and go

to Step 5. If not OK, repair the open fused ignition

switch output (run) circuit to the intelligent power

module fuse as required.

(5) Test the heated seat switch(es) as shown in the

Heated Seat Switch Test chart (Fig. 6). If OK, go to

Step 6. If not OK, replace the faulty heated seat

switch(es).

PASSENGER HEATED SEAT SWITCH TEST

SWITCH

POSITIONRESISTANCE

BETWEENRESISTANCE

(OHMS)

Off Pin3&4OPEN

Low Pin3&43570

High Pin3&41430

All resistance values are61%.

(6) Disconnect the instrument panel wire harness

connector from the Body Control Module (BCM) con-

nector receptacle. Check for continuity between the

seat heater switch sensor ground circuit cavity of the

instrument panel wire harness connector for the

inoperative heated seat switch(es) and a good ground.

There should be no continuity. If OK, go to Step 7. If

not OK, repair the shorted seat heater switch sensor

ground circuit as required.

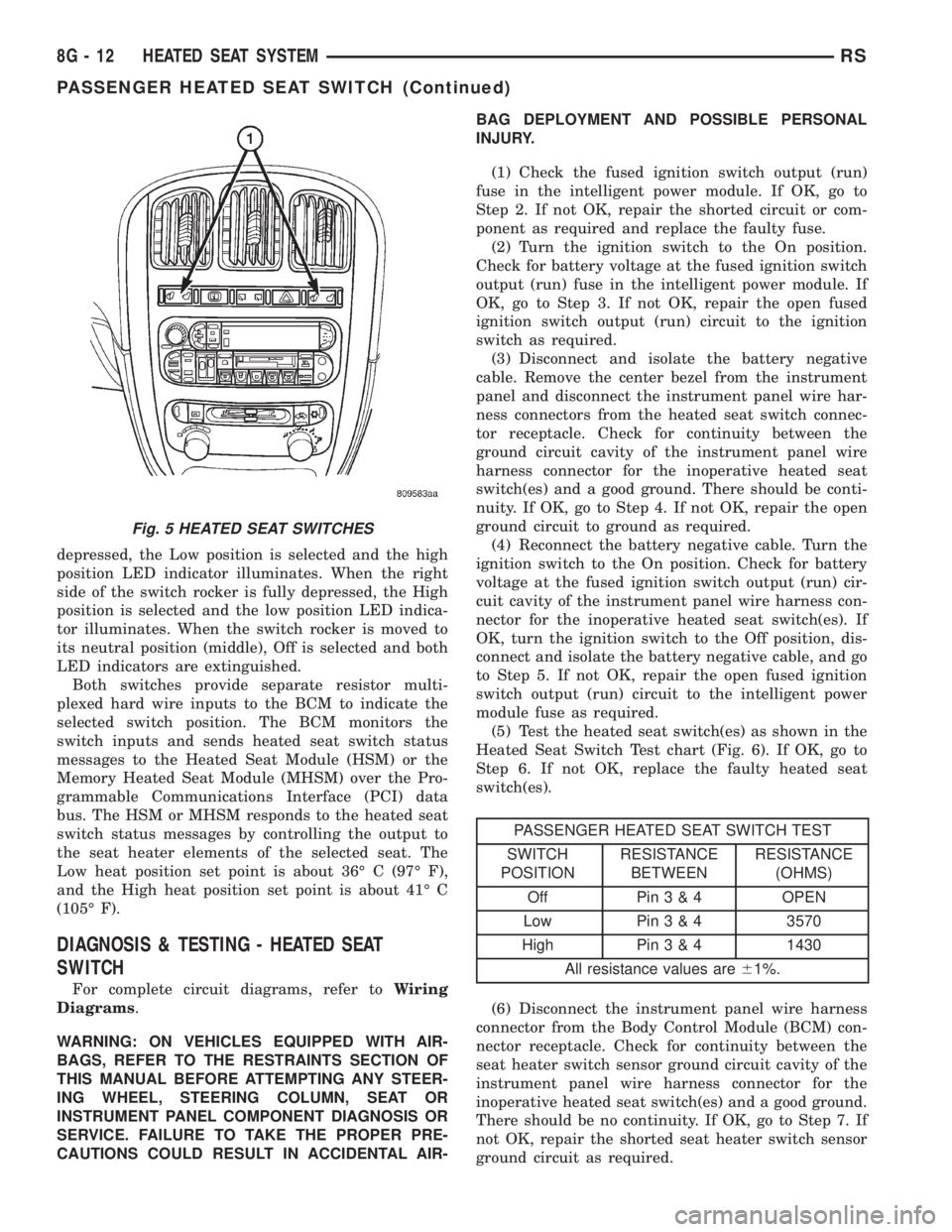

Fig. 5 HEATED SEAT SWITCHES

8G - 12 HEATED SEAT SYSTEMRS

PASSENGER HEATED SEAT SWITCH (Continued)

