belt CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2954 of 4284

(4) Install the power steering fluid pressure line

into the pressure output fitting of the power steering

pump (Fig. 11). Tighten the pressure line to pump fit-

ting tube nut to a torque of 31 N´m (275 in. lbs.).

(5) Install the power steering fluid low-pressure

return hose on the power steering pump low pressure

fitting (Fig. 11).Be sure hose clamps are prop-

erly reinstalled.

(6) Raise the vehicle.

(7) Install the routing clip on the engine for the

pressure hose (Fig. 10).

(8) Tighten the pump thru-bolt (Fig. 9). Tighten to

54 N´m (40 ft. lbs.) torque.

(9) Install the serpentine drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(10) Install the drive belt splash shield.

(11) Lower the vehicle.

(12) Install the wiper module (unit)(Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - INSTALLATION).

(13) Connect the negative battery cable on the

negative battery post.

(14) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

(15) Inspect for leaks.

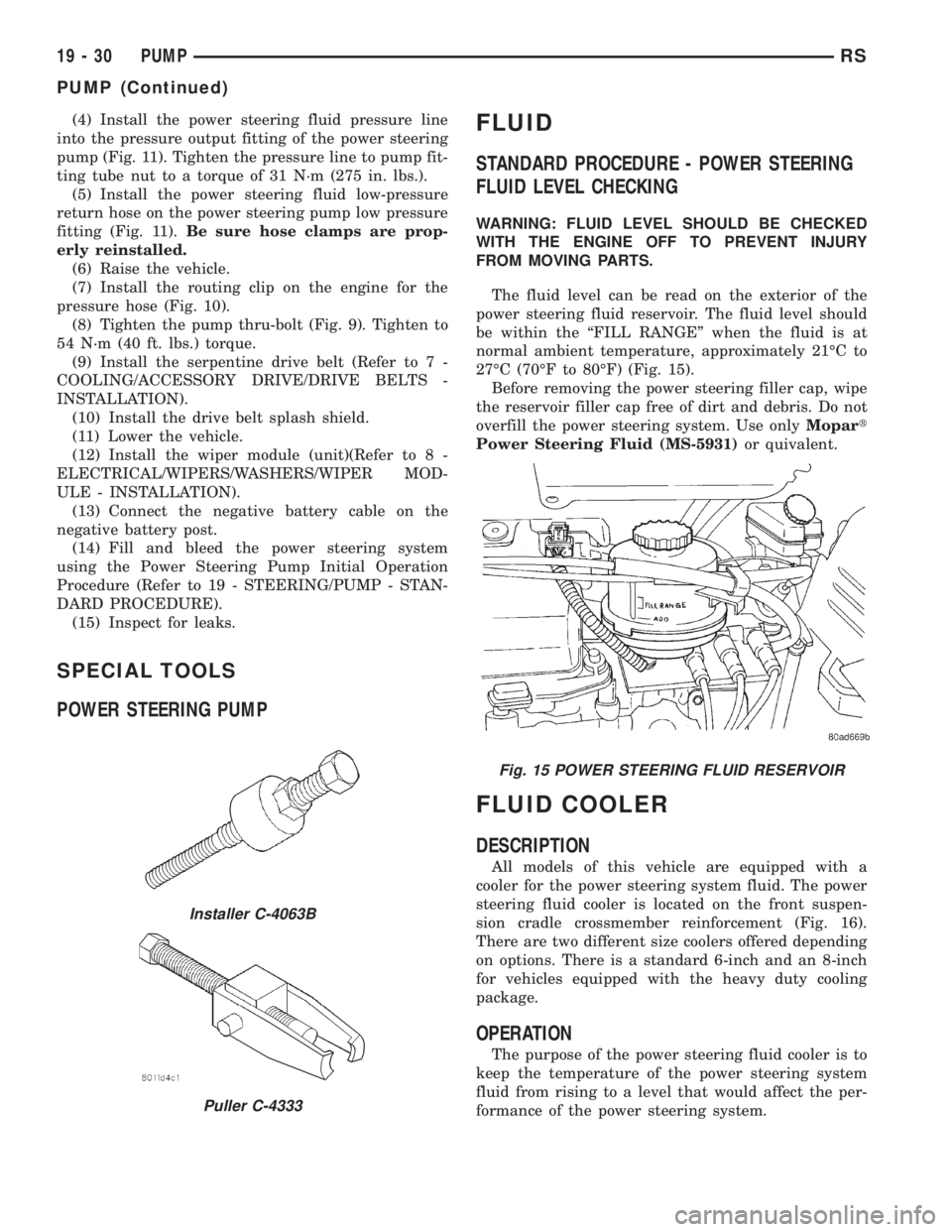

SPECIAL TOOLS

POWER STEERING PUMP

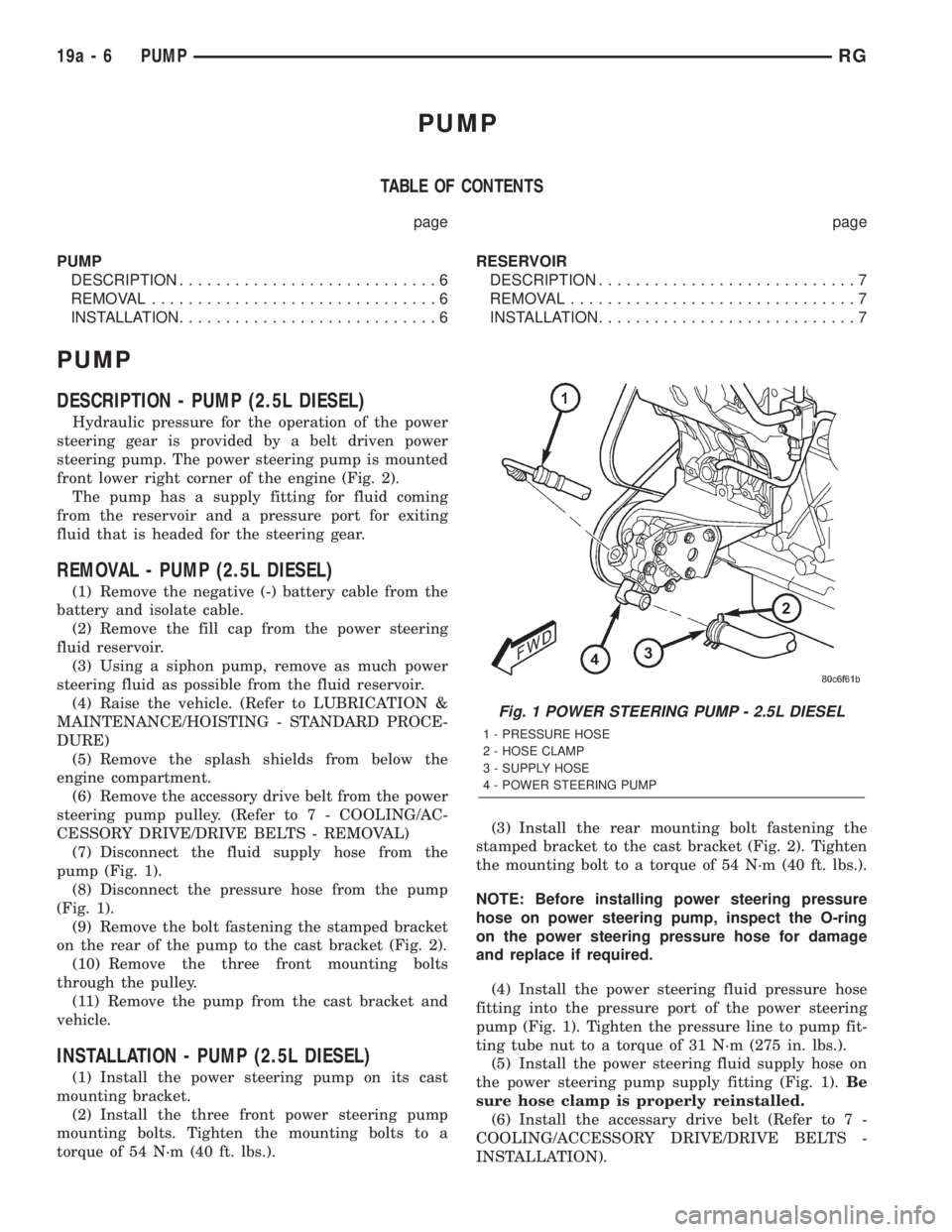

FLUID

STANDARD PROCEDURE - POWER STEERING

FLUID LEVEL CHECKING

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT INJURY

FROM MOVING PARTS.

The fluid level can be read on the exterior of the

power steering fluid reservoir. The fluid level should

be within the ªFILL RANGEº when the fluid is at

normal ambient temperature, approximately 21ÉC to

27ÉC (70ÉF to 80ÉF) (Fig. 15).

