CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3131 of 4284

(18) Remove left and right halfshaft assemblies.

(Refer to 3 - DIFFERENTIAL & DRIVELINE/HALF

SHAFT - REMOVAL)

(19) Disconnect exhaust pipe at manifold (Fig. 13).

(20) Remove cradle plate.

(21) AWD models: Remove power transfer unit.

(Refer to 21 - TRANSMISSION/TRANSAXLE/

POWER TRANSFER UNIT - REMOVAL)

(22) Remove rear mount bracket-to-transaxle case

lower (horizontal) bolt (Fig. 12).

(23) Remove rear mount heat shield (Fig. 14).

(24) Remove rear mount-to-bracket thru-bolt and

nut (Fig. 15).

(25) Remove front mount/bracket assembly.

(26) Remove starter motor.

(27) Remove lateral bending brace.(28) Remove inspection cover.

(29) Remove torque converter-to-drive plate bolts.

(30) Support engine/transaxle assembly at engine

oil pan with screw jack and wood block.

(31) Partially remove left wheelhouse splash shield

to gain access to and remove upper mount thru-bolt

(Fig. 16).

(32) Lower engine/transaxle assembly with screw

jack.

(33) Obtain helper and transmission jack. Secure

transmission jack to transaxle assembly.

(34) Remove upper mount bracket from transaxle

(Fig. 16).

(35) Remove remaining transaxle bellhousing-to-

engine bolts.

(36) Remove transaxle assembly from vehicle.

Fig. 12 Rear Mount Bracket - Typical

1 - BOLT - VERTICAL

2 - BRACKET - REAR MOUNT3 - BOLT - HORIZONTAL

RSAUTOMATIC - 41TE21 - 167

AUTOMATIC - 41TE (Continued)

