jump start CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 565 of 4284

TEST ACTION APPLICABILITY

3CAUTION: The work area ambient temperature must be above 15.6ÉC (60ÉF)

to test A/C system operation.

Turn the ignition on.

With the DRBIIIt, check the PCM/ECM for DTCs.

Are any DTCs present?All

Ye s®Refer to Powertrain Diagnostic information for the related symp-

tom(s). After the repair is complete, with the DRBIIIt, erase the

DTC(s). Cycle the ignition switch. With the DRBIIIt, actuate the

Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 4

4 Turn the ignition off.

Disconnect the Evaporator Temperature Sensor harness connector.

Turn the ignition on.

With the DRBIIItin Sensor Display, read the Evaporator Temperature Sensor

voltage.

Is the voltage above 4.9 volts?All

Ye s®Go To 5

No®Go To 6

5 Turn the ignition off.

Disconnect the Evaporator Temperature Sensor harness connector.

Connect a jumper wire between the Evaporator Temperature Sensor Signal circuit

and the Sensor Ground circuit at the Evaporator Temperature Sensor harness

connector.

Turn the ignition on.

With the DRBIIItin Sensor Display, read the Evaporator Temperature Sensor

voltage.

Is the voltage 0.0 volts?All

Ye s®Replace the Evaporator Temperature Sensor in accordance with

the Service Information. After repair is complete, rerun the

Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

No®Go To 6

6NOTE: Ensure that the voltmeter leads meet the terminals in the connector

and that there is good terminal to wire connection.

NOTE: Ensure the voltmeter leads are connected for positive polarity.

Back probe the Sensor Ground circuit between the Evaporator Temperature Sensor

harness connector and the A/C - Heater Control Module C1 harness connector.

Turn the ignition on.

Is the voltage below 0.10 volt?All

Ye s®Go To 7

No®Repair the high resistance in the Sensor Ground circuit. After

repair is complete, rerun the Cooldown Test.

Perform BODY VERIFICATION TEST - VER 1.

536

HEATING & A/C

COOLDOWN TEST TOO COLD TO START - MANUAL A/C ÐContinued

Page 1019 of 4284

BODY VERIFICATION TEST - VER 1 APPLICABILITY

1. Disconnect all jumper wires and reconnect all previously disconnected components and

connectors.

2. With the DRBIIIt, record and erase all DTCs from ALL modules. Cycle the ignition on then

off

3. If the Sentry Key Immobilizer Module (SKIM), the Powertrain Control Module (PCM), or the

Engine Control Module (ECM) was replaced, proceed to number 9. If the SKIM, PCM, or ECM

was not replaced, continue to the next number.

4. If the Body Control Module (BCM) was replaced, turn the ignition on for 15 seconds (to allow

the new BCM to learn VIN) or engine may not start (if VTSS equipped). If the vehicle is

equipped with VTSS, use the DRBIIItand enable VTSS.

5. Program all other options as needed.

6. If any actuators were replaced in the HVAC System, with the DRBIIItin HVAC, select

System Tests then select HVAC Door Recalibration (manual temperature system only).

7. If any actuators were replaced in the ATC System, with the DRBIIItin Automatic Temp

Control, select Miscellaneous then select Reset ATC Head.

8. If any repairs were made to the power sliding door or power liftgate, use the DRBIIItand

perform the open and close system tests. Observe the instructions on the DRBIIItscreen.

Proceed to number 16.

9. Obtain the vehicle's unique PIN assigned to it's original SKIM from either the vehicle's

invoice or from Chrysler's Customer Assistance Center (1-800-992-1997).

10. NOTE: Once Secured Access Mode is active, the SKIM will remain in that mode for 60

seconds.

11. With the DRBIIIt, select THEFT ALARM, SKIM, MISCELLANEOUS and select SKIM

REPLACED. Enter the 4 digit PIN to put the SKIM in Secured Access Mode.

12. The DRBIIItwill prompt for the following steps. (1) Program the country code into the

SKIM's memory. (2) Program the vehicle's VIN into the SKIM memory. (3) Transfer the

vehicle's Secret Key data from the PCM.

