fuse box CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 1071 of 4284

FRONT BLOWER MODULE C1 (ATC) - BLACK 4 WAYCAV CIRCUIT FUNCTION

1- -

2 Z134 12BK/OR GROUND

3 C56 20DB/LB BLOWER MOTOR CONTROL

4 C7 12DB FUSED FRONT BLOWER MOTOR RELAY OUTPUT

FRONT BLOWER MODULE C2 (ATC) - BLACK 2 WAYCAV CIRCUIT FUNCTION

1 C7 12DB (EXCEPT BUILT-

UP-EXPORT)HIGH SPEED BLOWER MOTOR

1 C7 12DG (BUILT-UP-

EXPORT)HIGH SPEED BLOWER MOTOR

2 C70 12BK (BUILT-UP-

EXPORT)REAR BLOWER HIGH SPEED

2 C70 12DB/YL (EXCEPT

BUILT-UP-EXPORT)REAR BLOWER HIGH SPEED

FRONT READING LAMPS/SWITCH - BLACK 6 WAYCAV CIRCUIT FUNCTION

1 E15 20OR/DB (EXCEPT

BASE)ASH/RECEIVER LAMP FEED

2 Z137 20BK/LB GROUND

3- -

4 M27 20YL/LB READING LAMPS DRIVER

5 M24 20YL/WT COURTESY LAMPS DRIVER

6- -

GLOVE BOX LAMP - BLUE 2 WAYCAV CIRCUIT FUNCTION

1 M28 20YL/TN GLOVE BOX LAMP DRIVER

2 Z328 20BK/TN GROUND

HALO LAMP - BLUE 2 WAYCAV CIRCUIT FUNCTION

1 Z326 20BK/OR GROUND

2 M26 20YL/DB HALO LAMP DRIVER

C

O

N

N

E

C

T

O

R

P

I

N

O

U

T

S

1042

CONNECTOR PINOUTS

Page 1163 of 4284

4.3 WARNINGS

4.3.1 VEHICLE DAMAGE WARNINGS

Before disconnecting any control module, make

sure the ignition is ``off ''. Failure to do so could

damage the module.

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation, this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

4.3.2 ROAD TESTING A COMPLAINT

VEHICLE

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

WARNING: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED.

DURING THE TEST DRIVE, DO NOT TRY TO

READ THE DRB SCREEN WHILE IN MOTION.

DO NOT HANG THE DRBIIITFROM THE

REAR VIEW MIRROR OR OPERATE IT

YOURSELF. HAVE AN ASSISTANT

AVAILABLE TO OPERATE THE DRBIIIT.

4.4 DIAGNOSIS

1. Your diagnostic test procedure must begin with a

thorough visual inspection of the ABS system for

damaged components or disconnected connec-

tors. The brake lamps must be operational, and

if they are not, repair them prior to continuing.

2. Connect the DRBIIItto the data link connector,

which is located under the dash to the left of the

steering column. If the DRBIIItdoes not power

up, check the power and ground supplies to the

connector.

3. Turn the ignition on. Select ªAntilock Brakesº. If

the DRBIIItdisplays ªNo Responseº condition

you must diagnose that first.

4. Read and record all ABS diagnostic trouble

codes. If the ªCAB Power Feed Circuitº diagnos-

tic trouble code is present, it must be repaired

prior to addressing any other DTC's. If any

additional DTC's are present, proceed to theappropriate test by locating the matching test in

the Table of Contents and begin to diagnose the

symptom.

5. If there are no diagnostic trouble codes present,

identify the customer complaint. Select ªInputs/

Outputsº and read the brake switch input as you

press and release the brake pedal. If the display

does not match the state of the pedal, perform

the proper test by locating the matching test in

the Table of Contents and begin to diagnose the

symptom. If a problem exists with the yellow

ªABSº warning indicator or the red ªBrakeº

indicator exists, refer to the proper tests by

locating the matching test in the Table of Con-

tents and begin to diagnose the symptom. Read

the traction control switch input as you press

and release the switch. If the display does not

match the state of the indicator perform the

proper test by locating the matching test in the

Table of Contents and begin to diagnose the

symptom.

6. If no other problems are found, it will be neces-

sary to road test the vehicle. Perform several

antilock stops from above 50 Km/h (30 mph) and

then repeat step 4. If any diagnostic trouble

codes are present, proceed to the appropriate test.

7. The following conditions should be considered

ªNORMALº operation, and no repairs should be

attempted to correct them.

± Brake pedal feedback during an ABS stop

(clicking, vibrating).

± Clicking, groaning or buzzing at 25 Km/h (15

mph) or 40 Km/h (24 mph) (drive off self test).

