ignition CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 597 of 4284

TEST ACTION APPLICABILITY

4 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Headlamp Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Measure the voltage of the Front Fog Lamp Indicator circuit in the Headlamp Switch

harness connector.

Is the voltage above 0.5 volt?All

Ye s®Repair the Front Fog Lamp Indicator circuit for a short to voltage.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 If there are no possible causes remaining, view repair. All

Repair

Replace the Headlamp Switch.

Perform BODY VERIFICATION TEST - VER 1.

6 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Headlamp Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance of the Front Fog Lamp Indicator circuit from the Body

Control Module harness connector to the Headlamp Switch harness connector.

Is the resistance above 5.0 ohms?All

Ye s®Repair the Front Fog Lamp Indicator circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 7

7 If there are no possible causes remaining, view repair. All

Repair

Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

8 The conditions necessary to set this DTC are not present at this time.

Using the schematics as a guide, inspect the wiring and connectors specific to this

circuit.

Wiggle the wiring while checking for shorts and open circuits.

Were there any problems found?All

Ye s®Repair as necessary.

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

568

INSTRUMENT CLUSTER

FRONT FOG LAMP INDICATOR OPEN ÐContinued

Page 598 of 4284

Symptom:

FRONT FOG LAMP INDICATOR SHORT TO GROUND

POSSIBLE CAUSES

INTERMITTENT WIRING AND CONNECTORS

FRONT FOG LAMP INDICATOR CIRCUIT SHORT TO GROUND

HEADLAMP SWITCH

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, record and erase Body Control Module DTC's.

Turn the ignition off, wait 15 seconds, then turn the ignition on.

With the DRBIIIt, read DTCs.

Does the DRBIIItdisplay FRONT FOG LAMP INDICATOR SHORT TO GROUND?All

Ye s®Go To 2

No®Go To 6

2 Turn the ignition off to the lock position.

Note: Check connectors - Clean/repair as necessary.

Ignition on, engine not running.

Turn ON the Front Fog Lamps.

Using a 12-volt test light connected to ground, back probe the Rear Fog Lamp

Indicator circuit in the Headlamp Switch harness connector.

NOTE: The test light must illuminate brightly. Compare the brightness to

that of a direct connection to the battery.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Go To 4

3 If there are no possible causes remaining, view repair. All

Repair

Replace the Headlamp Switch.

Perform BODY VERIFICATION TEST - VER 1.

4 Turn the ignition off to the lock position.

Disconnect the Body Control Module harness connector.

Disconnect the Headlamp Switch harness connector.

Note: Check connectors - Clean/repair as necessary.

Measure the resistance between ground and the Front Fog Lamp Indicator circuit.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Front Fog Lamp Indicator circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 If there are no possible causes remaining, view repair. All

