ECO mode CHRYSLER VOYAGER 2001 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 2026 of 4284

AUTOMATIC DAY / NIGHT

MIRROR

DESCRIPTION

An automatic dimming inside day/night rear view

mirror and an automatic dimming driver side outside

rear view mirror are available factory-installed

options on this model. Following is a general descrip-

tion of this optional equipment.

The automatic day/night mirror is able to automat-

ically change its reflectance. A thin layer of electro-

chromic material between two pieces of conductive

glass make up the face of the mirror. Two photocell

sensors are used to monitor light levels and adjust

the reflectance of the mirror to reduce the glare of

headlamps approaching the vehicle from the rear.

For removal procedures, (Refer to 23 - BODY/IN-

TERIOR/REAR VIEW MIRROR - REMOVAL).

OPERATION

The ambient photocell sensor faces forward, to

detect the outside light levels. A second sensor facesrearward to detect the light level received through

the vehicles back window. When the difference

between the two light levels becomes too great (the

light level received at the rear of the mirror is much

higher than that at the front of the mirror), the mir-

ror begins to darken.

The mirror switch allows the driver a manual con-

trol of whether the automatic dimming feature is

operational. When AUTO is selected a small Light-

Emitting Diode (LED), to the right of the mirror

switch, is illuminated. The automatic dimming fea-

ture will only operate when the ignition switch is in

the On position. The mirror also senses the backup

lamp circuit, and will automatically disable its self-

dimming feature whenever the transmission gear

selector is in the Reverse position.

NOTE: The mirror always defaults to an ON state

upon ignition.

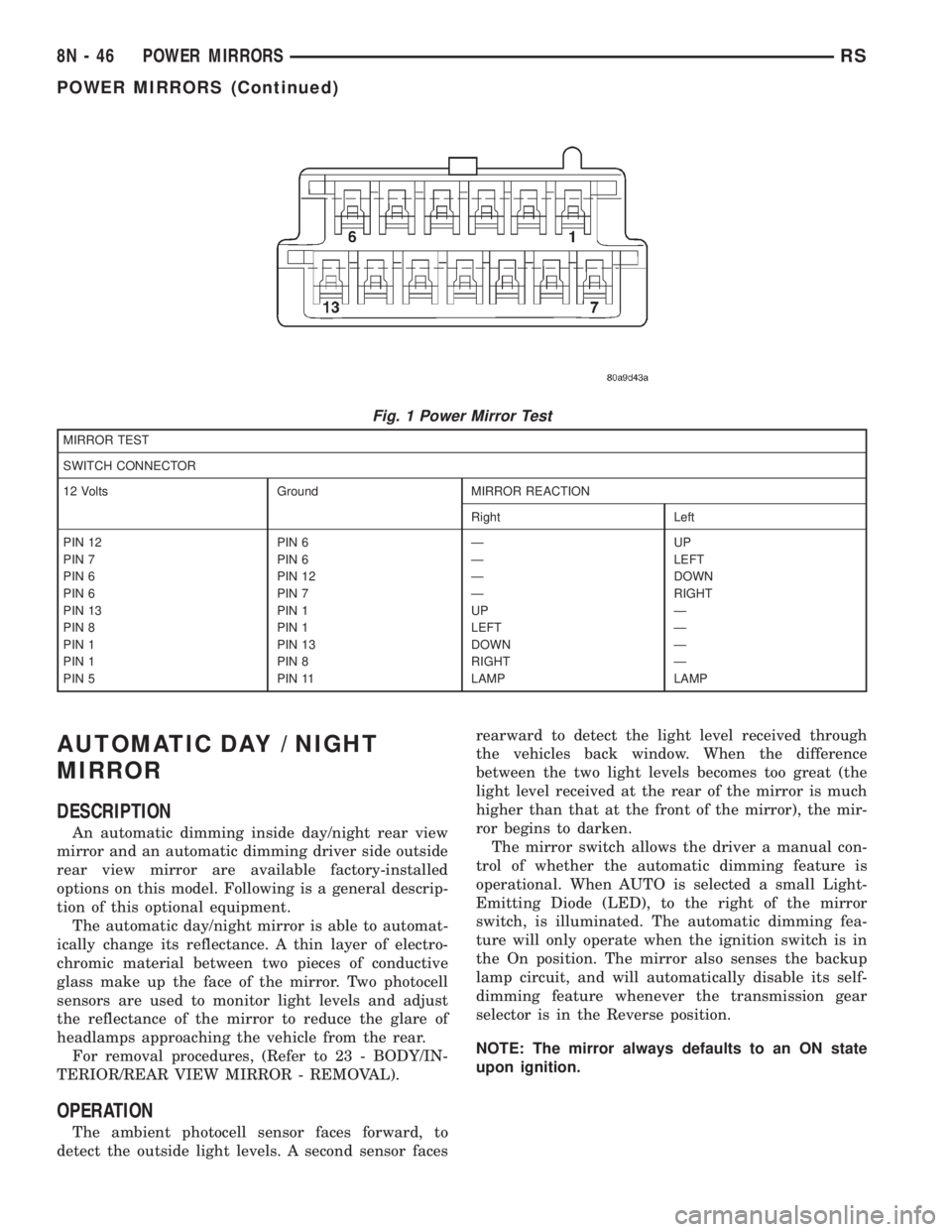

Fig. 1 Power Mirror Test

MIRROR TEST

SWITCH CONNECTOR

12 Volts Ground MIRROR REACTION

Right Left

PIN 12 PIN 6 Ð UP

PIN 7 PIN 6 Ð LEFT

PIN 6 PIN 12 Ð DOWN

PIN 6 PIN 7 Ð RIGHT

PIN 13 PIN 1 UP Ð

PIN 8 PIN 1 LEFT Ð

PIN 1 PIN 13 DOWN Ð

PIN 1 PIN 8 RIGHT Ð

PIN 5 PIN 11 LAMP LAMP

8N - 46 POWER MIRRORSRS

POWER MIRRORS (Continued)

Page 2030 of 4284

A eight-way power seat is standard on highline

models and optional on others. This option includes a

six-way adjustable seat cushion track and a two-way

power seat back.

The eight-way power seat is also available with the

heated seat and memory seat system that automati-

cally positions the power seat for two different driv-

ers. Refer toHeated Seat Systemfor more

information on the heated seat option. Refer toMem-

ory Systemin the Memory System section of this

group for more information on the memory system.

The power seat system includes the following com-

ponents:

²Power seat recliner

²Power seat switch

²Power seat track.

The power seat system with memory and heated

seat options includes the following components:

²Power seat recliner

²Power seat switch

²Power seat track.

