engine diesel CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2838 of 4284

OPERATION

The balance shaft is driven by the crankshaft. The

balance shafts are connected by heelical gears. The

dual-counter rotating shafts decrease second order

vertical shaking forces caused by component move-

ment.

REMOVAL

(1) Disconnect negative battery cable.

(2) Raise vehicle on hoist.

(3) Remove oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - REMOVAL).

(4) Remove balance shaft assembly (Fig. 87).

Fig. 86 BALANCE SHAFT ASSEMBLY

1 - BALANCE SHAFT

2 - OIL JET RETAINING BOLT

3 - OIL JET

4 - ENGINE BLOCK

5 - CRANKSHAFT

6 - BALANCE SHAFT RETAINING BOLTS

7 - OIL DIPSTICK TUBE RETAINER

8 - RUBBER BUSHING

9 - RETAINING BOLT

Fig. 87 BALANCE SHAFT ASSEMBLY

1 - BALANCE SHAFT

2 - OIL JET RETAINING BOLT

3 - OIL JET

4 - ENGINE BLOCK

5 - CRANKSHAFT

6 - BALANCE SHAFT RETAINING BOLTS

7 - OIL DIPSTICK TUBE RETAINER

8 - RUBBER BUSHING

9 - RETAINING BOLT

9a - 56 ENGINE 2.5L TURBO DIESELRG

BALANCE SHAFT (Continued)

Page 2839 of 4284

INSTALLATION

(1) Before installation of the balance shaft assem-

bly, the # 1 cylinder must be brought to TDC. Using

special tool VM.1051, roll engine over by hand until

tool can be inserted into engine block locking fly-

wheel from turning (Fig. 88). Once the # 1 cylinder is

brought to TDC, the balance shaft assembly can be

installed.

(2) With balance shaft assembly on work bench.

Insert special tool VM.1056 into balance shaft assem-

bly (Fig. 89). This will ensure proper balance shaft

and crankshaft timing after assembly.

(3) Install balance shaft assembly and retaining

bolts (Fig. 87). Torque bolts to 32.4N´m.

(4) Install oil pan (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION).

(5) Refill engine oil to proper level.

(6) Connect negative battery cable.

TIMING BELT / CHAIN

COVER(S)

REMOVAL - TIMING BELT OUTER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover retaining bolts

and remove cover (Fig. 90).

REMOVAL - TIMING BELT INNER COVER

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine mount

and bracket.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

Fig. 88 TDC AND 90 DEGREES AFTER TDC

ALIGNMENT PIN LOCATION

1 - ENGINE BLOCK

2 - VM.1051 TDC PIN OR VM.1068 90 DEGREES ATDC PIN

3 - FLYWHEEL

Fig. 89 BALANCE SHAFT ALIGNMENT PIN VM.1056

1 - VM.1056

2 - BALANCE SHAFT ASSEMBLY

RGENGINE 2.5L TURBO DIESEL9a-57

BALANCE SHAFT (Continued)

Page 2840 of 4284

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(10) Remove timing belt idler pulleys (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT IDLER

PULLEY - REMOVAL).

(11) Using special tool VM.1055, remove camshaft

sprockets (Fig. 91).

(12) Remove timing belt tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

TENSIONER&PULLEY - REMOVAL) .(13) Remove injection pump sprocket (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - REMOVAL).

(14) Remove timing belt inner cover retaining bolts

and remove cover (Fig. 92).INSTALLATION - TIMING BELT OUTER COVER

(1) Install timing belt outer cover seal and cover

(Fig. 90). Torque 3mm bolts to 10.8N´m and 8mm

bolts to 10.8N´m.

(2) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(3) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(4) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(5) Install right engine mount.

(6) Install air cleaner housing.

(7) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(8) Connect negative battery cable.

Fig. 90 TIMING BELT COVER (OUTER)

1 - SEAL

2 - TIMING BELT OUTER COVER

3 - RETAINING BOLTS

Fig. 91 CAMSHAFT SPROCKET REMOVAL/

INSTALLATION

1 - TIMING BELT INNER COVER

2 - CAMSHAFT SPROCKET

3 - IDLER PULLEYS

4 - CAMSHAFT SPROCKET

5 - VM.1055

9a - 58 ENGINE 2.5L TURBO DIESELRG

TIMING BELT / CHAIN COVER(S) (Continued)

Page 2841 of 4284

INSTALLATION - TIMING BELT INNER COVER

(1) Install timing belt inner cover to engine front

cover seal (Fig. 92).

