warning CHRYSLER VOYAGER 2001 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2001, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2001Pages: 4284, PDF Size: 83.53 MB

Page 4 of 4284

TABLE OF CONTENTS

1.0 INTRODUCTION.........................................................1

1.1SYSTEM COVERAGE...............................................1

1.2SIX-STEP TROUBLESHOOTING PROCEDURE..........................1

2.0 IDENTIFICATION OF SYSTEM.............................................1

3.0 SYSTEM DESCRIPTION AND FUNCTIONAL OPERATION......................1

3.1AIRBAG SYSTEM/OCCUPANT RESTRAINT CONTROLLER SYSTEM........2

3.1.1DRIVER AIRBAG...........................................3

3.1.2CLOCKSPRING............................................4

3.1.3PASSENGER AIRBAG......................................4

3.1.4SEAT BELT TENSIONER (SBT)...............................5

3.1.5SEAT BELT SWITCHES (SBS)................................5

3.1.6SIDE IMPACT AIRBAG CONTROL MODULE (SIACM)............5

3.1.7SEAT AIRBAGS (SAB)......................................6

3.1.8ORC/SIACM DIAGNOSTIC TROUBLE CODES..................6

3.1.9ACTIVE CODES...........................................7

3.1.10STORED CODES..........................................7

3.2AUDIO SYSTEM....................................................7

3.2.1REMOTE RADIO CONTROLS................................8

3.2.2CD CHANGER.............................................8

3.3BODY CONTROL MODULE...........................................8

3.4CHIME WARNING SYSTEM...........................................9

3.4.1CHIME PRIORITY..........................................9

3.4.2CHIME ON CONDITIONS....................................9

3.4.3WARNING LAMP ANNOUNCEMENT.........................10

3.4.4OTHER CHIME ON CONDITIONS............................10

3.5COMMUNICATION.................................................11

3.6DOOR AJAR SYSTEM..............................................12

3.7EXTERIOR LIGHTING SYSTEM......................................12

3.7.1HEADLAMP POWER......................................12

3.7.2HEADLAMP SWITCH......................................12

3.7.3PARK LAMP RELAY.......................................12

3.7.4FOG LAMP RELAY........................................12

3.7.5FOG LAMPS.............................................12

3.7.6EXTERIOR LIGHTING BATTERY SAVER......................13

3.7.7AUTO HEADLAMPS.......................................13

3.8FRONT CONTROL MODULE.........................................13

3.8.1CONTROLLED POWER FEEDS.............................13

3.8.2RELAY CONTROLS.......................................14

3.8.3ELECTRICAL INPUTS.....................................15

3.9HEATING & A/C...................................................16

3.9.1AUTOMATIC TEMPERATURE CONTROL (ATC)................16

3.9.1.1CABIN HEATER..........................................16

3.9.1.2SYSTEM OPERATION.....................................16

3.9.1.3BLOWER MOTOR OPERATION.............................16

3.9.1.4INFRARED SENSORS.....................................16

3.9.1.5REAR ATC SWITCH.......................................16

3.9.1.6COOLDOWN TESTING....................................16

3.9.1.7ACTIVE AND STORED TROUBLE CODES....................17

3.9.2MANUAL TEMPERATURE CONTROL.........................17

i

Page 6 of 4284

TABLE OF CONTENTS - Continued

3.18.3SYSTEM INHIBITORS.....................................26

3.19REAR WINDOW DEFOG/HEATED MIRROR/FRONT WIPER DE-ICE........26

3.20VEHICLE THEFT SECURITY SYSTEM.................................26

3.20.1BASE ALARM SYSTEM....................................26

3.20.2THATCHAM ALARM SYSTEM...............................27

3.21WIPER SYSTEM...................................................27

3.21.1FRONT WIPER...........................................27

3.21.2SPEED SENSITIVE INTERMITTENT WIPE MODE..............27

3.21.3PULSE WIPE.............................................27

3.21.4PARK AFTER IGNITION OFF................................27

3.21.5WIPE AFTER WASH.......................................27

3.21.6REAR WIPER............................................27

3.21.7SPEED SENSITIVE INTERMITTENT WIPE MODE..............27

3.21.8WIPE AFTER WASH.......................................28

3.22USING THE DRBIIIT.......................................28

3.22.1DRBIIITERROR MESSAGES...............................28

3.22.2DRBIIITDOES NOT POWER UP (BLANK SCREEN).............28

3.22.3DISPLAY IS NOT VISIBLE..................................28

4.0 DISCLAIMERS, SAFETY, WARNINGS......................................28

4.1DISCLAIMERS.....................................................28

4.2SAFETY..........................................................28

4.2.1TECHNICIAN SAFETY INFORMATION........................28

4.2.2VEHICLE PREPARATION FOR TESTING......................29

4.2.3SERVICING SUB-ASSEMBLIES.............................29

4.2.4DRBIIITSAFETY INFORMATION............................29

4.3WARNINGS.......................................................29

4.3.1VEHICLE DAMAGE WARNINGS.............................29

4.3.2ROAD TESTING A COMPLAINT VEHICLE.....................29

5.0 REQUIRED TOOLS AND EQUIPMENT.....................................30

6.0 GLOSSARY OF TERMS..................................................30

7.0 DIAGNOSTIC INFORMATION AND PROCEDURES...........................31

AIRBAG

FCM, ORC RUN ONLY DRIVER OPEN - ACTIVE.............................32

FCM, ORC RUN ONLY DRIVER OVER CURRENT - ACTIVE....................32