²Memory Heated Seat Module (MHSM)

²Memory set switch

²Heated seat switch

²Electronic Vehicle Information Center (EVIC)

²Programmable Communications Interface (PCI)

data bus network

Refer to Wiring Diagrams for complete circuit dia-

grams. Following are general descriptions and opera-

tions for the major components in the power seat

system and memory seat system.

DESCRIPTION - MEMORY SEAT SYSTEM

An electronic memory and heated seat system is

available on some models. The memory system is

able to store and recall the driver side power seat

positions (including the power recliner position), and

both outside power mirror positions for two drivers.

For vehicles with a radio and heated / memory seat

system connected to the Programmable Communica-

tions Interface (PCI) data bus network, the memory

system is also able to store and recall radio station

presets for two drivers. The memory system also will

store and recall the last station listened to for each

driver, even if it is not one of the preset stations.

The memory system will automatically return to

all of these settings when the corresponding num-

bered and button of the memory switch on the driver

side seat side shield is depressed, or when the doors

are unlocked using the Remote Keyless Entry (RKE)

transmitter. A customer programmable feature of the

memory system allows the RKE recall of memory fea-

tures to be disabled in cases where there are more

than two drivers of the vehicle.

A Memory Heated Seat Module (MHSM) is used on

some models to control and integrate the many elec-tronic functions and features included in the memory

/ heated seat system.

The memory system includes the following compo-

nents:

²Heated seat switch

²Memory heated seat module (MHSM)

²Memory switch

²Position potentiometers on both outside power

mirrors

²Position potentiometers on the driver side power

seat track and power seat recliner motors.

²Radio receiver (if PCI data bus capable).

Certain functions and features of the memory system

rely upon resources shared with other electronic mod-

ules in the vehicle over the Programmable Communica-

tions Interface (PCI) J1850 data bus network. The PCI

data bus network allows the sharing of sensor informa-

tion. This helps to reduce wire harness complexity,

internal controller hardware, and component sensor cur-

rent loads. At the same time, this system provides

increased reliability, enhanced diagnostics, and allows

the addition of many new feature capabilities. For diag-

nosis of these electronic modules or of the PCI data bus

network, the use of a DRBtscan tool and the proper

Diagnostic Procedures manual are recommended.

The other electronic modules that may affect mem-

ory system operation are as follows:

²Body Control Module (BCM)- Refer toBody

Control Modulein Electronic Control Modules for

more information.

²

Electronic Vehicle Information Center (EVIC)

- Refer toElectronic Vehicle Information Center

in Overhead Console Systems for more information.

²Powertrain Control Module (PCM)- Refer to

Powertrain Control Modulein Electronic Control

Modules for more information.

²Radio Receiver- Refer toRadio Receiverin

Audio Systems for more information.

Refer toHeated Seat Systemfor more informa-

tion on the heated seat system. Refer toRemote

Keyless Entry Systemin Power Lock Systems for

more information on the RKE system. Refer to

Power Mirrorin Power Mirrors for more informa-

tion on the mirror position potentiometers. Refer to

Power Seat TrackandPower Seat Reclinerin

the Power Seat System section of this group for more

information on the driver side power seat position

potentiometers.

Refer toPower Seatin the Contents of Wiring

Diagrams for complete circuit diagrams. Following

are general descriptions of the remaining major com-

ponents in the factory-installed memory system.

OPERATION - POWER SEAT SYSTEM

The power seat system allows the driver and/or

front passenger seating positions to be adjusted elec-

8N - 50 POWER SEATSRS

POWER SEATS (Continued)

Page 2032 of 4284

upon the second energizing is the amount the soft

stops have been reprogrammed.

Repeat this procedure for each direction of seat

movement (One at a time).

NOTE: Checking and resetting of the power mem-

ory seat soft stops will not affect the customer's

programmed positions.

DIAGNOSIS AND TESTING MEMORY SYSTEM

In order to obtain conclusive testing of the memory

system, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the memory system requires the use of a

DRB IIItscan tool and the proper Diagnostic Proce-

dures manual. The DRB IIItscan tool can provide

confirmation that the PCI data bus is functional, that

all of the electronic modules are sending and receiv-

ing the proper messages on the PCI data bus, and

that the memory system is receiving the proper hard

wired inputs and relaying the proper hard wired out-

puts to perform its functions.

Following are diagnostic routines that are built

into the module which can be performed without the

use of a diagnostic scan tool. Refer to Wiring Dia-

grams for complete circuit schematic or connector

pin-out information.

DIAGNOSTIC MODE 1

Diagnostic Mode 1 clears soft limits and sets mem-

ory selector switches (1 and 2) to predetermined val-

ues.

ACTIVATION-Press and hold the S and 1 buttons

for 5 seconds to enter diagnostic mode 1. This mode

is exited at the completion of the mode 1 tasks or

upon grounding the DATA G87 circuit input to the

module.

Mode 1 will:

²Clear all soft limits to their default hard limit

values

²Load memory 1 with default settings corre-

sponding to horizontal rearward, front down, rear

down, and recliner rearward positions

²Load memory 2 with default settings corre-

sponding to horizontal forward, front up, rear up,

and recliner forward positions

DIAGNOSTIC MODE 2

Diagnostic mode 2 provides a way to determine if

the seat/mirror motors and position sensors are con-

nected properly.

ACTIVATION-Press and hold the S and 2 buttons

for 5 seconds to enter diagnostic mode 2. This modeis exited after 5 seconds of switch inactivity or upon

grounding the DATA G87 circuit input by moving the

transmission out of the PARK position.

Mode 2 will:

²Place the seat and mirror motors at their mid-

point

²When a single axis of seat or mirror motion is

requested by pressing a switch, the corresponding

motor is energized. This tests switch input and motor

output

DRIVER SEAT SWITCH

DESCRIPTION

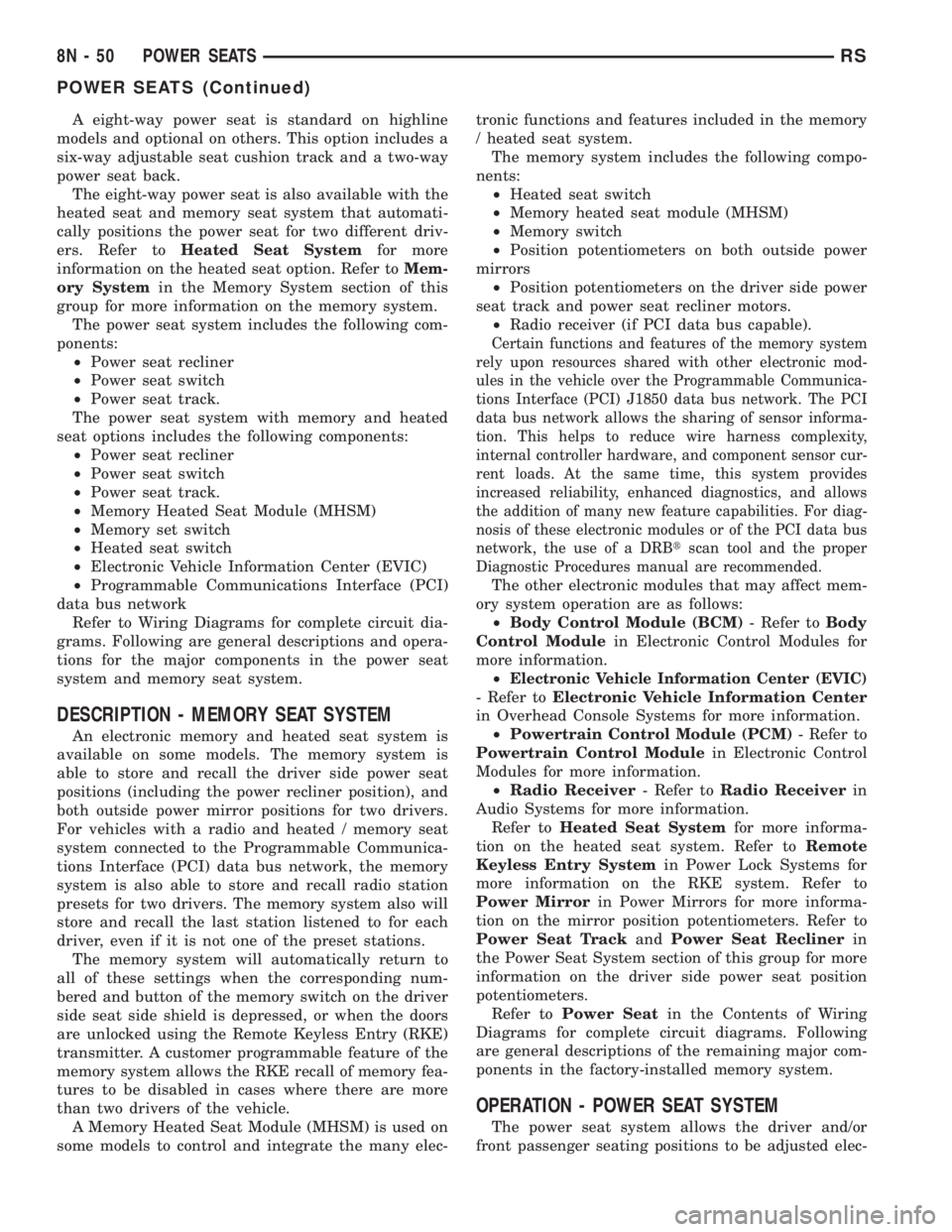

Vehicles equipped with power seats utilize a eight-

way power seat switch. This eight-way power seat

switch features two knobs ganged together on the

outboard seat cushion side shield (Fig. 2).

The switch is secured to the back of the seat cush-

ion side shield with two screws. However, the control

knobs for the seat switch unit must be removed

before the seat switch can be removed from the side

shield.

The power seat switch cannot be repaired. If one

switch is damaged or faulty, the entire power seat

switch unit must be replaced.

OPERATION

The power seat tracks can be adjusted in eight dif-

ferent ways using the power seat switches. See the

owner's manual in the vehicle glove box for more

information on the power seat switch functions and

the seat adjusting procedures.

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the power seat

track or recliner adjuster motor. The selected

adjuster motor operates to move the seat track or

recliner through its drive unit in the selected direc-

tion until the switch is released, or until the travel

Fig. 2 Power Seat Switch - Typical

8N - 52 POWER SEATSRS

POWER SEATS (Continued)

Page 2034 of 4284

(7) Remove the power seat switch from the out-

board seat cushion side shield.

INSTALLATION

(1) Position the power seat switch onto the out-

board seat cushion side shield.

(2) Install and tighten the screws that secure the

power seat switch to the inside of the outboard seat

cushion side shield. Tighten the screws to 1.5 N´m

(14 in. lbs.).

(3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.

(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.).

(6) Reconnect the battery negative cable.

MEMORY SET SWITCH

DESCRIPTION

Vehicles equipped with the memory system have a

memory switch mounted to the driver side front door

trim panel. This switch is used to set and recall all of

the memory system settings for up to two drivers.

The memory switch is a resistor multiplexed unit

that is hard wired to the Body Control Module

(BCM). The BCM sends out the memory system set

and recall requests to the other electronic modules

over the Programmable Communications Interface

(PCI) data bus.

The memory switch cannot be adjusted or repaired

and, if faulty or damaged, it must be replaced. For

complete circuit diagrams, refer toWiring Dia-

grams.

OPERATION

The memory switch has three momentary switch

buttons labeled Set, 1 and 2. The Driver 1 and Driver

2 buttons are back-lit with Light-Emitting Diodes

(LED) for visibility, and are also color-coded to coin-

cide with the color-coded Driver 1 and Driver 2

Remote Keyless Entry (RKE) transmitters. The

Driver 1 memory switch button and RKE transmitter

are black, and the Driver 2 memory switch button

and RKE transmitter are gray. The memory switch

Set button also has an LED that will illuminate and

flash to indicate that the memory system is in the set

mode. This LED will automatically be extinguished

when a set request has been successfully completed.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory switch.