Before removing the power steering filler cap, wipe

the reservoir filler cap free of dirt and debris. Do not

overfill the power steering system. Use onlyMopart

Power Steering Fluid (MS-5931)or quivalent.

FLUID COOLER

DESCRIPTION

All models of this vehicle are equipped with a

cooler for the power steering system fluid. The power

steering fluid cooler is located on the front suspen-

sion cradle crossmember reinforcement (Fig. 16).

There are two different size coolers offered depending

on options. There is a standard 6-inch and an 8-inch

for vehicles equipped with the heavy duty cooling

package.

OPERATION

The purpose of the power steering fluid cooler is to

keep the temperature of the power steering system

fluid from rising to a level that would affect the per-

formance of the power steering system.

Installer C-4063B

Puller C-4333

Fig. 15 POWER STEERING FLUID RESERVOIR

19 - 30 PUMPRS

PUMP (Continued)

Page 2962 of 4284

PUMP

TABLE OF CONTENTS

page page

PUMP

DESCRIPTION............................6

REMOVAL...............................6

INSTALLATION............................6RESERVOIR

DESCRIPTION............................7

REMOVAL...............................7

INSTALLATION............................7

PUMP

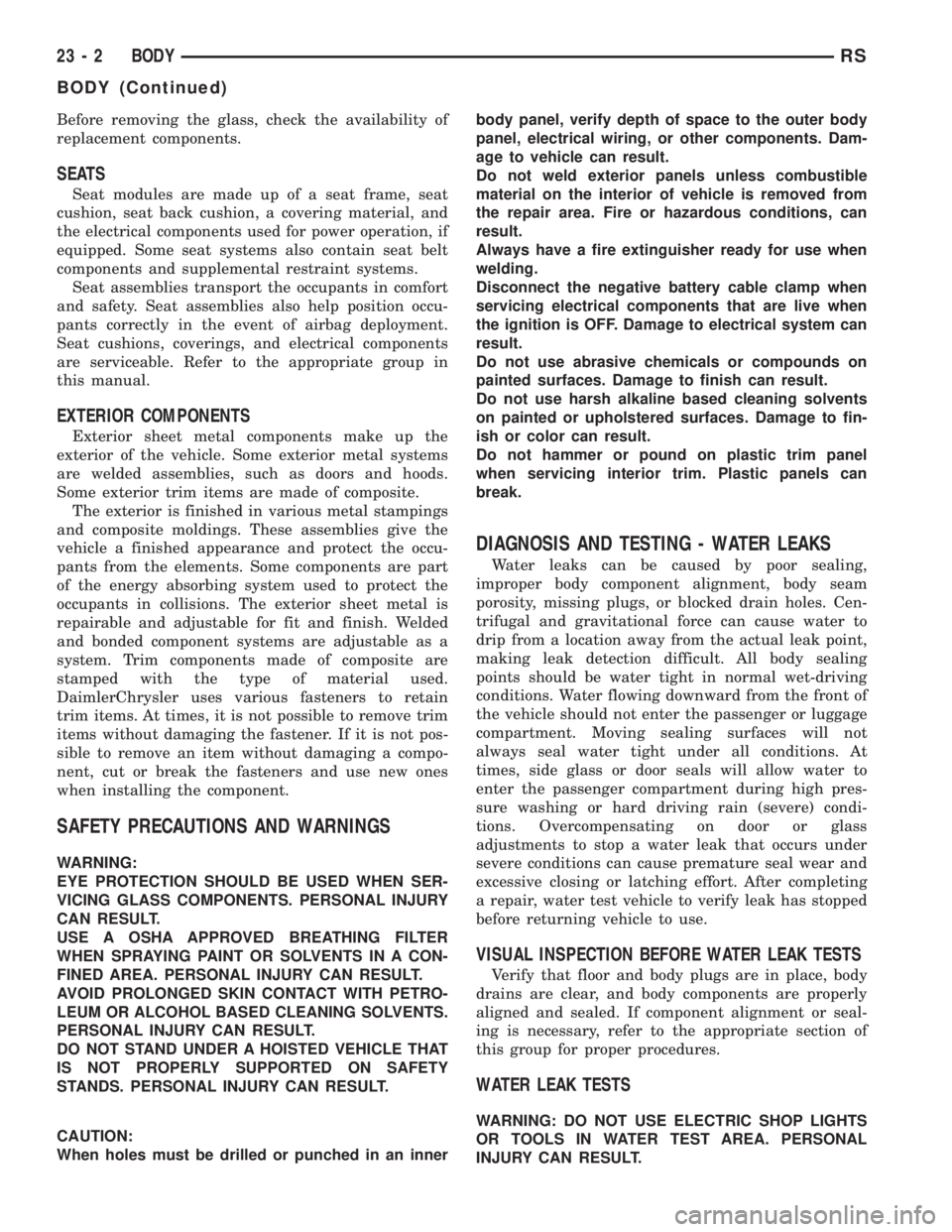

DESCRIPTION - PUMP (2.5L DIESEL)

Hydraulic pressure for the operation of the power

steering gear is provided by a belt driven power

steering pump. The power steering pump is mounted

front lower right corner of the engine (Fig. 2).