(2) Install timing belt inner cover to cylinder head

cover gaskets (Fig. 92).

(3) Install timing belt inner cover and retaining

bolts (Fig. 92). Torque 10mm bolts to 47.1N´m and

8mm bolts to 10.8N´m.

(4) Install injection pump sprocket (Refer to 14 -

FUEL SYSTEM/FUEL DELIVERY/FUEL INJEC-

TION PUMP - INSTALLATION).

(5) Install camshaft sprockets (Fig. 91). Torque

bolts to 108N´m.(6) Install timing belt idler pulleys (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT IDLER

PULLEY - INSTALLATION).

(7) Install timing belt and tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

AND SPROCKETS - INSTALLATION) .

(8) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(9) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(10) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(11) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(12) Install right engine mount assembly.

(13) Install air cleaner housing.

(14) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(15) Connect negative battery cable.

TIMING BELT IDLER PULLEY

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine

mount.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

NOTE: Idler pulley retaining bolts are LHD thread.

(10) Remove timing belt idler pulleys (Fig. 93).Fig. 92 TIMING BELT COVER - INNER

1 - TIMING BELT COVER TO CYLINDER HEAD COVER GASKET

2 - TIMING BELT COVER TO FRONT ENGINE COVER SEAL

3 - RUBBER GROMMET

4 - BUSHING

5 - TIMING BELT COVER - INNER

6 - RETAINING BOLT

7 - RETAINING BOLT

8 - RETAINING BOLT

9 - BUSHING

10 - RUBBER GROMMET

RGENGINE 2.5L TURBO DIESEL9a-59

TIMING BELT / CHAIN COVER(S) (Continued)

Page 2842 of 4284

INSTALLATION

(1) Install timing belt idler pulleys (Fig. 93).

Torque bolts to 47.1N´m.

(2) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .(3) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(4) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(5) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(6) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(7) Install right engine mount.

(8) Install air cleaner housing.

(9) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(10) Connect negative battery cable.

TIMING BELT/CHAIN

TENSIONER

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing.

(4) Support engine and remove right engine

mount.

(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Loosen and remove timing belt tensioner (Fig.

94).

INSTALLATION

(1) Install timing belt tensioner and retaining bolt

(Fig. 94).

Fig. 93 TIMING BELT AND SPROCKETS

1 -CAMSHAFT SPROCKETS

2 - INJECTION PUMP SPROCKET

3 - INJECTION PUMP SPROCKET RETAINING NUT

4 - TIMING BELT

5 - TIMING BELT TENSIONER RETAINING BOLT

6 - TIMING BELT TENSIONER

7 - TENSIONER ALIGNMENT PIN

8 - IDLER PULLEY

9 - CAMSHAFT SPROCKET RETAINING BOLT

9a - 60 ENGINE 2.5L TURBO DIESELRG

TIMING BELT IDLER PULLEY (Continued)

Page 2843 of 4284

(2) Adjust timing belt tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

TENSIONER & PULLEY - ADJUSTMENTS) .

(3) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).(4) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(5) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(6) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(7) Install right engine mount.

(8) Install air cleaner housing.

(9) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(10) Connect negative battery cable.

ADJUSTMENT - TIMING BELT TENSIONER

(1) With timing belt outer cover removed and tim-

ing belt installed.

(2) Loosen timing belt tensioner (Fig. 95).

Fig. 94 TIMING BELT AND SPROCKETS

1 -CAMSHAFT SPROCKETS

2 - INJECTION PUMP SPROCKET

3 - INJECTION PUMP SPROCKET RETAINING NUT

4 - TIMING BELT

5 - TIMING BELT TENSIONER RETAINING BOLT

6 - TIMING BELT TENSIONER

7 - TENSIONER ALIGNMENT PIN

8 - IDLER PULLEY

9 - CAMSHAFT SPROCKET RETAINING BOLT

Fig. 95 TIMING BELT TENSIONER ADJUSTMENT

1 - TIMING BELT IDLER PULLEY

2 - ENGINE FRONT COVER

3 - CRANKSHAFT HUB

4 - TIMING BELT TENSIONER

5 - TIMING BELT

RGENGINE 2.5L TURBO DIESEL9a-61

TIMING BELT/CHAIN TENSIONER (Continued)

Page 2844 of 4284

(3) Align timing belt tensioner spring stop with

tensioner as shown (Fig. 96) and torque timing belt

tensioner retaining bolt to 34.7N´m.

