sensor CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3918 of 4284

Symptom:

P0401 - EGR SYSTEM FAILURE

When Monitored and Set Condition:

P0401 - EGR SYSTEM FAILURE

When Monitored: With the ignition on and the battery voltage greater than 10.4 volts.

Set Condition: Conditions are met, the EGR is turned off and on momentarily. The

oxygen sensor signal is monitor for changes in its output signal during this test. If no

significant change or too much change is seen, a flag is set.

POSSIBLE CAUSES

INTERMITTENT CONDITION

EGR SOLENOID VACUUM SUPPLY

EGR VALVE OPERATION (CLOSED)

EGR VALVE OPERATION (OPEN)

FUSED IGNITION SWITCH OUTPUT CIRCUIT OPEN

EGR SOLENOID CONTROL CKT SHORTED TO VOLTAGE

EGR SOLENOID CONTROL CKT OPEN

EGR SOLENOID (CLOSED)

EGR SOLENOID CONTROL CKT SHORT TO GND

EGR SOLENOID (OPEN)

PCM

PCM (CLOSED)

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 12

2 Start the engine.

Allow the engine to reach operating temperature.

Does the engine run rough or stall at idle?All

Ye s®Go To 3

No®Go To 6

124

DRIVEABILITY - GAS

Page 3925 of 4284

Symptom:

P0420-1/1 CATALYTIC CONVERTER EFFICIENCY

When Monitored and Set Condition:

P0420-1/1 CATALYTIC CONVERTER EFFICIENCY

When Monitored: After engine warm up to 70ÉC (158ÉF), 180 seconds of open throttle

operation, at a speed greater than 18 mph and less than 55 mph, with the engine at

1200-1700 rpm and MAP vacuum between 15.0 and 21.0 inches of mercury (Hg).

Set Condition: As catalyst efficiency deteriorates, the switch rate of the downstream O2

sensor approaches that of the upstream O2 sensor. If at any point during the test the

switch ratio reaches a predetermined value a counter is incremented by one.

POSSIBLE CAUSES

INTERMITTENT CONDITION

VISUALLY INSPECT CATALYTIC CONVERTER

EXHAUST LEAK

ENGINE MECHANICAL CONDITION

AGING O2 SENSOR

CATALYTIC CONVERTER

TEST ACTION APPLICABILITY

1NOTE: If a O2 Sensor DTC(s) set along with the Catalytic Converter

Efficiency DTC diagnose the O2 Sensor DTC(s) before continuing.

NOTE: Check for contaminates that may have damaged the O2 Sensor and

Catalytic Converter: contaminated fuel, unapproved silicone, oil and cool-

ant, repair necessary.

Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Inspect the Catalytic Converter for the following damage.

Damage Catalytic Converter, dent and holes.

Severe discoloration caused by overheating the Catalytic Converter.

Catalytic Converter broke internally.

Leaking Catalytic Converter.

Were any problems found?All

Ye s®Replace the Catalytic Converter. Repair the condition that may

have caused the failure.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

131

DRIVEABILITY - GAS

Page 3926 of 4284

TEST ACTION APPLICABILITY

3 Start the engine.

Inspect the exhaust for leak between the engine and the O2 sensor.

Inspect the exhaust for leaks between the engine and the appropriate rear O2 Sensor.

Are there any exhaust leaks?All

Ye s®Repair or replace the leaking exhaust parts as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Check the exhaust for excessive smoke caused by an internal problem in the engine.

Is a engine mechanical condition present?All

Ye s®Repair the engine mechanical condition as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 5

5 A new rear O2 Sensor along with an aging front O2 Sensor may cause the DTC to set.

Review the vehicles repair history.

Has the rear O2 Sensor been replace without replacing the front O2 Sensor?All

Ye s®Replace the O2 Sensor as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 6

6 If there are no possible cause remaining, view repair. All

Repair

replace the Catalytic Converter.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

7WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: Check for contaminates that may have damaged the O2 Sensor and

Catalytic Converter: contaminated fuel, unapproved silicone, oil and cool-

ant, repair necessary.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

A new rear O2 Sensor along with a aging front O2 Sensor may cause the DTC to set.