Page 3132 of 4284

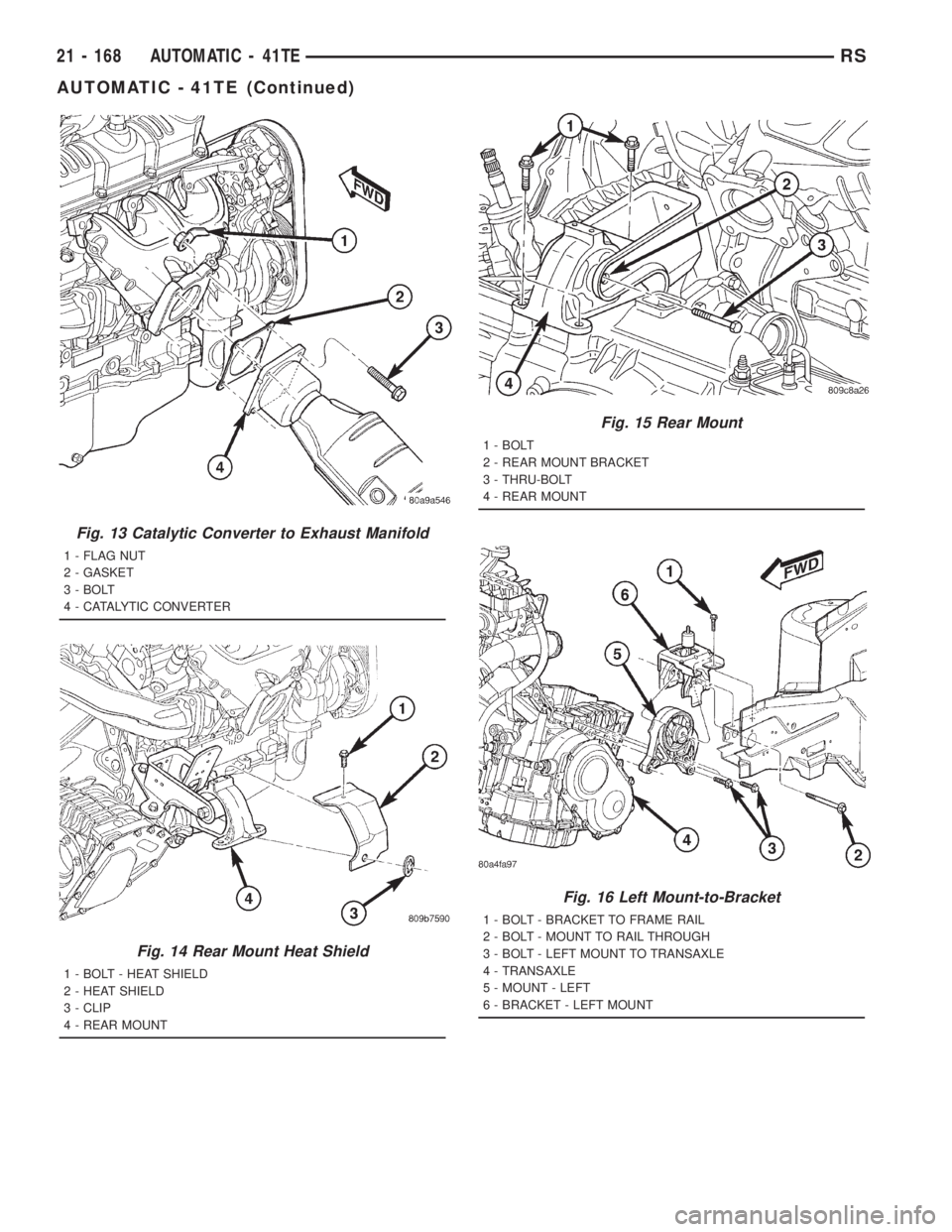

Fig. 13 Catalytic Converter to Exhaust Manifold

1 - FLAG NUT

2 - GASKET

3 - BOLT

4 - CATALYTIC CONVERTER

Fig. 14 Rear Mount Heat Shield

1 - BOLT - HEAT SHIELD

2 - HEAT SHIELD

3 - CLIP

4 - REAR MOUNT

Fig. 15 Rear Mount

1 - BOLT

2 - REAR MOUNT BRACKET

3 - THRU-BOLT

4 - REAR MOUNT

Fig. 16 Left Mount-to-Bracket

1 - BOLT - BRACKET TO FRAME RAIL

2 - BOLT - MOUNT TO RAIL THROUGH

3 - BOLT - LEFT MOUNT TO TRANSAXLE

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

21 - 168 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

Page 3133 of 4284

DISASSEMBLY

CAUTION: If transaxle failure has occurred, it is

necessary to flush the transaxle oil cooler and lines

to remove debris and particles that could contami-

nate and/or fail a new or rebuilt unit. (Refer to 7 -

COOLING/TRANSMISSION - STANDARD PROCE-

DURE)

NOTE: If transaxle is being overhauled (clutch

and/or seal replacement) or replaced, it is neces-

sary to perform the TCM Quick Learn Procedure.

(Refer to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

STANDARD PROCEDURE)

NOTE: This procedure does not include final drive

(differential) disassembly.

(1) Remove input and output speed sensors.

(2) Remove three (3) solenoid/pressure switch

assembly-to-case bolts.

(3) Remove solenoid/pressure switch assembly and

gasket (Fig. 17).(4) Remove oil pan-to-case bolts (Fig. 18).

(5) Remove oil pan (Fig. 19).

(6) Remove oil filter (Fig. 20).

(7) Turn manual valve fully clock-wise to get park

rod into position for removal.

(8) Remove valve body-to-case bolts (Fig. 21).

CAUTION: Do not handle the valve body assembly

from the manual valve. Damage can result.

Fig. 17 Solenoid/Pressure Switch Assembly and

Gasket

1 - SOLENOID/PRESSURE SWITCH ASSEMBLY

2 - GASKET

Fig. 18 Remove Oil Pan Bolts

1 - OIL PAN BOLTS (USE RTV UNDER BOLT HEADS)

Fig. 19 Remove Oil Pan

1 - OIL PAN

2 - 1/8 INCH BEAD OF RTV SEALANT

3 - OIL FILTER

RSAUTOMATIC - 41TE21 - 169

AUTOMATIC - 41TE (Continued)

Page 3134 of 4284

(9) Using a screwdriver, push park rod rollers

away from guide bracket (Fig. 22) and remove valve

body assembly (Fig. 23).

NOTE: Depending on engine application, some

accumulators will have two springs and others will

have one spring. The springs are color-coded

according to application and year. When disassem-

bling, mark accumulator spring location to ease

assembly.

Fig. 20 Remove Oil Filter

1 - OIL FILTER

2 - O-RING

Fig. 21 Remove Valve Body Attaching Bolts

1 - VALVE BODY ATTACHING BOLTS (18)

