ad blue CHRYSLER VOYAGER 2001 Owner's Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3556 of 4284

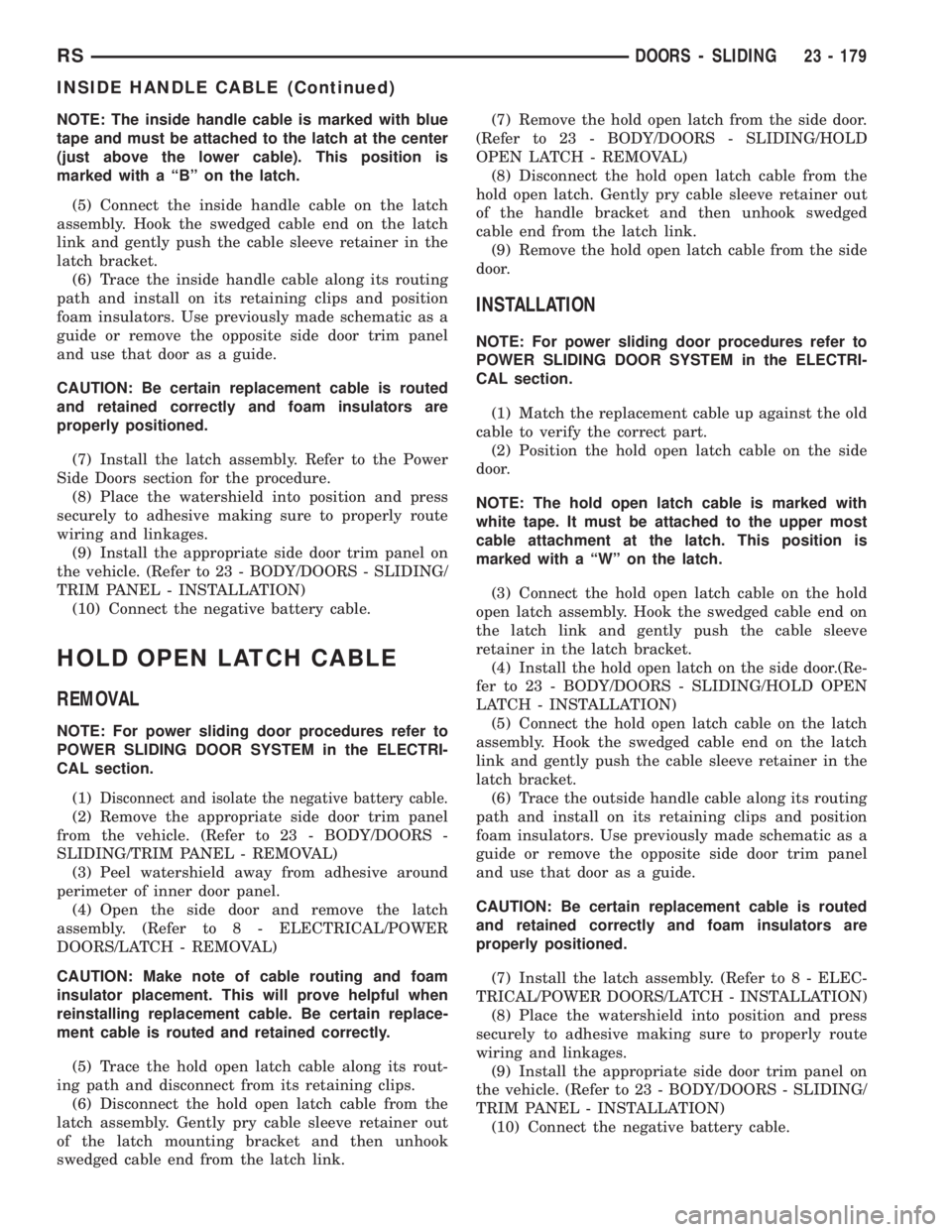

(7) Rotate latch release button away from mecha-

nism until flats on button pivots align with slots in

mechanism (Fig. 30).

(8) Remove button from release mechanism.

INSTALLATION

(1) Position button on release mechanism.

(2) Align and engage flats on button pivots into

slots in mechanism (Fig. 30).

(3) Rotate latch release button into mechanism.

(4) Place release mechanism in position on handle.

