steering CHRYSLER VOYAGER 2001 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1506 of 4284

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the lifted end of

the vehicle and lower the vehicle closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

²AWD models should not be flat towed. For addi-

tional information, refer toRECOMMENDED TOW-

ING EQUIPMENTin this section.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

The vehicle can be tied to a flat bed device using

the two pair of front slots on the bottom surface of

the rails, behind the front wheels. The two pair of

rear slots on the bottom of the rail between the

bumper extension bolts and on the bottom of the rail

just rearward of the jounce bumper. Vehicles

equipped with a rear sway bar have brackets at this

location.

TOWING ± FRONT WHEEL LIFT

If the vehicle is being towed from the front, when-

ever possible ensure at lest 10 inches road clearness

to the tires.

TOWING ± REAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lift, the rear wheels can be lifted provided the follow-

ing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

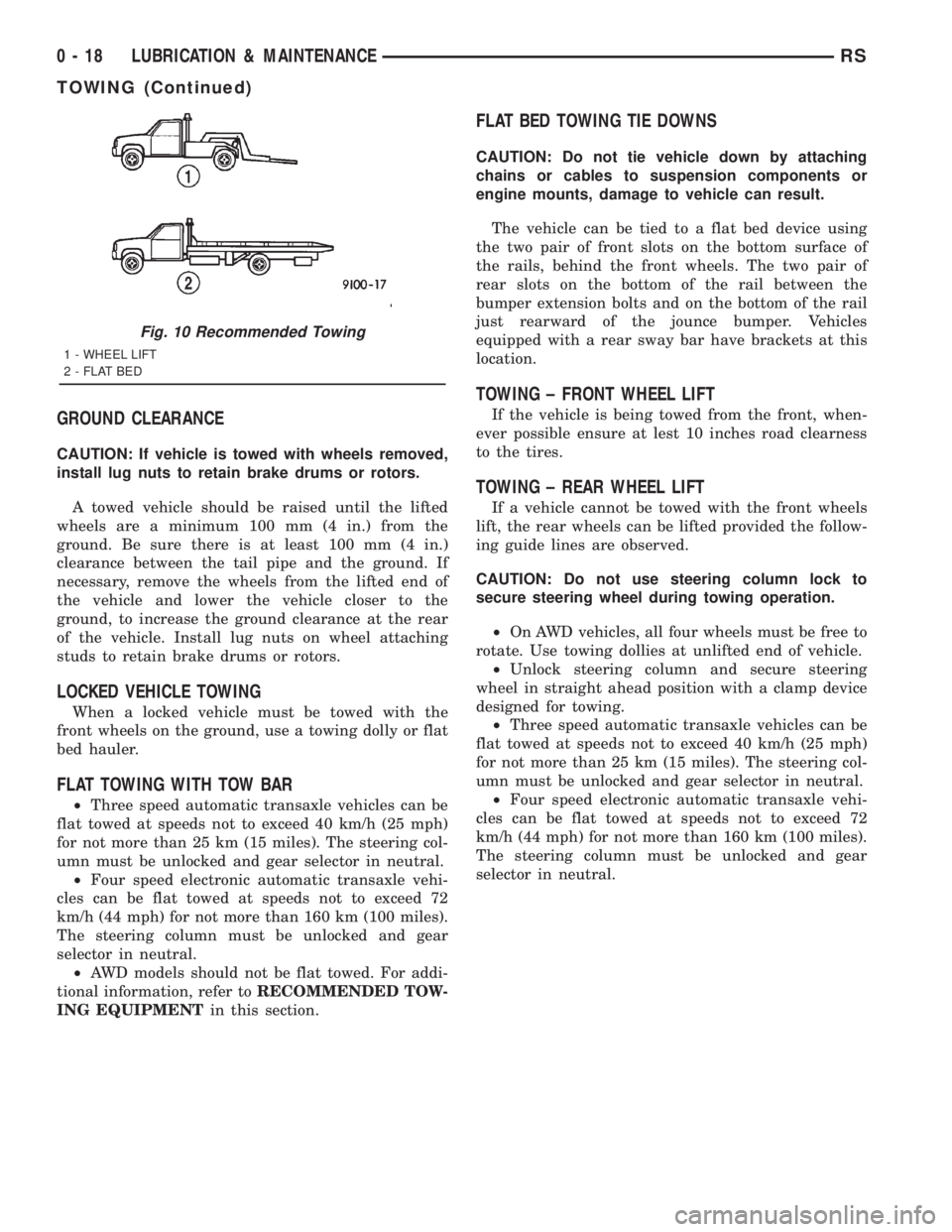

Fig. 10 Recommended Towing

1 - WHEEL LIFT

2 - FLAT BED

0 - 18 LUBRICATION & MAINTENANCERS

TOWING (Continued)

Page 1507 of 4284

LUBRICATION & MAINTENANCE - RG - 2.5 L TURBO

DIESEL

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE - RG - 2.5 L

TURBO DIESEL

SPECIFICATIONS.........................1

INTERNATIONAL SYMBOLS

DESCRIPTION............................2

FLUID TYPES

DESCRIPTION............................2

FLUID FILL/CHECK LOCATIONS

DESCRIPTION............................5

MAINTENANCE SCHEDULES

DESCRIPTION............................5HOISTING

STANDARD PROCEDURE...................7

HOISTING.............................7

JUMP STARTING

STANDARD PROCEDURE...................8

JUMP STARTING........................8

TOWING

STANDARD PROCEDURE...................8

TOWING RECOMMENDATIONS.............8

LUBRICATION &

MAINTENANCE - RG - 2.5 L

TURBO DIESEL

SPECIFICATIONS

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

Fuel Tank 75 L (20 gal.)

Fuel Tank (Diesel) 75 L (20 gal.)

Engine Oil* - 2.4 L 4.7 L (5.0 qts.)

Engine Oil* - 3.3 L 4.0 L (4.5 qts.)

Engine Oil* - 2.5 L 5.22 L (5.52 qts.)

Cooling System** - 2.4 L 10.7 L (11.4 qts.)

Cooling System** - 3.3 L

without Auxiliary Heater12.6 L (13.4 qts.)

Cooling System** - 3.3 L

with Auxiliary Heater15.4 L (16.3 qts.)

