Power steering pump CHRYSLER VOYAGER 2001 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2778 of 4284

(17) Remove the water pump for cover removal

clearance. (Refer to 7 - COOLING/ENGINE/WATER

PUMP - REMOVAL)

(18) Remove the bolt attaching the power steering

pump support strut to the front cover (Fig. 153).

(19) Remove the timing chain cover (Fig. 154).

INSTALLATION

(1) Be sure mating surfaces of chain case cover

and cylinder block are clean and free from burrs.

Crankshaft oil seal must be removed to insure cor-

rect oil pump engagement.

NOTE: DO NOT USE SEALER ON COVER GASKET

(2) Position new gasket on timing cover (Fig. 154).

Adhere new gasket to chain case cover, making sure

that the lower edge of the gasket is flush to 0.5 mm

(0.020 in.) passed the lower edge of the cover.

(3) Rotate crankshaft so that the oil pump drive

flats are in the vertical position.

(4) Position oil pump inner rotor so the mating

flats are in the same position as the crankshaft drive

flats (Fig. 154).

CAUTION: Make sure the oil pump is engaged on

the crankshaft correctly or severe damage may

result.

Fig. 149 OIL PICKUP TUBE

1 - BOLT

2 - OIL PICK-UP TUBE

3 - O-RING

Fig. 150 HEATER RETURN HOSE (Without Engine

Oil Cooler)

1 - CAP AND CLAMP (OIL COOLER EQUIPPED ONLY)

2 - HOSE ASSEMBLY - HEATER RETURN

3 - BOLT - HEATER TUBE ATTACHING

4 - BOLT - HEATER TUBE ATTACHING

Fig. 151 HEATER HOSES 3.3/3.8L (With Engine Oil

Cooler)

1 - HOSE - HEATER SUPPLY

2 - HOSE - HEATER RETURN

3 - TUBE ASSEMBLY - HEATER RETURN

4 - BOLT - TUBE ASSEMBLY

5 - BOLT - TUBE ASSEMBLY

6 - HOSE - HEATER RETURN/OIL COOLER OUTLET

9 - 154 ENGINE 3.3/3.8LRS

TIMING CHAIN COVER (Continued)

Page 2779 of 4284

(5) Install timing cover (Fig. 154).

(6) Install timing chain cover bolts. Tighten M8

bolts to 27 N´m (20 ft. lbs.) and M10 bolts to 54 N´m

(40 ft. lbs.) (Fig. 155).

(7) Install crankshaft front oil seal. (Refer to 9 -

ENGINE/ENGINE BLOCK/CRANKSHAFT OIL

SEAL - FRONT - INSTALLATION)(8) Install water pump and pulley. (Refer to 7 -

COOLING/ENGINE/WATER PUMP - INSTALLA-

TION)

(9) Install crankshaft vibration damper. (Refer to 9

- ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

(10) Install engine mount bracket (Fig. 152) and

tighten M10 to 54 N´m (40 ft. lbs.), M8 bolt to 28

N´m (21 ft. lb. lbs.).

(11) Install idler pulley on engine mount bracket

(Fig. 152).

(12) Install right side engine mount. (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION)

(13) Install camshaft sensor. Refer to IGNITION

SYSTEM for procedure.

(14) Connect the heater return hose at rear of tim-

ing chain cover (Fig. 150) or at water pump inlet

tube (if engine oil cooler equipped) (Fig. 151).

(15) Connect the radiator lower hose.

(16) Install A/C compressor.

(17) Install accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION)

(18) Install oil pump pick-up tube with new

O-ring. Tighten attaching bolt to 28 N´m (250 in.

lbs.).

(19) Install oil pan. (Refer to 9 - ENGINE/LUBRI-

CATION/OIL PAN - INSTALLATION)

(20) Install inner splash shield and right front

wheel.

(21) Fill crankcase with engine oil to proper level.

(22) Fill cooling system. (Refer to 7 - COOLING -

STANDARD PROCEDURE)

(23) Connect negative cable to battery.

