length CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 40 of 4284

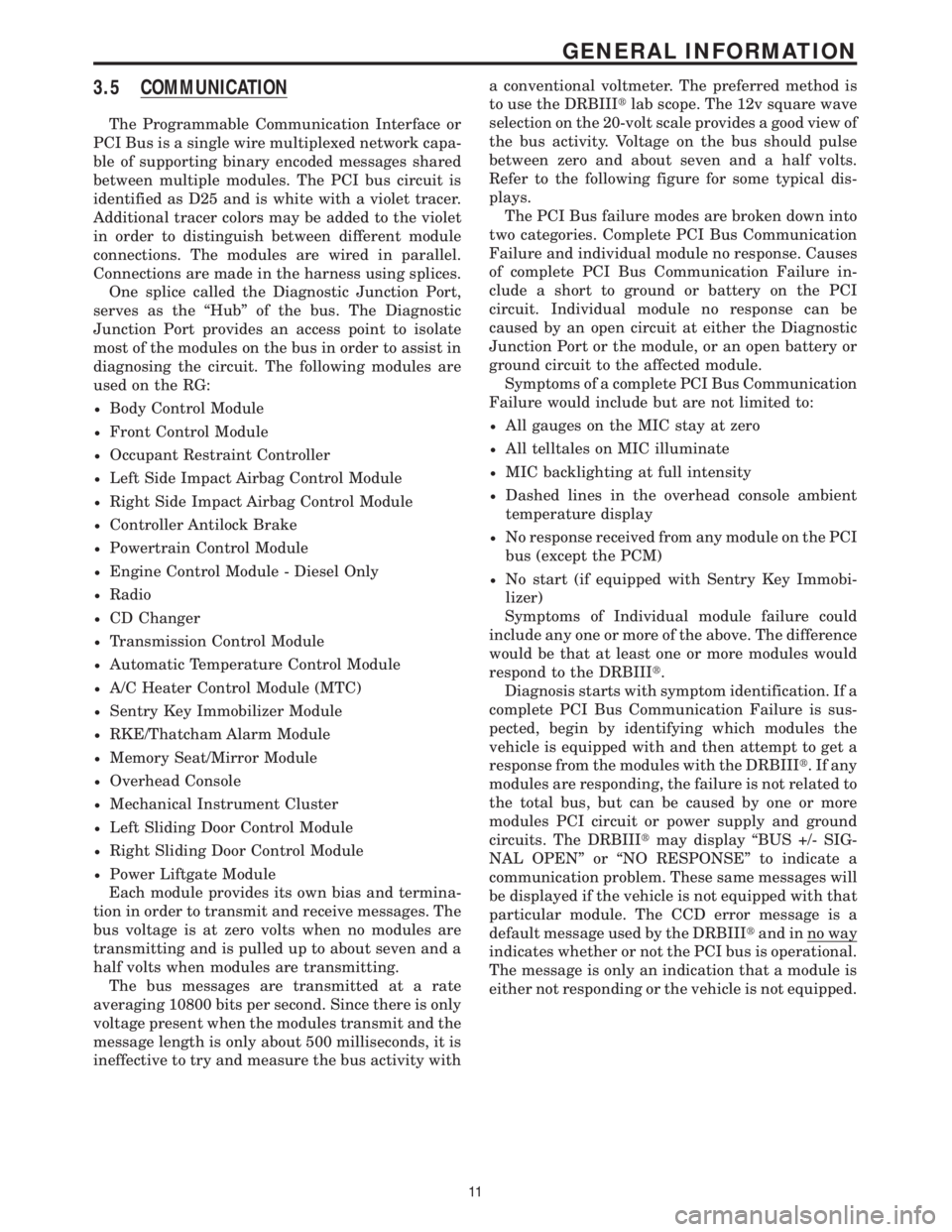

3.5 COMMUNICATION

The Programmable Communication Interface or

PCI Bus is a single wire multiplexed network capa-

ble of supporting binary encoded messages shared

between multiple modules. The PCI bus circuit is

identified as D25 and is white with a violet tracer.

Additional tracer colors may be added to the violet

in order to distinguish between different module

connections. The modules are wired in parallel.

Connections are made in the harness using splices.

One splice called the Diagnostic Junction Port,

serves as the ªHubº of the bus. The Diagnostic

Junction Port provides an access point to isolate

most of the modules on the bus in order to assist in

diagnosing the circuit. The following modules are

used on the RG:

²Body Control Module

²Front Control Module

²Occupant Restraint Controller

²Left Side Impact Airbag Control Module

²Right Side Impact Airbag Control Module

²Controller Antilock Brake

²Powertrain Control Module

²Engine Control Module - Diesel Only

²Radio

²CD Changer

²Transmission Control Module

²Automatic Temperature Control Module

²A/C Heater Control Module (MTC)

²Sentry Key Immobilizer Module

²RKE/Thatcham Alarm Module

²Memory Seat/Mirror Module

²Overhead Console

²Mechanical Instrument Cluster

²Left Sliding Door Control Module

²Right Sliding Door Control Module

²Power Liftgate Module

Each module provides its own bias and termina-

tion in order to transmit and receive messages. The

bus voltage is at zero volts when no modules are

transmitting and is pulled up to about seven and a

half volts when modules are transmitting.

The bus messages are transmitted at a rate

averaging 10800 bits per second. Since there is only

voltage present when the modules transmit and the

message length is only about 500 milliseconds, it is

ineffective to try and measure the bus activity witha conventional voltmeter. The preferred method is

to use the DRBIIItlab scope. The 12v square wave

selection on the 20-volt scale provides a good view of

the bus activity. Voltage on the bus should pulse

between zero and about seven and a half volts.

Refer to the following figure for some typical dis-

plays.

The PCI Bus failure modes are broken down into

two categories. Complete PCI Bus Communication

Failure and individual module no response. Causes

of complete PCI Bus Communication Failure in-

clude a short to ground or battery on the PCI

circuit. Individual module no response can be

caused by an open circuit at either the Diagnostic

Junction Port or the module, or an open battery or

ground circuit to the affected module.