Cooling System** - 2.5 L

Turbo Diesel without

Auxiliary Heater13.8 L (14.6 qts.)

DESCRIPTION SPECIFICATION

Cooling System** - 2.5 L

Turbo Diesel with

Auxiliary Heater16.6 L (17.5 qts.)

Automatic Transaxle -

Service Fill3.8 L (4.0 qts.)

Automatic Transaxle -

31TH Overhaul Fill8.6 L (9.1 qts.)

Automatic Transaxle -

41TE Overhaul Fill9.2 L (9.7 qts.)

Manual Transaxle (T850

5-speed)2.4-2.7 L (2.5-2.9 qts.)

AWD Power Transfer Unit 1.15 L (2.4 pts.)

Power Steering 1.2 L (2.5 pts.)

AWD Bi-directional

Overrunning Clutch0.575 L (1.22 pts.)

AWD Rear Carrier 0.7 L (1.48 pts.)

*(includes oil filter)

**(includes heater and recovery/reserve bottle)

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-1

Page 1511 of 4284

FLUID FILL/CHECK

LOCATIONS

DESCRIPTION

The fluid check/fill points and lubrication locations

are located in each applicable service manual section.

MAINTENANCE SCHEDULES

MAINTENANCE SCHEDULES - DIESEL ENGINE

There are two maintenance schedules that show

proper service for the vehicle.

First is ScheduleªAº. It lists all the scheduled

maintenance to be performed under ªnormalº operat-

ing conditions.

Second is ScheduleªBº. It is a schedule for vehi-

cles that are operated under the conditions listed at

the beginning of the schedule.

Use the schedule that best describes the driving

conditions.

Where time and mileage are listed, follow the

interval that occurs first.

At Each Stop for Fuel

²Check the engine oil level, add as required.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check the tire pressure and look for unusual

wear or damage.

²Inspect the battery and clean and tighten termi-

nals as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transaxle and

add as needed.

²Check all lights and all other electrical items for

correct operation.

²Check the rubber seals on each side of the radi-

ator for proper fit.

At Each Oil Change

²Replace the engine oil filter at each oil change.

²Inspect exhaust system.

²Inspect brake hoses

²Inspect the CV joints and front suspension com-

ponents

²Rotate the tires at each oil change interval

shown on schedule ªAº 20 000 km or every other

interval shown on schedule ªBº 20 000 km.

²Check the coolant level, hoses, and clamps.

²Inspect brake linings, hoses and calipers.

²Inspect engine accessory drive belts.

²Inspect for presence of water in fuel filter/water

separator, drain if necessary.

SCHEDULE ªAº

20 000 km (12 000 miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

40 000 km (24 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

60 000 km (37 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

80 000 km (49 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

100 000 km (62 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

120 000 km (75 000 Miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Replace air filter element.

²Replace fuel filter/water separator element. (2)

²Check alignment.

140 000 km (86 000 miles)

²Change engine oil. (1)

²Replace engine oil filter.

²Inspect air filter element. Replace as necessary.

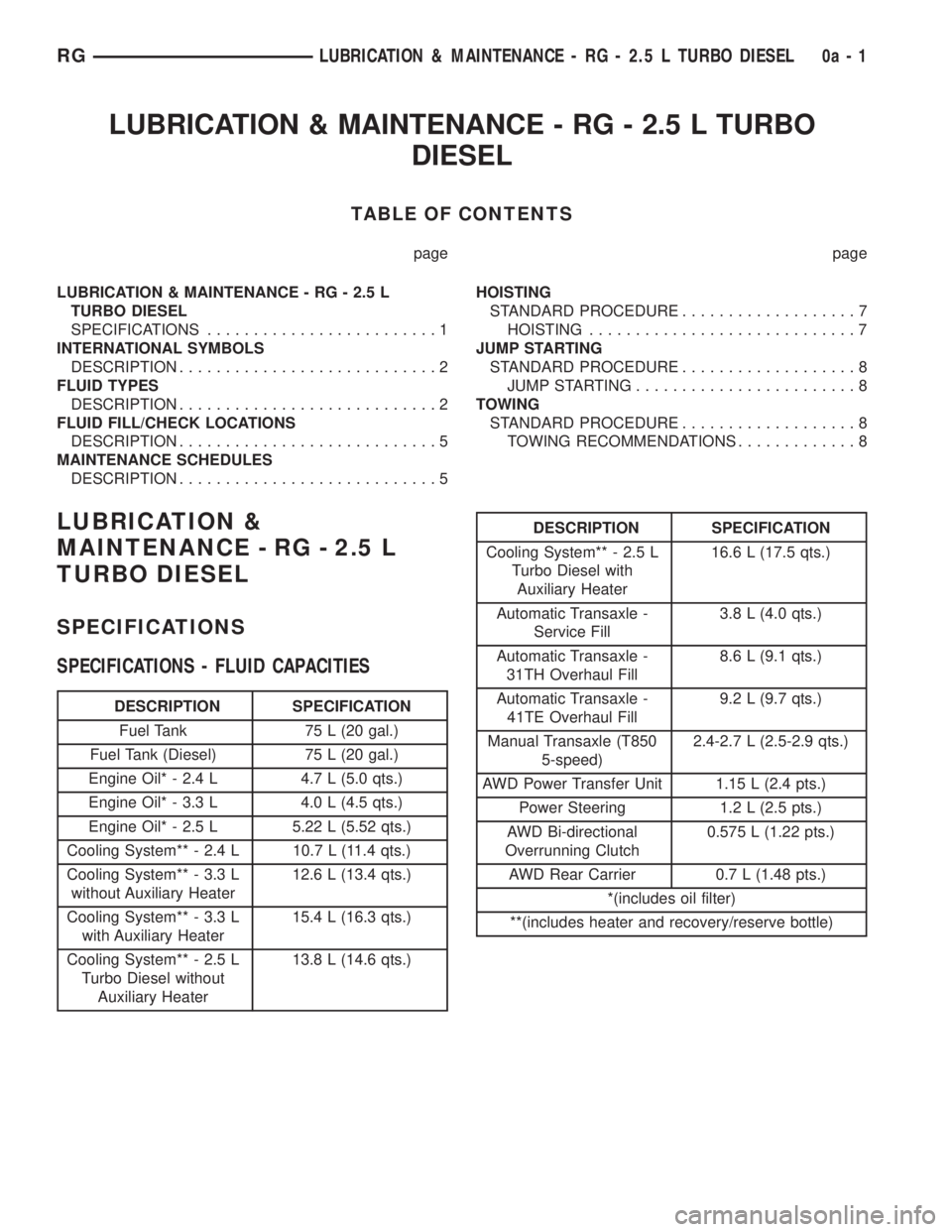

Fig. 6 Engine Oil Viscosity Recommendation ±

Diesel Engines

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-5

FLUID TYPES (Continued)

Page 1514 of 4284

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

(1) Raise hood on disabled vehicle and visually

inspect engine compartment for:

²Battery cable clamp condition, clean if necessary.