FCM, ORC RUN ONLY DRIVER OVER TEMP - ACTIVE.......................32

FCM, ORC RUN ONLY DRIVER OVER VOLT - ACTIVE........................32

FCM, ORC RUN ONLY DRIVER SHORT TO GROUND - ACTIVE................32

ORC, LOSS OF IGNITION RUN ONLY - ACTIVE..............................32

FCM, ORC RUN ONLY DRIVER OPEN - STORED............................37

FCM, ORC RUN ONLY DRIVER OVER CURRENT - STORED..................37

FCM, ORC RUN ONLY DRIVER OVER TEMP - STORED......................37

FCM, ORC RUN ONLY DRIVER OVER VOLT - STORED.......................37

FCM, ORC RUN ONLY DRIVER SHORT TO GROUND - STORED...............37

FCM, ORC RUN-START DRIVER OPEN - STORED...........................37

FCM, ORC RUN-START DRIVER OVER CURRENT - STORED.................37

FCM, ORC RUN-START DRIVER OVER TEMP - STORED.....................37

FCM, ORC RUN-START DRIVER OVER VOLT - STORED......................37

FCM, ORC RUN-START DRIVER SHORT TO GROUND - STORED..............37

iii

Page 8 of 4284

TABLE OF CONTENTS - Continued

ORC, CALIBRATION MISMATCH - STORED.................................75

ORC, CLUSTER MESSAGE MISMATCH - STORED...........................75

ORC, DRIVER SBS OPEN - STORED......................................75

ORC, DRIVER SBS SHORT TO BATTERY - STORED.........................75

ORC, DRIVER SBS SHORT TO GROUND - STORED.........................75

ORC, DRIVER SBT CIRCUIT OPEN - STORED..............................75

ORC, DRIVER SBT CIRCUIT SHORT - STORED.............................75

ORC, DRIVER SBT SHORT TO BATTERY - STORED.........................75

ORC, DRIVER SBT SHORT TO GROUND - STORED.........................75

ORC, DRIVER SQUIB 1 CIRCUIT OPEN - STORED...........................75

ORC, DRIVER SQUIB 1 CIRCUIT SHORT - STORED.........................75

ORC, DRIVER SQUIB 1 SHORT TO BATTERY - STORED......................75

ORC, DRIVER SQUIB 1 SHORT TO GROUND - STORED......................75

ORC, DRIVER SQUIB 2 CIRCUIT OPEN - STORED...........................75

ORC, DRIVER SQUIB 2 CIRCUIT SHORT - STORED.........................75

ORC, DRIVER SQUIB 2 SHORT TO BATTERY - STORED......................75

ORC, DRIVER SQUIB 2 SHORT TO GROUND - STORED......................75

ORC, LOSS OF IGNITION RUN ONLY - STORED.............................75

ORC, LOSS OF IGNITION RUN-START - STORED............................75

ORC, NO CLUSTER MESSAGE - STORED..................................75

ORC, NO ODOMETER MESSAGE - STORED................................75

ORC, PASSENGER SBS OPEN - STORED..................................75

ORC, PASSENGER SBS SHORT TO BATTERY - STORED.....................75

ORC, PASSENGER SBS SHORT TO GROUND - STORED.....................75

ORC, PASSENGER SBT CIRCUIT OPEN - STORED..........................75

ORC, PASSENGER SBT CIRCUIT SHORT - STORED.........................75

ORC, PASSENGER SBT SHORT TO BATTERY - STORED.....................75

ORC, PASSENGER SBT SHORT TO GROUND - STORED.....................75

ORC, PASSENGER SQUIB 1 CIRCUIT OPEN - STORED......................75

ORC, PASSENGER SQUIB 1 CIRCUIT SHORT - STORED.....................75

ORC, PASSENGER SQUIB 1 SHORT TO BATTERY - STORED.................75

ORC, PASSENGER SQUIB 1 SHORT TO GROUND - STORED.................75

ORC, PASSENGER SQUIB 2 CIRCUIT OPEN - STORED......................75

ORC, PASSENGER SQUIB 2 CIRCUIT SHORT - STORED.....................75

ORC, PASSENGER SQUIB 2 SHORT TO BATTERY - STORED.................75

ORC, PASSENGER SQUIB 2 SHORT TO GROUND - STORED.................75

ORC, VEHICLE BODY STYLE UNKNOWN - STORED.........................75

ORC, WARNING INDICATOR CIRCUIT OPEN - STORED......................75

ORC, WARNING INDICATOR CIRCUIT SHORT - STORED.....................75

ORC, CLUSTER MESSAGE MISMATCH - ACTIVE............................82

ORC, DRIVER SBS OPEN - ACTIVE.......................................84

ORC, DRIVER SBS SHORT TO BATTERY - ACTIVE..........................86

ORC, DRIVER SBS SHORT TO GROUND - ACTIVE..........................88

ORC, DRIVER SBT CIRCUIT OPEN - ACTIVE................................90

ORC, DRIVER SBT CIRCUIT SHORT - ACTIVE..............................92

ORC, DRIVER SBT SHORT TO BATTERY - ACTIVE..........................94

ORC, DRIVER SBT SHORT TO GROUND - ACTIVE...........................96

ORC, DRIVER SQUIB 1 CIRCUIT OPEN - ACTIVE............................98

ORC, DRIVER SQUIB 1 CIRCUIT SHORT - ACTIVE..........................101

ORC, DRIVER SQUIB 1 SHORT TO BATTERY - ACTIVE......................104

ORC, DRIVER SQUIB 1 SHORT TO GROUND - ACTIVE......................107

ORC, DRIVER SQUIB 2 CIRCUIT OPEN - ACTIVE...........................110

ORC, DRIVER SQUIB 2 CIRCUIT SHORT - ACTIVE..........................113

v

Page 9 of 4284

TABLE OF CONTENTS - Continued

ORC, DRIVER SQUIB 2 SHORT TO BATTERY - ACTIVE......................116

ORC, DRIVER SQUIB 2 SHORT TO GROUND - ACTIVE......................119

ORC, INTERROGATE LEFT SIACM - ACTIVE...............................122

ORC, INTERROGATE RIGHT SIACM - ACTIVE..............................123

ORC, INTERROGATE RIGHT SIACM - STORED.............................124

ORC, NO RIGHT SIACM MESSAGE - STORED.............................124

RIGHT SIACM, NO PCI TRANSMISSION - STORED.........................124

RIGHT SIACM, NO PCM MESSAGE - STORED.............................124

RIGHT SIACM, SEAT SQUIB CIRCUIT OPEN - STORED......................124

RIGHT SIACM, SEAT SQUIB CIRCUIT SHORT - STORED....................124

RIGHT SIACM, SEAT SQUIB SHORT TO BATTERY - STORED................124