Fig. 152 Engine Mount Bracket

1 - CAMSHAFT SENSOR

2 - BOLT - CAMSHAFT SENSOR

3 - BOLT - MOUNT BRACKET (VERTICAL)

4 - BRACKET - ENGINE MOUNT

5 - BOLT - MOUNT BRACKET (HORIZONTAL)

6 - PULLEY - IDLER

7 - BOLT - IDLER PULLEY

8 - SPACER - IDLER PULLEY BOLT

9 - BOLT - MOUNT BRACKET (HORIZONTAL)

Fig. 153 Power Steering Pump Strut

1 - BOLT - LOWER

2 - STRUT - P/S PUMP

3 - BOLT - UPPER

Fig. 154 Timing Chain Cover and Gasket

1 - GASKET

2 - TIMING CHAIN COVER

RSENGINE 3.3/3.8L9 - 155

TIMING CHAIN COVER (Continued)

Page 2785 of 4284

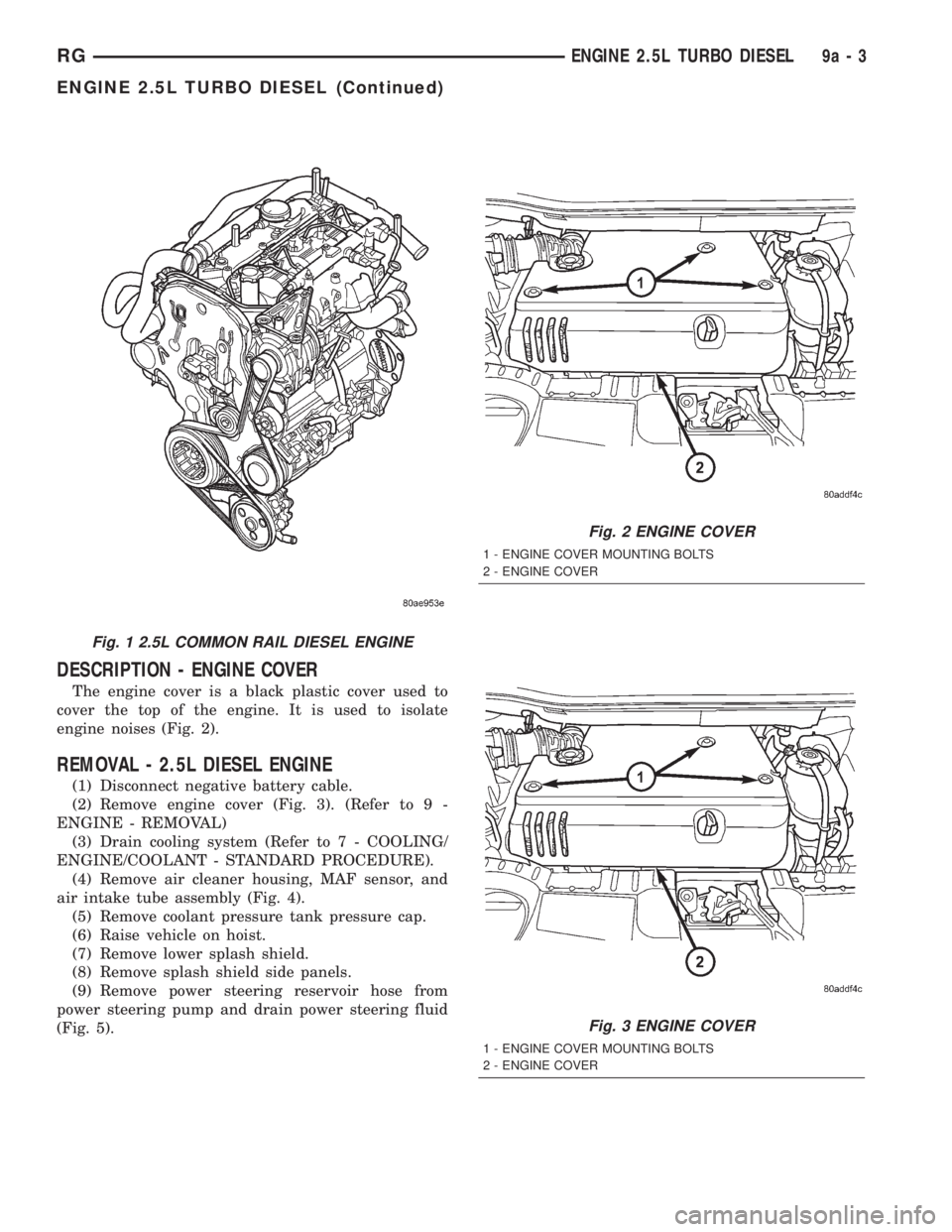

DESCRIPTION - ENGINE COVER

The engine cover is a black plastic cover used to

cover the top of the engine. It is used to isolate

engine noises (Fig. 2).