The pump has a supply fitting for fluid coming

from the reservoir and a pressure port for exiting

fluid that is headed for the steering gear.

REMOVAL - PUMP (2.5L DIESEL)

(1) Remove the negative (-) battery cable from the

battery and isolate cable.

(2) Remove the fill cap from the power steering

fluid reservoir.

(3) Using a siphon pump, remove as much power

steering fluid as possible from the fluid reservoir.

(4) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(5) Remove the splash shields from below the

engine compartment.

(6) Remove the accessory drive belt from the power

steering pump pulley. (Refer to 7 - COOLING/AC-

CESSORY DRIVE/DRIVE BELTS - REMOVAL)

(7) Disconnect the fluid supply hose from the

pump (Fig. 1).

(8) Disconnect the pressure hose from the pump

(Fig. 1).

(9) Remove the bolt fastening the stamped bracket

on the rear of the pump to the cast bracket (Fig. 2).

(10) Remove the three front mounting bolts

through the pulley.

(11) Remove the pump from the cast bracket and

vehicle.

INSTALLATION - PUMP (2.5L DIESEL)

(1) Install the power steering pump on its cast

mounting bracket.

(2) Install the three front power steering pump

mounting bolts. Tighten the mounting bolts to a

torque of 54 N´m (40 ft. lbs.).(3) Install the rear mounting bolt fastening the

stamped bracket to the cast bracket (Fig. 2). Tighten

the mounting bolt to a torque of 54 N´m (40 ft. lbs.).

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

(4) Install the power steering fluid pressure hose

fitting into the pressure port of the power steering

pump (Fig. 1). Tighten the pressure line to pump fit-

ting tube nut to a torque of 31 N´m (275 in. lbs.).

(5) Install the power steering fluid supply hose on

the power steering pump supply fitting (Fig. 1).Be

sure hose clamp is properly reinstalled.

(6) Install the accessary drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

Fig. 1 POWER STEERING PUMP - 2.5L DIESEL

1 - PRESSURE HOSE

2 - HOSE CLAMP

3 - SUPPLY HOSE

4 - POWER STEERING PUMP

19a - 6 PUMPRG

Page 3382 of 4284

Before removing the glass, check the availability of

replacement components.

SEATS

Seat modules are made up of a seat frame, seat

cushion, seat back cushion, a covering material, and

the electrical components used for power operation, if

equipped. Some seat systems also contain seat belt

components and supplemental restraint systems.

Seat assemblies transport the occupants in comfort

and safety. Seat assemblies also help position occu-

pants correctly in the event of airbag deployment.

Seat cushions, coverings, and electrical components

are serviceable. Refer to the appropriate group in

this manual.

EXTERIOR COMPONENTS

Exterior sheet metal components make up the

exterior of the vehicle. Some exterior metal systems

are welded assemblies, such as doors and hoods.

Some exterior trim items are made of composite.

The exterior is finished in various metal stampings

and composite moldings. These assemblies give the

vehicle a finished appearance and protect the occu-

pants from the elements. Some components are part

of the energy absorbing system used to protect the

occupants in collisions. The exterior sheet metal is

repairable and adjustable for fit and finish. Welded

and bonded component systems are adjustable as a

system. Trim components made of composite are

stamped with the type of material used.

DaimlerChrysler uses various fasteners to retain

trim items. At times, it is not possible to remove trim

items without damaging the fastener. If it is not pos-

sible to remove an item without damaging a compo-

nent, cut or break the fasteners and use new ones

when installing the component.

SAFETY PRECAUTIONS AND WARNINGS

WARNING:

EYE PROTECTION SHOULD BE USED WHEN SER-

VICING GLASS COMPONENTS. PERSONAL INJURY

CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL BASED CLEANING SOLVENTS.

PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THAT

IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION:

When holes must be drilled or punched in an innerbody panel, verify depth of space to the outer body

panel, electrical wiring, or other components. Dam-

age to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative battery cable clamp when

servicing electrical components that are live when

the ignition is OFF. Damage to electrical system can

result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

23 - 2 BODYRS

BODY (Continued)

