relay CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3657 of 4284

and is accessed for service by rolling down the glove

box from the instrument panel.

The power module heat sink will get hot when in

use. Do not touch the heat sink if the blower motor

has been running. The blower power module cannot

be adjusted or repaired and, if faulty or damaged, it

must be replaced.

OPERATION

The blower power module is connected to the vehi-

cle electrical system through a dedicated take out

and connector of the instrument panel wire harness.

A second connector receptacle receives the pigtail

wire connector from the blower motor. The blower

power module allows the microprocessor-based Auto-

matic Temperature Control (ATC) heater-A/C control

module to calculate and provide infinitely variable

blower motor speeds based upon either manual

blower switch input or the ATC programming using a

Pulse Width Modulated (PWM) circuit strategy. The

PWM voltage is applied to a comparator circuit

which compares the PWM signal voltage to the

blower motor feedback voltage. The resulting output

drives the power module circuitry, which adjusts the

voltage output received from the blower motor relay

to change or maintain the desired blower speed. The

blower power module is diagnosed using a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Open the glove box.

(3) Flex both sides of the glove box bin inward

near the top far enough for the rubber glove box stop

bumpers to clear the sides of the glove box opening,

then roll the glove box downward.

(4) Reach through the glove box opening to access

and disconnect the instrument panel wire harness

connector for the power module from the module con-

nector receptacle.

(5) Reach through the glove box opening to access

and disconnect the blower motor pigtail wire connec-

tor from the power module connector receptacle.

(6) Remove the two screws that secure the power

module to the evaporator housing.

(7) Remove the power module from the evaporator

housing.

INSTALLATION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Position the power module into the evaporator

housing.

Fig. 23 Power Module

1 - POWER MODULE

2 - LOWER GLOVE BOX OPENING REINFORCEMENT

3 - EVAPORATOR HOUSING

RSCONTROLS - FRONT24-27

POWER MODULE (Continued)