± Groaning noise during an ABS stop.

± Slight brake pedal drop and pop noise when

ignition is initially turned on.

± Brake pedal ratcheting down at the end of an

ABS stop.

8. If the complaint is ABS ªcyclingº at the end of a

stop at low speeds, it may be caused by a

marginal wheel speed sensor signal. The sensor

air gap, tone wheel condition, and/or brakes

hanging up are possible causes of this condition.

9. After a road test in which no problems were

found, refer to any Technical Service Bulletins

that may apply.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box)

jumper wires

ohmmeter

voltmeter

test light

6

GENERAL INFORMATION

Page 1227 of 4284

4.3 WARNINGS AND CAUTIONS

4.3.1 ROAD TEST WARNINGS

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

CAUTION: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED. DUR-

ING THE TEST DRIVE, DO NOT HANG THE

DRBIIITFROM THE REAR VIEW MIRROR. DO

NOT ATTEMPT TO READ THE DRBIIITWHILE

DRIVING. HAVE AN ASSISTANT AVAILABLE

TO OPERATE THE DRBIIIT.

4.3.2 VEHICLE DAMAGE CAUTIONS

Before disconnecting any control module, make

sure the ignition is off. Failure to do so could

damage the module. When testing voltage or circuit

integrity at any control module, use the terminal

side (not the wire end) of the harness connector. Do

not probe through the insulation; this will damage

it and eventually cause it to fail because of corro-

sion.

Be careful when performing electrical test so as to

prevent accidental shorting of terminals. Such a

mistake can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box) scan tool

vacuum gauge

ammeter

ohmmeter

jumper wires and probes

oscilloscope

6.0 GLOSSARY OF TERMS

A/Cair conditioning

APPaccelerator pedal position (sensor)

backfire,

popbackfuel ignites in either the intake or

the exhaust system

BCMbody control module

BPboost pressure (sensor)CKPcrankshaft position (sensor)

CMPcamshaft position (sensor)

cuts out,

missesa steady pulsation or the inability of

the engine to maintain a consistent

rpm

DLCdata link connector

detona-

tion,

spark

knocka mild to severe ping, especially un-

der loaded engine conditions

ECMengine control module

ECTengine coolant temperature (sensor)

EGRexhaust gas recirculation

(solenoid/valve)

hard

startthe engine takes longer than usual

to start, even though it is able to

crank at normal speed.

IATintake air temperature (sensor)

IPMintelligent power module

lack of

power,

sluggishthe engine power output has been

reduced

MAFmass air flow (sensor)

MILmalfunction indicator lamp

msmillisecond(s)

PDCpower distribution center

poor fuel

economythere is significantly less fuel mile-

age than other vehicles of the same

design and configuration

runs

rough/

unstable

idlethe engine runs unevenly at idle

causing the engine to shake if it is

severe enough

S/Cspeed control

SKIMsentry key immobilizer module

SKISsentry key immobilizer system

start and

stallThe engine starts but immediately

dies (stalls)

surgeengine rpm fluctuation without cor-

responding change in accelerator

pedal position

SRCsignal range check

WIFwater in fuel (sensor)

VSSvehicle speed sensor

8

GENERAL INFORMATION

Page 1904 of 4284

²Remote Keyless Entry Module (RKE)- Refer

toRemote Keyless Entry Modulein Power Locks

for more information.

²Electronic Vehicle Information Center

(EVIC)- Refer toElectronic Vehicle Information

Centerin Overhead Console for more information.

²Heated Seat Module (HSM)- Refer toHeated

Seat Modulein Electronic Control Modules for more

information.

²Memory Heated Seat Module (MHSM)-If

the vehicle is equipped with the Memory System,

refer toMemory Seat Mirror Module (MSMM)in

Electronic Control Modules for more information.

Refer toWiring Diagramsfor complete circuit

diagrams. Following are general descriptions of the

major components in the heated seat system.

OPERATION

The heated seat system will only operate when the

ignition switch is in the On position, and the surface

temperature at the front seat heating element sen-

sors is below the designed temperature set points of

the system. The heated seat system will not operate

in ambient temperatures greater than about 41É C

(105É F). The front seat heating elements and sensors

are hard wired to the Heated Seat Module (HSM) or

the Memory Heated Seat Module (MHSM).

The heated seat switches are hard wired to the

Body Control Module (BCM). The BCM monitors the

heated seat switch inputs, then sends heated seat

switch status messages to the HSM or MHSM over

the Programmable Communications Interface J1850

(PCI) data bus. The HSM or MHSM contains the con-

trol logic for the heated seat system. The HSM or

MHSM responds to the heated seat switch status

messages, ignition switch status messages, and the

front seat heating element sensor inputs by control-

ling the output to the front seat heating elements

through integral solid-state relays.

