belt CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2920 of 4284

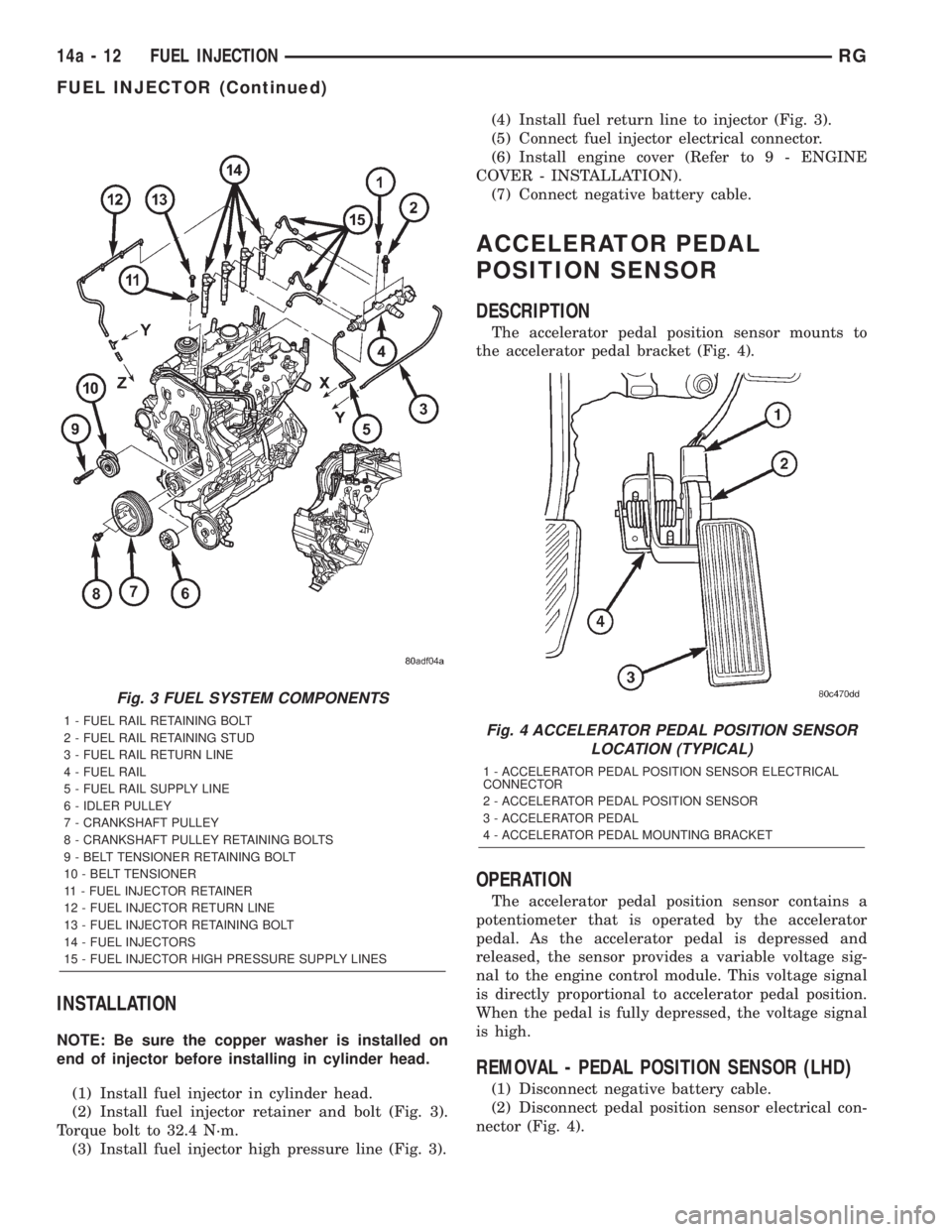

INSTALLATION

NOTE: Be sure the copper washer is installed on

end of injector before installing in cylinder head.

(1) Install fuel injector in cylinder head.

(2) Install fuel injector retainer and bolt (Fig. 3).

Torque bolt to 32.4 N´m.

(3) Install fuel injector high pressure line (Fig. 3).(4) Install fuel return line to injector (Fig. 3).

(5) Connect fuel injector electrical connector.

(6) Install engine cover (Refer to 9 - ENGINE

COVER - INSTALLATION).

(7) Connect negative battery cable.