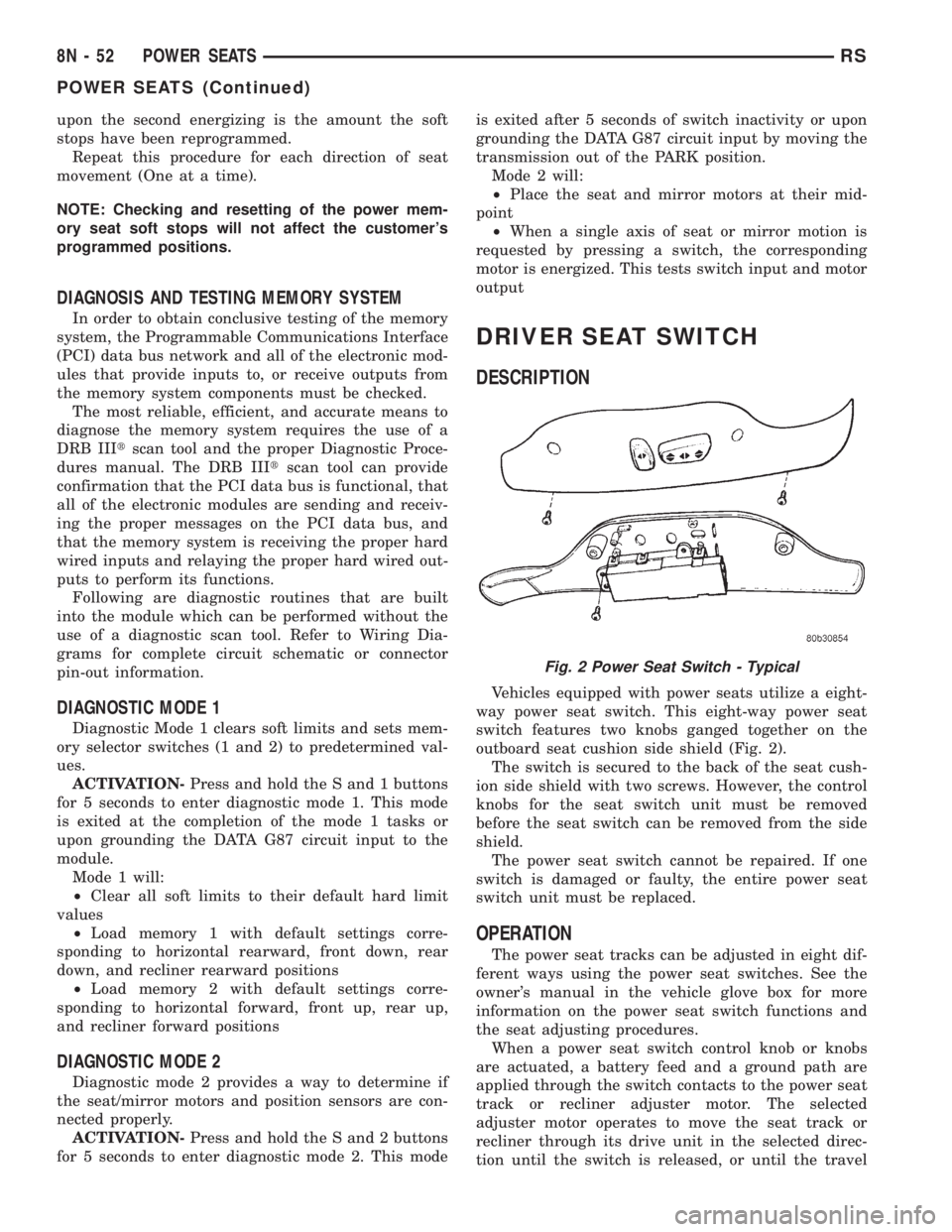

DIAGNOSIS AND TESTING - MEMORY SWITCH

For complete circuit diagrams, refer toWiring

Diagrams.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the driver side front door trim panel

switch bezel. Using a small thin bladed pry tool, gen-

tly pry the switch bezel away from the door trim

panel.

(3) Disconnect the memory switch wire harness

connector from the memory switch.

(4) Use an ohmmeter to test the resistances of the

memory switch in each switch position. See the Mem-

ory Switch Test chart. If OK, refer toMemory Sys-

temin the Diagnosis and Testing section of this

group. If not OK, replace the faulty memory switch.

MEMORY SWITCH TEST

MEMORY

SWITCH

POSITIONRESISTANCE

BETWEEN

PINSRESISTANCE

RANGE

(OHMS)

NEUTRAL 1&2 24560 1%

(24.56 k)

MEMORY 1 1&2 6830 1%

(6.83 k)

MEMORY 2 1&2 2090 1%

(2.09 k)

SET 1&2 4490 1%

(4.49 k)

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the front door trim panel switch bezel

from the driver side front door. Using a thin flat-

bladed pry tool, gently pry the switch bezel away

from the drivers door trim panel.

(3) Disconnect the memory switch wire harness

connector from the memory switch.

(4) Remove the two screws that secure the memory

switch to the back of the driver side front door trim

panel switch bezel.

(5) Remove the memory switch.

INSTALLATION

(1)Position the memory switch and install and

tighten the two screws that secure the memory switch

to the back of the driver side front door trim panel

switch bezel. Tighten the screws to 2.2 N´m (20 in. lbs.).

(2) Reconnect the memory switch wire harness

connector to the memory switch.

(3) Install the trim panel switch bezel onto the

driver side front door.

(4) Reconnect the battery negative cable.

8N - 54 POWER SEATSRS

DRIVER SEAT SWITCH (Continued)

