change time CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 3 of 4284

FOREWORD

The information contained in this service manual has been prepared for the professional automotive tech-

nician involved in daily repair operations. Information describing the operation and use of standard and

optional equipment is included in the Owner's Manual provided with the vehicle.

Information in this manual is divided into groups. These groups contain description, operation, diagnosis,

testing, adjustments, removal, installation, disassembly, and assembly procedures for the systems and compo-

nents. To assist in locating a group title page, use the Group Tab Locator by clicking to the following page. The

first page of the group has a contents section that lists major topics within the group.

A Service Manual Comment form is included at the rear of this manual. Use the form to provide

DaimlerChrysler Corporation with your comments and suggestions.

Tightening torques are provided as a specific value throughout this manual. This value represents the

midpoint of the acceptable engineering torque range for a given fastener application. These torque values are

intended for use in service assembly and installation procedures using the correct OEM fasteners. When

replacing fasteners, always use the same type (part number) fastener as removed.

DaimlerChrysler Corporation reserves the right to change testing procedures, specifications, diagnosis,

repair methods, or vehicle wiring at any time without prior notice or incurring obligation.

Page 10 of 4284

TABLE OF CONTENTS - Continued

AUDIO

ALL OUTPUTS SHORTED...............................................189

AM SECTION.........................................................192

CASS ERROR.........................................................192

CASSETTE COMMUNICATION FAULT.....................................192

CASSETTE EJECT FAILURE.............................................192

CASSETTE LOADING FAILURE..........................................192

CASSETTE TAPE TENSION HIGH........................................192

CASSETTE TAPE TENSION LOW.........................................192

CD ERROR...........................................................192

CD MECHANICAL FAILURE.............................................192

FM SECTION..........................................................192

MICRO OUTPUT FAILURE..............................................192

RADIO ERROR........................................................192

*AM/FM SWITCH INOPERATIVE..........................................192

*ANY STATION PRESET SWITCH INOPERATIVE............................192

*BALANCE INOPERATIVE...............................................192

*CD EJECT SWITCH INOPERATIVE.......................................192

*EQUALIZER INOPERATIVE.............................................192

*FADER INOPERATIVE.................................................192

*FF/RW SWITCH INOPERATIVE..........................................192

*HOUR/MINUTE SWITCHES INOPERATIVE................................192

*PAUSE/PLAY SWITCH INOPERATIVE....................................192

*PWR SWITCH INOPERATIVE...........................................192

*SCAN SWITCH INOPERATIVE..........................................192

*SEEK SWITCH INOPERATIVE...........................................192

*SET SWITCH INOPERATIVE............................................192

*TAPE EJECT SWITCH INOPERATIVE.....................................192

*TIME SWITCH INOPERATIVE...........................................192

*TUNE SWITCH INOPERATIVE...........................................192

CD CHANGER MECHANICAL FAILURE....................................195

CD CHANGER PLAY FAILURE...........................................196

CD CHANGER READ FAILURE...........................................196

IMPROPER DISK IN CD CHANGER.......................................196

CD CHANGER POWER SUPPLY TOO HIGH................................197

CD CHANGER TEMPERATURE HIGH.....................................198

CD CHANGER TEMPERATURE LOW.....................................198

CD PLAY FAILURE.....................................................199

CD READ FAILURE....................................................199

IMPROPER DISK IN CD.................................................199

CD TEMPERATURE HIGH...............................................200

CD TEMPERATURE LOW...............................................200

FRONT OUTPUT SHORT................................................201

LEFT OUTPUT SHORT.................................................204

NBS OUTPUT 1 OPEN..................................................207

NBS OUTPUT 2 OPEN..................................................207

NBS OUTPUT 1 SHORT TO BATT........................................209

NBS OUTPUT 2 SHORT TO BATT........................................209

NO ANTENNA CONNECTION............................................211

NO VIN RECEIVED.....................................................212

VIN MISMATCH........................................................212

POWER SUPPLY TOO HIGH.............................................213

REAR OUTPUT SHORT.................................................214

vii

Page 30 of 4284

1.0 INTRODUCTION

The procedures contained in this manual include

all the specifications, instructions and graphics

needed to diagnose 2001 body system problems. The

diagnostics in this manual are based on the failure

condition or symptom being present at the time of

diagnosis.

Please follow the recommendations below when

choosing your diagnostic path.

1. First make sure the DRBIIItis communicating

with the appropriate modules; i.e., if the

DRBIIItdisplays a ªNo Responseº or a ªBus6

Signals Openº condition, you must diagnose that

first.

2. Read DTC's (diagnostic trouble codes) with the

DRBIIIt.

3. If no DTC's are present, identify the customer

complaint.

4. Once the DTC or customer complaint is identi-

fied, locate the matching test in the Table of

Contents and begin to diagnose the symptom.

All component location views are in Section 8.0. All

connector pinouts are in Section 9.0. All schematics

are in Section 10.0. All Charts and Graphs are in

Section 11.0.

An * placed before the symptom description indi-

cated a customer complaint.

When repairs are required, refer to the appropri-

ate service information for the proper removal and

repair procedure.

Diagnostic procedures change every year. New

diagnostic systems may be added: carryover systems

may be enhanced. READ THIS MANUAL BEFORE

TRYING TO DIAGNOSE A VEHICLE DIAGNOS-

TIC TROUBLE CODE. It is recommended that you

review the entire manual to become familiar with all

the new and changed diagnostic procedures.

This book reflects many suggested changes from

readers of past issues. After using this book, if you

have any comments or suggestions, please fill out

the form in the back of this book and mail it back to

us.

