seats CHRYSLER VOYAGER 2001 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2039 of 4284

fails to operate in more than one direction, perform

the following tests. For complete circuit diagrams,

refer toPower Seatin Wiring Diagrams.

(1) Check the power seat circuit breaker under the

seat. If OK, go to Step 2. If not OK, replace the

faulty power seat circuit breaker.

(2) Check for battery voltage at the power seat cir-

cuit breaker under the seat. If OK, go to Step 3. If

not OK, repair the open fused B(+) circuit to the fuse

in the Intelligent Power Module as required.

(3) Remove the outboard seat cushion side shield

from the seat. Disconnect the seat wire harness con-

nector from the power seat switch connector recepta-

cle. Check for battery voltage at the fused B(+)

circuit cavity of the power seat wire harness connec-

tor for the power seat switch. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the

power seat circuit breaker under the seat as

required.

(4) Check for continuity between the ground cir-

cuit cavity of the power seat wire harness connector

for the power seat switch and a good ground. There

should be continuity. If OK, go to Step 5. If not OK,

repair the open ground circuit to ground as required.

(5) Test the power seat switch. Refer toPower

Seat Switchin the Diagnosis and Testing section of

this group. If the switch tests OK, test the circuits of

the power seat wire harness between the inoperative

power seat track adjuster motor and the power seat

switch for shorts or opens. If the circuits check OK,

replace the faulty power seat track unit. If the cir-

cuits are not OK, repair the power seat wire harness

as required.

REMOVAL

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS. BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.(1) Remove the appropriate seat from the vehicle.

Refer to Body for the procedure.

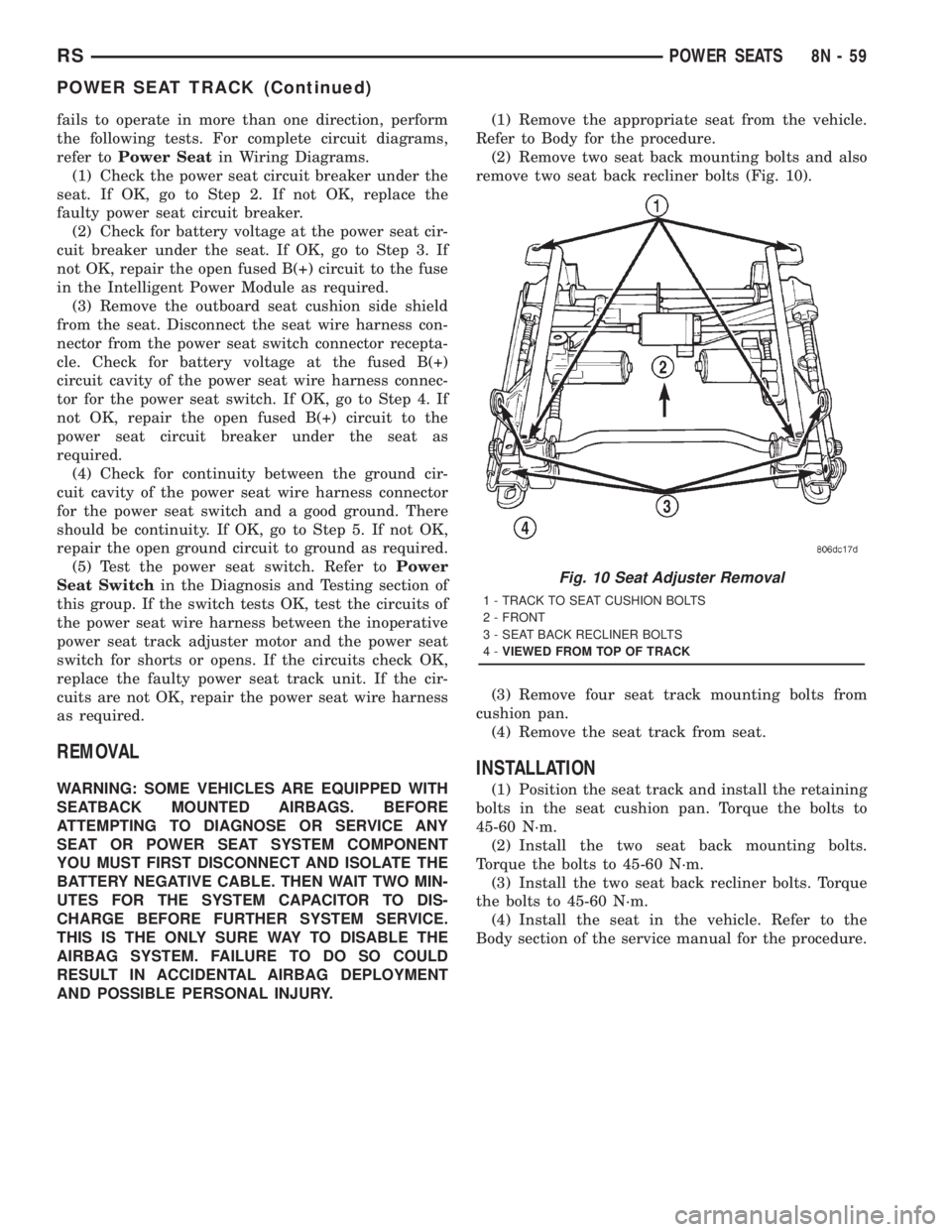

(2) Remove two seat back mounting bolts and also

remove two seat back recliner bolts (Fig. 10).

