wiring CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2939 of 4284

(3) Align the lock cylinder with the grooves in the

housing. Slide the lock cylinder into the housing

until the tab sticks through the opening in the hous-

ing.

(4) Turn the key to the Off position. Remove the

key.

(5) Install lower steering column shroud.

(6) Install steering column cover.

(7) Connect negative cable to battery.

GEAR SHIFT LEVER

REMOVAL

(1) Remove the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - REMOVAL).

(2) Remove the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - REMOVAL).

(3) Remove the upper and lower shrouds (Refer to

19 - STEERING/COLUMN/LOWER SHROUD -

REMOVAL).

(4) Remove the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

REMOVAL).

(5) Remove the fixed shroud from the column.

(6) Disconnect the electrical connector to the BTSI.

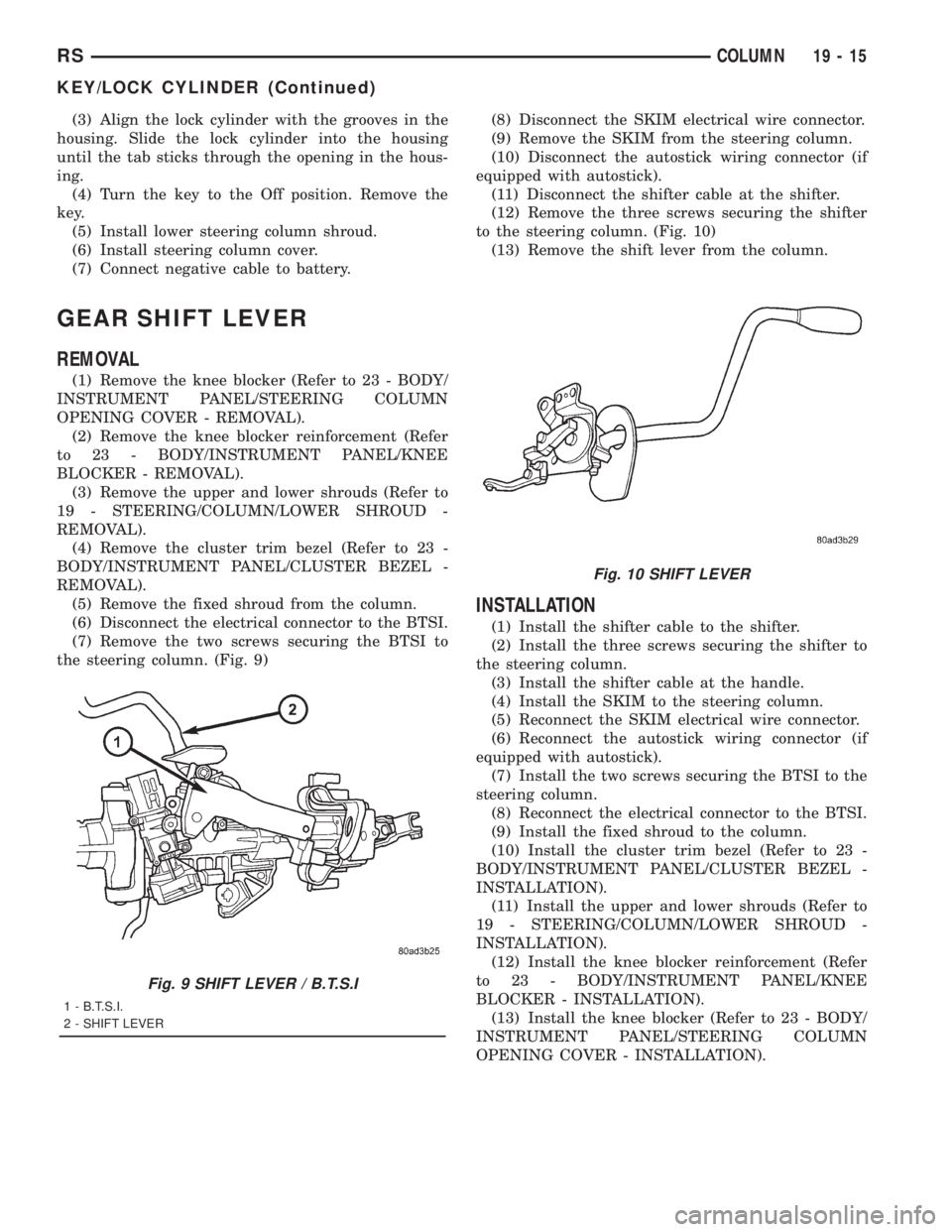

(7) Remove the two screws securing the BTSI to

the steering column. (Fig. 9)(8) Disconnect the SKIM electrical wire connector.

(9) Remove the SKIM from the steering column.

(10) Disconnect the autostick wiring connector (if

equipped with autostick).

(11) Disconnect the shifter cable at the shifter.

(12) Remove the three screws securing the shifter

to the steering column. (Fig. 10)

(13) Remove the shift lever from the column.

INSTALLATION

(1) Install the shifter cable to the shifter.

(2) Install the three screws securing the shifter to

the steering column.

(3) Install the shifter cable at the handle.

(4) Install the SKIM to the steering column.

(5) Reconnect the SKIM electrical wire connector.

(6) Reconnect the autostick wiring connector (if

equipped with autostick).

(7) Install the two screws securing the BTSI to the

steering column.

(8) Reconnect the electrical connector to the BTSI.

(9) Install the fixed shroud to the column.

(10) Install the cluster trim bezel (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(11) Install the upper and lower shrouds (Refer to

19 - STEERING/COLUMN/LOWER SHROUD -

INSTALLATION).

(12) Install the knee blocker reinforcement (Refer

to 23 - BODY/INSTRUMENT PANEL/KNEE

BLOCKER - INSTALLATION).

(13) Install the knee blocker (Refer to 23 - BODY/

INSTRUMENT PANEL/STEERING COLUMN

OPENING COVER - INSTALLATION).

Fig. 9 SHIFT LEVER / B.T.S.I

1 - B.T.S.I.

2 - SHIFT LEVER

Fig. 10 SHIFT LEVER

RSCOLUMN19-15

KEY/LOCK CYLINDER (Continued)

Page 2949 of 4284

SERVICE WARNINGS AND CAUTIONS

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.

DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

STANDARD PROCEDURE - POWER STEERING

PUMP INITIAL OPERATION

CAUTION: The fluid level should be checked with

engine off to prevent injury from moving compo-

nents. Use only MoparTPower Steering Fluid (MS-

5931) or approved equivalent. Do not overfill.

Read the fluid level through the side of the power

steering fluid reservoir. The fluid level should indi-

cateªFILL RANGEºwhen the fluid is at a temper-

ature of approximately 21ÉC to 27ÉC (70ÉF to 80ÉF).

(1) Wipe the filler cap and area clean, then remove

the cap.

(2) Fill the fluid reservoir to the proper level and

let the fluid settle for at least two (2) minutes.

(3) Start the engine and let run for a few seconds,

then turn the engine off.