13. Using the DRBIIIt, program all customer keys into the SKIM memory. This requires that

the SKIM be in Secured Access Mode, using the 4 digit PIN.

14. Note: If the PCM or ECM is replaced, the VIN and the unique Secret Key data must be

transferred from the SKIM to the PCM or ECM. This procedure requires the SKIM to be placed

in Secured Access Mode using the 4-digit PIN.

15. Note: If 3 attempts are made to enter Secured Access Mode using an incorrect PIN, Secured

Access Mode will be locked out for 1 hour which causes the DRBIIItto display9No Resp from

SKIM9. To exit this mode, turn ignition to Run for 1 hour.

16. Ensure that all accessories are turned off and the battery is fully charged.

17. Start and run the engine for 2 minutes. Operate all functions of the system that caused the

original concern.

18. Turn the ignition off and wait 5 seconds. Turn the ignition on and using the DRBIIIt, read

DTCs from ALL modules.

Are any DTC's present or is the original condition still present?All

Ye s®Repair is not complete, refer to the appropriate symptom.

No®Repair is complete.

990

VERIFICATION TESTS

Verification Tests ÐContinued

Page 1020 of 4284

CABIN HEATER VERIFICATION TEST - VER 1 APPLICABILITY

1. WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH AS A

GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILITIES. ALWAYS

VENT THE DCHA's EXHAUST WHEN OPERATING THE DCHA. FAILURE TO FOL-

LOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY OR DEATH.

2. WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORMING A

COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO FOLLOW

THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

3. NOTE: The DCHA Control will store up to three DTCs in its memory.

4. NOTE: If the DCHA Control detects a new fault in the DCHA system, one that is not

already stored in its memory, the DCHA Control will clear the oldest of the three

stored DTCs, and it will store the new fault's DTC.

5. NOTE: If the DCHA control detects a reoccurrence of a stored fault, the DCHA

control will overwrite that fault's DTC with the most recent occurrence.

6. Verify that the vehicle's battery is fully charged.

7. Verify that there is more than 1/8 of a tank of fuel in the vehicle's fuel tank. Add fuel, if

necessary.

8. Verify that all DCHA coolant hoses and fuel lines are securely fastened to their respective

components.

9. Disconnect all jumper wires and reconnect all previously disconnected components and

connectors.

10. If a heater installation/cooling system service was performed, purge the coolant circuit of

air in accordance with the Service Information.

11. Turn the ignition on.

12. Set the Blend Control to the max cool position.

13. Ensure that all accessories are turned off.

14. If a fuel system service requiring fuel to drain out of the DCHA fuel line was performed,

prime the DCHA Dosing Pump in accordance with the Service Information.

15. With the DRBIIIt, record and erase all DTCs from the Diesel Cabin Heater Assist (DCHA)

Control and the Front Control Module (FCM). Cycle the ignition off then on.

16. Start the engine.

17. Allow the engine to idle.

18. Turn the A/C - Heater Control Module's Power switch on.

19. Turn the Blower switch to the high speed position.

20. CAUTION: Do not activate the Diesel Cabin Heater Test with the engine off.

Failure to follow these instructions may result in internal damage to the DCHA

Heater Module.

21. NOTE: Do not disconnect the vehicle's battery or the DCHA's main power supply

while the DCHA is in operation or in run-down mode. Failure to follow these

instructions may result in excess emissions from the DCHA during heater operation.

22. NOTE: While performing the Diesel Cabin Heater Test, inspect the coolant and

fuel connections for leakage.

23. With the DRBIIItin HVAC, Systems Tests, select Diesel Cabin Heater Test and press #1.

24. Set the Blend Control to the max heat position. Allow the Diesel Cabin Heater Test to run

for five minutes. Upon completion of the test, proceed as follows:

25. Set the Blend Control to the max cool position.

26. Press #2 on the DRBIIItkeyboard.

27. Turn the Blower switch off.

28. Turn the A/C - Heater Control Module's Power switch off.

29. Turn the ignition off, wait 5 seconds, then turn the ignition on.

30. Using the DRBIIIt, read the Cabin Heater and Active FCM DTCs.

Are any DTC's present or is the original condition still present?All

Ye s®Repair is not complete, refer to the appropriate symptom.