(3) Remove four seat track mounting bolts from

cushion pan.

(4) Remove the seat track from seat.

INSTALLATION

(1) Position the seat track and install the retaining

bolts in the seat cushion pan. Torque the bolts to

45-60 N´m.

(2) Install the two seat back mounting bolts.

Torque the bolts to 45-60 N´m.

(3) Install the two seat back recliner bolts. Torque

the bolts to 45-60 N´m.

(4) Install the seat in the vehicle. Refer to the

Body section of the service manual for the procedure.

Fig. 10 Seat Adjuster Removal

1 - TRACK TO SEAT CUSHION BOLTS

2 - FRONT

3 - SEAT BACK RECLINER BOLTS

4-VIEWED FROM TOP OF TRACK

RSPOWER SEATS8N-59

POWER SEAT TRACK (Continued)

Page 2054 of 4284

(2) Remove cover from seat belt turning loop.

(3) Remove bolt attaching turning loop to shoulder

belt height adjuster (Fig. 2).

(4) Remove turning loop from B-pillar.

(5) Remove lower B-pillar trim cover or quarter

trim panel.

(6) Remove bolt attaching seat belt retractor to

B-pillar (Fig. 2).

(7) Lift retractor upward and disengage arrow

head retainer attaching retractor to B-pillar.

(8) Remove seat belt from vehicle.

INSTALLATION

Inspect the condition of the shoulder belt and lap

belt. Replace any belt that is cut, frayed, torn, or

damaged in any way. Also, replace the shoulder belt

if the retractor is either damaged or inoperative.

(1) Place seat belt into position.

(2) Lower retractor into position B-pillar.

(3) Install bolt attaching seat belt retractor to

B-pillar. Tighten all seat belt anchor bolts to 39 N´m

(29 ft. lbs.) torque.

(4) Install turning loop onto B-pillar.

(5) Install lower B-pillar trim cover or quarter

trim panel.

(6) Install bolt attaching turning loop to shoulder

belt height adjuster. Tighten all seat belt anchor

bolts to 39 N´m (29 ft. lbs.) torque.

(7) Press cover onto the seat belt turning loop.(8) Install shoulder harness height adjuster knob

by pushing onto the adjuster.

SEAT BELT FIRST ROW

ANCHOR BRACKET - LWB

REMOVAL

(1) Remove lower quarter trim panel.

(2) Remove bolt attaching first row seat belt

anchor bracket to floor.

(3) Remove bracket from vehicle.

INSTALLATION

(1) Position bracket to vehicle.

(2) Install bolt attaching first row seat belt anchor

bracket to floor.

(3) Install lower quarter trim panel.

NOTE: The tightening specification for all seat belt

anchor bolts is 39 N´m (29 ft. lbs.) torque.