(4) Add fluid if necessary. Repeat the above steps

until the fluid level remains constant after running

the engine.

(5) Raise the front wheels off the ground.

(6) Start the engine.

(7) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops.

(8) Add fluid if necessary.

(9) Lower the vehicle, then turn the steering wheel

slowly from lock-to-lock.

(10) Stop the engine. Check the fluid level and

refill as required.

(11) If the fluid is extremely foamy, allow the vehi-

cle to stabilize a few minutes, then repeat the above

procedure.

REMOVAL - PUMP (2.4L ENGINE)

(1) Remove the (-) negative battery cable from the

battery and isolate cable.

(2) Remove the cap from the power steering fluid

reservoir.

(3) Using a siphon pump, remove as much power

steering fluid as possible from the power steering

fluid reservoir.

(4) Raise the vehicle on jack stands or centered on

a frame contact type hoist. See Hoisting in Lubrica-

tion and Maintenance.

(5) Disconnect the oxygen sensor wiring harness

from the vehicle wiring harness at the rear engine

mount bracket.

NOTE: The exhaust system needs to be removed

from the engine to allow for an area to remove the

power steering pump from the vehicle.

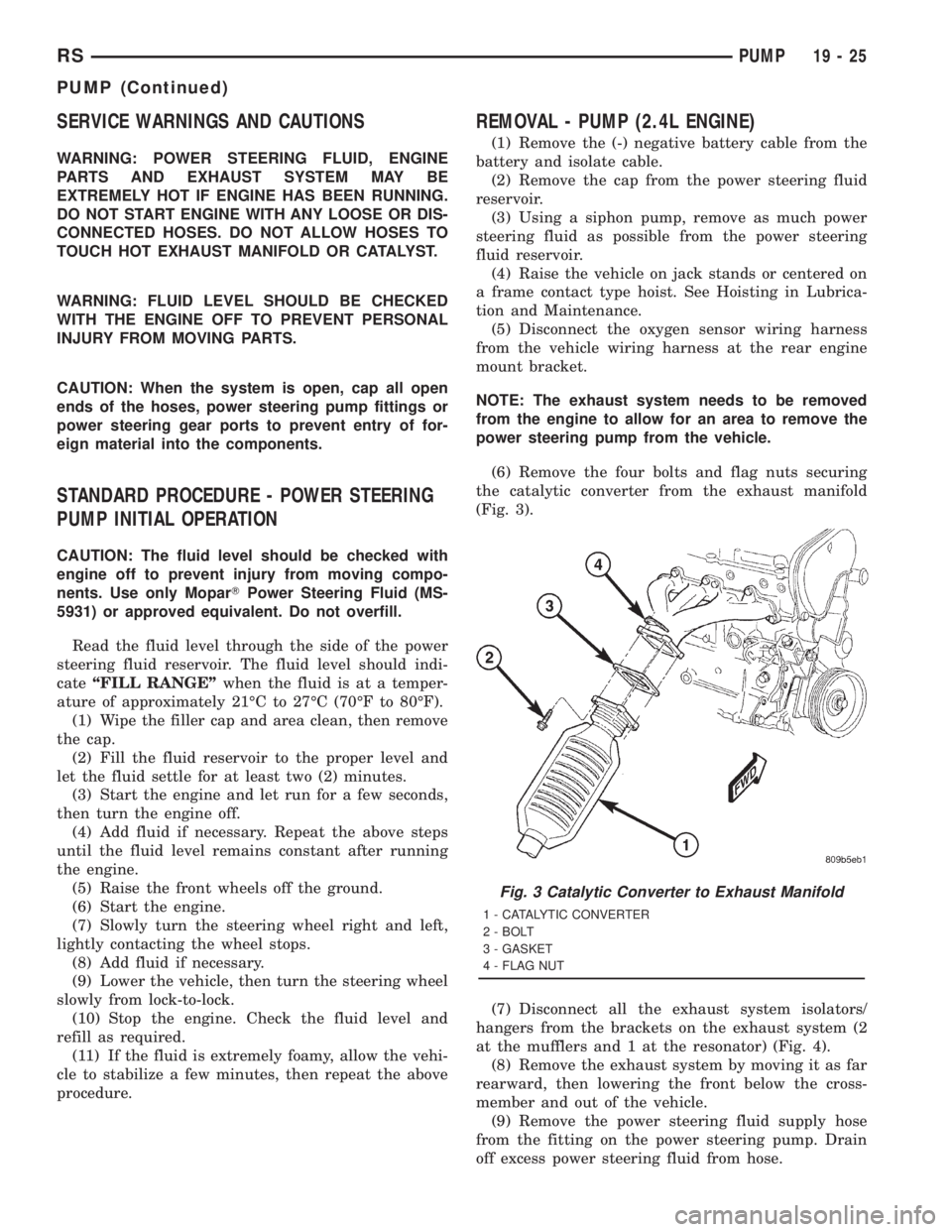

(6) Remove the four bolts and flag nuts securing

the catalytic converter from the exhaust manifold

(Fig. 3).

(7) Disconnect all the exhaust system isolators/

hangers from the brackets on the exhaust system (2

at the mufflers and 1 at the resonator) (Fig. 4).

(8) Remove the exhaust system by moving it as far

rearward, then lowering the front below the cross-

member and out of the vehicle.

(9) Remove the power steering fluid supply hose

from the fitting on the power steering pump. Drain

off excess power steering fluid from hose.

Fig. 3 Catalytic Converter to Exhaust Manifold

1 - CATALYTIC CONVERTER

2 - BOLT

3 - GASKET

4 - FLAG NUT

RSPUMP19-25

PUMP (Continued)

Page 2953 of 4284

INSTALLATION - PUMP (2.4L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

exhaust tunnel are of the vehicle.

(2) Install the power steering pump on its cast

mounting bracket (Fig. 7), then install the nut and

bolt attaching the front bracket to the cast bracket

(Fig. 8).Do not fully tighten at this time..

(3) Install the rear nut (Fig. 7).

(4) Install the power steering pump drive belt on

pulley and adjust (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - INSTALLATION).(5) Tighten the two adjustment slot bolts and the

one pivot bolt to 54 N´m (40 ft.lbs.) torque.

(6) Install the accessory drive splash shield.

NOTE: Before installing power steering fluid pres-

sure hose on power steering pump, inspect the

O-ring on the pressure hose for damage and

replace if necessary.

(7) Install the power steering fluid pressure line

onto the output fitting of the power steering pump

(Fig. 6). Tighten the pressure line to pump fitting

tube nut to a torque of 31 N´m (275 in. lbs.).

(8) Install the power steering fluid low pressure

return hose on the power steering pump low pressure

fitting (Fig. 6).Be sure hose clamps are properly

reinstalled.

(9) Install the power steering fluid supply hose on

the power steering pump fluid fitting.Be sure hose

is clear of accessory drive belts all hose clamps

are properly reinstalled.

(10) When used, properly position the protective

heat sleeve on the power steering return hose. Tie

strap the heat sleeve to the power steering hose to

keep in it's proper position.