No®Repair is complete.

991

VERIFICATION TESTS

Verification Tests ÐContinued

Page 1227 of 4284

4.3 WARNINGS AND CAUTIONS

4.3.1 ROAD TEST WARNINGS

Some complaints will require a test drive as part

of the repair verification procedure. The purpose of

the test drive is to try to duplicate the diagnostic

code or symptom condition.

CAUTION: BEFORE ROAD TESTING A

VEHICLE, BE SURE THAT ALL

COMPONENTS ARE REASSEMBLED. DUR-

ING THE TEST DRIVE, DO NOT HANG THE

DRBIIITFROM THE REAR VIEW MIRROR. DO

NOT ATTEMPT TO READ THE DRBIIITWHILE

DRIVING. HAVE AN ASSISTANT AVAILABLE

TO OPERATE THE DRBIIIT.

4.3.2 VEHICLE DAMAGE CAUTIONS

Before disconnecting any control module, make

sure the ignition is off. Failure to do so could

damage the module. When testing voltage or circuit

integrity at any control module, use the terminal

side (not the wire end) of the harness connector. Do

not probe through the insulation; this will damage

it and eventually cause it to fail because of corro-

sion.

Be careful when performing electrical test so as to

prevent accidental shorting of terminals. Such a

mistake can damage fuses or components. Also, a

second code could be set, making diagnosis of the

original problem more difficult.

5.0 REQUIRED TOOLS AND

EQUIPMENT

DRBIIIt(diagnostic read-out box) scan tool

vacuum gauge

ammeter

ohmmeter

jumper wires and probes

oscilloscope

6.0 GLOSSARY OF TERMS

A/Cair conditioning

APPaccelerator pedal position (sensor)

backfire,

popbackfuel ignites in either the intake or

the exhaust system

BCMbody control module

BPboost pressure (sensor)CKPcrankshaft position (sensor)

CMPcamshaft position (sensor)

cuts out,

missesa steady pulsation or the inability of

the engine to maintain a consistent

rpm

DLCdata link connector

detona-

tion,

spark

knocka mild to severe ping, especially un-

der loaded engine conditions

ECMengine control module

ECTengine coolant temperature (sensor)

EGRexhaust gas recirculation

(solenoid/valve)

hard

startthe engine takes longer than usual

to start, even though it is able to

crank at normal speed.

IATintake air temperature (sensor)

IPMintelligent power module

lack of

power,

sluggishthe engine power output has been

reduced

MAFmass air flow (sensor)

MILmalfunction indicator lamp

msmillisecond(s)

PDCpower distribution center

poor fuel

economythere is significantly less fuel mile-

age than other vehicles of the same

design and configuration

runs

rough/

unstable

idlethe engine runs unevenly at idle

causing the engine to shake if it is

severe enough

S/Cspeed control

SKIMsentry key immobilizer module

SKISsentry key immobilizer system

start and

stallThe engine starts but immediately

dies (stalls)

surgeengine rpm fluctuation without cor-

responding change in accelerator

pedal position

SRCsignal range check

WIFwater in fuel (sensor)

VSSvehicle speed sensor

8

GENERAL INFORMATION

Page 1329 of 4284

Symptom:

P0520-OIL PRESS SENSOR CKT MALF SUPPLY VOLTAGE TOO

HIGH OR LOW

When Monitored and Set Condition:

P0520-OIL PRESS SENSOR CKT MALF SUPPLY VOLTAGE TOO HIGH OR LOW

When Monitored: With the ignition on.

Set Condition: The Sensor Reference Voltage9A9voltage to the Oil Pressure Sensor is

below 4.8 volts or above 5.2 volts for at least 100 ms.