SEAT BELT LEFT FIRST ROW

OUTBOARD - SWB THREE

DOOR

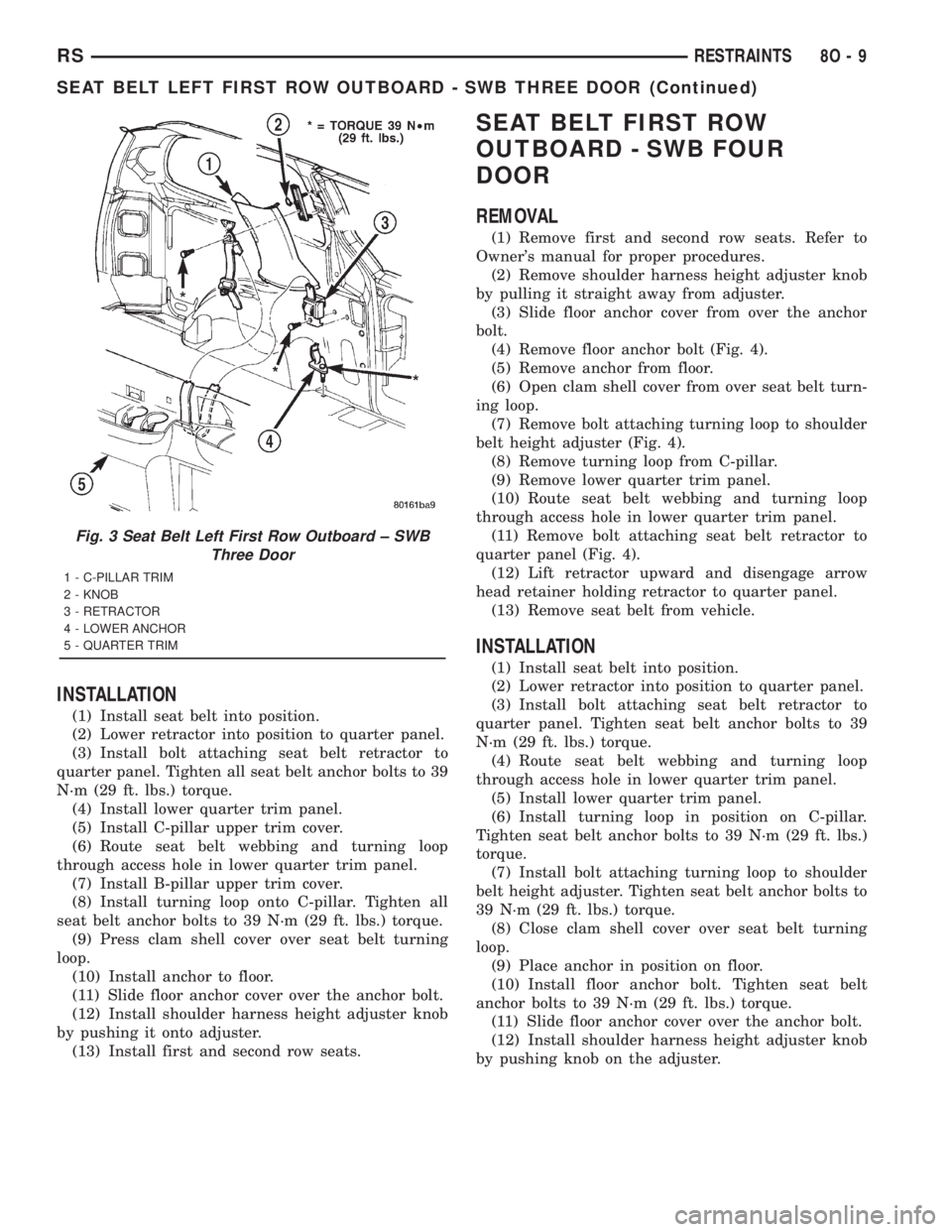

REMOVAL

(1) Remove first and second row seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt (Fig. 3).

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt attaching turning loop to shoulder

belt height adjuster.

(8) Remove turning loop from C-pillar.

(9) Remove B-pillar upper trim cover.

(10) Remove C-pillar upper trim cover.

(11) Remove lower quarter trim panel.

(12) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(13) Remove bolt attaching seat belt retractor to

quarter panel.

(14) Lift retractor upward and disengage arrow

head retainer attaching retractor to quarter panel

(Fig. 3).

(15) Remove seat belt from vehicle.

Fig. 2 SEAT BELT - OUTBOARD FRONT

1 - B-PILLAR TRIM LOWER

2 - BELT

3 - B-PILLAR TRIM UPPER

4 - HEIGHT ADJUSTER

5 - KNOB

6 - B-PILLAR TRIM LOWER

7 - FLOOR ANCHOR

8 - FLOOR ANCHOR

9 - 30É OUTBOARD

10 - RETRACTOR

8O - 8 RESTRAINTSRS

SEAT BELT OUTBOARD FRONT (Continued)

Page 2055 of 4284

INSTALLATION

(1) Install seat belt into position.

(2) Lower retractor into position to quarter panel.

(3) Install bolt attaching seat belt retractor to

quarter panel. Tighten all seat belt anchor bolts to 39

N´m (29 ft. lbs.) torque.

(4) Install lower quarter trim panel.

(5) Install C-pillar upper trim cover.

(6) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(7) Install B-pillar upper trim cover.

(8) Install turning loop onto C-pillar. Tighten all

seat belt anchor bolts to 39 N´m (29 ft. lbs.) torque.

(9) Press clam shell cover over seat belt turning

loop.

(10) Install anchor to floor.

(11) Slide floor anchor cover over the anchor bolt.

(12) Install shoulder harness height adjuster knob

by pushing it onto adjuster.

(13) Install first and second row seats.