Page 2036 of 4284

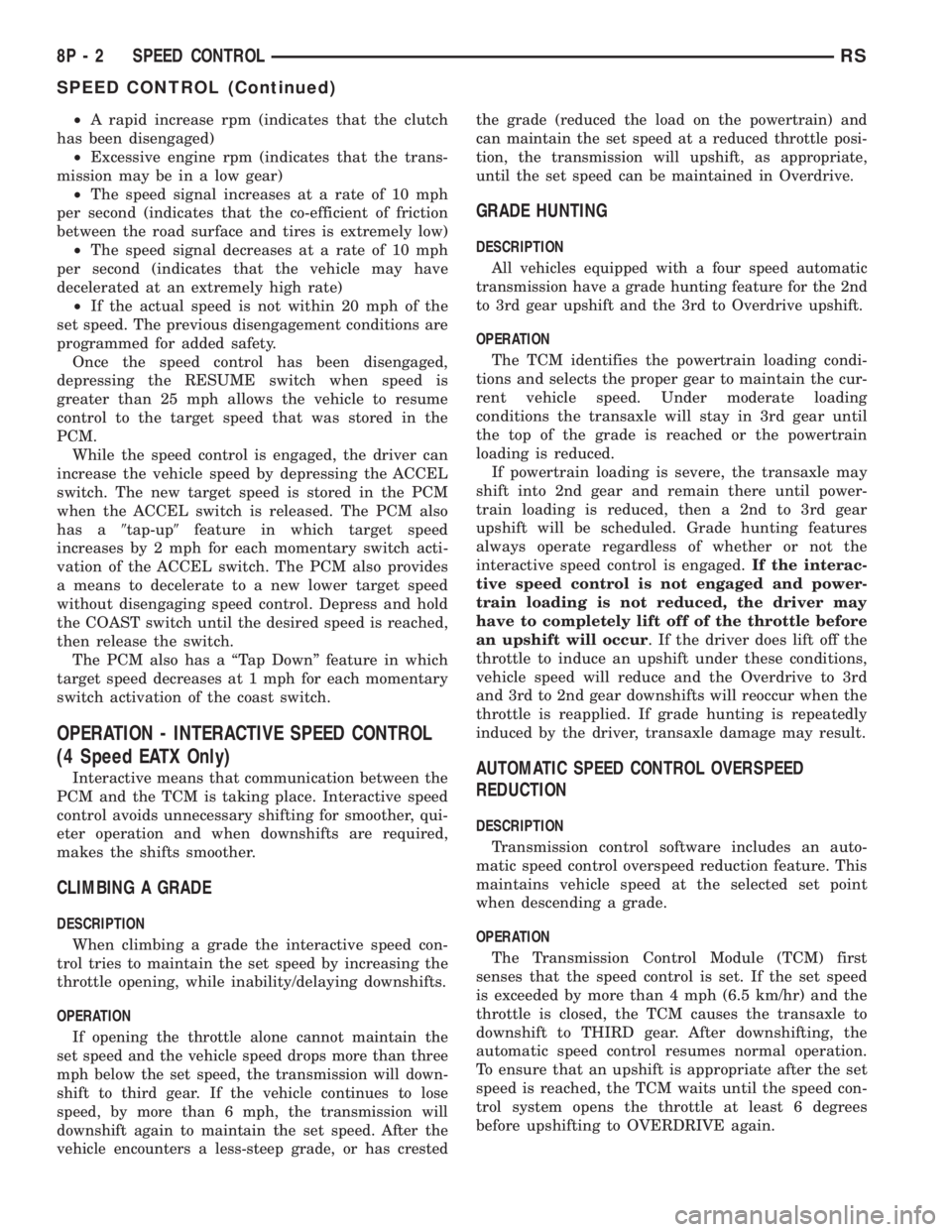

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) On models with the eight-way power seat sys-

tem only, using a push pin remover or another suit-

able wide flat-bladed tool, gently pry the power seat

and power recliner switch knobs off of the switch

stems (Fig. 7).

(3) Remove the screws that secure the outboard

seat cushion side shield to the seat cushion frame.

Refer to the Body section of the service manual for

the procedure.

(4) Pull the outboard seat cushion side shield away

from the seat cushion frame far enough to access the

power seat switch wire harness connector.

(5) Disconnect the power seat wire harness connec-

tor from the power seat switch connector receptacle.

(6) Remove the screws that secure the power seat

switch to the inside of the outboard seat cushion side

shield.(7) Remove the power seat switch from the out-

board seat cushion side shield.

INSTALLATION

(1) Position the power seat switch onto the out-

board seat cushion side shield.

(2) Install and tighten the screws that secure the

power seat switch to the inside of the outboard seat

cushion side shield. Tighten the screws to 1.5 N´m

(14 in. lbs.).

(3) Reconnect the power seat wire harness connec-

tor to the power seat switch connector receptacle.

(4) Position the outboard seat cushion side shield

onto the seat cushion frame

(5) Install and tighten the screws that secure the

outboard seat cushion side shield to the seat cushion

frame. Tighten the screws to 1.5 N´m (14 in. lbs.).

(6) Reconnect the battery negative cable.

RECLINER MOTOR

DESCRIPTION

The eight-way power seat option includes an elec-

trically operated seat back recliner mechanism. The

only visible evidence of this option is the separate

power seat recliner switch control knob that is

located on the outboard seat cushion side shield, just

behind the other power seat switch control knob.

The power seat recliner unit is mounted in the

place of a seat hinge on the outboard side of the seat

(Fig. 8). The upper hinge plate of the power seat

recliner mechanism is secured with screws to the

seat back frame and is concealed beneath the seat

back trim cover and padding. The lower hinge plate

and the motor and drive unit of the power seat

recliner mechanism is secured with screws to the

seat cushion frame, and is concealed by the outboard

seat cushion side shield.

The power seat recliner cannot be repaired. If the

unit is faulty or damaged, it must be replaced. Refer

toBucket Seat Reclinerin Body for the service

procedure.

OPERATION

The power seat recliner includes a reversible elec-

tric motor that is secured to the lower hinge plate of

the recliner unit. The motor is connected to a gearbox

that moves the upper hinge plate of the power seat

recliner through a screw-type drive unit. The driver

side power seat recliner motor used on models

equipped with the optional memory system also has

a position potentiometer integral to the motor assem-

bly, which electronically monitors the motor position.