POSSIBLE CAUSES

INTERMITTENT CONDITION

5-VOLT SUPPLY CIRCUIT SHORTED TO GROUND

5-VOLT SUPPLY CIRCUIT SHORTED TO SENSOR GROUND

5-VOLT SUPPLY CIRCUIT SHORTED TO VOLTAGE

ENGINE CONTROL MODULE

TEST ACTION APPLICABILITY

1NOTE: If DTC P0641 or P0651 is present with this DTC, diagnose DTCs

P0641 and P0651 before diagnosing this DTC.

Turn the ignition on.

With the DRB, erase ECM DTCs.

Turn the ignition off, wait 30 seconds, then start and idle the engine.

With the DRB, read ECM DTCs.

Did this DTC reset?All

Ye s®Go To 2

No®Go To 5

2 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the ECM/PCM Relay from the PDC.

Connect a jumper wire between cavity 30 and cavity 87 of the ECM/PCM Relay

connector.

Disconnect the Oil Pressure Sensor harness connector.

Turn the ignition on.

Measure the voltage between ground and the 5-volt Supply circuit at the Oil Pressure

Sensor harness connector.

Is the voltage above 1.0 volt?All

Ye s®Repair the 5-volt Supply circuit for a short to voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 3

11 0

DRIVEABILITY - DIESEL

Page 1332 of 4284

POSSIBLE CAUSES

A/C PRESSURE SENSOR SIGNAL CIRCUIT SHORTED TO SENSOR GROUND CIRCUIT

ECM - 5-VOLT SUPPLY CIRCUIT

ECM - A/C PRESSURE SENSOR SIGNAL

ECM - SIGNAL VOLTAGE HIGH

TEST ACTION APPLICABILITY

1NOTE: If DTC P0641 or P0651 is present with this DTC, diagnose DTCs

P0641 and P0651 before diagnosing this DTC.

NOTE: Ensure the A/C refrigerant System is properly charged per the

Service Information.

Start the engine.

With the DRBIIIt, read the A/C Pressure Sensor voltage.

Select the choice that best reflects the DRBIIItreading.All

Above 4.6 volts

Go To 2

Between 0.7 and 4.6 volts

Go To 9

Below 0.7 volt

Go To 10

2 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Disconnect the ECM harness connector.

Measure the resistance between the A/C Pressure Sensor Signal circuit and the 5-volt

Supply circuit in the A/C Pressure Sensor harness connector.

Is the resistance above 100k ohms?All

Ye s®Go To 3

No®Repair the A/C Pressure Sensor Signal circuit for a short to the

5-volt Supply circuit.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the A/C Pressure Sensor harness connector.

Disconnect the ECM harness connectors.

Remove the ECM/PCM Relay from the PDC.

Connect a jumper wire between cavity 30 and cavity 87 of the ECM/PCM Relay

connector.

Turn the ignition on.

Measure the voltage of the Sensor Ground circuit at the A/C Pressure Sensor and

ECM harness connectors.

Is the voltage above 1.0 volt at either connector?All

Ye s®Repair the A/C Pressure Sensor Ground circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

No®Go To 4

NOTE: If the Sensor Ground circuit had a short to voltage on it, the ECM

may have been damaged. Retest the A/C Pressure Sensor circuit.

11 3

DRIVEABILITY - DIESEL

P0530-A/C PRESSURE SENSOR CIRCUIT PLAUSIBILITY ÐContinued

Page 1378 of 4284

TEST ACTION APPLICABILITY

1WARNING: THE FUEL INJECTION PUMP SUPPLIES HIGH PRESSURE

FUEL TO EACH INDIVIDUAL INJECTOR THROUGH HIGH-PRESSURE

FUEL LINES. FUEL UNDER HIGH PRESSURE CAN PENETRATE SKIN

AND CAUSE PERSONAL INJURY. WEAR SAFETY GOGGLES AND ADE-

QUATE PROTECTIVE CLOTHING.

Turn the ignition on.

With the DRB, erase ECM DTCs.