Repair

Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

569

INSTRUMENT CLUSTER

Page 601 of 4284

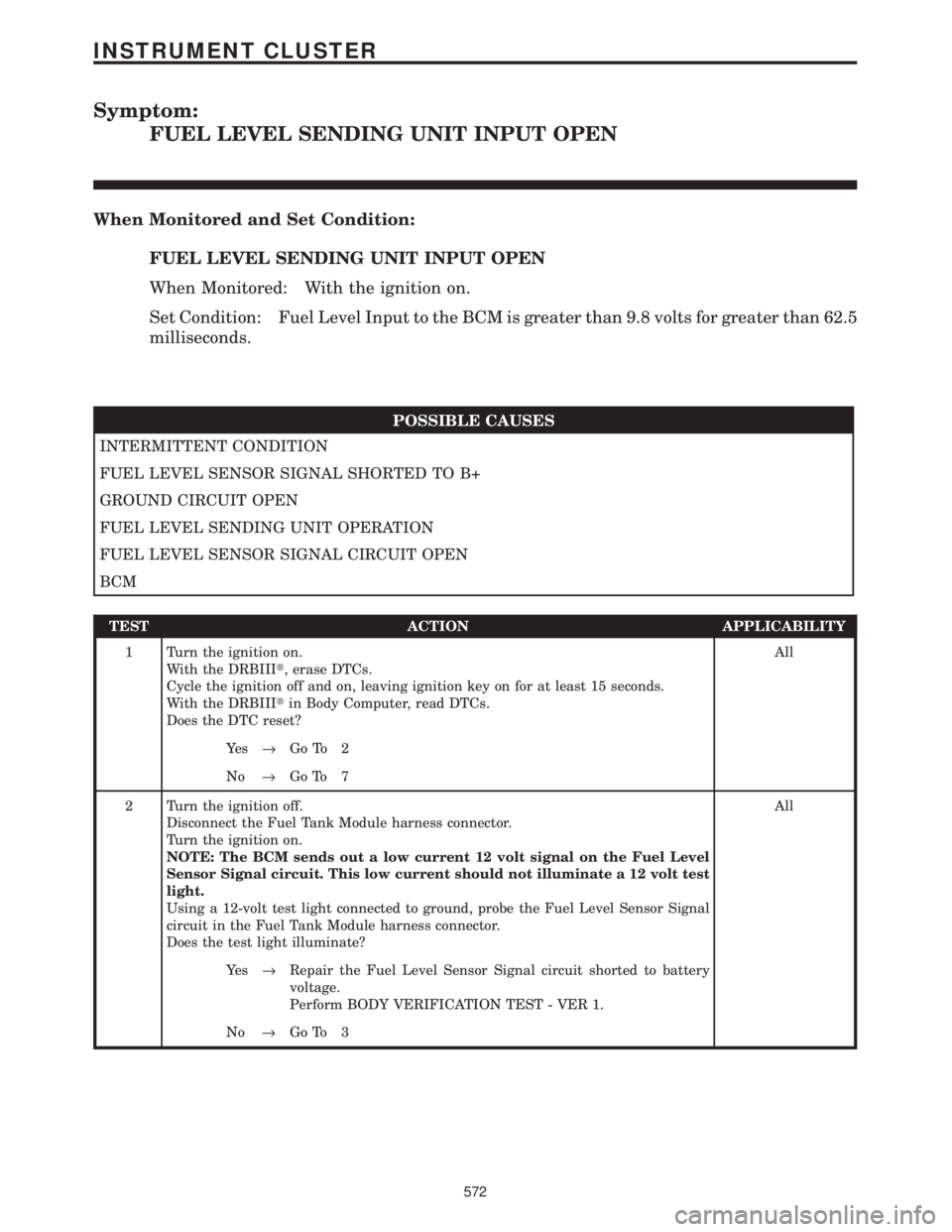

Symptom:

FUEL LEVEL SENDING UNIT INPUT OPEN

When Monitored and Set Condition:

FUEL LEVEL SENDING UNIT INPUT OPEN

When Monitored: With the ignition on.

Set Condition: Fuel Level Input to the BCM is greater than 9.8 volts for greater than 62.5

milliseconds.

POSSIBLE CAUSES

INTERMITTENT CONDITION

FUEL LEVEL SENSOR SIGNAL SHORTED TO B+

GROUND CIRCUIT OPEN

FUEL LEVEL SENDING UNIT OPERATION

FUEL LEVEL SENSOR SIGNAL CIRCUIT OPEN

BCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, erase DTCs.

Cycle the ignition off and on, leaving ignition key on for at least 15 seconds.

With the DRBIIItin Body Computer, read DTCs.

Does the DTC reset?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition off.

Disconnect the Fuel Tank Module harness connector.

Turn the ignition on.

NOTE: The BCM sends out a low current 12 volt signal on the Fuel Level

Sensor Signal circuit. This low current should not illuminate a 12 volt test

light.

Using a 12-volt test light connected to ground, probe the Fuel Level Sensor Signal

circuit in the Fuel Tank Module harness connector.

Does the test light illuminate?All

Ye s®Repair the Fuel Level Sensor Signal circuit shorted to battery

voltage.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

572

INSTRUMENT CLUSTER

Page 602 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition on.

Disconnect the Fuel Tank Module harness connector.

Measure the resistance of the Ground circuits in the Fuel Tank Module harness

connector.

Is the resistance below 5.0 ohms for both measurements?All

Ye s®Go To 4

No®Repair the Ground circuit for an open.

Perform BODY VERIFICATION TEST - VER 1.

4 Turn the ignition off.

Disconnect the Fuel Tank Module harness connector.

Turn the ignition on.

With the DRBIIItin Body Computer then Sensors, monitor the Fuel Sensor.

Using a jumper wire, jumper the Fuel Level Sensor Signal circuit to the ground

circuit in the Fuel Tank Module harness connector.

Does the DRB display below 0.5 volt?All

Ye s®Replace the Fuel Level Sending Unit.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 5

5 Turn the ignition off.

Disconnect the Fuel Tank Module harness connector.

Disconnect the BCM C3 harness connector.

Measure the resistance of the Fuel Level Sensor Signal circuit between the Fuel Tank

Module harness connector and the BCM harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the Fuel Level Sensor Signal for an open.

Perform BODY VERIFICATION TEST - VER 1.