(11) Install the exhaust system (Fig. 4). Install all

exhaust system isolators/hangers on the exhaust sys-

tem brackets, then the four bolts and flag nuts (Fig.

3).

(12) Connect the oxygen sensor wiring harness to

the vehicle wiring harness.

(13) Lower vehicle.

(14) Connect the negative battery cable on the

negative battery post.

(15) Perform the POWER STEERING PUMP INI-

TIAL OPERATION procedure to properly fill and

bleed the power steering system. (Refer to 19 -

STEERING/PUMP - STANDARD PROCEDURE)

(16) Inspect for leaks.

INSTALLATION - PUMP (3.3L/3.8L ENGINE)

(1) Install power steering pump back in vehicle

using the reverse order of its removal through the

engine compartment of the vehicle.

(2) Install the power steering pump on its mount-

ing bracket.

(3) Install the 3 front and 1 rear power steering

pump mounting bolts (Fig. 9). Remember to place

spacer between pump and rear mounting bracket

when installing rear mounting bolt. Tighten the

power steering pump mounting bolts to a torque of

54 N´m (40 ft. lbs.).

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

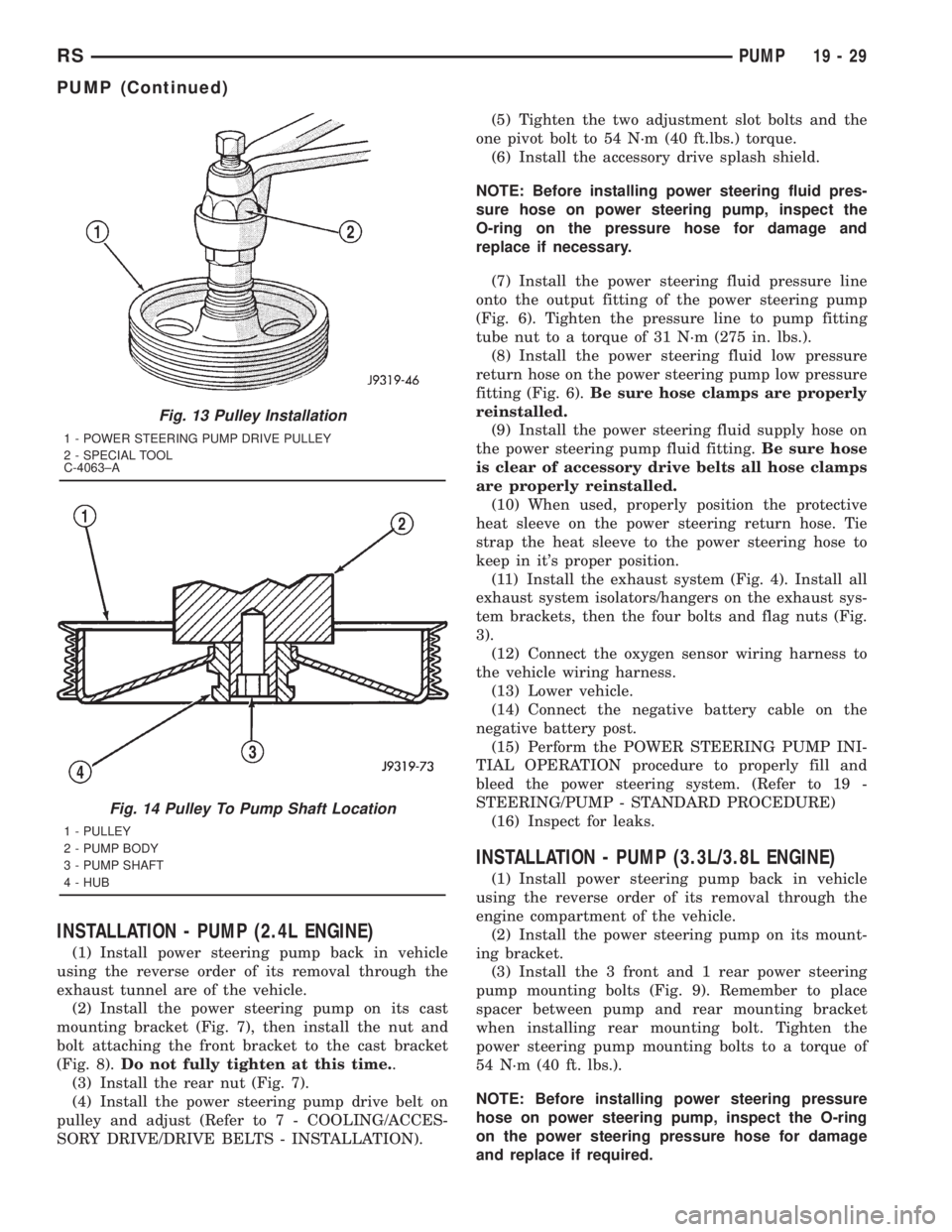

Fig. 13 Pulley Installation

1 - POWER STEERING PUMP DRIVE PULLEY

2 - SPECIAL TOOL

C-4063±A

Fig. 14 Pulley To Pump Shaft Location

1 - PULLEY

2 - PUMP BODY

3 - PUMP SHAFT

4 - HUB

RSPUMP19-29

PUMP (Continued)

