CHRYSLER VOYAGER 2001 Service Manual

Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4111 of 4284

Name of code:P1781(21) - OD Pressure Switch

Sense Circuit

When monitored:Whenever the engine is run-

ning.

Set condition:This code is set if the OD pressure

switch is open or closed at the wrong time in a given

gear (see chart below).

Theory of operation:The Transmission system

uses three pressure switches to monitor the fluid

pressure in the L-R, 2-4, and OD clutch circuits.

The pressure switches are continuously monitored

for the correct states in each gear as shown below.

Normal Pressure Switch States

Gear

L-R2-4OD

R OPOPOP

NCLOPOP

1st CL OP OP

2nd OP CL OP

3rd OP OP CL

4th OP CL CL

OP = switch is open

CL = switch is closed

Transmission Effects:Normal operation will be

experienced if no other codes are present. TCM will

ignore the code. Limp-in condition will only occur if

code P1781(21) is present with a code P0705(28).

Possible causes:

> If code P1791(35) is present, ignore code

P1781(21) and perform code P1791 diagnostic

procedures

> OD pressure switch sense circuit open or shorted

to ground between TCM and solenoid pack

> OD pressure switch sense circuit shorted to bat-

tery

> Solenoid pack

> Loose valve body bolts

> Plugged filter - internal transmission or torque

converter failure

> TCM

Name of code:P1782(22) - 2-4 Pressure Switch

Sense Circuit

When monitored:Whenever the engine is run-

ning.

Set condition:This code is set if the 2-4 pressure

switch is open or closed at the wrong time in a given

gear (see chart below).

Theory of operation:The Transmission system

uses three pressure switches to monitor the fluid

pressure in the L-R, 2-4, and OD elements. The

pressure switches are continuously monitored for

the correct states in each gear as shown below.

Normal Pressure Switch States

Gear

L-R2-4OD

R OPOPOP

NCLOPOP

1st CL OP OP

2nd OP CL OP

3rd OP OP CL

4th OP CL CL

OP = switch is open

CL = switch is closed

Transmission Effects: If the 2-4 pressure switch is

identified as closed in P or N, the code will imme-

diately be set and normal operation will be allowed

for that given key start. If the problem is identified

for 3 successive key starts, the transmission will go

into relay open limp-in mode. If the 2-4 pressure

switch is identified as being closed in 1st or 3rd gear

and was not identified as being closed in P or N,

then 2nd gear or 4th gear will be substituted for 1st

or 3rd gear depending on throttle angle and vehicle

speed. A short period of time after the gear substi-

tution, the transmission will return to normal op-

erating mode. If the transmission is shifted back

into 1st or 3rd gear through normal operation, and

the 2-4 pressure switch remains closed, 2nd or 4th

gear will be substituted briefly and then resume

normal operation. If four gear substitutions occur in

a given key start, the transmission will go into relay

open limp-in mode.

If the 2-4 pressure switch is open (indicating no

2-4 clutch pressure) in 2nd or 4th gear, the TCM

sets code P1782(22) and continues with normal

operation. The transmission will only go into relay

open limp-in mode if a code P0705(28) is also

present. If no 2-4 clutch pressure is present a speed

ratio code P0732(52) or P0734(54) will be set and

cause the limp-in condition.

Possible causes:

> If code P1791(35) is present, ignore code

P1782(22) and perform code P1791 diagnostic

procedures

> 2-4 pressure switch sense circuit open or shorted

to ground between TCM and solenoid pack

>

2-4 pressure switch sense circuit shorted to battery

> Solenoid pack

> Transmission overheated - Excessive regulator

valve leakage in valve body causing high line

pressure which results in 2-4 solenoid blow-off in

1st or 3rd gear. May require new valve body if it

happens only when hot.

> Loose valve body bolts

> Plugged filter - internal transmission or torque

converter failure

> TCM

7

GENERAL INFORMATION

Page 4112 of 4284

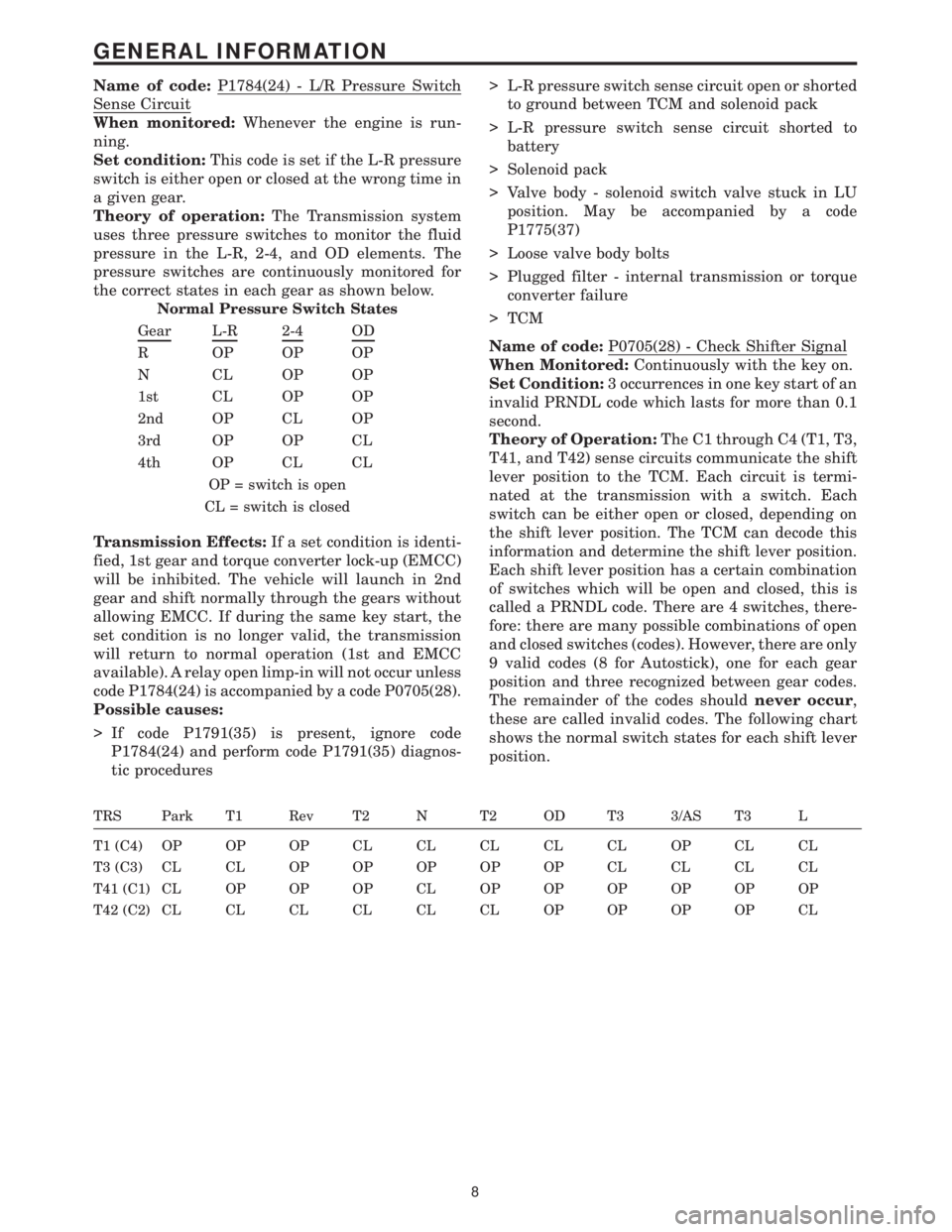

Name of code:P1784(24) - L/R Pressure Switch

Sense Circuit

When monitored:Whenever the engine is run-

ning.