Review repair history of the vehicle and repair as necessary.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

132

DRIVEABILITY - GAS

P0420-1/1 CATALYTIC CONVERTER EFFICIENCY ÐContinued

Page 3936 of 4284

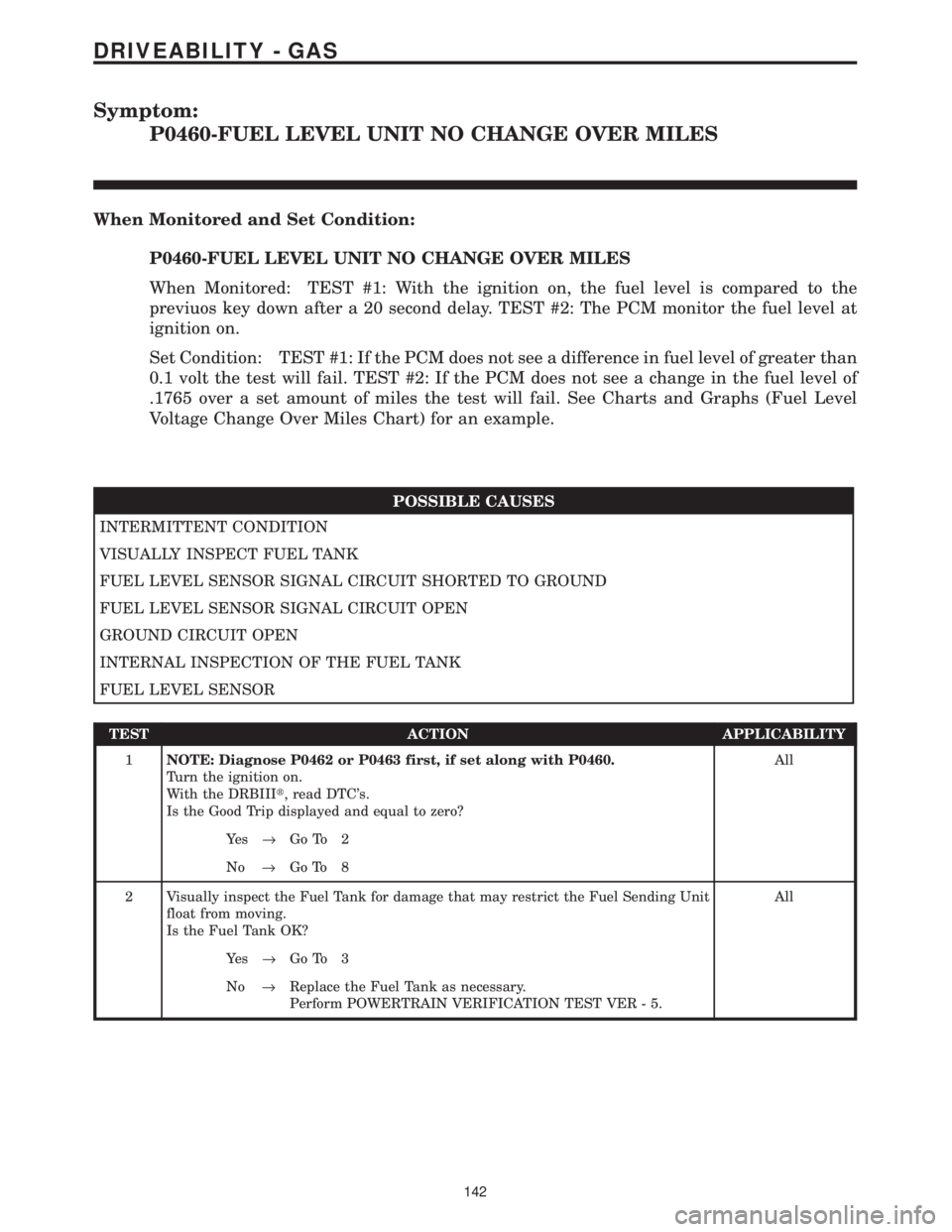

Symptom:

P0460-FUEL LEVEL UNIT NO CHANGE OVER MILES

When Monitored and Set Condition:

P0460-FUEL LEVEL UNIT NO CHANGE OVER MILES

When Monitored: TEST #1: With the ignition on, the fuel level is compared to the

previuos key down after a 20 second delay. TEST #2: The PCM monitor the fuel level at

ignition on.

Set Condition: TEST #1: If the PCM does not see a difference in fuel level of greater than

0.1 volt the test will fail. TEST #2: If the PCM does not see a change in the fuel level of

.1765 over a set amount of miles the test will fail. See Charts and Graphs (Fuel Level

Voltage Change Over Miles Chart) for an example.