Page 3419 of 4284

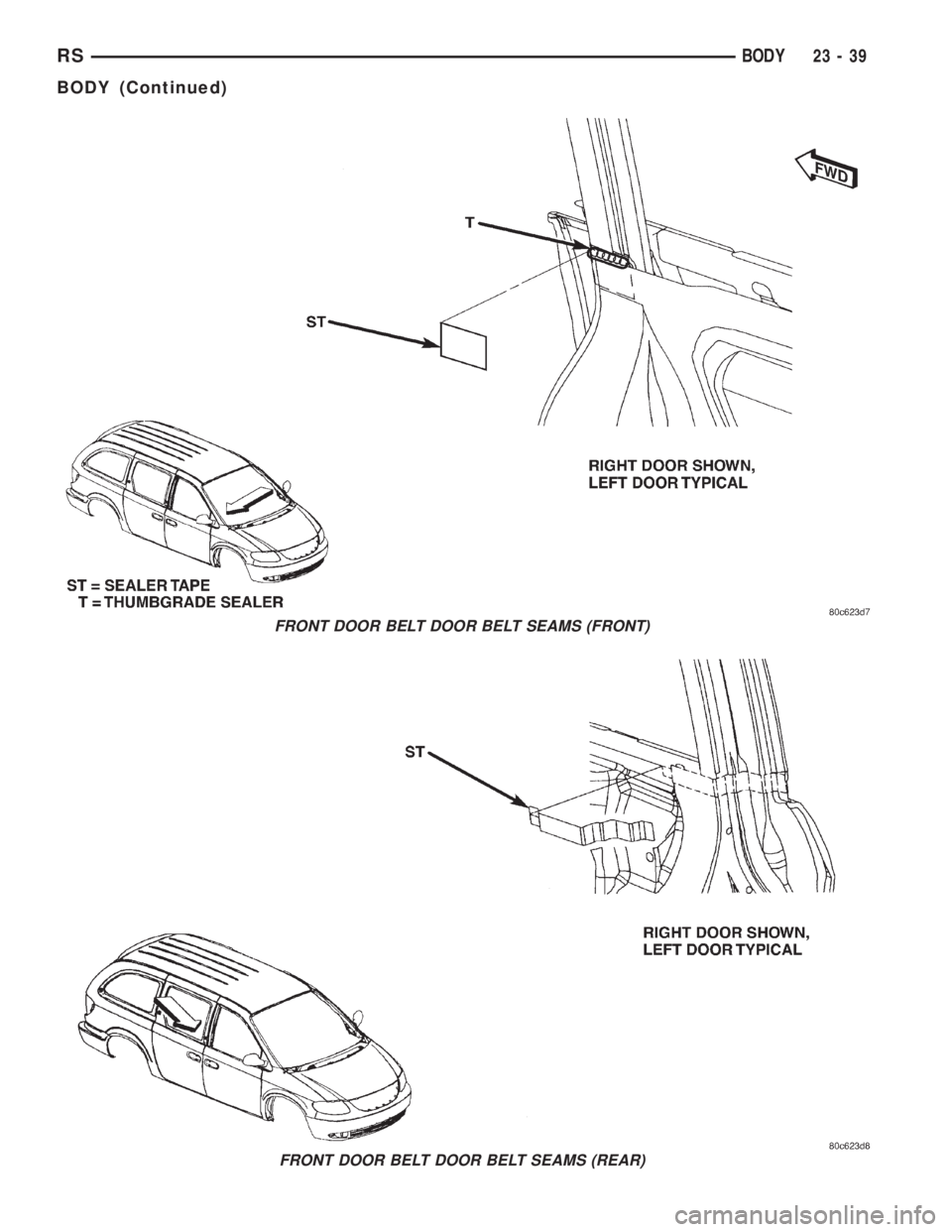

FRONT DOOR BELT DOOR BELT SEAMS (FRONT)

FRONT DOOR BELT DOOR BELT SEAMS (REAR)

RSBODY23-39

BODY (Continued)

Page 3484 of 4284

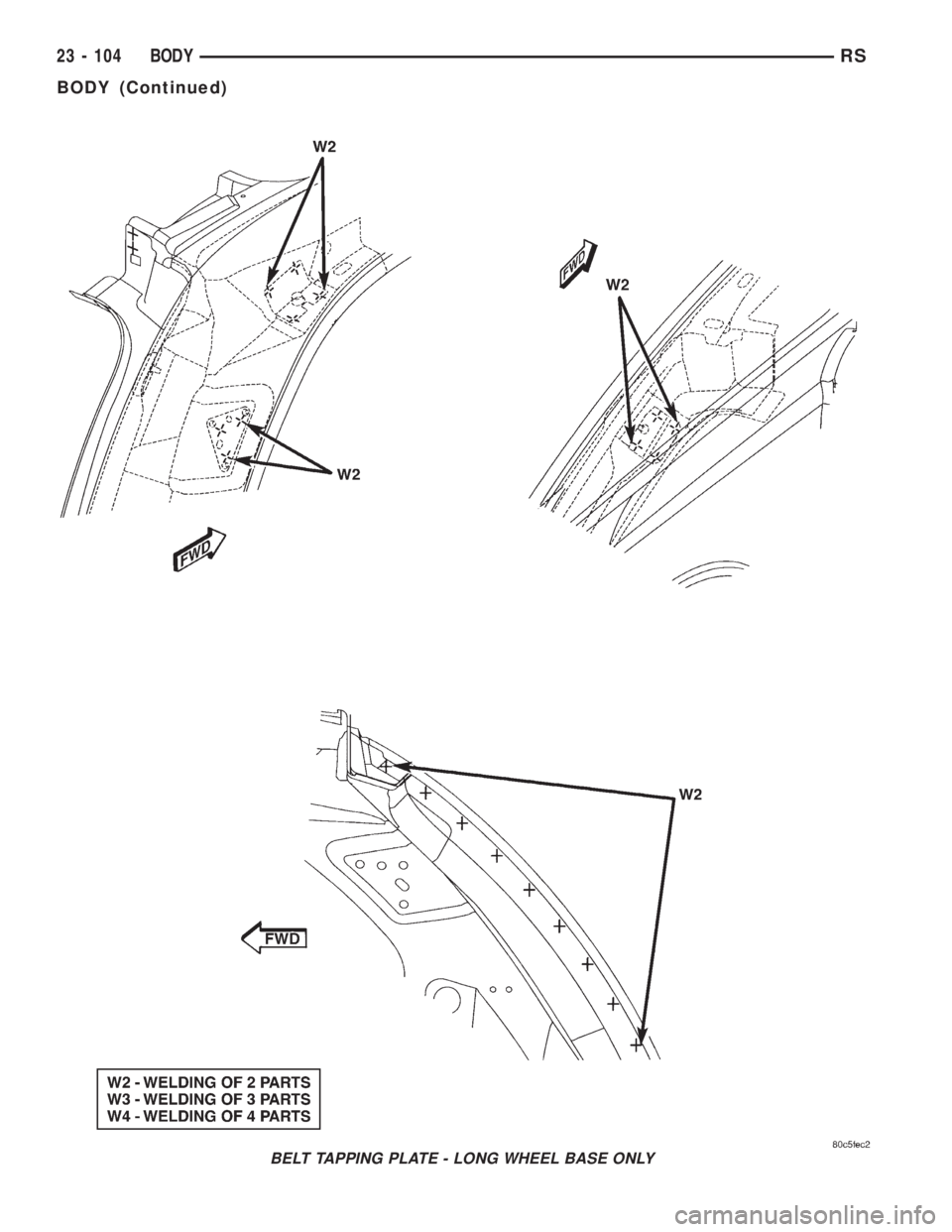

BELT TAPPING PLATE - LONG WHEEL BASE ONLY

23 - 104 BODYRS

BODY (Continued)