Page 3660 of 4284

CONTROLS - REAR

TABLE OF CONTENTS

page page

A/C-HEATER CONTROL

REMOVAL..............................30

INSTALLATION...........................31

BLEND DOOR ACTUATOR

DESCRIPTION...........................31

OPERATION.............................31

REMOVAL..............................32

INSTALLATION...........................32

BLOWER MOTOR RELAY

DESCRIPTION...........................33

OPERATION.............................33

DIAGNOSIS AND TESTING.................34

BLOWER MOTOR RELAY.................34

REMOVAL..............................34

INSTALLATION...........................34

BLOWER MOTOR RESISTOR

DESCRIPTION...........................35

OPERATION.............................35

DIAGNOSIS AND TESTING.................35BLOWER MOTOR RESISTOR.............35

REMOVAL..............................36

INSTALLATION...........................36

EXPANSION VALVE SOLENOID

DESCRIPTION...........................36

OPERATION.............................37

INFRARED TEMPERATURE SENSOR

DESCRIPTION...........................37

OPERATION.............................37

MODE DOOR ACTUATOR

DESCRIPTION...........................37

OPERATION.............................38

REMOVAL..............................38

INSTALLATION...........................38

POWER MODULE

DESCRIPTION...........................39

OPERATION.............................39

REMOVAL..............................40

INSTALLATION...........................40

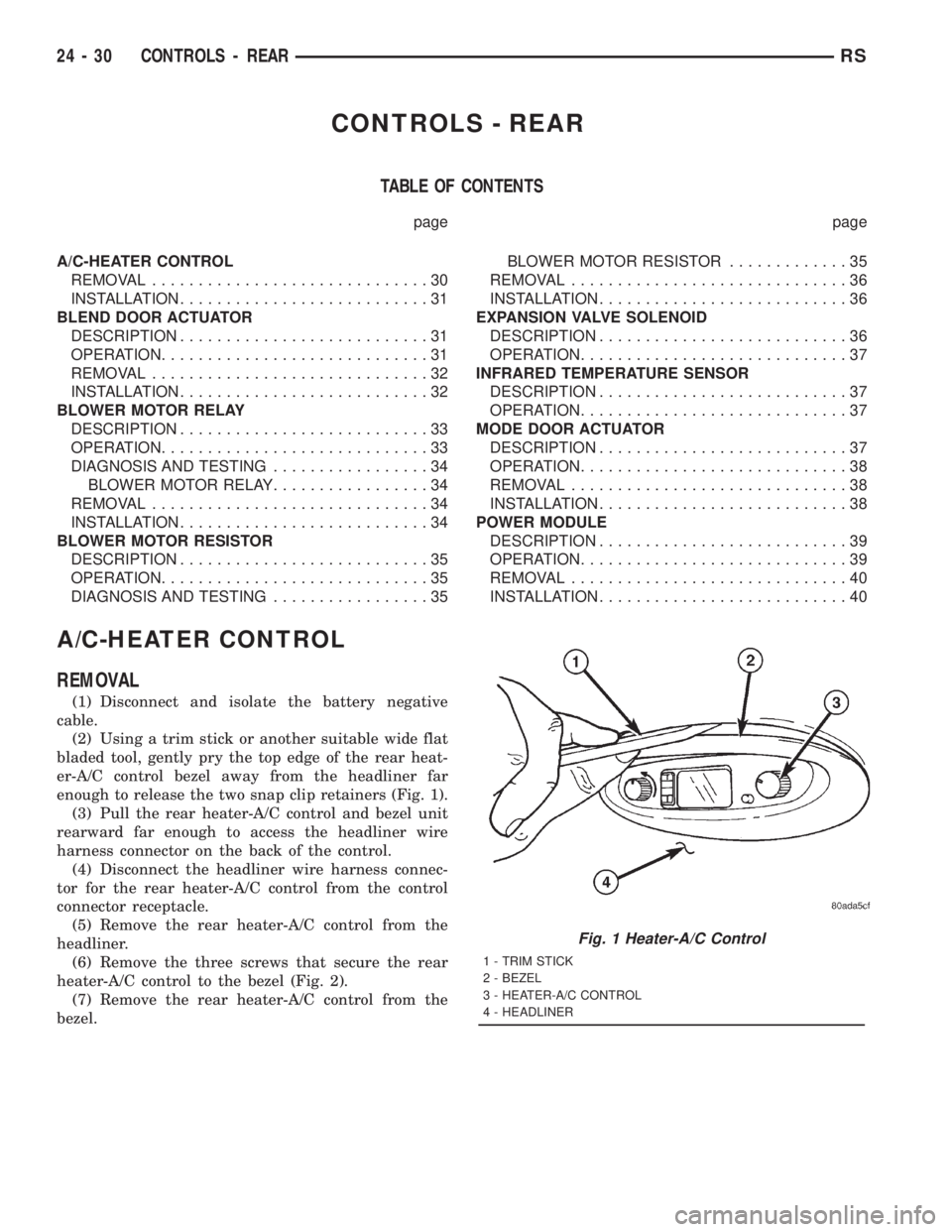

A/C-HEATER CONTROL

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a trim stick or another suitable wide flat

bladed tool, gently pry the top edge of the rear heat-

er-A/C control bezel away from the headliner far

enough to release the two snap clip retainers (Fig. 1).

(3) Pull the rear heater-A/C control and bezel unit

rearward far enough to access the headliner wire

harness connector on the back of the control.

(4) Disconnect the headliner wire harness connec-

tor for the rear heater-A/C control from the control

connector receptacle.

(5) Remove the rear heater-A/C control from the

headliner.

(6) Remove the three screws that secure the rear

heater-A/C control to the bezel (Fig. 2).

(7) Remove the rear heater-A/C control from the

bezel.

Fig. 1 Heater-A/C Control

1 - TRIM STICK

2 - BEZEL

3 - HEATER-A/C CONTROL

4 - HEADLINER

24 - 30 CONTROLS - REARRS

Page 3663 of 4284

quarter inner panel. Tighten the screw to 11 N´m (97

in. lbs.).

(7) Install and tighten the screw that secures the

back of the rear heater-A/C unit housing to the right

D-pillar. Tighten the screw to 11 N´m (97 in. lbs.).

(8) Install and tighten the two screws that secure

the top of the quarter trim panel attaching bracket to

the quarter inner panel. Tighten the screws to 1.7

N´m (15 in. lbs.).

(9) Reinstall the right quarter trim panel and

right D-pillar trim panel onto the quarter inner

panel. (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

(10) Reconnect the battery negative cable.

(11) Perform the heater-A/C control calibration

procedure. (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/A/C-HEATER CON-

TROL - STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION).