ACCELERATOR PEDAL

POSITION SENSOR

DESCRIPTION

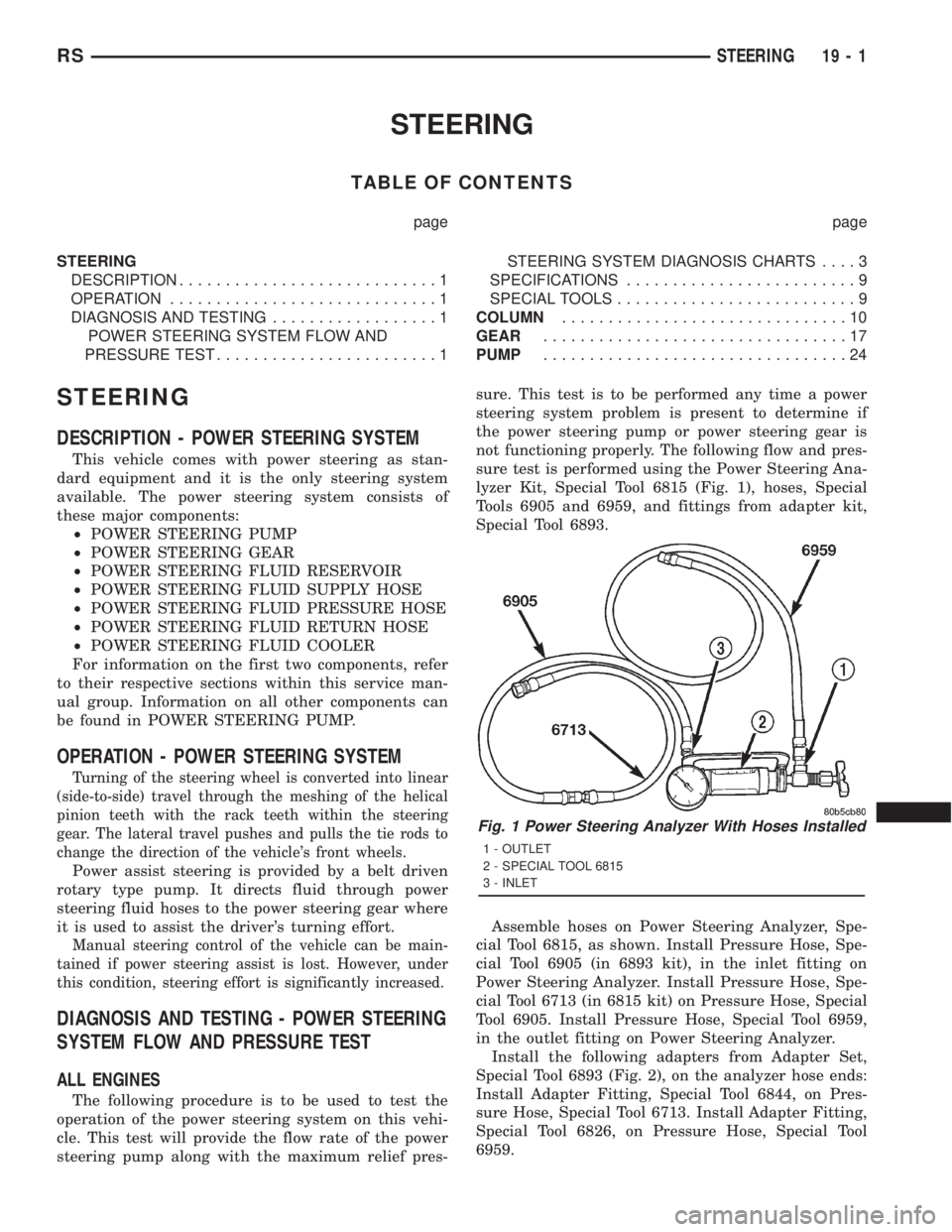

The accelerator pedal position sensor mounts to

the accelerator pedal bracket (Fig. 4).

OPERATION

The accelerator pedal position sensor contains a

potentiometer that is operated by the accelerator

pedal. As the accelerator pedal is depressed and

released, the sensor provides a variable voltage sig-

nal to the engine control module. This voltage signal

is directly proportional to accelerator pedal position.

When the pedal is fully depressed, the voltage signal

is high.

REMOVAL - PEDAL POSITION SENSOR (LHD)

(1) Disconnect negative battery cable.

(2) Disconnect pedal position sensor electrical con-

nector (Fig. 4).

Fig. 3 FUEL SYSTEM COMPONENTS

1 - FUEL RAIL RETAINING BOLT

2 - FUEL RAIL RETAINING STUD

3 - FUEL RAIL RETURN LINE

4 - FUEL RAIL

5 - FUEL RAIL SUPPLY LINE

6 - IDLER PULLEY

7 - CRANKSHAFT PULLEY

8 - CRANKSHAFT PULLEY RETAINING BOLTS

9 - BELT TENSIONER RETAINING BOLT

10 - BELT TENSIONER

11 - FUEL INJECTOR RETAINER

12 - FUEL INJECTOR RETURN LINE

13 - FUEL INJECTOR RETAINING BOLT

14 - FUEL INJECTORS

15 - FUEL INJECTOR HIGH PRESSURE SUPPLY LINESFig. 4 ACCELERATOR PEDAL POSITION SENSOR

LOCATION (TYPICAL)

1 - ACCELERATOR PEDAL POSITION SENSOR ELECTRICAL

CONNECTOR

2 - ACCELERATOR PEDAL POSITION SENSOR

3 - ACCELERATOR PEDAL

4 - ACCELERATOR PEDAL MOUNTING BRACKET

14a - 12 FUEL INJECTIONRG

FUEL INJECTOR (Continued)

Page 2925 of 4284

STEERING

TABLE OF CONTENTS

page page

STEERING

DESCRIPTION............................1

OPERATION.............................1

DIAGNOSIS AND TESTING..................1

POWER STEERING SYSTEM FLOW AND

PRESSURE TEST........................1STEERING SYSTEM DIAGNOSIS CHARTS....3

SPECIFICATIONS.........................9

SPECIAL TOOLS..........................9

COLUMN...............................10

GEAR.................................17

PUMP.................................24

STEERING

DESCRIPTION - POWER STEERING SYSTEM

This vehicle comes with power steering as stan-

dard equipment and it is the only steering system

available. The power steering system consists of

these major components:

²POWER STEERING PUMP

²POWER STEERING GEAR

²POWER STEERING FLUID RESERVOIR

²POWER STEERING FLUID SUPPLY HOSE

²POWER STEERING FLUID PRESSURE HOSE

²POWER STEERING FLUID RETURN HOSE

²POWER STEERING FLUID COOLER

For information on the first two components, refer

to their respective sections within this service man-

ual group. Information on all other components can

be found in POWER STEERING PUMP.

OPERATION - POWER STEERING SYSTEM

Turning of the steering wheel is converted into linear

(side-to-side) travel through the meshing of the helical

pinion teeth with the rack teeth within the steering

gear. The lateral travel pushes and pulls the tie rods to

change the direction of the vehicle's front wheels.

Power assist steering is provided by a belt driven

rotary type pump. It directs fluid through power

steering fluid hoses to the power steering gear where

it is used to assist the driver's turning effort.

Manual steering control of the vehicle can be main-

tained if power steering assist is lost. However, under

this condition, steering effort is significantly increased.