²Frozen battery.

²Yellow or bright color test indicator, if equipped.

²Low battery fluid level.

²Generator drive belt condition and tension.

²Fuel fumes or leakage, correct if necessary.

CAUTION: If the cause of starting problem on dis-

abled vehicle is severe, damage to booster vehicle

charging system can result.

(2) When using another vehicle as a booster

source, park the booster vehicle within cable reach.

Turn off all accessories, set the parking brake, place

the automatic transmission in PARK or the manual

transmission in NEUTRAL and turn the ignition

OFF.

(3)

On disabled vehicle, place gear selector in park

or neutral and set park brake. Turn off all accessories.

(4) Connect jumper cables to booster battery. RED

clamp to positive terminal (+). BLACK clamp to neg-

ative terminal (-). DO NOT allow clamps at opposite

end of cables to touch, electrical arc will result.

Review all warnings in this procedure.

(5) On disabled vehicle, connect RED jumper cable

clamp to positive (+) terminal. Connect BLACK

jumper cable clamp to engine ground as close to the

ground cable attaching point as possible (Fig. 8).

(6) Start the engine in the vehicle which has the

booster battery, let the engine idle a few minutes,

then start the engine in the vehicle with the dis-

charged battery.

CAUTION: Do not crank starter motor on disabled

vehicle for more than 15 seconds, starter will over-

heat and could fail.

(7) Allow battery in disabled vehicle to charge to

at least 12.4 volts (75% charge) before attempting to

start engine. If engine does not start within 15 sec-

onds, stop cranking engine and allow starter to cool

(15 minutes), before cranking again.