REMOVAL - 2.5L DIESEL ENGINE

(1) Disconnect negative battery cable.

(2) Remove engine cover (Fig. 3). (Refer to 9 -

ENGINE - REMOVAL)

(3) Drain cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(4) Remove air cleaner housing, MAF sensor, and

air intake tube assembly (Fig. 4).

(5) Remove coolant pressure tank pressure cap.

(6) Raise vehicle on hoist.

(7) Remove lower splash shield.

(8) Remove splash shield side panels.

(9) Remove power steering reservoir hose from

power steering pump and drain power steering fluid

(Fig. 5).

Fig. 1 2.5L COMMON RAIL DIESEL ENGINE

Fig. 2 ENGINE COVER

1 - ENGINE COVER MOUNTING BOLTS

2 - ENGINE COVER

Fig. 3 ENGINE COVER

1 - ENGINE COVER MOUNTING BOLTS

2 - ENGINE COVER

RGENGINE 2.5L TURBO DIESEL9a-3

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2786 of 4284

(10) Disconnect high pressure line at pump (Fig.

5).

(11) Disconnect power steering pump return hose

clamp (Fig. 5).

(12) Remove power steering return line retaining

clamp (Fig. 5).

(13) Remove power steering line clamps from oil

pan (Fig. 5).

(14) Remove power steering pump reservoir and

bracket (Fig. 5).

(15) Drain coolant system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(16) Remove coolant pressure tank (Fig. 6).

(17) Remove battery shield.

(18) Remove charge air cooler outlet hose.

(19) Remove charge air cooler inlet hose (Fig. 7).

(20) Disconnect upper radiator hose at engine (Fig.

8).

(21) Disconnect lower radiator hose at engine (Fig.

8).

(22) Disconnet brake booster vacuum supply hose.

(23) Disconnect heater core return hose at engine.

Fig. 4 MASS AIR FLOW (MAF) SENSOR LOCATION

1 - MAF SENSOR ELECTRICAL CONNECTOR

2 - RETAINING CLAMPS

3 - MASS AIR FLOW (MAF) SENSOR

4 - AIR CLEANER HOUSING

Fig. 5 RESERVOIR AND HOSES - 2.5L DIESEL

1 - RESERVOIR

2 - RESERVOIR BRACKET

3 - SUPPLY HOSE BRACKET

4 - RETURN HOSE FROM GEAR

5 - ROUTING CLIP

6 - PRESSURE HOSE TO GEAR

7 - SUPPLY HOSE (PUMP END)

8 - PRESSURE HOSE (PUMP END)

9 - SUPPLY HOSE

10 - RETURN HOSE

Fig. 6 COOLANT RECOVERY PRESSURE

CONTAINER LOCATION

1 - PRESSURE/VENT CAP

2 - BRAKE MASTER CYLINDER

3 - BATTERY

4 - BATTERY SHIELD

5 - COOLANT RECOVERY PRESSURE CONTAINER RETAING

CLIP

6 - ENGINE COVER

7 - COOLANT RECOVERY PRESSURE CONTAINER

9a - 4 ENGINE 2.5L TURBO DIESELRG

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2789 of 4284

(7) Attach front engine mount bracket to lower

radiator support. Torque to 54N´m (40 ft. lbs.)

(8) Connect cabin heater coolant hose.

(9) Connect exhaust pipe to the turbocharger

downpipe flange. Torque to 28 N´m (250 in. lbs.)

(10) Connect reverse lamp electrical connector at

transmission.

(11) Connect both shifter cables (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL/GEAR

SHIFT CABLE - INSTALLATION).

(12) Connect the clutch slave cylinder quick dis-

connect connector (RHD only)(Refer to 6 - CLUTCH/

SLAVE CYLINDER - INSTALLATION).

(13) Install engine harness into bracket on trans-

mission.

(14) Lower vehicle.

(15) Connect fuel supply and return lines.

(16) Connect A/C lines to A/C compressor. Torque

to 23N´m (17 ft. lbs.)

(17) Route engine wiring harnes to proper location.

(18) Connect engine harness ground cables to

engine block

(19) Connect starter solenoid electrical connector

and battery feed wire to starter. Torque to 10N´m (90

in. lbs.)