1.1 SYSTEM COVERAGE

This diagnostic procedures manual covers all

2001 Chrysler Voyager and Caravan vehicles. This

diagnostic procedures manual also covers both left

hand drive (LHD) and right hand drive (RHD)

vehicles. There may be some slight differences in

the location views of components. If the location

views shown are on a LHD vehicle, a RHD vehicle

will be symmetrically opposite.

1.2 SIX-STEP TROUBLESHOOTING

PROCEDURE

Diagnosis of the body system is done in six basic

steps:

²verification of complaint

²verification of any related symptoms

²symptom analysis

²problem isolation

²repair of isolated problem

²verification of proper operation

2.0 IDENTIFICATION OF

SYSTEM

The vehicle systems that are part of the ªbodyº

system are:

²Airbag

²Audio

²Cabin Heater

²Chime

²Communication

²Door Ajar System

²Electrically heated system

²Exterior lighting

²Heating and A/C

²Instrument Cluster

²Interior Lighting

²Manual Temperature Control

²Memory Seat

²Overhead Console

²Power Door Lock/RKE

²Power Folding Mirrors

²Power Sliding Doors

²Power Liftgate

²Power windows

²Vehicle Theft Security System (VTSS)

²Windshield Wiper and Washer

3.0 SYSTEM DESCRIPTION AND

FUNCTIONAL OPERATION

The body system on the 2001 RG consists of a

combination of modules that communicate over the

PCI bus (Programmable Communication Interface

multiplex system). Through the PCI bus, informa-

tion about the operation of vehicle components and

circuits is relayed quickly to the appropriate mod-

ule(s). All modules receive all the information trans-

1

GENERAL INFORMATION

Page 33 of 4284

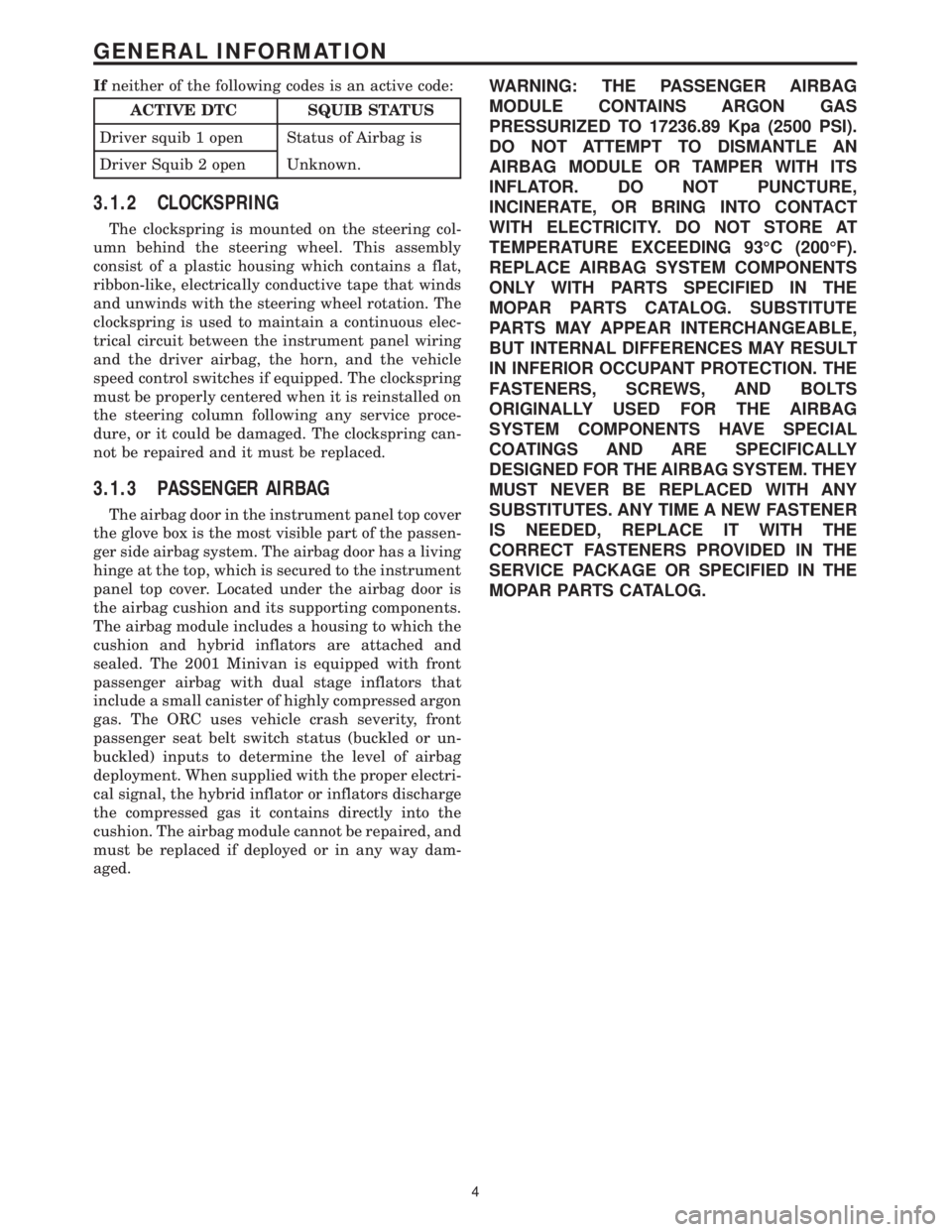

Ifneither of the following codes is an active code:

ACTIVE DTC SQUIB STATUS

Driver squib 1 open Status of Airbag is

Driver Squib 2 open Unknown.