BLOWER MOTOR RELAY

DESCRIPTION

TERMINAL LEGEND

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

The blower motor relay (Fig. 5) is a International

Standards Organization (ISO) mini-relay. Relays con-

forming to the ISO specifications have common phys-ical dimensions, current capacities, terminal

patterns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The blower

motor relay is located in the Intelligent Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout map

molded into the inner surface of the IPM cover for

compressor clutch relay identification and location.

The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal. The

ISO terminal designations are as follows:

²30 (Common Feed)- This terminal is con-

nected to the movable contact point of the relay.

²85 (Coil Ground)- This terminal is connected

to the ground feed side of the relay control coil.

²86 (Coil Battery)- This terminal is connected

to the battery feed side of the relay control coil.

²87 (Normally Open)- This terminal is con-

nected to the normally open fixed contact point of the

relay.

²87A (Normally Closed)- This terminal is con-

nected to the normally closed fixed contact point of

the relay.

The factory-installed blower motor relay cannot be

adjusted or repaired. If the relay is damaged or

faulty, it must be replaced.

OPERATION

The blower motor relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control the high current

output to the blower motor resistor (manual heater-

A/C control) or blower power module (automatic heat-

er-A/C control). The movable common feed contact

point is held against the fixed normally closed con-

tact point by spring pressure. When the relay coil is

energized, an electromagnetic field is produced by the

coil windings. This electromagnetic field draws the

movable relay contact point away from the fixed nor-

mally closed contact point, and holds it against the

fixed normally open contact point. When the relay

coil is de-energized, spring pressure returns the mov-

able contact point back against the fixed normally

closed contact point. The resistor or diode is con-

nected in parallel with the relay coil in the relay, and

helps to dissipate voltage spikes and electromagnetic

interference that can be generated as the electromag-

netic field of the relay coil collapses.

Fig. 5 Blower Motor Relay

RSCONTROLS - REAR24-33

BLEND DOOR ACTUATOR (Continued)

Page 3664 of 4284

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Intelligent Power Module (IPM). The inputs and

outputs of the compressor clutch relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused rear blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

DIAGNOSIS AND TESTING - BLOWER MOTOR

RELAY

The rear blower motor relay (Fig. 5) is located in

the Intelligent Power Module (IPM), which is in the

engine compartment near the battery. See the fuse

and relay layout map molded into the inner surface

of the IPM cover for rear blower motor relay identi-

fication and location. Remove the relay from the IPM

to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, use a DRBIIItscan tool to perform

further diagnosis of the relay circuits. Refer to the

appropriate diagnostic information. If not OK,

replace the faulty relay.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Intelli-

gent Power Module (IPM) (Fig. 6).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for rear blower

motor relay identification and location.

(4) Remove the rear blower motor relay from the

IPM.

INSTALLATION

(1) See the fuse and relay layout map molded into

the inner surface of the Intelligent Power Module

(IPM) cover for rear blower motor relay identification

and location (Fig. 6).

(2) Position the rear blower motor relay to the

proper receptacle in the IPM.

(3) Align the rear blower motor relay terminals

with the terminal cavities in the IPM relay recepta-

cle.

(4) Push down firmly on the rear blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install and latch the cover onto the IPM.

(6) Reconnect the battery negative cable.

Fig. 6 Intelligent Power Module

1 - BATTERY THERMAL GUARD

2 - INTELLIGENT POWER MODULE

3 - FRONT CONTROL MODULE

24 - 34 CONTROLS - REARRS

BLOWER MOTOR RELAY (Continued)