(20) Connect A/C compressor, injection pump, glow

plugs, and coolant temperature sensor electrical con-

nectors.

(21) Connect generator electrical connector. Torque

to 9N´m (75 in. lbs.)

(22) Connect the fuel injector, fuel pressure sensor,

boost pressure/intake air temp sensor, cam sensor,

and egr solenoid electrical connectors (Fig. 9).

(23) Connect egr solenoid vacuum supply line to

brake boost vacuum supply line.

(24) Connect brake booster vacuum supply line.

(25) Connect heater core return hose to coolant

pipe.

(26) Connect lower radiator hose to engine (Fig. 8).

(27) Install charger air cooler inlet hose (Fig. 7).

(28) Install charge air cooler outlet hose (Fig. 7).

(29) Connect upper radiator hose to engine (Fig.

8).

(30) Install battery shield.

(31) Install coolant reserve pressure container

(Refer to 7 - COOLING/ENGINE/COOLANT RECOV-

ERY PRESS CONTAINER - INSTALLATION).

(32) Install power steering reservoir and bracket

(Fig. 5).

(33) Raise vehicle

(34) Connect oil pressure sensor, oil temperature

sensor, engine speed sensor, and vehicle speed sensor

electrical connector (Fig. 10).(35) Install suspension cradle in vehicle (Refer to

13 - FRAME & BUMPERS/FRAME/ENGINE CRA-

DLE CROSSMEMBER - INSTALLATION).

(36) Install both axle shaft assemblies (Refer to 3 -

DIFFERENTIAL & DRIVELINE/HALF SHAFT -

INSTALLATION).

(37) Connect the power steering supply, pressure,

and return lines to power steering pump (Fig. 5).

(38) Install the power steering line brackets on oil

pan (Fig. 5).

(39) Install lower splash shield and side panels.

(40) Install both front wheel and tire assemblies.

(41) Lower vehicle.

(42) Install air cleaner housing, MAF sensor, and

air intake tube assembly (Fig. 4).

(43) Refill transmission to proper level (Refer to 21

- TRANSMISSION/TRANSAXLE/MANUAL/FLUID -

STANDARD PROCEDURE).

(44) Refill engine coolant (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(45) Recharge A/C system (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING/REFRIGER-

ANT - STANDARD PROCEDURE) .

(46) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION) (Fig. 3).

(47) Connect negative battery cable.

INSTALLATION - ENGINE COVER

(1) Install engine cover on engine.

(2) Install the engine cover mounting bolts (Fig.

11).