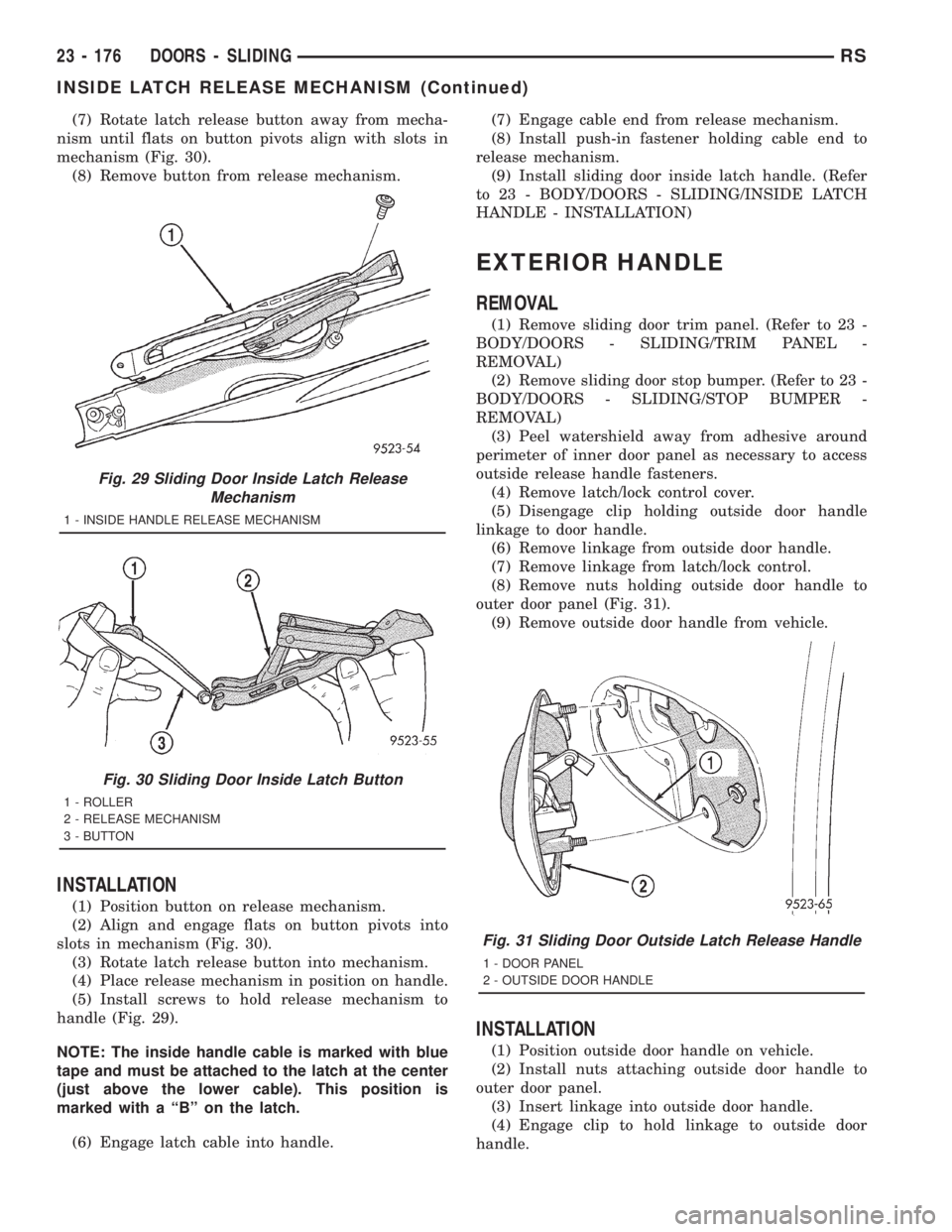

(5) Install screws to hold release mechanism to

handle (Fig. 29).

NOTE: The inside handle cable is marked with blue

tape and must be attached to the latch at the center

(just above the lower cable). This position is

marked with a ªBº on the latch.

(6) Engage latch cable into handle.(7) Engage cable end from release mechanism.

(8) Install push-in fastener holding cable end to

release mechanism.

(9) Install sliding door inside latch handle. (Refer

to 23 - BODY/DOORS - SLIDING/INSIDE LATCH

HANDLE - INSTALLATION)

EXTERIOR HANDLE

REMOVAL

(1) Remove sliding door trim panel. (Refer to 23 -

BODY/DOORS - SLIDING/TRIM PANEL -

REMOVAL)

(2) Remove sliding door stop bumper. (Refer to 23 -

BODY/DOORS - SLIDING/STOP BUMPER -

REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel as necessary to access

outside release handle fasteners.