Symptoms of a complete PCI Bus Communication

Failure would include but are not limited to:

²All gauges on the MIC stay at zero

²All telltales on MIC illuminate

²MIC backlighting at full intensity

²Dashed lines in the overhead console ambient

temperature display

²No response received from any module on the PCI

bus (except the PCM)

²No start (if equipped with Sentry Key Immobi-

lizer)

Symptoms of Individual module failure could

include any one or more of the above. The difference

would be that at least one or more modules would

respond to the DRBIIIt.

Diagnosis starts with symptom identification. If a

complete PCI Bus Communication Failure is sus-

pected, begin by identifying which modules the

vehicle is equipped with and then attempt to get a

response from the modules with the DRBIIIt.Ifany

modules are responding, the failure is not related to

the total bus, but can be caused by one or more

modules PCI circuit or power supply and ground

circuits. The DRBIIItmay display ªBUS +/- SIG-

NAL OPENº or ªNO RESPONSEº to indicate a

communication problem. These same messages will

be displayed if the vehicle is not equipped with that

particular module. The CCD error message is a

default message used by the DRBIIItand in no way

indicates whether or not the PCI bus is operational.

The message is only an indication that a module is

either not responding or the vehicle is not equipped.

11

GENERAL INFORMATION

Page 331 of 4284

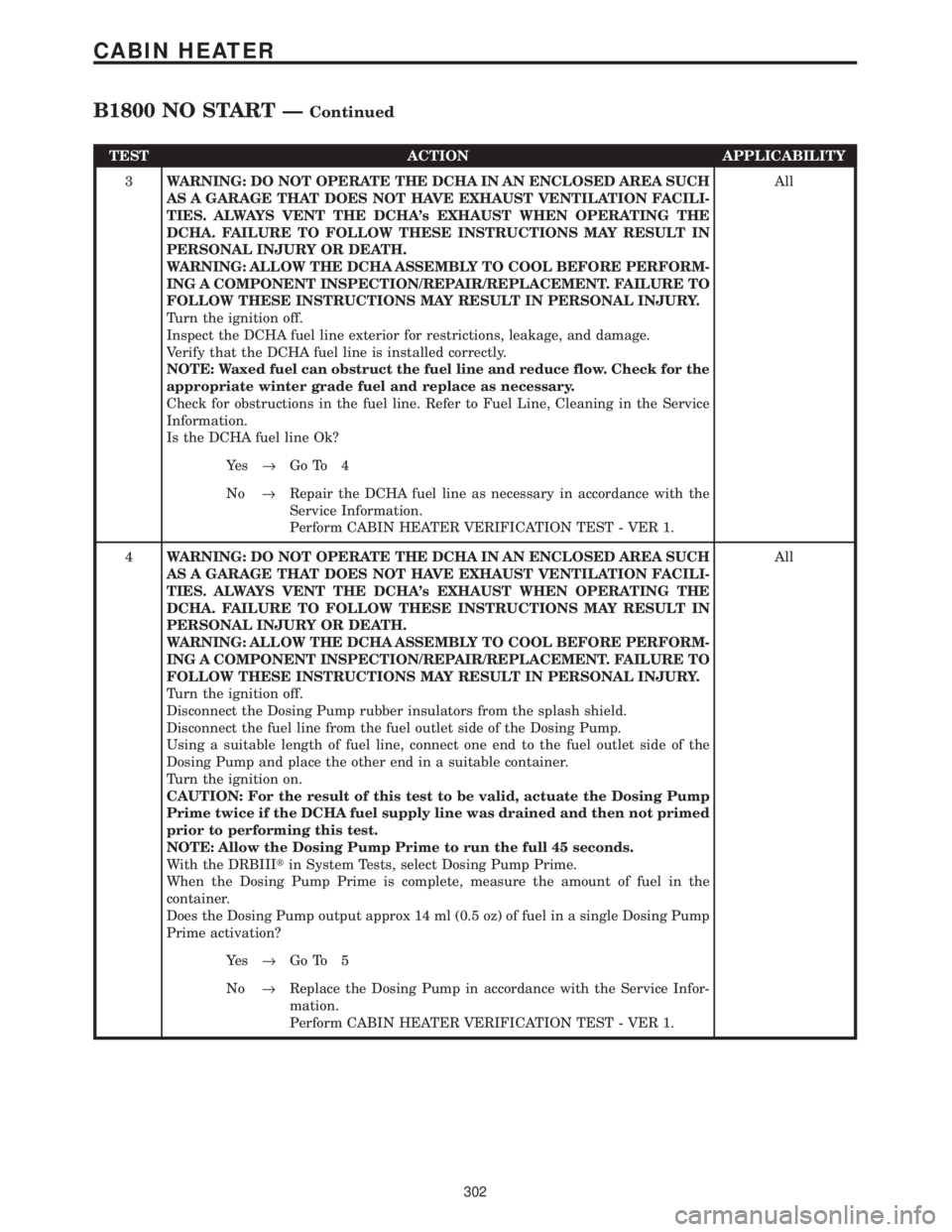

TEST ACTION APPLICABILITY

3WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORM-

ING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Turn the ignition off.

Inspect the DCHA fuel line exterior for restrictions, leakage, and damage.

Verify that the DCHA fuel line is installed correctly.

NOTE: Waxed fuel can obstruct the fuel line and reduce flow. Check for the

appropriate winter grade fuel and replace as necessary.

Check for obstructions in the fuel line. Refer to Fuel Line, Cleaning in the Service

Information.

Is the DCHA fuel line Ok?All

Ye s®Go To 4

No®Repair the DCHA fuel line as necessary in accordance with the

Service Information.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

4WARNING: DO NOT OPERATE THE DCHA IN AN ENCLOSED AREA SUCH

AS A GARAGE THAT DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA's EXHAUST WHEN OPERATING THE

DCHA. FAILURE TO FOLLOW THESE INSTRUCTIONS MAY RESULT IN

PERSONAL INJURY OR DEATH.

WARNING: ALLOW THE DCHA ASSEMBLY TO COOL BEFORE PERFORM-

ING A COMPONENT INSPECTION/REPAIR/REPLACEMENT. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN PERSONAL INJURY.

Turn the ignition off.

Disconnect the Dosing Pump rubber insulators from the splash shield.

Disconnect the fuel line from the fuel outlet side of the Dosing Pump.

Using a suitable length of fuel line, connect one end to the fuel outlet side of the

Dosing Pump and place the other end in a suitable container.