RIGHT SIACM, SEAT SQUIB SHORT TO GROUND - STORED.................124

ORC, NO CLUSTER MESSAGE - ACTIVE..................................126

ORC, NO LEFT SIACM MESSAGE - ACTIVE...............................128

ORC, NO ODOMETER MESSAGE - ACTIVE................................129

ORC, NO PCI TRANSMISSION - STORED.................................130

ORC, NO RIGHT SIACM MESSAGE - ACTIVE..............................131

ORC, NOT CONFIGURED FOR SAB - ACTIVE..............................132

ORC, NOT CONFIGURED FOR SAB - STORED.............................134

ORC, PASSENGER SBS OPEN - ACTIVE..................................135

ORC, PASSENGER SBS SHORT TO BATTERY - ACTIVE.....................137

ORC, PASSENGER SBS SHORT TO GROUND - ACTIVE.....................139

ORC, PASSENGER SBT CIRCUIT OPEN - ACTIVE..........................141

ORC, PASSENGER SBT CIRCUIT SHORT - ACTIVE.........................143

ORC, PASSENGER SBT SHORT TO BATTERY - ACTIVE.....................145

ORC, PASSENGER SBT SHORT TO GROUND - ACTIVE.....................147

ORC, PASSENGER SQUIB 1 CIRCUIT OPEN - ACTIVE......................149

ORC, PASSENGER SQUIB 1 CIRCUIT SHORT - ACTIVE.....................152

ORC, PASSENGER SQUIB 1 SHORT TO BATTERY - ACTIVE.................154

ORC, PASSENGER SQUIB 1 SHORT TO GROUND - ACTIVE.................157

ORC, PASSENGER SQUIB 2 CIRCUIT OPEN - ACTIVE......................159

ORC, PASSENGER SQUIB 2 CIRCUIT SHORT - ACTIVE.....................162

ORC, PASSENGER SQUIB 2 SHORT TO BATTERY - ACTIVE.................164

ORC, PASSENGER SQUIB 2 SHORT TO GROUND - ACTIVE.................167

ORC, VEHICLE BODY STYLE UNKNOWN - ACTIVE.........................169

ORC, WARNING INDICATOR CIRCUIT OPEN - ACTIVE......................171

ORC, WARNING INDICATOR CIRCUIT SHORT - ACTIVE.....................171

RIGHT SIACM ACCELEROMETER 1 - ACTIVE..............................173

RIGHT SIACM ACCELEROMETER1-STORED.............................173

RIGHT SIACM ACCELEROMETER 2 - ACTIVE..............................173

RIGHT SIACM ACCELEROMETER2-STORED.............................173

RIGHT SIACM INTERNAL 1 - ACTIVE.....................................173

RIGHT SIACM INTERNAL 1 - STORED....................................173

RIGHT SIACM OUTPUT DRIVER 1 - ACTIVE...............................173

RIGHT SIACM OUTPUT DRIVER1-STORED..............................173

RIGHT SIACM, LOSS OF IGNITION RUN-START - ACTIVE....................173

RIGHT SIACM, NO PCI TRANSMISSION - ACTIVE..........................173

RIGHT SIACM, NO PCM MESSAGE - ACTIVE..............................176

RIGHT SIACM, SEAT SQUIB CIRCUIT OPEN - ACTIVE.......................177

RIGHT SIACM, SEAT SQUIB CIRCUIT SHORT - ACTIVE.....................180

RIGHT SIACM, SEAT SQUIB SHORT TO BATTERY - ACTIVE..................182

RIGHT SIACM, SEAT SQUIB SHORT TO GROUND - ACTIVE..................185

*AIRBAG INDICATOR ON WITHOUT ACTIVE TROUBLE CODES...............188

vi

Page 13 of 4284

TABLE OF CONTENTS - Continued

B1823 WATER PUMP CIRCUIT: OPEN.....................................323

B1823 WATER PUMP CIRCUIT: SHORT TO GROUND........................323

B1824 FAN SWITCH LINE SHORT TO GROUND............................324

CABIN HEATER CONTROL CIRCUIT OPEN (ACTIVE)........................325

CABIN HEATER CONTROL CIRCUIT SHORT TO BATTERY (ACTIVE)...........329

*CABIN HEATER INOPERABLE FROM A/C - HEATER MODULE...............332

CHIME

*CHIME INOPERATIVE..................................................334

*KEY IN IGNITION AND DRIVER'S DOOR OPEN CHIME NOT OPERATING

PROPERLY...........................................................336

*PROBLEM WITH THE HIGH VEHICLE SPEED WARNING CHIME.............337

COMMUNICATION

ATC MESSAGES NOT RECEIVED........................................338

AUDIO MESSAGES NOT RECEIVED......................................339

BCM, PCI BUS SHORTED TO BATTERY...................................340

BCM, PCI BUS SHORTED TO GROUND...................................340

FCM, PCI BUS SHORTED TO BATTERY...................................340

FCM, PCI BUS SHORTED TO GROUND...................................340

COUNTRY CODE NOT PROGRAMMED...................................342

FCM MESSAGES NOT RECEIVED........................................343

FCM, BCM COMMUNICATION FAULT.....................................344

FCM, HVAC COMMUNICATION FAULT....................................345

FCM, PCI INTERNAL FAULT.............................................346

FCM, PCM COMMUNICATION FAULT.....................................347

FCM, RADIO COMMUNICATION FAULT...................................348

FCM, TCM COMMUNICATION FAULT.....................................349

IGNITION MUX SWITCH INPUT OPEN....................................350

IGNITION MUX SWITCH INPUT SHORT...................................352

IGNITION RUN OUTPUT SHORT.........................................353

INTERNAL BCM FAILURE...............................................357

LEFT PSD MESSAGES NOT RECEIVED...................................358

LIFTGATE MODULE MESSAGES NOT RECEIVED...........................359

MIC MESSAGES NOT RECEIVED........................................360

MSM MESSAGES NOT RECEIVED.......................................361

NO PCI MESSAGES FROM CD CHANGER.................................362

ORC MESSAGES NOT RECEIVED........................................364

OTIS MESSAGES NOT RECEIVED.......................................365

PCI INTERNAL HARDWARE FAILURE.....................................366

PCM MESSAGES NOT RECEIVED........................................367