6 If there are no possible causes remaining, view repair. All

Repair

Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

573

INSTRUMENT CLUSTER

FUEL LEVEL SENDING UNIT INPUT OPEN ÐContinued

Page 603 of 4284

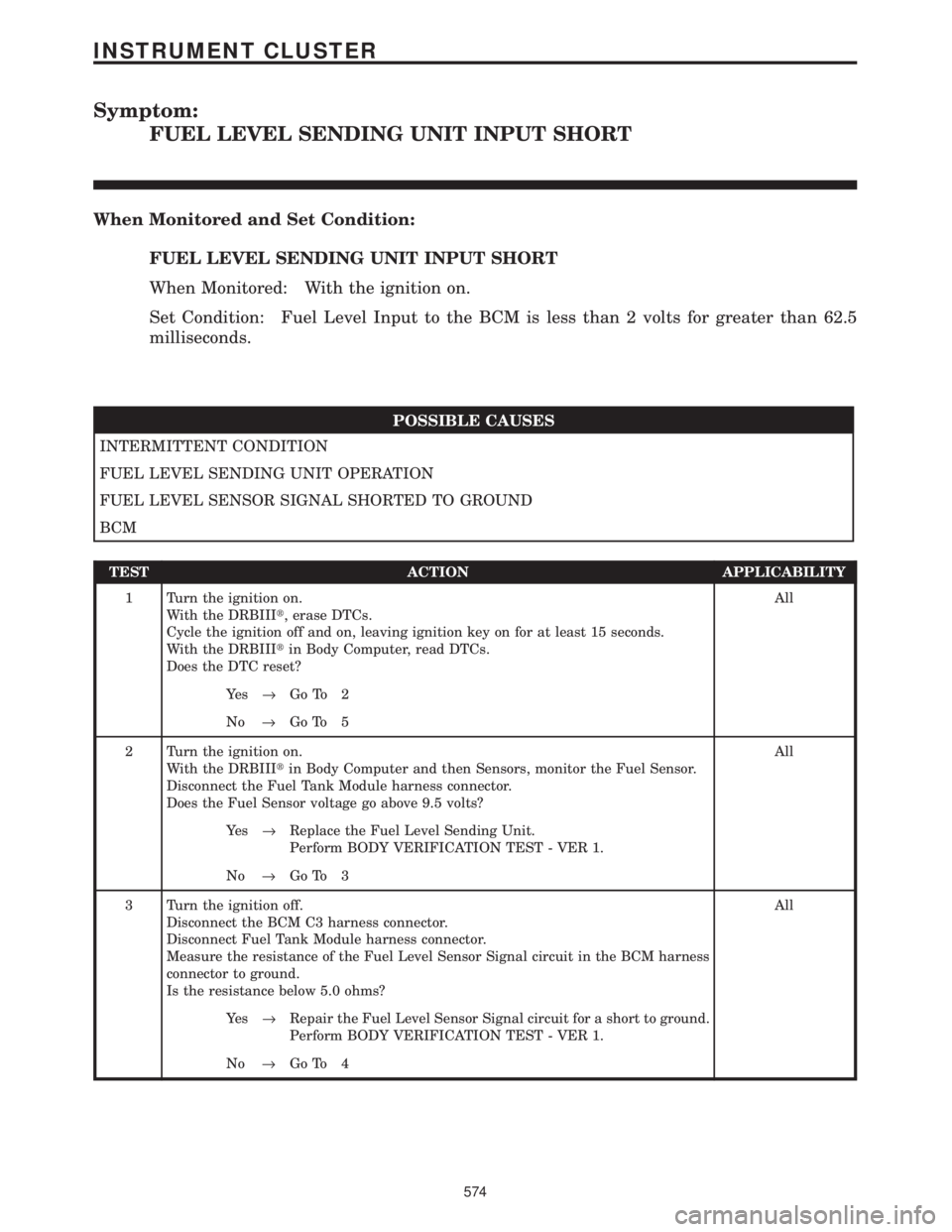

Symptom:

FUEL LEVEL SENDING UNIT INPUT SHORT

When Monitored and Set Condition:

FUEL LEVEL SENDING UNIT INPUT SHORT

When Monitored: With the ignition on.

Set Condition: Fuel Level Input to the BCM is less than 2 volts for greater than 62.5

milliseconds.

POSSIBLE CAUSES

INTERMITTENT CONDITION

FUEL LEVEL SENDING UNIT OPERATION

FUEL LEVEL SENSOR SIGNAL SHORTED TO GROUND

BCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, erase DTCs.

Cycle the ignition off and on, leaving ignition key on for at least 15 seconds.

With the DRBIIItin Body Computer, read DTCs.