Page 3529 of 4284

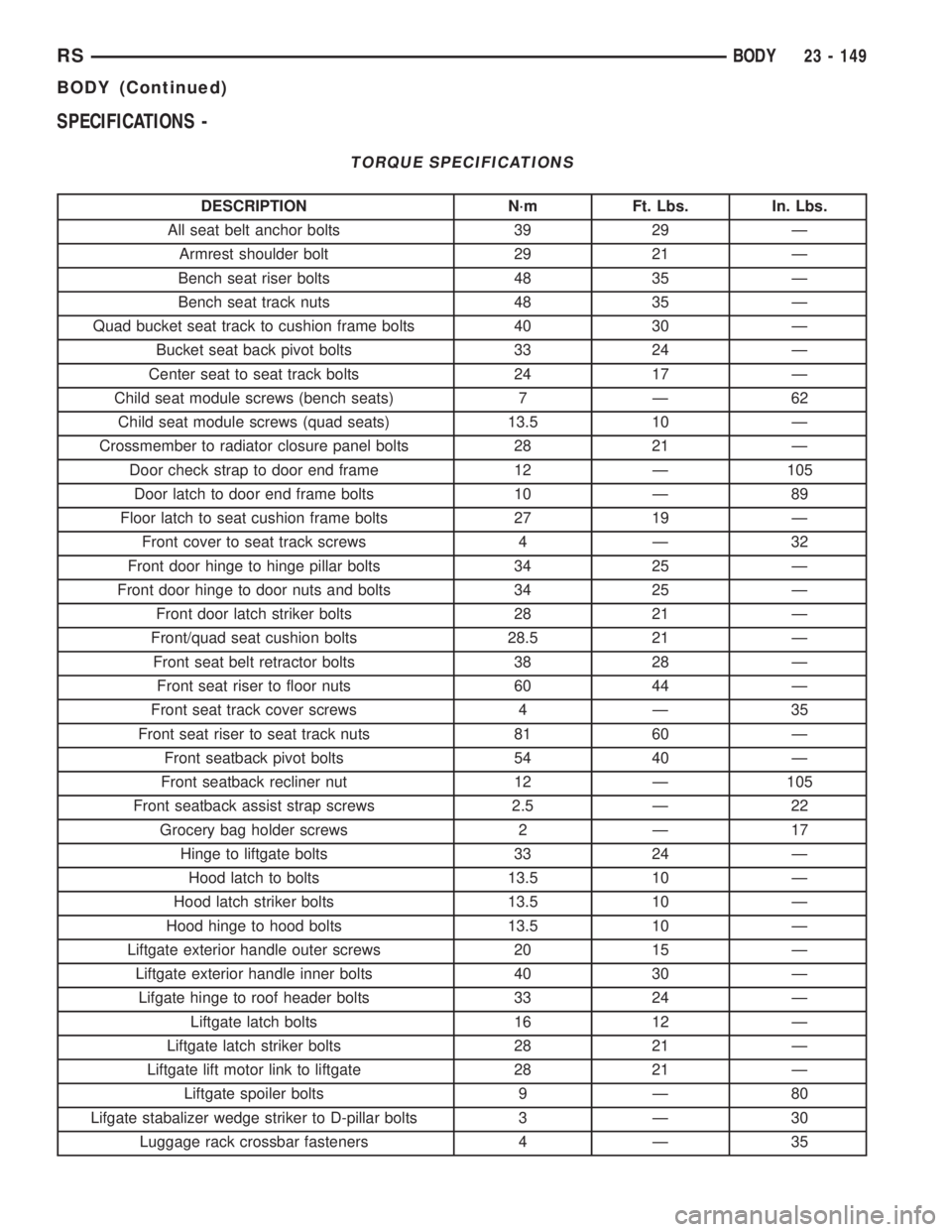

SPECIFICATIONS -

TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

All seat belt anchor bolts 39 29 Ð

Armrest shoulder bolt 29 21 Ð

Bench seat riser bolts 48 35 Ð

Bench seat track nuts 48 35 Ð

Quad bucket seat track to cushion frame bolts 40 30 Ð

Bucket seat back pivot bolts 33 24 Ð

Center seat to seat track bolts 24 17 Ð

Child seat module screws (bench seats) 7 Ð 62

Child seat module screws (quad seats) 13.5 10 Ð

Crossmember to radiator closure panel bolts 28 21 Ð

Door check strap to door end frame 12 Ð 105

Door latch to door end frame bolts 10 Ð 89

Floor latch to seat cushion frame bolts 27 19 Ð

Front cover to seat track screws 4 Ð 32

Front door hinge to hinge pillar bolts 34 25 Ð

Front door hinge to door nuts and bolts 34 25 Ð

Front door latch striker bolts 28 21 Ð

Front/quad seat cushion bolts 28.5 21 Ð

Front seat belt retractor bolts 38 28 Ð

Front seat riser to floor nuts 60 44 Ð

Front seat track cover screws 4 Ð 35

Front seat riser to seat track nuts 81 60 Ð

Front seatback pivot bolts 54 40 Ð

Front seatback recliner nut 12 Ð 105

Front seatback assist strap screws 2.5 Ð 22

Grocery bag holder screws 2 Ð 17

Hinge to liftgate bolts 33 24 Ð

Hood latch to bolts 13.5 10 Ð

Hood latch striker bolts 13.5 10 Ð

Hood hinge to hood bolts 13.5 10 Ð

Liftgate exterior handle outer screws 20 15 Ð

Liftgate exterior handle inner bolts 40 30 Ð

Lifgate hinge to roof header bolts 33 24 Ð

Liftgate latch bolts 16 12 Ð

Liftgate latch striker bolts 28 21 Ð

Liftgate lift motor link to liftgate 28 21 Ð

Liftgate spoiler bolts 9 Ð 80

Lifgate stabalizer wedge striker to D-pillar bolts 3 Ð 30

Luggage rack crossbar fasteners 4 Ð 35

RSBODY23 - 149

BODY (Continued)