Turn the ignition on.

CAUTION: For the result of this test to be valid, actuate the Dosing Pump

Prime twice if the DCHA fuel supply line was drained and then not primed

prior to performing this test.

NOTE: Allow the Dosing Pump Prime to run the full 45 seconds.

With the DRBIIItin System Tests, select Dosing Pump Prime.

When the Dosing Pump Prime is complete, measure the amount of fuel in the

container.

Does the Dosing Pump output approx 14 ml (0.5 oz) of fuel in a single Dosing Pump

Prime activation?All

Ye s®Go To 5

No®Replace the Dosing Pump in accordance with the Service Infor-

mation.

Perform CABIN HEATER VERIFICATION TEST - VER 1.

302

CABIN HEATER

B1800 NO START ÐContinued

Page 1174 of 4284

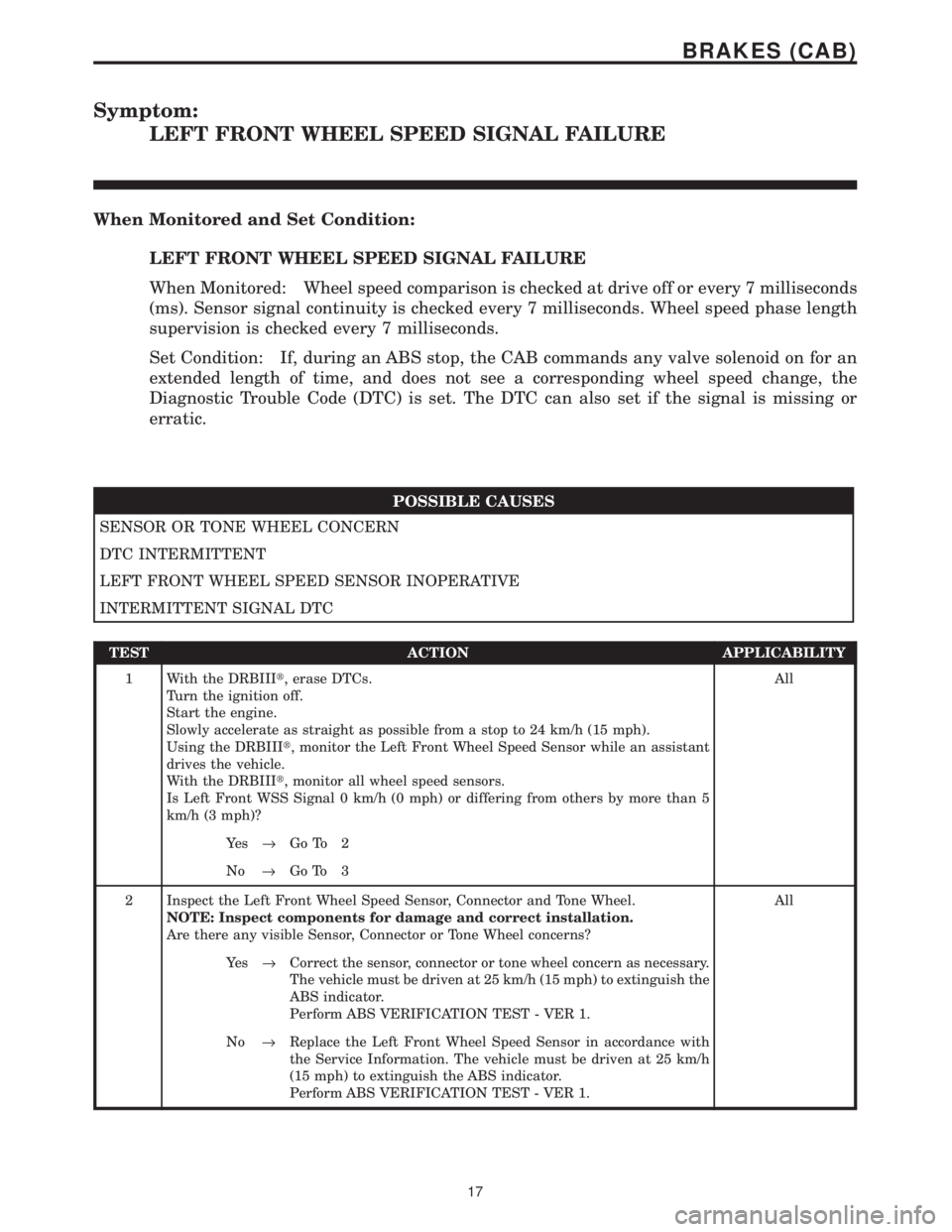

Symptom:

LEFT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

LEFT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Sensor signal continuity is checked every 7 milliseconds. Wheel speed phase length

supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

LEFT FRONT WHEEL SPEED SENSOR INOPERATIVE

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Left Front Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Left Front WSS Signal 0 km/h (0 mph) or differing from others by more than 5

km/h (3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Left Front Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Left Front Wheel Speed Sensor in accordance with

the Service Information. The vehicle must be driven at 25 km/h

(15 mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

17

BRAKES (CAB)