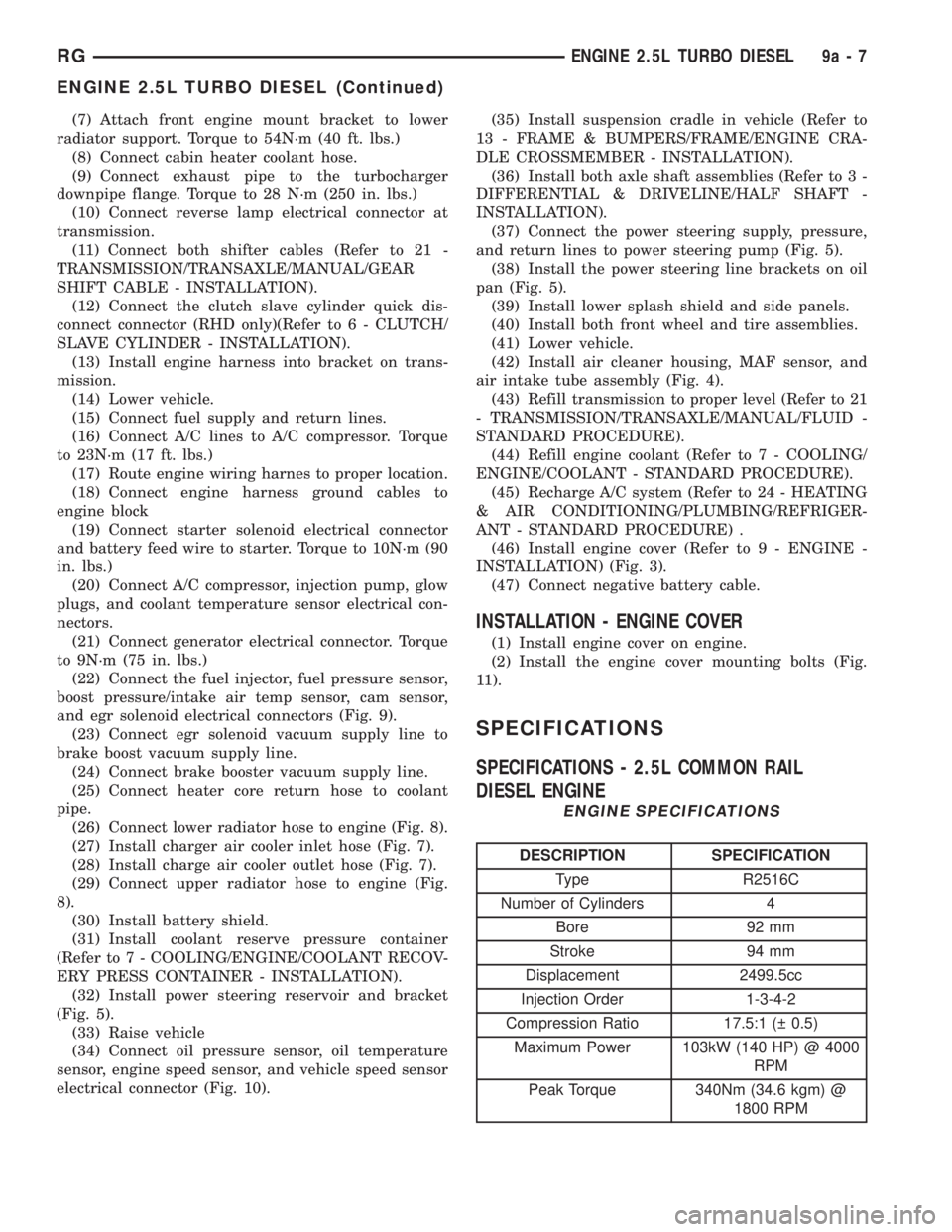

SPECIFICATIONS

SPECIFICATIONS - 2.5L COMMON RAIL

DIESEL ENGINE

ENGINE SPECIFICATIONS

DESCRIPTION SPECIFICATION

Type R2516C

Number of Cylinders 4

Bore 92 mm

Stroke 94 mm

Displacement 2499.5cc

Injection Order 1-3-4-2

Compression Ratio 17.5:1 ( 0.5)