Page 1911 of 4284

HORN

TABLE OF CONTENTS

page page

HORN

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................1

HORN

DIAGNOSIS AND TESTING..................3

REMOVAL...............................4INSTALLATION............................5

HORN RELAY

DIAGNOSIS AND TESTING..................5

REMOVAL...............................5

INSTALLATION............................5

HORN SWITCH

DESCRIPTION............................5

HORN

DESCRIPTION

HORN SYSTEM

WARNING:

ON VEHICLES EQUIPPED WITH AIRBAG, REFER TO

ELECTRICAL, RESTRAINTS FOR SAFETY PRECAU-

TIONS. DISCONNECT THE NEGATIVE CABLE FROM

THE BATTERY BEFORE SERVICING COMPONENTS

INVOLVING THE AIRBAG SYSTEM. ACCIDENTAL

DEPLOYMENT OF AIRBAG AND PERSONAL INJURY

CAN RESULT.

The horn circuit consists of a horn switch, clock-

spring, horn relay, horns and intelligent power mod-

ule. The horn switch is a membrane switch located in

the airbag trim cover. The horns are located forward

of the left front wheel behind the bumper fascia.

OPERATION

The horn relay plugs into the intelligent power

module which is located in the engine compartment.

For circuit information and component locations,

refer to the appropriate wiring information. The wir-

ing information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

The horns will not function if the switch is

ªCLOSEDº for more than 30 seconds. Once the

switch is ªOPENº, a 20±30 second delay will occur

before the horns are functional again.

DIAGNOSIS AND TESTING

Refer to Horn System Test below. If the horn does

not sound, check horn fuse located in the intelligent

power module. If the fuse is blown, replace with the

correct fuse. If the horns fail to sound and the new

fuse blows when depressing the horn switch, a short

circuit in the horn or the horn wiring between the

fuse terminal and the horn is responsible, or a defec-

tive horn switch allowed the horn to burn out is

responsible.

If the fuse is OK, test horn relay (Refer to 8 -

ELECTRICAL/HORN/HORN RELAY - DIAGNOSIS

AND TESTING).

If the relay is OK, test horn. Refer to Horn System

Test.

CAUTION:

Continuous sounding of horn may cause horn relay

to fail.

Should the horn sound continuously:

²Unplug the horn relay from intelligent power

module.

²Refer to (Refer to 8 - ELECTRICAL/HORN/

HORN RELAY - DIAGNOSIS AND TESTING).

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

RSHORN8H-1

Page 1913 of 4284

CONDITION POSSIBLE CAUSE CORRECTION

FUSE BLOWS WHEN HORN

SOUNDS(1) SHORT CIRCUIT IN HORN OR

HORN WIRING.(1) REMOVE HORN RELAY,

CHECK FOR SHORTED HORN OR

HORN WIRING. DISCONNECT

HORN WIRE HARNESS TO

ISOLATE SHORT AND REPAIR AS

NECESSARY.

(2) FAULTY CLOCKSPRING. (2) REPLACE CLOCKSPRING.

FUSE BLOWS WITHOUT

BLOWING HORN(1) SHORT CIRCUIT. (1) REMOVE RELAY, INSTALL

NEW FUSE, IF FUSE DOES NOT

BLOW REPLACE HORN RELAY. IF

FUSE BLOWS WITH RELAY

REMOVED, CHECK FOR SHORT

TO GROUND WITH OHMMETER

ON CIRCUIT BETWEEN

TERMINALS 30 & 86 AND THE

FUSE TERMINAL. REPAIR AS

NECESSARY.

(2) FAULTY CLOCKSPRING. (2) REPLACE CLOCKSPRING.