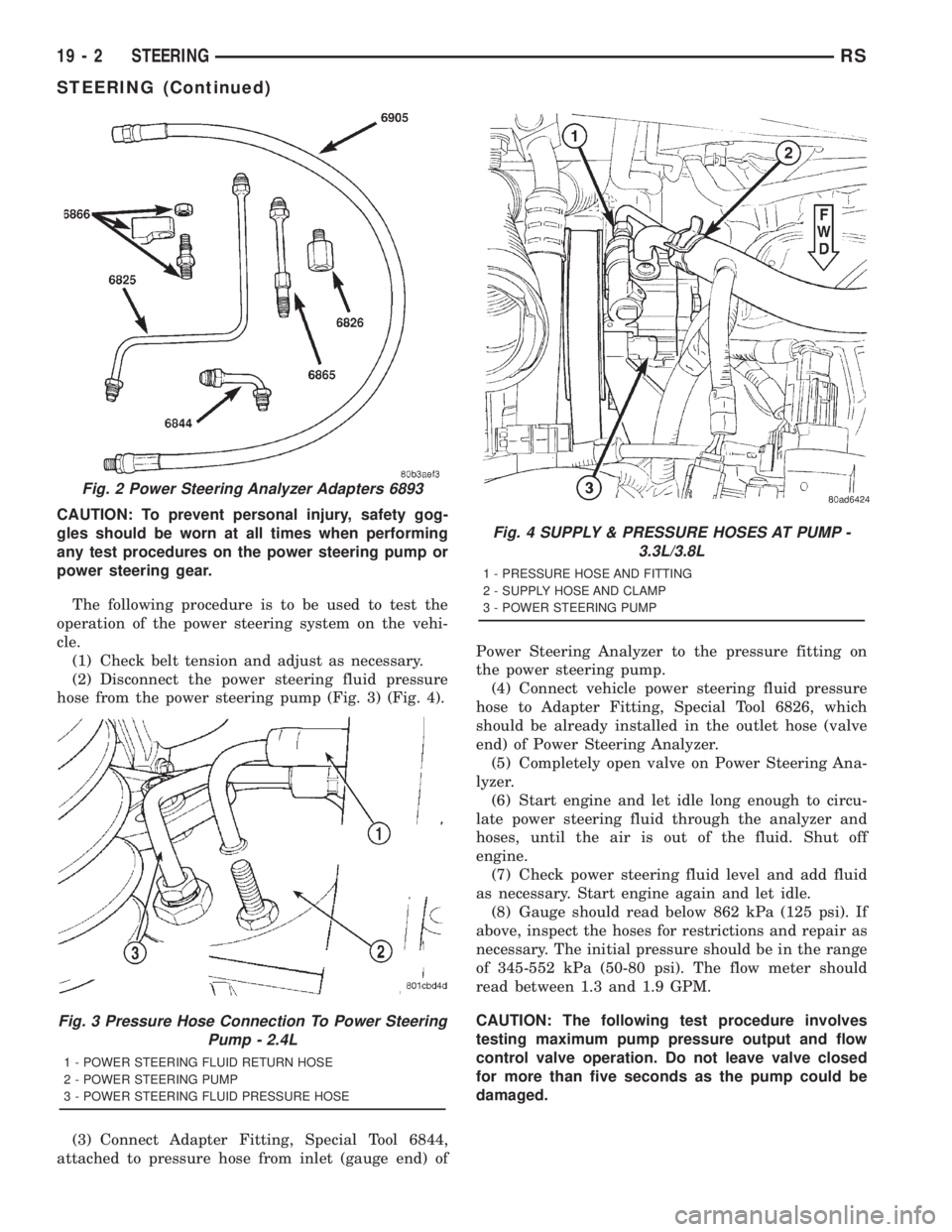

DIAGNOSIS AND TESTING - POWER STEERING

SYSTEM FLOW AND PRESSURE TEST

ALL ENGINES

The following procedure is to be used to test the

operation of the power steering system on this vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-sure. This test is to be performed any time a power

steering system problem is present to determine if

the power steering pump or power steering gear is

not functioning properly. The following flow and pres-

sure test is performed using the Power Steering Ana-

lyzer Kit, Special Tool 6815 (Fig. 1), hoses, Special

Tools 6905 and 6959, and fittings from adapter kit,

Special Tool 6893.

Assemble hoses on Power Steering Analyzer, Spe-

cial Tool 6815, as shown. Install Pressure Hose, Spe-

cial Tool 6905 (in 6893 kit), in the inlet fitting on

Power Steering Analyzer. Install Pressure Hose, Spe-

cial Tool 6713 (in 6815 kit) on Pressure Hose, Special

Tool 6905. Install Pressure Hose, Special Tool 6959,

in the outlet fitting on Power Steering Analyzer.

Install the following adapters from Adapter Set,

Special Tool 6893 (Fig. 2), on the analyzer hose ends:

Install Adapter Fitting, Special Tool 6844, on Pres-

sure Hose, Special Tool 6713. Install Adapter Fitting,

Special Tool 6826, on Pressure Hose, Special Tool

6959.

Fig. 1 Power Steering Analyzer With Hoses Installed

1 - OUTLET

2 - SPECIAL TOOL 6815

3 - INLET

RSSTEERING19-1

Page 2926 of 4284

CAUTION: To prevent personal injury, safety gog-

gles should be worn at all times when performing

any test procedures on the power steering pump or

power steering gear.

The following procedure is to be used to test the

operation of the power steering system on the vehi-

cle.

(1) Check belt tension and adjust as necessary.

(2) Disconnect the power steering fluid pressure

hose from the power steering pump (Fig. 3) (Fig. 4).

(3) Connect Adapter Fitting, Special Tool 6844,

attached to pressure hose from inlet (gauge end) ofPower Steering Analyzer to the pressure fitting on

the power steering pump.

(4) Connect vehicle power steering fluid pressure

hose to Adapter Fitting, Special Tool 6826, which

should be already installed in the outlet hose (valve

end) of Power Steering Analyzer.

(5) Completely open valve on Power Steering Ana-

lyzer.

(6) Start engine and let idle long enough to circu-

late power steering fluid through the analyzer and

hoses, until the air is out of the fluid. Shut off

engine.

(7) Check power steering fluid level and add fluid

as necessary. Start engine again and let idle.

(8) Gauge should read below 862 kPa (125 psi). If

above, inspect the hoses for restrictions and repair as

necessary. The initial pressure should be in the range

of 345-552 kPa (50-80 psi). The flow meter should

read between 1.3 and 1.9 GPM.

CAUTION: The following test procedure involves

testing maximum pump pressure output and flow

control valve operation. Do not leave valve closed

for more than five seconds as the pump could be

damaged.

Fig. 2 Power Steering Analyzer Adapters 6893

Fig. 3 Pressure Hose Connection To Power Steering

Pump - 2.4L

1 - POWER STEERING FLUID RETURN HOSE

2 - POWER STEERING PUMP

3 - POWER STEERING FLUID PRESSURE HOSE

Fig. 4 SUPPLY & PRESSURE HOSES AT PUMP -

3.3L/3.8L

1 - PRESSURE HOSE AND FITTING

2 - SUPPLY HOSE AND CLAMP

3 - POWER STEERING PUMP

19 - 2 STEERINGRS

STEERING (Continued)