Page 2994 of 4284

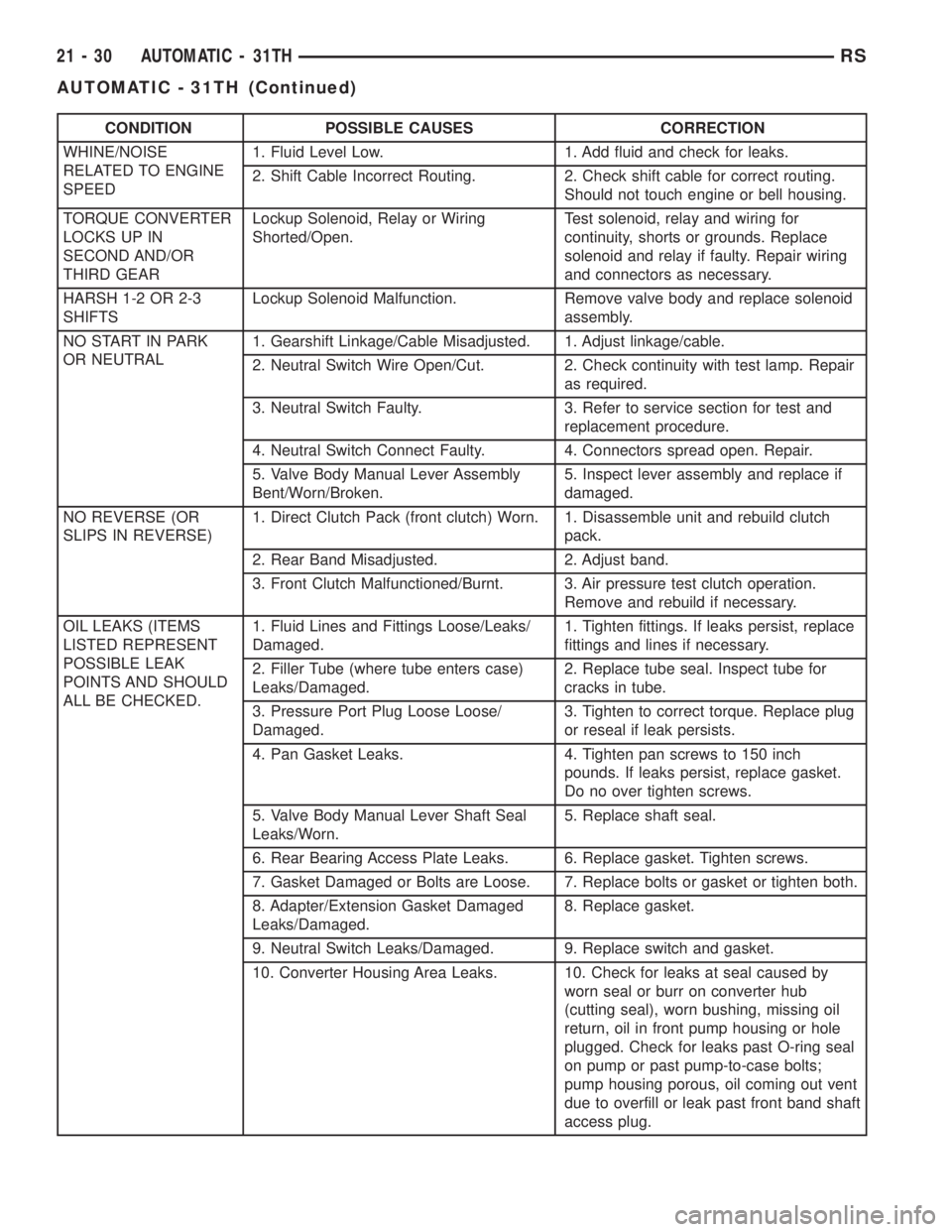

CONDITION POSSIBLE CAUSES CORRECTION

WHINE/NOISE

RELATED TO ENGINE

SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing.

Should not touch engine or bell housing.

TORQUE CONVERTER

LOCKS UP IN

SECOND AND/OR

THIRD GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

HARSH 1-2 OR 2-3

SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

NO START IN PARK

OR NEUTRAL1. Gearshift Linkage/Cable Misadjusted. 1. Adjust linkage/cable.

2. Neutral Switch Wire Open/Cut. 2. Check continuity with test lamp. Repair

as required.

3. Neutral Switch Faulty. 3. Refer to service section for test and

replacement procedure.

4. Neutral Switch Connect Faulty. 4. Connectors spread open. Repair.

5. Valve Body Manual Lever Assembly

Bent/Worn/Broken.5. Inspect lever assembly and replace if

damaged.

NO REVERSE (OR

SLIPS IN REVERSE)1. Direct Clutch Pack (front clutch) Worn. 1. Disassemble unit and rebuild clutch

pack.

2. Rear Band Misadjusted. 2. Adjust band.

3. Front Clutch Malfunctioned/Burnt. 3. Air pressure test clutch operation.

Remove and rebuild if necessary.

OIL LEAKS (ITEMS

LISTED REPRESENT

POSSIBLE LEAK

POINTS AND SHOULD

ALL BE CHECKED.1. Fluid Lines and Fittings Loose/Leaks/

Damaged.1. Tighten fittings. If leaks persist, replace

fittings and lines if necessary.

2. Filler Tube (where tube enters case)

Leaks/Damaged.2. Replace tube seal. Inspect tube for

cracks in tube.

3. Pressure Port Plug Loose Loose/

Damaged.3. Tighten to correct torque. Replace plug

or reseal if leak persists.

4. Pan Gasket Leaks. 4. Tighten pan screws to 150 inch

pounds. If leaks persist, replace gasket.

Do no over tighten screws.

5. Valve Body Manual Lever Shaft Seal

Leaks/Worn.5. Replace shaft seal.

6. Rear Bearing Access Plate Leaks. 6. Replace gasket. Tighten screws.

7. Gasket Damaged or Bolts are Loose. 7. Replace bolts or gasket or tighten both.

8. Adapter/Extension Gasket Damaged

Leaks/Damaged.8. Replace gasket.

9. Neutral Switch Leaks/Damaged. 9. Replace switch and gasket.

10. Converter Housing Area Leaks. 10. Check for leaks at seal caused by

worn seal or burr on converter hub

(cutting seal), worn bushing, missing oil

return, oil in front pump housing or hole

plugged. Check for leaks past O-ring seal

on pump or past pump-to-case bolts;

pump housing porous, oil coming out vent

due to overfill or leak past front band shaft

access plug.

21 - 30 AUTOMATIC - 31THRS

AUTOMATIC - 31TH (Continued)

Page 3070 of 4284

PARK/NEUTRAL POSITION

SWITCH

DIAGNOSIS AND TESTING - PARK/NEUTRAL

POSITION SWITCH

The park/neutral starting switch is the center ter-

minal of the 3 terminal switch. It provides ground for

the starter solenoid circuit through the selector lever

in only Park (P) and Neutral (N) positions.

(1) To test switch, remove wiring connector from

switch and test for continuity between center pin of

switch and transaxle case. Continuity should exist

only when transaxle is in Park or Neutral.

(2) Check gearshift cable adjustment before replac-

ing a switch which tests bad.

REMOVAL

(1) Unscrew switch from transaxle case allowing

fluid to drain into a container. Move selector lever to

Park, then to Neutral position, and inspect to see the

switch operating lever fingers are centered in switch

opening.