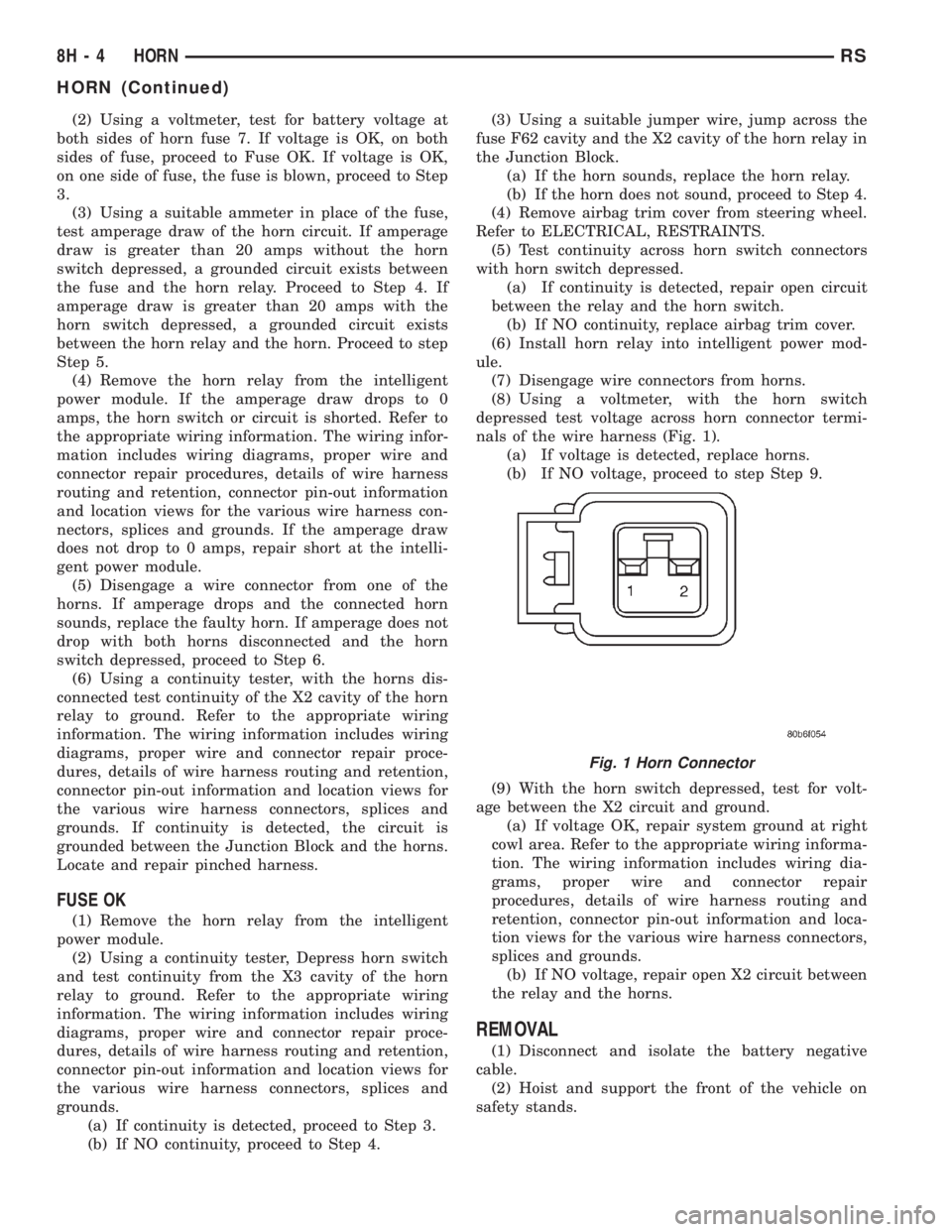

HORN

DIAGNOSIS AND TESTING

HORN

(1) Disconnect wire connector at horn.

(2) Using a voltmeter, connect one lead to ground

terminal and the other lead to the positive wire ter-

minal (Fig. 1).

(3) Depress the horn switch, battery voltage

should be present.

(4) If no voltage, refer toHORNS WILL NOT

SOUND. If voltage is OK, go to step Step 5.

(5) Using ohmmeter, test ground wire for continu-

ity to ground.

(6) If no ground repair as necessary.

(7) If wires test OK and horn does not sound,

replace horn.

HORNS SOUND CONTINUOUSLY

CAUTION:

Continuous sounding of horns may cause relay to

fail.