2 - VALVE BODY

Fig. 22 Push Park Rod Rollers from Guide Bracket

1 - PARK SPRAG ROLLERS

2 - SCREWDRIVER

3 - PARK SPRAG GUIDE BRACKET

Fig. 23 Remove Valve Body

1 - VALVE BODY

21 - 170 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

Page 3135 of 4284

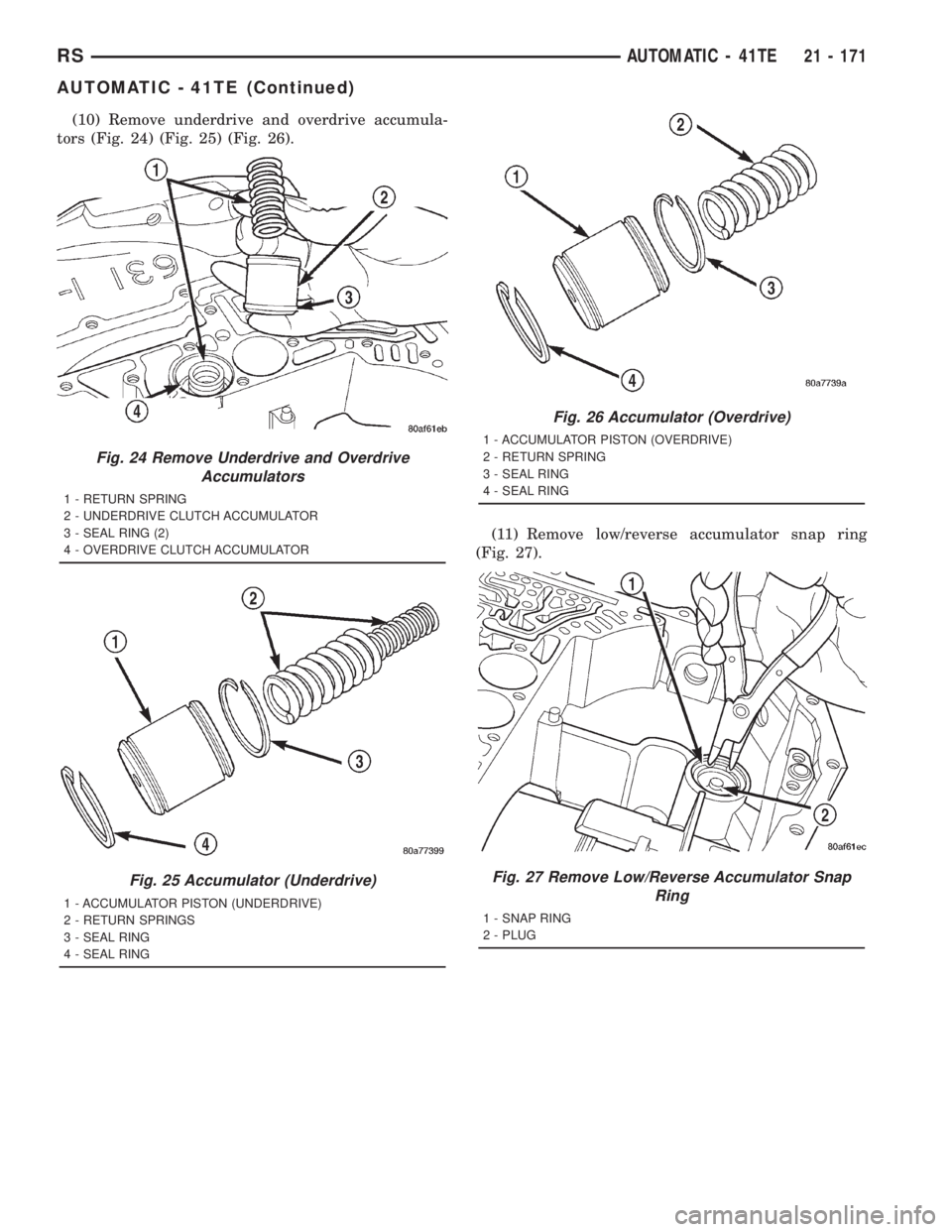

(10) Remove underdrive and overdrive accumula-

tors (Fig. 24) (Fig. 25) (Fig. 26).

(11) Remove low/reverse accumulator snap ring

(Fig. 27).

Fig. 24 Remove Underdrive and Overdrive

Accumulators

1 - RETURN SPRING

2 - UNDERDRIVE CLUTCH ACCUMULATOR

3 - SEAL RING (2)

4 - OVERDRIVE CLUTCH ACCUMULATOR

Fig. 25 Accumulator (Underdrive)

1 - ACCUMULATOR PISTON (UNDERDRIVE)

2 - RETURN SPRINGS

3 - SEAL RING

4 - SEAL RING

Fig. 26 Accumulator (Overdrive)

1 - ACCUMULATOR PISTON (OVERDRIVE)

2 - RETURN SPRING

3 - SEAL RING

4 - SEAL RING

Fig. 27 Remove Low/Reverse Accumulator Snap

Ring

1 - SNAP RING

2 - PLUG

RSAUTOMATIC - 41TE21 - 171

AUTOMATIC - 41TE (Continued)