Set condition:This code is set if the L-R pressure

switch is either open or closed at the wrong time in

a given gear.

Theory of operation:The Transmission system

uses three pressure switches to monitor the fluid

pressure in the L-R, 2-4, and OD elements. The

pressure switches are continuously monitored for

the correct states in each gear as shown below.

Normal Pressure Switch States

Gear

L-R2-4OD

R OPOPOP

NCLOPOP

1st CL OP OP

2nd OP CL OP

3rd OP OP CL

4th OP CL CL

OP = switch is open

CL = switch is closed

Transmission Effects:If a set condition is identi-

fied, 1st gear and torque converter lock-up (EMCC)

will be inhibited. The vehicle will launch in 2nd

gear and shift normally through the gears without

allowing EMCC. If during the same key start, the

set condition is no longer valid, the transmission

will return to normal operation (1st and EMCC

available). A relay open limp-in will not occur unless

code P1784(24) is accompanied by a code P0705(28).

Possible causes:

> If code P1791(35) is present, ignore code

P1784(24) and perform code P1791(35) diagnos-

tic procedures> L-R pressure switch sense circuit open or shorted

to ground between TCM and solenoid pack

> L-R pressure switch sense circuit shorted to

battery

> Solenoid pack

> Valve body - solenoid switch valve stuck in LU

position. May be accompanied by a code

P1775(37)

> Loose valve body bolts

> Plugged filter - internal transmission or torque

converter failure

> TCM

Name of code:P0705(28) - Check Shifter Signal

When Monitored:Continuously with the key on.

Set Condition:3 occurrences in one key start of an

invalid PRNDL code which lasts for more than 0.1

second.

Theory of Operation:The C1 through C4 (T1, T3,

T41, and T42) sense circuits communicate the shift

lever position to the TCM. Each circuit is termi-

nated at the transmission with a switch. Each

switch can be either open or closed, depending on

the shift lever position. The TCM can decode this

information and determine the shift lever position.

Each shift lever position has a certain combination

of switches which will be open and closed, this is

called a PRNDL code. There are 4 switches, there-

fore: there are many possible combinations of open

and closed switches (codes). However, there are only

9 valid codes (8 for Autostick), one for each gear

position and three recognized between gear codes.

The remainder of the codes shouldnever occur,

these are called invalid codes. The following chart

shows the normal switch states for each shift lever

position.

TRS Park T1 Rev T2 N T2 OD T3 3/AS T3 L

T1 (C4) OP OP OP CL CL CL CL CL OP CL CL

T3 (C3) CL CL OP OP OP OP OP CL CL CL CL

T41 (C1) CL OP OP OP CL OP OP OP OP OP OP

T42 (C2) CL CL CL CL CL CL OP OP OP OP CL

8

GENERAL INFORMATION

Page 4113 of 4284

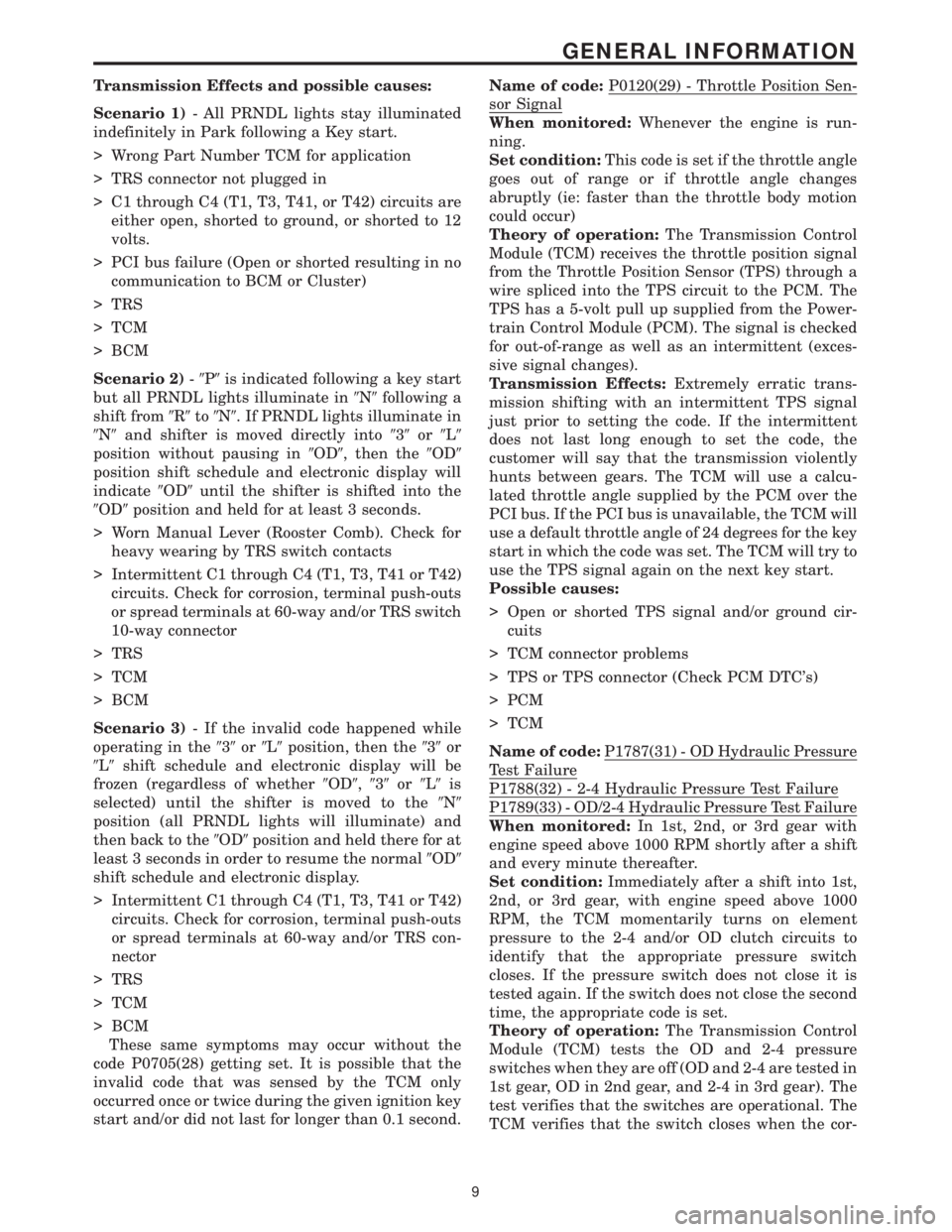

Transmission Effects and possible causes:

Scenario 1)- All PRNDL lights stay illuminated

indefinitely in Park following a Key start.