Page 3667 of 4284

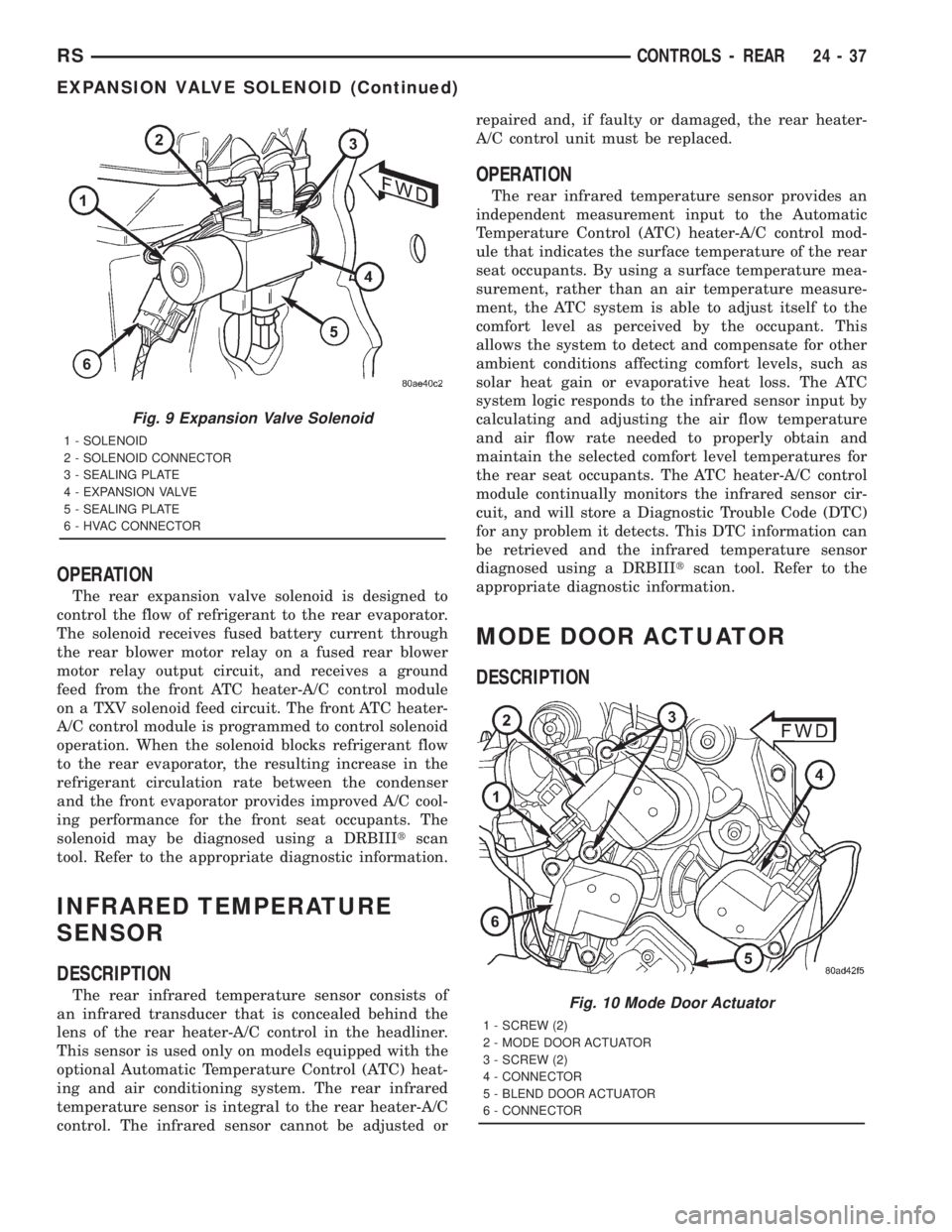

OPERATION

The rear expansion valve solenoid is designed to

control the flow of refrigerant to the rear evaporator.

The solenoid receives fused battery current through

the rear blower motor relay on a fused rear blower

motor relay output circuit, and receives a ground

feed from the front ATC heater-A/C control module

on a TXV solenoid feed circuit. The front ATC heater-

A/C control module is programmed to control solenoid

operation. When the solenoid blocks refrigerant flow

to the rear evaporator, the resulting increase in the

refrigerant circulation rate between the condenser

and the front evaporator provides improved A/C cool-

ing performance for the front seat occupants. The

solenoid may be diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

INFRARED TEMPERATURE

SENSOR

DESCRIPTION

The rear infrared temperature sensor consists of

an infrared transducer that is concealed behind the

lens of the rear heater-A/C control in the headliner.

This sensor is used only on models equipped with the

optional Automatic Temperature Control (ATC) heat-

ing and air conditioning system. The rear infrared

temperature sensor is integral to the rear heater-A/C

control. The infrared sensor cannot be adjusted orrepaired and, if faulty or damaged, the rear heater-

A/C control unit must be replaced.