3.1.2 CLOCKSPRING

The clockspring is mounted on the steering col-

umn behind the steering wheel. This assembly

consist of a plastic housing which contains a flat,

ribbon-like, electrically conductive tape that winds

and unwinds with the steering wheel rotation. The

clockspring is used to maintain a continuous elec-

trical circuit between the instrument panel wiring

and the driver airbag, the horn, and the vehicle

speed control switches if equipped. The clockspring

must be properly centered when it is reinstalled on

the steering column following any service proce-

dure, or it could be damaged. The clockspring can-

not be repaired and it must be replaced.

3.1.3 PASSENGER AIRBAG

The airbag door in the instrument panel top cover

the glove box is the most visible part of the passen-

ger side airbag system. The airbag door has a living

hinge at the top, which is secured to the instrument

panel top cover. Located under the airbag door is

the airbag cushion and its supporting components.

The airbag module includes a housing to which the

cushion and hybrid inflators are attached and

sealed. The 2001 Minivan is equipped with front

passenger airbag with dual stage inflators that

include a small canister of highly compressed argon

gas. The ORC uses vehicle crash severity, front

passenger seat belt switch status (buckled or un-

buckled) inputs to determine the level of airbag

deployment. When supplied with the proper electri-

cal signal, the hybrid inflator or inflators discharge

the compressed gas it contains directly into the

cushion. The airbag module cannot be repaired, and

must be replaced if deployed or in any way dam-

aged.

WARNING: THE PASSENGER AIRBAG

MODULE CONTAINS ARGON GAS

PRESSURIZED TO 17236.89 Kpa (2500 PSI).

DO NOT ATTEMPT TO DISMANTLE AN

AIRBAG MODULE OR TAMPER WITH ITS

INFLATOR. DO NOT PUNCTURE,

INCINERATE, OR BRING INTO CONTACT

WITH ELECTRICITY. DO NOT STORE AT

TEMPERATURE EXCEEDING 93ÉC (200ÉF).

REPLACE AIRBAG SYSTEM COMPONENTS

ONLY WITH PARTS SPECIFIED IN THE

MOPAR PARTS CATALOG. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE,

BUT INTERNAL DIFFERENCES MAY RESULT

IN INFERIOR OCCUPANT PROTECTION. THE

FASTENERS, SCREWS, AND BOLTS

ORIGINALLY USED FOR THE AIRBAG

SYSTEM COMPONENTS HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY

DESIGNED FOR THE AIRBAG SYSTEM. THEY

MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANY TIME A NEW FASTENER

IS NEEDED, REPLACE IT WITH THE

CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

MOPAR PARTS CATALOG.

4

GENERAL INFORMATION

Page 35 of 4284

if the system is functioning properly. If the test

finds a problem the SIACM will set both active and

stored diagnostic trouble codes. If a DTC is active

the SIACM will request that the airbag warning

lamp be turned on. The results of the system test

are transmitted on the PCI Bus to the ORC once

each second or on change in lamp state. If the

warning lamp status message from the either SI-

ACM contains a lamp on request, the ORC will set

an active DTC. At the same time as the DTC is set

the ORC sends a PCI Bus message to the mechan-

ical instrument cluster (MIC) requesting the airbag

warning lamp be turned on. Observe all ORC warn-

ing and caution statements when servicing or han-

dling the SIACM. SIACM are not repairable and

must be replaced if they are dropped.

WARNING: THE AIRBAG SYSTEM IS A

SENSITIVE, COMPLEX ELECTRO-

MECHANICAL UNIT. BEFORE ATTEMPTING

TO DIAGNOSE OR SERVICE ANY AIRBAG

SYSTEM OR RELATED STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENTS YOU MUST FIRST

DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE FURTHER SYSTEM

SERVICE. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIRBAG SYSTEM. FAILURE

TO DO THIS COULD RESULT IN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. NEVER STRIKE OR

KICK THE AIRBAG CONTROL MODULE, AS

IT CAN DAMAGE THE IMPACT SENSOR OR

AFFECT ITS CALIBRATION. IF AN AIRBAG

CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE

MUST BE SCRAPPED AND REPLACED WITH

A NEW UNIT.

The airbag warning lamp is the only point at

which the customer can observe symptoms of a

system malfunction. Whenever the ignition key is

turned to the run or start position, the MIC per-

forms a lamp check by turning the airbag warning

indicator on for 6-8 seconds. After the lamp check, if

the indicator turns on, it means that the ORC has

checked the system and found it to be free of

discernible malfuctions. If the lamp remains on,

there could be an active fault in the system or the

MIC lamp circuit may be internally shorted to

ground. If the lamp comes on and stays on for a

period longer than 6-8 seconds then goes off, there

is usually an intermittent problem in the system.

3.1.7 SEAT AIRBAGS (SAB)

The left and right seat airbag modules are located

in the outboard end of the front seat backs. The

airbag module contains a bag, an inflator (a small

canister of highly compressed argon gas) and a

mounting bracket. The seat airbag module cannot

be repaired and must be replaced if deployed or in

any way damaged. When supplied with the proper

electrical signal the inflator seals the hole in the

airbag cushion so it can discharge the compressed

gas it contains directly into the cushion. Upon

deployment, the seat back trim cover will tear open

and allow the seat airbag to fully deploy between

the seat and the door.