The horn switch (membrane) sometimes can be the

cause without the switch being depressed.

(1) Remove the horn relay from the intelligent

power module.

(2) Using a continuity tester, test continuity from

the X3 cavity of the horn relay to ground. Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harnessrouting and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

(a) If continuity is detected, proceed to step Step

3.

(b) If NO continuity, replace the horn relay.

(3) Remove the airbag trim cover from the steering

wheel and disengage horn connector.

(4) Install horn relay into intelligent power mod-

ule.

(a) If horn does not sound, replace airbag trim

cover.

(b) If horn sounds, repair grounded X3 circuit

from intelligent power module to clockspring in the

steering column. Refer to the appropriate wiring

information. The wiring information includes wir-

ing diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and loca-

tion views for the various wire harness connectors,

splices and grounds.HORNS WILL NOT SOUND

Check horn fuse#8intheintelligent power mod-

ule. If fuse is blown, check for a shorted switch in the

airbag module. and refer to FUSE BLOWN section. If

fuse is OK, refer to FUSE OK section.

FUSE BLOWN

(1) Verify condition of battery terminals and volt-

age, (Refer to 8 - ELECTRICAL/BATTERY SYSTEM

- DIAGNOSIS AND TESTING). If battery connec-

tions and battery charge is OK proceed to Step 2.

RSHORN8H-3

HORN (Continued)

Page 1914 of 4284

(2) Using a voltmeter, test for battery voltage at

both sides of horn fuse 7. If voltage is OK, on both

sides of fuse, proceed to Fuse OK. If voltage is OK,

on one side of fuse, the fuse is blown, proceed to Step

3.

(3) Using a suitable ammeter in place of the fuse,

test amperage draw of the horn circuit. If amperage

draw is greater than 20 amps without the horn

switch depressed, a grounded circuit exists between

the fuse and the horn relay. Proceed to Step 4. If

amperage draw is greater than 20 amps with the

horn switch depressed, a grounded circuit exists

between the horn relay and the horn. Proceed to step

Step 5.

(4) Remove the horn relay from the intelligent

power module. If the amperage draw drops to 0

amps, the horn switch or circuit is shorted. Refer to

the appropriate wiring information. The wiring infor-

mation includes wiring diagrams, proper wire and

connector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds. If the amperage draw

does not drop to 0 amps, repair short at the intelli-

gent power module.

(5) Disengage a wire connector from one of the

horns. If amperage drops and the connected horn

sounds, replace the faulty horn. If amperage does not

drop with both horns disconnected and the horn

switch depressed, proceed to Step 6.

(6) Using a continuity tester, with the horns dis-

connected test continuity of the X2 cavity of the horn

relay to ground. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds. If continuity is detected, the circuit is

grounded between the Junction Block and the horns.

Locate and repair pinched harness.

FUSE OK

(1) Remove the horn relay from the intelligent

power module.

(2) Using a continuity tester, Depress horn switch

and test continuity from the X3 cavity of the horn

relay to ground. Refer to the appropriate wiring

information. The wiring information includes wiring

diagrams, proper wire and connector repair proce-

dures, details of wire harness routing and retention,

connector pin-out information and location views for

the various wire harness connectors, splices and

grounds.

(a) If continuity is detected, proceed to Step 3.

(b) If NO continuity, proceed to Step 4.(3) Using a suitable jumper wire, jump across the

fuse F62 cavity and the X2 cavity of the horn relay in

the Junction Block.

(a) If the horn sounds, replace the horn relay.

(b) If the horn does not sound, proceed to Step 4.

(4) Remove airbag trim cover from steering wheel.

Refer to ELECTRICAL, RESTRAINTS.

(5) Test continuity across horn switch connectors

with horn switch depressed.

(a) If continuity is detected, repair open circuit

between the relay and the horn switch.

(b) If NO continuity, replace airbag trim cover.

(6) Install horn relay into intelligent power mod-

ule.

(7) Disengage wire connectors from horns.

(8) Using a voltmeter, with the horn switch

depressed test voltage across horn connector termi-

nals of the wire harness (Fig. 1).

(a) If voltage is detected, replace horns.

(b) If NO voltage, proceed to step Step 9.

(9) With the horn switch depressed, test for volt-

age between the X2 circuit and ground.