> Wrong Part Number TCM for application

> TRS connector not plugged in

> C1 through C4 (T1, T3, T41, or T42) circuits are

either open, shorted to ground, or shorted to 12

volts.

> PCI bus failure (Open or shorted resulting in no

communication to BCM or Cluster)

> TRS

> TCM

> BCM

Scenario 2)-9P9is indicated following a key start

but all PRNDL lights illuminate in9N9following a

shift from9R9to9N9. If PRNDL lights illuminate in

9N9and shifter is moved directly into939or9L9

position without pausing in9OD9, then the9OD9

position shift schedule and electronic display will

indicate9OD9until the shifter is shifted into the

9OD9position and held for at least 3 seconds.

> Worn Manual Lever (Rooster Comb). Check for

heavy wearing by TRS switch contacts

> Intermittent C1 through C4 (T1, T3, T41 or T42)

circuits. Check for corrosion, terminal push-outs

or spread terminals at 60-way and/or TRS switch

10-way connector

> TRS

> TCM

> BCM

Scenario 3)- If the invalid code happened while

operating in the939or9L9position, then the939or

9L9shift schedule and electronic display will be

frozen (regardless of whether9OD9,939or9L9is

selected) until the shifter is moved to the9N9

position (all PRNDL lights will illuminate) and

then back to the9OD9position and held there for at

least 3 seconds in order to resume the normal9OD9

shift schedule and electronic display.

> Intermittent C1 through C4 (T1, T3, T41 or T42)

circuits. Check for corrosion, terminal push-outs

or spread terminals at 60-way and/or TRS con-

nector

> TRS

> TCM

> BCM

These same symptoms may occur without the

code P0705(28) getting set. It is possible that the

invalid code that was sensed by the TCM only

occurred once or twice during the given ignition key

start and/or did not last for longer than 0.1 second.Name of code:P0120(29) - Throttle Position Sen-

sor Signal

When monitored:Whenever the engine is run-

ning.

Set condition:This code is set if the throttle angle

goes out of range or if throttle angle changes

abruptly (ie: faster than the throttle body motion

could occur)

Theory of operation:The Transmission Control

Module (TCM) receives the throttle position signal

from the Throttle Position Sensor (TPS) through a

wire spliced into the TPS circuit to the PCM. The

TPS has a 5-volt pull up supplied from the Power-

train Control Module (PCM). The signal is checked

for out-of-range as well as an intermittent (exces-

sive signal changes).

Transmission Effects:Extremely erratic trans-

mission shifting with an intermittent TPS signal

just prior to setting the code. If the intermittent

does not last long enough to set the code, the

customer will say that the transmission violently

hunts between gears. The TCM will use a calcu-

lated throttle angle supplied by the PCM over the

PCI bus. If the PCI bus is unavailable, the TCM will

use a default throttle angle of 24 degrees for the key

start in which the code was set. The TCM will try to

use the TPS signal again on the next key start.

Possible causes:

> Open or shorted TPS signal and/or ground cir-

cuits

> TCM connector problems

> TPS or TPS connector (Check PCM DTC's)

> PCM

> TCM

Name of code:P1787(31) - OD Hydraulic Pressure

Test Failure

P1788(32) - 2-4 Hydraulic Pressure Test Failure

P1789(33) - OD/2-4 Hydraulic Pressure Test Failure

When monitored:In 1st, 2nd, or 3rd gear with

engine speed above 1000 RPM shortly after a shift

and every minute thereafter.

Set condition:Immediately after a shift into 1st,

2nd, or 3rd gear, with engine speed above 1000

RPM, the TCM momentarily turns on element

pressure to the 2-4 and/or OD clutch circuits to

identify that the appropriate pressure switch

closes. If the pressure switch does not close it is

tested again. If the switch does not close the second

time, the appropriate code is set.