WARNING: SEAT AIRBAG CONTAINS ARGON

GAS PRESSURIZED TO OVER 17236.89 Kpa

(2500 PSI). DO NOT ATTEMPT TO

DISMANTLE AN AIRBAG MODULE OR

TAMPER WITH ITS INFLATOR. DO NOT

PUNCTURE, INCINERATE, OR BRING INTO

CONTACT WITH ELECTRICITY. DO NOT

STORE AT TEMPERATURE EXCEEDING 93ÉC

(200ÉF). REPLACE AIRBAG SYSTEM

COMPONENTS ONLY WITH PARTS

SPECIFIED IN THE CHRYSLER MOPAR

PARTS CATALOG. SUBSTITUTE PARTS MAY

APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN

INFERIOR OCCUPANT PROTECTION. THE

FASTENERS, SCREWS, AND BOLTS

ORIGINALLY USED FOR THE AIRBAG

SYSTEM COMPONENTS HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY

DESIGNED FOR THE AIRBAG SYSTEM. THEY

MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANY TIME A NEW FASTENER

IS NEEDED, REPLACE IT WITH THE

CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

MOPAR PARTS CATALOG.

3.1.8 ORC/SIACM DIAGNOSTIC TROUBLE

CODES

Airbag diagnostic trouble codes consist of active

and stored codes. If more than one code exists,

diagnostic priority should be given to the active

codes. Each diagnostic trouble code is diagnosed by

following a specific testing procedure. The diagnos-

tic test procedures contain step-by-step instructions

for determining the cause of the trouble codes. It is

not necessary to perform all of the tests in this book

to diagnose an individual code. Always begin by

reading the diagnostic trouble codes using the DRB.

Always begin diagnostic with the Table of Contents

6

GENERAL INFORMATION

Page 36 of 4284

section 7.0. This will direct you to the specific test(s)

that must be performed. Active diagnostic trouble

codes for the airbag system are not permanent and

will change the moment the reason for the code is

corrected. In certain test procedures within this

manual, diagnostic trouble codes are used as a

diagnostic tool.

3.1.9 ACTIVE CODES

The code becomes active as soon as the malfunc-

tion is detected or key-on, whichever occurs first. An

active trouble code indicates an on-going malfunc-

tion. This means that the defect is currently there

every time the airbag control module checks that

circuit or component. It is impossible to erase an

active code. Active codes automatically erase by

themselves when the reason for the code has been

corrected. With the exception of the warning lamp

trouble codes or malfunctions, when a malfunction

is detected, the airbag lamp remains lit for a mini-

mum of 12 seconds or as long as the malfunction is

present.

3.1.10 STORED CODES

Airbag codes are automatically stored in the

ORC's memory as soon as the malfunction is de-

tected. The exception is the Loss of Ignition Run

Only code which is an active code only. A stored code

indicates there was an active code present at some

time. However, the code currently may not be

present as an active code, although another code

could be active. When a trouble code occurs, the

airbag warning indicator illuminates for 12 seconds

minimum (even if the problem existed for less than

12 seconds). The code is stored, along with the time

in minutes it was active, and the number of times

the ignition has been cycled since the problem was

last detected. The minimum time shown for any

code will be one minute, even if the code was

actually present for less than one minute. Thus, the

time shown for a code will be one minute, even if the

code was actually present for less than one minute.

Thus, the time shown for a code that was present

for two minutes 13 seconds, for example, would be

three minutes. If a malfunction is detected a diag-

nostic trouble code is stored and will remain stored.

When and if the malfunction ceases to exist, an

ignition cycle count will be initiated for that code. If

the ignition cycle count reaches 100 without a

reoccurrence of the same malfunction, the diagnos-

tic trouble code is erased and that ignition cycle

counter is reset to zero. If the malfunction reoccurs

before the count reaches 100, then the ignition cycle

counter will be reset and diagnostic trouble code

will continue to be a stored code. If a malfunction is

not active while performing a diagnostic test proce-

dure, the active code diagnostic test will not locatethe source of the problem. In this case, the stored

code can indicate an area to inspect. If no obvious

problems are found, erase stored codes, and with

the ignition on wiggle the wire harness and connec-

tors, rotate the steering wheel from stop to stop.

Recheck for codes periodically as you work through

the system. This procedure may uncover a malfunc-

tion that is difficult to locate.

3.2 AUDIO SYSTEM

The following radios are all on the PCI Bus

system - RBB, RBK, RAZ, RAD, RBT, and RBY. The

remaining radio also available, the RAS, is NOT on

the PCI Bus. The PCI Bus inputs into the radio are

used for VF dimming, remote steering wheel con-

trols and cabin EQ preference. PCI Bus outputs

from the radio are used for the Name Brand

Speaker (NBS) relay activation, as well as cabin EQ

preference.

The RBB and RBK radios have the capability of

containing multiple vehicle unique equalization

curves (cabin EQ preferences) within the radio.

These curves will reside in the radio's flash memory.

The radio is capable of storing up to 20 unique

equalization curves. The latent curves can be se-

lected via the Front Control Module transmitting a

PCI Bus message to the radio in response to a radio

request for equalization message. Upon receipt of a

valid equalization select message response, the ra-

dio will switch to output the corresponding equal-

ization curve.

All the radios, except the RAS, are capable of

displaying faults and allowing certain actuation

tests through the use of the DRBIIIt. When at-

tempting to perform PCI Bus diagnostics, the first

step is to identify the radio in use in the vehicle.