When a seat heater is turned on, the sensor

located on the seat cushion electric heater element

provides the HSM or MHSM with an input indicating

the surface temperature of the seat cushion. If the

surface temperature input is below the temperature

set point for the selected Low or High heated seat

switch position, the HSM or MHSM energizes the

integral solid-state relay, which supplies battery cur-

rent to the heating elements in the seat cushion and

back. When the sensor input indicates the correct

temperature set point has been achieved, the HSM or

MHSM de-energizes the solid-state relay. The HSM

or MHSM will continue to cycle the solid-state relay

as needed to maintain the temperature set point.

The HSM or MHSM and the seat heater elements

operate on non-switched battery current supplied

through the power seat fuse in the intelligent powermodule. However, the HSM or MHSM will automati-

cally turn off the heating elements if it detects an

open in the sensor circuit, a short in the heating ele-

ment circuit causing an excessive current draw, or

when the ignition switch is turned to the Off posi-

tion.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the heated seat system.

DRIVER HEATED SEAT

SWITCH

DESCRIPTION

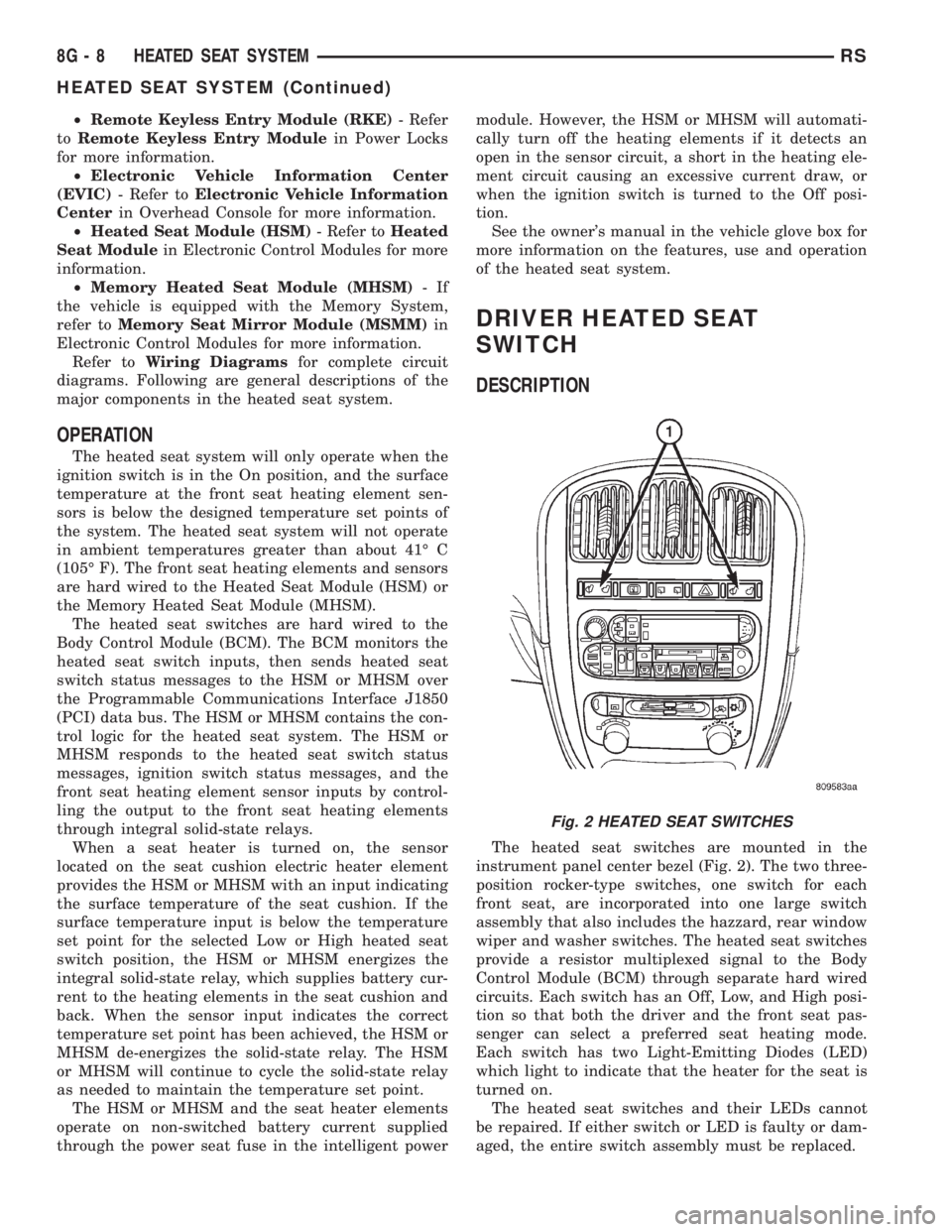

The heated seat switches are mounted in the

instrument panel center bezel (Fig. 2). The two three-

position rocker-type switches, one switch for each

front seat, are incorporated into one large switch

assembly that also includes the hazzard, rear window

wiper and washer switches. The heated seat switches

provide a resistor multiplexed signal to the Body

Control Module (BCM) through separate hard wired

circuits. Each switch has an Off, Low, and High posi-

tion so that both the driver and the front seat pas-

senger can select a preferred seat heating mode.

Each switch has two Light-Emitting Diodes (LED)

which light to indicate that the heater for the seat is

turned on.

The heated seat switches and their LEDs cannot

be repaired. If either switch or LED is faulty or dam-

aged, the entire switch assembly must be replaced.

Fig. 2 HEATED SEAT SWITCHES

8G - 8 HEATED SEAT SYSTEMRS

HEATED SEAT SYSTEM (Continued)

Page 2031 of 4284

trically and independently using the separate power

seat switches found on the outboard seat cushion

side shield of each front seat. See the owner's manual

in the vehicle glove box for more information on the

features, use and operation of the power seat system.

OPERATION - MEMORY SYSTEM

The Memory Seat/Mirror Module (MSMM) will

drive a maximum of 2 motors at a time in a given

direction. If conflicting directions are requested, the

priority for response will be as follows:

²Seat Track Rearward

²Seat Front Down

²Seat Rear Down

²Recliner Rearward

²Seat Track Forward

²Seat Front Up

²Seat Rear Up