Start the engine several times, turning the ignition off for at least 30 seconds

between each run cycle.

Monitor the DRB for ECM DTCs.

Did this DTC reset?All

Ye s®Go To 2

No®Go To 8

2 Turn the ignition off.

Disconnect the Fuel Pressure Solenoid harness connector.

Turn the ignition on.

Using a 12-volt test light connected to ground, check the ECM/PCM Relay Output

circuit.

Does the test light illuminate brightly?All

Ye s®Go To 3

No®Repair the ECM/PCM Relay Output circuit for an open.

Perform ROAD TEST VERIFICATION - VER-2.

3 Turn the ignition off.

Disconnect the Fuel Pressure Solenoid harness connector.

Disconnect the ECM harness connectors.

Remove the ECM/PCM Relay from the PDC.

Connect a jumper wire between cavity 30 and cavity 87 of the ECM/PCM Relay

connector.

Turn the ignition on.

Measure the voltage of the Fuel Pressure Solenoid Control circuit.

Is the voltage below 1.0 volt?All

Ye s®Go To 4

No®Repair the Fuel Pressure Solenoid Control circuit for a short to

voltage.

Perform ROAD TEST VERIFICATION - VER-2.

4 Turn the ignition off.

Disconnect the Fuel Pressure Solenoid harness connector.

Disconnect the ECM harness connectors.

Measure the resistance between ground and the Fuel Pressure Solenoid Control

circuit.

NOTE: The Fuel Pressure Solenoid Control circuit is duplicated at ECM

cavities C2-80 and C2-81.

Is the resistance above 100k ohms?All

Ye s®Go To 5

No®Repair the Fuel Pressure Solenoid Control circuit for a short to

ground.

Perform ROAD TEST VERIFICATION - VER-2.

159

DRIVEABILITY - DIESEL

P1131-FUEL PRESSURE SOLENOID OPEN CIRCUIT ÐContinued

Page 1430 of 4284

TEST ACTION APPLICABILITY

3 Turn the ignition off.

Remove the Starter Relay from the PDC.

WARNING: THE TRANSMISSION MUST BE IN NEUTRAL AND THE PARK

BRAKE MUST BE SET FOR THIS TEST.

WARNING: THE ENGINE MAY CRANK IN THE NEXT STEP. WHEN THE

ENGINE IS CRANKING, DO NOT STAND IN A DIRECT LINE WITH THE

FAN. DO NOT PUT YOUR HANDS NEAR THE PULLEYS, BELTS OR FAN.

DO NOT WEAR LOOSE CLOTHING.

Momentarily jumper Starter Relay connector cavities 30 and 87 in the IPM

connector.

Did the engine crank?All

Ye s®Go To 4

No®Go To 11

4 Remove the Starter Relay from the PDC.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit while fully depressing the clutch pedal and turning the ignition switch

to the START position.

Does the test light illuminate with the ignition switch in the START position?All

Ye s®Go To 5

No®Go To 9

5 Turn the ignition off.

Remove the Starter Relay From the PDC.

Install a substitute relay in place of the Starter Relay.

Attempt to start the engine.

Does the engine crank?All

Ye s®Replace the Starter Relay.

Perform NO START VERIFICATION - VER-1.

No®Go To 6

6 Turn the ignition off.

Disconnect the ECM harness connectors.

Using a 12-volt test light connected to ground, probe ECM harness connector cavity

49 while fully depressing the clutch pedal and turning the ignition switch to the

START position.

Does the test light illuminate while the ignition is in the Start position.All

Ye s®Go To 7

No®Repair the Ignition Switch Start Output circuit to the ECM.

Perform NO START VERIFICATION - VER-1.

211

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1431 of 4284

TEST ACTION APPLICABILITY

7 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Remove the ECM/PCM Relay from the IPM.

Using a jumper wire, connect ECM/PCM relay connector cavities 30 and 87 in the

IPM.

Turn the ignition on.

Measure the voltage of the Starter Relay Control circuit.