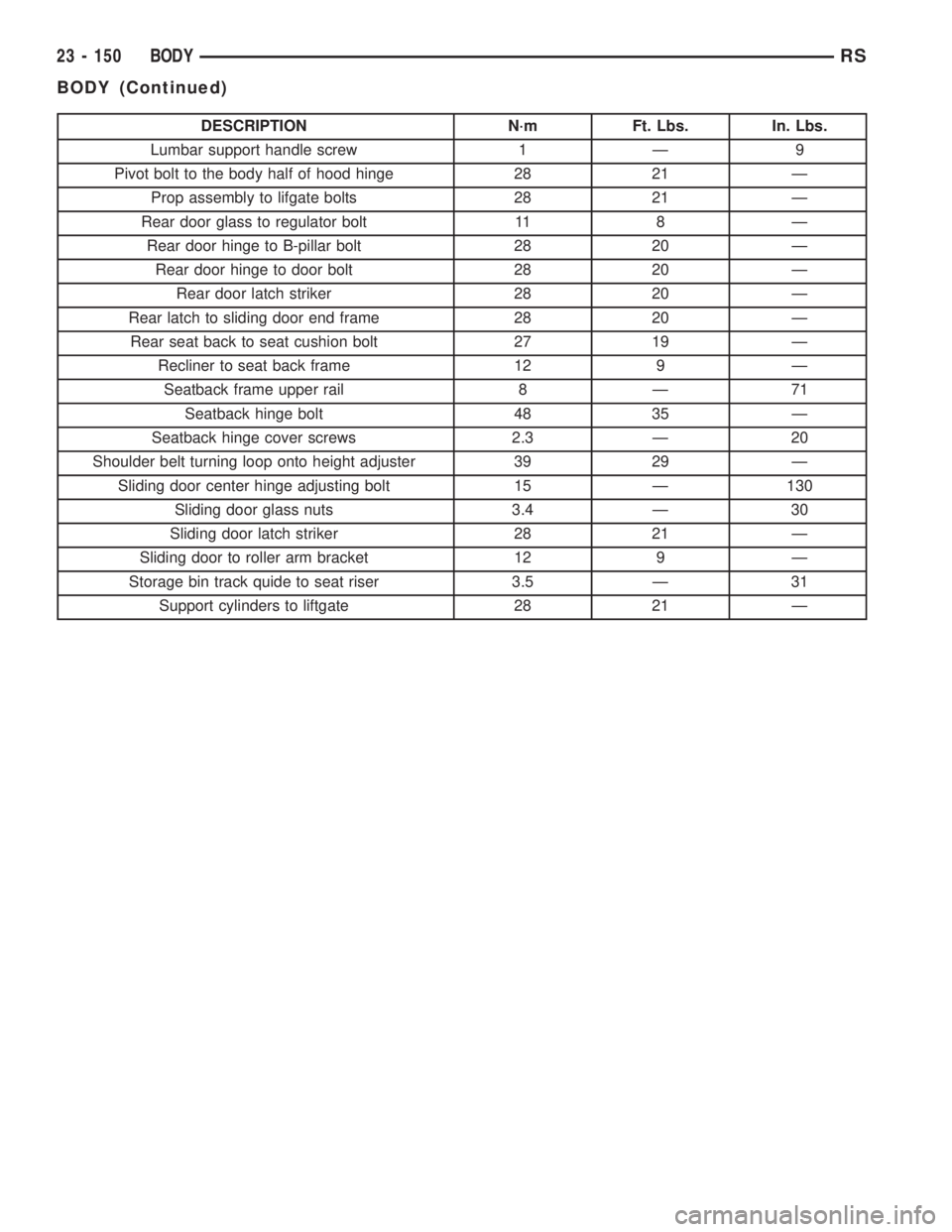

Page 3530 of 4284

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Lumbar support handle screw 1 Ð 9

Pivot bolt to the body half of hood hinge 28 21 Ð

Prop assembly to lifgate bolts 28 21 Ð

Rear door glass to regulator bolt 11 8 Ð

Rear door hinge to B-pillar bolt 28 20 Ð

Rear door hinge to door bolt 28 20 Ð

Rear door latch striker 28 20 Ð

Rear latch to sliding door end frame 28 20 Ð

Rear seat back to seat cushion bolt 27 19 Ð

Recliner to seat back frame 12 9 Ð

Seatback frame upper rail 8 Ð 71

Seatback hinge bolt 48 35 Ð

Seatback hinge cover screws 2.3 Ð 20

Shoulder belt turning loop onto height adjuster 39 29 Ð

Sliding door center hinge adjusting bolt 15 Ð 130

Sliding door glass nuts 3.4 Ð 30

Sliding door latch striker 28 21 Ð

Sliding door to roller arm bracket 12 9 Ð

Storage bin track quide to seat riser 3.5 Ð 31

Support cylinders to liftgate 28 21 Ð

23 - 150 BODYRS

BODY (Continued)

Page 3532 of 4284

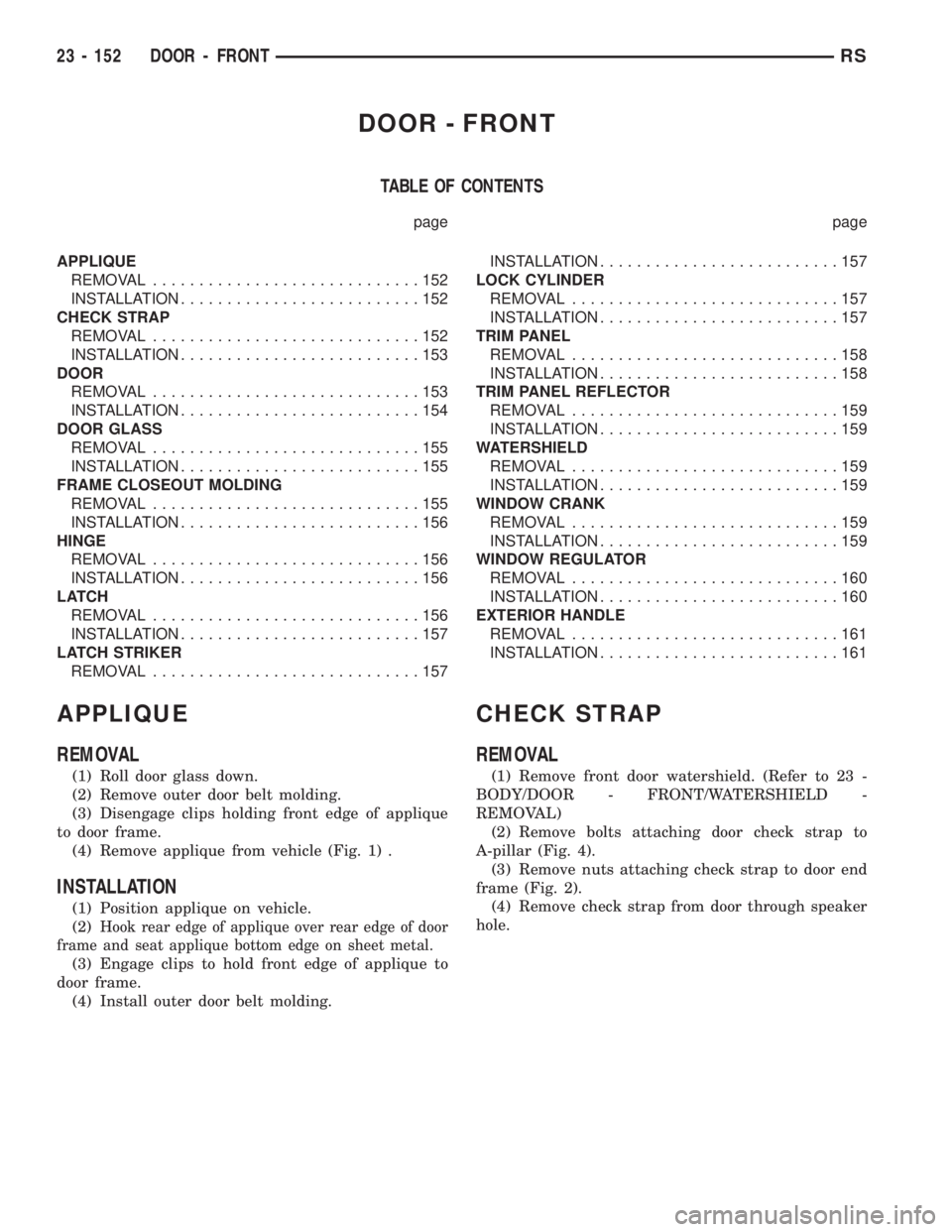

DOOR - FRONT

TABLE OF CONTENTS

page page

APPLIQUE

REMOVAL.............................152

INSTALLATION..........................152

CHECK STRAP

REMOVAL.............................152

INSTALLATION..........................153

DOOR

REMOVAL.............................153

INSTALLATION..........................154

DOOR GLASS

REMOVAL.............................155

INSTALLATION..........................155

FRAME CLOSEOUT MOLDING

REMOVAL.............................155

INSTALLATION..........................156

HINGE

REMOVAL.............................156

INSTALLATION..........................156

LATCH

REMOVAL.............................156

INSTALLATION..........................157

LATCH STRIKER

REMOVAL.............................157INSTALLATION..........................157

LOCK CYLINDER

REMOVAL.............................157

INSTALLATION..........................157

TRIM PANEL

REMOVAL.............................158

INSTALLATION..........................158

TRIM PANEL REFLECTOR

REMOVAL.............................159

INSTALLATION..........................159

WATERSHIELD

REMOVAL.............................159

INSTALLATION..........................159

WINDOW CRANK

REMOVAL.............................159

INSTALLATION..........................159

WINDOW REGULATOR

REMOVAL.............................160

INSTALLATION..........................160

EXTERIOR HANDLE

REMOVAL.............................161

INSTALLATION..........................161

APPLIQUE

REMOVAL

(1) Roll door glass down.

