fuel CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1501 of 2399

REMOVAL

REMOVAL - PEDAL POSITION SENSOR (LHD)

(1) Disconnect negative battery cable.

(2) Disconnect pedal position sensor electrical con-

nector (Fig. 4).

(3) Remove 2 pedal position sensor retaining nuts

(Fig. 4).

(4) Remove pedal position sensor from vehicle.

REMOVAL - PEDAL POSITION SENSOR (RHD)

(1) Disconnect negative battery cable.

(2) Disconnect pedal position sensor electrical con-

nector (Fig. 4).

(3) Remove 2 pedal position sensor retaining nuts

(Fig. 4).

(4) Remove pedal position sensor from vehicle.

INSTALLATION

INSTALLATION - PEDAL POSITION SENSOR

(LHD)

(1) Position pedal position sensor in vehicle.

(2) Install pedal position sensor retaining nuts

(Fig. 4).

(3) Connect pedal position sensor electrical connec-

tor (Fig. 4).

(4) Connect negative battery cable.

INSTALLATION - PEDAL POSITION SENSOR

(RHD)

(1) Position pedal position sensor in vehicle.

(2) Install 2 pedal position sensor retaining nuts

(Fig. 4).

(3) Connect pedal position sensor electrical connec-

tor (Fig. 4).

(4) Connect negative battery cable.

BOOST PRESSURE SENSOR

DESCRIPTION

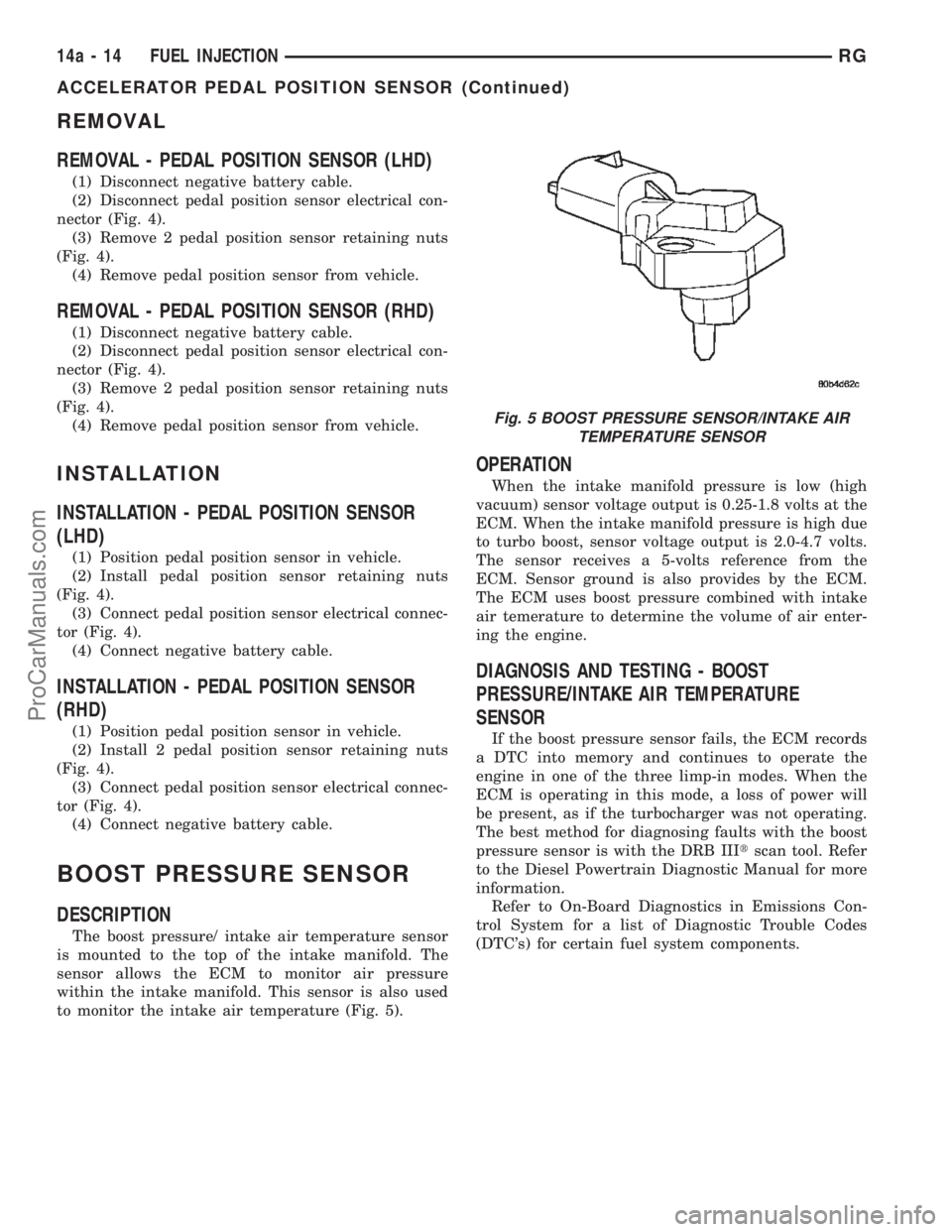

The boost pressure/ intake air temperature sensor

is mounted to the top of the intake manifold. The

sensor allows the ECM to monitor air pressure

within the intake manifold. This sensor is also used

to monitor the intake air temperature (Fig. 5).

OPERATION

When the intake manifold pressure is low (high

vacuum) sensor voltage output is 0.25-1.8 volts at the

ECM. When the intake manifold pressure is high due

to turbo boost, sensor voltage output is 2.0-4.7 volts.