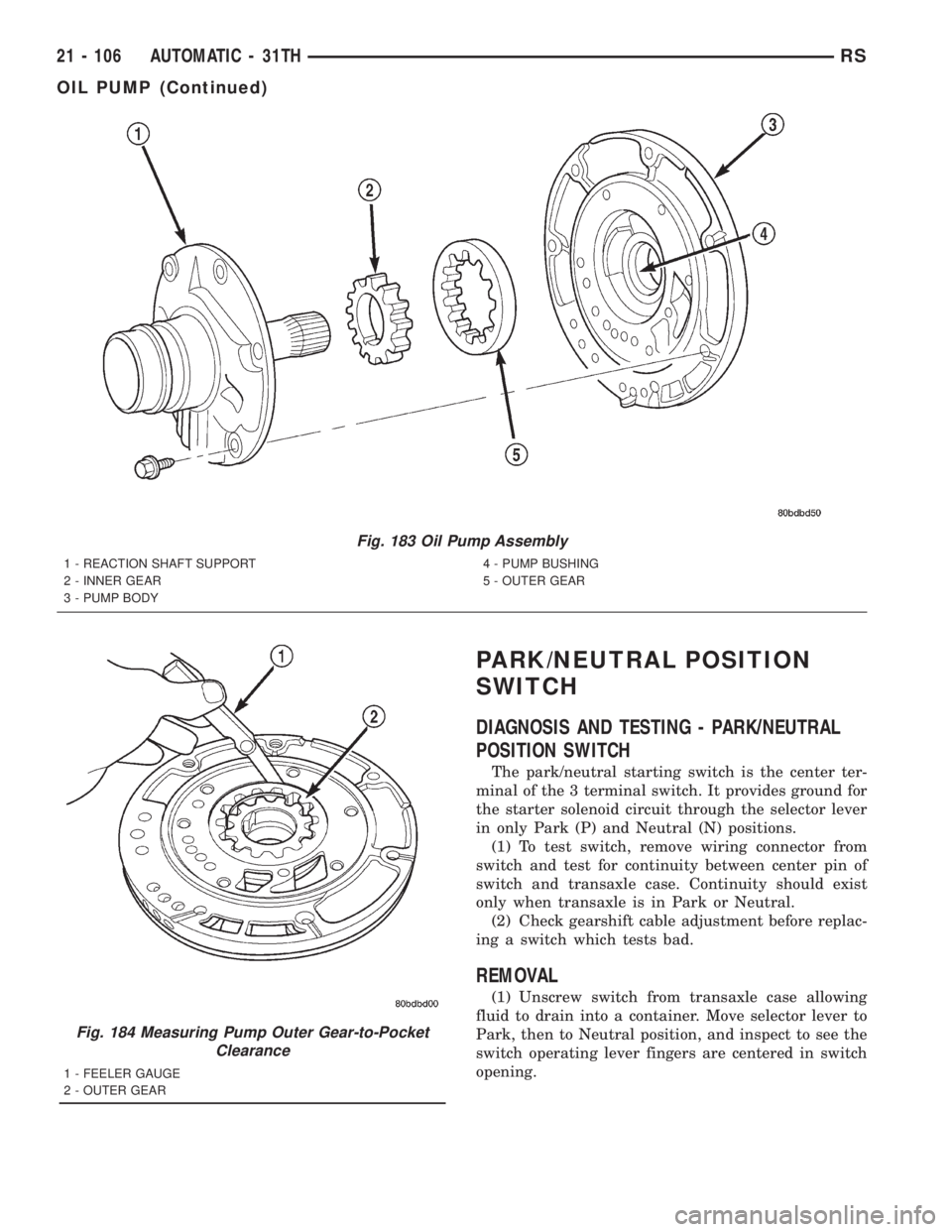

Fig. 183 Oil Pump Assembly

1 - REACTION SHAFT SUPPORT

2 - INNER GEAR

3 - PUMP BODY4 - PUMP BUSHING

5 - OUTER GEAR

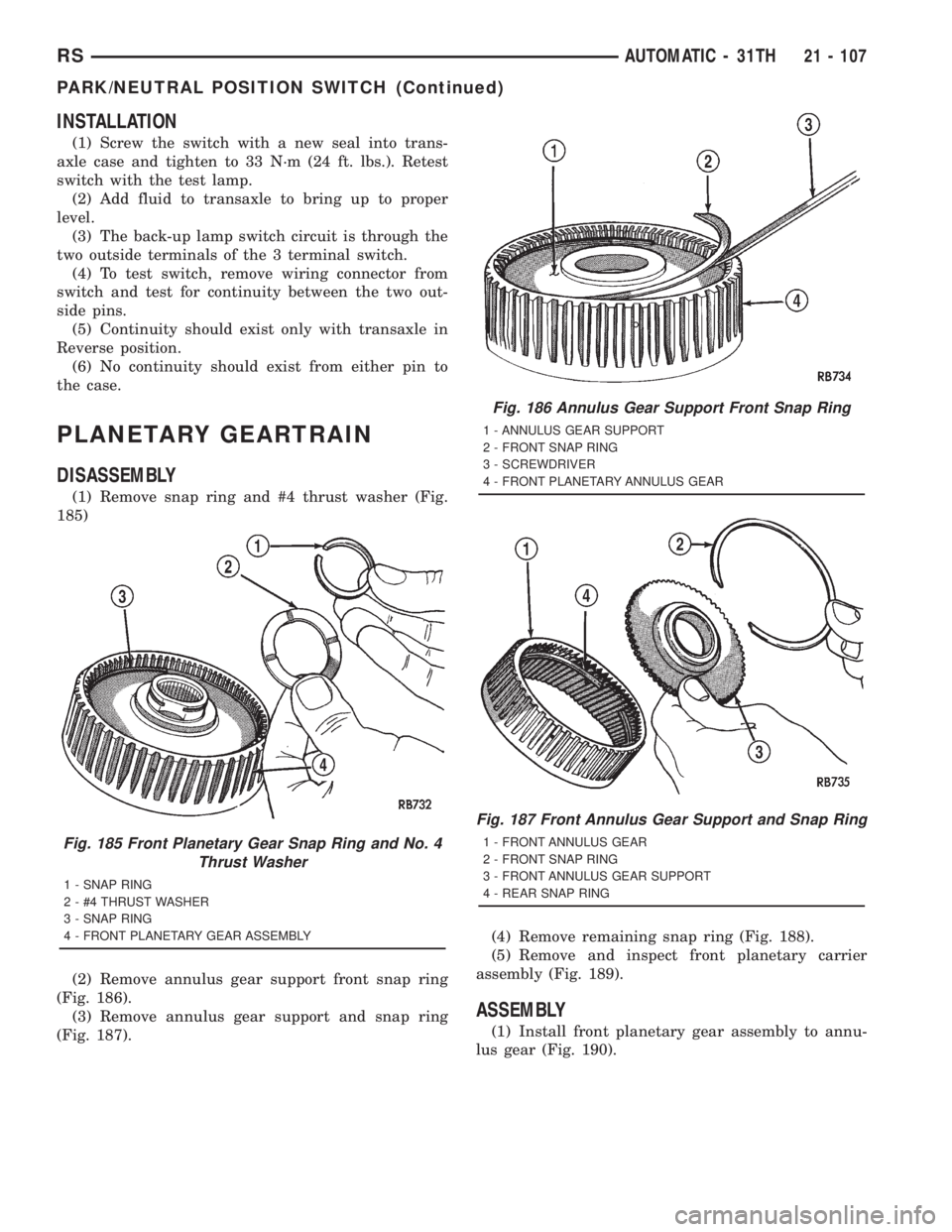

Fig. 184 Measuring Pump Outer Gear-to-Pocket

Clearance

1 - FEELER GAUGE

2 - OUTER GEAR

21 - 106 AUTOMATIC - 31THRS

OIL PUMP (Continued)

Page 3071 of 4284

INSTALLATION

(1) Screw the switch with a new seal into trans-

axle case and tighten to 33 N´m (24 ft. lbs.). Retest

switch with the test lamp.

(2) Add fluid to transaxle to bring up to proper

level.

(3) The back-up lamp switch circuit is through the

two outside terminals of the 3 terminal switch.

(4) To test switch, remove wiring connector from

switch and test for continuity between the two out-

side pins.

(5) Continuity should exist only with transaxle in

Reverse position.

(6) No continuity should exist from either pin to

the case.