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING

TOWING RECOMMENDATIONS

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

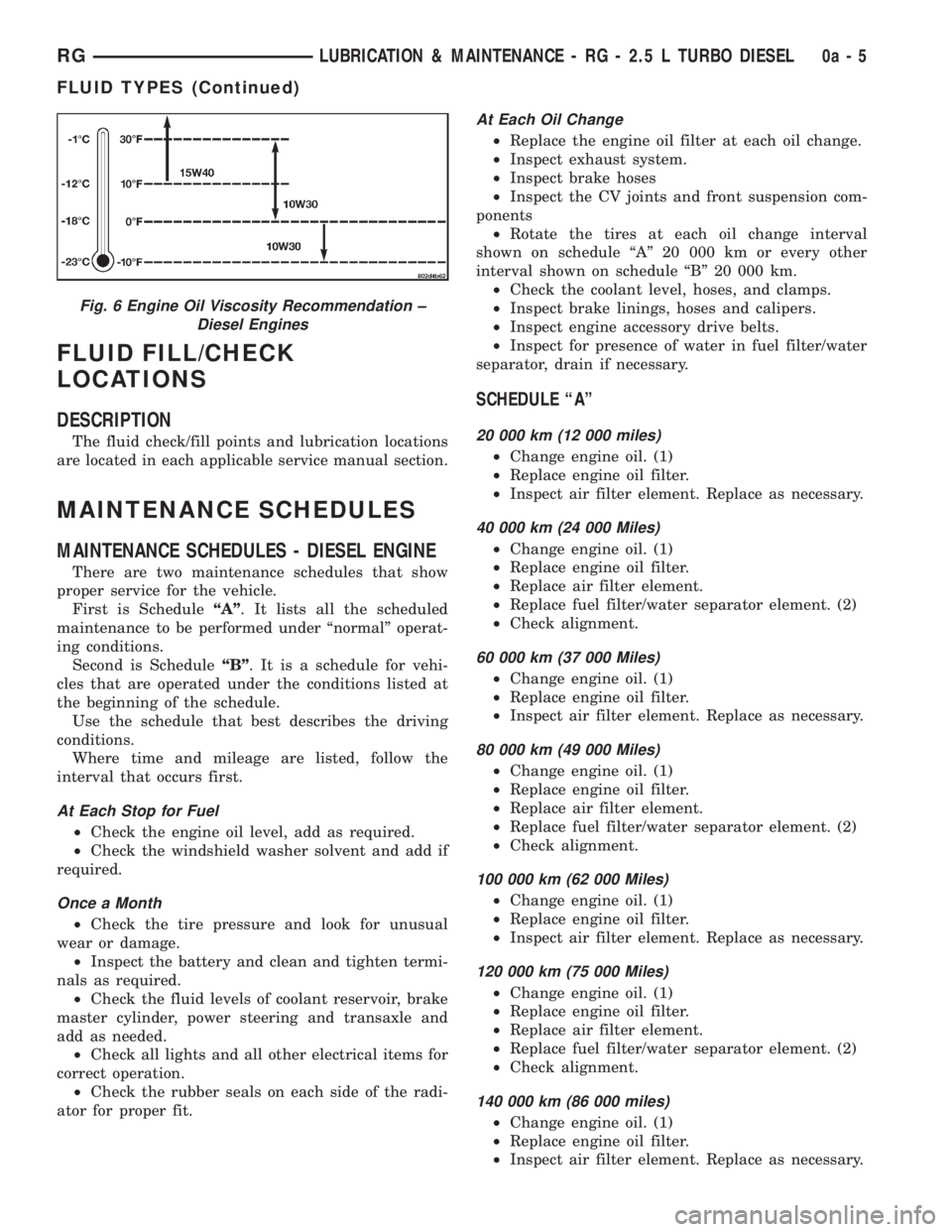

Fig. 8 Jumper Cable Clamp Connections

1 - BATTERY POSITIVE CABLE

2 - POSITIVE JUMPER CABLE

3 - TEST INDICATOR

4 - BATTERY NEGATIVE CABLE

5 - BATTERY

6 - NEGATIVE JUMPER CABLE

7 - ENGINE GROUND

0a - 8 LUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESELRG

Page 1515 of 4284

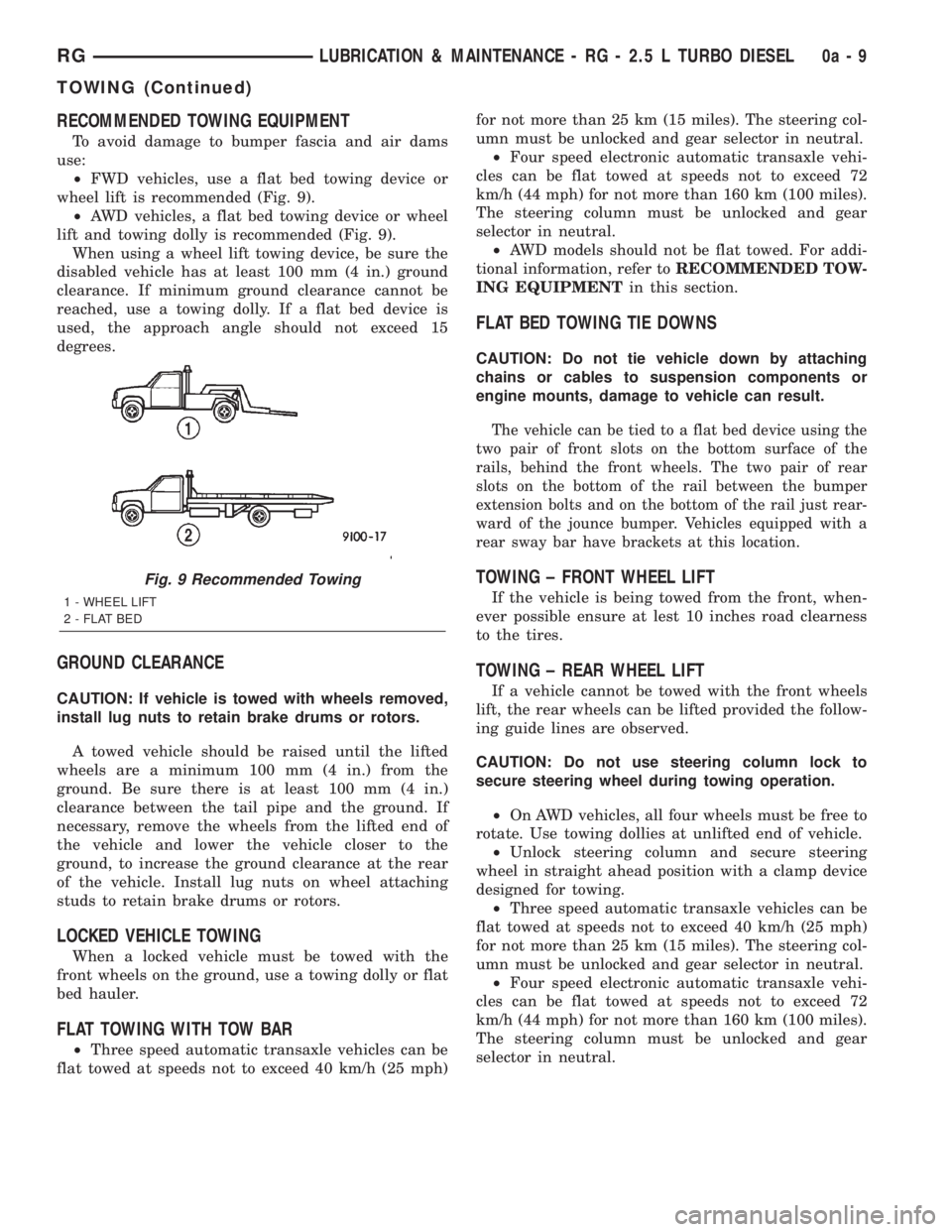

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

²FWD vehicles, use a flat bed towing device or

wheel lift is recommended (Fig. 9).

²AWD vehicles, a flat bed towing device or wheel

lift and towing dolly is recommended (Fig. 9).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the lifted end of

the vehicle and lower the vehicle closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

²AWD models should not be flat towed. For addi-

tional information, refer toRECOMMENDED TOW-

ING EQUIPMENTin this section.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

The vehicle can be tied to a flat bed device using the

two pair of front slots on the bottom surface of the

rails, behind the front wheels. The two pair of rear

slots on the bottom of the rail between the bumper

extension bolts and on the bottom of the rail just rear-

ward of the jounce bumper. Vehicles equipped with a

rear sway bar have brackets at this location.

TOWING ± FRONT WHEEL LIFT

If the vehicle is being towed from the front, when-

ever possible ensure at lest 10 inches road clearness

to the tires.

TOWING ± REAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lift, the rear wheels can be lifted provided the follow-