SEAT BELT FIRST ROW

OUTBOARD - SWB FOUR

DOOR

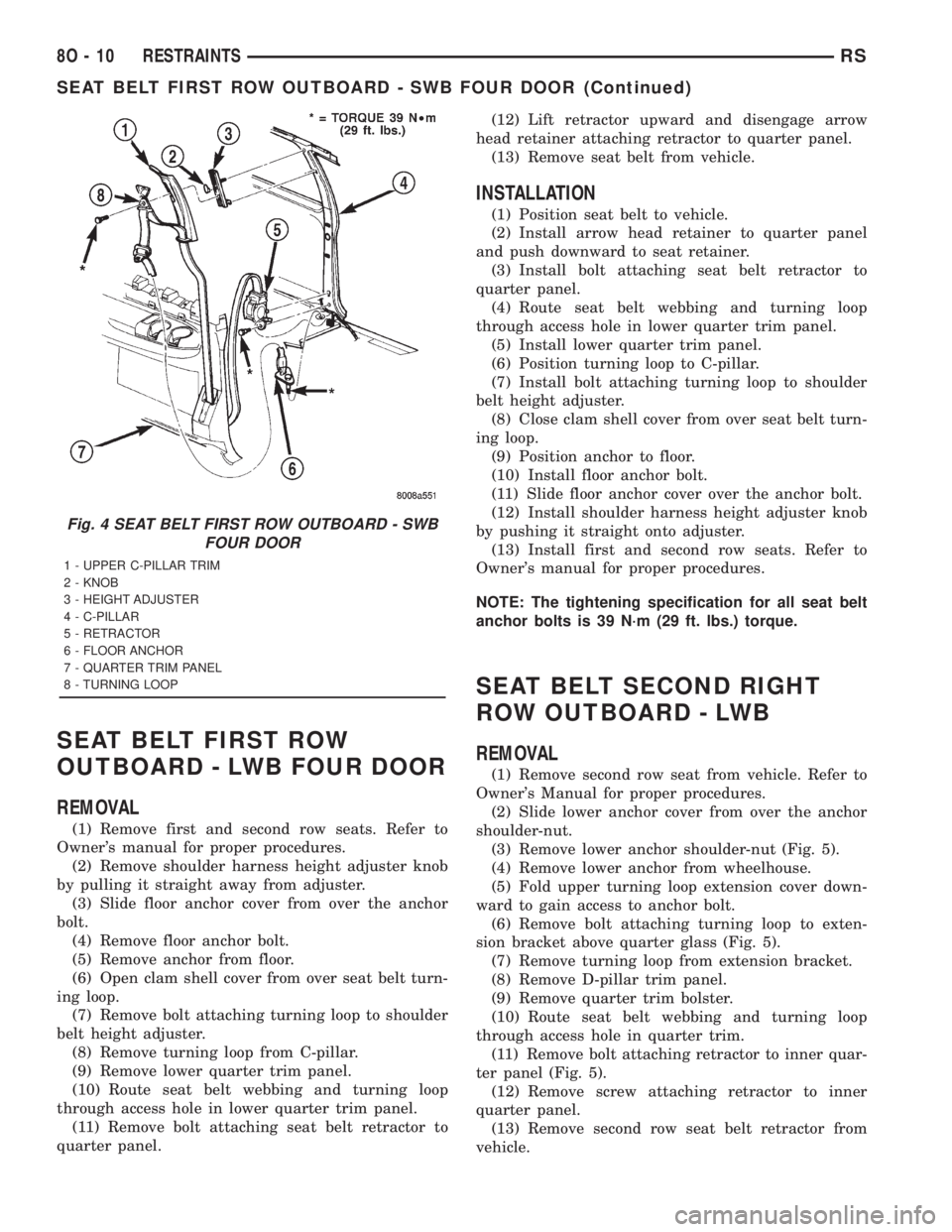

REMOVAL

(1) Remove first and second row seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt (Fig. 4).

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt attaching turning loop to shoulder

belt height adjuster (Fig. 4).

(8) Remove turning loop from C-pillar.

(9) Remove lower quarter trim panel.

(10) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(11) Remove bolt attaching seat belt retractor to

quarter panel (Fig. 4).

(12) Lift retractor upward and disengage arrow

head retainer holding retractor to quarter panel.

(13) Remove seat belt from vehicle.

INSTALLATION

(1) Install seat belt into position.

(2) Lower retractor into position to quarter panel.

(3) Install bolt attaching seat belt retractor to

quarter panel. Tighten seat belt anchor bolts to 39

N´m (29 ft. lbs.) torque.

(4) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(5) Install lower quarter trim panel.

(6) Install turning loop in position on C-pillar.

Tighten seat belt anchor bolts to 39 N´m (29 ft. lbs.)

torque.

(7) Install bolt attaching turning loop to shoulder

belt height adjuster. Tighten seat belt anchor bolts to

39 N´m (29 ft. lbs.) torque.

(8) Close clam shell cover over seat belt turning

loop.

(9) Place anchor in position on floor.

(10) Install floor anchor bolt. Tighten seat belt

anchor bolts to 39 N´m (29 ft. lbs.) torque.

(11) Slide floor anchor cover over the anchor bolt.

(12) Install shoulder harness height adjuster knob

by pushing knob on the adjuster.

Fig. 3 Seat Belt Left First Row Outboard ± SWB

Three Door

1 - C-PILLAR TRIM

2 - KNOB

3 - RETRACTOR

4 - LOWER ANCHOR

5 - QUARTER TRIM

RSRESTRAINTS8O-9

SEAT BELT LEFT FIRST ROW OUTBOARD - SWB THREE DOOR (Continued)

Page 2056 of 4284

SEAT BELT FIRST ROW

OUTBOARD - LWB FOUR DOOR

REMOVAL

(1) Remove first and second row seats. Refer to

Owner's manual for proper procedures.

(2) Remove shoulder harness height adjuster knob

by pulling it straight away from adjuster.

(3) Slide floor anchor cover from over the anchor

bolt.

(4) Remove floor anchor bolt.

(5) Remove anchor from floor.