Theory of operation:The Transmission Control

Module (TCM) tests the OD and 2-4 pressure

switches when they are off (OD and 2-4 are tested in

1st gear, OD in 2nd gear, and 2-4 in 3rd gear). The

test verifies that the switches are operational. The

TCM verifies that the switch closes when the cor-

9

GENERAL INFORMATION

Page 4114 of 4284

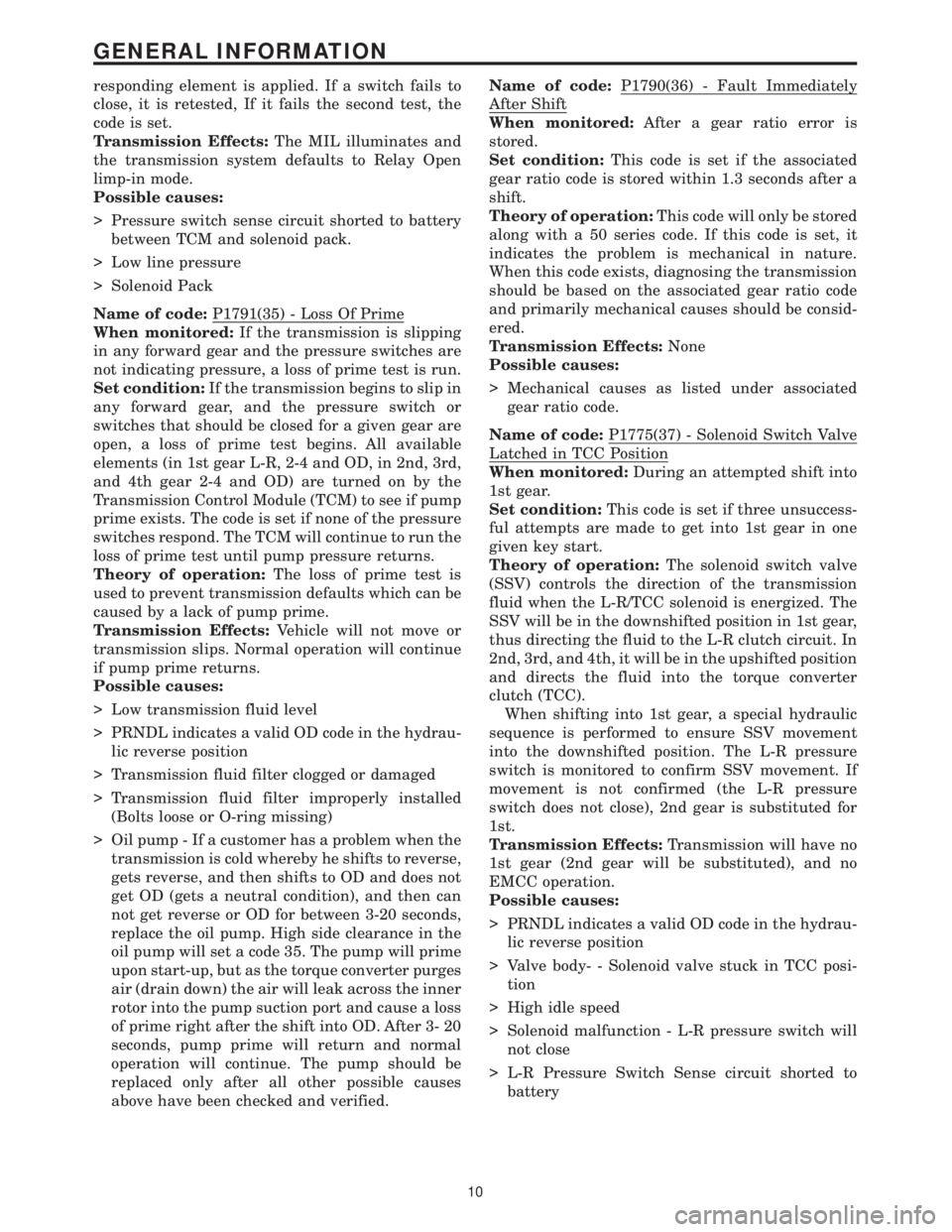

responding element is applied. If a switch fails to

close, it is retested, If it fails the second test, the

code is set.

Transmission Effects:The MIL illuminates and

the transmission system defaults to Relay Open

limp-in mode.

Possible causes:

> Pressure switch sense circuit shorted to battery

between TCM and solenoid pack.

> Low line pressure

> Solenoid Pack

Name of code:P1791(35) - Loss Of Prime

When monitored:If the transmission is slipping

in any forward gear and the pressure switches are

not indicating pressure, a loss of prime test is run.

Set condition:If the transmission begins to slip in

any forward gear, and the pressure switch or

switches that should be closed for a given gear are

open, a loss of prime test begins. All available

elements (in 1st gear L-R, 2-4 and OD, in 2nd, 3rd,

and 4th gear 2-4 and OD) are turned on by the

Transmission Control Module (TCM) to see if pump

prime exists. The code is set if none of the pressure

switches respond. The TCM will continue to run the

loss of prime test until pump pressure returns.

Theory of operation:The loss of prime test is

used to prevent transmission defaults which can be

caused by a lack of pump prime.

Transmission Effects:Vehicle will not move or

transmission slips. Normal operation will continue

if pump prime returns.

Possible causes:

> Low transmission fluid level

> PRNDL indicates a valid OD code in the hydrau-

lic reverse position

> Transmission fluid filter clogged or damaged

> Transmission fluid filter improperly installed

(Bolts loose or O-ring missing)

> Oil pump - If a customer has a problem when the

transmission is cold whereby he shifts to reverse,

gets reverse, and then shifts to OD and does not

get OD (gets a neutral condition), and then can

not get reverse or OD for between 3-20 seconds,

replace the oil pump. High side clearance in the

oil pump will set a code 35. The pump will prime

upon start-up, but as the torque converter purges

air (drain down) the air will leak across the inner

rotor into the pump suction port and cause a loss

of prime right after the shift into OD. After 3- 20

seconds, pump prime will return and normal

operation will continue. The pump should be

replaced only after all other possible causes

above have been checked and verified.Name of code:P1790(36) - Fault Immediately

After Shift

When monitored:After a gear ratio error is

stored.

Set condition:This code is set if the associated

gear ratio code is stored within 1.3 seconds after a

shift.

Theory of operation:This code will only be stored

along with a 50 series code. If this code is set, it

indicates the problem is mechanical in nature.

When this code exists, diagnosing the transmission

should be based on the associated gear ratio code

and primarily mechanical causes should be consid-

ered.

Transmission Effects:None

Possible causes:

> Mechanical causes as listed under associated

gear ratio code.

Name of code:P1775(37) - Solenoid Switch Valve

Latched in TCC Position

When monitored:During an attempted shift into

1st gear.

Set condition:This code is set if three unsuccess-

ful attempts are made to get into 1st gear in one

given key start.

Theory of operation:The solenoid switch valve

(SSV) controls the direction of the transmission

fluid when the L-R/TCC solenoid is energized. The

SSV will be in the downshifted position in 1st gear,

thus directing the fluid to the L-R clutch circuit. In

2nd, 3rd, and 4th, it will be in the upshifted position

and directs the fluid into the torque converter

clutch (TCC).

When shifting into 1st gear, a special hydraulic

sequence is performed to ensure SSV movement

into the downshifted position. The L-R pressure

switch is monitored to confirm SSV movement. If

movement is not confirmed (the L-R pressure

switch does not close), 2nd gear is substituted for

1st.

Transmission Effects:Transmission will have no

1st gear (2nd gear will be substituted), and no

EMCC operation.

Possible causes:

> PRNDL indicates a valid OD code in the hydrau-

lic reverse position

> Valve body- - Solenoid valve stuck in TCC posi-

tion

> High idle speed

> Solenoid malfunction - L-R pressure switch will

not close

> L-R Pressure Switch Sense circuit shorted to

battery

10

GENERAL INFORMATION

Page 4115 of 4284

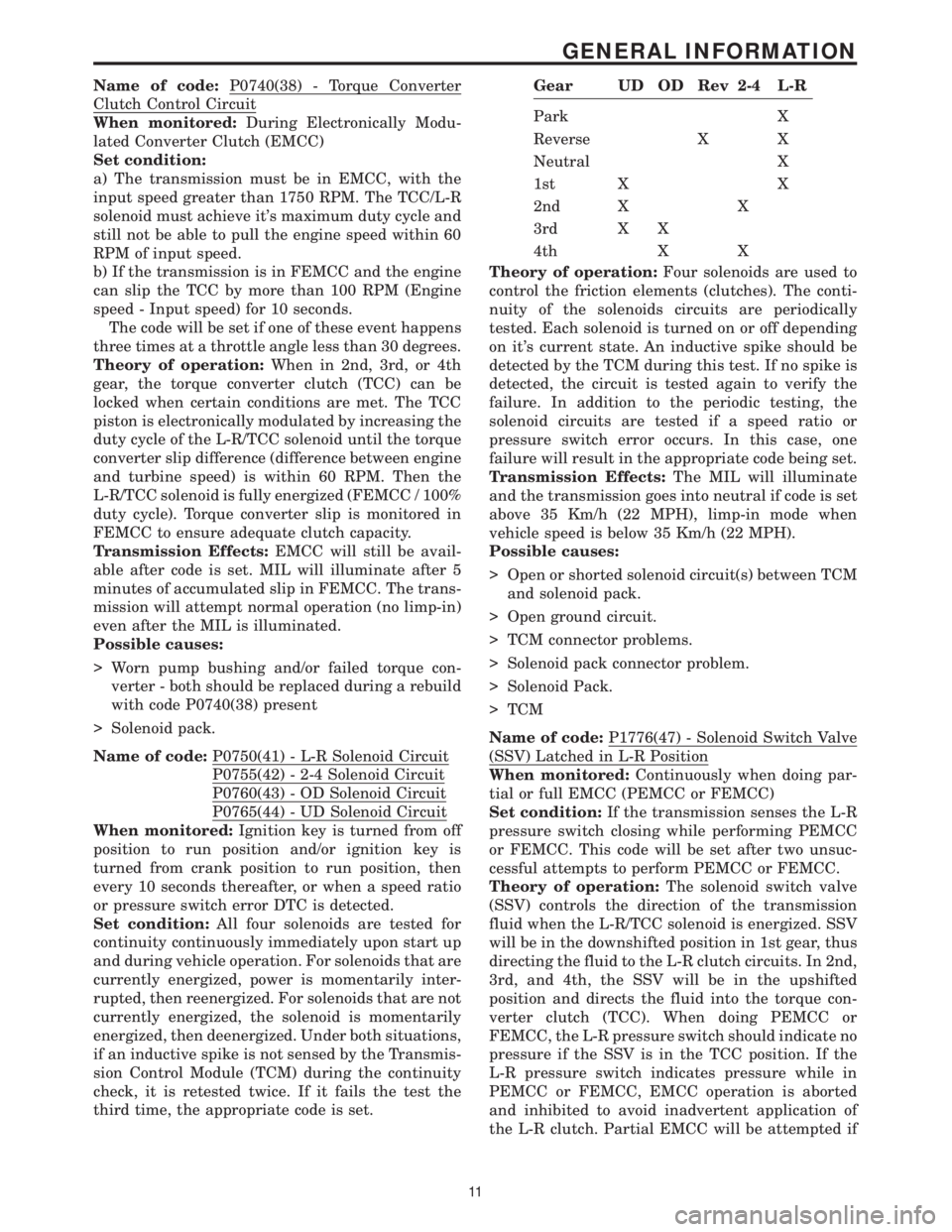

Name of code:P0740(38) - Torque Converter

Clutch Control Circuit

When monitored:During Electronically Modu-

lated Converter Clutch (EMCC)

Set condition:

a) The transmission must be in EMCC, with the

input speed greater than 1750 RPM. The TCC/L-R

solenoid must achieve it's maximum duty cycle and

still not be able to pull the engine speed within 60

RPM of input speed.

b) If the transmission is in FEMCC and the engine

can slip the TCC by more than 100 RPM (Engine

speed - Input speed) for 10 seconds.

The code will be set if one of these event happens

three times at a throttle angle less than 30 degrees.

Theory of operation:When in 2nd, 3rd, or 4th

gear, the torque converter clutch (TCC) can be

locked when certain conditions are met. The TCC

piston is electronically modulated by increasing the

duty cycle of the L-R/TCC solenoid until the torque

converter slip difference (difference between engine

and turbine speed) is within 60 RPM. Then the

L-R/TCC solenoid is fully energized (FEMCC / 100%

duty cycle). Torque converter slip is monitored in

FEMCC to ensure adequate clutch capacity.

Transmission Effects:EMCC will still be avail-

able after code is set. MIL will illuminate after 5

minutes of accumulated slip in FEMCC. The trans-

mission will attempt normal operation (no limp-in)

even after the MIL is illuminated.

Possible causes:

> Worn pump bushing and/or failed torque con-

verter - both should be replaced during a rebuild

with code P0740(38) present

> Solenoid pack.

Name of code:P0750(41) - L-R Solenoid Circuit

P0755(42) - 2-4 Solenoid Circuit

P0760(43) - OD Solenoid Circuit

P0765(44) - UD Solenoid Circuit

When monitored:Ignition key is turned from off

position to run position and/or ignition key is

turned from crank position to run position, then

every 10 seconds thereafter, or when a speed ratio

or pressure switch error DTC is detected.

Set condition:All four solenoids are tested for

continuity continuously immediately upon start up

and during vehicle operation. For solenoids that are

currently energized, power is momentarily inter-

rupted, then reenergized. For solenoids that are not

currently energized, the solenoid is momentarily

energized, then deenergized. Under both situations,

if an inductive spike is not sensed by the Transmis-

sion Control Module (TCM) during the continuity

check, it is retested twice. If it fails the test the

third time, the appropriate code is set.

Gear UD OD Rev 2-4 L-R

Park X

Reverse X X

Neutral X

1st X X

2nd X X

3rd X X

4th X X

Theory of operation:Four solenoids are used to

control the friction elements (clutches). The conti-

nuity of the solenoids circuits are periodically

tested. Each solenoid is turned on or off depending

on it's current state. An inductive spike should be

detected by the TCM during this test. If no spike is

detected, the circuit is tested again to verify the

failure. In addition to the periodic testing, the

solenoid circuits are tested if a speed ratio or

pressure switch error occurs. In this case, one

failure will result in the appropriate code being set.

Transmission Effects:The MIL will illuminate

and the transmission goes into neutral if code is set

above 35 Km/h (22 MPH), limp-in mode when

vehicle speed is below 35 Km/h (22 MPH).

Possible causes:

> Open or shorted solenoid circuit(s) between TCM

and solenoid pack.

> Open ground circuit.

> TCM connector problems.

> Solenoid pack connector problem.

> Solenoid Pack.

> TCM

Name of code:P1776(47) - Solenoid Switch Valve

(SSV) Latched in L-R Position

When monitored:Continuously when doing par-

tial or full EMCC (PEMCC or FEMCC)

Set condition:If the transmission senses the L-R

pressure switch closing while performing PEMCC

or FEMCC. This code will be set after two unsuc-

cessful attempts to perform PEMCC or FEMCC.

Theory of operation:The solenoid switch valve

(SSV) controls the direction of the transmission

fluid when the L-R/TCC solenoid is energized. SSV

will be in the downshifted position in 1st gear, thus

directing the fluid to the L-R clutch circuits. In 2nd,

3rd, and 4th, the SSV will be in the upshifted

position and directs the fluid into the torque con-

verter clutch (TCC). When doing PEMCC or

FEMCC, the L-R pressure switch should indicate no

pressure if the SSV is in the TCC position. If the

L-R pressure switch indicates pressure while in

PEMCC or FEMCC, EMCC operation is aborted

and inhibited to avoid inadvertent application of

the L-R clutch. Partial EMCC will be attempted if

11

GENERAL INFORMATION

Page 4116 of 4284

the L-R pressure switch does not indicate pressure.

A second detection of L-R pressure results in setting

the code.

Transmission Effects:At speeds above 72 Km/h

(45 MPH), EMCC is inhibited. Once speed falls

below 72 Km/h (45 MPH), the transmission will go

into relay open limp-in mode and the MIL will

illuminate.