Page 2928 of 4284

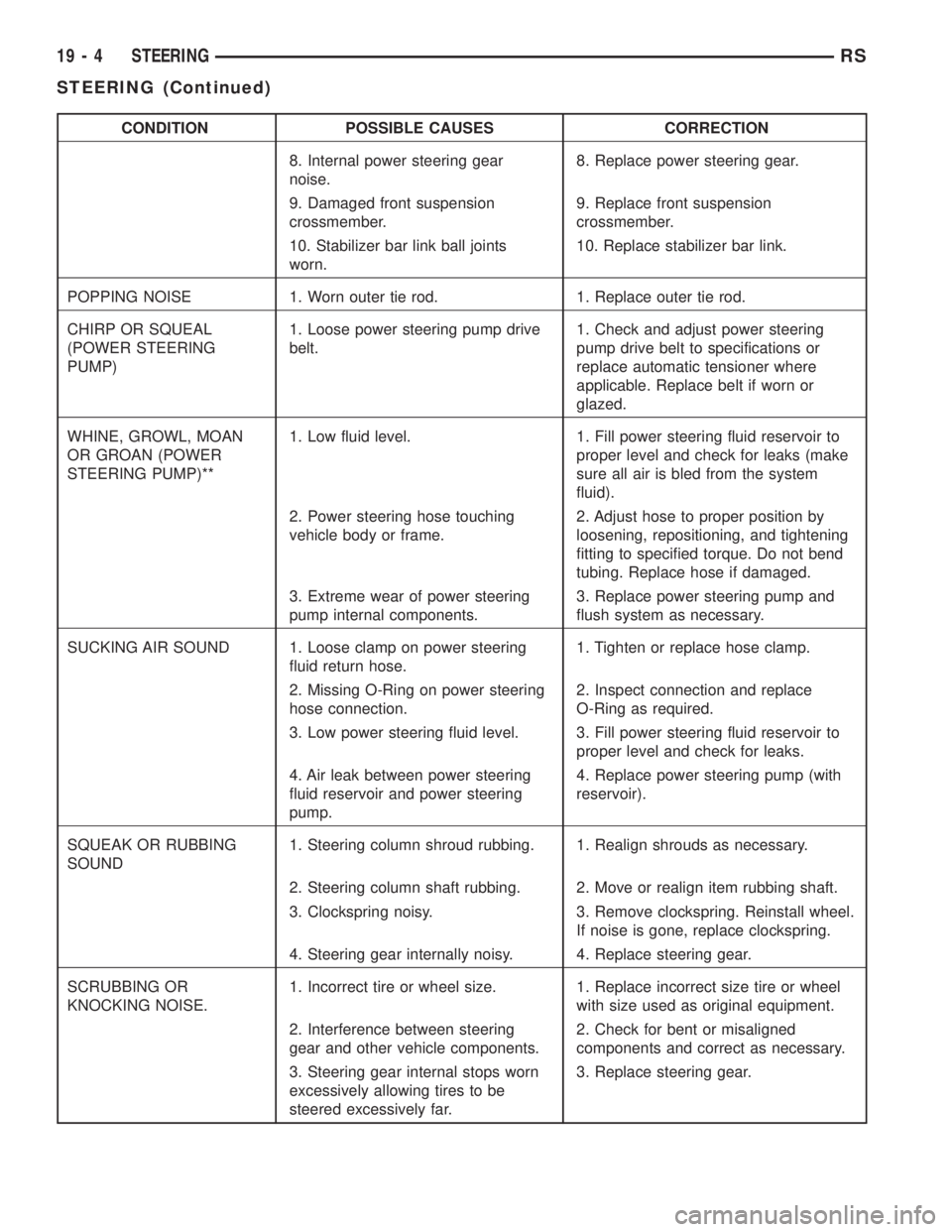

CONDITION POSSIBLE CAUSES CORRECTION

8. Internal power steering gear

noise.8. Replace power steering gear.

9. Damaged front suspension

crossmember.9. Replace front suspension

crossmember.

10. Stabilizer bar link ball joints

worn.10. Replace stabilizer bar link.

POPPING NOISE 1. Worn outer tie rod. 1. Replace outer tie rod.

CHIRP OR SQUEAL

(POWER STEERING

PUMP)1. Loose power steering pump drive

belt.1. Check and adjust power steering

pump drive belt to specifications or

replace automatic tensioner where

applicable. Replace belt if worn or

glazed.

WHINE, GROWL, MOAN

OR GROAN (POWER

STEERING PUMP)**1. Low fluid level. 1. Fill power steering fluid reservoir to

proper level and check for leaks (make

sure all air is bled from the system

fluid).

2. Power steering hose touching

vehicle body or frame.2. Adjust hose to proper position by

loosening, repositioning, and tightening

fitting to specified torque. Do not bend

tubing. Replace hose if damaged.

3. Extreme wear of power steering

pump internal components.3. Replace power steering pump and

flush system as necessary.

SUCKING AIR SOUND 1. Loose clamp on power steering

fluid return hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power steering

hose connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level. 3. Fill power steering fluid reservoir to

proper level and check for leaks.

4. Air leak between power steering

fluid reservoir and power steering

pump.4. Replace power steering pump (with

reservoir).

SQUEAK OR RUBBING

SOUND1. Steering column shroud rubbing. 1. Realign shrouds as necessary.

2. Steering column shaft rubbing. 2. Move or realign item rubbing shaft.

3. Clockspring noisy. 3. Remove clockspring. Reinstall wheel.

If noise is gone, replace clockspring.

4. Steering gear internally noisy. 4. Replace steering gear.

SCRUBBING OR

KNOCKING NOISE.1. Incorrect tire or wheel size. 1. Replace incorrect size tire or wheel

with size used as original equipment.

2. Interference between steering

gear and other vehicle components.2. Check for bent or misaligned

components and correct as necessary.

3. Steering gear internal stops worn

excessively allowing tires to be

steered excessively far.3. Replace steering gear.

19 - 4 STEERINGRS

STEERING (Continued)

Page 2930 of 4284

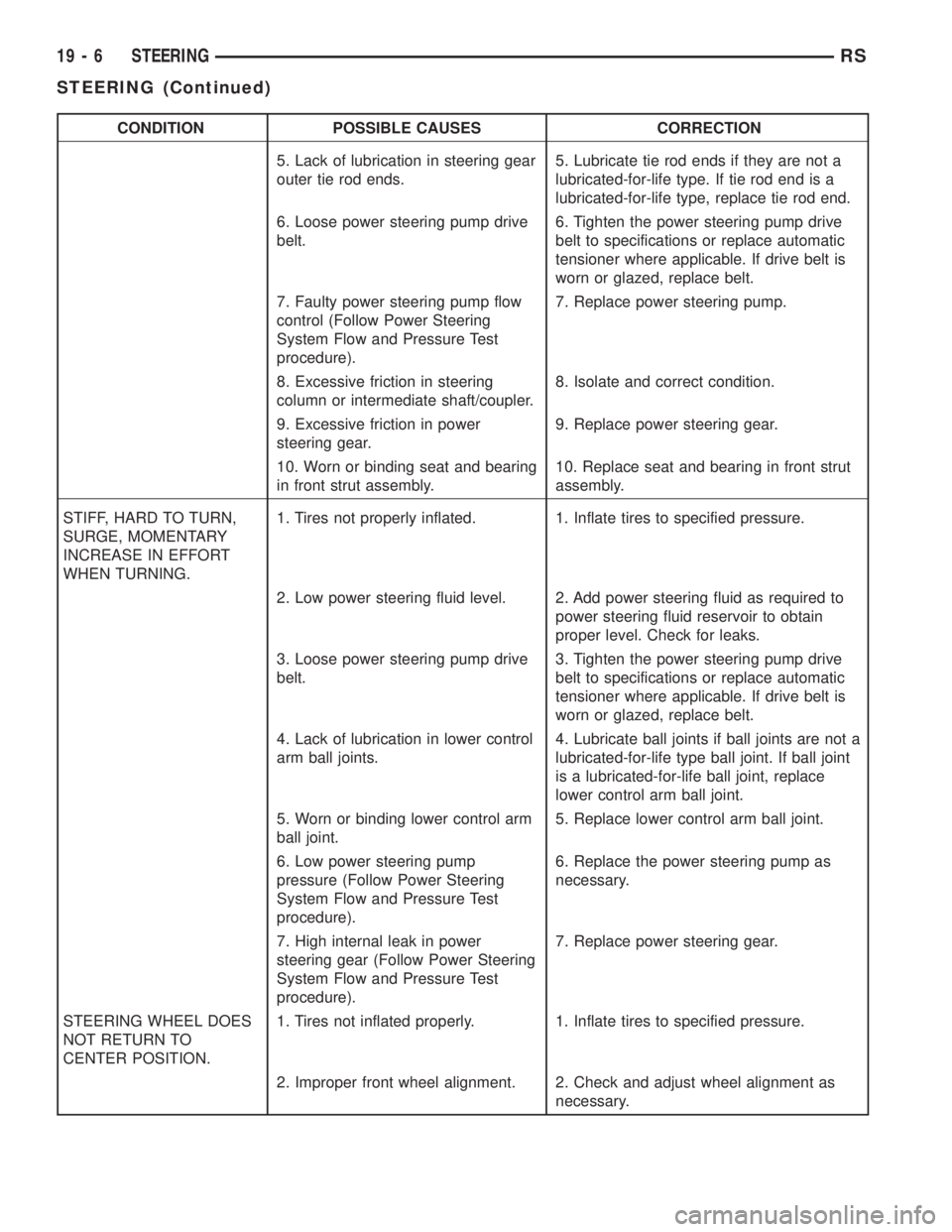

CONDITION POSSIBLE CAUSES CORRECTION

5. Lack of lubrication in steering gear

outer tie rod ends.5. Lubricate tie rod ends if they are not a

lubricated-for-life type. If tie rod end is a

lubricated-for-life type, replace tie rod end.