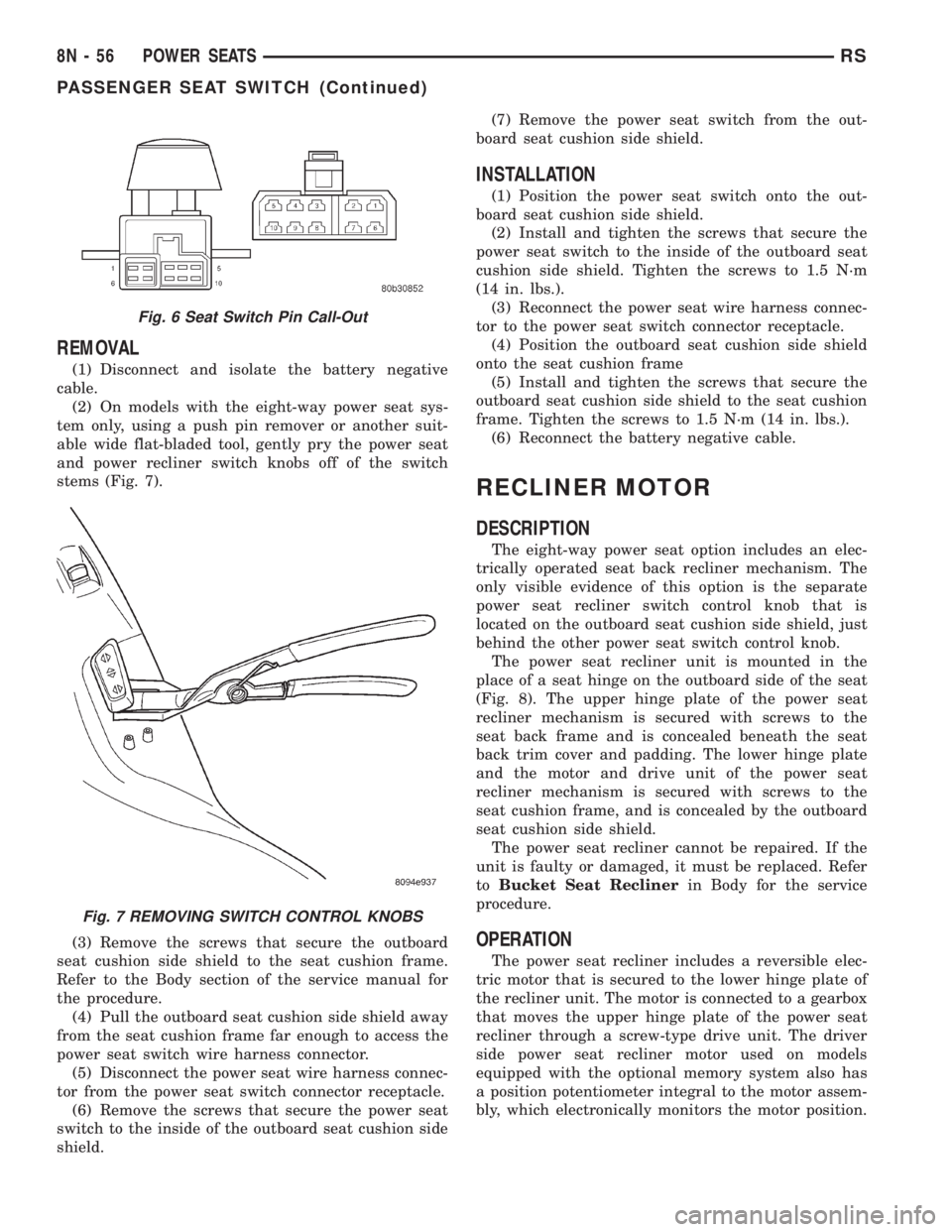

Fig. 6 Seat Switch Pin Call-Out

Fig. 7 REMOVING SWITCH CONTROL KNOBS

8N - 56 POWER SEATSRS

PASSENGER SEAT SWITCH (Continued)

Page 2050 of 4284

(4) Remove steering wheel.

(5) Depress the two plastic locking pins to disen-

gage lock mechanism.

(6) With lock mechanism disengaged, rotate the

clock spring rotor clockwise until the rotor stops. Do

not apply excessive force.

(7) From the end of travel, rotate the rotor three

turns counterclockwise. The wires should end up at

the top. Release locking pins to engage clock spring

lock mechanism.

(8) Install steering wheel and airbag.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood. Disconnect

and isolate the battery negative cable.

(3) Remove driver airbag from steering wheel.

(4) Disconnect wire connectors from back of driver

airbag.

(5) Disconnect the 2±way connector from remote

radio control harness.

(6) Remove steering wheel.

(7) Remove steering column shrouds.

(8) Disconnect 2-way and 5-way connectors

between the clock spring and the instrument panel

wiring harness.

(9) Remove clock spring from housing assembly by

removing the two retaining screws retaining the

clock spring.

INSTALLATION

(1) Position the clock spring into the housing.

Install the two retaining screws to clock spring.

(2) Connect the two way and five way harness

between the clock spring and the instrument panel.

(3) Install the steering wheel. Refer to Steering,

Column, Steering Wheel, Installation.

(4) Connect the harness connector to the driver

airbag.

(5) Connect the remote radio control harness.

(6)

Install the driver airbag into the steering wheel.

(7) Install the steering column upper and lower

shrouds.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

DRIVER AIRBAG

DESCRIPTION

The Driver Airbag is located in the center of the

steering wheel. The most visible part of the airbag is

the cover/horn switch.

OPERATION

The Driver Airbag cover contains the horn switch,

inflator device, and a fabric bag. The airbag cover/

horn switch is serviced separately from the inflator

and bag components.

WHEN THE FRONT AIRBAG SYSTEM IS

DEPLOYED BECAUSE OF A COLLISION, THE

FOLLOWING MUST BE REPLACED:

²COMPLETE STEERING COLUMN ASSEMBLY

²LOWER STEERING COUPLER

²STEERING WHEEL

²STEERING COLUMN CLOCK SPRING

²DRIVER AIRBAG

²PASSENGER AIRBAG

²UPPER INSTRUMENT PANEL WITH PAD

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

STANDARD PROCEDURE - DEPLOYED DRIVER

AIRBAG CLEAN UP

Roll or fold the driver airbag towards the steering

wheel and then tape the bag to the steering wheel.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well. If

HVAC was in RECIRC mode at time of airbag

deployment, operate HVAC blower on low speed/heat

and vacuum powder residue expelled from the heat

outlets. Multiple vacuum cleaning may be necessary

to decontaminate the interior of the vehicle.

SERVICE OF DEPLOYED AIRBAG

If a Driver Airbag has been deployed, but not due

to a collision, replace the following:

²Driver Airbag

²Clock Spring Assembly

8O - 4 RESTRAINTSRS

CLOCK SPRING (Continued)

Page 2052 of 4284

CAUTION: Use correct screws when installing the

ORC.

(1) Install the ORC assembly into vehicle.

(2) Connect the wire connector to the ORC.

(3) Install three bolts holding ORC to floor

bracket. Torque bolts to 7.3 - 9.6 N´m (65 to 85 in.

lbs.)

(4) Install the storage bin onto the instrument

panel. Refer to Body, Instrument Panel, Storage Bin,

Installation.

WARNING: DO NOT CONNECT THE BATTERY NEG-

ATIVE CABLE. REFER TO ELECTRICAL,

RESTRAINTS, DIAGNOSIS AND TESTING - AIRBAG

SYSTEM FIRST.

PASSENGER AIRBAG

DESCRIPTION

WARNING: NEVER DISASSEMBLE THE PASSEN-

GER AIRBAG, THE PASSENGER AIRBAG HAS NO

SERVICEABLE PARTS.

The Passenger Airbag is located beneath the

instrument panel and pad assembly. The airbag is

mounted to the back side of the instrument panel

reinforcement.

The instrument panel top pad is the most visible

part of the passenger airbag system. Located under

the instrument panel top pad are the airbag door, the

passenger airbag cushion and the airbag cushion

supporting components.

The passenger airbag includes a magnesium hous-

ing within which the cushion and inflator are

mounted and sealed.

Following a passenger airbag deployment, the pas-

senger airbag and the instrument panel must be

replaced. The passenger airbag cannot be repaired,

and must be replaced if deployed or damaged in any

way.

OPERATION

The passenger airbag is equipped with two infla-

tors, each with three levels of pressure output. The

inflators seal the hole in the airbag cushion so it can

discharge the gas it produces directly into the cush-

ion when supplied with the proper electrical signal.

Following an airbag deployment, the airbag cushion

quickly deflates by venting this gas through the

cushion material towards the instrument panel.

The passenger airbag is secured with screws to the

instrument panel beneath the instrument panel top

pad and above the glove box opening. The instrumentpanel top pad above the glove box opening conceals

the airbag door and a predetermined hinge line

beneath its decorative cover. Upon airbag deploy-

ment, the top pad will bend at the hinge line and the

door will fold back out of the way onto the top of the

instrument panel.