ing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

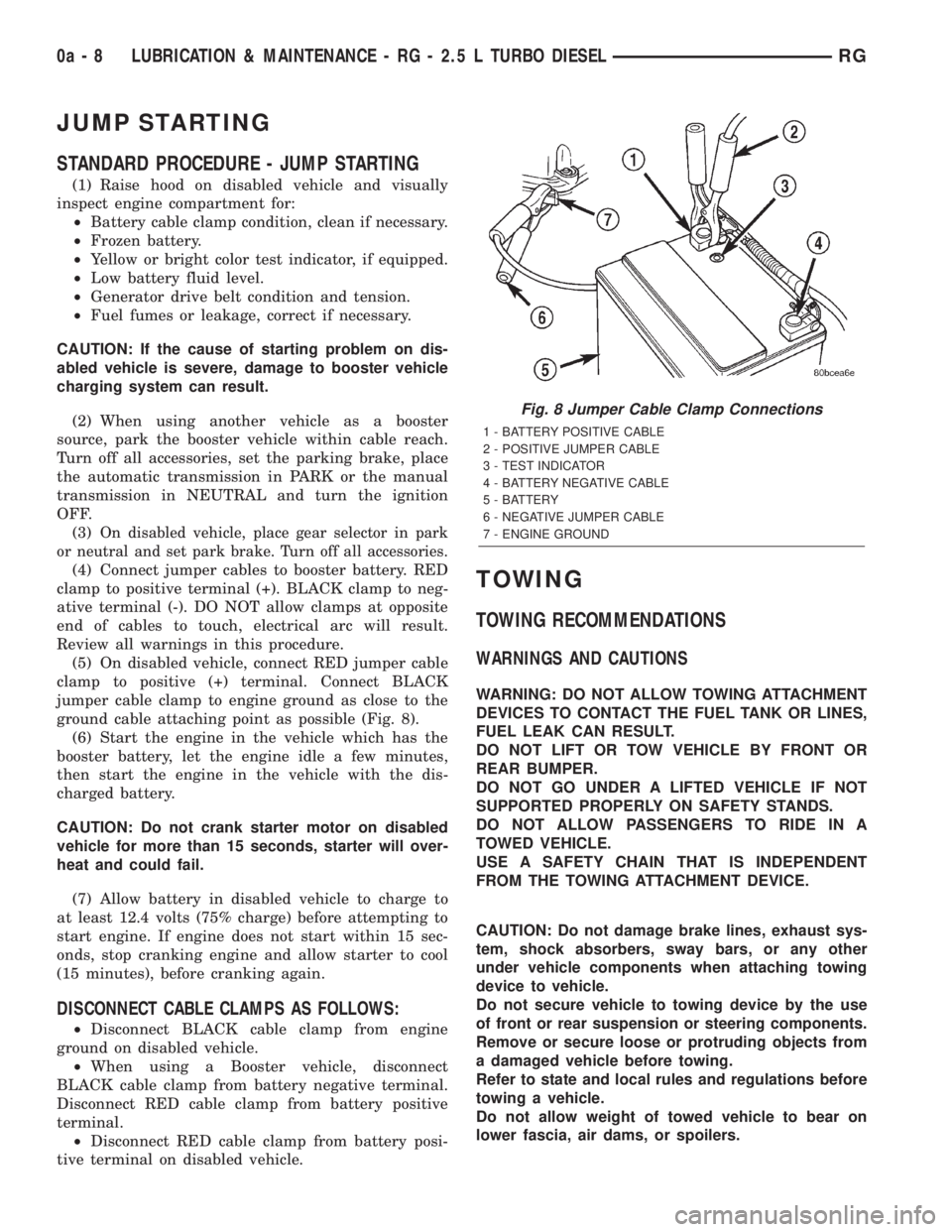

Fig. 9 Recommended Towing

1 - WHEEL LIFT

2 - FLAT BED

RGLUBRICATION & MAINTENANCE - RG - 2.5 L TURBO DIESEL0a-9

TOWING (Continued)

Page 1518 of 4284

A strut assembly is used in place of the front sus-

pension upper control arm and upper ball joint.

When a vehicle strikes a bump, the force is trans-

ferred through the hub, bearing, and knuckle, into

the strut assembly to absorb the force and dampen it.

The top of the strut is mounted directly to the strut

tower of the vehicle. During steering maneuvers, the

strut assembly (through a pivot bearing in the upper

strut mount) and steering knuckle (through the lower

ball joint) turn as an assembly.STANDARD PROCEDURE - LUBRICATION

There are no serviceable lubrication points on the

front suspension. The ball joints are sealed-for-life

and require no maintenance. The lower ball joints

have special grease fitting caps that prevent normal

grease gun attachment. This has been done to elimi-

nate the possibility of over-filling, damaging the non-

vented seal. Do not attempt to remove the special

grease fitting cap and replace it with a normal grease

zirc fitting.

CAUTION: No attempt should be made to replace

the ball joint grease fitting cap with a normal zirc

fitting or fill the ball joint with grease. Damage to

the grease seal can result.

Fig. 1 Front Suspension

1 - TOWER

2 - CROSSMEMBER TAPPING PLATES

3 - LEFT STRUT ASSEMBLY

4 - LEFT STEERING KNUCKLE (WITH HUB AND BEARING)

5 - STABILIZER BAR LINK

6 - STABILIZER BAR

7 - LEFT LOWER CONTROL ARM

8 - CRADLE/CROSSMEMBER9 - CRADLE/CROSSMEMBER REINFORCEMENT

10 - BALL JOINT

11 - ISOLATOR BUSHING

12 - STEERING GEAR TIE ROD

13 - RIGHT STEERING KNUCKLE

14 - RIGHT HUB AND BEARING

15 - RIGHT STRUT ASSEMBLY

2 - 2 FRONTRS

FRONT (Continued)