PLANETARY GEARTRAIN

DISASSEMBLY

(1) Remove snap ring and #4 thrust washer (Fig.

185)

(2) Remove annulus gear support front snap ring

(Fig. 186).

(3) Remove annulus gear support and snap ring

(Fig. 187).(4) Remove remaining snap ring (Fig. 188).

(5) Remove and inspect front planetary carrier

assembly (Fig. 189).

ASSEMBLY

(1) Install front planetary gear assembly to annu-

lus gear (Fig. 190).

Fig. 185 Front Planetary Gear Snap Ring and No. 4

Thrust Washer

1 - SNAP RING

2 - #4 THRUST WASHER

3 - SNAP RING

4 - FRONT PLANETARY GEAR ASSEMBLY

Fig. 186 Annulus Gear Support Front Snap Ring

1 - ANNULUS GEAR SUPPORT

2 - FRONT SNAP RING

3 - SCREWDRIVER

4 - FRONT PLANETARY ANNULUS GEAR

Fig. 187 Front Annulus Gear Support and Snap Ring

1 - FRONT ANNULUS GEAR

2 - FRONT SNAP RING

3 - FRONT ANNULUS GEAR SUPPORT

4 - REAR SNAP RING

RSAUTOMATIC - 31TH21 - 107

PARK/NEUTRAL POSITION SWITCH (Continued)

Page 3081 of 4284

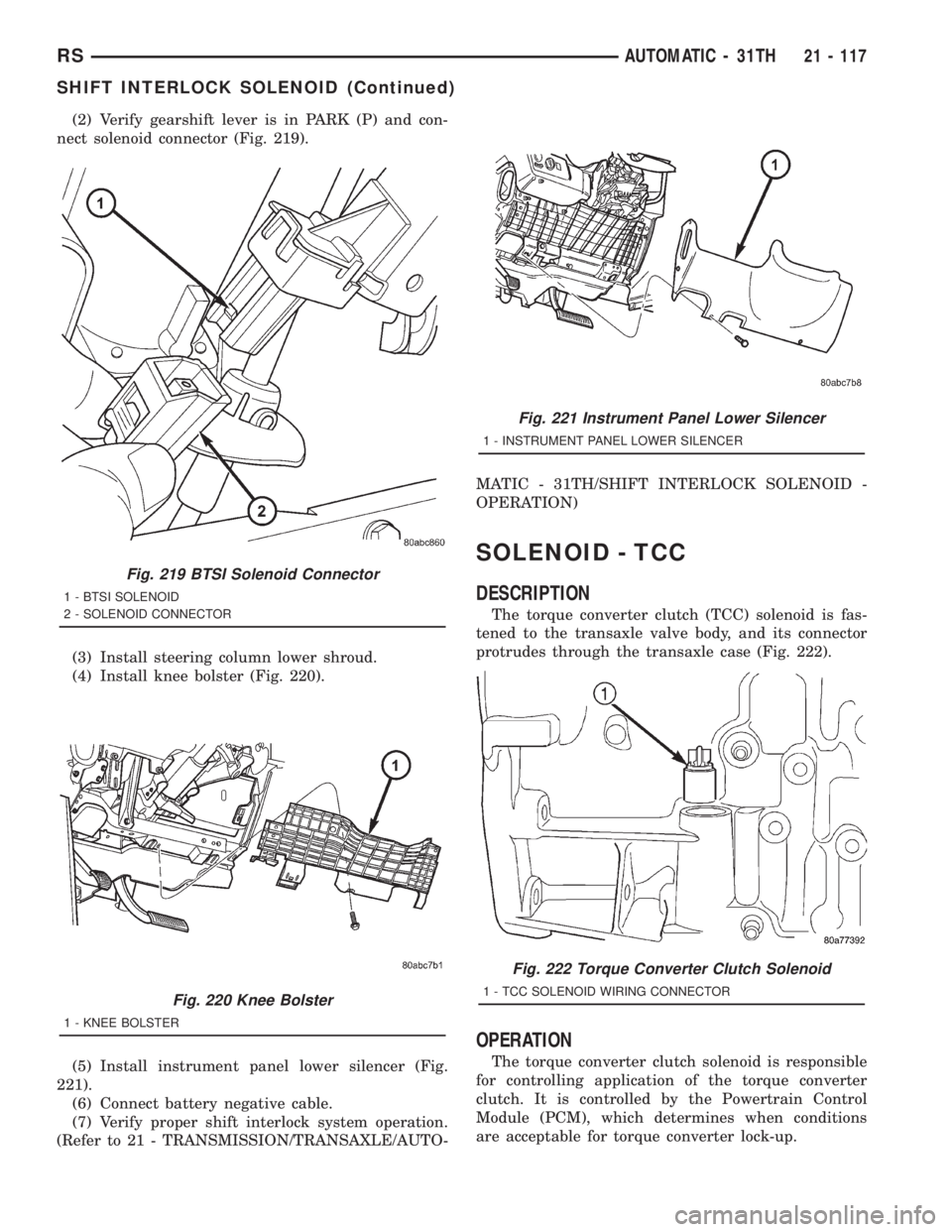

(2) Verify gearshift lever is in PARK (P) and con-

nect solenoid connector (Fig. 219).

(3) Install steering column lower shroud.

(4) Install knee bolster (Fig. 220).

(5) Install instrument panel lower silencer (Fig.

221).

(6) Connect battery negative cable.

(7) Verify proper shift interlock system operation.

(Refer to 21 - TRANSMISSION/TRANSAXLE/AUTO-MATIC - 31TH/SHIFT INTERLOCK SOLENOID -

OPERATION)

SOLENOID - TCC

DESCRIPTION

The torque converter clutch (TCC) solenoid is fas-

tened to the transaxle valve body, and its connector

protrudes through the transaxle case (Fig. 222).

OPERATION

The torque converter clutch solenoid is responsible

for controlling application of the torque converter

clutch. It is controlled by the Powertrain Control

Module (PCM), which determines when conditions

are acceptable for torque converter lock-up.

Fig. 219 BTSI Solenoid Connector

1 - BTSI SOLENOID

2 - SOLENOID CONNECTOR

Fig. 220 Knee Bolster

1 - KNEE BOLSTER

Fig. 221 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 222 Torque Converter Clutch Solenoid

1 - TCC SOLENOID WIRING CONNECTOR

RSAUTOMATIC - 31TH21 - 117

SHIFT INTERLOCK SOLENOID (Continued)

Page 3303 of 4284

(21) Install battery thermal shield and clutch cable

eyelet (LHD only) (Fig. 99). Verify proper clutch cable

routing (LHD models). Cable should be routed over

guide, through eyelet, and around coolant bottle and

wiring harness.

(22) Connect battery cables.