Does the DTC reset?All

Ye s®Go To 2

No®Go To 5

2 Turn the ignition on.

With the DRBIIItin Body Computer and then Sensors, monitor the Fuel Sensor.

Disconnect the Fuel Tank Module harness connector.

Does the Fuel Sensor voltage go above 9.5 volts?All

Ye s®Replace the Fuel Level Sending Unit.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

3 Turn the ignition off.

Disconnect the BCM C3 harness connector.

Disconnect Fuel Tank Module harness connector.

Measure the resistance of the Fuel Level Sensor Signal circuit in the BCM harness

connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Fuel Level Sensor Signal circuit for a short to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

574

INSTRUMENT CLUSTER

Page 605 of 4284

Symptom:

IOD WAKEUP CLUSTER OUTPUT OPEN

When Monitored and Set Condition:

IOD WAKEUP CLUSTER OUTPUT OPEN

When Monitored: With the ignition on.

Set Condition: The BCM is active and the Instrument Cluster does not responed on the

Instrument Cluster Wake Up Sense circuit.

POSSIBLE CAUSES

INTERMITTENT CONDITION

INSTRUMENT CLUSTER WAKE UP SENSE CKT OPEN

INSTRUMENT CLUSTER WAKE UP SENSE CKT SHORT TO GROUND

INSTRUMENT CLUSTER

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, erase DTCs.

Cycle the ignition off and on several times, leaving ignition key on for at least 15

seconds.

With the DRBIIItin Body Computer, read DTCs.

Does the DTC reset?All

Ye s®Go To 2

No®Go To 5

2 Turn the ignition off.

Disconnect the BCM C4 harness connector.

Turn the ignition on.

Measure the voltage of the Instrument Cluster Wake Up Sense circuit in the BCM C4

harness connector.

Is the voltage above 10.0 volts?All

Ye s®Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 3

576

INSTRUMENT CLUSTER

Page 606 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the Instrument Cluster harness connector.

Disconnect the BCM C4 harness connector.

Measure the resistance of the Instrument Cluster Wake Up Sense circuit between the

BCM C4 harness connector and the MIC harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 4

No®Repair the Instrument Cluster Wake Up Sense circuit for an

open.

Perform BODY VERIFICATION TEST - VER 1.

4 Turn the ignition off.

Disconnect the Instrument Cluster harness connector.

Disconnect the BCM C4 harness connector.

Measure the resistance of the Instrument Cluster Wake Up Sense circuit in the MIC

harness connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Repair the Instrument Cluster Wake Up Sense circuit for a

shorted to ground.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1.

5WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

577

INSTRUMENT CLUSTER

IOD WAKEUP CLUSTER OUTPUT OPEN ÐContinued

Page 607 of 4284

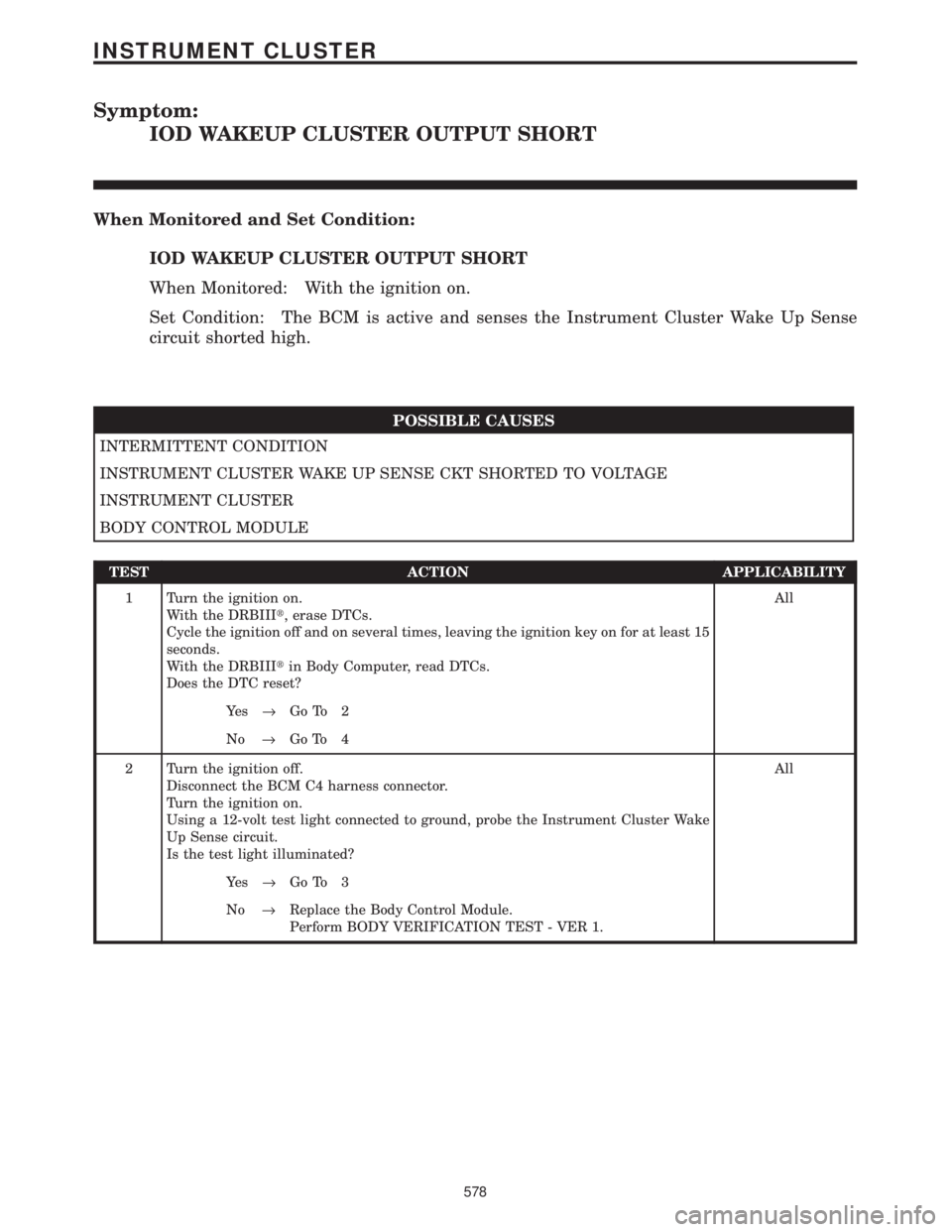

Symptom:

IOD WAKEUP CLUSTER OUTPUT SHORT

When Monitored and Set Condition:

IOD WAKEUP CLUSTER OUTPUT SHORT

When Monitored: With the ignition on.

Set Condition: The BCM is active and senses the Instrument Cluster Wake Up Sense

circuit shorted high.

POSSIBLE CAUSES

INTERMITTENT CONDITION

INSTRUMENT CLUSTER WAKE UP SENSE CKT SHORTED TO VOLTAGE

INSTRUMENT CLUSTER

BODY CONTROL MODULE

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, erase DTCs.

Cycle the ignition off and on several times, leaving the ignition key on for at least 15

seconds.

With the DRBIIItin Body Computer, read DTCs.

Does the DTC reset?All

Ye s®Go To 2

No®Go To 4

2 Turn the ignition off.

Disconnect the BCM C4 harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Instrument Cluster Wake

Up Sense circuit.

Is the test light illuminated?All

Ye s®Go To 3

No®Replace the Body Control Module.

Perform BODY VERIFICATION TEST - VER 1.

578

INSTRUMENT CLUSTER

Page 608 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the BCM C4 harness connector.

Disconnect the Instrument Cluster harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, probe the Instrument Cluster Wake

Up Sense circuit.

Is the test light illuminated?All

Ye s®Repair the Instrument Cluster Wake Up Sense circuit for a short

to voltage.

Perform BODY VERIFICATION TEST - VER 1.

No®Replace the Instrument Cluster.

Perform BODY VERIFICATION TEST - VER 1.

4WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

579

INSTRUMENT CLUSTER

IOD WAKEUP CLUSTER OUTPUT SHORT ÐContinued

Page 609 of 4284

Symptom:

LEFT TURN SIGNAL INDICATOR OPEN (HIGHLINE)

When Monitored and Set Condition:

LEFT TURN SIGNAL INDICATOR OPEN (HIGHLINE)

When Monitored: With the ignition on.

Set Condition: The BCM detects an open in the Left Turn Indicator Driver.

POSSIBLE CAUSES

INTERMITTENT CONDITION

FUSED B+ CIRCUIT

MESSAGE CENTER OPERATION

LEFT TURN INDICATOR DRIVER SHORTED TO GROUND

LEFT TURN INDICATOR DRIVER OPEN

BCM

TEST ACTION APPLICABILITY

1 Turn the ignition on.

Monitor the Left Turn Signal Indicator.

Operate the Left Turn Signal.

Is the Indicator lamp operating correctly?All

Ye s®Go To 2

No®Go To 3

2WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform BODY VERIFICATION TEST - VER 1.

No®Test Complete.

580

INSTRUMENT CLUSTER