Page 1519 of 4284

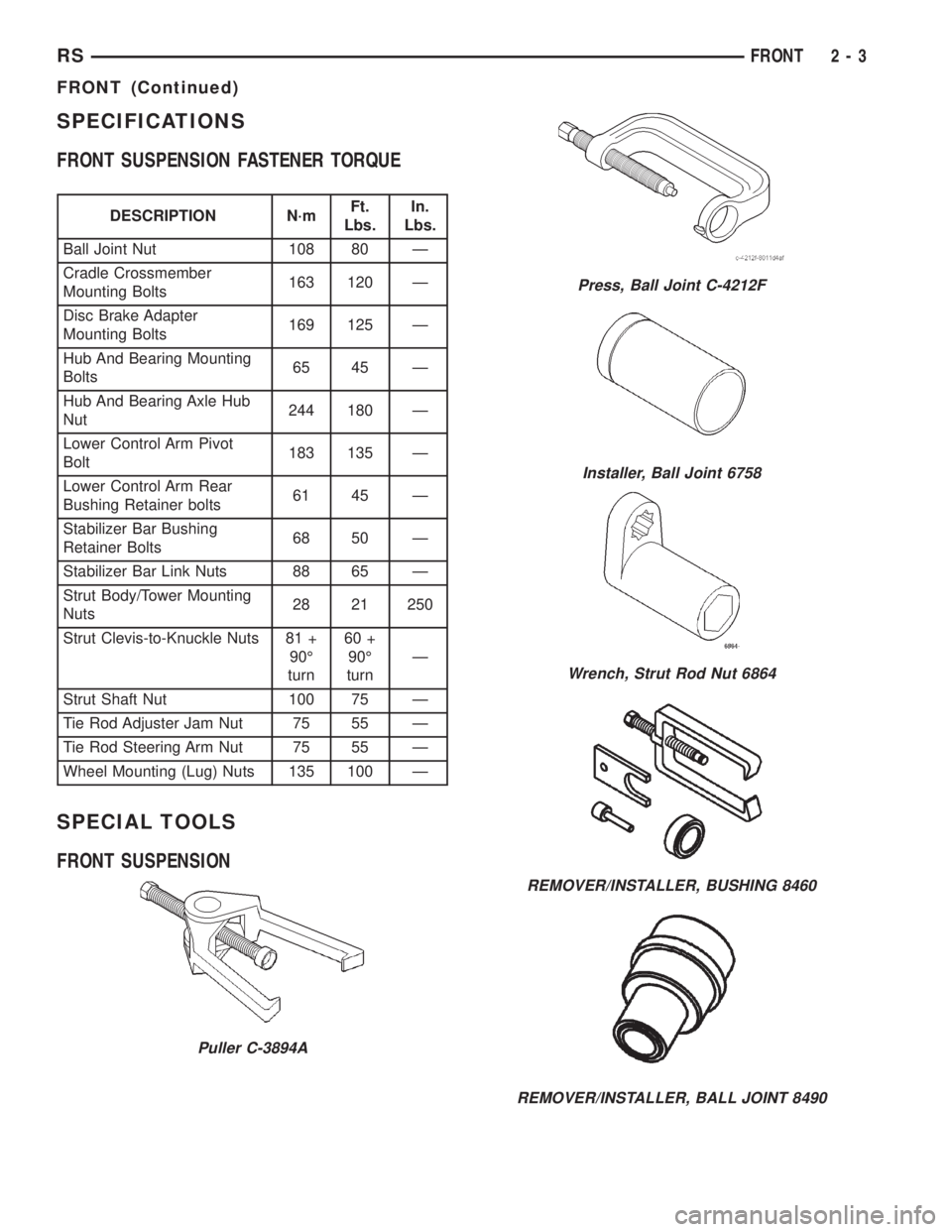

SPECIFICATIONS

FRONT SUSPENSION FASTENER TORQUE

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Ball Joint Nut 108 80 Ð

Cradle Crossmember

Mounting Bolts163 120 Ð

Disc Brake Adapter

Mounting Bolts169 125 Ð

Hub And Bearing Mounting

Bolts65 45 Ð

Hub And Bearing Axle Hub

Nut244 180 Ð

Lower Control Arm Pivot

Bolt183 135 Ð

Lower Control Arm Rear

Bushing Retainer bolts61 45 Ð

Stabilizer Bar Bushing

Retainer Bolts68 50 Ð

Stabilizer Bar Link Nuts 88 65 Ð

Strut Body/Tower Mounting

Nuts28 21 250

Strut Clevis-to-Knuckle Nuts 81 +

90É

turn60 +

90É

turnÐ

Strut Shaft Nut 100 75 Ð

Tie Rod Adjuster Jam Nut 75 55 Ð

Tie Rod Steering Arm Nut 75 55 Ð

Wheel Mounting (Lug) Nuts 135 100 Ð

SPECIAL TOOLS

FRONT SUSPENSION

Puller C-3894A

Press, Ball Joint C-4212F

Installer, Ball Joint 6758

Wrench, Strut Rod Nut 6864

REMOVER/INSTALLER, BUSHING 8460

REMOVER/INSTALLER, BALL JOINT 8490

RSFRONT2-3

FRONT (Continued)

Page 1520 of 4284

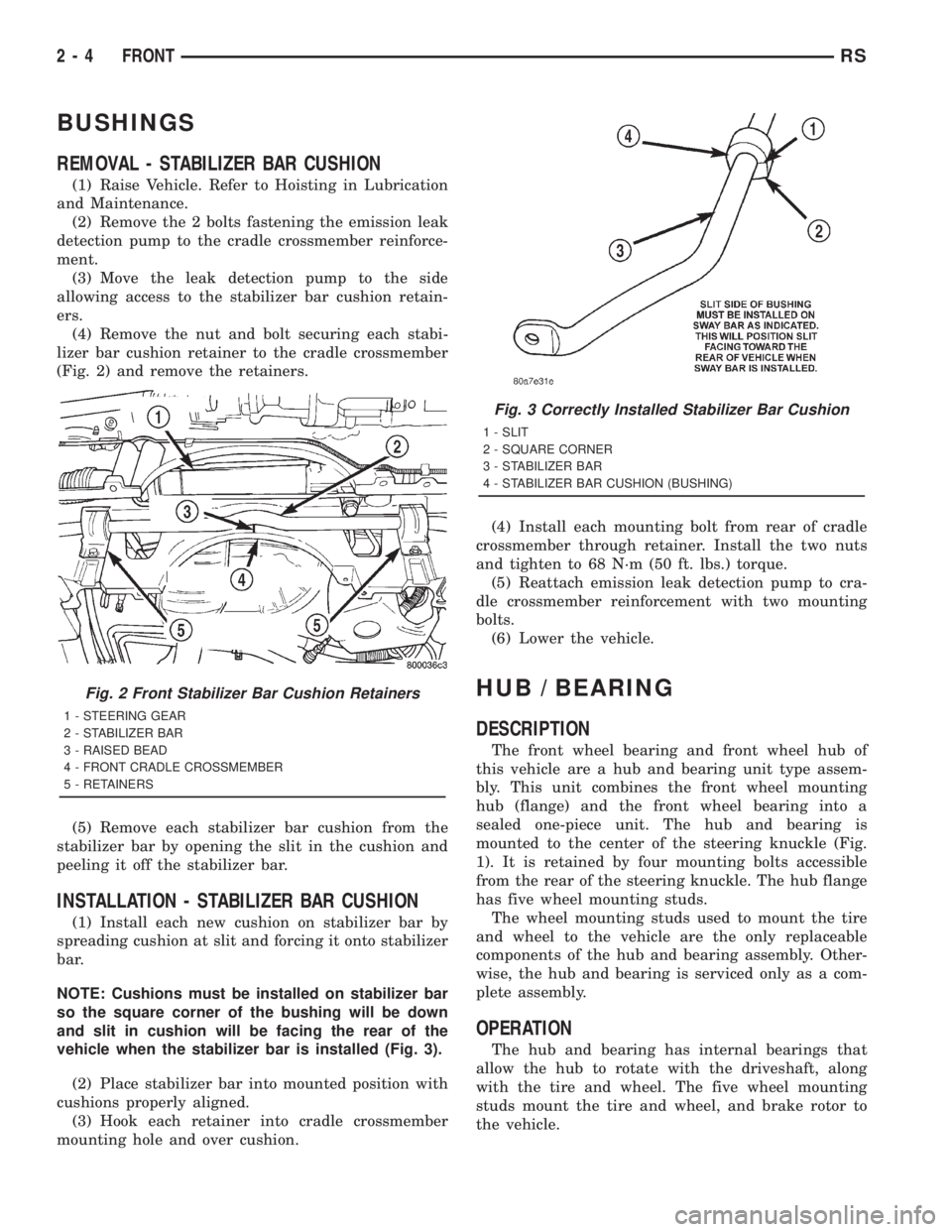

BUSHINGS

REMOVAL - STABILIZER BAR CUSHION

(1) Raise Vehicle. Refer to Hoisting in Lubrication

and Maintenance.