Maximum Power 103kW (140 HP) @ 4000

RPM

Peak Torque 340Nm (34.6 kgm) @

1800 RPM

RGENGINE 2.5L TURBO DIESEL9a-7

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2796 of 4284

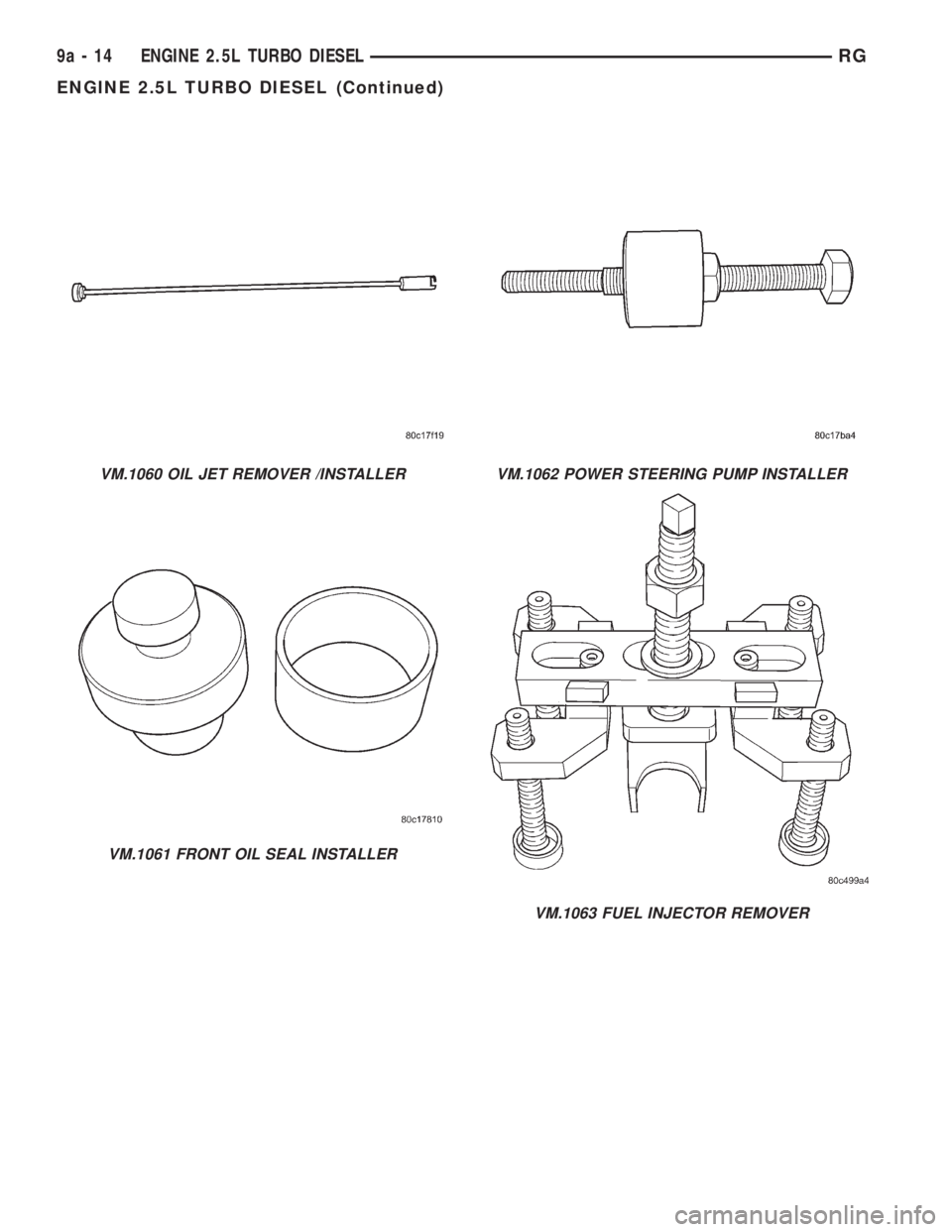

VM.1060 OIL JET REMOVER /INSTALLER

VM.1061 FRONT OIL SEAL INSTALLER

VM.1062 POWER STEERING PUMP INSTALLER

VM.1063 FUEL INJECTOR REMOVER

9a - 14 ENGINE 2.5L TURBO DIESELRG

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2797 of 4284

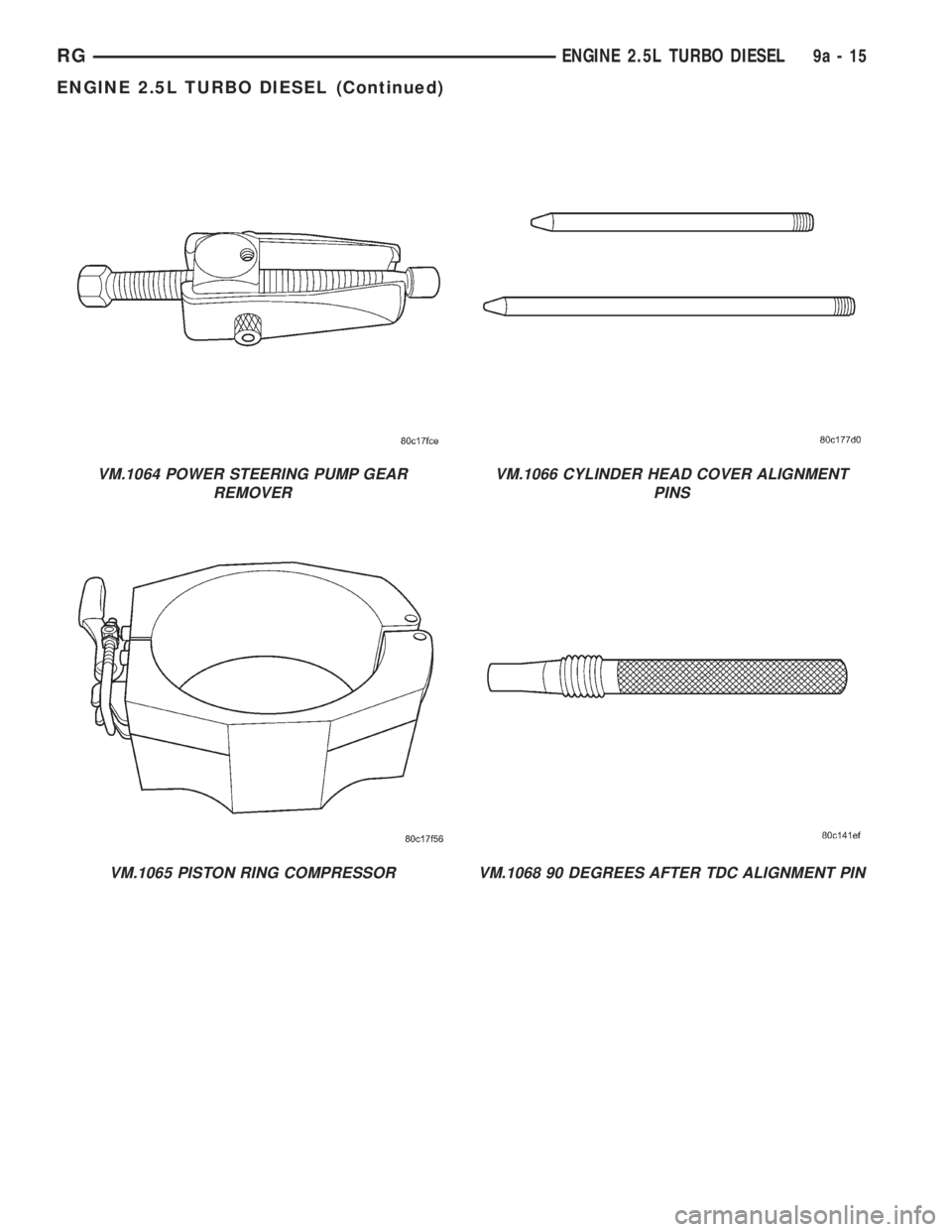

VM.1064 POWER STEERING PUMP GEAR

REMOVER

VM.1065 PISTON RING COMPRESSOR

VM.1066 CYLINDER HEAD COVER ALIGNMENT

PINS

VM.1068 90 DEGREES AFTER TDC ALIGNMENT PIN

RGENGINE 2.5L TURBO DIESEL9a-15

ENGINE 2.5L TURBO DIESEL (Continued)

Page 2807 of 4284

(7) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(8) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(9) Remove generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - REMOVAL).

(10) Support engine and remove right engine

mount (Refer to 9 - ENGINE/ENGINE MOUNTING/

RIGHT MOUNT - REMOVAL).

(11) Remove outer timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(12) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(13) Remove inner timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(14) Disconnect camshaft position sensor, boost

pressure/intake air temperature sensor, EGR sole-