When trouble shooting output shorts or ªoutputº

error messages, the following applies:

On radios without an external amplifier, the term

output refers to the path between the radio and the

speaker. This type of circuit can be monitored all

the way through the speaker connections by the

radio assembly. When the radio displays a shorted

output DTC with this type of system, the speaker,

radio, or wiring could be at fault. The output DTC

could refer to the front or rear output or a left or

right output. The reason for the difference is the

pairing of the output sections of the radio. Some are

paired left and right, others are paired front and

rear.

On radios with an external amplifier, the term

ªoutputº refers to the circuit between the radio

connector and the amplifier. The radio is capable of

monitoring only this portion and can tell nothing

about the circuit between the amplifier and the

speakers. Consequently, a shorted output DTC on

7

GENERAL INFORMATION

Page 37 of 4284

this type of system would only refer to this circuit.

A faulty speaker could not cause this DTC.

3.2.1 REMOTE RADIO CONTROLS

These radios can be controlled via remote radio

switches (optional). These switches are located on

the back side of the steering wheel. They control

mode, preset, seek up, seek down, volume up and

volume down functions.

These functions are inputs to the Body Control

Module and can be read with the DRBIIItunder

ªbody computerº. The switches are a multiplexed

signal to the BCM. The radio control MUX circuit is

a 5 volt line that is pulled to ground through

different value resistors built into the switches.

This causes a voltage drop to be seen by the BCM

and it sends a specific message to the radio on the

PCI Bus circuit. The radio then responses to the

message.

This circuit is fairly simple to troubleshoot. The

circuit must be complete from the switches in the

steering wheel to the BCM. The ground must be

complete so that the switches can cause the voltage

drop for the BCM to see. The circuit passes through

the clockspring so continuity through this devise

must be verified.

3.2.2 CD CHANGER

The new in-dash CD Changer is designed to fit

into the existing cubby bin in the center stack. This

new cartridge-less CD Changer is controlled by

your radio, and allows you to individually load up to

four discs at a time. However, due to its compact

design, the CD Changer can only carry out one

operation at a time. For example, you can not load

a new disc while playing another at the same time.

Each operation happens sequentially.

The radio unit installed with your system pro-

vides control over all features of the CD Changer

with the exception of the CD load and eject func-

tions, which are controlled by buttons located on the

front of the CD Changer. The radio also supplies the

power, ground, PCI Bus, left and right speaker

output thru a single DIN cable. All features you

would expect, such as Disc Up/Down, Track Up/

Down, Random and Scan are controlled by the

radio, which also displays all relevant CD Changer

information on the radio display.

The CD Changer contains a Load/Eject button

and an indicator light for each of the four disc

positions. The individual light indicates whether a

CD is currently loaded in that particular chamber of

the CD Changer. Pressing the individual Load/Eject

button for a particular chamber will eject a disc

currently present in that chamber. If the chamber iscurrently empty, actuating the Load/Eject button

will position that chamber to receive and load a new

disc in that chamber.

3.3 BODY CONTROL MODULE

The body control module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the module is interfaced to the

vehicle's serial bus communications network (PCI).

This network consists of the powertrain control

module (PCM), the engine control module (ECM) -

diesel only, the transmission control module (TCM),

the mechanical instrument cluster (MIC), the front

control module (FCM), the occupant restraint con-

troller (ORC), the compass/mini-trip (CMTC), the

electronic vehicle information center (EVIC), the

controller antilock brake (CAB), the HVAC control

module (ATC & MTC), the power sliding door (Left

& Right) modules (PSD), the power liftgate module

(PLG), the Audio system, the side impact airbag

control (left & right) modules (SIACM), the memory

seat/mirror module (MSMM), the RKE/thatcham

alarm module and the sentry key immobilizer mod-

ule (SKIM). The BCM is operational when battery

power is supplied to the module.

The body control module provides the following

features:

²Power Door Locks

²Automatic Door Lock

²Door Lock Inhibit

²Central Locking (with VTSS Only)

²Battery Protection

²The BCM will automatically turn off all exterior

lamps after 3 minutes and all interior lamps after

15 minutes after the ignition is turned off, if they

are not turned off by the driver.

²Chime

²Compass/Minitrip Support

²Interior Lighting (Courtesy/Reading Lamps)

²BCM Diagnostic Reporting

²Electronic Liftgate Release (with Power Door

Locks)

²Exterior Lighting

²Power Folding Mirrors

²Remote Radio Controls

²Headlamp Time Delay (with/without Autohead-

lamps)

²Automatic Headlamps (with electrochromatic

mirror)