(2) Remove the 2 bolts fastening the emission leak

detection pump to the cradle crossmember reinforce-

ment.

(3) Move the leak detection pump to the side

allowing access to the stabilizer bar cushion retain-

ers.

(4) Remove the nut and bolt securing each stabi-

lizer bar cushion retainer to the cradle crossmember

(Fig. 2) and remove the retainers.

(5) Remove each stabilizer bar cushion from the

stabilizer bar by opening the slit in the cushion and

peeling it off the stabilizer bar.

INSTALLATION - STABILIZER BAR CUSHION

(1) Install each new cushion on stabilizer bar by

spreading cushion at slit and forcing it onto stabilizer

bar.

NOTE: Cushions must be installed on stabilizer bar

so the square corner of the bushing will be down

and slit in cushion will be facing the rear of the

vehicle when the stabilizer bar is installed (Fig. 3).

(2) Place stabilizer bar into mounted position with

cushions properly aligned.

(3) Hook each retainer into cradle crossmember

mounting hole and over cushion.(4) Install each mounting bolt from rear of cradle

crossmember through retainer. Install the two nuts

and tighten to 68 N´m (50 ft. lbs.) torque.

(5) Reattach emission leak detection pump to cra-

dle crossmember reinforcement with two mounting

bolts.

(6) Lower the vehicle.

HUB / BEARING

DESCRIPTION

The front wheel bearing and front wheel hub of

this vehicle are a hub and bearing unit type assem-

bly. This unit combines the front wheel mounting

hub (flange) and the front wheel bearing into a

sealed one-piece unit. The hub and bearing is

mounted to the center of the steering knuckle (Fig.

1). It is retained by four mounting bolts accessible

from the rear of the steering knuckle. The hub flange

has five wheel mounting studs.

The wheel mounting studs used to mount the tire

and wheel to the vehicle are the only replaceable

components of the hub and bearing assembly. Other-

wise, the hub and bearing is serviced only as a com-

plete assembly.

OPERATION

The hub and bearing has internal bearings that

allow the hub to rotate with the driveshaft, along

with the tire and wheel. The five wheel mounting

studs mount the tire and wheel, and brake rotor to

the vehicle.

Fig. 2 Front Stabilizer Bar Cushion Retainers

1 - STEERING GEAR

2 - STABILIZER BAR

3 - RAISED BEAD

4 - FRONT CRADLE CROSSMEMBER

5 - RETAINERS

Fig. 3 Correctly Installed Stabilizer Bar Cushion

1 - SLIT

2 - SQUARE CORNER

3 - STABILIZER BAR

4 - STABILIZER BAR CUSHION (BUSHING)

2 - 4 FRONTRS

Page 1521 of 4284

DIAGNOSIS AND TESTING - HUB AND

BEARING (FRONT)

The condition of the front hub and bearing assem-

bly is diagnosed using the inspection and testing pro-

cedure detailed below.

The bearing contained in the Unit III front hub/

bearing assembly will produce noise and vibration

when worn or damaged. The noise will generally

change when the bearings are loaded. A road test of

the vehicle is normally required to determine the

location of a worn or damaged bearing.

Find a smooth level road surface and bring the

vehicle up to a constant speed. When vehicle is at a

constant speed, swerve the vehicle back and forth

from the left and to the right. This will load and

unload the bearings and change the noise level.

Where axle bearing damage is slight, the noise is

usually not noticeable at speeds above 48 km/h (30

mph).