(2) Remove outer door belt molding.

(3) Disengage clips holding front edge of applique

to door frame.

(4) Remove applique from vehicle (Fig. 1) .

INSTALLATION

(1) Position applique on vehicle.

(2)

Hook rear edge of applique over rear edge of door

frame and seat applique bottom edge on sheet metal.

(3) Engage clips to hold front edge of applique to

door frame.

(4) Install outer door belt molding.

CHECK STRAP

REMOVAL

(1) Remove front door watershield. (Refer to 23 -

BODY/DOOR - FRONT/WATERSHIELD -

REMOVAL)

(2) Remove bolts attaching door check strap to

A-pillar (Fig. 4).

(3) Remove nuts attaching check strap to door end

frame (Fig. 2).

(4) Remove check strap from door through speaker

hole.

23 - 152 DOOR - FRONTRS

Page 3535 of 4284

DOOR GLASS

REMOVAL

(1) Remove watershield. (Refer to 23 - BODY/

DOOR - FRONT/WATERSHIELD - REMOVAL)

(2) Remove inner belt molding.(Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR INNER BELT

WEATHERSTRIP - REMOVAL)

(3) Remove outer belt molding.(Refer to 23 -

BODY/WEATHERSTRIP/SEALS/FDR OUTER BELT

MOLDING - REMOVAL)

(4) Position glass to gain access to front and rear

regulator lift plates through front and rear access

holes in door panel.

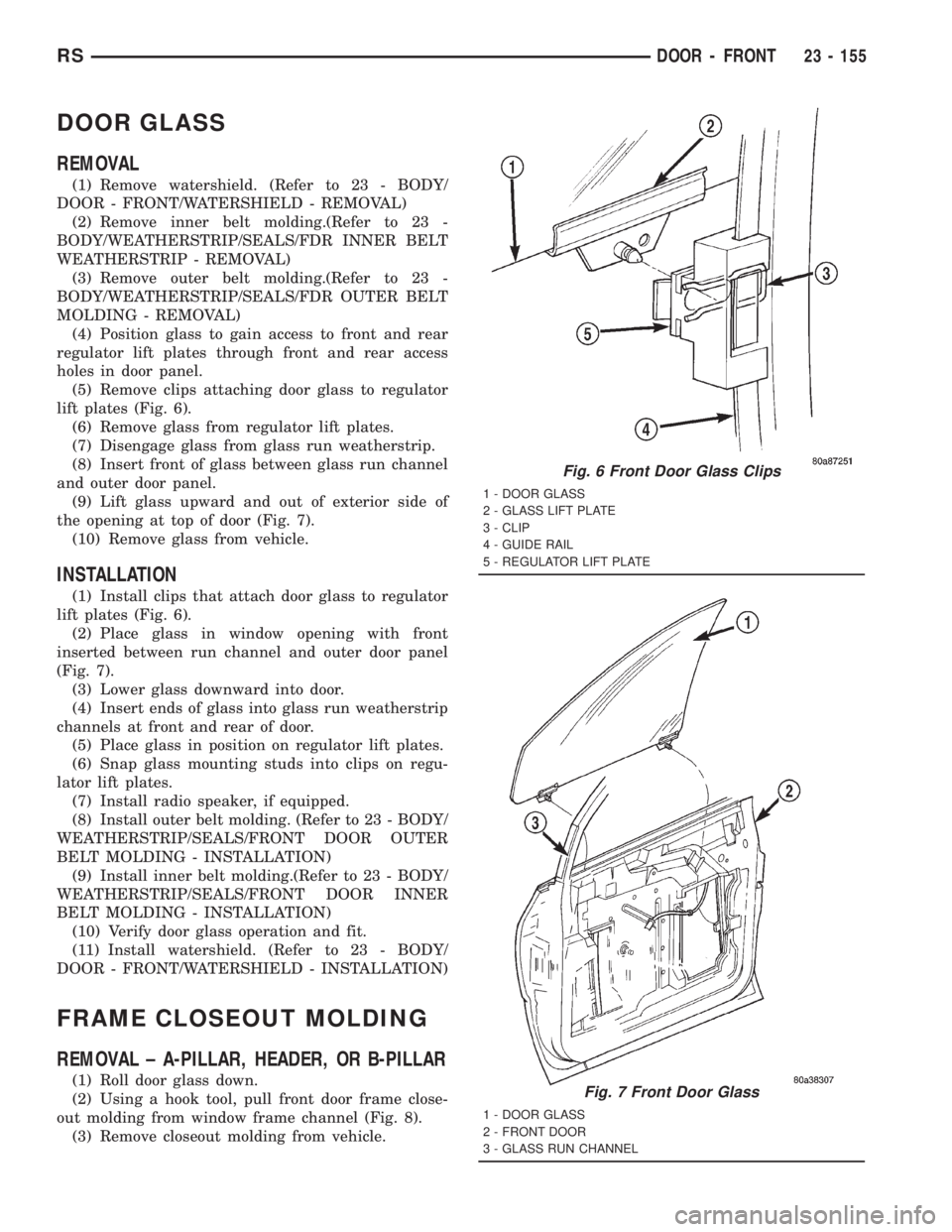

(5) Remove clips attaching door glass to regulator

lift plates (Fig. 6).

(6) Remove glass from regulator lift plates.

(7) Disengage glass from glass run weatherstrip.

(8) Insert front of glass between glass run channel

and outer door panel.

(9) Lift glass upward and out of exterior side of

the opening at top of door (Fig. 7).

(10) Remove glass from vehicle.

INSTALLATION

(1) Install clips that attach door glass to regulator

lift plates (Fig. 6).

(2) Place glass in window opening with front

inserted between run channel and outer door panel

(Fig. 7).

(3) Lower glass downward into door.

(4) Insert ends of glass into glass run weatherstrip

channels at front and rear of door.

(5) Place glass in position on regulator lift plates.

(6) Snap glass mounting studs into clips on regu-

lator lift plates.

(7) Install radio speaker, if equipped.

(8) Install outer belt molding. (Refer to 23 - BODY/

WEATHERSTRIP/SEALS/FRONT DOOR OUTER

BELT MOLDING - INSTALLATION)

(9) Install inner belt molding.(Refer to 23 - BODY/

WEATHERSTRIP/SEALS/FRONT DOOR INNER

BELT MOLDING - INSTALLATION)

(10) Verify door glass operation and fit.