POSSIBLE CAUSES

INTERMITTENT CONDITION

VISUALLY INSPECT FUEL TANK

FUEL LEVEL SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

FUEL LEVEL SENSOR SIGNAL CIRCUIT OPEN

GROUND CIRCUIT OPEN

INTERNAL INSPECTION OF THE FUEL TANK

FUEL LEVEL SENSOR

TEST ACTION APPLICABILITY

1NOTE: Diagnose P0462 or P0463 first, if set along with P0460.

Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 8

2 Visually inspect the Fuel Tank for damage that may restrict the Fuel Sending Unit

float from moving.

Is the Fuel Tank OK?All

Ye s®Go To 3

No®Replace the Fuel Tank as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

142

DRIVEABILITY - GAS

Page 3937 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Measure the resistance of the Fuel Level Sensor Signal circuit in the Fuel Pump

Module harness connector to ground.

Is the resistance below 100 ohms?All

Ye s®Repair the Fuel Level Sensor Signal circuit for a short to ground

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 4

4 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Disconnect the BCM harness connector.

Measure the resistance of the Fuel Level Sensor Signal circuit between the Fuel

Pump Module harness connector and the BCM harness connector.

Is the resistance below 5.0 ohms?All

Ye s®Go To 5

No®Repair the Fuel Level Sensor Signal circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

5 Turn the ignition off.

Disconnect the Fuel Pump Module harness connector.

Measure the resistance of the Ground circuit in the Fuel Pump Module harness

connector to ground.

Is the resistance below 5.0 ohms?All

Ye s®Go To 6

No®Repair the Ground circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

6WARNING: The fuel system is under a contant pressure even with the

engine off. Before opening the fuel system the fuel pressure must be release.

Relieve the fuel pressure in accordance with the servive information.

Remove the Fuel Tank in accordance with the Service Information.

Remove the Fuel Pump Module.

Visually inspect the inside of the Fuel Tank for any obstructions or deformities.

Inspect the Fuel Pump Module Float arm for damage.

Were any problem found?All

Ye s®Repair or replace as necessary.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 7