Page 3136 of 4284

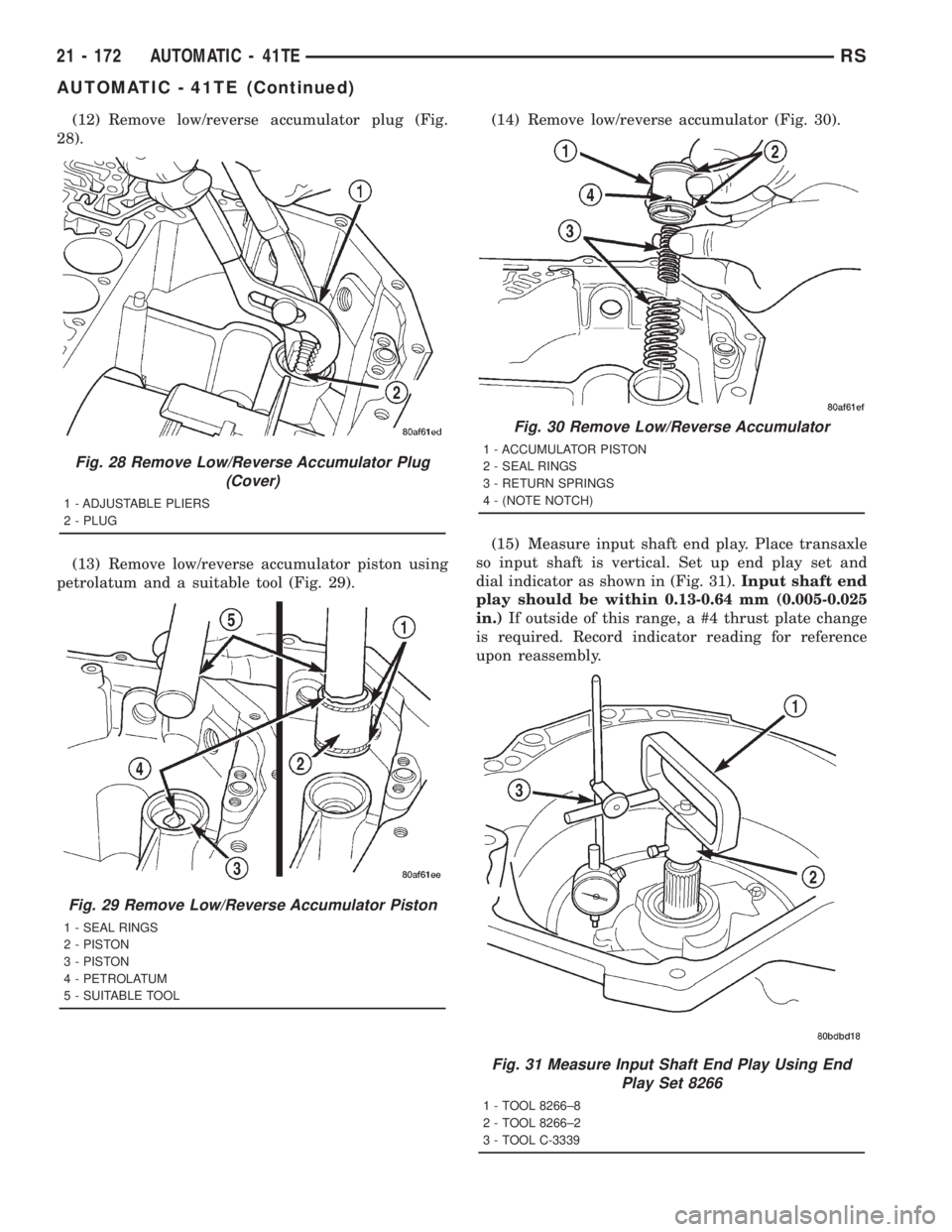

(12) Remove low/reverse accumulator plug (Fig.

28).

(13) Remove low/reverse accumulator piston using

petrolatum and a suitable tool (Fig. 29).(14) Remove low/reverse accumulator (Fig. 30).

(15) Measure input shaft end play. Place transaxle

so input shaft is vertical. Set up end play set and

dial indicator as shown in (Fig. 31).Input shaft end

play should be within 0.13-0.64 mm (0.005-0.025

in.)If outside of this range, a #4 thrust plate change

is required. Record indicator reading for reference

upon reassembly.

Fig. 28 Remove Low/Reverse Accumulator Plug

(Cover)

1 - ADJUSTABLE PLIERS

2 - PLUG

Fig. 29 Remove Low/Reverse Accumulator Piston

1 - SEAL RINGS

2 - PISTON

3 - PISTON

4 - PETROLATUM

5 - SUITABLE TOOL

Fig. 30 Remove Low/Reverse Accumulator

1 - ACCUMULATOR PISTON

2 - SEAL RINGS

3 - RETURN SPRINGS

4 - (NOTE NOTCH)