Is the voltage above 1.0 volt?All

Ye s®Repair the Starter Relay Control circuit for a short to voltage.

Perform NO START VERIFICATION - VER-1.

No®Go To 8

8 Turn the ignition off.

Disconnect the ECM harness connectors.

Remove the Starter Relay from the IPM.

Turn the ignition on.

Measure the resistance of the Starter Relay Control circuit.

Is the resistance below 10.0 ohms?All

Ye s®Replace and program the ECM in accordance with the Service

Information.

Perform NO START VERIFICATION - VER-1.

No®Repair the Starter Relay Control circuit for an open.

Perform NO START VERIFICATION - VER-1.

9 Turn the ignition off.

Remove the Starter Relay from the PDC.

Disconnect the Clutch Interlock Switch harness connector.

Connect a jumper wire across the Clutch Interlock Switch harness connector.

Using a 12-volt test light connected to ground, check the Ignition Switch Start

Output circuit at the Starter Relay connector in the PDC and turning the ignition

switch to the crank position.

Does the test light illuminate with the ignition switch in the crank position?All

Ye s®Replace the Clutch Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Go To 10

10 Turn the ignition off.

Disconnect the Clutch Interlock Switch harness connector.

Remove the Starter Relay from the PDC.

Measure the resistance of the Clutch Interlock Switch Output circuit between the

PDC and the Clutch Interlock Switch harness connector.

Is the resistance below 10.0 ohms?All

Ye s®Repair the Ignition Switch Start Output circuit to the Clutch

Interlock Switch.

Perform NO START VERIFICATION - VER-1.

No®Repair the Clutch Interlock Switch Output circuit for an open.

Perform NO START VERIFICATION - VER-1.

212

DRIVEABILITY - DIESEL

*ENGINE WILL NOT CRANK ÐContinued

Page 1489 of 4284

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE

SPECIFICATIONS.........................1

INTERNATIONAL SYMBOLS

DESCRIPTION............................1

PARTS & LUBRICANT RECOMMENDATION

STANDARD PROCEDURE...................2

LUBRICANT CLASSIFICATIONS.............2

PARTS AND LUBRICANT

RECOMMENDATIONS....................2

FLUID TYPES

DESCRIPTION............................3

OPERATION.............................7

FLUID FILL/CHECK LOCATIONS

DESCRIPTION............................7MAINTENANCE SCHEDULES

DESCRIPTION............................7

HOISTING

STANDARD PROCEDURE..................16

HOISTING............................16

JUMP STARTING

STANDARD PROCEDURE..................16

JUMP STARTING.......................16

TOWING

STANDARD PROCEDURE..................17

TOWING RECOMMENDATIONS............17

LUBRICATION &

MAINTENANCE

SPECIFICATIONS

SPECIFICATIONS - FLUID CAPACITIES

DESCRIPTION SPECIFICATION

Fuel Tank 75 L (20 gal.)

Engine Oil* - 2.4L 4.7 L (5.0 qts.)

Engine Oil* - 3.3/3.8L 4.0 L (4.5 qts.)

Cooling System** - 2.4L 10.7 L (11.4 qts.)

Cooling System** -

3.3/3.8L without Rear

Heater12.6 L (13.4 qts.)

Cooling System** -

3.3/3.8L with Rear Heater15.4 L (16.3 qts.)

Automatic Transaxle -

Service Fill3.8 L (4.0 qts.)

Automatic Transaxle -

31TH Overhaul Fill8.6 L (9.1 qts.)

Automatic Transaxle -

41TE Overhaul Fill9.2 L (9.7 qts.)

AWD Power Transfer Unit 1.15 L (2.4 pts.)

Power Steering 1.2 L (2.5 pts.)

AWD Bi-directional

Overrunning Clutch0.575 L (1.22 pts.)

DESCRIPTION SPECIFICATION

AWD Rear Carrier 0.7 L (1.48 pts.)