(4) Remove latch/lock control cover.

(5) Disengage clip holding outside door handle

linkage to door handle.

(6) Remove linkage from outside door handle.

(7) Remove linkage from latch/lock control.

(8) Remove nuts holding outside door handle to

outer door panel (Fig. 31).

(9) Remove outside door handle from vehicle.

INSTALLATION

(1) Position outside door handle on vehicle.

(2) Install nuts attaching outside door handle to

outer door panel.

(3) Insert linkage into outside door handle.

(4) Engage clip to hold linkage to outside door

handle.

Fig. 29 Sliding Door Inside Latch Release

Mechanism

1 - INSIDE HANDLE RELEASE MECHANISM

Fig. 30 Sliding Door Inside Latch Button

1 - ROLLER

2 - RELEASE MECHANISM

3 - BUTTON

Fig. 31 Sliding Door Outside Latch Release Handle

1 - DOOR PANEL

2 - OUTSIDE DOOR HANDLE

23 - 176 DOORS - SLIDINGRS

INSIDE LATCH RELEASE MECHANISM (Continued)

Page 3559 of 4284

NOTE: The inside handle cable is marked with blue

tape and must be attached to the latch at the center

(just above the lower cable). This position is

marked with a ªBº on the latch.

(5) Connect the inside handle cable on the latch

assembly. Hook the swedged cable end on the latch

link and gently push the cable sleeve retainer in the

latch bracket.

(6) Trace the inside handle cable along its routing

path and install on its retaining clips and position

foam insulators. Use previously made schematic as a

guide or remove the opposite side door trim panel

and use that door as a guide.

CAUTION: Be certain replacement cable is routed

and retained correctly and foam insulators are

properly positioned.

(7) Install the latch assembly. Refer to the Power

Side Doors section for the procedure.

(8) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(9) Install the appropriate side door trim panel on

the vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - INSTALLATION)

(10) Connect the negative battery cable.

HOLD OPEN LATCH CABLE

REMOVAL

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1)

Disconnect and isolate the negative battery cable.

(2) Remove the appropriate side door trim panel

from the vehicle. (Refer to 23 - BODY/DOORS -

SLIDING/TRIM PANEL - REMOVAL)

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

(4) Open the side door and remove the latch

assembly. (Refer to 8 - ELECTRICAL/POWER

DOORS/LATCH - REMOVAL)

CAUTION: Make note of cable routing and foam

insulator placement. This will prove helpful when

reinstalling replacement cable. Be certain replace-

ment cable is routed and retained correctly.

(5) Trace the hold open latch cable along its rout-

ing path and disconnect from its retaining clips.

(6) Disconnect the hold open latch cable from the

latch assembly. Gently pry cable sleeve retainer out

of the latch mounting bracket and then unhook

swedged cable end from the latch link.(7) Remove the hold open latch from the side door.

(Refer to 23 - BODY/DOORS - SLIDING/HOLD

OPEN LATCH - REMOVAL)

(8) Disconnect the hold open latch cable from the

hold open latch. Gently pry cable sleeve retainer out

of the handle bracket and then unhook swedged

cable end from the latch link.

(9) Remove the hold open latch cable from the side

door.

INSTALLATION

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

(1) Match the replacement cable up against the old

cable to verify the correct part.

(2) Position the hold open latch cable on the side

door.

NOTE: The hold open latch cable is marked with

white tape. It must be attached to the upper most

cable attachment at the latch. This position is

marked with a ªWº on the latch.

(3) Connect the hold open latch cable on the hold

open latch assembly. Hook the swedged cable end on

the latch link and gently push the cable sleeve

retainer in the latch bracket.

(4) Install the hold open latch on the side door.(Re-

fer to 23 - BODY/DOORS - SLIDING/HOLD OPEN

LATCH - INSTALLATION)

(5) Connect the hold open latch cable on the latch

assembly. Hook the swedged cable end on the latch

link and gently push the cable sleeve retainer in the

latch bracket.

(6) Trace the outside handle cable along its routing

path and install on its retaining clips and position

foam insulators. Use previously made schematic as a

guide or remove the opposite side door trim panel

and use that door as a guide.

CAUTION: Be certain replacement cable is routed

and retained correctly and foam insulators are

properly positioned.