The sensor receives a 5-volts reference from the

ECM. Sensor ground is also provides by the ECM.

The ECM uses boost pressure combined with intake

air temerature to determine the volume of air enter-

ing the engine.

DIAGNOSIS AND TESTING - BOOST

PRESSURE/INTAKE AIR TEMPERATURE

SENSOR

If the boost pressure sensor fails, the ECM records

a DTC into memory and continues to operate the

engine in one of the three limp-in modes. When the

ECM is operating in this mode, a loss of power will

be present, as if the turbocharger was not operating.

The best method for diagnosing faults with the boost

pressure sensor is with the DRB IIItscan tool. Refer

to the Diesel Powertrain Diagnostic Manual for more

information.

Refer to On-Board Diagnostics in Emissions Con-

trol System for a list of Diagnostic Trouble Codes

(DTC's) for certain fuel system components.

Fig. 5 BOOST PRESSURE SENSOR/INTAKE AIR

TEMPERATURE SENSOR

14a - 14 FUEL INJECTIONRG

ACCELERATOR PEDAL POSITION SENSOR (Continued)

ProCarManuals.com

Page 1502 of 2399

INTAKE AIR TEMPERATURE

SENSOR

DESCRIPTION

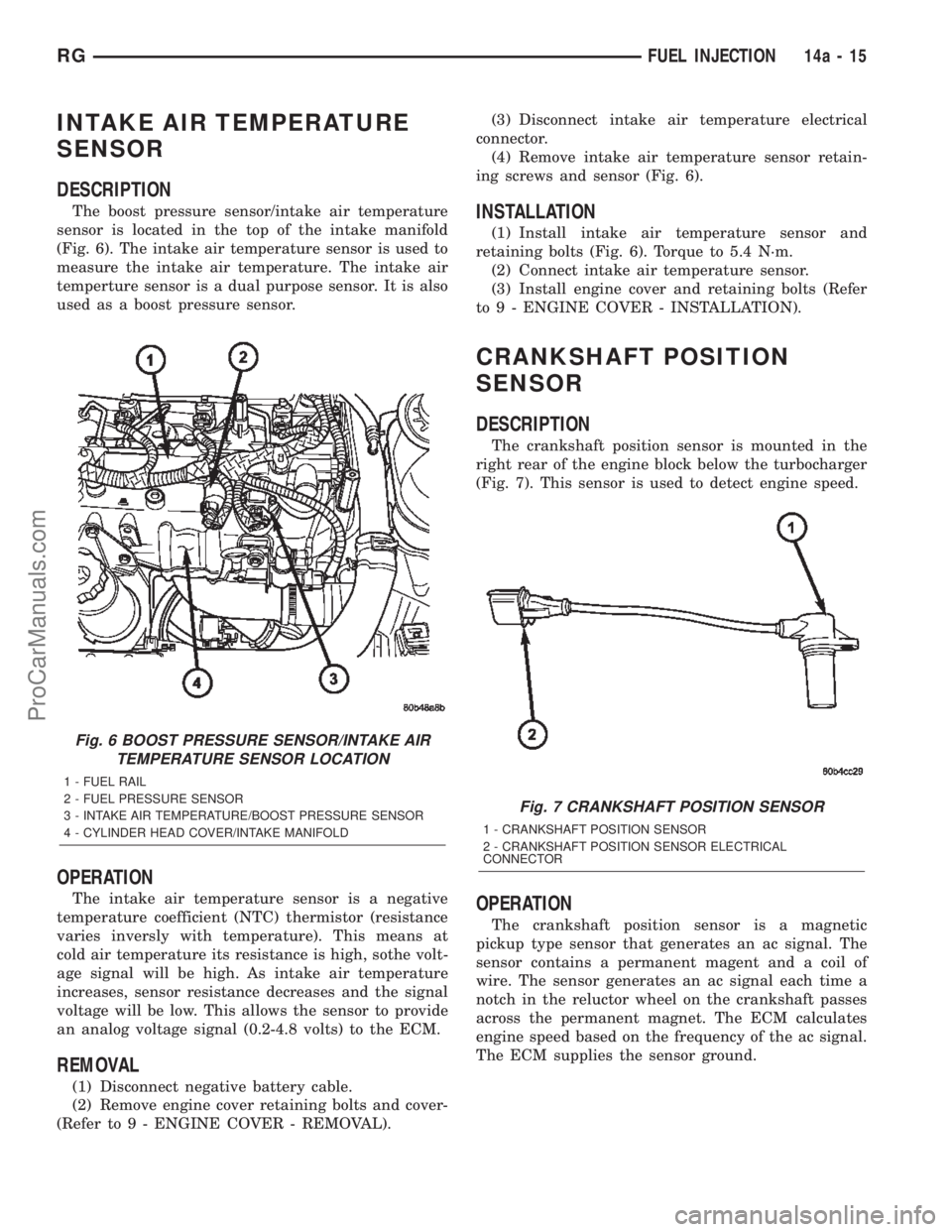

The boost pressure sensor/intake air temperature

sensor is located in the top of the intake manifold

(Fig. 6). The intake air temperature sensor is used to

measure the intake air temperature. The intake air

temperture sensor is a dual purpose sensor. It is also

used as a boost pressure sensor.

OPERATION

The intake air temperature sensor is a negative

temperature coefficient (NTC) thermistor (resistance

varies inversly with temperature). This means at

cold air temperature its resistance is high, sothe volt-

age signal will be high. As intake air temperature

increases, sensor resistance decreases and the signal

voltage will be low. This allows the sensor to provide

an analog voltage signal (0.2-4.8 volts) to the ECM.

REMOVAL

(1) Disconnect negative battery cable.