Fig. 31 Measure Input Shaft End Play Using End

Play Set 8266

1 - TOOL 8266±8

2 - TOOL 8266±2

3 - TOOL C-3339

21 - 172 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

Page 3137 of 4284

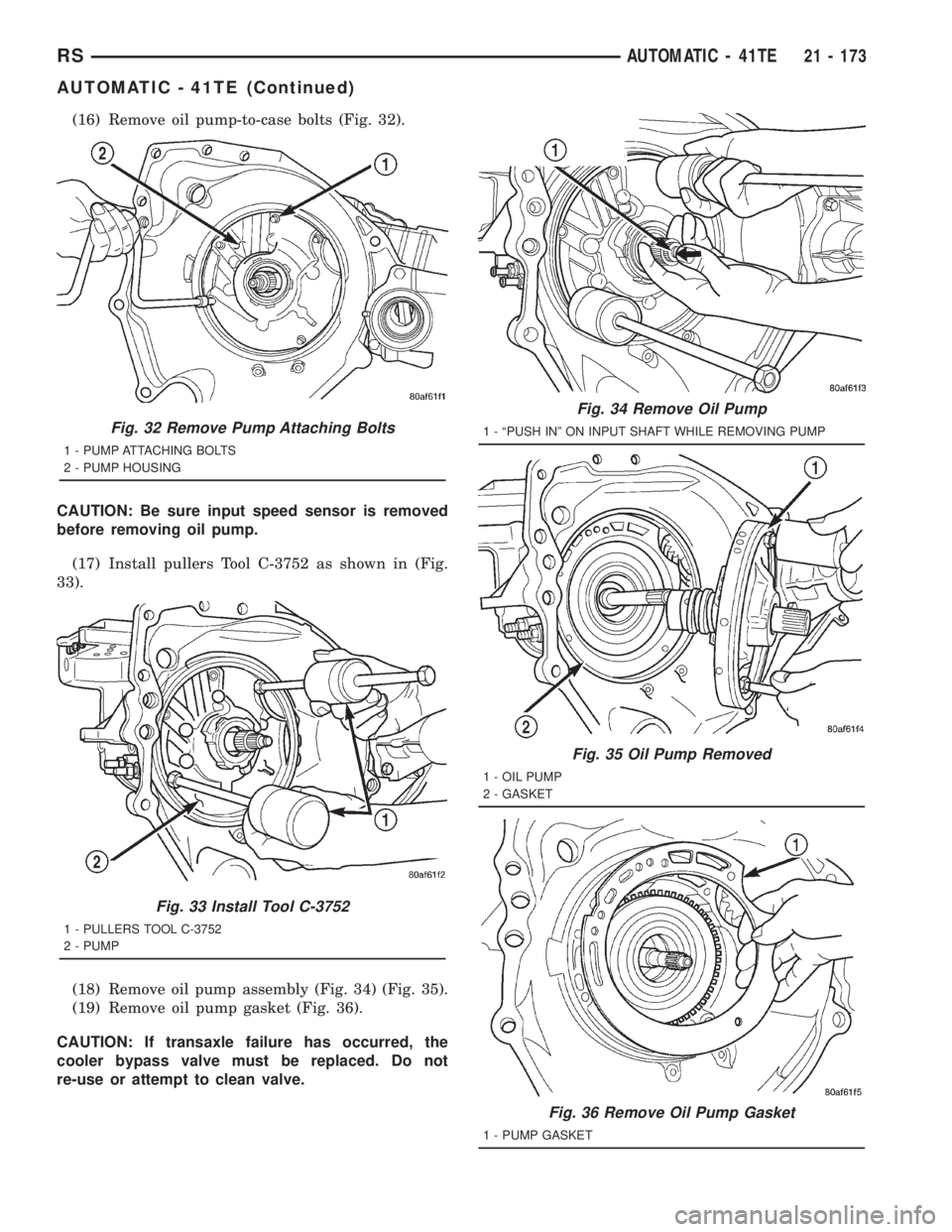

(16) Remove oil pump-to-case bolts (Fig. 32).

CAUTION: Be sure input speed sensor is removed

before removing oil pump.

(17) Install pullers Tool C-3752 as shown in (Fig.

33).

(18) Remove oil pump assembly (Fig. 34) (Fig. 35).

(19) Remove oil pump gasket (Fig. 36).

CAUTION: If transaxle failure has occurred, the

cooler bypass valve must be replaced. Do not

re-use or attempt to clean valve.

Fig. 32 Remove Pump Attaching Bolts

1 - PUMP ATTACHING BOLTS

2 - PUMP HOUSING

Fig. 33 Install Tool C-3752

1 - PULLERS TOOL C-3752

2 - PUMP

Fig. 34 Remove Oil Pump

1 - ªPUSH INº ON INPUT SHAFT WHILE REMOVING PUMP

Fig. 35 Oil Pump Removed

1 - OIL PUMP

2 - GASKET

Fig. 36 Remove Oil Pump Gasket

1 - PUMP GASKET

RSAUTOMATIC - 41TE21 - 173

AUTOMATIC - 41TE (Continued)