(7) Install the latch assembly. (Refer to 8 - ELEC-

TRICAL/POWER DOORS/LATCH - INSTALLATION)

(8) Place the watershield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(9) Install the appropriate side door trim panel on

the vehicle. (Refer to 23 - BODY/DOORS - SLIDING/

TRIM PANEL - INSTALLATION)

(10) Connect the negative battery cable.

RSDOORS - SLIDING23 - 179

INSIDE HANDLE CABLE (Continued)

Page 3600 of 4284

PAINT

TABLE OF CONTENTS

page page

PAINT

SPECIFICATIONS........................220

PAINT CODE

DESCRIPTION..........................221

BASE COAT/CLEAR COAT FINISH

DESCRIPTION..........................221PAINT TOUCH-UP

DESCRIPTION..........................221

WET SANDING/BUFFING & POLISHING

DESCRIPTION..........................221

PAINT

SPECIFICATIONS

COLOR CODE CHARTS

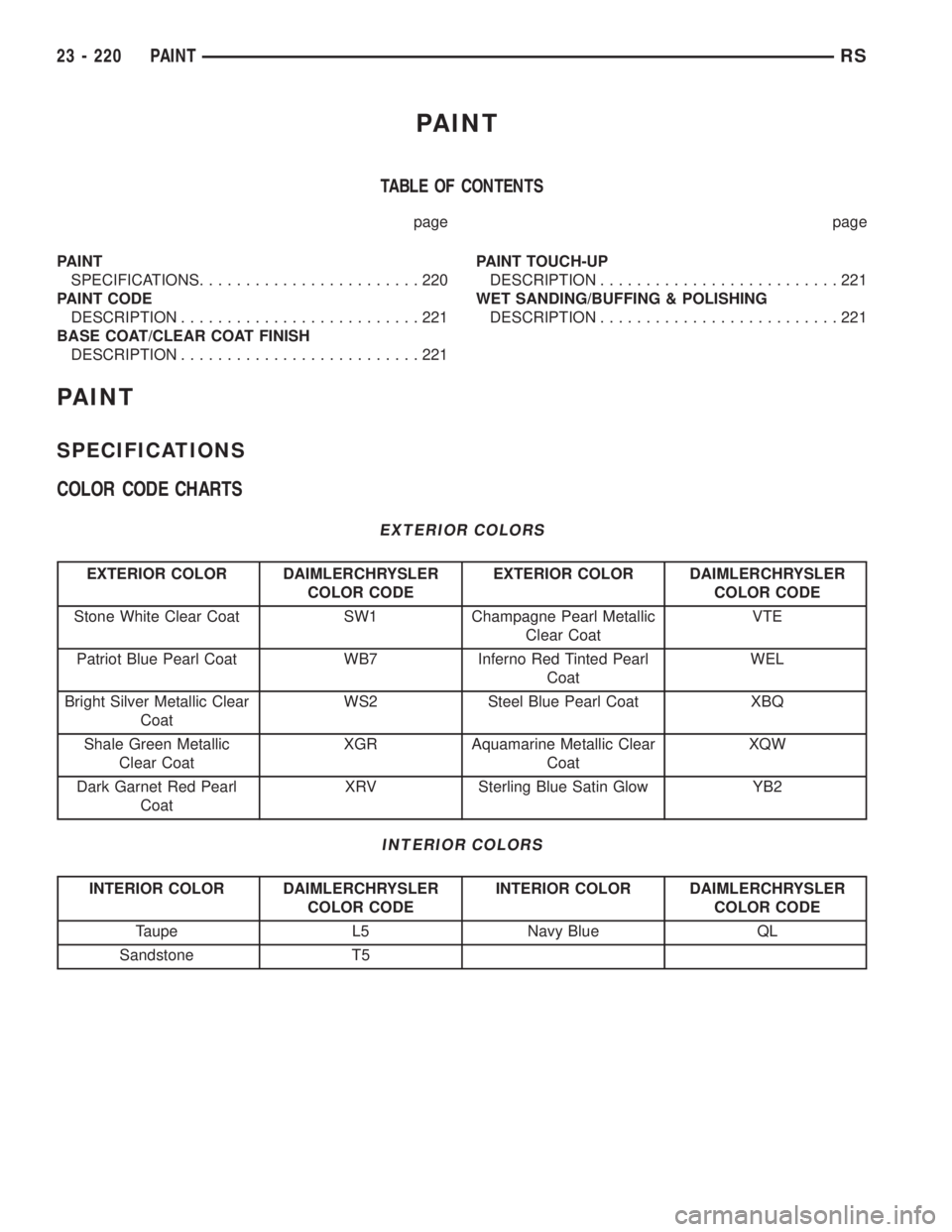

EXTERIOR COLORS

EXTERIOR COLOR DAIMLERCHRYSLER

COLOR CODEEXTERIOR COLOR DAIMLERCHRYSLER

COLOR CODE

Stone White Clear Coat SW1 Champagne Pearl Metallic

Clear CoatVTE

Patriot Blue Pearl Coat WB7 Inferno Red Tinted Pearl

CoatWEL

Bright Silver Metallic Clear

CoatWS2 Steel Blue Pearl Coat XBQ

Shale Green Metallic

Clear CoatXGR Aquamarine Metallic Clear

CoatXQW

Dark Garnet Red Pearl

CoatXRV Sterling Blue Satin Glow YB2

INTERIOR COLORS

INTERIOR COLOR DAIMLERCHRYSLER

COLOR CODEINTERIOR COLOR DAIMLERCHRYSLER

COLOR CODE

Taupe L5 Navy Blue QL

Sandstone T5

23 - 220 PAINTRS

Page 3720 of 4284

valves at the service port connector ends. This will

prevent refrigerant from being released into the

atmosphere.

²LOW PRESSURE GAUGE HOSE- The low

pressure hose (Blue with Black stripe) attaches to

the suction (low side) service port. This port is

located on the suction line, near the compressor at

the front of the engine compartment.

²HIGH PRESSURE GAUGE HOSE- The high

pressure hose (Red with Black stripe) attaches to the

discharge (high side) service port. This port is located

on the liquid line near the filter-drier at the rear of

the engine compartment.

²RECOVERY/RECYCLING/EVACUATION/

CHARGING HOSE- The center manifold hose (Yel-

low, or White, with Black stripe) is used to recover,

evacuate, and charge the refrigerant system. When

the low or high pressure valves on the manifold