RADIO MEM MSG NOT RECEIVED.......................................368

RIGHT PSD MESSAGES NOT RECEIVED..................................369

RUN/START HARDWIRE INPUT FAILURE..................................370

SKIM MESSAGES NOT RECEIVED.......................................371

TCM MESSAGES NOT RECEIVED........................................372

*BUS +/- SIGNALS OPEN FROM AUTOMATIC TEMPERATURE CONTROL

MODULE.............................................................373

*BUS +/- SIGNALS OPEN FROM MEMORY SEAT/MIRROR MODULE...........375

*BUS +/- SIGNALS OPEN FROM SENTRY KEY IMMOBILIZER MODULE........377

*BUS +/- SIGNALS OPEN OR NO RESPONSE FROM BODY CONTROL

MODULE.............................................................379

*BUS +/- SIGNALS OPEN OR NO RESPONSE FROM HVAC..................381

x

Page 31 of 4284

mitted on the bus even though a module may not

require all information to perform its function. It

will only respond to messages ªaddressedº to it

through binary coding process. This method of data

transmission significantly reduces the complexity

of the wiring in the vehicle and the size of wiring

harnesses. All of the information about the func-

tioning of all the systems is organized, controlled,

and communicated by the PCI bus, which is de-

scribed in the Communication Section of this gen-

eral information.

3.1 AIRBAG SYSTEM/OCCUPANT

RESTRAINT CONTROLLER SYSTEM

The 2001 Minivan Airbag System contain the

following components: Occupant Restraint Control-

ler (ORC), Airbag Warning Indicator, Clockspring,

Driver and Passenger Airbags, Seat belt Tensioners

(SBT), Hall-effect Seat Belt Switches (SBS), Left

and Right Side Airbag Control Module (SIACM),

and Seat (mounted side) Airbags.

The Occupant Restraint Controller (ORC) is a

new type of Airbag Control Module (ACM) that

supports staged airbag deployment. Staged deploy-

ment is the ability to trigger airbag system squib

inflators all at once or individually as needed to

provide the appropriate restraint for the severity of

the impact. The ORC has four major functions: PCI

Bus communications, onboard diagnostics, impact

sensing, and component deployment. The ORC also

contains an energy-storage capacitor. This capaci-

tor stores enough electrical energy to deploy the

front airbag components for two seconds following a

battery disconnect or failure during an impact. The

ORC is secured to the floor panel transmission

tunnel below the instrument panel inside the vehi-

cle. The ORC cannot be repaired or adjusted and

must be replaced.

The ORC sends and/or receives PCI Bus mes-

sages with the Instrument Cluster (MIC), Body

Control Module (BCM), and Powertrain Control

Module (PCM). Diagnostic trouble codes will be set

if the communication with these modules is lost or

contains invalid information.

The microprocessor in the ORC monitors the

impact sensor signal and the airbag system electri-

cal circuits to determine the system readiness. The

ORC also monitors bus messages from both SIACM.

If the ORC detects a monitored system fault or

SIACM fault, it sends a message to the instrument

cluster via PCI bus to turn on the airbag warning

indicator. The ORC can set both active and stored

diagnostic trouble codes to aid in the diagnosing

system problems. See ORC/SIACM DIAGNOSTIC

TROUBLE CODES in this section.

The ORC has an internal accelerometer that

senses the rate of vehicle deceleration, which pro-vides verification of the direction and severity of an

impact. A pre-programmed decision algorithm in

the ORC microprocessor determines when the de-

celeration rate is severe enough to require airbag

system protection. The Occupant Restraint Control-

ler (ORC) also uses the driver and front passenger

seat belt switch status (buckled or unbuckled) as

inputs to determine the level of airbag deployment,

low, medium, or high as well as whether or not the

seat belt tensioners should deploy. The ORC also

uses the crash severity to determine the level of

driver and front passenger deployment, low me-

dium or high. When the programmed conditions are

met, the ORC sends an electrical signal to deploy

the appropriate airbag system components.WARNING: THE AIRBAG SYSTEM IS A

SENSITIVE, COMPLEX ELECTRO-

MECHANICAL UNIT. BEFORE ATTEMPTING

TO DIAGNOSE OR SERVICE ANY AIRBAG

SYSTEM OR RELATED STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENTS YOU MUST FIRST

DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE FURTHER SYSTEM

SERVICE. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIRBAG SYSTEM. FAILURE

TO DO THIS COULD RESULT IS ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. NEVER STRIKE OR

KICK THE AIRBAG CONTROL MODULE, AS

IT CAN DAMAGE THE IMPACT SENSOR OR

AFFECT ITS CALIBRATION. IF AN AIRBAG

CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE

MUST BE SCRAPPED AND REPLACED WITH

A NEW UNIT.

The airbag warning lamp is the only point at

which the customer can observe symptoms of a

system malfunction. Whenever the ignition key is

turned to the run or start position, the MIC per-

forms a lamp check by turning the airbag warning

indicator on for 6-8 seconds. After the lamp check, if

the indicator turns on, it means that the ORC has

checked the system and found it to be free of

discernible malfunctions. If the lamp remains on,

there could be an active fault in the system or the

MIC lamp circuit may be internally shorted to

ground. If the lamp comes on and stays on for a

period longer than 6-8 seconds then goes off, there

is usually an intermittent problem in the system.