6. Loose power steering pump drive

belt.6. Tighten the power steering pump drive

belt to specifications or replace automatic

tensioner where applicable. If drive belt is

worn or glazed, replace belt.

7. Faulty power steering pump flow

control (Follow Power Steering

System Flow and Pressure Test

procedure).7. Replace power steering pump.

8. Excessive friction in steering

column or intermediate shaft/coupler.8. Isolate and correct condition.

9. Excessive friction in power

steering gear.9. Replace power steering gear.

10. Worn or binding seat and bearing

in front strut assembly.10. Replace seat and bearing in front strut

assembly.

STIFF, HARD TO TURN,

SURGE, MOMENTARY

INCREASE IN EFFORT

WHEN TURNING.1. Tires not properly inflated. 1. Inflate tires to specified pressure.

2. Low power steering fluid level. 2. Add power steering fluid as required to

power steering fluid reservoir to obtain

proper level. Check for leaks.

3. Loose power steering pump drive

belt.3. Tighten the power steering pump drive

belt to specifications or replace automatic

tensioner where applicable. If drive belt is

worn or glazed, replace belt.

4. Lack of lubrication in lower control

arm ball joints.4. Lubricate ball joints if ball joints are not a

lubricated-for-life type ball joint. If ball joint

is a lubricated-for-life ball joint, replace

lower control arm ball joint.

5. Worn or binding lower control arm

ball joint.5. Replace lower control arm ball joint.

6. Low power steering pump

pressure (Follow Power Steering

System Flow and Pressure Test

procedure).6. Replace the power steering pump as

necessary.

7. High internal leak in power

steering gear (Follow Power Steering

System Flow and Pressure Test

procedure).7. Replace power steering gear.

STEERING WHEEL DOES

NOT RETURN TO

CENTER POSITION.1. Tires not inflated properly. 1. Inflate tires to specified pressure.

2. Improper front wheel alignment. 2. Check and adjust wheel alignment as

necessary.

19 - 6 STEERINGRS

STEERING (Continued)

Page 2948 of 4284

PUMP

TABLE OF CONTENTS

page page

PUMP

DESCRIPTION...........................24

OPERATION.............................24

CAUTION...............................25

STANDARD PROCEDURE..................25

POWER STEERING PUMP INITIAL

OPERATION...........................25

REMOVAL..............................25

DISASSEMBLY...........................28

ASSEMBLY.............................28

INSTALLATION...........................29SPECIAL TOOLS.........................30

FLUID

STANDARD PROCEDURE..................30

POWER STEERING FLUID LEVEL

CHECKING............................30

FLUID COOLER

DESCRIPTION...........................30

OPERATION.............................30

REMOVAL..............................31

INSTALLATION...........................31

PUMP

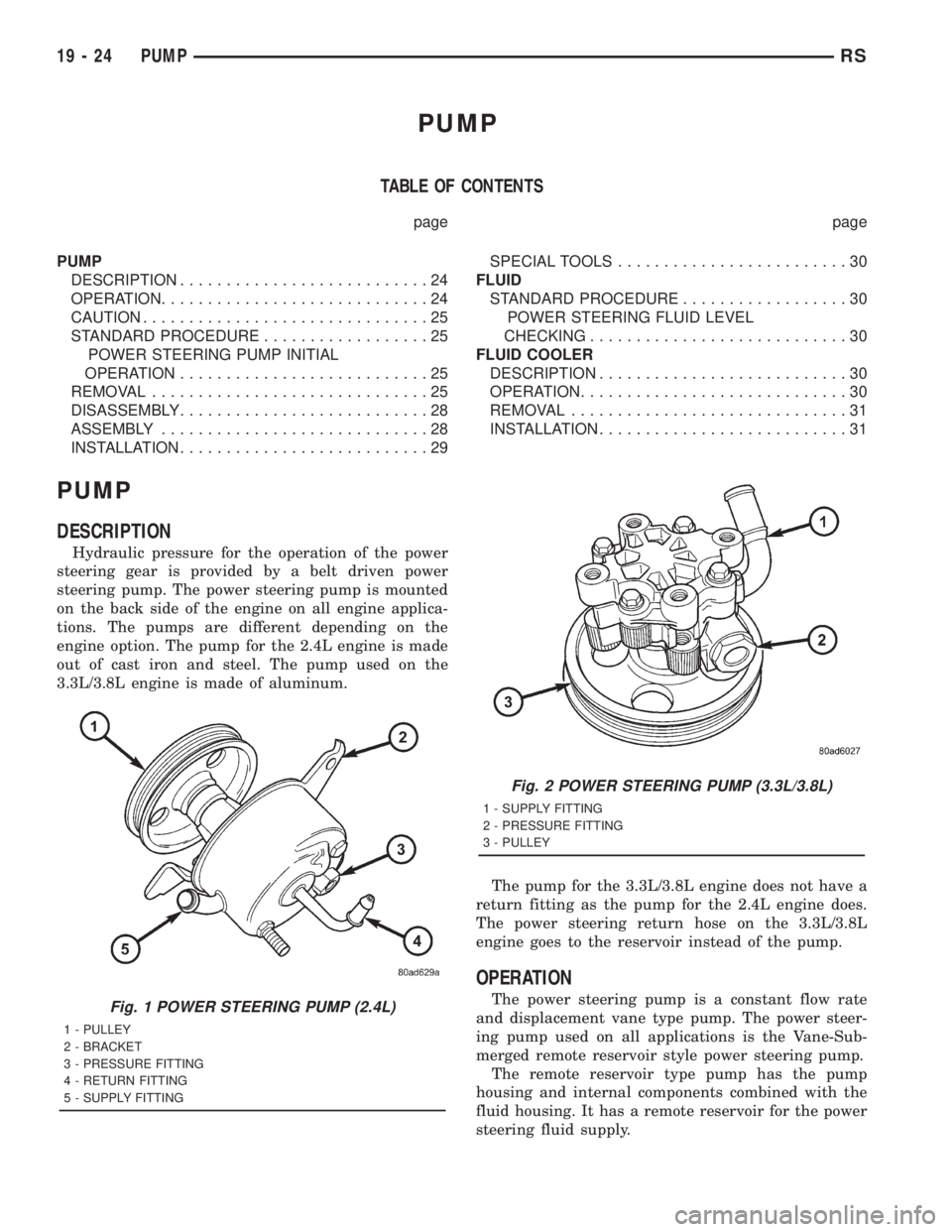

DESCRIPTION

Hydraulic pressure for the operation of the power

steering gear is provided by a belt driven power

steering pump. The power steering pump is mounted

on the back side of the engine on all engine applica-

tions. The pumps are different depending on the

engine option. The pump for the 2.4L engine is made

out of cast iron and steel. The pump used on the

3.3L/3.8L engine is made of aluminum.