WHEN THE FRONT AIRBAG SYSTEM IS

DEPLOYED BECAUSE OF A COLLISION, THE

FOLLOWING MUST BE REPLACED:

²COMPLETE STEERING COLUMN ASSEMBLY

²LOWER STEERING COUPLER

²STEERING WHEEL

²STEERING COLUMN CLOCK SPRING

²DRIVER AIRBAG COVER/HORN SWITCH

²DRIVER AIRBAG

²PASSENGER AIRBAG

²UPPER INSTRUMENT PANEL WITH PAD

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

STANDARD PROCEDURE - DEPLOYED

PASSENGER AIRBAG CLEAN UP

Roll or fold the passenger airbag towards the

instrument panel surface and close the door over the

folded bag. Then tape the door shut.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well. If

HVAC was in RECIRC mode at time of airbag

deployment, operate HVAC blower on low speed/heat

and vacuum powder residue expelled from the heat

outlets. Multiple vacuum cleaning may be necessary

to decontaminate the interior of the vehicle.

SERVICE OF DEPLOYED AIRBAG

If a Passenger Airbag has been deployed, but not

due to a collision, replace the following:

²Passenger Airbag

²Upper instrument panel with pad

The component above must be replaced because

they cannot be reused. Inspect the heat duct near the

passenger airbag for any damage replace as neces-

sary. Replace any other passenger airbag system

components if damaged.

8O - 6 RESTRAINTSRS

OCCUPANT RESTRAINT CONTROLLER (Continued)

Page 2064 of 4284

²A rapid increase rpm (indicates that the clutch

has been disengaged)

²Excessive engine rpm (indicates that the trans-

mission may be in a low gear)

²The speed signal increases at a rate of 10 mph

per second (indicates that the co-efficient of friction

between the road surface and tires is extremely low)

²The speed signal decreases at a rate of 10 mph

per second (indicates that the vehicle may have

decelerated at an extremely high rate)

²If the actual speed is not within 20 mph of the

set speed. The previous disengagement conditions are

programmed for added safety.

Once the speed control has been disengaged,

depressing the RESUME switch when speed is

greater than 25 mph allows the vehicle to resume

control to the target speed that was stored in the

PCM.

While the speed control is engaged, the driver can

increase the vehicle speed by depressing the ACCEL

switch. The new target speed is stored in the PCM

when the ACCEL switch is released. The PCM also

has a9tap-up9feature in which target speed

increases by 2 mph for each momentary switch acti-

vation of the ACCEL switch. The PCM also provides

a means to decelerate to a new lower target speed

without disengaging speed control. Depress and hold

the COAST switch until the desired speed is reached,

then release the switch.

The PCM also has a ªTap Downº feature in which

target speed decreases at 1 mph for each momentary

switch activation of the coast switch.

OPERATION - INTERACTIVE SPEED CONTROL

(4 Speed EATX Only)

Interactive means that communication between the

PCM and the TCM is taking place. Interactive speed

control avoids unnecessary shifting for smoother, qui-

eter operation and when downshifts are required,

makes the shifts smoother.

CLIMBING A GRADE

DESCRIPTION

When climbing a grade the interactive speed con-

trol tries to maintain the set speed by increasing the

throttle opening, while inability/delaying downshifts.

OPERATION

If opening the throttle alone cannot maintain the

set speed and the vehicle speed drops more than three

mph below the set speed, the transmission will down-

shift to third gear. If the vehicle continues to lose

speed, by more than 6 mph, the transmission will

downshift again to maintain the set speed. After the

vehicle encounters a less-steep grade, or has crestedthe grade (reduced the load on the powertrain) and

can maintain the set speed at a reduced throttle posi-

tion, the transmission will upshift, as appropriate,

until the set speed can be maintained in Overdrive.

GRADE HUNTING

DESCRIPTION

All vehicles equipped with a four speed automatic

transmission have a grade hunting feature for the 2nd

to 3rd gear upshift and the 3rd to Overdrive upshift.

OPERATION

The TCM identifies the powertrain loading condi-

tions and selects the proper gear to maintain the cur-

rent vehicle speed. Under moderate loading

conditions the transaxle will stay in 3rd gear until

the top of the grade is reached or the powertrain

loading is reduced.

If powertrain loading is severe, the transaxle may

shift into 2nd gear and remain there until power-

train loading is reduced, then a 2nd to 3rd gear

upshift will be scheduled. Grade hunting features

always operate regardless of whether or not the

interactive speed control is engaged.If the interac-

tive speed control is not engaged and power-

train loading is not reduced, the driver may

have to completely lift off of the throttle before

an upshift will occur. If the driver does lift off the

throttle to induce an upshift under these conditions,

vehicle speed will reduce and the Overdrive to 3rd

and 3rd to 2nd gear downshifts will reoccur when the

throttle is reapplied. If grade hunting is repeatedly

induced by the driver, transaxle damage may result.

AUTOMATIC SPEED CONTROL OVERSPEED

REDUCTION

DESCRIPTION

Transmission control software includes an auto-

matic speed control overspeed reduction feature. This

maintains vehicle speed at the selected set point

when descending a grade.

OPERATION

The Transmission Control Module (TCM) first

senses that the speed control is set. If the set speed

is exceeded by more than 4 mph (6.5 km/hr) and the

throttle is closed, the TCM causes the transaxle to

downshift to THIRD gear. After downshifting, the

automatic speed control resumes normal operation.

To ensure that an upshift is appropriate after the set

speed is reached, the TCM waits until the speed con-

trol system opens the throttle at least 6 degrees

before upshifting to OVERDRIVE again.

8P - 2 SPEED CONTROLRS

SPEED CONTROL (Continued)

Page 2072 of 4284

OPERATION

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the SKIM has a unique

9Secret Key9code programmed into it by the manu-

facturer as well. When a Sentry Key is programmed

into the memory of the SKIM, the SKIM stores the

transponder identification code from the Sentry Key,

and the Sentry Key learns the9Secret Key9code from

the SKIM. Once the Sentry Key learns the9Secret

Key9code of the SKIM, it is also permanently pro-

grammed into the transponder's memory. Therefore,

blank keys for the SKIS must be programmed by the

SKIM in addition to being cut to match the mechan-

ical coding of the ignition lock cylinder. Refer to Elec-

trical, Vehicle Theft Security, Transponder Key,

Standard Procedure - Transponder Programming.

The Sentry Key's transponder is within the range

of the SKIM's transceiver antenna ring when it is

inserted into the ignition lock cylinder. When the

ignition switch is turned to the ON position, the

SKIM communicates with the Sentry Key via a radio

frequency (RF) signal. The SKIM determines if a

valid key is present based on the information it

receives from the Sentry Key. If a valid key is

detected, that fact is communicated to the PCM via

the PCI bus and the vehicle is allowed to continue

running. If an invalid key is received by the PCM or

no status at all is communicated, the vehicle will

stall after two (2) seconds of running. The indicator

light will be flashing at this point. The Sentry Key's

transponder can not be repaired. If it is faulty or

damaged, it must be replaced.