(4) Rotate engine 2 complete revolution and then

recheck tensioner alignment. Readjust tensioner

alignment as necessary.

TIMING BELT/CHAIN AND

SPROCKETS

REMOVAL

CAUTION: Before removing the timing belt, the

engine must put at 90É after TDC. Failure to do so

could result in valve and/or piston damage during

reassembly. (Refer to 9 - ENGINE/VALVE TIMING -

STANDARD PROCEDURE)

(1) Disconnect negative battery cable.

(2) Remove engine cover (Refer to 9 - ENGINE -

REMOVAL).

(3) Remove air cleaner housing assembly.

(4) Support engine and remove right engine

mount.(5) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(6) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove vibration damper (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL).

(8) Remove timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(9) Loosen timing belt tensioner and remove tim-

ing belt (Fig. 97).

Fig. 96 TIMING BELT TENSIONER ALIGNMENT

1 - TENSIONER SPRING STOP

2 - TIMING BELT TENSIONER

3 - TIMING BELT TENSIONER

4 - TIMING BELT

5 - TIMING BELT INNER COVER

Fig. 97 TIMING BELT AND SPROCKETS

1 -CAMSHAFT SPROCKETS

2 - INJECTION PUMP SPROCKET

3 - INJECTION PUMP SPROCKET RETAINING NUT

4 - TIMING BELT

5 - TIMING BELT TENSIONER RETAINING BOLT

6 - TIMING BELT TENSIONER

7 - TENSIONER ALIGNMENT PIN

8 - IDLER PULLEY

9 - CAMSHAFT SPROCKET RETAINING BOLT

9a - 62 ENGINE 2.5L TURBO DIESELRG

TIMING BELT/CHAIN TENSIONER (Continued)

Page 2845 of 4284

INSTALLATION

(1) With both camshaft alignment pins still

installed and the engine locked at 90É after TDC.

(2) Align timing mark on injection pump sprocket

with timing mark on timing belt (Fig. 98).

(3) Install timing belt.

(4) Adjust the timing belt tensioner (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT/CHAIN

TENSIONER & PULLEY - ADJUSTMENTS) .

(5) Remove both camshaft alignm²ent pins from

cylinder head cover/intake manifold and engine lock-

ing pin from engine block (Refer to 9 - ENGINE/

VALVE TIMING - STANDARD PROCEDURE).

(6) Install timing belt outer cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(7) Install vibration damper (Refer to 9 - ENGINE/

ENGINE BLOCK/VIBRATION DAMPER - INSTAL-

LATION).

(8) Install accessory drive belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(9) Install power steering belt (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION).

(10) Install right engine mount.

(11) Install air cleaner housing.

(12) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(13) Connect negative battery cable.

Fig. 98 INJECTION PUMP GEAR TIMING MARKS

1 - TIMING MARK ON COVER

2 - TIMING MARK ON INJECTION PUMP SPROCKET

3 - INJECTION PUMP SPROCKET

RGENGINE 2.5L TURBO DIESEL9a-63

TIMING BELT/CHAIN AND SPROCKETS (Continued)

Page 2855 of 4284

EXHAUST SYSTEM AND TURBOCHARGER

TABLE OF CONTENTS

page page

EXHAUST SYSTEM AND TURBOCHARGER

DESCRIPTION............................1

SPECIFICATIONS.........................1

TURBOCHARGER SYSTEM

DESCRIPTION............................2

OPERATION.............................2

TURBOCHARGER

REMOVAL...............................4CLEANING...............................5

INSTALLATION............................5

HEAT SHIELDS

REMOVAL...............................5

INSTALLATION............................6

EXHAUST SYSTEM AND

TURBOCHARGER

DESCRIPTION

The basic exhaust system consists of an engine

exhaust manifold, turbocharger, exhaust down pipe,

exhaust pipe, exhaust heat shield(s), muffler and

exhaust tailpipe

The exhaust system uses a single muffler.

The exhaust system must be properly aligned to

prevent stress, leakage and body contact. If the sys-

tem contacts any body panel, it will transfer objec-

tionable noises originating from the engine to the

body.