(2) Remove engine cover retaining bolts and cover-

(Refer to 9 - ENGINE COVER - REMOVAL).(3) Disconnect intake air temperature electrical

connector.

(4) Remove intake air temperature sensor retain-

ing screws and sensor (Fig. 6).

INSTALLATION

(1) Install intake air temperature sensor and

retaining bolts (Fig. 6). Torque to 5.4 N´m.

(2) Connect intake air temperature sensor.

(3) Install engine cover and retaining bolts (Refer

to 9 - ENGINE COVER - INSTALLATION).

CRANKSHAFT POSITION

SENSOR

DESCRIPTION

The crankshaft position sensor is mounted in the

right rear of the engine block below the turbocharger

(Fig. 7). This sensor is used to detect engine speed.

OPERATION

The crankshaft position sensor is a magnetic

pickup type sensor that generates an ac signal. The

sensor contains a permanent magent and a coil of

wire. The sensor generates an ac signal each time a

notch in the reluctor wheel on the crankshaft passes

across the permanent magnet. The ECM calculates

engine speed based on the frequency of the ac signal.

The ECM supplies the sensor ground.

Fig. 6 BOOST PRESSURE SENSOR/INTAKE AIR

TEMPERATURE SENSOR LOCATION

1 - FUEL RAIL

2 - FUEL PRESSURE SENSOR

3 - INTAKE AIR TEMPERATURE/BOOST PRESSURE SENSOR

4 - CYLINDER HEAD COVER/INTAKE MANIFOLD

Fig. 7 CRANKSHAFT POSITION SENSOR

1 - CRANKSHAFT POSITION SENSOR

2 - CRANKSHAFT POSITION SENSOR ELECTRICAL

CONNECTOR

RGFUEL INJECTION14a-15

ProCarManuals.com

Page 1503 of 2399

MASS AIR FLOW (MAF)

SENSOR

DESCRIPTION

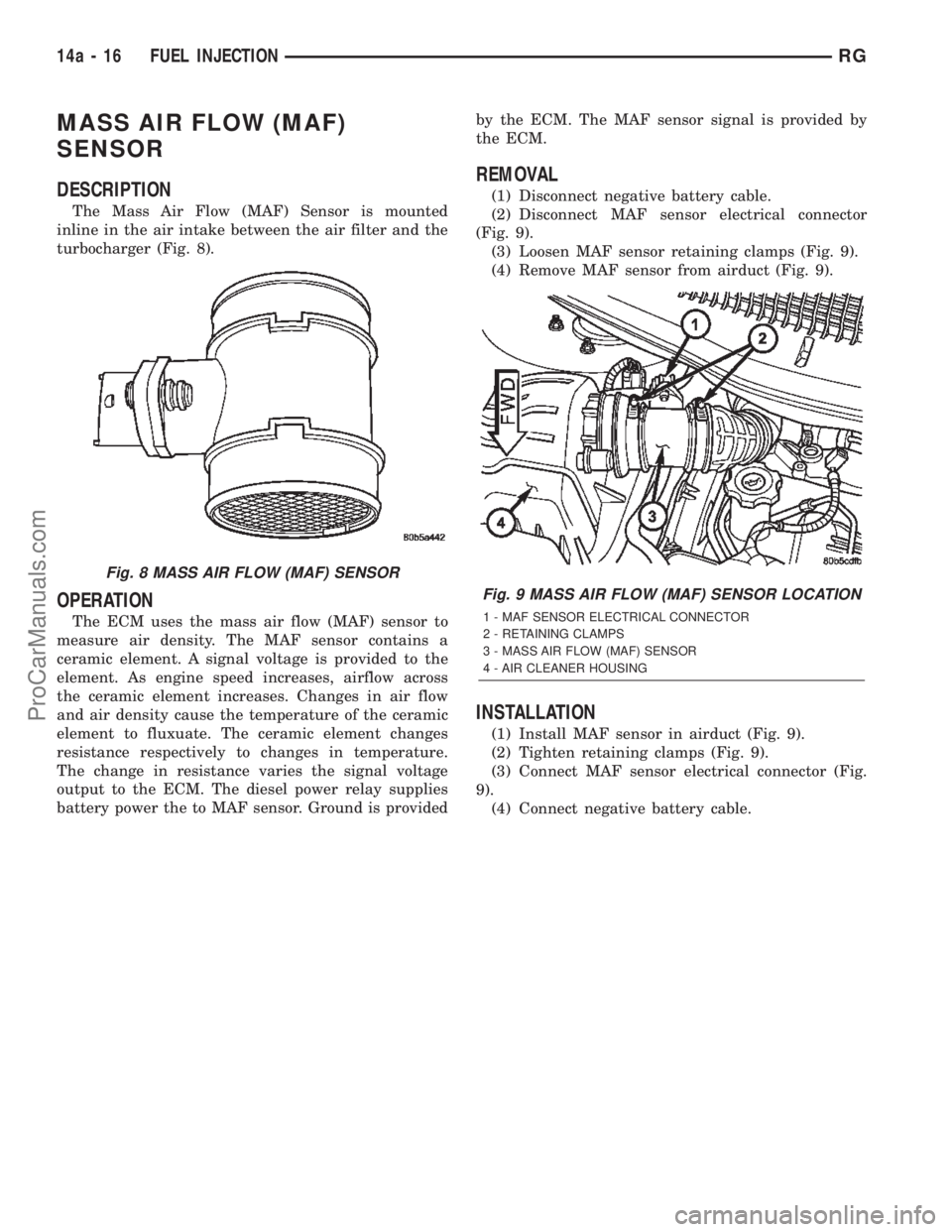

The Mass Air Flow (MAF) Sensor is mounted

inline in the air intake between the air filter and the

turbocharger (Fig. 8).