Page 1176 of 4284

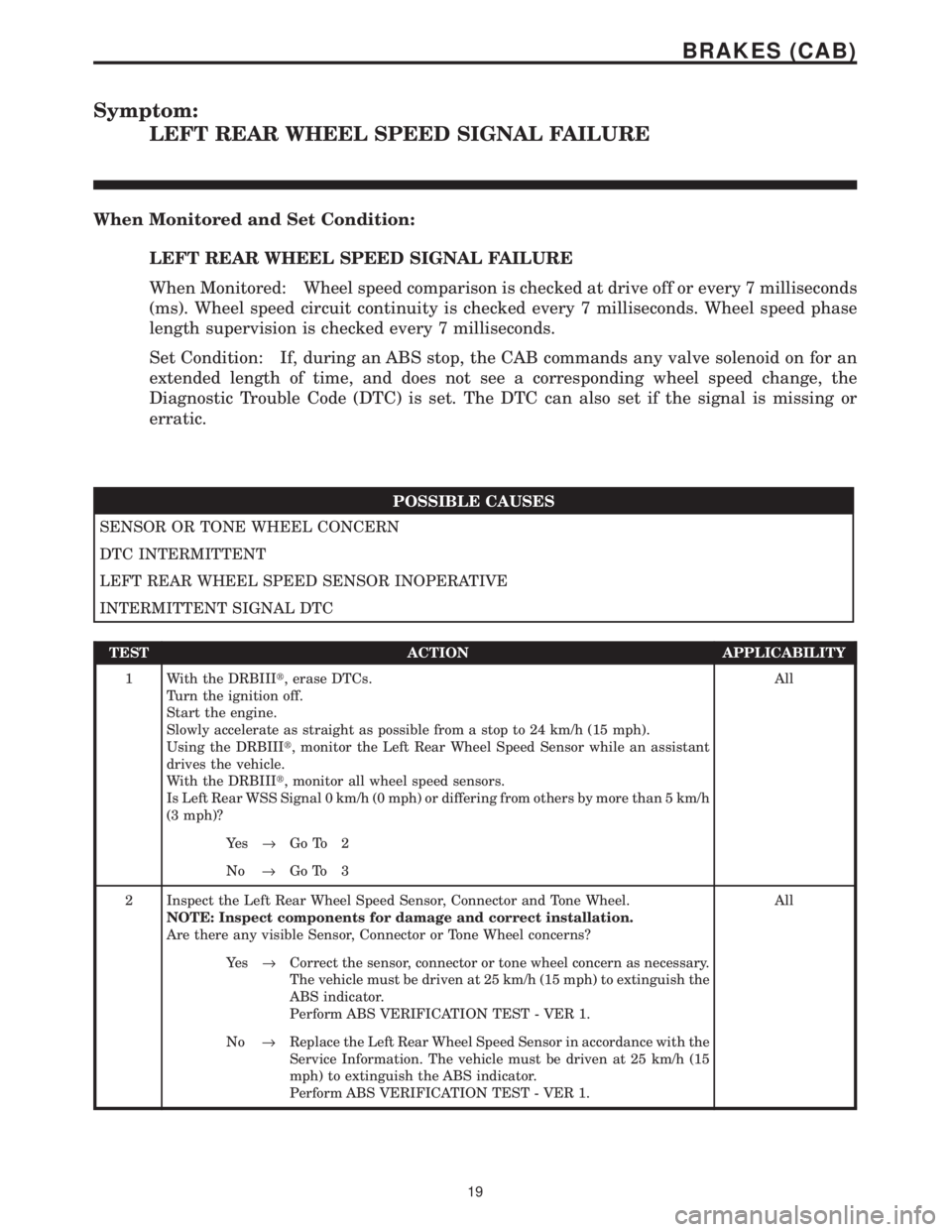

Symptom:

LEFT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

LEFT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Wheel speed circuit continuity is checked every 7 milliseconds. Wheel speed phase

length supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

LEFT REAR WHEEL SPEED SENSOR INOPERATIVE

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Left Rear Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Left Rear WSS Signal 0 km/h (0 mph) or differing from others by more than 5 km/h

(3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Left Rear Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Left Rear Wheel Speed Sensor in accordance with the

Service Information. The vehicle must be driven at 25 km/h (15

mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

19

BRAKES (CAB)

Page 1181 of 4284

Symptom:

RIGHT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

RIGHT FRONT WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Wheel speed continuity is checked every 7 milliseconds. Wheel speed phase length

supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

RIGHT FRONT WHEEL SPEED SENSOR INOPERATIVE

CAB - WON'T RESPOND TO RIGHT FRONT WHEEL SPEED SENSOR SIGNAL

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Right Front Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Right Front WSS Signal 0 km/h (0 mph) or differing from others by more than 5

km/h (3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Right Front Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Right Front Wheel Speed Sensor in accordance with

the Service Information. The vehicle must be driven at 25 km/h

(15 mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

24

BRAKES (CAB)

Page 1183 of 4284

Symptom:

RIGHT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored and Set Condition:

RIGHT REAR WHEEL SPEED SIGNAL FAILURE

When Monitored: Wheel speed comparison is checked at drive off or every 7 milliseconds

(ms). Wheel speed circuit continuity is checked every 7 milliseconds. Wheel speed phase

length supervision is checked every 7 milliseconds.

Set Condition: If, during an ABS stop, the CAB commands any valve solenoid on for an

extended length of time, and does not see a corresponding wheel speed change, the

Diagnostic Trouble Code (DTC) is set. The DTC can also set if the signal is missing or

erratic.

POSSIBLE CAUSES

SENSOR OR TONE WHEEL CONCERN

DTC INTERMITTENT

RIGHT REAR WHEEL SPEED SENSOR INOPERATIVE

INTERMITTENT SIGNAL DTC

TEST ACTION APPLICABILITY

1 With the DRBIIIt, erase DTCs.

Turn the ignition off.

Start the engine.

Slowly accelerate as straight as possible from a stop to 24 km/h (15 mph).

Using the DRBIIIt, monitor the Right Rear Wheel Speed Sensor while an assistant

drives the vehicle.

With the DRBIIIt, monitor all wheel speed sensors.

Is Right Rear WSS Signal 0 km/h (0 mph) or differing from others by more than 5

km/h (3 mph)?All

Ye s®Go To 2

No®Go To 3

2 Inspect the Right Rear Wheel Speed Sensor, Connector and Tone Wheel.

NOTE: Inspect components for damage and correct installation.

Are there any visible Sensor, Connector or Tone Wheel concerns?All

Ye s®Correct the sensor, connector or tone wheel concern as necessary.

The vehicle must be driven at 25 km/h (15 mph) to extinguish the

ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

No®Replace the Left Rear Wheel Speed Sensor in accordance with the

Service Information. The vehicle must be driven at 25 km/h (15

mph) to extinguish the ABS indicator.

Perform ABS VERIFICATION TEST - VER 1.