When inspecting an exhaust system, critically

inspect for cracked or loose joints, stripped screw orbolt threads, corrosion damage and worn, cracked or

broken hangers. Replace all components that are

badly corroded or damaged. DO NOT attempt to

repair.

When replacement is required, use original equip-

ment parts (or equivalent). This will assure proper

alignment and provide acceptable exhaust noise lev-

els.

CAUTION: Avoid application of rust prevention com-

pounds or undercoating materials to exhaust sys-

tem floor pan exhaust heat shields. Light overspray

near the edges is permitted. Application of coating

will result in excessive floor pan temperatures and

objectionable fumes.

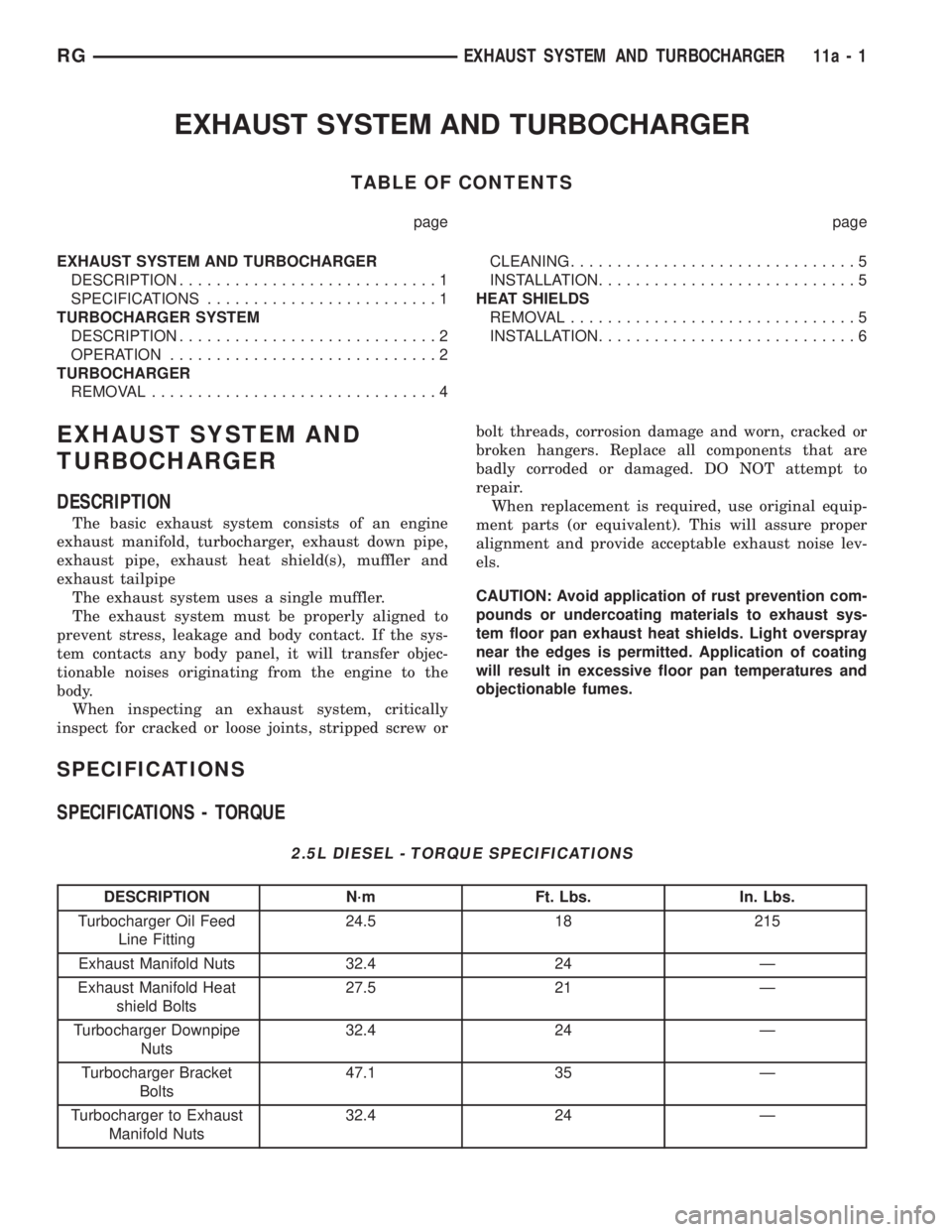

SPECIFICATIONS

SPECIFICATIONS - TORQUE

2.5L DIESEL - TORQUE SPECIFICATIONS

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Turbocharger Oil Feed

Line Fitting24.5 18 215

Exhaust Manifold Nuts 32.4 24 Ð

Exhaust Manifold Heat

shield Bolts27.5 21 Ð

Turbocharger Downpipe

Nuts32.4 24 Ð

Turbocharger Bracket

Bolts47.1 35 Ð

Turbocharger to Exhaust

Manifold Nuts32.4 24 Ð

RGEXHAUST SYSTEM AND TURBOCHARGER11a-1

Page 2909 of 4284

FUEL SYSTEM

TABLE OF CONTENTS

page page

FUEL SYSTEM 2.5L TURBO DIESEL

DESCRIPTION............................1

WARNING...............................1

DIAGNOSIS AND TESTING..................1

AIR IN FUEL SYSTEM....................1

FUEL SUPPLY RESTRICTIONS.............1STANDARD PROCEDURE...................2

WATER DRAINING AT FUEL FILTER.........2

CLEANING FUEL SYSTEM PARTS...........2

SPECIFICATIONS.........................2

FUEL DELIVERY..........................3

FUEL INJECTION........................10

FUEL SYSTEM 2.5L TURBO

DIESEL

DESCRIPTION - DIESEL FUEL DELIVERY

SYSTEM

The fuel system on the 2.5L Common Rail Diesel

Engine uses a fuel injection pump and an Electronic

Control Module (ECM).

The fuel delivery system consists of the:

²Accelerator pedal

²Air cleaner housing/element

²Fuel filter/water separator

²Fuel heater

²Fuel heater relay

²Fuel transfer (lift) pump

²Fuel injection pump

²Fuel injectors

²Fuel tank

²Fuel tank filler/vent tube assembly

²Fuel tank filler tube cap

²Fuel tank module containing the rollover valve

and a fuel gauge sending unit (fuel level sensor).