Possible causes:

> Valve body - Solenoid valve stuck in L-R position

> Intermittent short to ground or open circuit in

L-R Pressure Switch Sense circuit (with code 24

only)

> Solenoid pack (with code P1784(24) only)

> TCM (with code P1784(24) only)

Name of Code:P1793(48) - Torque Reduction

(TRD) Link Communication Error

Note: The MIL may set on some engines (3.3L, 3.8L,

3.5L)

When Monitored:Whenever the engine is run-

ning

Set condition:This code is set when the TCM

sends multiple torque reduction messages to the

PCM and the TCM does not receive a response from

the PCM.

Theory of Operation:During high torque shifts

the TCM will send a message requesting that the

PCM reduce engine power until the shift is com-

pleted. This message is sent from the TCM to the

Powertrain Control Module across the Torque Man-

agement Request Sense Circuit. The PCM will

acknowledge the TCM request by sending a mes-

sage across the PCI bus within a specific amount of

time. The TRD Link communication is also tested

periodically for operation whenever the engine is

running and the vehicle is not moving with zero

degrees throttle.

Transmission Effects:Maximum throttle angle

used by TCM will be 54 degrees. As a result a

customer my complain about loss of performance or

of short shifting when driving aggressively.

Possible Causes:

> Sticky Throttle Position Sensor (TPS)

> Wiring or Connector problems in the Torque

Management Request Sense Circuit

> PCM

> TCM

Name of code:P0736(50) - Gear Ratio Error in

Reverse

P0731(51) - Gear Ratio Error in 1st

P0732(52) - Gear Ratio Error in 2nd

P0733(53) - Gear Ratio Error in 3rd

P0734(54) - Gear Ratio Error in 4th

P0715(56) - Input Speed Sensor Error

P0720(57) - Output Speed Sensor Error

P1794(58) - Speed Sensor Ground Error

When monitored:The transmission gear ratio is

monitored continuously while the transmission is in

gear.

Set condition:This code is set if the gear ratio is

not correct for a period of time.

± Codes 50 through 54 sets if the ratio of the

input RPM (Nt) to the output RPM (No) does

not match the given gear ratio.

± Code 56 sets if there is an excessive change in

input RPM in any gear

± Code 57 sets if there is an excessive change in

output RPM in any gear

± Code 58 sets after a TCM reset in neutral and

Nt/No equals a ratio of input to output of 2.50

A hard code sets within 3 seconds, an intermit-

tent code sets within 15 seconds.

Theory of operation:The transmission system

uses two speed sensors, one to measure input RPM

and one to measure output RPM. These inputs are

essential for proper transmission operation. There-

fore, the integrity of this data is verified through

the following checks:

1. When in gear, if the gear ratio does not compare

to a known gear ratio, the corresponding in-gear

trouble code is set (codes 50 through 54).

2. An excessive change in input or output speeds

indicating signal intermittent will result in

codes 56 and/or 57 being set.

3. After a TCM reset in neutral, observing erratic

output and input speed sensor signals indicates

a loss of the common speed sensors ground. This

sets a code 58.

Transmission Effects:The transmission will not

go into relay open limp-in mode until three gear

ratio error events occur in a given key start. This

allows for intermittent problems to correct them-

selves without opening the relay. However, if a gear

ratio error develops, a code is always set, but if the

condition corrects itself the transmission will con-

tinue without requiring the ignition key to be cycled

on and off. Many different events could occur given

the range of failures possible for codes 50 through

58. The following are a few examples:

± Codes 51, 52, 53, 54, 56, and 57 at speeds

above 72 Km/h (45 MPH) - The appropriate

code is set, EMCC is aborted and current gear

is maintained. If while still traveling above 72

Km/h (45 MPH), the gear ratio becomes valid

again, EMCC will reengage and normal oper-

ation will resume. If the gear ratio becomes

intermittent and recovers three times in a

given key start, the current gear will be main-

tained and EMCC inhibited, then the trans-

mission will go into relay open limp-in mode if

12

GENERAL INFORMATION

Page 4117 of 4284

throttle is applied below 72 Km/h (45 MPH) or

at 35 Km/h (22 MPH) with closed throttle.

± Codes 51, 52, 53, 54, 56, and 57 (at speeds

between 35 and 72 Km/h (22 and 45 MPH) - If

one of these codes is set between 35 and 72

Km/h (22 and 45 MPH), the current gear will

be maintained until the gear ratio problem

corrects itself. If throttle is applied, the trans

will go to 2nd gear. If this happens and the

gear ratio problem goes away, normal opera-

tion will resume. If three gear ratio problems

are identified in a given key start, the current

gear will be frozen until throttle is applied.

The transmission will then go into relay open

limp-in mode with throttle applied at speeds

between 35 and 72 Km/h (22 and 45 MPH).

± Codes 51, 52, 53, 54, 56, and 57 (at speeds

below 35 Km/h (22 MPH) - If a gear ratio

problem is identified below 35 Km/h (22 MPH),

the transmission will immediately substitute

second gear for the current gear. If the gear

ratio problem goes away, normal operation will

resume. If three gear ratio problems are iden-

tified in a given key start, the transmission

will go into relay open limp-in mode.

Possible causes:

Code P0736(50) - Excludes geartrain failures which

should be obvious upon disassembly

> If code P1791(35) is also set, follow diagnostic

procedure for code P1791(35) first

> Valve body - #1 ball check or LR switch valve

sticking - may also set code P0731(51)

> Speed sensor or associated wiring

± may also set codes P0731(51), P0715(56), or

P0720(57)

> Failed or slipping LR clutch - may also set code

P0731(51)

> LR seal leakage (Intermittent no drive or re-

verse)

> Sticky LR accumulator seals (Intermittent no

drive or reverse)

> Failed reverse clutch (hard code)

± OD/Rev lip seal leakage

± Worn reaction shaft support seal rings

± Snap ring out of position

Code P0731(51) - Excludes geartrain failures which

should be obvious upon disassembly

> If code P1791(35) is also set, follow diagnostic

procedure for code P1791(35) first

> Valve body - #1 ball check or LR switch valve

sticking - may also set code P0736(56) or have no

Reverse

> Speed sensor or associated wiring - may also set

codes P0736(50), P0715(56), or P0720(57)> Failed or intermittent slipping UD clutch - may

also set P0732(52), or P0733(53)

± UD seal leakage (intermittent)

± Worn input clutch hub bushing (hard code at

heavy throttle)

± Sticky UD accumulator seals (intermittent)

± Worn reaction shaft support seal rings (hard

code at heavy throttle)

± Solenoid pack (UD pressure in 4th gear)

> Failed or slipping LR clutch - may also set code

P0736(56) or have no Reverse

± LR seal leakage (Intermittent)

± Sticky LR accumulator seals (Intermittent)

Code P0732(52) - Excludes geartrain failures which

should be obvious upon disassembly

> If code P1791(35) is also set, follow diagnostic

procedure for code P1791(35) first

> Failed or slipping 2-4 clutch - may also set code

P0734(54)

± 2-4 seal leakage (intermittent)

± Sticky accumulator seals (intermittent)