2

GENERAL INFORMATION

Page 32 of 4284

3.1.1 DRIVER AIRBAG

The airbag protective trim cover is the most

visible part of the driver side airbag system. The

protective trim cover is fitted to the front of the

airbag module and forms a decorative cover in the

center of the steering wheel. The module is

mounted directly to the steering wheel. Located

under the trim cover are the horn switch, the airbag

cushion, and the airbag cushion supporting compo-

nents. The airbag module includes a housing to

which the cushion and hybrid inflator are attached

and sealed. The 2001 Minivan is equipped with

driver airbag with dual stage inflators that include

a small canister of highly compressed argon gas.

The Occupant Restraint Controller (ORC) uses ve-

hicle crash severity, driver seat belt switch status

(buckled or unbuckled) as inputs to determine the

level of airbag deployment. When supplied with the

proper electrical signal, the hybrid inflator or infla-

tors discharge the compressed gas it contains di-

rectly into the cushion. The airbag module cannot

be repaired, and must be replaced if deployed or in

any way damaged.

WARNING: THE DRIVER AIRBAG MODULE

CONTAINS ARGON GAS PRESSURIZED TO

OVER 17236.89 Kpa (2500 PSI). DO NOT

ATTEMPT TO DISMANTLE AN AIRBAG

MODULE OR TAMPER WITH ITS INFLATOR.

DO NOT PUNCTURE, INCINERATE, OR

BRING INTO CONTACT WITH ELECTRICITY.

DO NOT STORE AT TEMPERATURE

EXCEEDING 93ÉC (200ÉF). REPLACE AIRBAG

SYSTEM COMPONENTS ONLY BUT

INTERNAL DIFFERENCES MAY RESULT IN

INFERIOR OCCUPANT PROTECTION. THE

FASTENERS, SCREWS, AND BOLTS

ORIGINALLY USED FOR THE AIRBAG

SYSTEM COMPONENTS HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY

DESIGNED FOR THE AIRBAG SYSTEM. THEY

MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANY TIME A NEW FASTENER

IS NEEDED, REPLACE IT WITH THE

CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

MOPAR PARTS CATALOG.

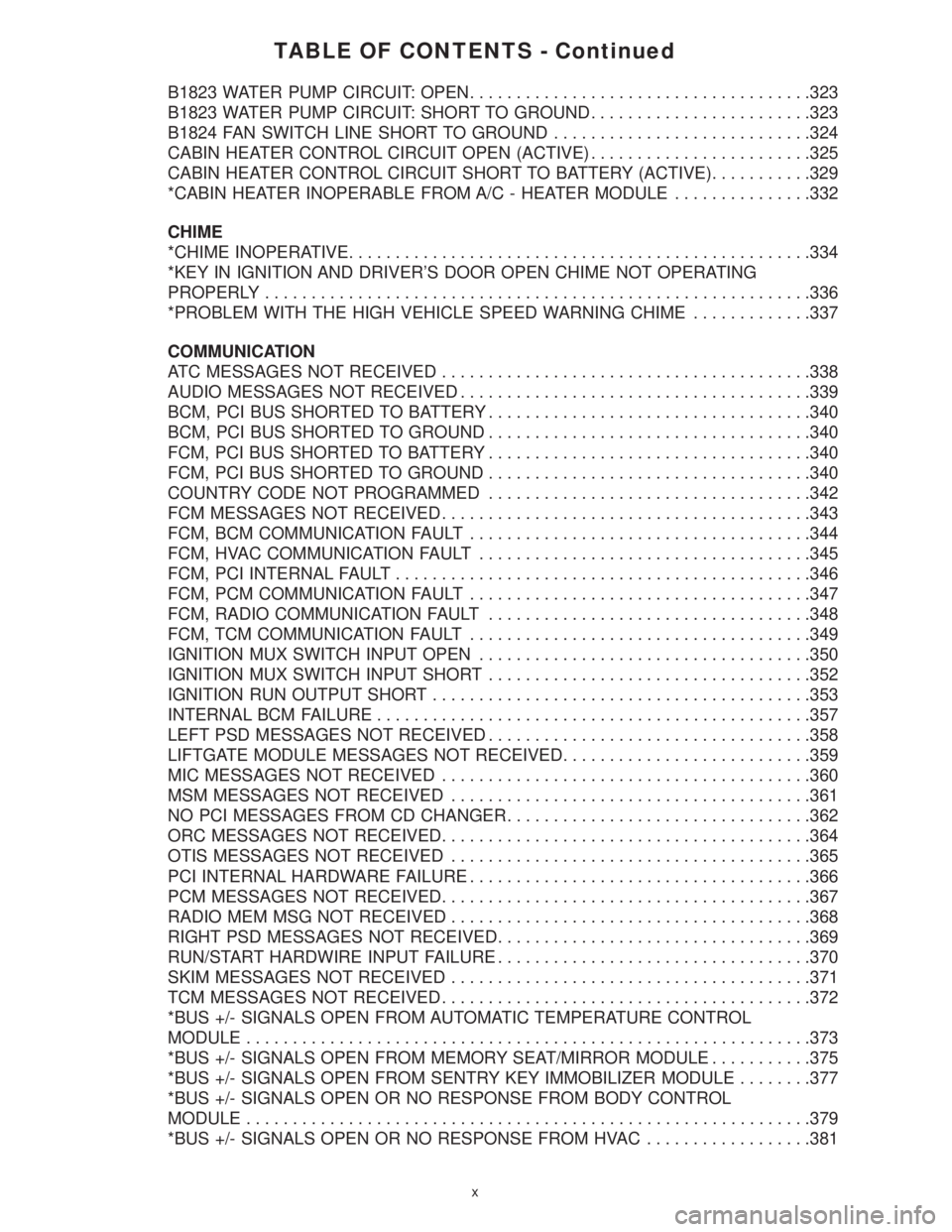

CAUTION: Deployed Front Air Bags may or may not have live pyrotechnic material within the

air bag inflator. Do not dispose of 2001 Model Year Driver and Passenger Airbags unless you

are sure of complete deployment. Please refer to the Hazardous Substance Control System for

Proper Disposal. Dispose of deployed air bags in a manner consistent with state, provincial,

local, and federal regulations. Use the following table to identify the status of the Airbag Squib.