Page 3138 of 4284

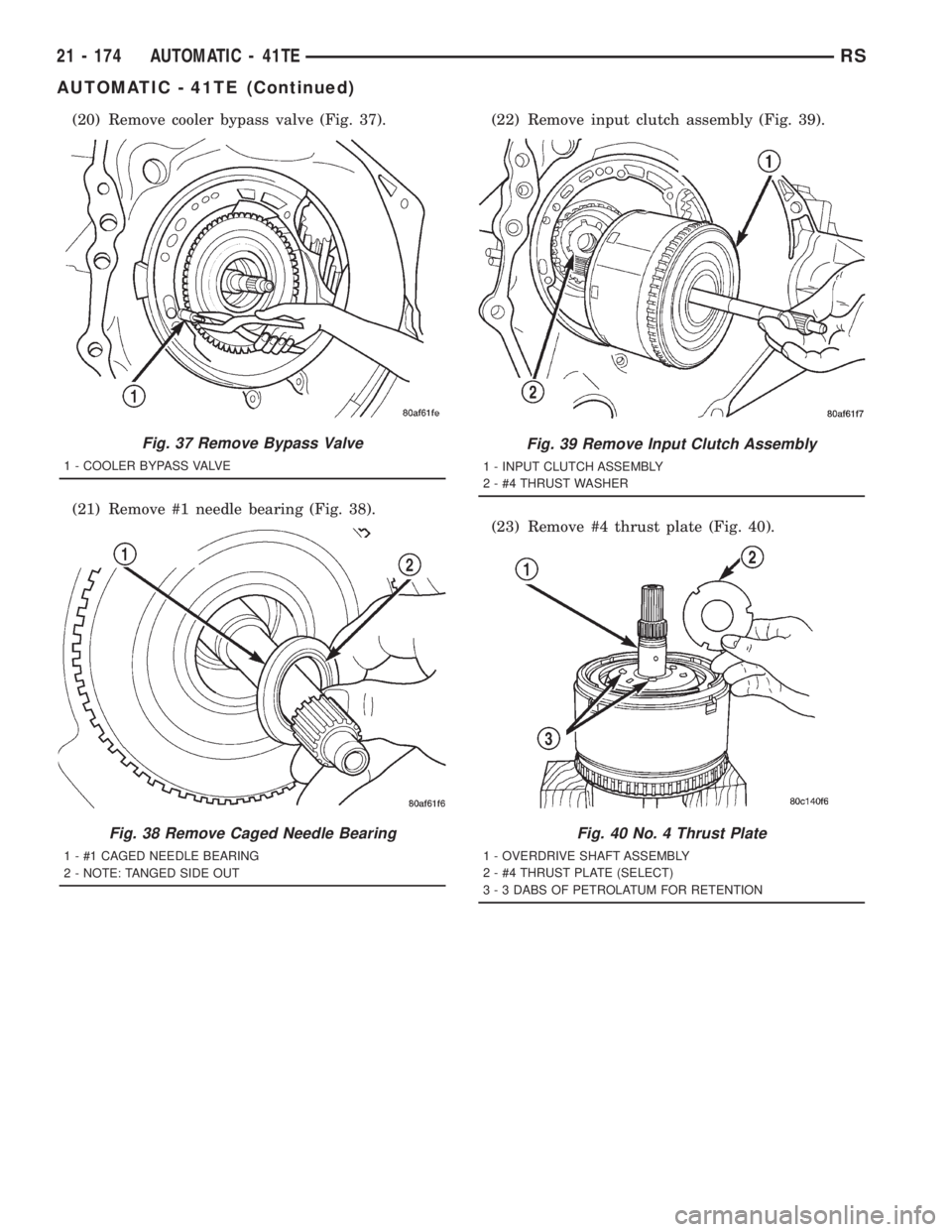

(20) Remove cooler bypass valve (Fig. 37).

(21) Remove #1 needle bearing (Fig. 38).(22) Remove input clutch assembly (Fig. 39).

(23) Remove #4 thrust plate (Fig. 40).

Fig. 37 Remove Bypass Valve

1 - COOLER BYPASS VALVE

Fig. 38 Remove Caged Needle Bearing

1 - #1 CAGED NEEDLE BEARING

2 - NOTE: TANGED SIDE OUT

Fig. 39 Remove Input Clutch Assembly

1 - INPUT CLUTCH ASSEMBLY

2 - #4 THRUST WASHER

Fig. 40 No. 4 Thrust Plate

1 - OVERDRIVE SHAFT ASSEMBLY

2 - #4 THRUST PLATE (SELECT)

3 - 3 DABS OF PETROLATUM FOR RETENTION

21 - 174 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)