OPERATION

The ECM uses the mass air flow (MAF) sensor to

measure air density. The MAF sensor contains a

ceramic element. A signal voltage is provided to the

element. As engine speed increases, airflow across

the ceramic element increases. Changes in air flow

and air density cause the temperature of the ceramic

element to fluxuate. The ceramic element changes

resistance respectively to changes in temperature.

The change in resistance varies the signal voltage

output to the ECM. The diesel power relay supplies

battery power the to MAF sensor. Ground is providedby the ECM. The MAF sensor signal is provided by

the ECM.

REMOVAL

(1) Disconnect negative battery cable.

(2) Disconnect MAF sensor electrical connector

(Fig. 9).

(3) Loosen MAF sensor retaining clamps (Fig. 9).

(4) Remove MAF sensor from airduct (Fig. 9).

INSTALLATION

(1) Install MAF sensor in airduct (Fig. 9).

(2) Tighten retaining clamps (Fig. 9).

(3) Connect MAF sensor electrical connector (Fig.

9).

(4) Connect negative battery cable.

Fig. 8 MASS AIR FLOW (MAF) SENSOR

Fig. 9 MASS AIR FLOW (MAF) SENSOR LOCATION

1 - MAF SENSOR ELECTRICAL CONNECTOR

2 - RETAINING CLAMPS

3 - MASS AIR FLOW (MAF) SENSOR

4 - AIR CLEANER HOUSING

14a - 16 FUEL INJECTIONRG

ProCarManuals.com

Page 1679 of 2399

ADJUSTMENTS

THROTTLE VALVE LINKAGE ADJUSTMENT

The throttle valve linkage adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too short, early shifts and slippage

between shifts may occur. If the setting is too long,

shifts may be delayed and part throttle downshifts

may be very sensitive.

LINKAGE ADJUSTMENT PROCEDURE

(1) Perform transaxle throttle valve linkage

adjustment while engine is at normal operating tem-

perature.

(2) Using small screwdriver, disengage adjustment

lock at transaxle.

(3) Rotate lever at transaxle all the way to the left

side of vehicle against stop.

(4) Slide cable adjuster until cable core end

touches clip at throttle valve lever.

(5) Press adjuster lock (Fig. 228) to retain setting.

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 229) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the fluid cooler and lines.

Fig. 228 Throttle Valve Cable Adjustment Lock

1 - ADJUSTER LOCK

Fig. 229 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

21 - 122 31TH AUTOMATIC TRANSAXLERS

THROTTLE VALVE CABLE (Continued)