OPERATION

The rear infrared temperature sensor provides an

independent measurement input to the Automatic

Temperature Control (ATC) heater-A/C control mod-

ule that indicates the surface temperature of the rear

seat occupants. By using a surface temperature mea-

surement, rather than an air temperature measure-

ment, the ATC system is able to adjust itself to the

comfort level as perceived by the occupant. This

allows the system to detect and compensate for other

ambient conditions affecting comfort levels, such as

solar heat gain or evaporative heat loss. The ATC

system logic responds to the infrared sensor input by

calculating and adjusting the air flow temperature

and air flow rate needed to properly obtain and

maintain the selected comfort level temperatures for

the rear seat occupants. The ATC heater-A/C control

module continually monitors the infrared sensor cir-

cuit, and will store a Diagnostic Trouble Code (DTC)

for any problem it detects. This DTC information can

be retrieved and the infrared temperature sensor

diagnosed using a DRBIIItscan tool. Refer to the

appropriate diagnostic information.

MODE DOOR ACTUATOR

DESCRIPTION

Fig. 9 Expansion Valve Solenoid

1 - SOLENOID

2 - SOLENOID CONNECTOR

3 - SEALING PLATE

4 - EXPANSION VALVE

5 - SEALING PLATE

6 - HVAC CONNECTOR

Fig. 10 Mode Door Actuator

1 - SCREW (2)

2 - MODE DOOR ACTUATOR

3 - SCREW (2)

4 - CONNECTOR

5 - BLEND DOOR ACTUATOR

6 - CONNECTOR

RSCONTROLS - REAR24-37

EXPANSION VALVE SOLENOID (Continued)