7 If there are no possible causes remaining, view repair. All

Repair

Replace the Fuel Level Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

143

DRIVEABILITY - GAS

P0460-FUEL LEVEL UNIT NO CHANGE OVER MILES ÐContinued

Page 3939 of 4284

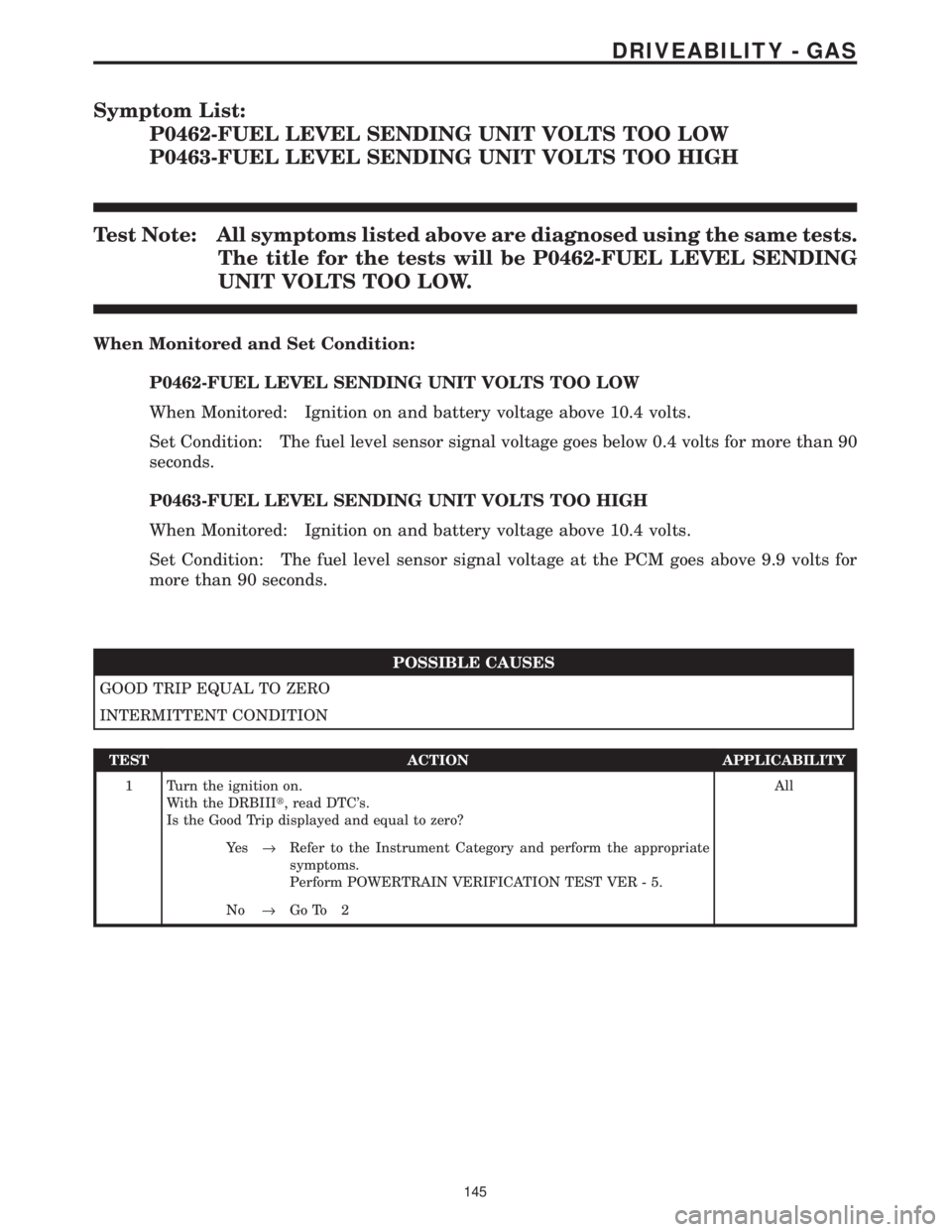

Symptom List:

P0462-FUEL LEVEL SENDING UNIT VOLTS TOO LOW

P0463-FUEL LEVEL SENDING UNIT VOLTS TOO HIGH

Test Note: All symptoms listed above are diagnosed using the same tests.

The title for the tests will be P0462-FUEL LEVEL SENDING

UNIT VOLTS TOO LOW.

When Monitored and Set Condition:

P0462-FUEL LEVEL SENDING UNIT VOLTS TOO LOW

When Monitored: Ignition on and battery voltage above 10.4 volts.

Set Condition: The fuel level sensor signal voltage goes below 0.4 volts for more than 90

seconds.

P0463-FUEL LEVEL SENDING UNIT VOLTS TOO HIGH

When Monitored: Ignition on and battery voltage above 10.4 volts.

Set Condition: The fuel level sensor signal voltage at the PCM goes above 9.9 volts for

more than 90 seconds.

POSSIBLE CAUSES

GOOD TRIP EQUAL TO ZERO

INTERMITTENT CONDITION

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Refer to the Instrument Category and perform the appropriate

symptoms.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 2

145

DRIVEABILITY - GAS

Page 3941 of 4284

Symptom:

P0500-NO VEHICLE SPEED SIGNAL (3SP AUTO AND MANUAL

TRANSMISSIONS)

When Monitored and Set Condition:

P0500-NO VEHICLE SPEED SIGNAL (3SP AUTO AND MANUAL TRANSMIS-

SIONS)

When Monitored: With the engine running, transmission not in park or neutral, brakes

not applied, and engine rpm greater than 1800.

Set Condition: This code will set if no vehicle speed signal is received from the Vehicle

Speed Sensor for more than 7.2 seconds for 2 consecutive trips.

POSSIBLE CAUSES

INTERMITTENT CONDITION

8 VOLT SUPPLY CIRCUIT OPEN

VEHICLE SPEED SENSOR SIGNAL CIRCUIT SHORTED TO GROUND

VEHICLE SPEED SENSOR SIGNAL CIRCUIT OPEN

PCM VSS SIGNAL

SENSOR GROUND CIRCUIT OPEN

VEHICLE SPEED SENSOR

TEST ACTION APPLICABILITY

1 Raise the drive wheels off the ground.

WARNING: BE SURE TO KEEP HANDS AND FEET CLEAR OF ROTATING

WHEELS.

Start the engine.

With the DRBIIIt, monitor the Vehicle Speed Sensor

Place the transmission in any forward gear.

Allow the wheels to rotate.