ProCarManuals.com

Page 1842 of 2399

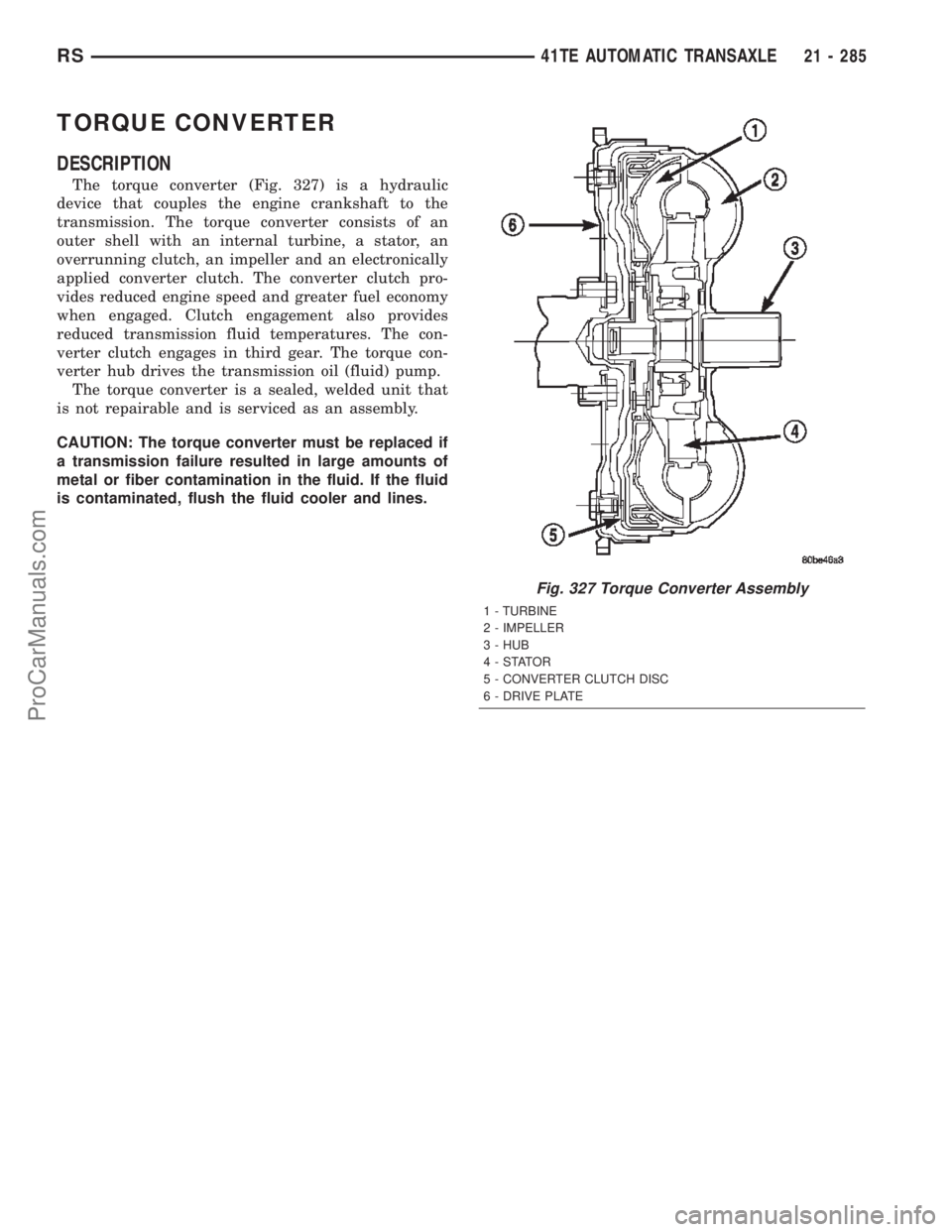

TORQUE CONVERTER

DESCRIPTION

The torque converter (Fig. 327) is a hydraulic

device that couples the engine crankshaft to the

transmission. The torque converter consists of an

outer shell with an internal turbine, a stator, an

overrunning clutch, an impeller and an electronically

applied converter clutch. The converter clutch pro-

vides reduced engine speed and greater fuel economy

when engaged. Clutch engagement also provides

reduced transmission fluid temperatures. The con-

verter clutch engages in third gear. The torque con-

verter hub drives the transmission oil (fluid) pump.

The torque converter is a sealed, welded unit that

is not repairable and is serviced as an assembly.

CAUTION: The torque converter must be replaced if

a transmission failure resulted in large amounts of

metal or fiber contamination in the fluid. If the fluid

is contaminated, flush the fluid cooler and lines.

Fig. 327 Torque Converter Assembly

1 - TURBINE

2 - IMPELLER

3 - HUB

4-STATOR

5 - CONVERTER CLUTCH DISC

6 - DRIVE PLATE

RS41TE AUTOMATIC TRANSAXLE21 - 285

ProCarManuals.com

Page 1850 of 2399

is requested when the TCM pulses this signal to

ground. The PCM recognizes this request and

responds by retarding ignition timing, killing fuel

injectors, etc. The PCM sends a confirmation of the

request to the TCM via the communication bus.

Torque reduction is not noticable by the driver, and

usually lasts for a very short period of time.

If the confirmation signal is not received by the

TCM after two sequential request messages, a diag-

nostic trouble code will be set.

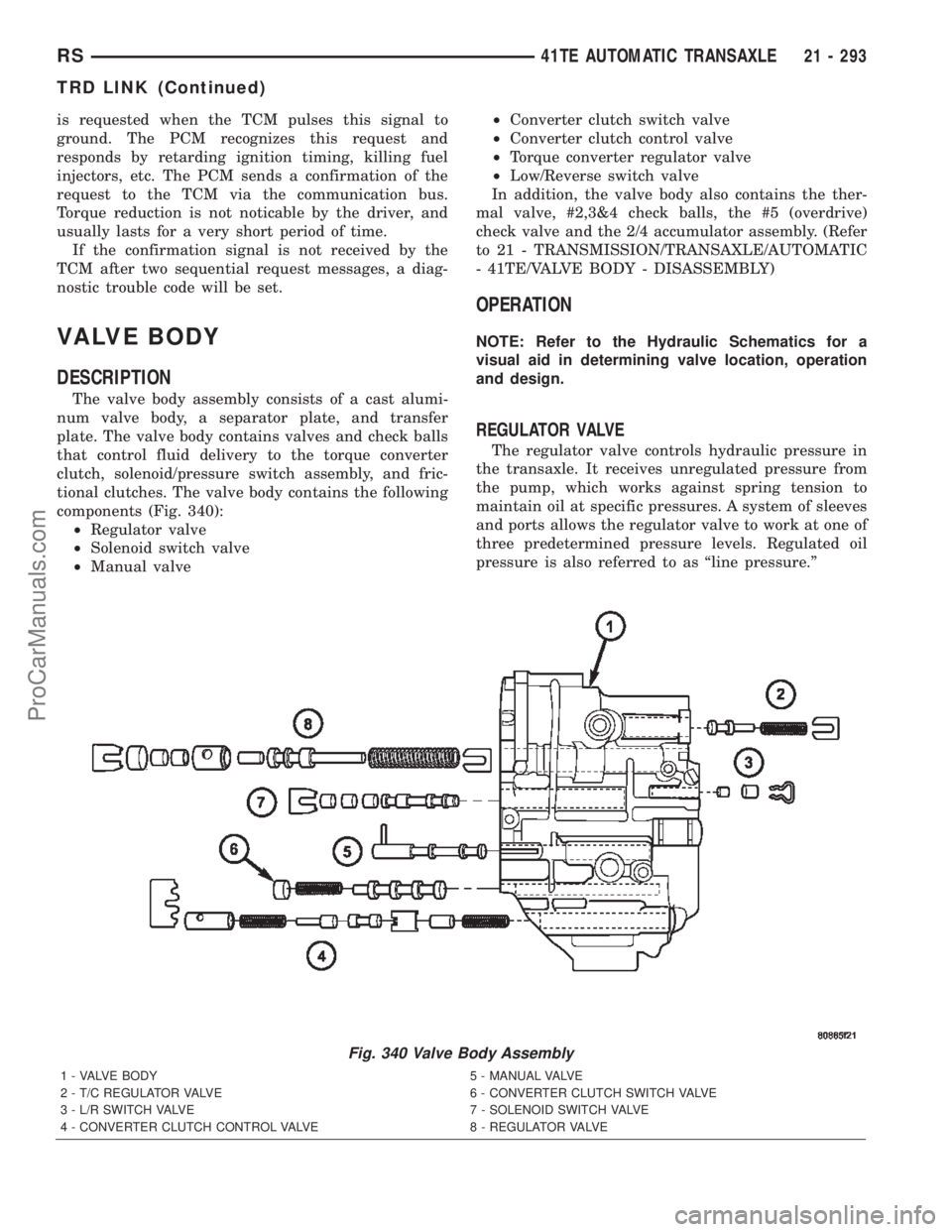

VALVE BODY

DESCRIPTION

The valve body assembly consists of a cast alumi-

num valve body, a separator plate, and transfer

plate. The valve body contains valves and check balls

that control fluid delivery to the torque converter

clutch, solenoid/pressure switch assembly, and fric-

tional clutches. The valve body contains the following

components (Fig. 340):