(a) If voltage OK, repair system ground at right

cowl area. Refer to the appropriate wiring informa-

tion. The wiring information includes wiring dia-

grams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and loca-

tion views for the various wire harness connectors,

splices and grounds.

(b) If NO voltage, repair open X2 circuit between

the relay and the horns.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Hoist and support the front of the vehicle on

safety stands.

Fig. 1 Horn Connector

8H - 4 HORNRS

HORN (Continued)

Page 1915 of 4284

(3) From behind the front fascia and forward of

the left front wheel, disconnect the wire connectors

from horn.

(4) Remove the mounting bracket attaching nut

from the bottom of radiator closure panel. Do not

remove the horn from mounting bracket.

(5) Separate the horn(s) from vehicle.

INSTALLATION

(1) Install the horns to the vehicle.

(2) Install the mounting bracket nut.

(3) Reconnect the wire connectors to the horns.

(4) Lower the vehicle.

(5) Reconnect the battery negative cable.

HORN RELAY

DIAGNOSIS AND TESTING

(1) Remove horn relay.

(2) Using ohmmeter, test between relay connector

terminals 85 to 86 for 70 to 75 ohms resistance. If

resistance not OK, replace relay.

(3) Test for continuity between ground and termi-

nal 85 of horn relay.

(a) When the horn switch is not depressed, no

continuity should be present.

(b) Continuity to ground when horn switch is

depressed.

(c) If continuity is not correct repair horn

switch or wiring as necessary, refer to the appro-

priate wiring information. The wiring information

includes wiring diagrams, proper wire and connec-

tor repair procedures, details of wire harness rout-

ing and retention, connector pin-out information

and location views for the various wire harness

connectors, splices and grounds.

(4) Using voltmeter, test voltage at:

(a) Terminals 30 and 86 of the horn relay to

body ground.(b) If NO voltage check fuse 8 of the intelligent

power module.

(c) If incorrect voltage, repair as necessary. Refer

to the appropriate wiring information. The wiring

information includes wiring diagrams, proper wire

and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

(5) Insert a jumper wire between terminal 30 and

87 of the intelligent power module.

(a) If horn sounds replace relay.

(b) If the horn does not sound, install horn relay

and refer to Horn Test.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove cover from the intelligent power mod-

ule.

(3) Remove relay from intelligent power module.

INSTALLATION

(1) Push relay into intelligent power module.

(2) Install cover.

(3) Reconnect battery negative cable.

HORN SWITCH

DESCRIPTION

The horn switch is molded into the airbag trim

cover. The horn switch can not be serviced separately.

For service procedures, refer to ELECTRICAL /

RESTRAINTS.

RSHORN8H-5

HORN (Continued)

Page 1942 of 4284

LAMPS/LIGHTING - EXTERIOR

DESCRIPTION

LAMP SYSTEMS

RS vehicles use lighting on the interior and exte-

rior of the vehicle for illuminating and indicating

purposes. Lighting circuits are protected by fuses.

Lighting circuits require an overload protected power

source, on/off device, lamps and body ground to oper-

ate properly. Plastic lamps require a wire in the har-

ness to supply body ground to the lamp socket.

Replace sockets and bulbs that are corroded.

Some of the interior and exterior lighting functions

are governed by the Body Control Module. The head-

lamp, dome, and the door ajar switches provide sig-

nals to the Body Control Module. The Body Control

Module in turn sends a J1850 message to the Front

Control Module (FCM) to enable the necessary driv-

ers to set the required illumination configuration.

Wire connectors can make intermittent contact or

become corroded. Before coupling wire connectors,

inspect the terminals inside the connector. Male termi-

nals should not be bent or disengaged from the insu-

lator. Female terminals should not be sprung open or

disengaged from the insulator. Bent and sprung termi-

nals can be repaired using needle nose pliers and pick

tool. Corroded terminals appear chalky or green. Cor-

roded terminals should be replaced to avoid recur-

rence of the problem symptoms.

Begin electrical system failure diagnosis by testing

related fuses in the fuse block and intelligent power

module. Verify that bulbs are in good condition and

test continuity of the circuit ground. Refer to the

appropriate wiring information. The wiring informa-

tion includes wiring diagrams, proper wire and con-

nector repair procedures, details of wire harness

routing and retention, connector pin-out information

and location views for the various wire harness con-

nectors, splices and grounds.