Page 3670 of 4284

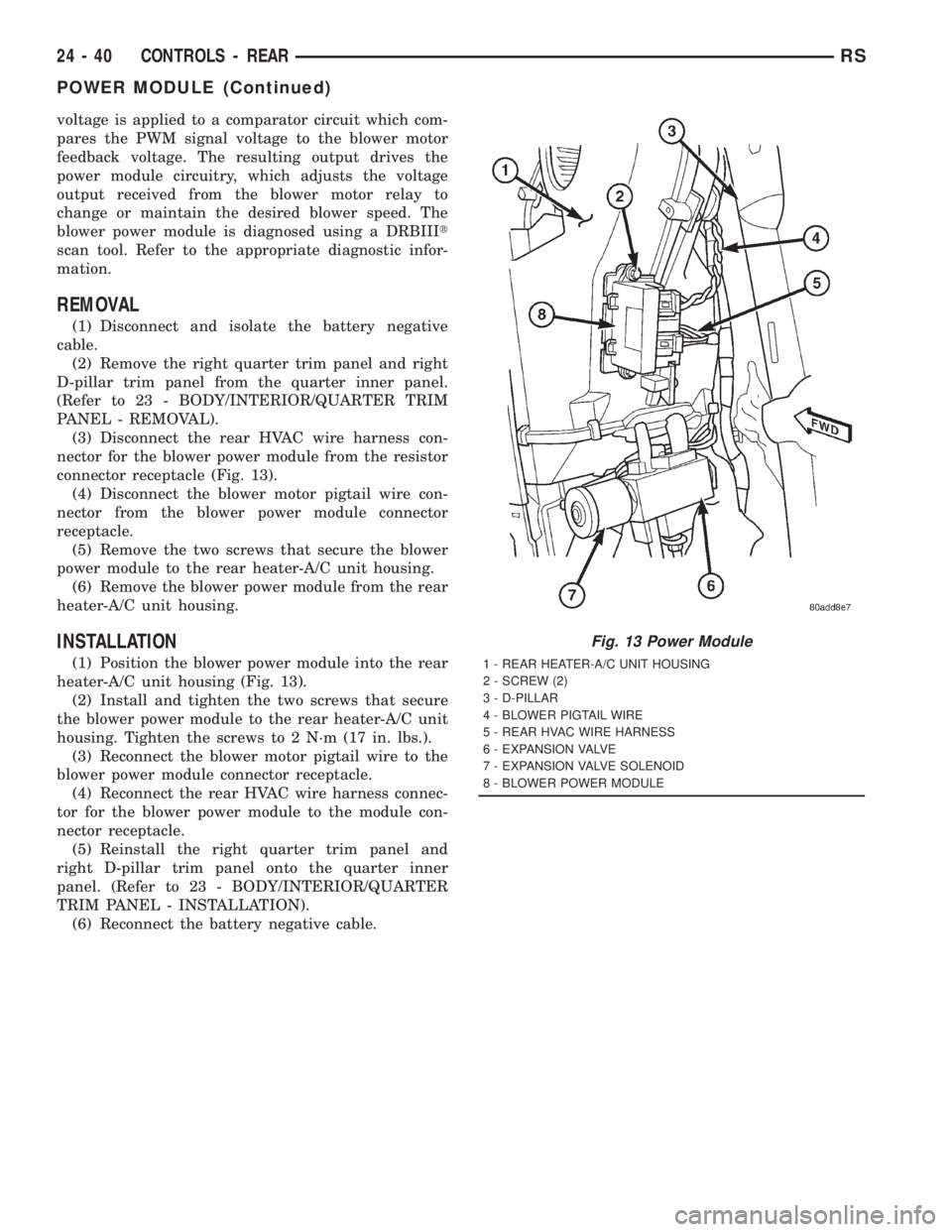

voltage is applied to a comparator circuit which com-

pares the PWM signal voltage to the blower motor

feedback voltage. The resulting output drives the

power module circuitry, which adjusts the voltage

output received from the blower motor relay to

change or maintain the desired blower speed. The

blower power module is diagnosed using a DRBIIIt

scan tool. Refer to the appropriate diagnostic infor-

mation.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the right quarter trim panel and right

D-pillar trim panel from the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(3) Disconnect the rear HVAC wire harness con-

nector for the blower power module from the resistor

connector receptacle (Fig. 13).

(4) Disconnect the blower motor pigtail wire con-

nector from the blower power module connector

receptacle.

(5) Remove the two screws that secure the blower

power module to the rear heater-A/C unit housing.

(6) Remove the blower power module from the rear

heater-A/C unit housing.

INSTALLATION

(1) Position the blower power module into the rear

heater-A/C unit housing (Fig. 13).

(2) Install and tighten the two screws that secure

the blower power module to the rear heater-A/C unit

housing. Tighten the screws to 2 N´m (17 in. lbs.).

(3) Reconnect the blower motor pigtail wire to the

blower power module connector receptacle.

(4) Reconnect the rear HVAC wire harness connec-

tor for the blower power module to the module con-

nector receptacle.

(5) Reinstall the right quarter trim panel and

right D-pillar trim panel onto the quarter inner

panel. (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - INSTALLATION).

(6) Reconnect the battery negative cable.

Fig. 13 Power Module

1 - REAR HEATER-A/C UNIT HOUSING

2 - SCREW (2)

3 - D-PILLAR

4 - BLOWER PIGTAIL WIRE

5 - REAR HVAC WIRE HARNESS

6 - EXPANSION VALVE

7 - EXPANSION VALVE SOLENOID

8 - BLOWER POWER MODULE

24 - 40 CONTROLS - REARRS

POWER MODULE (Continued)

Page 3675 of 4284

BLOWER MOTOR

DESCRIPTION

The blower motor is a 12-volt, Direct Current (DC)

motor with a squirrel cage-type blower wheel that is

secured to the blower motor shaft (Fig. 7). The

blower motor and wheel are located near the passen-

ger side end of the heater-A/C unit within the two

halves of the intake air housing in the passenger

compartment below the instrument panel. The

instrument panel must be rolled rearward to access

the blower motor and blower wheel for service. The

blower motor and blower motor wheel are a factory

balanced unit and cannot be adjusted or repaired. If

faulty or damaged, the blower motor and blower

wheel must be replaced as a unit.

OPERATION

The blower motor will operate whenever the igni-

tion switch is in the On position and the heater-A/C

control power is turned on. The blower motor can

only be turned off by turning off the power at the

heater-A/C control. The blower motor receives battery

current whenever the front blower motor relay is

energized. The front blower motor relay output cir-

cuit is protected by a fuse in the Intelligent Power

Module (IPM) located in the engine compartment

near the battery. In the Manual system, the blower

motor speed is controlled by regulating the path to

ground through the blower control switch and the

blower motor resistor. In the ATC system, the blower

motor speed is controlled by an electronic blower

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel are

used to control the velocity of air moving through the

heater-A/C unit housing. The blower motor controls

the velocity of the air flowing through the heater-A/C

housing by spinning the blower wheel within the

housing at the selected speed or, in the ATC system,

at the selected or programmed speed.