Page 3139 of 4284

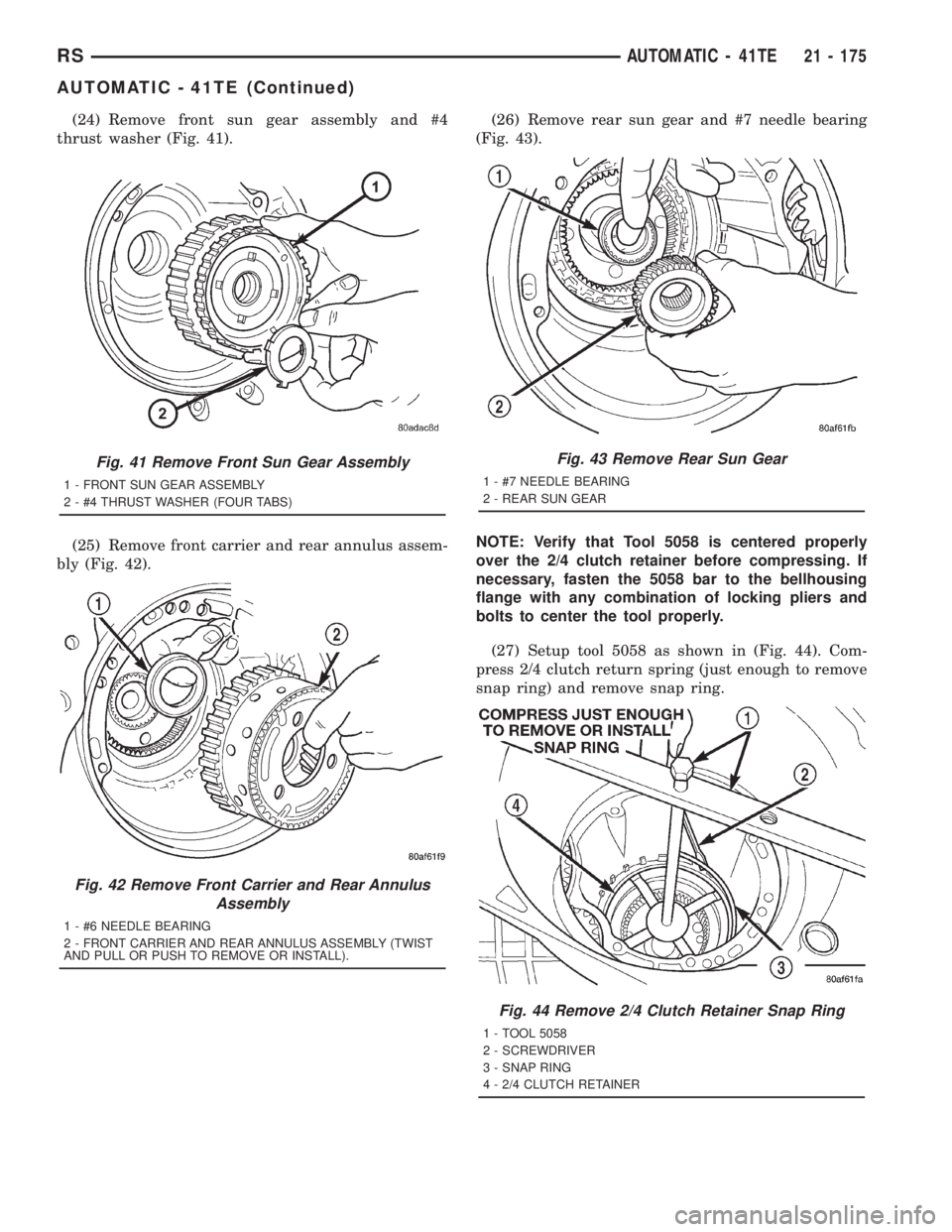

(24) Remove front sun gear assembly and #4

thrust washer (Fig. 41).

(25) Remove front carrier and rear annulus assem-

bly (Fig. 42).(26) Remove rear sun gear and #7 needle bearing

(Fig. 43).

NOTE: Verify that Tool 5058 is centered properly

over the 2/4 clutch retainer before compressing. If

necessary, fasten the 5058 bar to the bellhousing

flange with any combination of locking pliers and

bolts to center the tool properly.

(27) Setup tool 5058 as shown in (Fig. 44). Com-

press 2/4 clutch return spring (just enough to remove

snap ring) and remove snap ring.

Fig. 41 Remove Front Sun Gear Assembly

1 - FRONT SUN GEAR ASSEMBLY

2 - #4 THRUST WASHER (FOUR TABS)

Fig. 42 Remove Front Carrier and Rear Annulus

Assembly

1 - #6 NEEDLE BEARING

2 - FRONT CARRIER AND REAR ANNULUS ASSEMBLY (TWIST

AND PULL OR PUSH TO REMOVE OR INSTALL).