26

BRAKES (CAB)

Page 1529 of 4284

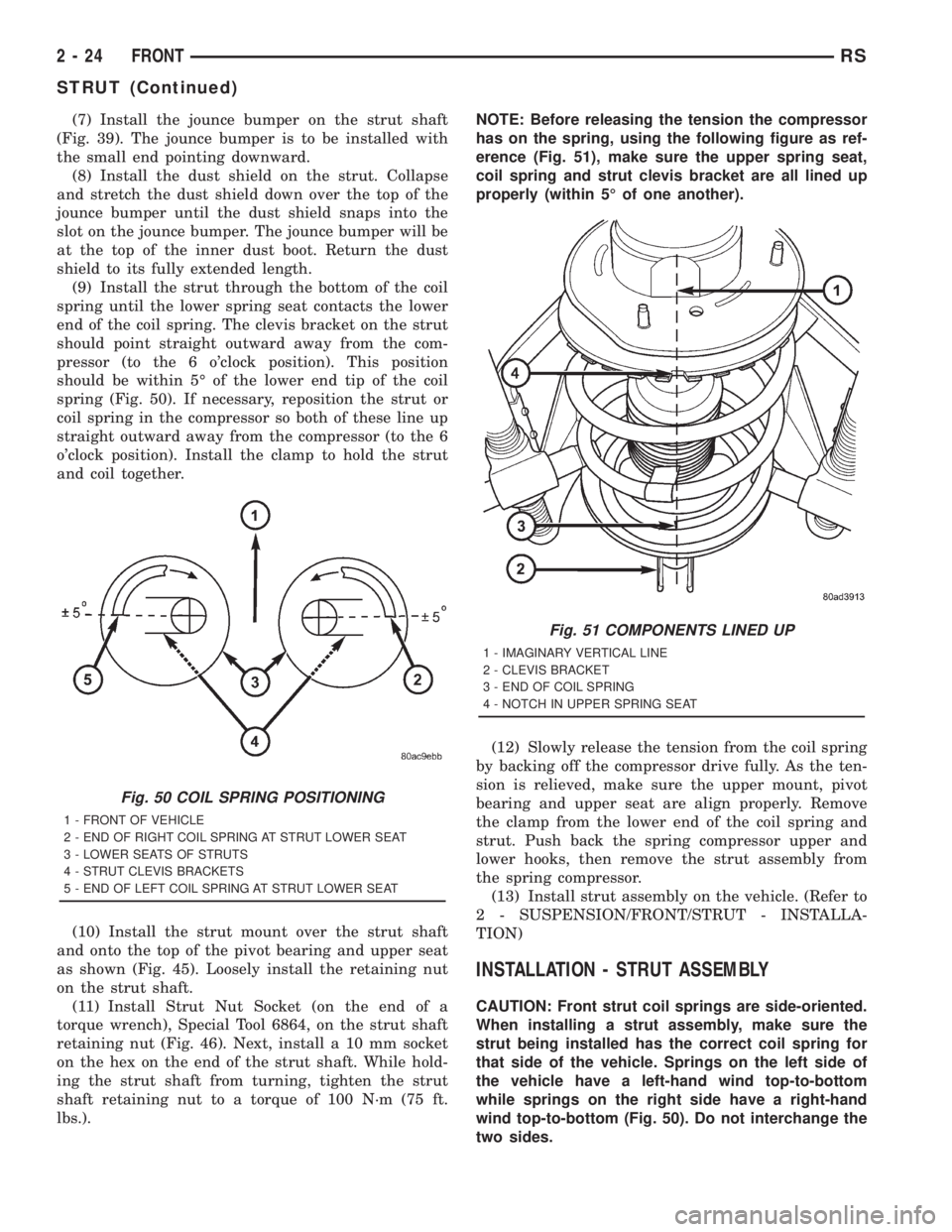

(3) Using a sharp knife (such as a razor), slit the

bushing lengthwise (Fig. 24) to allow its removal

from the lower control arm (Fig. 24).

(4) Remove the bushing from the lower control

arm.

DISASSEMBLY - LOWER CONTROL ARM

(REAR BUSHING - HYDRO)

(1) Remove the lower control arm from the front

suspension cradle. (Refer to 2 - SUSPENSION/

FRONT/LOWER CONTROL ARM - REMOVAL)

(2) Mount the lower control arm in a visewithout

using excessive clamping force.

(3) Install Remover, Special Tool 8460, on hydro-

bushing as shown (Fig. 25). Removal Pin, Special

Tool 8460±3, must extend though hole in center of

bushing rear.(4) Tighten forcing screw of Bridge (Special Tool

8460±1), removing bushing from lower control arm.INSPECTION - LOWER CONTROL ARM

Inspect lower control arm for signs of damage from

contact with the ground or road debris. If lower con-

trol arm shows any sign of damage, inspect lower

control arm for distortion. Do not attempt to repair

or straighten a broken or bent lower control arm. If

damaged, the lower control arm casting is serviced

only as a complete component.

Inspect both lower control arm isolator bushings

for severe deterioration, and replace as required.