²Recliner Forward

The inputs from these switches to the MSMM is a

current limited battery source fed by the MSMM.

This protects the MSMM printed circuit board traces

from acting as fuses. All of these switch contact

inputs to the MSMM are normally closed to ground,

except when actuated.

Soft stops are incorporated to prevent the motor

from being driven into a stall. Should the seat have

restricted travel, refer to Resetting Soft Stops in this

section.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the memory system. For diagnosis of the MSM, the

PCI data bus, or the other electronic modules on the

PCI data bus that provide inputs and outputs for the

memory system, the use of a DRBtscan tool and the

proper Diagnostic Procedures manual are recom-

mended.

ELECTRONIC VEHICLE INFORMATION CENTER

The Electronic Vehicle Information Center (EVIC)

serves as the user interface for the memory system.

It displays memory system status messages and pro-

vides the user with the means for enabling and dis-

abling the many customer programmable features

available on the vehicle, including those for the mem-

ory system.

See the owner's manual in the vehicle glove box for

more information on the features, use and operation

of the EVIC. Refer toElectronic Vehicle Informa-

tion Centerin Overhead Console Systems for more

information on the EVIC.

DIAGNOSIS AND TESTING - POWER SEAT

SYSTEM

Following are tests that will help to diagnose the

hard wired components and circuits of the power seatsystem. However, if the vehicle is also equipped with

the optional memory system, these tests may not

prove conclusive in the diagnosis of the driver side

power seat. In order to obtain conclusive testing of

the driver side power seat with the memory system

option, the Programmable Communications Interface

(PCI) data bus network and all of the electronic mod-

ules that provide inputs to, or receive outputs from

the memory system components must be checked.

The most reliable, efficient, and accurate means to

diagnose the driver side power seat with the memory

system option requires the use of a DRBtscan tool

and the proper Diagnostic Procedures manual. The

DRBtscan tool can provide confirmation that the

PCI data bus is functional, that all of the electronic

modules are sending and receiving the proper mes-

sages on the PCI data bus, and that the memory sys-

tem is receiving the proper hard wired inputs and

relaying the proper hard wired outputs to perform its

driver side power seat functions.

WARNING: SOME VEHICLES ARE EQUIPPED WITH

SEATBACK MOUNTED AIRBAGS (Fig. 1). BEFORE

ATTEMPTING TO DIAGNOSE OR SERVICE ANY

SEAT OR POWER SEAT SYSTEM COMPONENT

YOU MUST FIRST DISCONNECT AND ISOLATE THE

BATTERY NEGATIVE CABLE. THEN WAIT TWO MIN-

UTES FOR THE SYSTEM CAPACITOR TO DIS-

CHARGE BEFORE FURTHER SYSTEM SERVICE.