²Regulator valve

²Solenoid switch valve

²Manual valve²Converter clutch switch valve

²Converter clutch control valve

²Torque converter regulator valve

²Low/Reverse switch valve

In addition, the valve body also contains the ther-

mal valve, #2,3&4 check balls, the #5 (overdrive)

check valve and the 2/4 accumulator assembly. (Refer

to 21 - TRANSMISSION/TRANSAXLE/AUTOMATIC

- 41TE/VALVE BODY - DISASSEMBLY)

OPERATION

NOTE: Refer to the Hydraulic Schematics for a

visual aid in determining valve location, operation

and design.

REGULATOR VALVE

The regulator valve controls hydraulic pressure in

the transaxle. It receives unregulated pressure from

the pump, which works against spring tension to

maintain oil at specific pressures. A system of sleeves

and ports allows the regulator valve to work at one of

three predetermined pressure levels. Regulated oil

pressure is also referred to as ªline pressure.º

Fig. 340 Valve Body Assembly

1 - VALVE BODY 5 - MANUAL VALVE

2 - T/C REGULATOR VALVE 6 - CONVERTER CLUTCH SWITCH VALVE

3 - L/R SWITCH VALVE 7 - SOLENOID SWITCH VALVE

4 - CONVERTER CLUTCH CONTROL VALVE 8 - REGULATOR VALVE

RS41TE AUTOMATIC TRANSAXLE21 - 293

TRD LINK (Continued)

ProCarManuals.com

Page 1977 of 2399

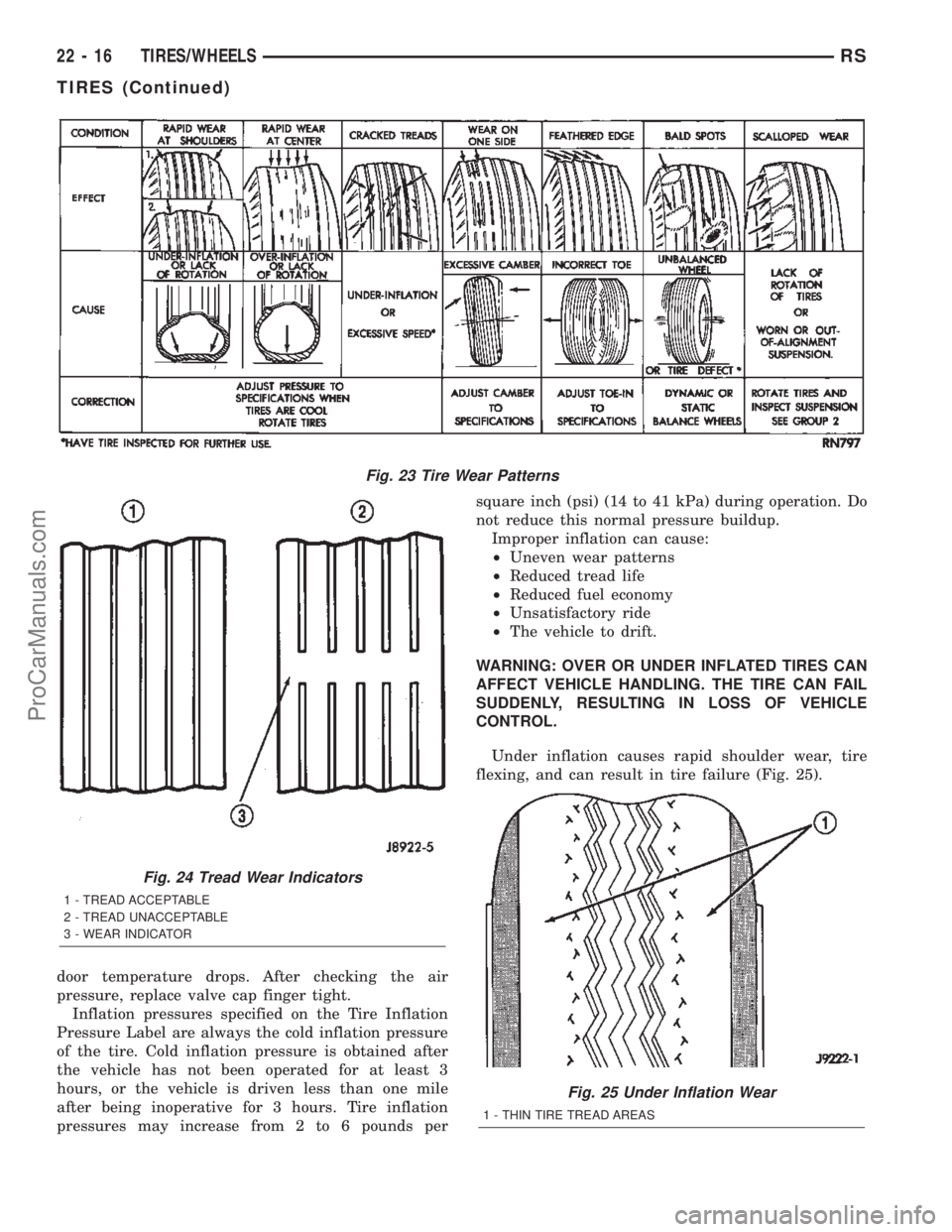

door temperature drops. After checking the air

pressure, replace valve cap finger tight.