Inspect the rear hydro-bushing for seepage. Both

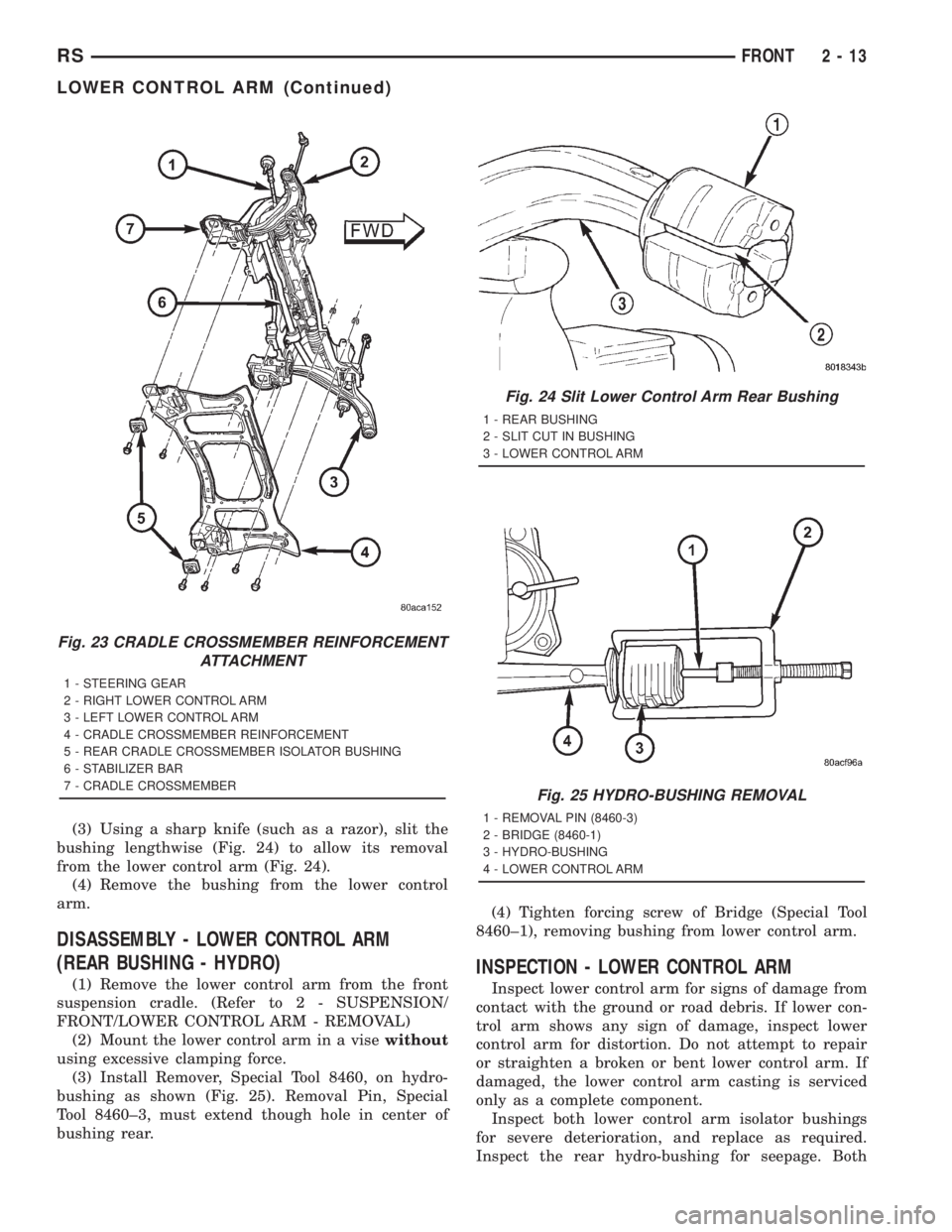

Fig. 23 CRADLE CROSSMEMBER REINFORCEMENT

ATTACHMENT

1 - STEERING GEAR

2 - RIGHT LOWER CONTROL ARM

3 - LEFT LOWER CONTROL ARM

4 - CRADLE CROSSMEMBER REINFORCEMENT

5 - REAR CRADLE CROSSMEMBER ISOLATOR BUSHING

6 - STABILIZER BAR

7 - CRADLE CROSSMEMBER

Fig. 24 Slit Lower Control Arm Rear Bushing

1 - REAR BUSHING

2 - SLIT CUT IN BUSHING

3 - LOWER CONTROL ARM

Fig. 25 HYDRO-BUSHING REMOVAL

1 - REMOVAL PIN (8460-3)

2 - BRIDGE (8460-1)

3 - HYDRO-BUSHING

4 - LOWER CONTROL ARM

RSFRONT2-13

LOWER CONTROL ARM (Continued)

Page 1540 of 4284

(7) Install the jounce bumper on the strut shaft

(Fig. 39). The jounce bumper is to be installed with

the small end pointing downward.

(8) Install the dust shield on the strut. Collapse

and stretch the dust shield down over the top of the

jounce bumper until the dust shield snaps into the

slot on the jounce bumper. The jounce bumper will be

at the top of the inner dust boot. Return the dust

shield to its fully extended length.