> Failed or intermittent slipping UD clutch - may

also set code P0731(51) and/or P0733(53)

± UD seal leakage (intermittent)

± Worn input clutch hub bushing (hard code at

heavy throttle)

± Sticky UD accumulator seals (intermittent)

± Worn reaction shaft support seal rings (hard

code at heavy throttle)

± Solenoid pack (UD pressure in 4th gear)

Code P0733(53) - Excludes geartrain failures which

should be obvious upon disassembly

> If code P1791(35) is also set, follow diagnostic

procedure for code P1791(35) first

> Failed or slipping OD clutch - may also set code

P0734(54)

± OD and Reverse inner and outer lip seal leak-

age (usually hard code)

± Sticky OD accumulator seals (intermittent)

± Worn reaction shaft support seal rings (hard

code at heavy throttle)

± Broken OD/UD tapered snap ring - (hard code

at heavy throttle)

> Failed or intermittent slipping UD clutch - may

also set code P0731(51) and/or P0732(52)

± UD seal leakage (intermittent)

± Worn input clutch hub bushing (hard code at

heavy throttle)

± Sticky UD accumulator seals (intermittent)

± Worn reaction shaft support seal rings (hard

code at heavy throttle)

13

GENERAL INFORMATION

Page 4118 of 4284

± Solenoid pack (UD pressure in 4th gear)

Code P0734(54) - Excludes geartrain failures which

should be obvious upon disassembly

> If code P1791(35) is also set, follow diagnostic

procedure for code P1791(35) first

> Failed or slipping OD clutch - may also set code

P0733(53)

± OD and Reverse inner and outer lip seal leak-

age (usually hard code)

± Sticky OD accumulator seals (intermittent)

± Worn reaction shaft support seal rings (hard

code at heavy throttle)

± Broken OD/UD tapered snap ring - (hard code

at heavy throttle)

> Failed or slipping 2-4 clutch - may also set code

P0732(52)

± 2-4 seal leakage (intermittent)

± Sticky accumulator seals (intermittent)

Codes P0715(56) and P0720(57)

> Failed input or output speed sensor (intermittent

or hard code)

> Shorted or open wiring between TCM and speed

sensor(s) (intermittent)

> Connector problems at 60 TCM connector and/or

speed sensor connector

Code P1794(58)

> Open or shorted speed sensor ground (speed

sensor ground is different from chassis ground)

> Open or shorted Temperature Sensor wiring to

TRS

> TRS - Will also set code P1799(74)

> TCM

Name of code:P1796(70) - Autostick Sensor Cir-

cuit (If equipped)

Note: RS is a MUXED Autostick system

When monitored:Whenever the engine is run-

ning.

Set condition:

1) The transmission shift lever is not in AutoStick

and either the upshift or downshift switch is closed.

2) Upshift and downshift switches closed at the

same time.

Theory of operation:In the AutoStick Mode

(manual shift mode), upshifts and downshifts are

actuated manually. Shift requests are detected by

monitoring the MUXED upshift and downshift

switches. The Transmission Control Module (TCM)

monitors the above set conditions. A set condition

will be tolerated for up to 15 seconds before setting

a code.Transmission Effects:The OD position shift

schedule is substituted while operating in the au-

tostick gear selector position. No limp-in mode

occurs.

Possible causes:

> Wiring or connector problems

> AutoStick switch failure

> TCM

Name of code:P1797(71)- Manual Shift Overheat

When monitored:Whenever the engine is run-

ning.

Set condition:1) If the engine temperature ex-

ceeds 124C (255 ÉF) while operating in AutoStick

mode.

2) If the transmission temperature exceeds 135C

(275 ÉF) while in AutoStick mode

Theory of operation:Transmission and engine

temperatures are monitored during vehicle opera-

tion. If conditions occur causing the engine or

transmission to overheat, the AutoStick mode will

be canceled, and a code will be set.

Transmission Effects:The 3 position shift sched-

ule that is used in non-AutoStick applications is

substituted while operating in the AutoStick gear

selector position. No limp-in mode occurs.

Possible causes:

> Engine overheat - refer to service manual for

diagnosis and repair

> Transmission Overheat

± Restricted transmission cooling system

± Transmission fluid overfilled

± Radiator fan not functioning properly

± Extended driving in low gear

Note:Strenuous driving conditions may cause the

vehicle to overheat. If the driver operates in or

initiates AutoStick with an overheated vehicle, the

code will be set.

Name of code:P1798 (73) - Deteriorated Transaxle

Fluid

When monitored:At every Fully Electronically

Modulated Converter Clutch (FEMCC) to Partial

Electronically Modulated Converter Clutch (PEM-

CC) transition miles when A/C compressor clutch is

being cycled.

Set condition:The code will be set if vehicle

shudder is detected 20 times when the A/C clutch is

cycled.

Theory of operation:While in 3rd or 4th gear

FEMCC and just before the A/C clutch engages, the

Powertrain Control Module (PCM) requests the

Transmission Control Module (TCM) to momen-

tarily establish PEMCC operation. If vehicle shud-

der is detected during the FEMCC to PEMCC

transition, a counter is incremented. If the count

reaches 20, the trouble code is set. The driver may

14

GENERAL INFORMATION

Page 4119 of 4284

then notice harsh bumps when the A/C clutch is

being cycled, but vehicle shudder will be elimi-

nated. After 35 OBDII (EURO STAGE III OBD)

warm-up starts or if the code is cleared, PEMCC

will be reactivated to see if shudder is still present.

If one shudder event occurs, the code will be reset.

Clearing the code and running battery disconnect

with the DRBIIItis the only way to reset the

shudder counter from 20 back to zero.

Transmission Effects:This code does not cause

the transmission to go into limp-in mode. However,

once the code is set, FEMCC to PEMCC operation

before the A/C clutch engagement will be disabled

for 35 OBDII (EURO STAGE III OBD) warm up

starts.

Possible causes:

> Degraded transmission fluid

> Wheels severely out of alignment

> Internal torque converter problem

Name of Code:P1799(74) - Calculated Oil Temper-

ature in Use

When Monitored:When ever the Engine is run-

ning.

Set condition:The code is set if any of the follow-

ing conditions exist for three consecutive key starts:

> The Temperature Sensor voltage is out of range

(below 0.07 volts or greater than 4.94 volts)

> If continuous erratic Temperature Sensor voltage

is sensed.

> The Temperature Sensor temperature stays be-

low 27C (80ÉF) for an extended period of time.

Theory of Operation:The TCM uses a Tempera-

ture Sensor to monitor the transmission sump tem-

perature. This temperature is used to determine

which shift schedule the TCM is to use. (See Trans-

mission Operation and Shift Scheduling at Various

Sump Temperatures in this diagnostic manual) If

the Temperature Sensor circuit fails to operate

properly the TCM will use the calculated oil tem-

perature routine found in prior model year TCM. If

this occurs for three consecutive key starts, the code

will be set. The TCM will then test the Temperature

Sensor circuit after every 35 OBDII (EURO STAGE

III OBD) warm-up starts. If the Temperature Sen-

sor circuit is OK, the Temperature Sensor data is

used in place of the Calculated Oil Temperature

data.