Inflation pressures specified on the Tire Inflation

Pressure Label are always the cold inflation pressure

of the tire. Cold inflation pressure is obtained after

the vehicle has not been operated for at least 3

hours, or the vehicle is driven less than one mile

after being inoperative for 3 hours. Tire inflation

pressures may increase from 2 to 6 pounds persquare inch (psi) (14 to 41 kPa) during operation. Do

not reduce this normal pressure buildup.

Improper inflation can cause:

²Uneven wear patterns

²Reduced tread life

²Reduced fuel economy

²Unsatisfactory ride

²The vehicle to drift.

WARNING: OVER OR UNDER INFLATED TIRES CAN

AFFECT VEHICLE HANDLING. THE TIRE CAN FAIL

SUDDENLY, RESULTING IN LOSS OF VEHICLE

CONTROL.

Under inflation causes rapid shoulder wear, tire

flexing, and can result in tire failure (Fig. 25).

Fig. 23 Tire Wear Patterns

Fig. 24 Tread Wear Indicators

1 - TREAD ACCEPTABLE

2 - TREAD UNACCEPTABLE

3 - WEAR INDICATOR

Fig. 25 Under Inflation Wear

1 - THIN TIRE TREAD AREAS

22 - 16 TIRES/WHEELSRS

TIRES (Continued)

ProCarManuals.com

Page 1996 of 2399

MOPARTSPRAY WHITE LUBE OR EQUIVALENT

²Door Check Straps

²Liftgate Latches

²Liftgate Prop Pivots

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Liftgate Latch

MOPARTMultipurpose GREASE OR EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Liftgate Lock Cylinder

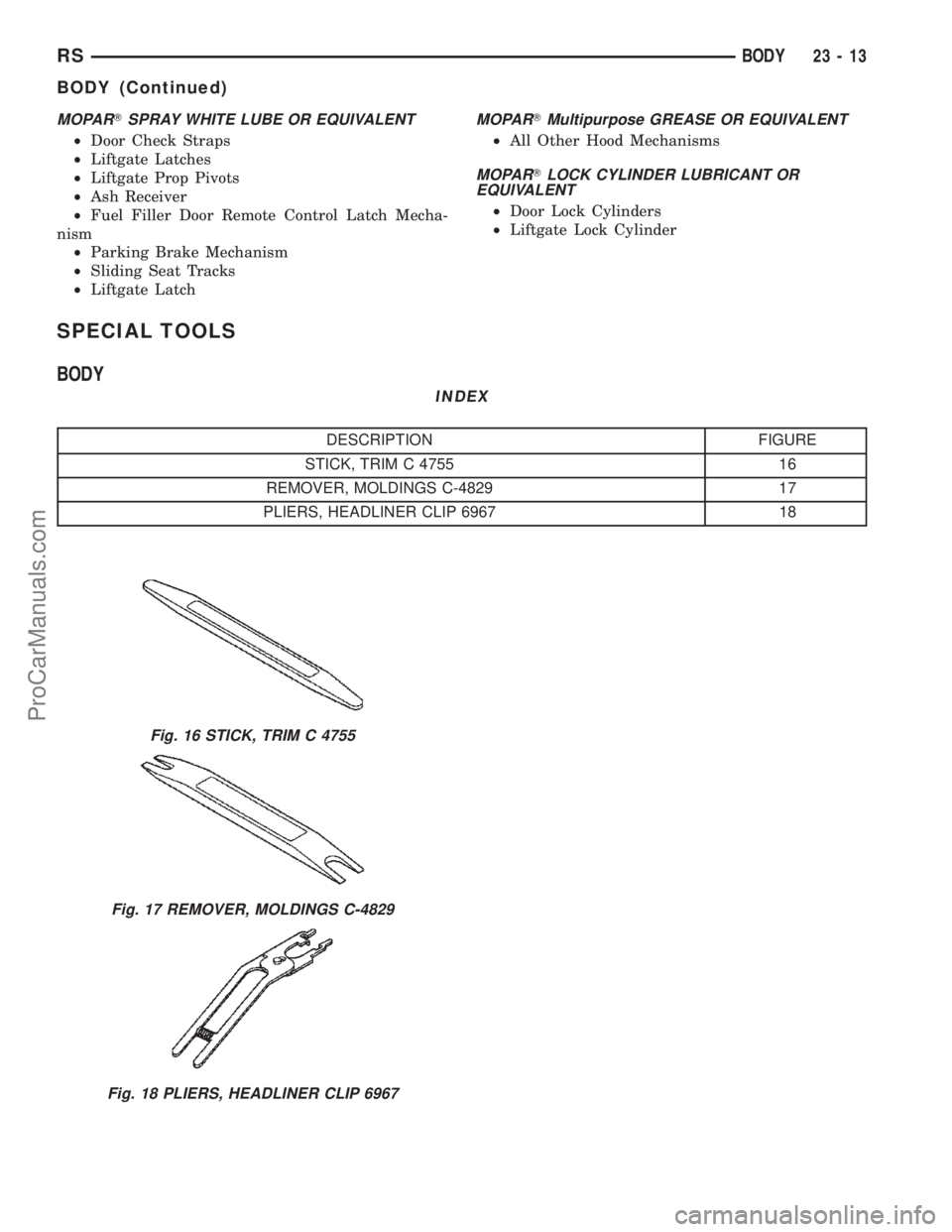

SPECIAL TOOLS

BODY

INDEX

DESCRIPTION FIGURE

STICK, TRIM C 4755 16

REMOVER, MOLDINGS C-4829 17

PLIERS, HEADLINER CLIP 6967 18

Fig. 16 STICK, TRIM C 4755

Fig. 17 REMOVER, MOLDINGS C-4829

Fig. 18 PLIERS, HEADLINER CLIP 6967

RSBODY23-13

BODY (Continued)