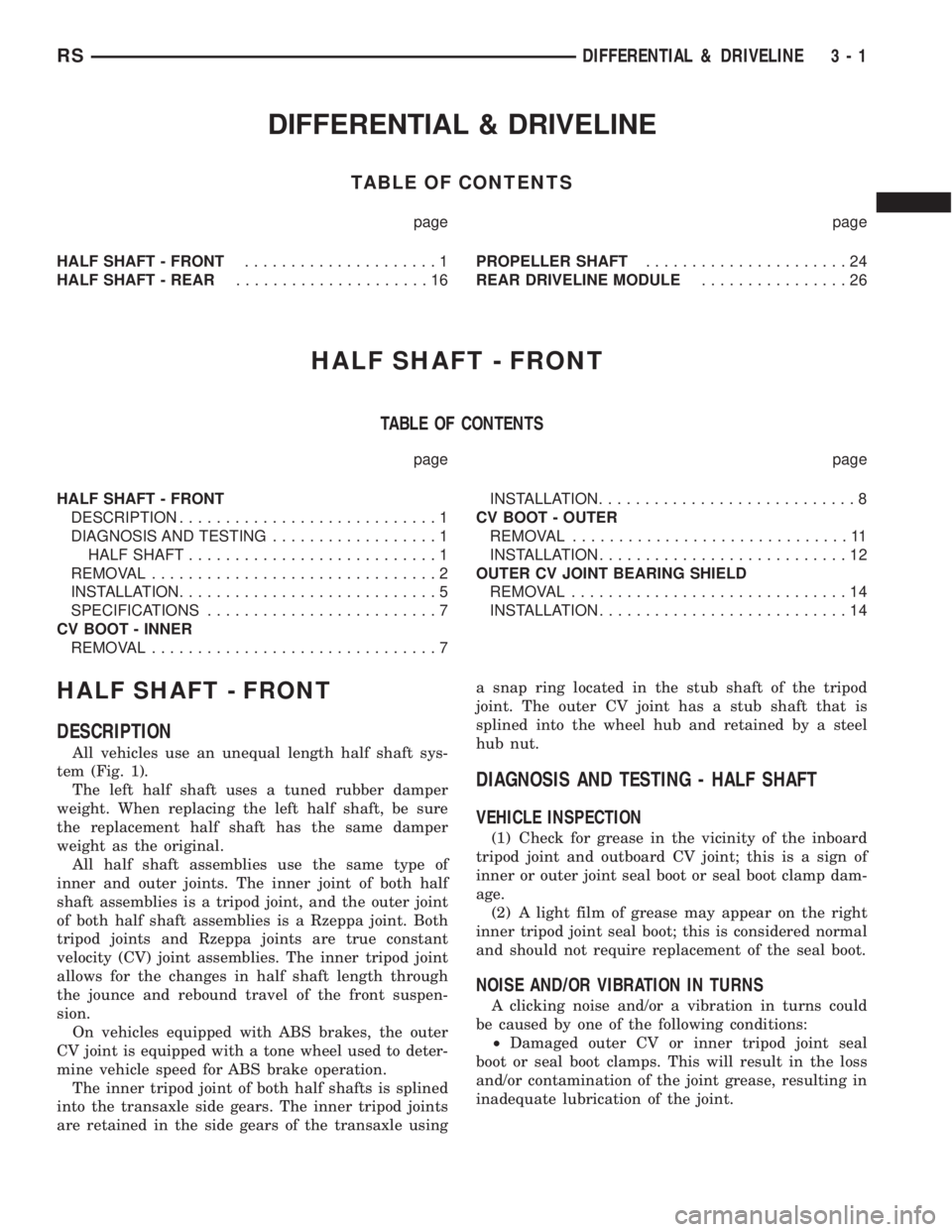

(9) Install the strut through the bottom of the coil

spring until the lower spring seat contacts the lower

end of the coil spring. The clevis bracket on the strut

should point straight outward away from the com-

pressor (to the 6 o'clock position). This position

should be within 5É of the lower end tip of the coil

spring (Fig. 50). If necessary, reposition the strut or

coil spring in the compressor so both of these line up

straight outward away from the compressor (to the 6

o'clock position). Install the clamp to hold the strut

and coil together.

(10) Install the strut mount over the strut shaft

and onto the top of the pivot bearing and upper seat

as shown (Fig. 45). Loosely install the retaining nut

on the strut shaft.

(11) Install Strut Nut Socket (on the end of a

torque wrench), Special Tool 6864, on the strut shaft

retaining nut (Fig. 46). Next, install a 10 mm socket

on the hex on the end of the strut shaft. While hold-

ing the strut shaft from turning, tighten the strut

shaft retaining nut to a torque of 100 N´m (75 ft.

lbs.).NOTE: Before releasing the tension the compressor

has on the spring, using the following figure as ref-

erence (Fig. 51), make sure the upper spring seat,

coil spring and strut clevis bracket are all lined up

properly (within 5É of one another).

(12) Slowly release the tension from the coil spring

by backing off the compressor drive fully. As the ten-

sion is relieved, make sure the upper mount, pivot

bearing and upper seat are align properly. Remove

the clamp from the lower end of the coil spring and

strut. Push back the spring compressor upper and

lower hooks, then remove the strut assembly from

the spring compressor.

(13) Install strut assembly on the vehicle. (Refer to

2 - SUSPENSION/FRONT/STRUT - INSTALLA-

TION)

INSTALLATION - STRUT ASSEMBLY

CAUTION: Front strut coil springs are side-oriented.

When installing a strut assembly, make sure the

strut being installed has the correct coil spring for

that side of the vehicle. Springs on the left side of

the vehicle have a left-hand wind top-to-bottom

while springs on the right side have a right-hand

wind top-to-bottom (Fig. 50). Do not interchange the

two sides.

Fig. 50 COIL SPRING POSITIONING

1 - FRONT OF VEHICLE

2 - END OF RIGHT COIL SPRING AT STRUT LOWER SEAT

3 - LOWER SEATS OF STRUTS

4 - STRUT CLEVIS BRACKETS

5 - END OF LEFT COIL SPRING AT STRUT LOWER SEAT

Fig. 51 COMPONENTS LINED UP

1 - IMAGINARY VERTICAL LINE

2 - CLEVIS BRACKET

3 - END OF COIL SPRING

4 - NOTCH IN UPPER SPRING SEAT

2 - 24 FRONTRS

STRUT (Continued)