²Illuminated Entry

²Fade to Off

8

GENERAL INFORMATION

Page 41 of 4284

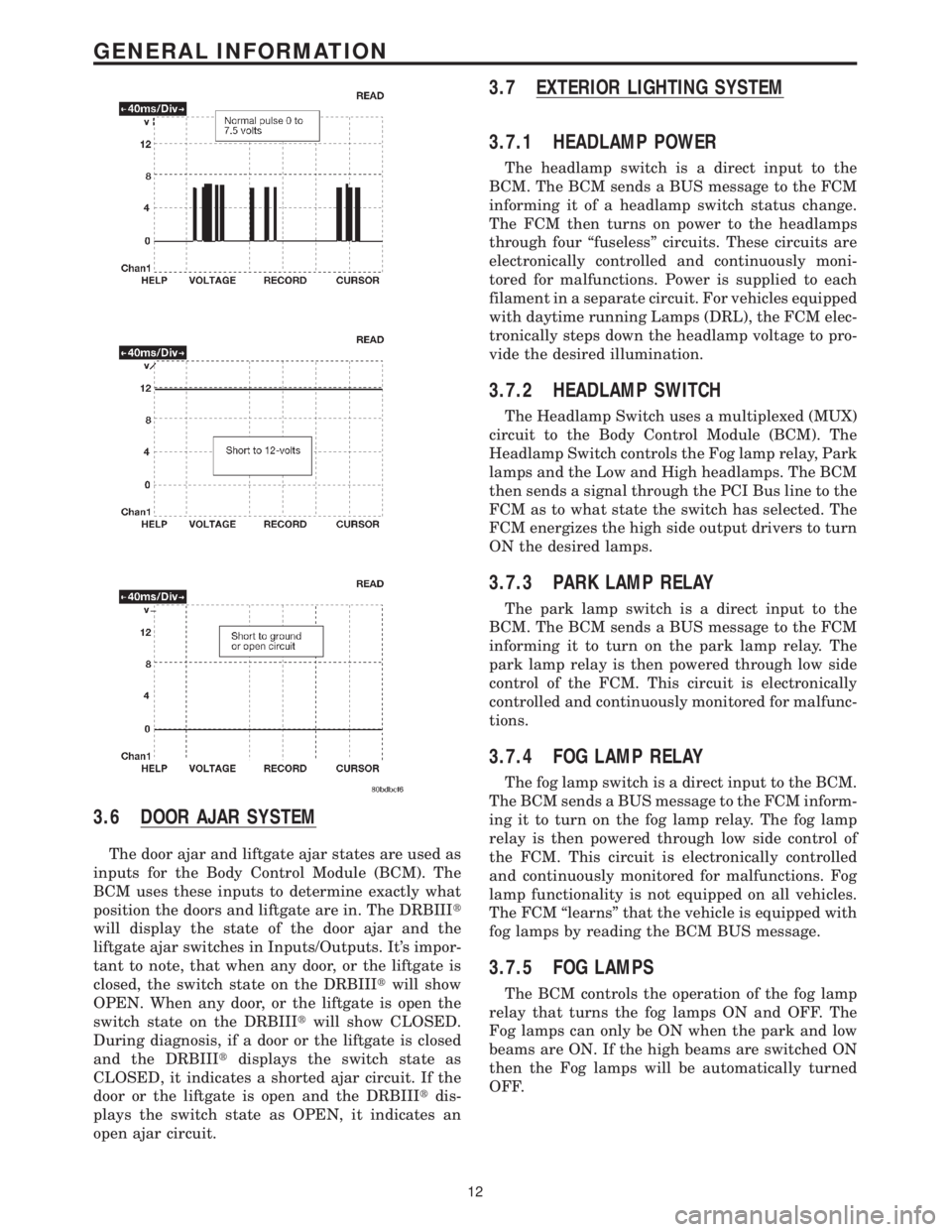

3.6 DOOR AJAR SYSTEM

The door ajar and liftgate ajar states are used as

inputs for the Body Control Module (BCM). The

BCM uses these inputs to determine exactly what

position the doors and liftgate are in. The DRBIIIt

will display the state of the door ajar and the

liftgate ajar switches in Inputs/Outputs. It's impor-

tant to note, that when any door, or the liftgate is

closed, the switch state on the DRBIIItwill show

OPEN. When any door, or the liftgate is open the

switch state on the DRBIIItwill show CLOSED.

During diagnosis, if a door or the liftgate is closed

and the DRBIIItdisplays the switch state as

CLOSED, it indicates a shorted ajar circuit. If the

door or the liftgate is open and the DRBIIItdis-

plays the switch state as OPEN, it indicates an

open ajar circuit.

3.7 EXTERIOR LIGHTING SYSTEM

3.7.1 HEADLAMP POWER

The headlamp switch is a direct input to the

BCM. The BCM sends a BUS message to the FCM

informing it of a headlamp switch status change.

The FCM then turns on power to the headlamps

through four ªfuselessº circuits. These circuits are

electronically controlled and continuously moni-

tored for malfunctions. Power is supplied to each

filament in a separate circuit. For vehicles equipped

with daytime running Lamps (DRL), the FCM elec-

tronically steps down the headlamp voltage to pro-

vide the desired illumination.

3.7.2 HEADLAMP SWITCH

The Headlamp Switch uses a multiplexed (MUX)

circuit to the Body Control Module (BCM). The

Headlamp Switch controls the Fog lamp relay, Park

lamps and the Low and High headlamps. The BCM

then sends a signal through the PCI Bus line to the

FCM as to what state the switch has selected. The

FCM energizes the high side output drivers to turn

ON the desired lamps.

3.7.3 PARK LAMP RELAY

The park lamp switch is a direct input to the

BCM. The BCM sends a BUS message to the FCM

informing it to turn on the park lamp relay. The

park lamp relay is then powered through low side

control of the FCM. This circuit is electronically

controlled and continuously monitored for malfunc-

tions.

3.7.4 FOG LAMP RELAY

The fog lamp switch is a direct input to the BCM.

The BCM sends a BUS message to the FCM inform-

ing it to turn on the fog lamp relay. The fog lamp

relay is then powered through low side control of

the FCM. This circuit is electronically controlled

and continuously monitored for malfunctions. Fog

lamp functionality is not equipped on all vehicles.

The FCM ªlearnsº that the vehicle is equipped with

fog lamps by reading the BCM BUS message.

3.7.5 FOG LAMPS

The BCM controls the operation of the fog lamp

relay that turns the fog lamps ON and OFF. The

Fog lamps can only be ON when the park and low

beams are ON. If the high beams are switched ON

then the Fog lamps will be automatically turned

OFF.