The pump for the 3.3L/3.8L engine does not have a

return fitting as the pump for the 2.4L engine does.

The power steering return hose on the 3.3L/3.8L

engine goes to the reservoir instead of the pump.

OPERATION

The power steering pump is a constant flow rate

and displacement vane type pump. The power steer-

ing pump used on all applications is the Vane-Sub-

merged remote reservoir style power steering pump.

The remote reservoir type pump has the pump

housing and internal components combined with the

fluid housing. It has a remote reservoir for the power

steering fluid supply.Fig. 1 POWER STEERING PUMP (2.4L)

1 - PULLEY

2 - BRACKET

3 - PRESSURE FITTING

4 - RETURN FITTING

5 - SUPPLY FITTING

Fig. 2 POWER STEERING PUMP (3.3L/3.8L)

1 - SUPPLY FITTING

2 - PRESSURE FITTING

3 - PULLEY

19 - 24 PUMPRS

Page 2950 of 4284

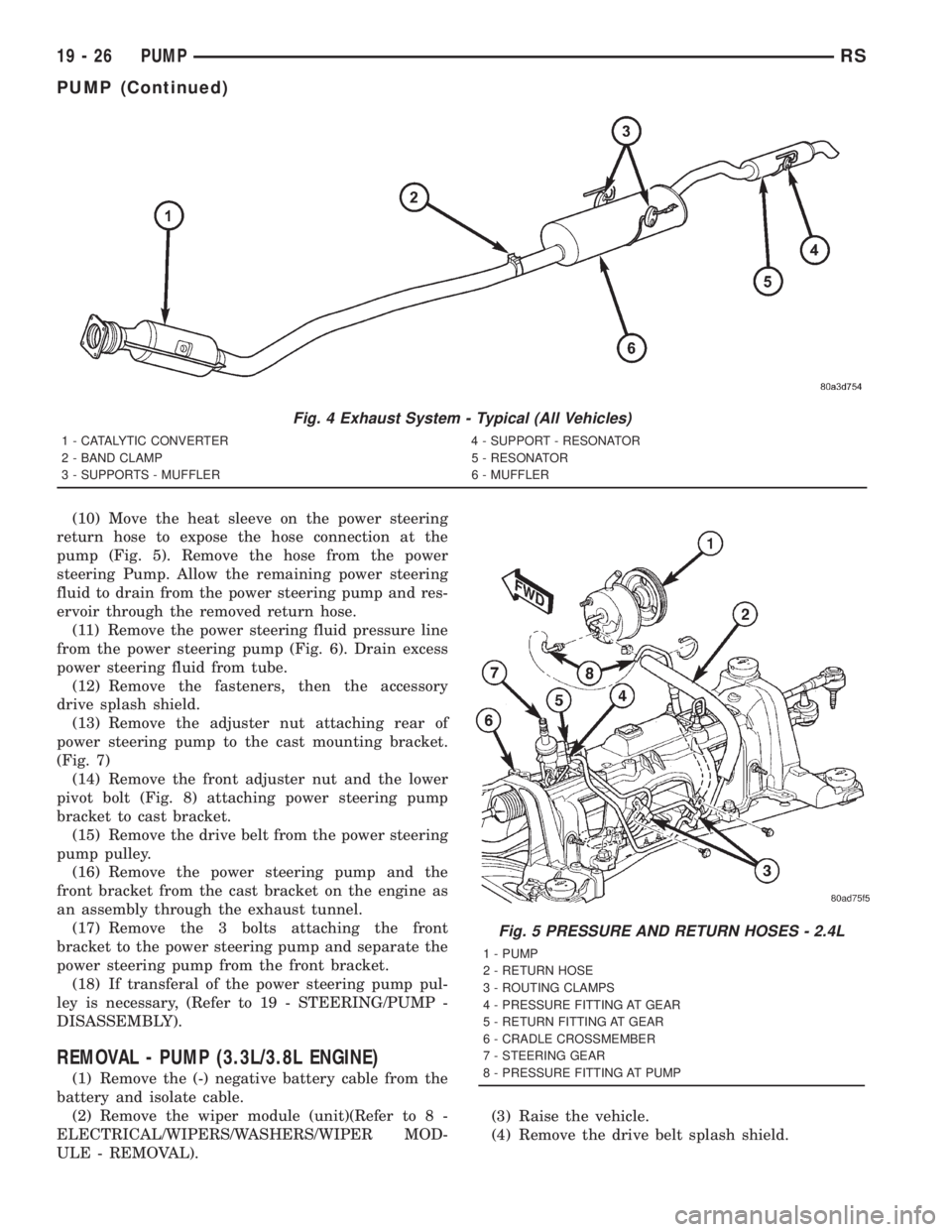

(10) Move the heat sleeve on the power steering

return hose to expose the hose connection at the

pump (Fig. 5). Remove the hose from the power

steering Pump. Allow the remaining power steering

fluid to drain from the power steering pump and res-

ervoir through the removed return hose.

(11) Remove the power steering fluid pressure line

from the power steering pump (Fig. 6). Drain excess

power steering fluid from tube.

(12) Remove the fasteners, then the accessory

drive splash shield.

(13) Remove the adjuster nut attaching rear of

power steering pump to the cast mounting bracket.

(Fig. 7)

(14) Remove the front adjuster nut and the lower

pivot bolt (Fig. 8) attaching power steering pump

bracket to cast bracket.

(15) Remove the drive belt from the power steering

pump pulley.

(16) Remove the power steering pump and the

front bracket from the cast bracket on the engine as

an assembly through the exhaust tunnel.

(17) Remove the 3 bolts attaching the front

bracket to the power steering pump and separate the

power steering pump from the front bracket.

(18) If transferal of the power steering pump pul-

ley is necessary, (Refer to 19 - STEERING/PUMP -

DISASSEMBLY).

REMOVAL - PUMP (3.3L/3.8L ENGINE)

(1) Remove the (-) negative battery cable from the

battery and isolate cable.

(2) Remove the wiper module (unit)(Refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER MOD-

ULE - REMOVAL).(3) Raise the vehicle.

(4) Remove the drive belt splash shield.