²Fuel tubes/lines/hoses

²High-pressure fuel injector lines

²Low-pressure fuel supply lines

²Low-pressure fuel return line

²Overflow valve

²Quick-connect fittings

²Water draining

WARNING - HIGH FUEL SYSTEM PRESSURE

WARNING: THE INJECTION PUMP SUPPLIES HIGH-

PRESSURE FUEL TO EACH INDIVIDUAL INJECTOR

THROUGH HIGH-PRESSURE LINES. FUEL UNDER

THIS AMOUNT OF PRESSURE CAN PENETRATE

SKIN AND CAUSE PERSONAL INJURY. WEAR

SAFETY GOGGLES AND ADEQUATE PROTECTIVE

CLOTHING. AVOID CONTACT WITH FUEL SPRAY

WHEN BLEEDING HIGH-PRESSURE FUEL LINES.

DIAGNOSIS AND TESTING - AIR IN FUEL

SYSTEM

Air will enter the fuel system whenever fuel supply

lines, separator filters, injection pump, high-pressure

lines or injectors are removed or disconnected. Air

trapped in the fuel system can result in hard start-

ing, a rough running engine, engine misfire, low

power, excessive smoke and fuel knock. After service

is performed, air must be bled from the system

before starting the engine.

Inspect the fuel system from the fuel transfer

pump to the injectors for loose connections. Leaking

fuel is an indicator of loose connections or defective

seals. Air can also enter the fuel system between the

fuel tank and the transfer pump. Inspect the fuel

tank and fuel lines for damage that might allow air

into the system.

DIAGNOSIS AND TESTING - FUEL SUPPLY

RESTRICTIONS

LOW-PRESSURE LINES

Fuel supply line restrictions or a defective fuel

transfer pump can cause starting problems and pre-

vent engine from accelerating. The starting problems

include; low power and/or white fog like exhaust.

Test all fuel supply lines for restrictions or block-

age. Flush or replace as necessary. Bleed fuel system

of air once a fuel supply line has been replaced. Refer

to Air Bleed Procedure for procedures.

To test for fuel line restrictions, a vacuum restric-

tion test may be performed. Refer to Fuel Transfer

Pump Pressure Test.

HIGH-PRESSURE LINES

Restricted (kinked or bent) high-pressure lines can

cause starting problems, poor engine performance,

engine mis-fire and white smoke from exhaust.

Examine all high-pressure lines for any damage.

Each radius on each high-pressure line must be

smooth and free of any bends or kinks.

RGFUEL SYSTEM14a-1