Does the DRBIIItdisplay vehicle speed above 0 MPH/KMH?All

Ye s®Go To 2

No®Go To 3

147

DRIVEABILITY - GAS

Page 3942 of 4284

TEST ACTION APPLICABILITY

2WARNING: WHEN THE ENGINE IS OPERATING, DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR HANDS NEAR THE

PULLEYS, BELTS OR FAN. DO NOT WEAR LOOSE CLOTHING.

NOTE: The conditions that set the DTC are not present at this time. The

following list may help in identifying the intermittent condition.

Remove and inspect the pinion gear, ensure the gear is free from damage.

With the engine running at normal operating temperature, monitor the DRB

parameters related to the DTC while wiggling the wiring harness. Look for param-

eter values to change and/or a DTC to set.

Review the DRB Freeze Frame information. If possible, try to duplicate the

conditions under which the DTC was set.

Refer to any Technical Service Bulletins (TSB) that may apply.

Visually inspect the related wiring harness. Look for any chafed, pierced, pinched, or

partially broken wires.

Visually inspect the related wiring harness connectors. Look for broken, bent, pushed

out, or corroded terminals.

Were any of the above conditions present?All

Ye s®Repair as necessary

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Test Complete.

3 Turn the ignition off.

Disconnect the Vehicle Speed Sensor harness connector.

Turn the ignition on.

Measure the voltage of the 8 Volt Supply circuit in the VSS harness connector.

Is the voltage above 7.0 volts?All

Ye s®Go To 4

No®Repair the 8 Volt Supply circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

4 Turn the ignition off.

Disconnect the Vehicle Speed Sensor harness connector.

Turn the ignition on.

Measure the voltage of the Vehicle Speed Sensor Signal circuit in the VSS harness

connector.

Is the voltage between 4.5 to 5.0 volts?All

Ye s®Go To 5

No®Go To 6

5 Turn the ignition off.

Disconnect the Vehicle Speed Sensor harness connector.

Measure the resistance of the Sensor ground circuit between the VSS harness

connector and ground.

Is the resistance below 5.0 ohms?All

Ye s®Remove and inspect the Pinion Gear. If OK, replace the Vehicle

Speed Sensor.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Repair the Sensor ground circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