Fig. 4 Exhaust System - Typical (All Vehicles)

1 - CATALYTIC CONVERTER 4 - SUPPORT - RESONATOR

2 - BAND CLAMP 5 - RESONATOR

3 - SUPPORTS - MUFFLER 6 - MUFFLER

Fig. 5 PRESSURE AND RETURN HOSES - 2.4L

1 - PUMP

2 - RETURN HOSE

3 - ROUTING CLAMPS

4 - PRESSURE FITTING AT GEAR

5 - RETURN FITTING AT GEAR

6 - CRADLE CROSSMEMBER

7 - STEERING GEAR

8 - PRESSURE FITTING AT PUMP

19 - 26 PUMPRS

PUMP (Continued)

Page 2951 of 4284

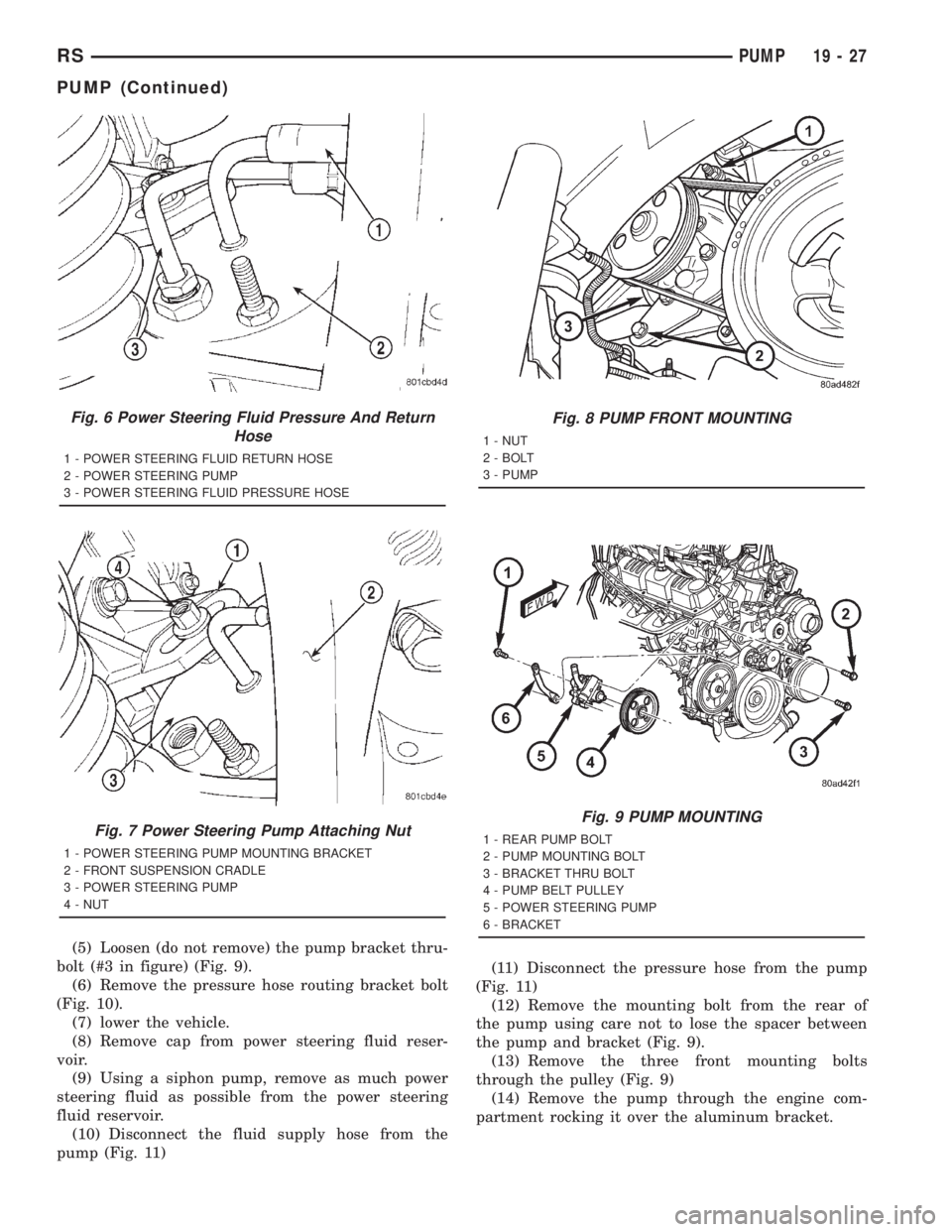

(5) Loosen (do not remove) the pump bracket thru-

bolt (#3 in figure) (Fig. 9).

(6) Remove the pressure hose routing bracket bolt

(Fig. 10).

(7) lower the vehicle.

(8) Remove cap from power steering fluid reser-

voir.

(9) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(10) Disconnect the fluid supply hose from the

pump (Fig. 11)(11) Disconnect the pressure hose from the pump

(Fig. 11)

(12) Remove the mounting bolt from the rear of

the pump using care not to lose the spacer between

the pump and bracket (Fig. 9).

(13) Remove the three front mounting bolts

through the pulley (Fig. 9)

(14) Remove the pump through the engine com-

partment rocking it over the aluminum bracket.

Fig. 6 Power Steering Fluid Pressure And Return

Hose

1 - POWER STEERING FLUID RETURN HOSE

2 - POWER STEERING PUMP

3 - POWER STEERING FLUID PRESSURE HOSE

Fig. 7 Power Steering Pump Attaching Nut

1 - POWER STEERING PUMP MOUNTING BRACKET

2 - FRONT SUSPENSION CRADLE

3 - POWER STEERING PUMP

4 - NUT

Fig. 8 PUMP FRONT MOUNTING

1 - NUT

2 - BOLT

3 - PUMP

Fig. 9 PUMP MOUNTING

1 - REAR PUMP BOLT

2 - PUMP MOUNTING BOLT

3 - BRACKET THRU BOLT

4 - PUMP BELT PULLEY

5 - POWER STEERING PUMP

6 - BRACKET

RSPUMP19-27

PUMP (Continued)

Page 2952 of 4284

DISASSEMBLY - PUMP (PULLEY)

The only serviceable part of the power steering

pump is the pulley. The procedure following is for

removal and installation of the pulley from the pump

once the pump is removed from the vehicle.(1) Remove the power steering pump from the

vehicle. Refer to Removal And Installation in this

section of the service manual.

(2) Remove the pulley from the shaft of the power

steering pump using Puller C-4333 or C-4068 (Fig.

12).

CAUTION: Do not hammer on power steering pump

pulley. This will damage the pulley and the power

steering pump.

(3) Replace pulley if it is found to be bent, cracked,

or loose.