(23) Check transaxle fluid and engine coolant lev-

els. Adjust if necessary. (Refer to 21 - TRANSMIS-

SION/TRANSAXLE/MANUAL/FLUID - STANDARD

PROCEDURE)

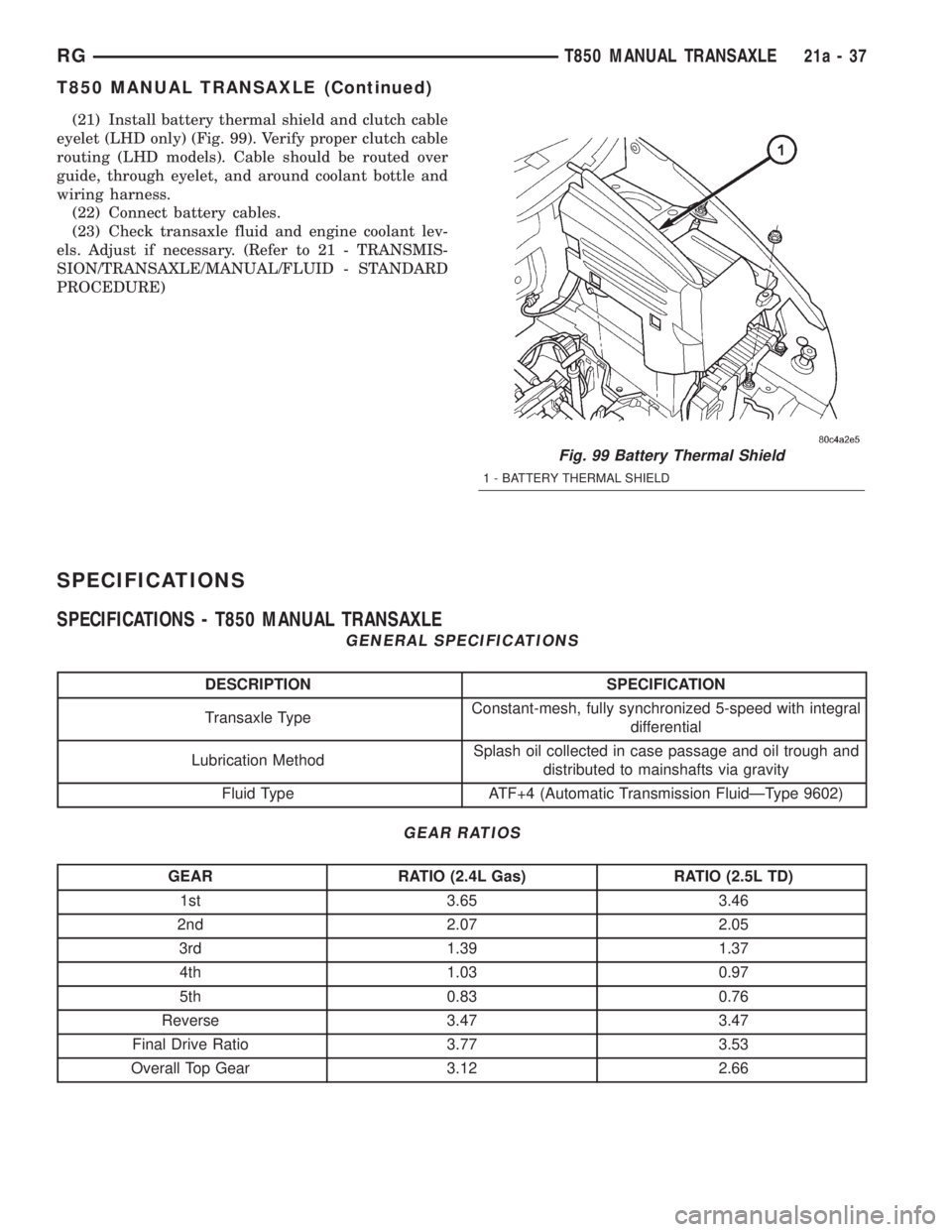

SPECIFICATIONS

SPECIFICATIONS - T850 MANUAL TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeConstant-mesh, fully synchronized 5-speed with integral

differential

Lubrication MethodSplash oil collected in case passage and oil trough and

distributed to mainshafts via gravity

Fluid Type ATF+4 (Automatic Transmission FluidÐType 9602)

GEAR RATIOS

GEAR RATIO (2.4L Gas) RATIO (2.5L TD)

1st 3.65 3.46

2nd 2.07 2.05

3rd 1.39 1.37

4th 1.03 0.97

5th 0.83 0.76

Reverse 3.47 3.47

Final Drive Ratio 3.77 3.53

Overall Top Gear 3.12 2.66

Fig. 99 Battery Thermal Shield

1 - BATTERY THERMAL SHIELD

RGT850 MANUAL TRANSAXLE21a-37

T850 MANUAL TRANSAXLE (Continued)

Page 3382 of 4284

Before removing the glass, check the availability of

replacement components.

SEATS

Seat modules are made up of a seat frame, seat

cushion, seat back cushion, a covering material, and

the electrical components used for power operation, if

equipped. Some seat systems also contain seat belt

components and supplemental restraint systems.

Seat assemblies transport the occupants in comfort

and safety. Seat assemblies also help position occu-

pants correctly in the event of airbag deployment.

Seat cushions, coverings, and electrical components

are serviceable. Refer to the appropriate group in

this manual.

EXTERIOR COMPONENTS

Exterior sheet metal components make up the

exterior of the vehicle. Some exterior metal systems

are welded assemblies, such as doors and hoods.

Some exterior trim items are made of composite.

The exterior is finished in various metal stampings

and composite moldings. These assemblies give the

vehicle a finished appearance and protect the occu-

pants from the elements. Some components are part

of the energy absorbing system used to protect the

occupants in collisions. The exterior sheet metal is

repairable and adjustable for fit and finish. Welded

and bonded component systems are adjustable as a

system. Trim components made of composite are

stamped with the type of material used.

DaimlerChrysler uses various fasteners to retain

trim items. At times, it is not possible to remove trim

items without damaging the fastener. If it is not pos-

sible to remove an item without damaging a compo-

nent, cut or break the fasteners and use new ones

when installing the component.

SAFETY PRECAUTIONS AND WARNINGS

WARNING:

EYE PROTECTION SHOULD BE USED WHEN SER-

VICING GLASS COMPONENTS. PERSONAL INJURY

CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH PETRO-

LEUM OR ALCOHOL BASED CLEANING SOLVENTS.

PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE THAT

IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION:

When holes must be drilled or punched in an innerbody panel, verify depth of space to the outer body

panel, electrical wiring, or other components. Dam-

age to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use when

welding.

Disconnect the negative battery cable clamp when

servicing electrical components that are live when

the ignition is OFF. Damage to electrical system can

result.

Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning solvents

on painted or upholstered surfaces. Damage to fin-

ish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

DIAGNOSIS AND TESTING - WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

23 - 2 BODYRS

BODY (Continued)

Page 3384 of 4284

moldings. After each length is applied, drive the vehi-

cle. If noise goes away after a piece of tape is applied,

remove tape, locate, and repair defect.

POSSIBLE CAUSE OF WIND NOISE

²Moldings standing away from body surface can

catch wind and whistle.