AIRBAG SQUIB STATUS

(1) Using a DRBIIItread Airbag DTC'sIfthe following active codes are present:

ACTIVE DTC CONDITIONS SQUIB STATUS

Driver Squib 1 open

Driver Squib 2 openCheck the stored DTC'sAND IFthe stored min-

utes for both are within 15 minutes of each other.Both Driver Squib 1

and 2 were used.

Driver Squib 1 open

Driver Squib 2 openCheck the stored DTC'sAND IFthe stored min-

utes for Driver Squib 2 open is GREATER than

the stored minutes for Driver Squib 1 by 15 min-

utes or more.Driver Squib 1 was

used;

Driver Squib 2 is live.

Driver Squib 1 open

Driver Squib 2 openCheck the stored DTC'sAND IFthe stored min-

utes for Driver Squib 1 open is GREATER than

the stored minutes for Driver Squib 2 by 15 min-

utes or more.Driver Squib 1 is live;

Driver Squib 2 was

used.

IfDriver Squib 1 openAND IFDriver Squib 2 opens is NOT an active

code.Driver Squib 1 was

used;

Driver Squib 2 is live.

IfDriver Squib 2 openAND IFDriver Squib 1 open is NOT an active

code.Driver Squib 1 is live;

Driver Squib 2 was

used.

3

GENERAL INFORMATION

Page 33 of 4284

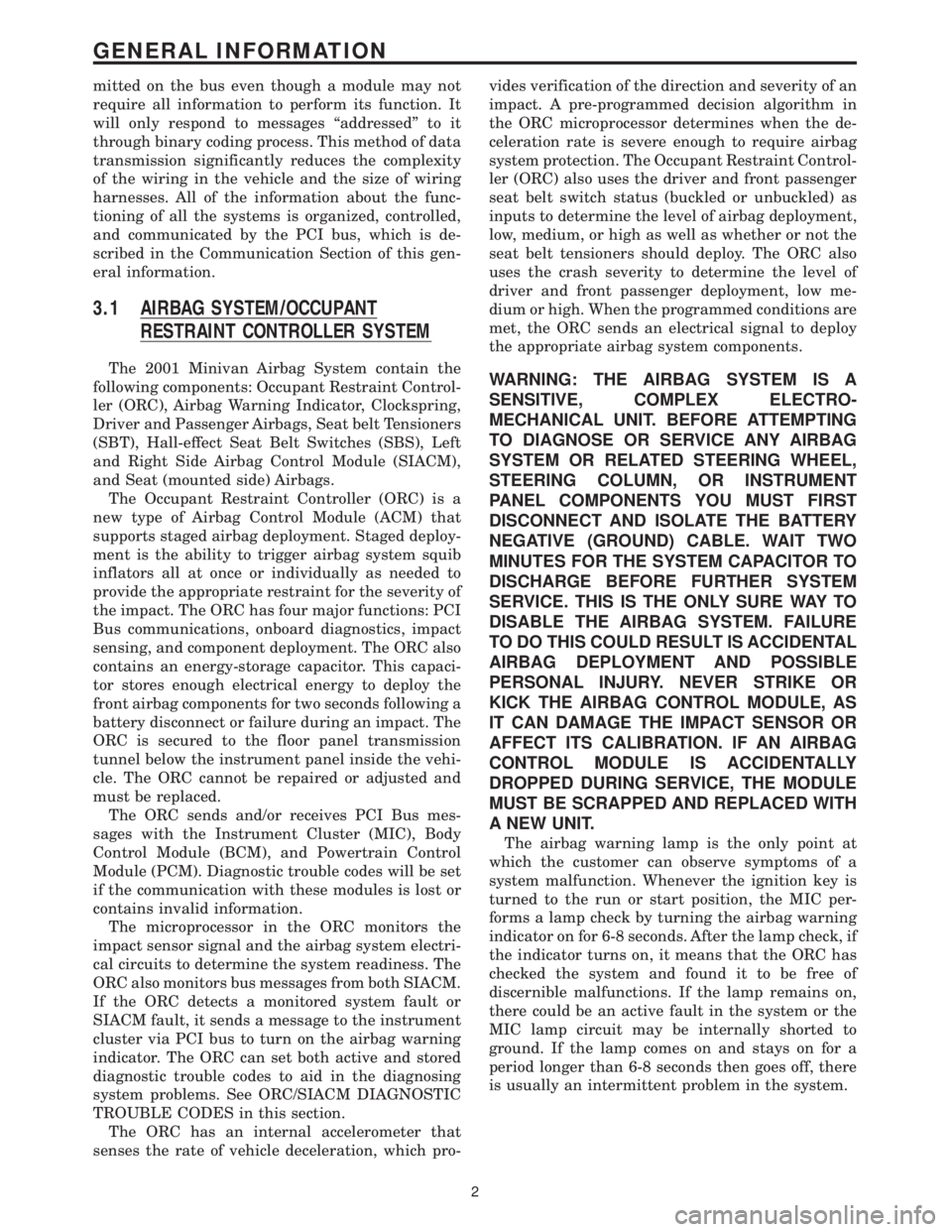

Ifneither of the following codes is an active code:

ACTIVE DTC SQUIB STATUS

Driver squib 1 open Status of Airbag is

Driver Squib 2 open Unknown.