(6) Open clam shell cover from over seat belt turn-

ing loop.

(7) Remove bolt attaching turning loop to shoulder

belt height adjuster.

(8) Remove turning loop from C-pillar.

(9) Remove lower quarter trim panel.

(10) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(11) Remove bolt attaching seat belt retractor to

quarter panel.(12) Lift retractor upward and disengage arrow

head retainer attaching retractor to quarter panel.

(13) Remove seat belt from vehicle.

INSTALLATION

(1) Position seat belt to vehicle.

(2) Install arrow head retainer to quarter panel

and push downward to seat retainer.

(3) Install bolt attaching seat belt retractor to

quarter panel.

(4) Route seat belt webbing and turning loop

through access hole in lower quarter trim panel.

(5) Install lower quarter trim panel.

(6) Position turning loop to C-pillar.

(7) Install bolt attaching turning loop to shoulder

belt height adjuster.

(8) Close clam shell cover from over seat belt turn-

ing loop.

(9) Position anchor to floor.

(10) Install floor anchor bolt.

(11) Slide floor anchor cover over the anchor bolt.

(12) Install shoulder harness height adjuster knob

by pushing it straight onto adjuster.

(13) Install first and second row seats. Refer to

Owner's manual for proper procedures.

NOTE: The tightening specification for all seat belt

anchor bolts is 39 N´m (29 ft. lbs.) torque.

SEAT BELT SECOND RIGHT

ROW OUTBOARD - LWB

REMOVAL

(1) Remove second row seat from vehicle. Refer to

Owner's Manual for proper procedures.

(2) Slide lower anchor cover from over the anchor

shoulder-nut.

(3) Remove lower anchor shoulder-nut (Fig. 5).

(4) Remove lower anchor from wheelhouse.

(5) Fold upper turning loop extension cover down-

ward to gain access to anchor bolt.

(6) Remove bolt attaching turning loop to exten-

sion bracket above quarter glass (Fig. 5).

(7) Remove turning loop from extension bracket.

(8) Remove D-pillar trim panel.

(9) Remove quarter trim bolster.

(10) Route seat belt webbing and turning loop

through access hole in quarter trim.

(11) Remove bolt attaching retractor to inner quar-

ter panel (Fig. 5).

(12) Remove screw attaching retractor to inner

quarter panel.

(13) Remove second row seat belt retractor from

vehicle.

Fig. 4 SEAT BELT FIRST ROW OUTBOARD - SWB

FOUR DOOR

1 - UPPER C-PILLAR TRIM

2 - KNOB

3 - HEIGHT ADJUSTER

4 - C-PILLAR

5 - RETRACTOR

6 - FLOOR ANCHOR

7 - QUARTER TRIM PANEL

8 - TURNING LOOP

8O - 10 RESTRAINTSRS

SEAT BELT FIRST ROW OUTBOARD - SWB FOUR DOOR (Continued)