THIS IS THE ONLY SURE WAY TO DISABLE THE

AIRBAG SYSTEM. FAILURE TO DO SO COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Before any testing of the power seat system is

attempted, the battery should be fully-charged and

all of the power seat system wire harness connections

and pins cleaned and tightened to ensure proper cir-

cuit continuity and ground paths. For complete cir-

cuit diagrams, refer toPower Seatin Wiring

Diagrams.

With the dome lamp on, apply the power seat

switch in the direction of the failure. If the dome

lamp dims, the seat may be jamming. Check under

and behind the seat for binding or obstructions. If

the dome lamp does not dim, proceed with testing of

the individual components and circuits.

DIAGNOSIS AND TESTING - MEMORY SYSTEM

CHECK AND RESET SOFT STOPS

To check and reset the power memory seat soft

stops, use the power seat control switches to move

the seat in one direction to the end of travel, allow a

couple of seconds before re-energizing the seat in the

same direction until it stops and for three additional

seconds after it stops. (The amount the seat moved

RSPOWER SEATS8N-51

POWER SEATS (Continued)

Page 2099 of 4284

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch Relay........... 8Wa-42

A/C Compressor Clutch................ 8Wa-42

A/C-Heater Control................... 8Wa-42

A/C Pressure Sensor.................. 8Wa-42

Accelerator Pedal Position Sensor........ 8Wa-30

Accessory Relay...................... 8Wa-10

Airbags............................. 8Wa-43

Ambient Temp Sensor................. 8Wa-49

Antenna............................ 8Wa-47

ATC Remote Sensor................... 8Wa-42

Auto Shut Down Relay................. 8Wa-30

Auto Temp Control.................... 8Wa-42

Automatic Day/Night Mirror............ 8Wa-49

Autostick Switch..................... 8Wa-31

Back-Up Lamp Switch................. 8Wa-51

Battery Temperature Sensor............ 8Wa-20

Battery............................. 8Wa-20

Blend Door Actuators.................. 8Wa-42

Blower Motor Resistor................. 8Wa-42

Body Control Module.................. 8Wa-45

Boost Pressure Sensor................. 8Wa-30

B-Pillar Switches..................... 8Wa-61

Brake Fluid Level Switch............... 8Wa-40

Brake Lamp Switch................... 8Wa-51

Brake Transmission Shift Interlock

Solenoid.......................... 8Wa-31

Cabin Heater Assist................... 8Wa-30

Camshaft Position Sensor.............. 8Wa-30

CD Changer......................... 8Wa-47

Center High Mounted Stop Lamp........ 8Wa-51

Cinch/Release Motors.................. 8Wa-61

Clockspring................. 8Wa-33, 41, 43, 47

Clutch Pedal Interlock Switch Jumper..... 8Wa-10

Clutch Pedal Interlock Switch........... 8Wa-10

Clutch Pedal Upstop Switch............. 8Wa-30

Combination Relays................... 8Wa-54

Controller Antilock Brake.............. 8Wa-35

Crank Case Ventilation Heater.......... 8Wa-30

Crankshaft Position Sensor............. 8Wa-30

Cylinder Lock Switches................ 8Wa-39

Data Link Connector.................. 8Wa-18

Defogger Relay....................... 8Wa-48

Diagnostic Junction Port............... 8Wa-18

Dome Lamps........................ 8Wa-44

Door Ajar Switches.................... 8Wa-39

Door Courtesy Lamps.................. 8Wa-44

Door Lock Motor/Ajar Switches.......... 8Wa-61

Door Lock Switches................... 8Wa-61

Dosing Pump........................ 8Wa-30

Driver Heated Seat Module............. 8Wa-63

ECM/PCM Relay..................... 8Wa-30

EGR Solenoid........................ 8Wa-30Component Page

Electric Wiper De-Icer................. 8Wa-48

Engine Control Module................ 8Wa-30

Engine Coolant Temp Sensor............ 8Wa-30

Engine Oil Pressure Sensor............. 8Wa-30

Engine Oil Pressure Switch............. 8Wa-30

Engine Oil Temperature Sensor.......... 8Wa-30