Transmission Effects:If the Temperature Sensor

indicates a temperature below -18C (0É F) or above

115C (240É F) at start up, The TCM compares the

calculated oil temperature to the indicated Temper-

ature Sensor oil temperature. If the calculated oil

temperature differs significantly from the Temper-

ature Sensor value, the calculated oil temperature

will be used for that key start.Possible Causes:

> Wiring or Connector problems in the transmis-

sion temperature sensor signal circuit.

> TRS

> TCM

Name of Code:P1738(75) - High Temperature

Operation Activated.

When Monitored:Whenever the engine is running.

Set Condition:Immediately once the Overheat

Shift Schedule is activated.

Theory of Operation:If the transmission oil tem-

perature rises above 115C (240ÉF), the overheat

shift schedule is activated refer to Transmission

Operation as a function of Transmission Oil Tem-

perature and the code is set. The DTC is an infor-

mation code only and is being set to aid the techni-

cian in determining root cause of a customer

driveability issue. The code is also intended to alert

the technician to determine if a cooling system

malfunction has occurred or if an additional trans-

mission air to oil cooler should be added to the

vehicle if the customer regularly drives in a manner

that overheats the transmission. Extended opera-

tion above 115C (240ÉF) will reduce the durability of

the transmission and should be avoided. Correcting

the cooling system malfunction or installing an

additional transmission oil cooler will improve

transmission durability especially for customers

who operate in city/construction stop and go traffic,

tow trailers regularly, drive aggressively in low gear

or drive regularly in mountainous areas.

Transmission Effects:Information only code. -

Overheat shift schedule was activated, no limp-in

condition occurs. 2nd gear partial EMCC above 40

Km/h (25 MPH), 3rd gear EMCC from 45-69 Km/h

(28-43 MPH), delayed 3-4 upshift at 69 Km/h (43

MPH), early 4-3 coastdown at 66 Km/h (41 MPH),

EMCC operation under all conditions above 40

Km/h (25 MPH) except at closed throttle or 1st gear.

Possible Causes:

± Transmission Overfilled with Oil

± Engine cooling fan failure

± Engine thermostat stuck closed

± Radiator corroded or packed with dirt

± Transmission Oil Cooler Plugged

± Customer driving pattern requires additional

transmission cooling

Name Of Code:P1739(76) - Power-Up at Speed

When Monitored:When TCM (transmission con-

trol module) initially powers-up.

Set Condition:If the TCM powers up while in the

9Drive9position and the vehicle is going above 32

Km/h (20 MPH), the code is set.

Theory of Operation:If a vehicle loses power to

the TCM, the vehicle will go to the 2nd gear mode

15

GENERAL INFORMATION

Page 4120 of 4284

since there is no power available to control the

transmission solenoids. However if power is re-

stored, the TCM will power-up and normal opera-

tion will be restored. This DTC identifies that

power to the TCM was restored when the gear

selector was in a9Drive9position while the vehicle

was moving at speeds above 32 Km/h (20 MPH). If

a person shifts to Neutral and cycles the ignition

key and quickly shifts to9Drive9while moving

before the TCM comes out of its START ROUTINE,

the DTC can be set. Therefore it is critical that this

DTC diagnosis repair procedure should only be used

if the vehicle is experiencing intermittent 2nd gear

operation and subsequently a return to normal

operation during normal driving.

Transmission Effects:No limp-in condition. The

DTC is for information only when trying to diagno-

sis intermittent 2nd gear operation and subse-

quently a return to normal operation.

Possible Causes:

± No Problem if vehicle is started in9neutral9at

speeds above 32 Km/h (20 MPH) and shifted

quickly to9Drive9before TCM comes out of the

START ROUTINE.

FOR INTERMITTENT 2ND GEAR OPER-

ATION AND THEN A SUBSEQUENT RE-

TURN TO NORMAL OPERATION WITH-

OUT CYCLING THE IGNITION KEY

± Intermittent Direct Battery connection be-

tween TCM (60-way pin 56) and battery.

± Intermittent Fused Ignition Switch Output

between TCM (60-way pin 11) and ignition

switch.

± Intermittent Ground to TCM (60 way pins 53

and 57).

Name of code:P1717(77) - No Communication

with Mechanical Instrument Cluster (MIC)

When monitored:Continuously with key on.

Set condition:If no PCI bus messages are received

from the Mechanical Instrument Cluster (MIC) for

25 seconds.

Theory of operation:The TCM communicates

with the MIC using the PCI bus. It relies on certain

information to function properly. The TCM contin-

uously monitors the PCI bus to check for messages

broadcast from the PCM.

Transmission Effects:Possible improper TCM

AutoStick configuration.

Possible causes:

> Open or shorted PCI bus circuit from MIC

> MIC

> TCM (If other communications codes are stored

in the TCM only)

Name of code:P0600(78) - Serial Communication

Link Malfunction

When monitored:Continuously with key on.

Set condition:If no PCI bus messages are received

by the Transmission Control Module (TCM) for 10

seconds.

Theory of operation:The TCM communicates

with the other modules in the vehicle using the PCI

bus. It relies on certain information to function

properly. The TCM continuously monitors the PCI

bus to check for messages broadcast from the cer-

tain modules.

Transmission Effects:Possible improper TCM

AutoStick configuration and delayed 3-4 shifts. No

EMCC and early 3-4 shifts for a few minutes after

engine is started.

Possible causes:

> Open or shorted PCI bus circuit from BCM

> TCM

Name of code:P1714(79) Low Battery Voltage

When monitored:Continuously with engine run-

ning and Transmission Relay energized.

Set condition:If the voltage sensed at the Trans-

mission Control Relay Output circuit (pins 16 and

17 at TCM) for 15 seconds.

Theory of operation:The Transmission system

requires sufficient battery voltage in order to ener-

gize the transmission solenoids. The TCM continu-

ously monitors the voltage available to the sole-

noids.

Transmission Effects:At speeds above 72 Km/h

(45 MPH) the transmission system will default to

neutral. Below 72 Km/h (45 MPH) the transmission

system will default to relay open limp-in mode.

Park, Reverse, and Neutral are still available.

Possible causes:

> Charging system problem

> Poor/High resistance connection between TCM

and Battery/Alternator

> TCM pin 16 and 17 high resistance or poor

connection

> TCM ground pins 53 and 57 high resistance or

poor connection

> High resistance in Transmission Control Relay

contacts

> TCM

3.3.8 QUICK LEARN

The Quick Learn function customizes adaptive

parameters of the TCM to the transmission charac-

teristics of a vehicle. This gives the customer im-

proved9as received9shift quality compared to the

initial parameters stored in the TCM.

Notes about Quick Learn Features

The nature of the Quick Learn function requires

that certain features must be taken into consider-

ation.

16

GENERAL INFORMATION