Page 2085 of 4284

WIRING

TABLE OF CONTENTS

page page

WIRING DIAGRAM INFORMATION...... 8Wa-01-1

COMPONENT INDEX................. 8Wa-02-1

POWER DISTRIBUTION.............. 8Wa-10-1

GROUND DISTRIBUTION............. 8Wa-15-1

BUS COMMUNICATIONS............. 8Wa-18-1

CHARGING SYSTEM................. 8Wa-20-1

STARTING SYSTEM................. 8Wa-21-1

FUEL/IGNITION SYSTEM............. 8Wa-30-1

TRANSMISSION CONTROL SYSTEM.... 8Wa-31-1

VEHICLE SPEED CONTROL........... 8Wa-33-1

ANTILOCK BRAKES.................. 8Wa-35-1

VEHICLE THEFT SECURITY SYSTEM.... 8Wa-39-1

INSTRUMENT CLUSTER.............. 8Wa-40-1

HORN/CIGAR LIGHTER/POWER OUTLET . 8Wa-41-1

AIR CONDITIONING-HEATER.......... 8Wa-42-1

AIRBAG SYSTEM................... 8Wa-43-1

INTERIOR LIGHTING................. 8Wa-44-1

BODY CONTROL MODULE............ 8Wa-45-1MESSAGE CENTER.................. 8Wa-46-1

AUDIO SYSTEM.................... 8Wa-47-1

REAR WINDOW DEFOGGER........... 8Wa-48-1

OVERHEAD CONSOLE................ 8Wa-49-1

FRONT LIGHTING................... 8Wa-50-1

REAR LIGHTING.................... 8Wa-51-1

TURN SIGNALS..................... 8Wa-52-1

WIPERS........................... 8Wa-53-1

TRAILER TOW...................... 8Wa-54-1

POWER WINDOWS.................. 8Wa-60-1

POWER DOOR LOCKS............... 8Wa-61-1

POWER MIRRORS.................. 8Wa-62-1

POWER SEATS..................... 8Wa-63-1

SPLICE INFORMATION............... 8Wa-70-1

CONNECTOR PIN-OUTS.............. 8Wa-80-1

CONNECTOR/GROUND LOCATIONS BUX . 8Wa-90-1

SPLICE LOCATIONS BUX............. 8Wa-95-1 RGWIRING

8Wa-1

Page 2427 of 4284

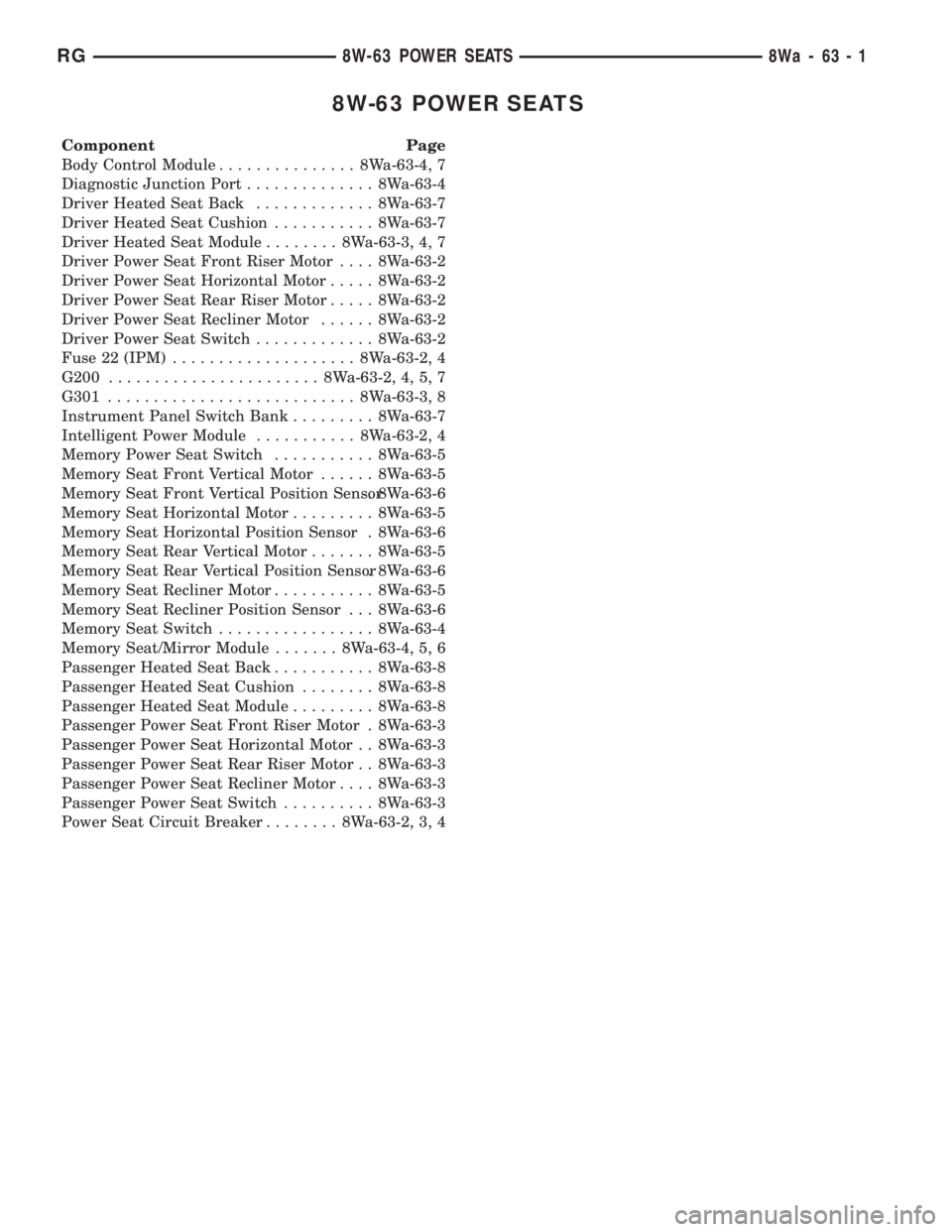

8W-63 POWER SEATS

Component Page

Body Control Module............... 8Wa-63-4, 7

Diagnostic Junction Port.............. 8Wa-63-4

Driver Heated Seat Back............. 8Wa-63-7

Driver Heated Seat Cushion........... 8Wa-63-7

Driver Heated Seat Module........ 8Wa-63-3, 4, 7

Driver Power Seat Front Riser Motor.... 8Wa-63-2

Driver Power Seat Horizontal Motor..... 8Wa-63-2

Driver Power Seat Rear Riser Motor..... 8Wa-63-2

Driver Power Seat Recliner Motor...... 8Wa-63-2

Driver Power Seat Switch............. 8Wa-63-2

Fuse 22 (IPM).................... 8Wa-63-2, 4

G200....................... 8Wa-63-2, 4, 5, 7

G301........................... 8Wa-63-3, 8

Instrument Panel Switch Bank......... 8Wa-63-7

Intelligent Power Module........... 8Wa-63-2, 4

Memory Power Seat Switch........... 8Wa-63-5

Memory Seat Front Vertical Motor...... 8Wa-63-5

Memory Seat Front Vertical Position Sensor. 8Wa-63-6

Memory Seat Horizontal Motor......... 8Wa-63-5

Memory Seat Horizontal Position Sensor . 8Wa-63-6

Memory Seat Rear Vertical Motor....... 8Wa-63-5

Memory Seat Rear Vertical Position Sensor. 8Wa-63-6

Memory Seat Recliner Motor........... 8Wa-63-5

Memory Seat Recliner Position Sensor . . . 8Wa-63-6

Memory Seat Switch................. 8Wa-63-4

Memory Seat/Mirror Module....... 8Wa-63-4, 5, 6

Passenger Heated Seat Back........... 8Wa-63-8

Passenger Heated Seat Cushion........ 8Wa-63-8

Passenger Heated Seat Module......... 8Wa-63-8

Passenger Power Seat Front Riser Motor . 8Wa-63-3

Passenger Power Seat Horizontal Motor . . 8Wa-63-3

Passenger Power Seat Rear Riser Motor . . 8Wa-63-3

Passenger Power Seat Recliner Motor.... 8Wa-63-3

Passenger Power Seat Switch.......... 8Wa-63-3

Power Seat Circuit Breaker........ 8Wa-63-2, 3, 4

RG8W-63 POWER SEATS8Wa-63-1

Page 2625 of 4284

ENGINE 2.4L

TABLE OF CONTENTS

page page

ENGINE 2.4L.............................. 1ENGINE 3.3/3.8L......................... 71

ENGINE 2.4L

TABLE OF CONTENTS

page page