EVAP/Purge Solenoid.................. 8Wa-30

Evaporator Temperature Sensor......... 8Wa-42

Floor Console Lamp................... 8Wa-44

Floor Console Power Outlet............. 8Wa-41

Fog Lamps.......................... 8Wa-50

Front Blower Module.................. 8Wa-42

Front Blower Motor Relay.............. 8Wa-42

Front Blower Motor................... 8Wa-42

Front Cigar Lighter................... 8Wa-41

Front Control Module.................. 8Wa-10

Front Fog Lamp Relay................. 8Wa-50

Front Intrusion Sensor................. 8Wa-39

Front Reading Lamps/Switch............ 8Wa-44

Front Washer Pump Motor.............. 8Wa-53

Front Wiper Hi/Low Relay.............. 8Wa-53

Front Wiper On/Off Relay.............. 8Wa-53

Fuel Heater Relay.................... 8Wa-10

Fuel Heater......................... 8Wa-30

Fuel Injectors........................ 8Wa-30

Fuel Pressure Sensor.................. 8Wa-30

Fuel Pressure Solenoid................. 8Wa-30

Fuel Pump Module.................... 8Wa-30

Fuel Pump Relay..................... 8Wa-30

Full Open Switches................... 8Wa-61

Fuselink............................ 8Wa-10

Fuses (IPM)......................... 8Wa-10

Generator........................... 8Wa-20

Glove Box Lamp...................... 8Wa-44

Glow Plug Relay...................... 8Wa-30

Glow Plugs.......................... 8Wa-30

Grounds............................ 8Wa-15

Halo Lamp.......................... 8Wa-44

Headlamp Leveling Motors............. 8Wa-50

Headlamp Switch..................... 8Wa-50

Headlamp Washer Pump Motor.......... 8Wa-53

Headlamp Washer Relay............... 8Wa-53

Headlamps.......................... 8Wa-50

Heated Seat Backs.................... 8Wa-63

Heated Seat Cushions................. 8Wa-63

High Beam Lamps.................... 8Wa-50

Hood Ajar Switch..................... 8Wa-39

Horn Relay.......................... 8Wa-41

Horn Switch......................... 8Wa-41

Horns.............................. 8Wa-41

Idle Air Control Motor................. 8Wa-30

Ignition Coil......................... 8Wa-30

RG8W-02 COMPONENT INDEX8Wa-02-1

Page 2309 of 4284

8W-44 INTERIOR LIGHTING

Component Page

A/C- Heater Control................. 8Wa-44-8

Accessory Relay..................... 8Wa-44-4

Auto Temp Control.................. 8Wa-44-8

Body Control Module..... 8Wa-44-2, 3, 4, 5, 6, 7, 8

Center Dome Lamp.................. 8Wa-44-5

Driver Door Courtesy Lamp........... 8Wa-44-2

Floor Console Lamp................. 8Wa-44-4

Front Cigar Lighter.................. 8Wa-44-7

Front Control Module................ 8Wa-44-4

Front Reading Lamps/Switch........ 8Wa-44-4, 5

Fuse 6 (IPM)....................... 8Wa-44-4

G200....................... 8Wa-44-2, 5, 7, 8

G300........................... 8Wa-44-2, 8

G301....................... 8Wa-44-2, 3, 5, 6

G302............................. 8Wa-44-4

G400............................. 8Wa-44-2

Glove Box Lamp.................... 8Wa-44-5

Halo Lamp........................ 8Wa-44-2

Headlamp Switch........... 8Wa-44-3, 5, 6, 7, 8

Instrument Cluster.................. 8Wa-44-7

Instrument Panel Switch Bank......... 8Wa-44-7

Intelligent Power Module............. 8Wa-44-4

Left Liftgate Flood Lamp............. 8Wa-44-2

Left Mid Reading Lamp.............. 8Wa-44-3

Left Rear Reading Lamp.............. 8Wa-44-3

Left Visor/Vanity Lamp............... 8Wa-44-6

Overhead Console................... 8Wa-44-5

Passenger Door Courtesy Lamp........ 8Wa-44-2

Power Mirror Switch................. 8Wa-44-8

Radio............................. 8Wa-44-7

Rear Auto Temp Control Switch........ 8Wa-44-8

Rear Blower Rear Control Switch....... 8Wa-44-8

Rear Dome Lamp................... 8Wa-44-5

Right Liftgate Flood Lamp............ 8Wa-44-2

Right Mid Reading Lamp............. 8Wa-44-3

Right Rear Reading Lamp............. 8Wa-44-3

Right Visor/Vanity Lamp.............. 8Wa-44-6