12

GENERAL INFORMATION

Page 42 of 4284

3.7.6 EXTERIOR LIGHTING BATTERY

SAVER

The BCM monitors the status of, and controls, the

Park Lamps, Headlamps and Fog Lamp relays. If

any exterior lamps are left ON after the ignition is

turned OFF, the BCM will turn them OFF after 3

minutes.

3.7.7 AUTO HEADLAMPS

This feature is available on vehicles equipped

with both the Electrocromatic Mirror (ECM) and

the Compass/Mini-Trip Computer (CMTC). When

the BCM detects a day/night signal from the CMTC,

an ECM is present and Auto Headlamp mode is

selected.

3.8 FRONT CONTROL MODULE

The Front Control Module (FCM) is an electrical

control and interface center located in the engine

compartment. When it is mated to the Power Dis-

tribution Center (PDC), it is referred to as the

Intelligent Power Module (IPM). The IPM, with its

fuses and relays provides power and signal distri-

bution throughout most of the vehicle. The FCM

receives both hard wire and digital electronic inputs

from the vehicle electrical system through the PDC.

Based on these inputs and the ignition switch

position, it provides direct power feeds and relay

control to some of the vehicles' most critical electri-

cal systems.

The Front Control Module provides the following

features:

Controlled power feeds:

²Front airbag system

²Side airbag system

²Headlamp power

²EATX module power (4 speed only)

²Front washer motor

²Rear washer motor

²Brake shift interlock system

Relay controls:

²Fog lamp relay (when equipped)

²Park lamp relay

²Front wiper on relay

²Front wiper high/low relay

²Accessory relay

²Horn relay

²Front & rear blower relay

²Name brand speakers (NBS) relay

²Electronic back light (EBL) run only relay

²Cabin heater relayElectrical inputs:

²Headlamp battery supplies1&2

²Module battery supply

²Power ground

²Ignition switch RUN or START position status

²Ignition switch START only status

²PCI Bus

²Stop lamp switch

²Horn switch

²Back-up switch

²Wiper park switch

²Washer fluid level switch

²Brake fluid level switch

²Ambient temperature sensor

²Right park lamp outage

²Left park lamp outage

²Battery IOD

²Battery (+) connection detection

²Flash reprogramming voltage

3.8.1 CONTROLLED POWER FEEDS

Front airbag system

The FCM provides power to the Occupant Re-

straint Control (ORC) system through two ªfuse-

lessº circuits (ORC RUN/START, and ORC RUN

only). These circuits are electronically controlled

and continuously monitored for malfunctions.

Power is supplied while the ignition switch is in the

RUN and START positions on pin 48 of the FCM

connector, and in the RUN only position on pin 29.

Side airbag system

The FCM provides power to the Side Impact

Airbag Control Module (SIACM) system through

one ªfuselessº circuit. This circuit is electronically

controlled and continuously monitored for malfunc-

tions. Power is supplied in the ignition RUN and

START positions on pin 28 of the FCM connector.

Headlamp power

The headlamp switch is a direct input to the

BCM. The BCM sends a PCI Bus message to the

FCM informing it of a headlamp switch status

change. The FCM then turns on power to the

headlamps through four ªfuselessº circuits. These

circuits are electronically controlled and continu-

ously monitored for malfunctions. Power is supplied

to each filament in a separate circuit (RH low on pin

6, RH high on pin 4, LH low on pin 3 and LH high

on pin 5). For vehicles equipped with Daytime

Running Lamps (DRL), the FCM electronically

steps down the headlamp voltage to provide the

desired illumination.

13

GENERAL INFORMATION

Page 52 of 4284

contains a potentiometer to monitor the seat posi-

tion. To monitor the position of the motor, the

MSMM sends out a 5-volt reference on the sensor

supply circuit. The sensor is grounded back to the

module on a common ground circuit. Based on the

position of the sensor, the MSMM monitors the

voltage change through the sensor on a separate

signal circuit.

The MSMM stores the input value of each of the

four seat potentiometers in memory when the sys-

tem requests a set. The driver can initiate a mem-

ory recall, using either the door mounted memory

switch or the RKE transmitter (if the remote linked

to memory feature is enabled via the EVIC). When

initiated, the MSMM adjusts the four seat sensors

(by using the motors) to match the memorized seat

position data.

For safety, the memory seat recall is disabled by

the MSMM when the vehicle is out of park position

or if the speed is not zero. Any obstruction to seat

movement over a 2-second delay will cause the seat

to stop moving in which case a stalled motor would

be detected by the MSMM and the corresponding

seat output would be deactivated. However, if the

object obstructing the seat is removed, the seat will

function normally again.

3.13.2 MEMORY MIRRORS

Each outside mirror contains vertical and hori-

zontal bi-directional drive positioning motors and

position sensors. The MSMM provides a 5-volt

reference on the signal circuit to each position

sensor. The sensors share a common ground circuit.

The MSMM monitors the position of the mirror

motors by measuring the voltage on each signal

circuit. When a memory position is set, the MSMM

monitors and stores the position of the outside

mirrors. The MSMM adjusts the mirrors to the

appropriate positions when a memory recall mes-

sage is received from the RKE or is requested from

the memory set switch.

The power mirror switch during non-memory

operation operates both mirrors independently of

the MSMM.

3.14 OVERHEAD CONSOLE

3.14.1 COMPASS/MINI-TRIP COMPUTER

(CMTC)

The compass/mini-trip computer is located in the

overhead console. It displays to the driver the

direction the vehicle is traveling and the current

outside temperature, as well as the following trav-

eler navigational information: average fuel econ-

omy (AVG ECO), distance to empty (DTE), instan-

taneous fuel economy (ECO), elapsed time (ET),and trip odometer (ODO). The information needed

for the CMTC functions is received over the PCI bus

from other modules.