²Gaps in sealed areas behind overhanging body

flanges can cause wind-rushing sounds.

²Misaligned movable components.

²Missing or improperly installed plugs in pillars.

²Weld burn through holes.

STANDARD PROCEDURE - PLASTIC BODY

PANEL REPAIR

Resin Transfer Molded (RTM) body panels are rein-

forced with a continuous fiberglass mesh. Epoxy

resin is injected into a gel-coated and fiberglass lined

mold to form a body panel. Sheet molded compound

(SMC) body panels are constructed with fiberglass

strands usually 1 inch or shorter, epoxy resin formed

into sheet stock and pressed in mold flowing material

to form a sheet molded compound (SMC) body panel.

RTM and SMC body panels can be repaired with

epoxy adhesive after market products. Refer to

instructions provided by the manufacturer of prod-

ucts being used to repair RTM or SMC.

DaimlerChrysler Corporation recommends that a

trained automotive body technician perform body

panel repair procedures (Fig. 1).

SAFETY PRECAUTION AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING RTM AND SMC COMPONENTS.

PERSONAL INJURE CAN RESULT.USE AN OSHA

APPROVED BREATHING DEVICE WHEN MIXING

EPOXY, GRINDING RTM AND SMC, AND SPRAYING

PAINT OR SOLVENTS IN A CONFINED AREA. PER-

SONAL INJURY CAN RESULT.AVOID PROLONGEDSKIN CONTACT WITH EPOXY RESIN, PETROLEUM,

OR ALCOHOL BASED SOLVENTS. PERSONAL

INJURY CAN RESULT.DO NOT VENTURE UNDER A

HOISTED VEHICLE THAT IS NOT PROPERLY SUP-

PORTED ON SAFETY STANDS. PERSONAL INJURY

CAN RESULT.

²When holes must be drilled or cut in body pan-

els, verify locations of internal body components and

electrical wiring. Damage to vehicle can result.

²Do not use abrasive chemicals or compounds on

undamaged painted surfaces around repair areas.

Damage to finish can result.

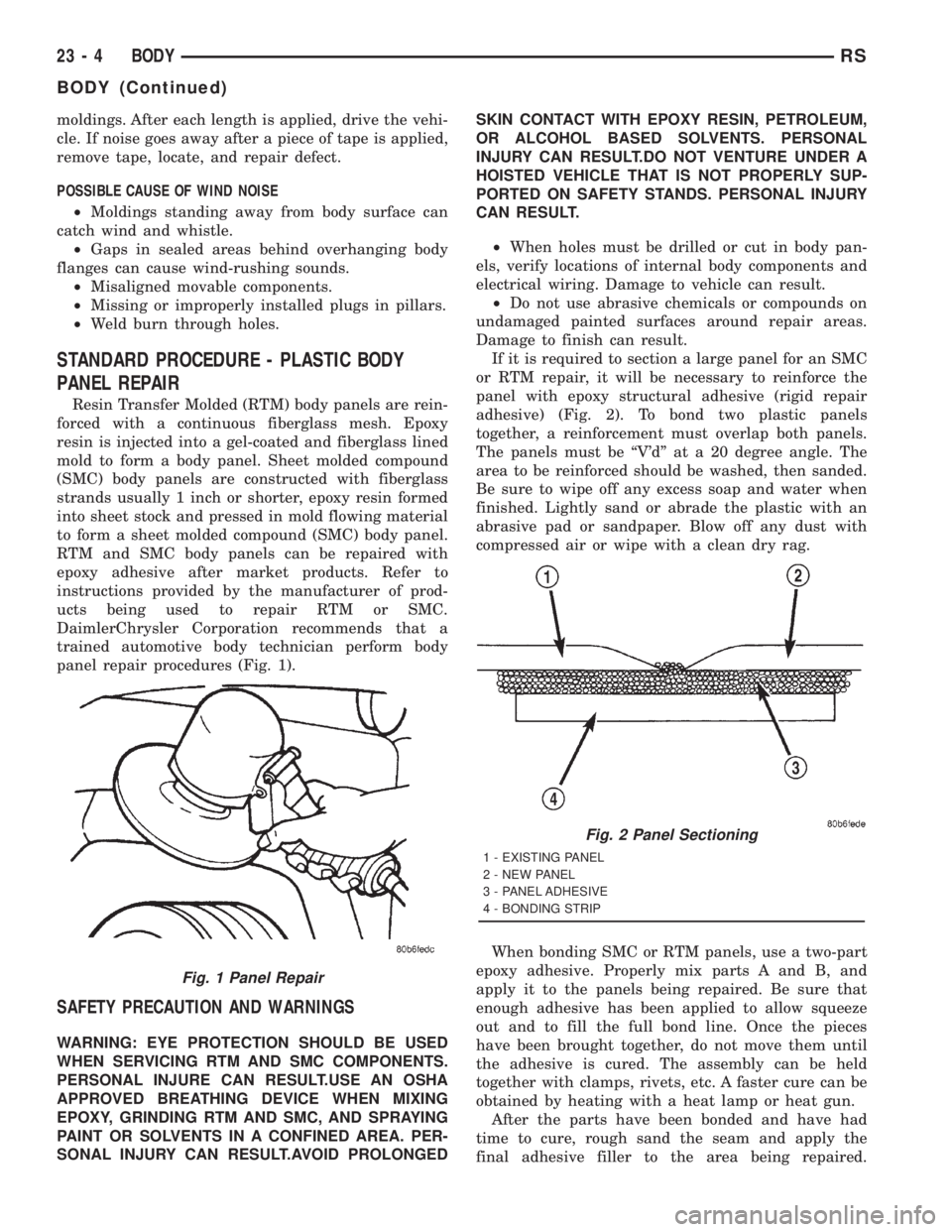

If it is required to section a large panel for an SMC

or RTM repair, it will be necessary to reinforce the

panel with epoxy structural adhesive (rigid repair

adhesive) (Fig. 2). To bond two plastic panels

together, a reinforcement must overlap both panels.

The panels must be ªV'dº at a 20 degree angle. The

area to be reinforced should be washed, then sanded.

Be sure to wipe off any excess soap and water when

finished. Lightly sand or abrade the plastic with an

abrasive pad or sandpaper. Blow off any dust with

compressed air or wipe with a clean dry rag.

When bonding SMC or RTM panels, use a two-part

epoxy adhesive. Properly mix parts A and B, and

apply it to the panels being repaired. Be sure that

enough adhesive has been applied to allow squeeze

out and to fill the full bond line. Once the pieces

have been brought together, do not move them until

the adhesive is cured. The assembly can be held

together with clamps, rivets, etc. A faster cure can be

obtained by heating with a heat lamp or heat gun.

After the parts have been bonded and have had

time to cure, rough sand the seam and apply the

final adhesive filler to the area being repaired.

Fig. 1 Panel Repair

Fig. 2 Panel Sectioning

1 - EXISTING PANEL

2 - NEW PANEL

3 - PANEL ADHESIVE

4 - BONDING STRIP

23 - 4 BODYRS

BODY (Continued)