Common communication problems:

²Two transponder keys too close together.

²Speed Pass too close to transponder key.

Solid indicator that there is a system failure.

²Loss of PCM communication.

²Failed antenna circuit.

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING

USING A DRB IIITSCAN TOOL

All Sentry Keys included with the vehicle are pre-

programmed to work with the Sentry Key Immobi-

lizer System (SKIS) when it is shipped from the

factory. The Sentry Key Immobilizer Module (SKIM)

can be programmed to recognize up to a total of eight

Sentry Keys. When programming a blank Sentry Key

transponder, the key must first be cut to match the

ignition lock cylinder of the vehicle for which it will

be used. The vehicle's four digit PIN code will be

required to complete this task since you will need it

to enter the Secured Access Mode in the SKIM. Thefollowing steps must be completed using a DRB IIIt

scan tool:

(1) Insert the blank key into the ignition and turn

it to the RUN position.

(2) Using a DRB IIItscan tool, select9Theft

Alarm,99SKIM,99Miscellaneous,9and then9Program

New Key.9

(3) Enter the four digit PIN code using the DRB

IIItscan tool. When programming is completed, the

SKIM will exit Secured Access Mode and the DRB

IIItscan tool will display the results of your attempt

to program the key. One of five distinct results may

be displayed. All five are listed below:

²(Programming Successful(is displayed if the

Sentry Key programming is successful.

²(Learned Key in Ignition(is displayed if the

key in the ignition has already been programmed

into that vehicle's SKIM.

²(Eight Keys Already Learned (At The Maxi-

mum) Programming Not Done(is displayed if

eight keys have already been programmed into the

SKIM. In this case, if a new key needs to be added

due to a lost or defective key, the9Erase All Keys9

command (which requires entering the Secured

Access Mode) has to be performed. Following the

9Erase All Keys9command, all keys that will be used

to operate the vehicleMUSTbe reprogrammed to

the SKIM.

²(Programming Not Attempted(is displayed

after an9Erase All Keys9function is executed.

²(Programming Key Failed(is displayed if fur-

ther diagnosis is required.

To learn additional keys, turn the ignition OFF,

remove the learned key, insert the next new blank

key, and repeat the steps from the beginning.

ªCUSTOMER LEARNº MODE

This feature is only available on domestic vehicles

or those which have a U.S. country code designator.

This procedure requires access to at least two valid

Sentry Keys. If two valid Sentry Keys are not avail-

able, Sentry Key programming will require the use of

a DRB IIItscan tool.

The steps required to program Sentry Keys with

two valid Sentry Keys follows:

(1) Obtain the blank Sentry Key(s) that need to be

programmed. Cut the keys to match the ignition lock

cylinder mechanical key codes.

(2) Insert one of the two valid Sentry Keys into the

ignition switch and turn the ignition switch to the

ON position.

(3) After the ignition switch has been in the ON

position for longer than three seconds, but no more

than fifteen seconds, cycle the ignition switch back to

8Q - 4 VEHICLE THEFT SECURITYRS

TRANSPONDER KEY (Continued)

Page 2073 of 4284

the OFF position. Replace the first valid Sentry Key

in the ignition lock cylinder with the second valid

Sentry Key and turn the ignition switch back to the

ON position. The second valid Sentry Key must be

inserted within 15 seconds of removing the first valid

Sentry key.

(4) About ten seconds after the completion of Step

3, the indicator light will start to flash and a single

audible chime tone will sound to indicate that the

system has entered the9Customer Learn9program-

ming mode.

(5) Within sixty seconds of entering the9Customer

Learn9programming mode, turn the ignition switch

to the OFF position, replace the valid Sentry Key

with a blank Sentry Key transponder, and turn the

ignition switch back to the ON position.

(6) About ten seconds after the completion of Step

5, a single audible chime tone will sound and the

indicator light will stop flashing and stay on solid for

three seconds and then turn off to indicate that the

blank Sentry Key has been successfully programmed.

The SKIS will immediately exit the9Customer

Learn9programming mode and the vehicle may be

started using the newly programmed Sentry Key.

These steps must be completed in their entirety for

each additional Sentry Key to be programmed. If any

of the above steps are not completed in the given

sequence, or within the allotted time, the SKIS will

exit the9Customer Learn9programming mode and

the programming will be unsuccessful. The SKIS will

also automatically exit the9Customer Learn9pro-

gramming mode if:

²It sees a non-blank Sentry Key when it should

see a blank.

²If it has already programmed eight (8) valid

Sentry Keys.

²If the ignition switch is turned to the OFF posi-

tion for more than about fifty (50) seconds.

NOTE: If you attempt to start the vehicle while in

ªCustomer Learnº mode (LED flashing), the vehicle

will behave as though an invalid key is being used

(i.e. the engine will stall after two (2) seconds of

running). No faults will be logged.

NOTE: Once a Sentry Key has been programmed to

a particular vehicle, it cannot be used on any other

vehicle.VTSS/SKIS INDICATOR LAMP

DESCRIPTION

The Sentry Key Immobilizer System (SKIS) uses

an indicator light to convey information on the status

of the system to the customer. This light is shared

with the Vehicle Theft Security System (VTSS). The

light is located in the Message Center. The indicator

light is controlled by the Body Control Module (BCM)

based upon messages it receives from the Sentry Key

Immobilizer Module (SKIM) on the PCI bus.

OPERATION

The BCM performs a four second bulb check,

regardless of SKIM messages. After the bulb check,

the lamp is controlled according to SKIM messages.

Then, the SKIM sends messages to the BCM to oper-

ate the light based upon the results of the SKIS self

tests. The light may be actuated in two possible

ways, flashing or on solid. If the light comes on and

stays on solid after a power-up test, this indicates

that the SKIM has detected a system malfunction. If

the SKIM detects an invalid key when the ignition

switch is moved to the ON position, it sends a mes-

sage on the PCI bus to the BCM, to flash the light.

The SKIM can also send a message to flash the light

and generate a single audible chime at the same

time. These two events occurring simultaneously

indicate that the SKIS has been placed into the9Cus-

tomer Learn9mode. Refer to Electrical, Vehicle Theft

Security, Transponder Key, Standard Procedure -

Transponder Programming for more information on

the9Customer Learn9mode. If the light comes on

and stays on after the power-up test, diagnosis of the

SKIS should be performed using a DRB IIItscan tool

and the appropriate Body Diagnostic Procedures

manual. The light is not a serviceable component.

RSVEHICLE THEFT SECURITY8Q-5

TRANSPONDER KEY (Continued)