3.1.2 CLOCKSPRING

The clockspring is mounted on the steering col-

umn behind the steering wheel. This assembly

consist of a plastic housing which contains a flat,

ribbon-like, electrically conductive tape that winds

and unwinds with the steering wheel rotation. The

clockspring is used to maintain a continuous elec-

trical circuit between the instrument panel wiring

and the driver airbag, the horn, and the vehicle

speed control switches if equipped. The clockspring

must be properly centered when it is reinstalled on

the steering column following any service proce-

dure, or it could be damaged. The clockspring can-

not be repaired and it must be replaced.

3.1.3 PASSENGER AIRBAG

The airbag door in the instrument panel top cover

the glove box is the most visible part of the passen-

ger side airbag system. The airbag door has a living

hinge at the top, which is secured to the instrument

panel top cover. Located under the airbag door is

the airbag cushion and its supporting components.

The airbag module includes a housing to which the

cushion and hybrid inflators are attached and

sealed. The 2001 Minivan is equipped with front

passenger airbag with dual stage inflators that

include a small canister of highly compressed argon

gas. The ORC uses vehicle crash severity, front

passenger seat belt switch status (buckled or un-

buckled) inputs to determine the level of airbag

deployment. When supplied with the proper electri-

cal signal, the hybrid inflator or inflators discharge

the compressed gas it contains directly into the

cushion. The airbag module cannot be repaired, and

must be replaced if deployed or in any way dam-

aged.

WARNING: THE PASSENGER AIRBAG

MODULE CONTAINS ARGON GAS

PRESSURIZED TO 17236.89 Kpa (2500 PSI).

DO NOT ATTEMPT TO DISMANTLE AN

AIRBAG MODULE OR TAMPER WITH ITS

INFLATOR. DO NOT PUNCTURE,

INCINERATE, OR BRING INTO CONTACT

WITH ELECTRICITY. DO NOT STORE AT

TEMPERATURE EXCEEDING 93ÉC (200ÉF).

REPLACE AIRBAG SYSTEM COMPONENTS

ONLY WITH PARTS SPECIFIED IN THE

MOPAR PARTS CATALOG. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE,

BUT INTERNAL DIFFERENCES MAY RESULT

IN INFERIOR OCCUPANT PROTECTION. THE

FASTENERS, SCREWS, AND BOLTS

ORIGINALLY USED FOR THE AIRBAG

SYSTEM COMPONENTS HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY

DESIGNED FOR THE AIRBAG SYSTEM. THEY

MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANY TIME A NEW FASTENER

IS NEEDED, REPLACE IT WITH THE

CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

MOPAR PARTS CATALOG.

4

GENERAL INFORMATION

Page 35 of 4284

if the system is functioning properly. If the test

finds a problem the SIACM will set both active and

stored diagnostic trouble codes. If a DTC is active

the SIACM will request that the airbag warning

lamp be turned on. The results of the system test

are transmitted on the PCI Bus to the ORC once

each second or on change in lamp state. If the

warning lamp status message from the either SI-

ACM contains a lamp on request, the ORC will set

an active DTC. At the same time as the DTC is set

the ORC sends a PCI Bus message to the mechan-

ical instrument cluster (MIC) requesting the airbag

warning lamp be turned on. Observe all ORC warn-

ing and caution statements when servicing or han-

dling the SIACM. SIACM are not repairable and

must be replaced if they are dropped.

WARNING: THE AIRBAG SYSTEM IS A

SENSITIVE, COMPLEX ELECTRO-

MECHANICAL UNIT. BEFORE ATTEMPTING

TO DIAGNOSE OR SERVICE ANY AIRBAG

SYSTEM OR RELATED STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT

PANEL COMPONENTS YOU MUST FIRST

DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. WAIT TWO

MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE FURTHER SYSTEM

SERVICE. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIRBAG SYSTEM. FAILURE

TO DO THIS COULD RESULT IN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY. NEVER STRIKE OR

KICK THE AIRBAG CONTROL MODULE, AS

IT CAN DAMAGE THE IMPACT SENSOR OR

AFFECT ITS CALIBRATION. IF AN AIRBAG

CONTROL MODULE IS ACCIDENTALLY

DROPPED DURING SERVICE, THE MODULE

MUST BE SCRAPPED AND REPLACED WITH

A NEW UNIT.

The airbag warning lamp is the only point at

which the customer can observe symptoms of a

system malfunction. Whenever the ignition key is

turned to the run or start position, the MIC per-

forms a lamp check by turning the airbag warning

indicator on for 6-8 seconds. After the lamp check, if

the indicator turns on, it means that the ORC has

checked the system and found it to be free of

discernible malfuctions. If the lamp remains on,

there could be an active fault in the system or the

MIC lamp circuit may be internally shorted to

ground. If the lamp comes on and stays on for a

period longer than 6-8 seconds then goes off, there

is usually an intermittent problem in the system.

3.1.7 SEAT AIRBAGS (SAB)

The left and right seat airbag modules are located

in the outboard end of the front seat backs. The

airbag module contains a bag, an inflator (a small

canister of highly compressed argon gas) and a

mounting bracket. The seat airbag module cannot

be repaired and must be replaced if deployed or in

any way damaged. When supplied with the proper

electrical signal the inflator seals the hole in the

airbag cushion so it can discharge the compressed

gas it contains directly into the cushion. Upon

deployment, the seat back trim cover will tear open

and allow the seat airbag to fully deploy between

the seat and the door.