AUTOMATIC HEADLAMP SYSTEM

The Automatic Headlamp system turns the instru-

mentation and exterior illumination lamps ON when

the ambient light levels are Night and OFF when

light levels are Day.

DAYTIME RUNNING LAMPS

Operating the high-beam headlamps at reduced

power provides daytime running lamps, which are

required on all new Canadian vehicles.

HEADLAMPS ON WITH WINDSHIELD WIPERS

For vehicles equipped with the Automatic Head-

lamp System, the instrumentation and exterior illu-

mination lamps will be turned ON when theheadlamp switch is in the AUTO position, RPM >

450 and the windshield wipers have been in the

intermittent, low or high mode of operation for more

than ten seconds. When the windshield wipers are

turned OFF the Body Control Module will determine

if the instrumentation and exterior illumination

lamps should remain ON base upon the current

ambient light level.

HEADLAMP SYSTEM

The configuration of the headlamp system of head-

lamps, park lamps and fog lamps is determined by

the BCM. The BCM determines the lighting configu-

ration as a result of the inputs from the ignition

switch, headlamp switch and multifunction switch. A

J1850 is transmitted from the BCM to the FCM to

enable the necessary drivers to set the illumination

configuration. Four wires are connected between the

headlamp switch and the BCM. The first wire con-

tains information regarding the position of the head-

lamp switch (Off, Automatic Headlamps, Automatic

Headlamp switch fog, Park with Fog, Head, or Head

with Fog Lamps). The second wire contains informa-

tion regarding the position of the dimmer switch

(Dome Lamp, Daytime Brightness, Dimming Level or

Off). The third wire is a dedicated signal return

(ground) wire. The fourth wire provides power to the

front fog lamp indicator.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is controlled by

the Body Control Module (BCM) via a J1850 message

transmitted by the BCM to the FCM to turn off the

headlamps.

OPERATION

AUTOMATIC HEADLAMP SYSTEM

Automatic headlamps are controlled by the Body

Control Module (BCM). With the headlamp switch in

the AUTO position, the BCM will control the head-

lamp, parking, side marker, tail and instrumentation

lamps based on ambient light levels. Ambient light

levels are monitored by the BCM using the Day/

Night signal and Electrochromatic Mirror (ECM)

present from the Compass Mini Trip (CMTC) located

on the front windshield in front of the rear view mir-

ror (ECM). Ambient light readings are averaged to

limit cycling the lamps ON and OFF when passing

through areas with varying light levels. The auto-

matic headlamps will only function when the engine

is running with RPM > 450. When the headlamp

switch is in the AUTO position (Automatic mode), the

Headlamp Time Delay system will function when the

ignition switch is placed in any position other than

run/start.

8L - 2 LAMPS/LIGHTING - EXTERIORRS

Page 1943 of 4284

DAYTIME RUNNING LAMPS

Power is reduced using pulse-width modulation to

the high beams, where by the power is switched on

and off rapidly instead of remaining on continuously.

The duration and interval of the power pulses is pro-

grammed into the Front Control Module (FCM).

HEADLAMP SYSTEM

The headlamp system will default to headlamps

ON position when ignition switch is ON and when an

open or short circuit failure occurs on the headlamp

switch input. The system will return to normal oper-

ation when the open or short is repaired. A fault will

be reported by the BCM when a failure occurs on the

dimmer or headlamp switch input.

If the exterior lamps are ON and the headlamp

switch is in any position other than OFF or AUTO

and with the ignition switch OFF (LOCK) after 3

minutes the BCM sends a message via J1850 to the

FCM informing the FCM to turn off the headlamps,

park lamps and fog lamps. This feature prevents the

vehicle battery from being discharged when the vehi-

cle lights have been left ON.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is activated by

turning the headlamps ON (high or low beam) while

the engine is running, turning the ignition switch

OFF, and then turning the headlamp switch OFF

within 45 seconds. The system will not activate if

more than 45 seconds elapse between ignition switch

OFF and headlamp switch OFF. The BCM will allow

the headlamps to remain ON for 90 seconds (config-

urable) before they automatically turn off (If the key

is in the ignition during the headlamp time delay

mode, then both the headlamps and park lamps

(including panel dimming) will be ON). Refer to the

Owner's Manual for more information.