(11) Install watershield. (Refer to 23 - BODY/

DOOR - FRONT/WATERSHIELD - INSTALLATION)

FRAME CLOSEOUT MOLDING

REMOVAL ± A-PILLAR, HEADER, OR B-PILLAR

(1) Roll door glass down.

(2) Using a hook tool, pull front door frame close-

out molding from window frame channel (Fig. 8).

(3) Remove closeout molding from vehicle.

Fig. 6 Front Door Glass Clips

1 - DOOR GLASS

2 - GLASS LIFT PLATE

3 - CLIP

4 - GUIDE RAIL

5 - REGULATOR LIFT PLATE

Fig. 7 Front Door Glass

1 - DOOR GLASS

2 - FRONT DOOR

3 - GLASS RUN CHANNEL

RSDOOR - FRONT23 - 155

Page 3538 of 4284

(9) Verify door latch operation.

(10) Install watershield and door trim panel.

TRIM PANEL

REMOVAL

(1) Remove the plug and remove screw attaching

door pull cup to inner door panel.

(2) Remove screws attaching trim panel to door

from below map pocket.

(3) If equipped, remove window crank. (Refer to 23

- BODY/DOOR - FRONT/WINDOW CRANK -

REMOVAL)(4) Remove screw holding door trim to door panel

from behind inside latch release handle .

(5) Disengage clips attaching door trim to door

frame around perimeter of panel.

(6) Lift trim panel upward to disengage flange

from inner belt molding at top of door.

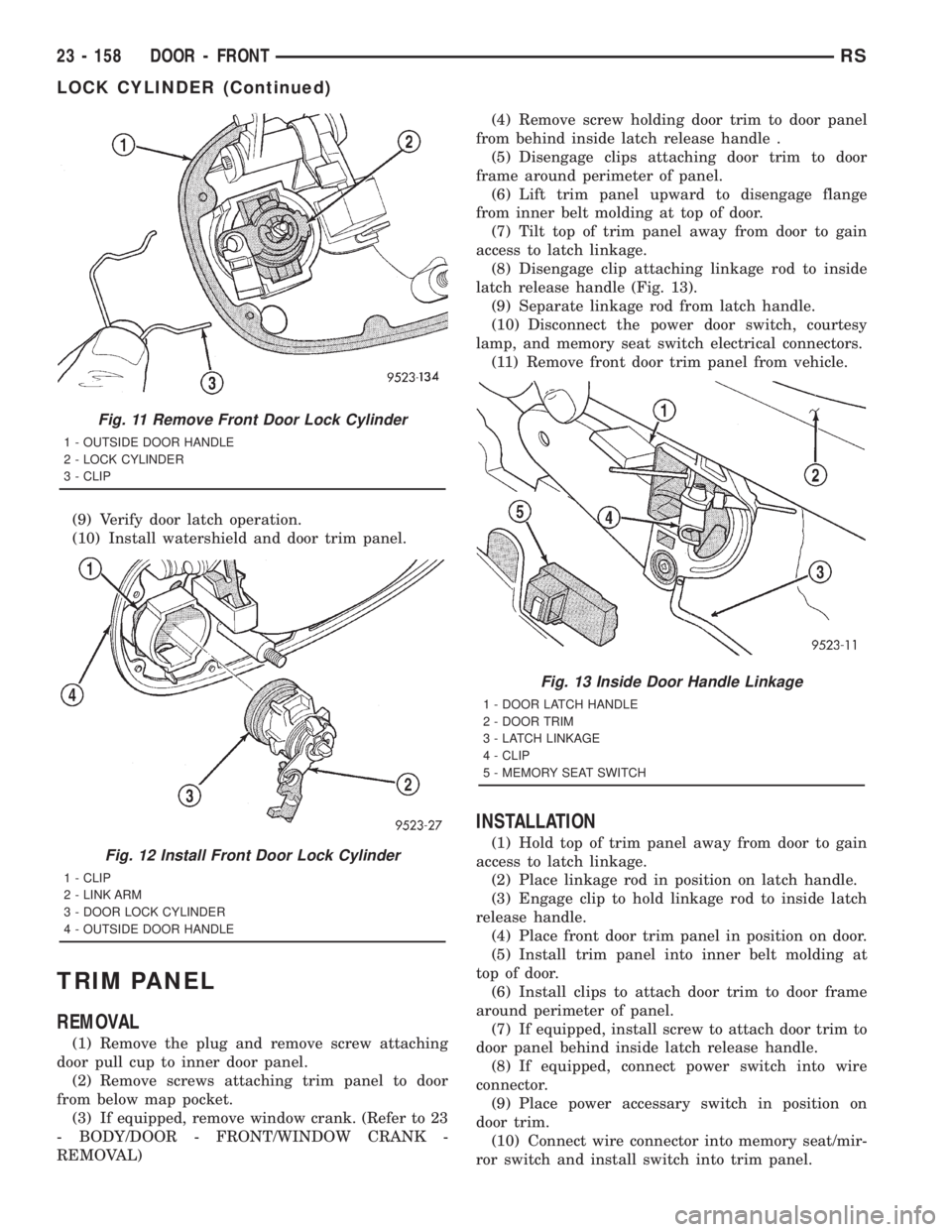

(7) Tilt top of trim panel away from door to gain

access to latch linkage.

(8) Disengage clip attaching linkage rod to inside

latch release handle (Fig. 13).

(9) Separate linkage rod from latch handle.

(10) Disconnect the power door switch, courtesy

lamp, and memory seat switch electrical connectors.

(11) Remove front door trim panel from vehicle.

INSTALLATION

(1) Hold top of trim panel away from door to gain

access to latch linkage.

(2) Place linkage rod in position on latch handle.

(3) Engage clip to hold linkage rod to inside latch

release handle.

(4) Place front door trim panel in position on door.

(5) Install trim panel into inner belt molding at

top of door.

(6) Install clips to attach door trim to door frame

around perimeter of panel.

(7) If equipped, install screw to attach door trim to

door panel behind inside latch release handle.

(8) If equipped, connect power switch into wire

connector.

(9) Place power accessary switch in position on

door trim.

(10) Connect wire connector into memory seat/mir-

ror switch and install switch into trim panel.

Fig. 11 Remove Front Door Lock Cylinder

1 - OUTSIDE DOOR HANDLE

2 - LOCK CYLINDER

3 - CLIP

Fig. 12 Install Front Door Lock Cylinder

1 - CLIP

2 - LINK ARM

3 - DOOR LOCK CYLINDER

4 - OUTSIDE DOOR HANDLE

Fig. 13 Inside Door Handle Linkage

1 - DOOR LATCH HANDLE

2 - DOOR TRIM

3 - LATCH LINKAGE

4 - CLIP

5 - MEMORY SEAT SWITCH

23 - 158 DOOR - FRONTRS

LOCK CYLINDER (Continued)