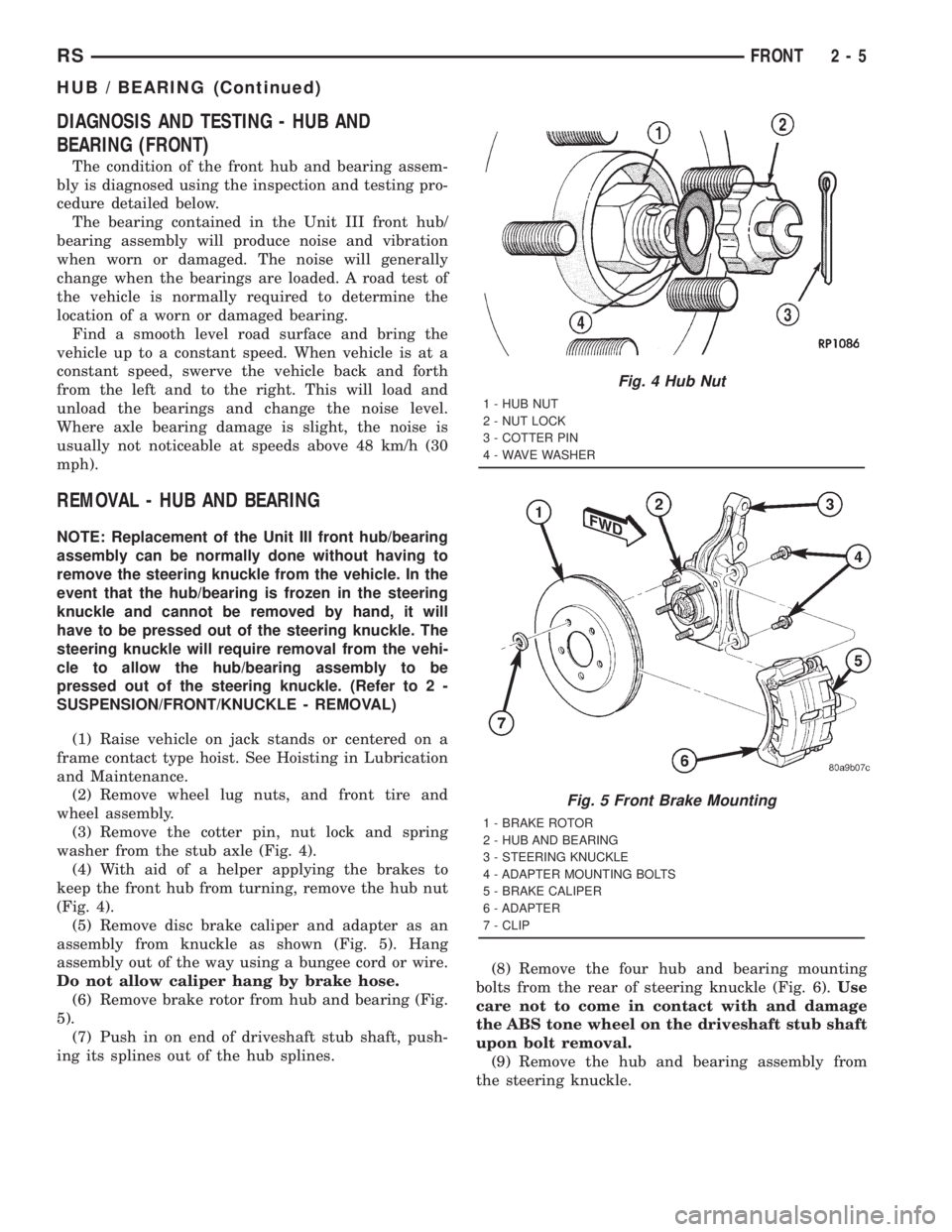

REMOVAL - HUB AND BEARING

NOTE: Replacement of the Unit III front hub/bearing

assembly can be normally done without having to

remove the steering knuckle from the vehicle. In the

event that the hub/bearing is frozen in the steering

knuckle and cannot be removed by hand, it will

have to be pressed out of the steering knuckle. The

steering knuckle will require removal from the vehi-

cle to allow the hub/bearing assembly to be

pressed out of the steering knuckle. (Refer to 2 -

SUSPENSION/FRONT/KNUCKLE - REMOVAL)

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove wheel lug nuts, and front tire and

wheel assembly.

(3) Remove the cotter pin, nut lock and spring

washer from the stub axle (Fig. 4).

(4) With aid of a helper applying the brakes to

keep the front hub from turning, remove the hub nut

(Fig. 4).

(5) Remove disc brake caliper and adapter as an

assembly from knuckle as shown (Fig. 5). Hang

assembly out of the way using a bungee cord or wire.

Do not allow caliper hang by brake hose.

(6) Remove brake rotor from hub and bearing (Fig.

5).

(7) Push in on end of driveshaft stub shaft, push-

ing its splines out of the hub splines.(8) Remove the four hub and bearing mounting

bolts from the rear of steering knuckle (Fig. 6).Use

care not to come in contact with and damage

the ABS tone wheel on the driveshaft stub shaft

upon bolt removal.

(9) Remove the hub and bearing assembly from

the steering knuckle.

Fig. 4 Hub Nut

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - WAVE WASHER

Fig. 5 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

RSFRONT2-5

HUB / BEARING (Continued)

Page 1522 of 4284

INSTALLATION - HUB AND BEARING

CAUTION: Hub and bearing assembly mounting

surfaces on the steering knuckle and stub axle (Fig.

7) must be smooth and completely free of foreign

material or nicks prior to installing hub and bearing

assembly.

CAUTION: When installing hub and bearing into

steering knuckle, be careful not to damage the

bearing seal (Fig. 7) on the outer C/V joint.(1) Install hub and bearing onto stub axle and into

steering knuckle until squarely seated on the face of

the steering knuckle.

(2) Install the 4 hub and bearing mounting bolts

from the rear of the knuckle. Equally tighten all 4

mounting bolts in a criss-cross pattern until hub/

bearing assembly is squarely seated against front of

steering knuckle. Tighten mounting bolts to a torque

of 65 N´m (45 ft. lbs.)

(3) Install the brake rotor on the hub and bearing

(Fig. 5).

(4) Install brake caliper and adapter assembly

back over brake rotor and align with mounting holes

on steering knuckle (Fig. 5). Install the mounting

bolts and tighten to 169 N´m (125 ft. lbs.) torque.

(5) Install the hub nut on the end of the stub axle

(Fig. 4). With aid of a helper applying the brakes to

keep the front hub from turning, tighten the hub nut

to Install the mounting bolts and tighten to 244 N´m

(180 ft. lbs.) torque.

(6) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(7) Lower vehicle to the ground.

(8) Check the front wheel alignment toe setting

and reset if not within specifications.

KNUCKLE

DESCRIPTION

The steering knuckle is a singlealuminumcast-

ing with legs machined for attachment of the strut

assembly, steering linkage, disc brake caliper

adapter, lower control arm ball joint and steering

linkage (Fig. 1). The hub and bearing assembly is

mounted in the center of the steering knuckle using

4 bolts. The driveshaft's constant velocity (C/V) stub

axle is splined through the center of the hub and

bearing and is held in place using a nut, nut lock and

cotter pin.

Service replacement of the front hub and bearing

assembly can be done with the steering knuckle

remaining on the vehicle.

OPERATION

The steering knuckle pivots with the strut assem-

bly between the lower ball joint and the pivot bearing

in the strut assembly. The steering gear outer tie rod

end connects to the trailing end of each knuckle,

allowing the vehicle to be steered.

The center of the knuckle supports the hub and

bearing and axle shaft.

Fig. 6 Hub And Bearing Mounting Bolts

1 - HUB

2 - STEERING KNUCKLE

3 - MOUNTING BOLTS (4)

4 - DRIVESHAFT

Fig. 7 Mounting Surfaces (Typical)

1 - BEARING SEAL

2 - STUB AXLE

3 - THESE SURFACES MUST BE CLEAN AND FREE OF NICKS

BEFORE INSTALLING BEARING ASSEMBLY

4 - STEERING KNUCKLE

2 - 6 FRONTRS

HUB / BEARING (Continued)