RG8W-44 INTERIOR LIGHTING8Wa-44-1

Page 2317 of 4284

8W-45 BODY CONTROL MODULE

Component Page

A/C-Heater Control.............. 8Wa-45-15, 18

Auto Temp Control.............. 8Wa-45-15, 18

Automatic Day/Night Mirror.......... 8Wa-45-11

Body Control Module . . 8Wa-45-2, 3, 4, 5, 6, 7, 8, 9,

10, 11, 12, 13, 14, 15, 16, 17, 18, 19

Center Dome Lamp............... 8Wa-45-9, 13

Clockspring....................... 8Wa-45-16

Controller Antilock Brake............ 8Wa-45-13

Diagnostic Junction Port............. 8Wa-45-12

Driver Door Courtesy Lamp.......... 8Wa-45-14

Driver Door Lock Switch.......... 8Wa-45-12, 14

Driver Heated Seat Module........... 8Wa-45-11

Floor Console Lamp................ 8Wa-45-13

Front Cigar Lighter................. 8Wa-45-16

Front Control Module................ 8Wa-45-3

Front Reading Lamps/Switch....... 8Wa-45-8, 13

Fuel Pump Module................. 8Wa-45-14

Fuse 14 (IPM)...................... 8Wa-45-3

Fuse 19 (IPM)...................... 8Wa-45-2

Fuse 20 (IPM)...................... 8Wa-45-2

Fuse 24 (IPM)...................... 8Wa-45-2

G301......................... 8Wa-45-5, 6, 8

Glove Box Lamp................... 8Wa-45-18

Halo Lamp....................... 8Wa-45-18

Headlamp Switch............. 8Wa-45-11, 15, 19

Hood Ajar Switch.................. 8Wa-45-12

Ignition Switch..................... 8Wa-45-3

Instrument Cluster.............. 8Wa-45-15, 18

Instrument Panel Switch Bank . . 8Wa-45-10, 11, 16,

18

Intelligent Power Module..... 8Wa-45-2, 3, 5, 6, 13

Left B-Pillar Switch................. 8Wa-45-9

Left Cylinder Lock Switch............ 8Wa-45-10

Left Front Door Lock Motor/Ajar Switch . 8Wa-45-4,

7

Left Liftgate Flood Lamp............ 8Wa-45-12

Left Mid Reading Lamp........... 8Wa-45-9, 14

Left Power Mirror.................. 8Wa-45-19

Left Rear Lamp Assembly........... 8Wa-45-5, 6

Left Rear Reading Lamp........... 8Wa-45-9, 14

Left Remote Radio Switch............ 8Wa-45-16

Left Repeater Lamp................ 8Wa-45-19

Left Sliding Door Control Module.... 8Wa-45-8, 10

Left Sliding Door Lock Motor.......... 8Wa-45-7

Left Sliding Door Lock Motor/Ajar Switch. 8Wa-45-7,

8

Left Stop/Turn Signal Relay........... 8Wa-45-5

Left Visor/Vanity Lamp.............. 8Wa-45-13

License Lamp...................... 8Wa-45-8

Liftgate Ajar Switch................ 8Wa-45-12

Liftgate Cinch/Release Motor......... 8Wa-45-12

Liftgate Cylinder Lock Switch.......... 8Wa-45-9Component Page

Memory Seat Switch................. 8Wa-45-4

Message Center.................... 8Wa-45-17

Multi- Function Switch.............. 8Wa-45-15

Name Brand Speaker Relay........... 8Wa-45-3

Overhead Console................ 8Wa-45-4, 11

Passenger Door Courtesy Lamp....... 8Wa-45-14

Passenger Door Lock Switch....... 8Wa-45-12, 14

Passenger Folding Mirror Relay....... 8Wa-45-19

Passenger Heated Seat Module........ 8Wa-45-11

Power Folding Mirror Switch......... 8Wa-45-19

Power Liftgate Module............... 8Wa-45-8

Power Mirror Switch................ 8Wa-45-15

Radio............................ 8Wa-45-16

Rear Auto Temp Control Switch.... 8Wa-45-10, 18

Rear Blower Rear Control Switch...... 8Wa-45-10

Rear Dome Lamp................... 8Wa-45-9

Rear Wiper Motor................... 8Wa-45-8

Remote Keyless Entry Module...... 8Wa-45-4, 15

Right B-Pillar Switch................ 8Wa-45-9

Right Combination Relay............. 8Wa-45-5

Right Cylinder Lock Switch........... 8Wa-45-10

Right Front Door Lock Motor/Ajar Switch. 8Wa-45-7,

9

Right Liftgate Flood Lamp........... 8Wa-45-12

Right Mid Reading Lamp.......... 8Wa-45-9, 14

Right Power Mirror................. 8Wa-45-19

Right Rear Lamp Assembly.......... 8Wa-45-5, 6

Right Rear Reading Lamp.......... 8Wa-45-9, 14

Right Remote Radio Switch........... 8Wa-45-16

Right Repeater Lamp............... 8Wa-45-19

Right Sliding Door Control Module . . . 8Wa-45-8, 10

Right Sliding Door Lock Motor......... 8Wa-45-7