ENGINE 2.4L

DESCRIPTION............................3

DIAGNOSIS AND TESTING..................3

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST.........................3

CYLINDER COMPRESSION PRESSURE

TEST.................................3

ENGINE OIL LEAK INSPECTION............4

ENGINE...............................5

ENGINE DIAGNOSIS - PERFORMANCE......5

ENGINE DIAGNOSIS - MECHANICAL.........7

STANDARD PROCEDURE...................9

ENGINE CORE AND OIL GALLERY PLUGS....9

REPAIR OF DAMAGED OR WORN

THREADS..............................9

HYDROSTATIC LOCKED ENGINE...........9

FORM-IN-PLACE GASKETS AND SEALERS. . . 10

ENGINE GASKET SURFACE PREPARATION . . 11

MEASURING WITH PLASTIGAGE..........11

REMOVAL..............................12

INSTALLATION...........................13

SPECIFICATIONS........................16

SPECIAL TOOLS.........................19

AIR CLEANER ELEMENT

REMOVAL..............................22

INSTALLATION...........................22

AIR CLEANER HOUSING

REMOVAL..............................22

INSTALLATION...........................22

CYLINDER HEAD

DESCRIPTION...........................22

OPERATION.............................23

DIAGNOSIS AND TESTING.................23

CYLINDER HEAD GASKET...............23

REMOVAL..............................23

CLEANING..............................24

INSPECTION............................24

INSTALLATION...........................24CAMSHAFT OIL SEAL(S)

REMOVAL..............................26

INSTALLATION...........................26

CAMSHAFT(S)

DESCRIPTION...........................26

OPERATION.............................27

STANDARD PROCEDURE..................27

CAMSHAFT END-PLAY..................27

REMOVAL..............................27

CLEANING..............................28

INSPECTION............................28

INSTALLATION...........................28

CYLINDER HEAD COVER

REMOVAL..............................29

CLEANING..............................29

INSPECTION............................29

INSTALLATION...........................29

INTAKE/EXHAUST VALVES & SEATS

DESCRIPTION...........................30

CLEANING..............................30

VALVE SPRINGS

REMOVAL..............................30

INSPECTION............................31

INSTALLATION...........................31

HYDRAULIC LIFTERS

DIAGNOSIS AND TESTING.................32

LASH ADJUSTER (TAPPET) NOISE

DIAGNOSIS...........................32

REMOVAL..............................32

INSTALLATION...........................32

ROCKER ARMS

REMOVAL..............................33

INSPECTION............................33

INSTALLATION...........................33

ENGINE BLOCK

DESCRIPTION...........................33

STANDARD PROCEDURE..................33

CYLINDER BORE AND PISTON - FITTING....33

CYLINDER BORE HONING...............34

RSENGINE 2.4L9-1

Page 2631 of 4284

DIAGNOSIS AND TESTING - ENGINE MECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in

crankcase.1. Check and correct engine oil

level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Thick oil 3. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

4. Low oil pressure. 4. Check and correct engine oil

level.

5. Dirt in tappets/lash adjusters. 5. Replace rocker arm/hydraulic

lash adjuster assembly.

6. Worn rocker arms. 6. Inspect oil supply to rocker arms.

7. Worn tappets/lash adjusters. 7. Install new rocker arm/hydraulic

lash adjuster assembly.

8. Worn valve guides. 8. Replace cylinder head assembly.

9. Excessive runout of valve seats

on valve faces.9. Grind valve seats and valves.