*(includes oil filter)

**(includes heater and recovery/reserve bottle)

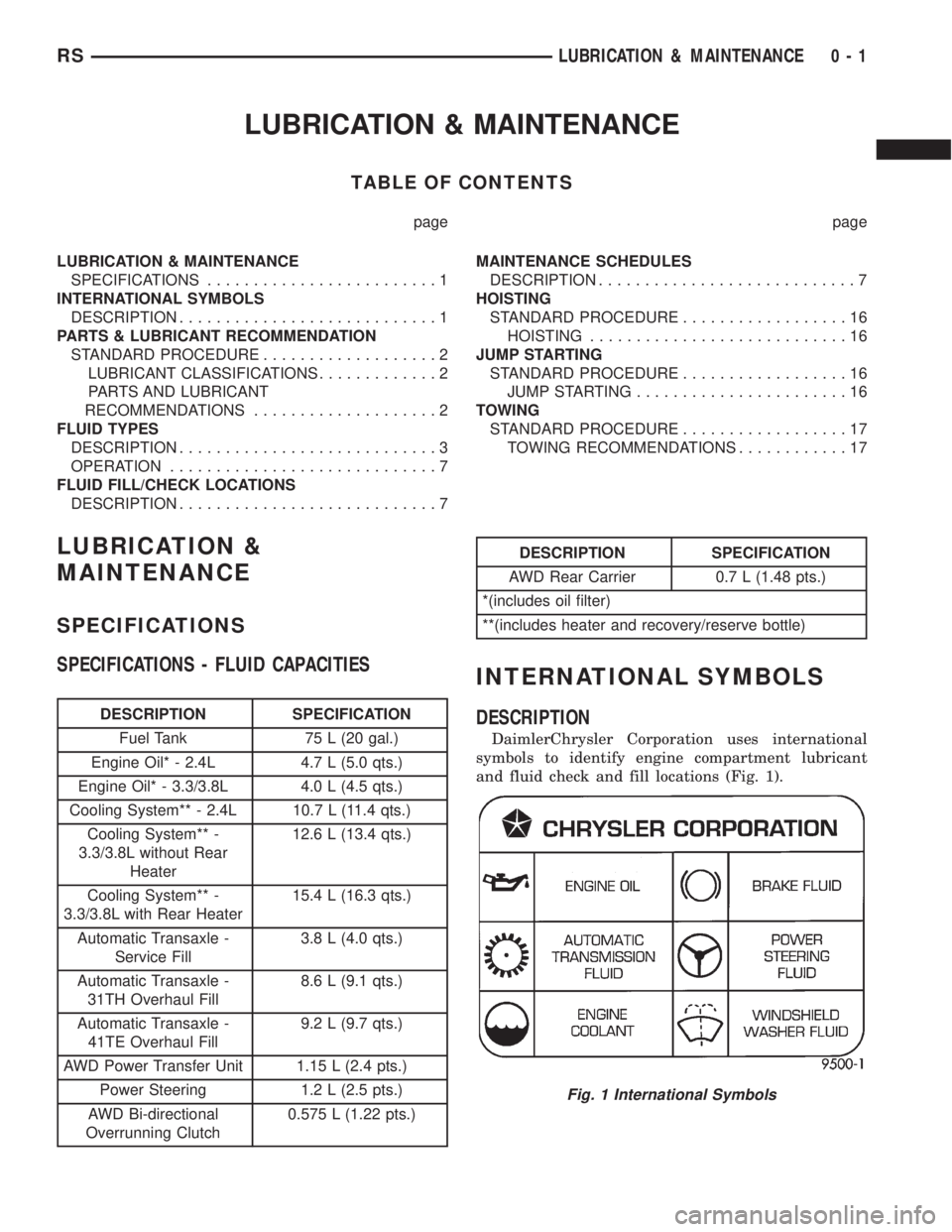

INTERNATIONAL SYMBOLS

DESCRIPTION

DaimlerChrysler Corporation uses international

symbols to identify engine compartment lubricant

and fluid check and fill locations (Fig. 1).

Fig. 1 International Symbols

RSLUBRICATION & MAINTENANCE0-1