DIAGNOSIS AND TESTING - FRONT BLOWER

MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

Fig. 7 Blower Motor

1 - BLOWER MOTOR

2 - RUBBER GROMMET

3 - BLOWER MOTOR CONNECTOR

4 - MOUNTING TABS

RSDISTRIBUTION - FRONT24-45

Page 3676 of 4284

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Intelligent Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the heater-A/C control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, proceed to diagnosis of the front blower motor

relay. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/BLOWER MOTOR

RELAY - DIAGNOSIS AND TESTING).

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor (Manual Temper-

ature Control) or the front blower power module

(Automatic Temperature Control) from the resistor or

module connector receptacle. Reconnect the battery

negative cable. Turn the ignition switch to the On

position. Be certain that the heater-A/C control

power is turned on. Check for battery voltage at the

fused front blower motor relay output circuit cavity

of the front HVAC wire harness connector for thefront blower motor resistor (MTC) or the front blower

power module (ATC). If OK, go to Step 4. If not OK,

repair the open fused front blower motor relay output

circuit to the IPM as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front blower motor pigtail wire con-

nector from the connector receptacle of the front

blower motor resistor (MTC) or the front blower

power module (ATC). Use jumper wires to connect a

battery and ground feeds to the blower motor pigtail

wire connector. The blower motor should operate. If

OK with MTC, proceed to diagnosis of the front

blower motor resistor. (Refer to 24 - HEATING & AIR

CONDITIONING/CONTROLS - FRONT/BLOWER

MOTOR RESISTOR - DIAGNOSIS AND TESTING).

If OK with ATC, use a DRBIII scan tool to diagnose

the front blower power module. Refer to the appropri-

ate diagnostic information. If not OK with MTC or

ATC, replace the faulty front blower motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart (Fig. 8).

24 - 46 DISTRIBUTION - FRONTRS

BLOWER MOTOR (Continued)

Page 3686 of 4284

system control switch on the front heater-A/C control

is not in the Off position. The blower motor can only

be turned off by turning off the rear system at the

front heater-A/C control. The blower motor receives

battery current whenever the rear blower motor

relay is energized. The rear blower motor relay out-

put circuit is protected by a fuse in the Intelligent

Power Module (IPM) located in the engine compart-

ment near the battery. In the MTC system, the

blower motor speed is controlled by regulating the

path to ground through the blower control switch and

the blower motor resistor. In the ATC system, the

blower motor speed is controlled by an electronic

blower power module, which uses a pulse width mod-

ulated input from the ATC module and feedback from

the blower motor to regulate the blower motor

ground path it provides. The blower motor and wheel

are used to control the velocity of air moving through

the rear heater-A/C unit housing. The blower motor

controls the velocity of the air flowing through the

rear heater-A/C housing by spinning the blower

wheel within the housing at the selected speed or, in

the ATC system, at the selected or programmed

speed.

DIAGNOSIS AND TESTING - REAR BLOWER

MOTOR

BLOWER MOTOR INOPERATIVE

(1) Check the fuse (Fuse 12 - 25 ampere) in the

Intelligent Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the rear heater-A/C control power is

turned on. Check for battery voltage at the fuse

(Fuse 12 - 25 ampere) in the IPM. If OK, go to Step

3. If not OK, proceed to diagnosis of the rear blower

motor relay. (Refer to 24 - HEATING & AIR CONDI-TIONING/CONTROLS - REAR/BLOWER MOTOR

RELAY - DIAGNOSIS AND TESTING).

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear HVAC wire harness connector for

the rear blower motor resistor (Manual Temperature

Control) or the rear blower power module (Automatic

Temperature Control) from the resistor or module

connector receptacle. Reconnect the battery negative

cable. Turn the ignition switch to the On position. Be

certain that the rear heater-A/C control power is

turned on. Check for battery voltage at the fused

rear blower motor relay output circuit cavity of the

rear HVAC wire harness connector for the rear

blower motor resistor (MTC) or the rear blower

power module (ATC). If OK, go to Step 4. If not OK,

repair the open fused front blower motor relay output

circuit to the IPM as required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the rear blower motor pigtail wire connec-

tor from the take out and connector of the rear

HVAC wire harness (MTC) or the connector recepta-

cle of the rear blower power module (ATC). Use

jumper wires to connect a battery and ground feeds

to the blower motor pigtail wire connector. The

blower motor should operate. If OK with MTC, pro-

ceed to diagnosis of the rear blower motor resistor.