gauge set are opened, the refrigerant in the system

will escape through this hose.

STANDARD PROCEDURE - REFRIGERANT

SYSTEM CHARGE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

After all refrigerant system leaks have been

repaired and the refrigerant system has been evacu-

ated, a refrigerant charge can be injected into the

system. For the proper amount of the refrigerant

charge, refer to REFRIGERANT CHARGE CAPAC-

ITY . A R-134a refrigerant recovery/recycling/charg-

ing station that meets SAE Standard J2210 must be

used to charge the refrigerant system with R-134a

refrigerant. See the operating instructions supplied

by the equipment manufacturer for proper care and

use of this equipment.

REFRIGERANT CHARGE CAPACITY

The R-134a refrigerant system charge capacity for

this vehicle is:

²Single or Dual Zone (Front Unit Only)- 0.96

kilograms (2.13 pounds or 34 ounces)

²Three Zone (Front and Rear Units)- 1.31

kilograms (2.88 pounds or 46 ounces)

CHARGING PROCEDURE

(1) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(2) A manifold gauge set and a R-134a refrigerant

recovery/recycling/charging station that meets SAE

Standard J2210 should still be connected to the

refrigerant system.

(3) Measure the proper amount of refrigerant and

heat it to 52É C (125É F) with the charging station.

See the operating instructions supplied by the equip-

ment manufacturer for proper use of this equipment.

(4) Open both the suction and discharge valves,

then open the charge valve to allow the heated

refrigerant to flow into the system.

(5) When the transfer of refrigerant has stopped,

close both the suction and discharge valves.

(6) If all of the refrigerant charge did not transfer

from the dispensing device, open all of the windows

in the vehicle and set the heater-air conditioner con-

trols so that the compressor is engaged and the

blower motor is operating at its lowest speed setting.

Run the engine at a steady high idle (about 1400

Fig. 33 Manifold Gauge Set - Typical

1 - HIGH PRESSURE GAUGE

2 - VALVE

3 - VACUUM/REFRIGERANT HOSE (YELLOW W/BLACK STRIPE)

4 - HIGH PRESSURE HOSE (RED W/BLACK STRIPE)

5 - LOW PRESSURE HOSE (BLUE W/BLACK STRIPE)

6 - VALVE

7 - LOW PRESSURE GAUGE

24 - 90 PLUMBING - FRONTRS

REFRIGERANT (Continued)