If the headlamp switch is in the Auto Headlamp

Position, the headlamps are ON due to the night sig-

nal from the CMTC and the ignition switch is in any

position other than run/start, the BCM shall enter a

90 second (configurable) Auto Headlamps time delay

mode. If the key is in the ignition during the head-

lamp time delay mode, then both the headlamps and

park lamps (including panel dimming) will be ON. If

the key is not in the ignition, then only the head-

lamps will be ON. The BCM will allow the head-

lamps to remain ON for 90 seconds before they

automatically turn OFF. Refer to the Owner's Man-

ual for more information.

LAMP OUTAGE

If one or more of the following lamps (Low and/or

High beams) are out, then a ªlamps outº indicator

located in the cluster will illuminate.

OPTICAL HORN/HIGH BEAMS

When the multifunction switch is pulled to the first

detent (optical horn) signal, the headlamps are ON,

key-in the ignition the BCM shall send a message via

J1850 to the FCM to turn on the headlamps drivers

to illuminate all four filaments (Low and High

beams). When the multifunction switch is pulled to

the second detent (high beam) signal and the head-

lamps are ON, the BCM shall send a message via

J1850 to the FCM to turn on the headlamps drivers.

The High Beams are illuminated and the Low Beams

and Fog Lamps (if ON) are extinguished. If the head-

lamps were in the high beam configuration when

power was removed from the headlamps, the head-

lamps will be configured as low beam the next time

they are activated.

DIAGNOSIS AND TESTING

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

When a vehicle experiences problems with the

headlamp system, verify the condition of the battery

connections, fuses, charging system, headlamp bulbs,

wire connectors, relay, high beam switch, dimmer

switch, and headlamp switch. Refer to the appropri-

ate wiring information. The wiring information

includes wiring diagrams, proper wire and connector

repair procedures, details of wire harness routing

and retention, connector pin-out information and

location views for the various wire harness connec-

tors, splices and grounds.

Each vehicle is equipped with various lamp assem-

blies. A good ground is necessary for proper lighting

operation. Grounding is provided by the lamp socket

when it comes in contact with the metal body, or

through a separate ground wire.

When changing lamp bulbs check the socket for

corrosion. If corrosion is present, clean it with a wire

brush.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

RSLAMPS/LIGHTING - EXTERIOR8L-3

LAMPS/LIGHTING - EXTERIOR (Continued)

Page 1946 of 4284

CONDITION POSSIBLE CAUSES CORRECTION

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices. Refer to Electrical, Wiring

Information.

5. Is relay engaging properly? 5. Verify function of fog lamp relay in IPM.

6. J1850 Bus Communication. 6. Verify J1850 message (fog lamp info)

transmitted from BCM and received by

FCM.

FOG LAMPS DO NOT

ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Electrical, Wiring

Information.

2. No Z349/Z248 ground at fog

lamps.2. Repair circuit ground. Refer to Electrical,

Wiring Information.

3. Faulty fog lamp switch (part of

headlamp switch).3. Replace headlamp switch.

4. Broken connector terminal or wire

splice in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Faulty or burned out bulb. 5. Replace bulb.

6. Is relay engaging? 6. Verify function of fog lamp relay in IPM.

7. J1850 Bus Communication. 7. Verify J1850 message (fog lamp info)

transmitted from BCM and received by

FCM.

DAYTIME RUNNING LAMP (CANADA ONLY)

CONDITION POSSIBLE CAUSES CORRECTION

DAYTIME RUNNING

LAMPS DO NOT

WORK

1. Parking brake engaged. 1. Disengage parking brake.

2. Parking brake circuit shorted to

ground.2. Check cluster telltale, refer to the appropriate

wiring information. The wiring information

includes wiring diagrams, proper wire and

connector repair procedures, further details on

wire harness routing and retention, as well as

pin-out and location views for the various wire

harness connectors, splices and grounds.

3. Headlamp circuit shorted to ground. 3. Refer to the appropriate wiring information.

The wiring information includes wiring

diagrams, proper wire and connector repair

procedures, further details on wire harness

routing and retention, as well as pin-out and

location views for the various wire harness

connectors, splices and grounds.

4. Faulty DRL relay. 4. Replace DRL relay.

5. Body controller not programed with

Canadian country code.5. Check country code.

8L - 6 LAMPS/LIGHTING - EXTERIORRS

LAMPS/LIGHTING - EXTERIOR (Continued)