Page 1577 of 4284

DIFFERENTIAL & DRIVELINE

TABLE OF CONTENTS

page page

HALF SHAFT - FRONT.....................1

HALF SHAFT - REAR.....................16PROPELLER SHAFT......................24

REAR DRIVELINE MODULE................26

HALF SHAFT - FRONT

TABLE OF CONTENTS

page page

HALF SHAFT - FRONT

DESCRIPTION............................1

DIAGNOSIS AND TESTING..................1

HALF SHAFT...........................1

REMOVAL...............................2

INSTALLATION............................5

SPECIFICATIONS.........................7

CV BOOT - INNER

REMOVAL...............................7INSTALLATION............................8

CV BOOT - OUTER

REMOVAL..............................11

INSTALLATION...........................12

OUTER CV JOINT BEARING SHIELD

REMOVAL..............................14

INSTALLATION...........................14

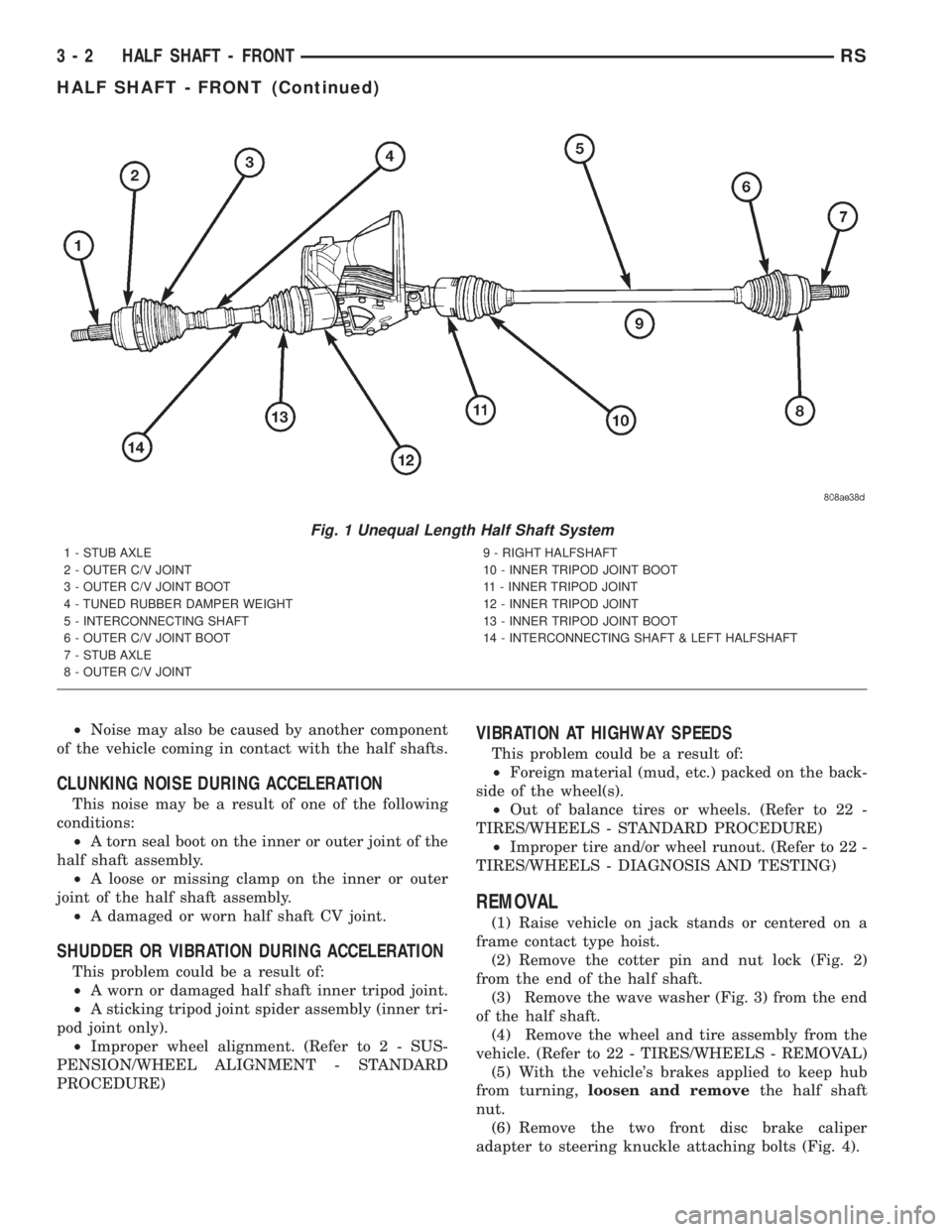

HALF SHAFT - FRONT

DESCRIPTION

All vehicles use an unequal length half shaft sys-

tem (Fig. 1).

The left half shaft uses a tuned rubber damper

weight. When replacing the left half shaft, be sure

the replacement half shaft has the same damper

weight as the original.

All half shaft assemblies use the same type of

inner and outer joints. The inner joint of both half

shaft assemblies is a tripod joint, and the outer joint

of both half shaft assemblies is a Rzeppa joint. Both

tripod joints and Rzeppa joints are true constant

velocity (CV) joint assemblies. The inner tripod joint

allows for the changes in half shaft length through

the jounce and rebound travel of the front suspen-

sion.

On vehicles equipped with ABS brakes, the outer

CV joint is equipped with a tone wheel used to deter-

mine vehicle speed for ABS brake operation.

The inner tripod joint of both half shafts is splined

into the transaxle side gears. The inner tripod joints

are retained in the side gears of the transaxle usinga snap ring located in the stub shaft of the tripod

joint. The outer CV joint has a stub shaft that is

splined into the wheel hub and retained by a steel

hub nut.

DIAGNOSIS AND TESTING - HALF SHAFT

VEHICLE INSPECTION

(1) Check for grease in the vicinity of the inboard

tripod joint and outboard CV joint; this is a sign of

inner or outer joint seal boot or seal boot clamp dam-

age.

(2) A light film of grease may appear on the right

inner tripod joint seal boot; this is considered normal

and should not require replacement of the seal boot.

NOISE AND/OR VIBRATION IN TURNS

A clicking noise and/or a vibration in turns could

be caused by one of the following conditions:

²Damaged outer CV or inner tripod joint seal

boot or seal boot clamps. This will result in the loss

and/or contamination of the joint grease, resulting in

inadequate lubrication of the joint.

RSDIFFERENTIAL & DRIVELINE3-1

Page 1578 of 4284

²Noise may also be caused by another component

of the vehicle coming in contact with the half shafts.

CLUNKING NOISE DURING ACCELERATION

This noise may be a result of one of the following

conditions:

²A torn seal boot on the inner or outer joint of the

half shaft assembly.

²A loose or missing clamp on the inner or outer

joint of the half shaft assembly.

²A damaged or worn half shaft CV joint.

SHUDDER OR VIBRATION DURING ACCELERATION

This problem could be a result of:

²A worn or damaged half shaft inner tripod joint.

²A sticking tripod joint spider assembly (inner tri-

pod joint only).

²Improper wheel alignment. (Refer to 2 - SUS-

PENSION/WHEEL ALIGNMENT - STANDARD

PROCEDURE)

VIBRATION AT HIGHWAY SPEEDS

This problem could be a result of:

²Foreign material (mud, etc.) packed on the back-

side of the wheel(s).

²Out of balance tires or wheels. (Refer to 22 -

TIRES/WHEELS - STANDARD PROCEDURE)

²Improper tire and/or wheel runout. (Refer to 22 -

TIRES/WHEELS - DIAGNOSIS AND TESTING)

REMOVAL

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist.

(2) Remove the cotter pin and nut lock (Fig. 2)

from the end of the half shaft.

(3) Remove the wave washer (Fig. 3) from the end

of the half shaft.

(4) Remove the wheel and tire assembly from the

vehicle. (Refer to 22 - TIRES/WHEELS - REMOVAL)

(5) With the vehicle's brakes applied to keep hub

from turning,loosen and removethe half shaft

nut.

(6) Remove the two front disc brake caliper

adapter to steering knuckle attaching bolts (Fig. 4).

Fig. 1 Unequal Length Half Shaft System

1 - STUB AXLE

2 - OUTER C/V JOINT

3 - OUTER C/V JOINT BOOT

4 - TUNED RUBBER DAMPER WEIGHT

5 - INTERCONNECTING SHAFT

6 - OUTER C/V JOINT BOOT

7 - STUB AXLE

8 - OUTER C/V JOINT9 - RIGHT HALFSHAFT

10 - INNER TRIPOD JOINT BOOT

11 - INNER TRIPOD JOINT

12 - INNER TRIPOD JOINT

13 - INNER TRIPOD JOINT BOOT

14 - INTERCONNECTING SHAFT & LEFT HALFSHAFT

3 - 2 HALF SHAFT - FRONTRS

HALF SHAFT - FRONT (Continued)