noid, and fuel pressure sensor electrical connectors

(Fig. 24).

(15) Disconnect vacuum lines at EGR solenoid.

(16) Position electrical harness out of way.(17) Remove fuel injectors (Refer to 14 - FUEL

SYSTEM/FUEL INJECTION/FUEL INJECTOR -

REMOVAL).

(18) Remove fuel rail (Refer to 14 - FUEL SYS-

TEM/FUEL DELIVERY/FUEL RAIL - REMOVAL).

(19) Remove power steering pump reservoir from

bracket.

(20) Remove oil dipstick tube retaining bolt at

intake manifold inlet.

(21) Disconnect oil separator outlet hose at separa-

tor.

(22) Remove turbo inlet tube retaining bolt at

intake manifold.

(23) Disconnect EGR tube at intake manifold inlet

tube.

Fig. 23 CYLINDER HEAD COVER/INTAKE

MANIFOLDFig. 24 ENGINE COMPONENT LOCATIONS

1 - FUEL INJECTOR RETURN LINE

2 - FUEL INJECTOR SUPPLY LINE

3 - OIL SEPARATOR

4 - FUEL INJECTOR

5 - CAMSHAFT POSITION SENSOR

6 - BOOST PRESSURE/INTAKE AIR TEMPERATURE SENSOR

7 - EGR SOLENOID

8 - FUEL PRESSURE SENSOR

9 - CYLINDER HEAD COVER/INTAKE MANIFOL

10 - FUEL RAIL

11 - WIRING HARNESS RETAINING CLIPS

RGENGINE 2.5L TURBO DIESEL9a-25

CYLINDER HEAD COVER(S) (Continued)

Page 2809 of 4284

(4) Install turbo inlet tube retaining bolt at intake

manifold. Torque bolt to 27.5 N´m.

(5) Connect oil separator outlet hose at separator.

(6) Install oil dipstick tube retaining bolt at intake

manifold inlet. Torque bolt to 10 N´m.