Right Sliding Door Lock Motor/Ajar Switch. 8Wa-45-7,

8

Right Visor/Vanity Lamp............. 8Wa-45-13

Thatcham Alarm Module............. 8Wa-45-10

Traction Control Switch............. 8Wa-45-16

RG8W-45 BODY CONTROL MODULE8Wa-45-1

Page 2503 of 4284

FUEL PRESSURE SOLENOID (DIESEL) - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 K342 16BR/WT ECM/PCM RELAY OUTPUT

2 K87 16BR FUEL PRESSURE SOLENOID CONTROL

FUEL PUMP MODULE - LT. GRAY 4 WAY

CAV CIRCUIT FUNCTION

1 Z201 16BK/OR (GAS) GROUND

2 Z201 18BK/OR (RHD/DIESEL) GROUND

2 Z201 20BK/DB (LHD/DIESEL) (GAS) GROUND

3 N4 18DB/WT FUEL LEVEL SENSOR SIGNAL

4 N1 16DB/OR (GAS) FUEL PUMP RELAY OUTPUT

GENERATOR - BLACK 2 WAY

CAV CIRCUIT FUNCTION

1 K342 16BR/WT (DIESEL) ECM/PCM RELAY OUTPUT

1 K342 16BR/WT (GAS) AUTOMATIC SHUTDOWN RELAY OUTPUT

2 K20 18BR/GY (GAS) GENERATOR FIELD CONTROL

2 K20 14BR/GY (DIESEL) GENERATOR FIELD CONTROL

GLOVE BOX LAMP - BLUE 2 WAY

CAV CIRCUIT FUNCTION

1 M28 20YL/TN GLOVE BOX LAMP DRIVER

2 Z328 20BK/TN GROUND

GLOW PLUG RELAY (DIESEL) - BLACK 4 WAY

CAV CIRCUIT FUNCTION

1 A202 10RD/WT FUSED B(+)

2 K152 20DB/WT GLOW PLUG RELAY CONTROL

3 K342 16BR/WT ECM/PCM RELAY OUTPUT

4 K154 10BR/OR GLOW PLUG RELAY OUTPUT

RG8W-80 CONNECTOR PIN-OUTS8Wa-80-63

Page 3806 of 4284

When testing voltage or continuity at any control

module, use the terminal side (not the wire end) of

the connector. Do not probe a wire through the

insulation; this will damage it and eventually cause

it to fail because of corrosion.

Be careful when performing electrical tests so as

to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, a

second DTC could be set, making diagnosis of the

original problem more difficult.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box) scan tool

Evaporative System Diagnostic Kit #6917

fuel filler adapter #8382

fuel pressure adapter (C-6631) or #6539

fuel pressure kit (C-4799-B) or #5069

fuel release hose (C-4799-1)

Min Air flow fitting #6714

jumper wires

ohmmeter

oscilloscope

vacuum gauge

voltmeter

12 volt test light minimum 25 ohms resistance

with probe #6801

CAUTION: A 12 VOLT TEST LIGHT SHOULD

NOT BE USED FOR THE FOLLOWING

CIRCUITS, DAMAGE TO THE POWERTRAIN

CONTROLLER WILL OCCUR.

²5 Volt Supply

²8 Volt Supply

²J1850 PCI Bus

²CCD Bus

²CKP Sensor Signal

²CMP Sensor Signal

²Vehicle Speed Sensor Signal

²O2 Sensor Signal

6.0 GLOSSARY OF TERMS

ABSanti-lock brake system

backfire,

popbackfuel ignites in either the intake or

the exhaust system

CKPcrank position sensor

CMPcamshaft position sensorcuts out,

missesa steady pulsation or the inability of

the engine to maintain a consistent

rpm

DLCdata link connector (previously

called engine diagnostic connector)

detona-

tion,

spark

knocka mild to severe ping, especially un-

der loaded engine conditions

ECTengine coolant temperature sensor

EGRexhaust gas recirculation valve

genera-

torpreviously called alternator

hard

startThe engine takes longer than usual

to start, even though it is able to

crank normally.

hesita-

tion, sag,

stumbleThere is a momentary lack of re-

sponse when the throttle is opened.

This can occur at all vehicle speeds.

If it is severe enough, the engine

may stall.

IATintake air temperature sensor

IACidle air control motor

JTECCombined engine and transmission

control module

lack of

power,

sluggishThe engine has less than expected

power, with little or no increase in

vehicle speed when the throttle is

opened.

LDPleak detection pump

MAPmanifold absolute pressure sensor

MILmalfunction indicator lamp

MTVmanifold tuning valve

O2Soxygen sensor

PCIprogrammable communication inter-

face

PCMpowertrain control module

PCVpositive crankcase ventilation

PEPperipheral expansion port

poor fuel

economyThere is significantly less fuel mile-

age than other vehicles of the same

design ad configuration

12

GENERAL INFORMATION