(Refer to 24 - HEATING & AIR CONDITIONING/

CONTROLS - REAR/BLOWER MOTOR RESISTOR -

DIAGNOSIS AND TESTING). If OK with ATC, use a

DRBIII scan tool to diagnose the rear blower power

module. Refer to the appropriate diagnostic informa-

tion. If not OK with MTC or ATC, replace the faulty

rear blower motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart (Fig. 4).

24 - 56 DISTRIBUTION - REARRS

BLOWER MOTOR (Continued)

Page 3753 of 4284

²Vehicle Speed Sensor

²Engine Coolant Temperature Sensor

²Throttle Position Sensor

²Engine Controller Self Test Faults

²Cam or Crank Sensor

²Injector and Coil

²Idle Air Control Motor

²EVAP Electrical

²EGR Solenoid Electrical

²Intake Air Temperature

²5 Volt Feed

ConflictÐThe Task Manager does not run the

Oxygen Sensor Monitor if any of the following condi-

tions are present:

²A/C ON (A/C clutch cycling temporarily sus-

pends monitor)

²Purge flow in progress

²Ethanel content learn is takeng place and the

ethenal used once flag is set

SuspendÐThe Task Manager suspends maturing

a fault for the Oxygen Sensor Monitor if an of the fol-

lowing are present:

²Oxygen Sensor Heater Monitor, Priority 1

²Misfire Monitor, Priority 2

OXYGEN SENSOR HEATER MONITOR

DESCRIPTIONÐIf there is an oxygen sensor

(O2S) DTC as well as a O2S heater DTC, the O2S

fault MUST be repaired first. After the O2S fault is

repaired, verify that the heater circuit is operating

correctly.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The heater element itself is not tested. The sensor

output is used to test the heater by isolating the

effect of the heater element on the O2S output volt-

age from the other effects. The resistance is normally

between 100 ohms and 4.5 megaohms. When oxygen

sensor temperature increases, the resistance in the

internal circuit decreases. The PCM sends a 5 volts

biased signal through the oxygen sensors to ground

this monitoring circuit. As the temperature increases,

resistance decreases and the PCM detects a lower

voltage at the reference signal. Inversely, as the tem-

perature decreases, the resistance increases and the

PCM detects a higher voltage at the reference signal.

The O2S circuit is monitored for a drop in voltage.

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF

and the O2 sensors have cooled. The PCM sends a 5

volt bias to the oxygen sensor every 1.6 seconds. ThePCM keeps it biased for 35 ms each time. As the sen-

sor cools down, the resistance increases and the PCM

reads the increase in voltage. Once voltage has

increased to a predetermined amount, higher than

when the test started, the oxygen sensor is cool

enough to test heater operation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle.

Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 5.1 minutes

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

Pending ConditionsÐThere are not conditions or

situations that prompt conflict or suspension of test-

ing. The oxygen sensor heater test is not run pending

resolution of MIL illumination due to oxygen sensor

failure.

SuspendÐThere are no conditions which exist for

suspending the Heater Monitor.

CATALYST MONITOR

To comply with clean air regulations, vehicles are

equipped with catalytic converters. These converters

reduce the emission of hydrocarbons, oxides of nitro-

gen and carbon monoxide.

Normal vehicle miles or engine misfire can cause a

catalyst to decay. A meltdown of the ceramic core can

cause a reduction of the exhaust passage. This can

increase vehicle emissions and deteriorate engine

performance, driveability and fuel economy.

The catalyst monitor uses dual oxygen sensors

(O2S's) to monitor the efficiency of the converter. The

dual O2S strategy is based on the fact that as a cat-

alyst deteriorates, its oxygen storage capacity and its

efficiency are both reduced. By monitoring the oxy-

gen storage capacity of a catalyst, its efficiency can

be indirectly calculated. The upstream O2S is used to

detect the amount of oxygen in the exhaust gas

before the gas enters the catalytic converter. The

RSEMISSIONS CONTROL25-3

EMISSIONS CONTROL (Continued)