Fig. 43 Remove Rear Sun Gear

1 - #7 NEEDLE BEARING

2 - REAR SUN GEAR

Fig. 44 Remove 2/4 Clutch Retainer Snap Ring

1 - TOOL 5058

2 - SCREWDRIVER

3 - SNAP RING

4 - 2/4 CLUTCH RETAINER

RSAUTOMATIC - 41TE21 - 175

AUTOMATIC - 41TE (Continued)

Page 3140 of 4284

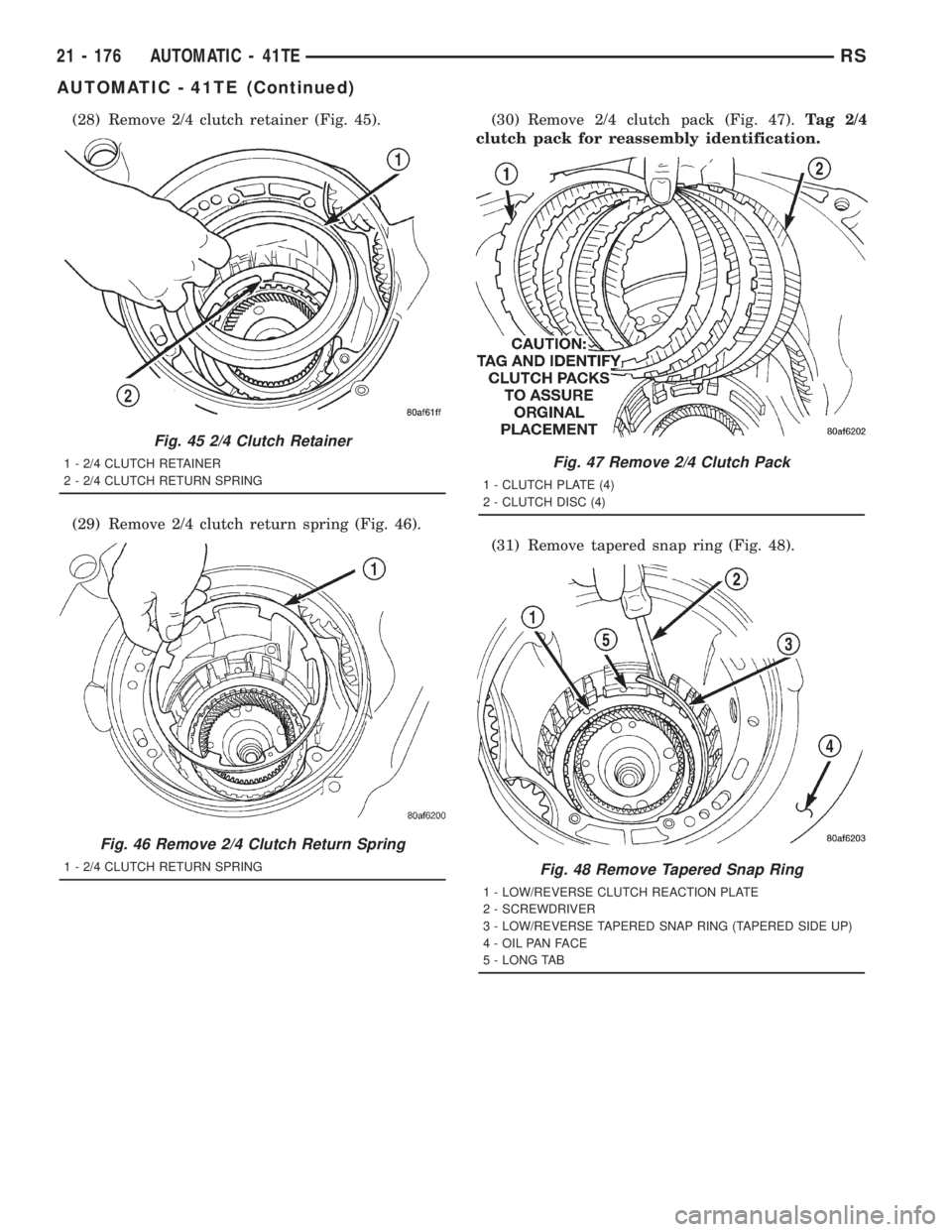

(28) Remove 2/4 clutch retainer (Fig. 45).

(29) Remove 2/4 clutch return spring (Fig. 46).(30) Remove 2/4 clutch pack (Fig. 47).Tag 2/4

clutch pack for reassembly identification.

(31) Remove tapered snap ring (Fig. 48).

Fig. 45 2/4 Clutch Retainer

1 - 2/4 CLUTCH RETAINER

2 - 2/4 CLUTCH RETURN SPRING

Fig. 46 Remove 2/4 Clutch Return Spring

1 - 2/4 CLUTCH RETURN SPRING

Fig. 47 Remove 2/4 Clutch Pack

1 - CLUTCH PLATE (4)

2 - CLUTCH DISC (4)

Fig. 48 Remove Tapered Snap Ring

1 - LOW/REVERSE CLUTCH REACTION PLATE

2 - SCREWDRIVER

3 - LOW/REVERSE TAPERED SNAP RING (TAPERED SIDE UP)

4 - OIL PAN FACE

5 - LONG TAB

21 - 176 AUTOMATIC - 41TERS

AUTOMATIC - 41TE (Continued)