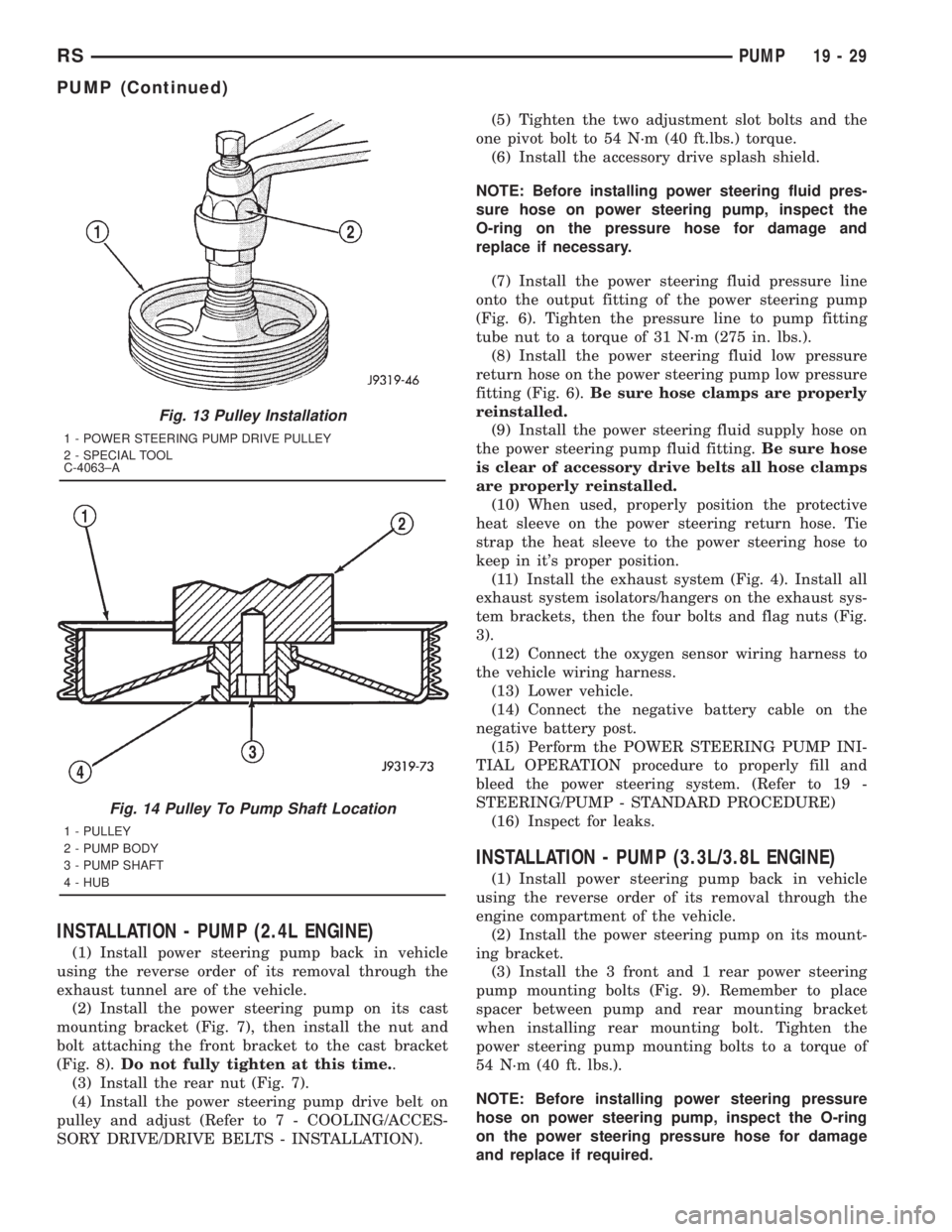

ASSEMBLY - PUMP (PULLEY)

The only serviceable part of the power steering

pump is the pulley. The procedure following is for

removal and installation of the pulley from the pump

once the pump is removed from the vehicle.

(1) Install the pulley with Installer C-4063 (Fig.

13). Do not use the tool adapters.

(2) Ensure that the tool and the pulley remain

aligned with the pump shaft. Prevent the pulley from

being cocked on the shaft.

(3) Install the pulley until it is flush with the end

of the power steering pump shaft (Fig. 14).

(4) Install the power steering pump on the vehicle.

NOTE: Once the pump is installed on the vehicle,

run the engine until it's warm (5 min.) and note any

belt chirp. If chirp exists, move the pulley outward

approximately 0.5 mm (0.020 in.). If noise increases,

press the pulley on 1.0 mm (0.040 in.). Be careful

that the pulley does not contact the pump mounting

bolts.

Fig. 10 PRESSURE HOSE ROUTING CLAMP

1 - PRESSURE HOSE TUBE

2 - STEERING GEAR

3 - CRADLE CROSSMEMBER

4 - DRIVESHAFT

5 - ROUTING CLAMP BRACKET

Fig. 11 SUPPLY & PRESSURE HOSES AT PUMP

1 - PRESSURE HOSE AND FITTING

2 - SUPPLY HOSE AND CLAMP

3 - POWER STEERING PUMP

Fig. 12 Pulley Removal

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL C-4333

19 - 28 PUMPRS

PUMP (Continued)

Page 2953 of 4284

INSTALLATION - PUMP (2.4L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel are of the vehicle.

(2) Install the power steering pump on its cast

mounting bracket (Fig. 7), then install the nut and

bolt attaching the front bracket to the cast bracket

(Fig. 8).Do not fully tighten at this time..

(3) Install the rear nut (Fig. 7).

(4) Install the power steering pump drive belt on

pulley and adjust (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - INSTALLATION).(5) Tighten the two adjustment slot bolts and the

one pivot bolt to 54 N´m (40 ft.lbs.) torque.

(6) Install the accessory drive splash shield.

NOTE: Before installing power steering fluid pres-

sure hose on power steering pump, inspect the

O-ring on the pressure hose for damage and

replace if necessary.

(7) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 6). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(8) Install the power steering fluid low pressure

return hose on the power steering pump low pressure

fitting (Fig. 6).Be sure hose clamps are properly

reinstalled.

(9) Install the power steering fluid supply hose on

the power steering pump fluid fitting.Be sure hose

is clear of accessory drive belts all hose clamps

are properly reinstalled.

(10) When used, properly position the protective

heat sleeve on the power steering return hose. Tie

strap the heat sleeve to the power steering hose to

keep in it's proper position.

(11) Install the exhaust system (Fig. 4). Install all

exhaust system isolators/hangers on the exhaust sys-

tem brackets, then the four bolts and flag nuts (Fig.

3).

(12) Connect the oxygen sensor wiring harness to

the vehicle wiring harness.

(13) Lower vehicle.

(14) Connect the negative battery cable on the

negative battery post.

(15) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(16) Inspect for leaks.

INSTALLATION - PUMP (3.3L/3.8L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

engine compartment of the vehicle.

(2) Install the power steering pump on its mount-

ing bracket.

(3) Install the 3 front and 1 rear power steering

pump mounting bolts (Fig. 9). Remember to place

spacer between pump and rear mounting bracket

when installing rear mounting bolt. Tighten the

power steering pump mounting bolts to a torque of

54 N´m (40 ft. lbs.).

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

Fig. 13 Pulley Installation

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL

C-4063±A

Fig. 14 Pulley To Pump Shaft Location

1 - PULLEY

2 - PUMP BODY

3 - PUMP SHAFT

4 - HUB

RSPUMP19-29

PUMP (Continued)