3.14.2 ELECTRONIC VEHICLE

INFORMATION CENTER (EVIC)

The Electronic Vehicle Information Center

(EVIC) includes all the same functions and is lo-

cated in the same area as the Compass/Mini-Trip

Computer, but it adds a number of warning mes-

sages. Also, the EVIC messages are spelled out on

the screen, for example, DISTANCE TO EMPTY,

where the Mini-Trip Computer displays only shows

DTE.

If the compass/mini-trip computer or EVIC has

been replaced, it may be necessary to reset the

calibration.

3.14.3 SETTING THE COMPASS

The compass/mini-trip computer and EVIC are

self-calibrated and requires no adjustment. The

word CAL will be displayed to indicate that the

compass is in the fast calibrating mode. CAL will

turn off after the vehicle has gone in three complete

circles without stopping, in an area free of magnetic

disturbance.

If the module displays the temperature while the

compass is blank or shows a false reading, the

vehicle must be demagnetized. See the service man-

ual for the proper procedure.

If the compass still goes blank after the vehicle is

demagnetized, the compass/mini-trip/EVIC module

must be replaced.

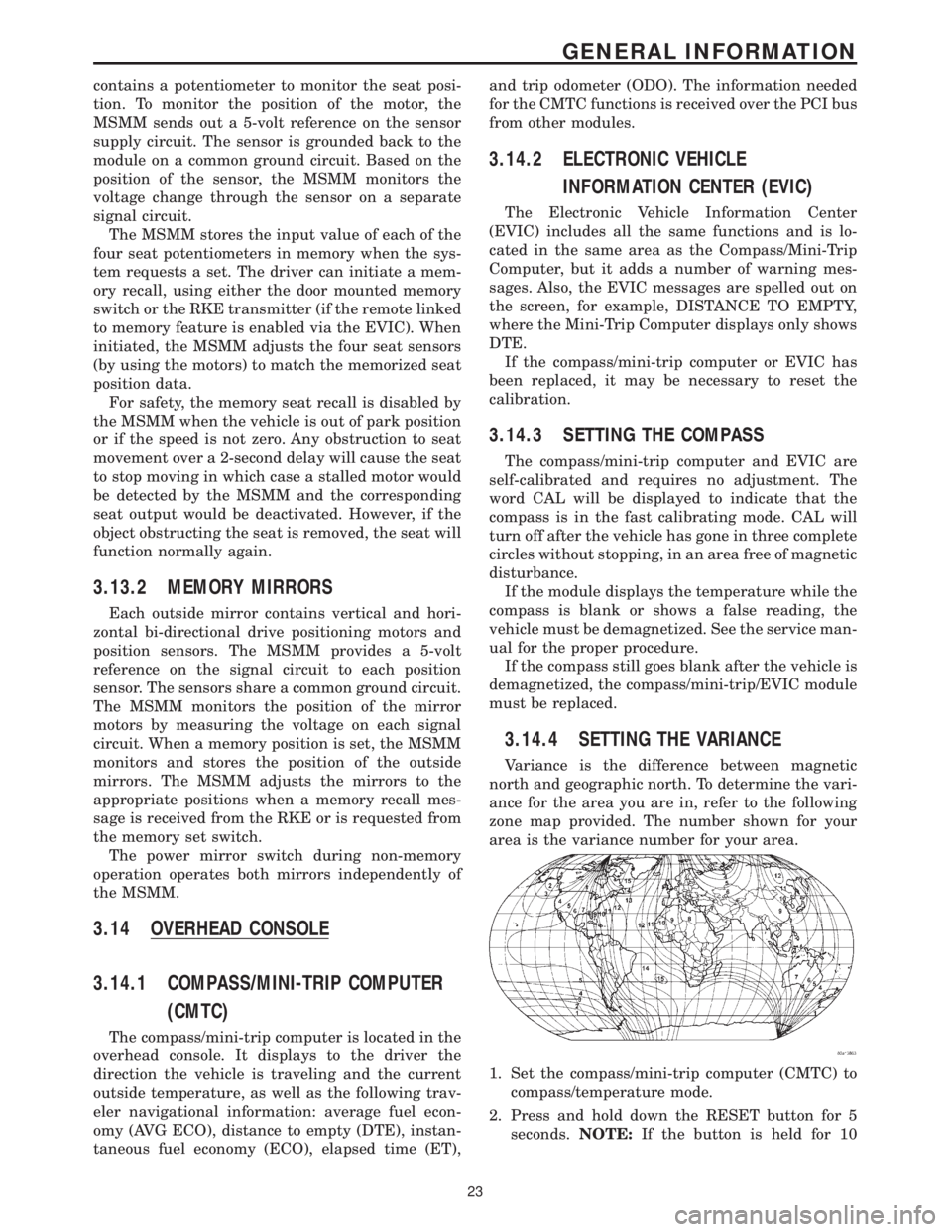

3.14.4 SETTING THE VARIANCE

Variance is the difference between magnetic

north and geographic north. To determine the vari-

ance for the area you are in, refer to the following

zone map provided. The number shown for your

area is the variance number for your area.

1. Set the compass/mini-trip computer (CMTC) to

compass/temperature mode.

2. Press and hold down the RESET button for 5

seconds.NOTE:If the button is held for 10

23

GENERAL INFORMATION