10. Missing adjuster pivot. 10. Replace rocker arm/hydraulic

lash adjuster assembly.

CONNECTING ROD NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Connecting rod journal

out-of-round.6. Replace crankshaft or grind

surface.

7. Misaligned connecting rods. 7. Replace bent connecting rods.

RSENGINE 2.4L9-7

ENGINE 2.4L (Continued)

Page 2646 of 4284

AIR CLEANER ELEMENT

REMOVAL

(1) Unsnap 2 clips.

(2) Lift cover and pull toward the engine and

remove cover tabs from air box.

(3) Lift cover and remove the element (Fig. 11).

INSTALLATION

(1) Install the air filter element into air box (Fig.

11).

(2) Move cover so that the tabs insert into the air

box.

(3) Push cover down and snap the 2 clips.

AIR CLEANER HOUSING

REMOVAL

(1) Disconnect the negative battery cable.(2) Disconnect the inlet air temperature sensor

(Fig. 12).

(3) Remove the inlet hose to throttle body (Fig. 11).

(4) Remove the bolt for air box at upper radiator

cross member.

(5) Pull air box up and off over the single locating

pin.

(6) Remove air box from vehicle

INSTALLATION

(1) Install air box into vehicle and onto the locat-

ing pin.

(2) Install bolt to hold air box to the upper radia-

tor cross member.

(3) Install the inlet hose to the throttle body.

(4) Connect the inlet air temperature sensor (Fig.

12).

(5) Connect the negative battery cable.

CYLINDER HEAD

DESCRIPTION

The cross flow designed, aluminum cylinder head

contains dual over-head camshafts with four valves

per cylinder (Fig. 13). The valves are arrange in two

in-line banks. The intake valves face toward the

front of the vehicle. The exhaust valves face the dash

panel. The cylinder head incorporates powdered

metal valve guides and seats. The cylinder head is

sealed to the block using a multi-layer steel head

gasket and retaining bolts.

Integral oil galleries providing lubrication passages

to the hydraulic lash adjusters, camshafts, and valve

mechanisms.

Cylinder Compression Pressure Adaptor 8116

Fig. 11 AIR BOX COVER

Fig. 12 IAT SENSOR 2.4L

9 - 22 ENGINE 2.4LRS

SPECIAL TOOLS (Continued)

Page 2654 of 4284

(3) Apply MopartEngine RTV GEN II at the

camshaft cap corners and at the top edges of the 1/2

round seal (Fig. 32).

(4) Install cylinder head cover assembly to cylin-

der head. Install all bolts, ensuring the two (2) bolts

containing the sealing washer are located in the cen-

ter locations of cover. Tighten bolts in sequence

shown in (Fig. 33). Using a 3 step torque method as

follows:

(a) Tighten all bolts to 4.5 N´m (40 in. lbs.).

(b) Tighten all bolts to 9.0 N´m (80 in. lbs.).

(c) Tighten all bolts to 12 N´m (105 in. lbs.).

(5) Install ignition coil and spark plug wires.

Tighten fasteners to 12 N´m (105 in. lbs.).

(6) If the PCV valve was removed, apply Mopart

Thread Sealant with Teflon to threads and install

valve to cylinder head cover. Tighten PCV valve to 8

N´m (70 in. lbs.).

(7) Connect PCV and make-up air hoses to cylin-

der head cover.(8) Install upper intake manifold. (Refer to 9 -

ENGINE/MANIFOLDS/INTAKE MANIFOLD -

INSTALLATION)

INTAKE/EXHAUST VALVES &

SEATS

DESCRIPTION

The valves are made of heat resistant steel. They

have chrome plated stems to prevent scuffing. Viton

rubber valve stem seals are integral with the spring

seats. The valves have three-bead lock keepers to

retain springs and to promote valve rotation.

CLEANING

(1) Clean all valves thoroughly and discard

burned, warped and cracked valves.

VALVE SPRINGS

REMOVAL - CYLINDER HEAD ON

(1) Remove camshafts.

(2) Rotate crankshaft until piston is at TDC on

compression.

(3) With air hose attached to adapter tool installed

in spark plug hole, apply 90-120 psi air pressure.

(4) Using Special Tool MD-998772-A with adapter

6779 (Fig. 34), compress valve springs and remove

valve locks.

(5) Remove valve spring(s).

(6) Remove valve stem seal(s) by a using valve

stem seal tool (Fig. 36).

REMOVAL - CYLINDER HEAD OFF

(1) With cylinder head removed, compress valve

springs using a universal valve spring compressor.

(2) Remove valve retaining locks, valve spring

retainers, valve stem seals and valve springs.

(3) Before removing valves,remove any burrs

from valve stem lock grooves to prevent dam-

Fig. 32 Sealer Locations

1 ± SEALER LOCATION

Fig. 33 Cylinder Head Cover Tightening Sequence

(Typical Cover Shown)

9 - 30 ENGINE 2.4LRS

CYLINDER HEAD COVER (Continued)