148

DRIVEABILITY - GAS

P0500-NO VEHICLE SPEED SIGNAL (3SP AUTO AND MANUAL TRANS-

MISSIONS) Ð

Continued

Page 3943 of 4284

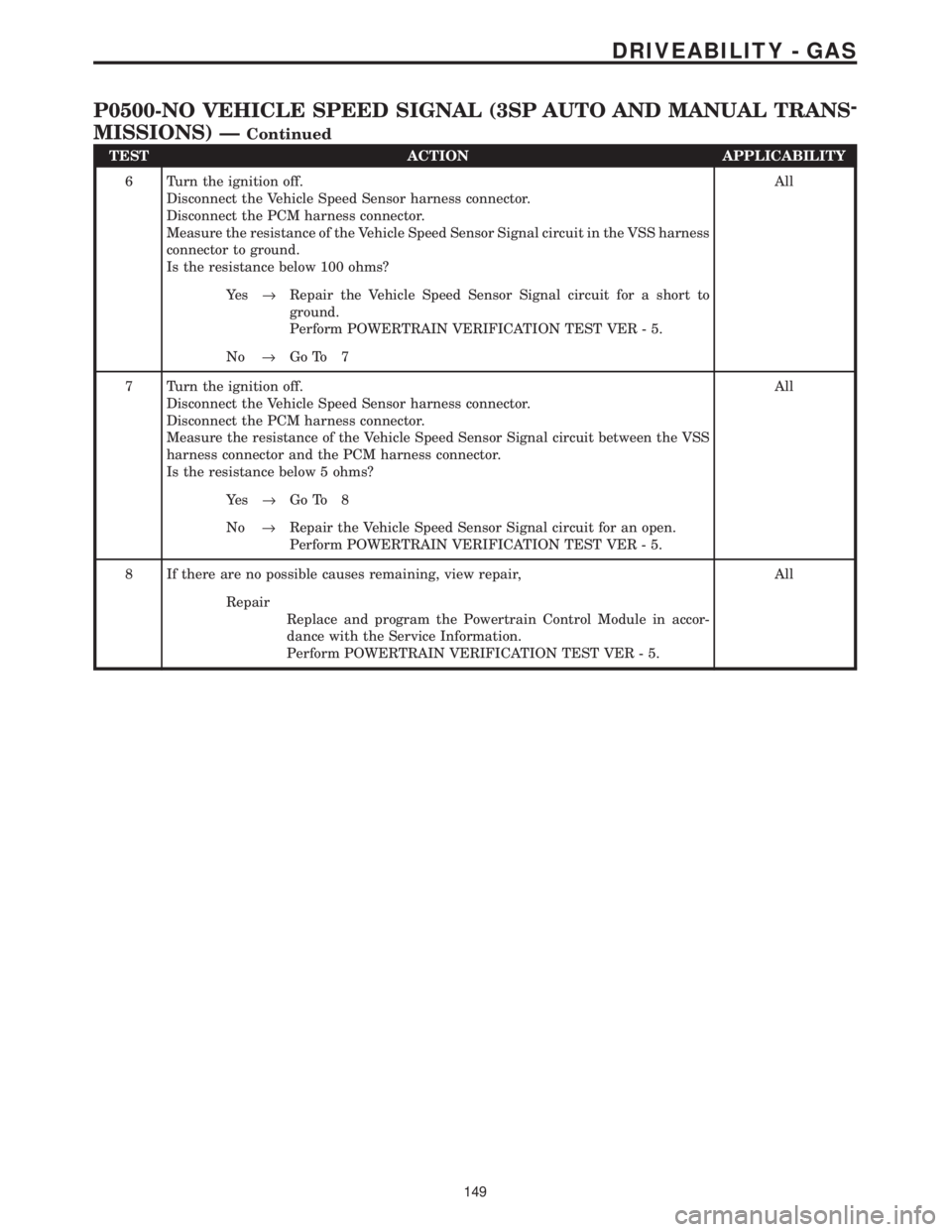

TEST ACTION APPLICABILITY

6 Turn the ignition off.

Disconnect the Vehicle Speed Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Vehicle Speed Sensor Signal circuit in the VSS harness

connector to ground.

Is the resistance below 100 ohms?All

Ye s®Repair the Vehicle Speed Sensor Signal circuit for a short to

ground.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 7

7 Turn the ignition off.

Disconnect the Vehicle Speed Sensor harness connector.

Disconnect the PCM harness connector.

Measure the resistance of the Vehicle Speed Sensor Signal circuit between the VSS

harness connector and the PCM harness connector.

Is the resistance below 5 ohms?All

Ye s®Go To 8

No®Repair the Vehicle Speed Sensor Signal circuit for an open.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

8 If there are no possible causes remaining, view repair, All

Repair

Replace and program the Powertrain Control Module in accor-

dance with the Service Information.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

149

DRIVEABILITY - GAS

P0500-NO VEHICLE SPEED SIGNAL (3SP AUTO AND MANUAL TRANS-

MISSIONS) Ð

Continued

Page 3944 of 4284

Symptom:

P0500-NO VEHICLE SPEED SIGNAL (4SP AUTO TRANS)

When Monitored and Set Condition:

P0500-NO VEHICLE SPEED SIGNAL (4SP AUTO TRANS)

When Monitored: With the engine running, transmission not in park or neutral, brakes

not applied, and engine rpm greater than 1800.

Set Condition: This code will set if no vehicle speed signal is received from the TCM

(transmission control module) for more than 7.2 seconds for 2 consecutive trips.

POSSIBLE CAUSES

INTERMITTENT CONDITION

VEHICLE SPEED SENSOR SIGNAL SHORTED VOLTAGE

VSS SIGNAL FROM TCM

VEHICLE SPEED SENSOR SIGNAL SHORTED TO GROUND

VEHICLE SPEED SENSOR SIGNAL OPEN

PCM VSS SIGNAL

TEST ACTION APPLICABILITY

1 Turn the ignition on.

With the DRBIIIt, read DTC's.

Is the Good Trip displayed and equal to zero?All

Ye s®Go To 2

No®Go To 7

2 Turn the ignition off.

Disconnect the TCM harness connector.

Turn the ignition on.

Measure the voltage of the VSS Signal circuit in the TCM harness connector.

Is the voltage above 6.0 volts?All

Ye s®Repair the Vehicle Speed Sensor Signal circuit for a short to

voltage.

Perform POWERTRAIN VERIFICATION TEST VER - 5.

No®Go To 3

150

DRIVEABILITY - GAS