(7) Install power steering pump reservoir in

bracket.

(8) Install fuel rail (Refer to 14 - FUEL SYSTEM/

FUEL DELIVERY/FUEL RAIL - INSTALLATION).

(9) Install fuel injectors and fuel injector supply

lines (Refer to 14 - FUEL SYSTEM/FUEL INJEC-

TION/FUEL INJECTOR - INSTALLATION).

(10) Connect vacuum lines at EGR solenoid.

(11) Clip wiring harness retainers on studs on fuel

rail (Fig. 24).

(12) Connect camshaft position sensor, boost pres-

sure/intake air temperature sensor, EGR solenoid,

and fuel pressure sensor electrical connectors (Fig.

24).

(13) Install inner timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(14) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - INSTALLATION) .

(15) Install outer timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(16) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(17) Install generator (Refer to 8 - ELECTRICAL/

CHARGING/GENERATOR - INSTALLATION).

(18) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(19) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(20) Install air cleaner housing assembly.

(21) Remove crankshaft and both camshaft locking

pins (Refer to 9 - ENGINE/VALVE TIMING - STAN-

DARD PROCEDURE).

(22) Refill cooling system (Refer to 7 - COOLING/

ENGINE/COOLANT - STANDARD PROCEDURE).

(23) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(24) Install front wiper unit (Refer to 8 - ELEC-

TRICAL/WIPERS/WASHERS/WIPER MODULE -

INSTALLATION).

(25) Connect negative battery cable.

Fig. 27 CYLINDER HEAD COVER/INTAKE

MANIFOLD ALIGNMENT STUDS VM.1066

1 - CYLINDER HEAD COVER/INTAKE MANIFOLD ALIGNMENT

STUDS VM.1066

2 - CYLINDER HEAD

Fig. 28 CYLINDER HEAD COVER/INTAKE

MANIFOLD TIGHTENING SEQUENCE

RGENGINE 2.5L TURBO DIESEL9a-27

CYLINDER HEAD COVER(S) (Continued)

Page 2818 of 4284

(8) Fit the liners in the crankcase making sure

that the shim is positioned correctly in the seat. Lock

the liners in position using special tool (VM.1076)

and bolts (Fig. 45). Clean the residual LOCTITE on

the upper surface of the block deck.

(9) Recheck the liner protrusion. It should be 0.01

- 0.06 mm.

NOTE: A period of six hours must elapse between

the liners being installed and engine start-up. If

engine assembly is not continued after liner instal-

lation, the liners need to be clamped for twelve

hours minimum.

(10) Reassemble engine.

(11) Install engine in vehicle.

INTERNAL VACUUM PUMP

DESCRIPTION

The diesel engine uses a internal vacuum pump.

This vacuum pump is mounted in the front of the

engine block under the engine front cover (Fig. 46).

The vacuum pump is driven by a sprocket on the

crankshaft.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove air cleaner housing.

(3) Remove power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(4) Remove accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(5) Support engine and remove right engine mount

(Refer to 9 - ENGINE/ENGINE MOUNTING/RIGHT

MOUNT - REMOVAL).

(6) Remove vibration damper/crankshaft pulley

(Refer to 9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(7) Remove outer timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

(8) Remove timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT/CHAIN AND

SPROCKETS - REMOVAL).

(9) Remove timing belt inner cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - REMOVAL).

NOTE: Crankshaft hub has LHD thread.

(10) Remove crankshaft hub.

(11) Remove front engine cover (Refer to 9 -

ENGINE/ENGINE BLOCK/ENGINE COVER -

REMOVAL).

(12) Remove crankshaft sprocket (Fig. 47).

(13) Remove vacuum pump (Fig. 47).

INSTALLATION

(1) Lubricate vacuum pump components and

install in engine block (Fig. 47). Torque bolts to

10.8N´m.

(2) Install crankshaft sprocket (Fig. 47). Torque

bolts to 10.8N´m.

(3) Install front engine cover (Refer to 9 -

ENGINE/ENGINE BLOCK/ENGINE COVER -

INSTALLATION).

Fig. 45 LINER CLAMP LOCATION

1 - ENGINE BLOCK

2 - LINER RETAINER VM.1076

3 - CYLINDER LINER

Fig. 46 VACUUM PUMP

9a - 36 ENGINE 2.5L TURBO DIESELRG

CYLINDER LINERS (Continued)