WARNING: SEAT AIRBAG CONTAINS ARGON

GAS PRESSURIZED TO OVER 17236.89 Kpa

(2500 PSI). DO NOT ATTEMPT TO

DISMANTLE AN AIRBAG MODULE OR

TAMPER WITH ITS INFLATOR. DO NOT

PUNCTURE, INCINERATE, OR BRING INTO

CONTACT WITH ELECTRICITY. DO NOT

STORE AT TEMPERATURE EXCEEDING 93ÉC

(200ÉF). REPLACE AIRBAG SYSTEM

COMPONENTS ONLY WITH PARTS

SPECIFIED IN THE CHRYSLER MOPAR

PARTS CATALOG. SUBSTITUTE PARTS MAY

APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN

INFERIOR OCCUPANT PROTECTION. THE

FASTENERS, SCREWS, AND BOLTS

ORIGINALLY USED FOR THE AIRBAG

SYSTEM COMPONENTS HAVE SPECIAL

COATINGS AND ARE SPECIFICALLY

DESIGNED FOR THE AIRBAG SYSTEM. THEY

MUST NEVER BE REPLACED WITH ANY

SUBSTITUTES. ANY TIME A NEW FASTENER

IS NEEDED, REPLACE IT WITH THE

CORRECT FASTENERS PROVIDED IN THE

SERVICE PACKAGE OR SPECIFIED IN THE

MOPAR PARTS CATALOG.

3.1.8 ORC/SIACM DIAGNOSTIC TROUBLE

CODES

Airbag diagnostic trouble codes consist of active

and stored codes. If more than one code exists,

diagnostic priority should be given to the active

codes. Each diagnostic trouble code is diagnosed by

following a specific testing procedure. The diagnos-

tic test procedures contain step-by-step instructions

for determining the cause of the trouble codes. It is

not necessary to perform all of the tests in this book

to diagnose an individual code. Always begin by

reading the diagnostic trouble codes using the DRB.

Always begin diagnostic with the Table of Contents

6

GENERAL INFORMATION

Page 36 of 4284

section 7.0. This will direct you to the specific test(s)

that must be performed. Active diagnostic trouble

codes for the airbag system are not permanent and

will change the moment the reason for the code is

corrected. In certain test procedures within this

manual, diagnostic trouble codes are used as a

diagnostic tool.

3.1.9 ACTIVE CODES

The code becomes active as soon as the malfunc-

tion is detected or key-on, whichever occurs first. An

active trouble code indicates an on-going malfunc-

tion. This means that the defect is currently there

every time the airbag control module checks that

circuit or component. It is impossible to erase an

active code. Active codes automatically erase by

themselves when the reason for the code has been

corrected. With the exception of the warning lamp

trouble codes or malfunctions, when a malfunction

is detected, the airbag lamp remains lit for a mini-

mum of 12 seconds or as long as the malfunction is

present.

3.1.10 STORED CODES

Airbag codes are automatically stored in the

ORC's memory as soon as the malfunction is de-

tected. The exception is the Loss of Ignition Run

Only code which is an active code only. A stored code

indicates there was an active code present at some

time. However, the code currently may not be

present as an active code, although another code

could be active. When a trouble code occurs, the

airbag warning indicator illuminates for 12 seconds

minimum (even if the problem existed for less than

12 seconds). The code is stored, along with the time

in minutes it was active, and the number of times

the ignition has been cycled since the problem was

last detected. The minimum time shown for any

code will be one minute, even if the code was

actually present for less than one minute. Thus, the

time shown for a code will be one minute, even if the

code was actually present for less than one minute.

Thus, the time shown for a code that was present

for two minutes 13 seconds, for example, would be

three minutes. If a malfunction is detected a diag-

nostic trouble code is stored and will remain stored.

When and if the malfunction ceases to exist, an

ignition cycle count will be initiated for that code. If

the ignition cycle count reaches 100 without a

reoccurrence of the same malfunction, the diagnos-

tic trouble code is erased and that ignition cycle

counter is reset to zero. If the malfunction reoccurs

before the count reaches 100, then the ignition cycle

counter will be reset and diagnostic trouble code

will continue to be a stored code. If a malfunction is

not active while performing a diagnostic test proce-

dure, the active code diagnostic test will not locatethe source of the problem. In this case, the stored

code can indicate an area to inspect. If no obvious

problems are found, erase stored codes, and with

the ignition on wiggle the wire harness and connec-

tors, rotate the steering wheel from stop to stop.

Recheck for codes periodically as you work through

the system. This procedure may uncover a malfunc-

tion that is difficult to locate.

3.2 AUDIO SYSTEM

The following radios are all on the PCI Bus

system - RBB, RBK, RAZ, RAD, RBT, and RBY. The

remaining radio also available, the RAS, is NOT on

the PCI Bus. The PCI Bus inputs into the radio are

used for VF dimming, remote steering wheel con-

trols and cabin EQ preference. PCI Bus outputs

from the radio are used for the Name Brand

Speaker (NBS) relay activation, as well as cabin EQ

preference.

The RBB and RBK radios have the capability of

containing multiple vehicle unique equalization

curves (cabin EQ preferences) within the radio.

These curves will reside in the radio's flash memory.

The radio is capable of storing up to 20 unique

equalization curves. The latent curves can be se-

lected via the Front Control Module transmitting a

PCI Bus message to the radio in response to a radio

request for equalization message. Upon receipt of a

valid equalization select message response, the ra-

dio will switch to output the corresponding equal-

ization curve.

All the radios, except the RAS, are capable of

displaying faults and allowing certain actuation

tests through the use of the DRBIIIt. When at-

tempting to perform PCI Bus diagnostics, the first

step is to identify the radio in use in the vehicle.

When trouble shooting output shorts or ªoutputº

error messages, the following applies:

On radios without an external amplifier, the term

output refers to the path between the radio and the

speaker. This type of circuit can be monitored all

the way through the speaker connections by the

radio assembly. When the radio displays a shorted

output DTC with this type of system, the speaker,

radio, or wiring could be at fault. The output DTC

could refer to the front or rear output or a left or

right output. The reason for the difference is the

pairing of the output sections of the radio. Some are

paired left and right, others are paired front and

rear.

On radios with an external amplifier, the term

ªoutputº refers to the circuit between the radio

connector and the amplifier. The radio is capable of

monitoring only this portion and can tell nothing

about the circuit between the amplifier and the

speakers. Consequently, a shorted output DTC on

7

GENERAL INFORMATION