ProCarManuals.com

Page 2013 of 2399

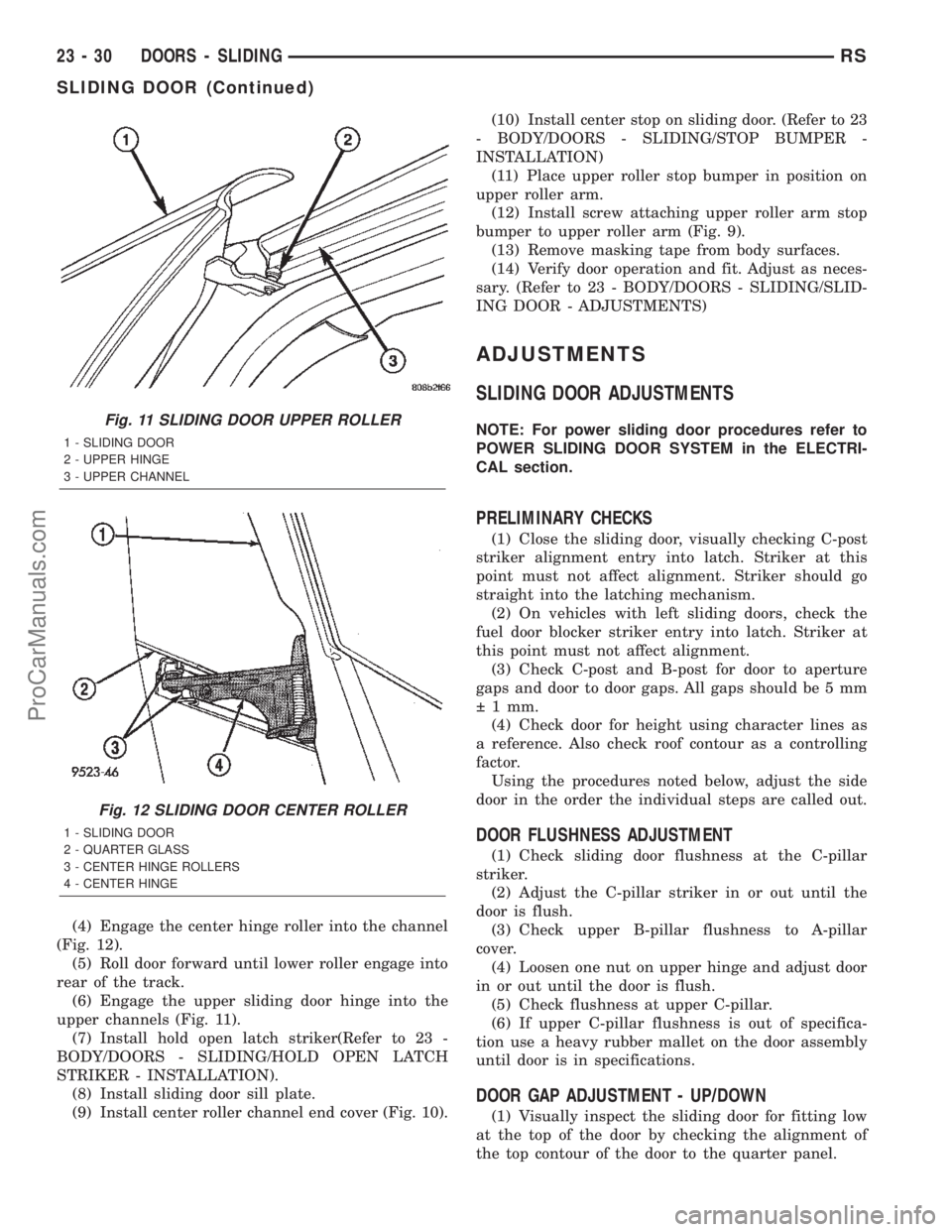

(4) Engage the center hinge roller into the channel

(Fig. 12).

(5) Roll door forward until lower roller engage into

rear of the track.

(6) Engage the upper sliding door hinge into the

upper channels (Fig. 11).

(7) Install hold open latch striker(Refer to 23 -

BODY/DOORS - SLIDING/HOLD OPEN LATCH

STRIKER - INSTALLATION).

(8) Install sliding door sill plate.

(9) Install center roller channel end cover (Fig. 10).(10) Install center stop on sliding door. (Refer to 23

- BODY/DOORS - SLIDING/STOP BUMPER -

INSTALLATION)

(11) Place upper roller stop bumper in position on

upper roller arm.

(12) Install screw attaching upper roller arm stop

bumper to upper roller arm (Fig. 9).

(13) Remove masking tape from body surfaces.

(14) Verify door operation and fit. Adjust as neces-

sary. (Refer to 23 - BODY/DOORS - SLIDING/SLID-

ING DOOR - ADJUSTMENTS)

ADJUSTMENTS

SLIDING DOOR ADJUSTMENTS

NOTE: For power sliding door procedures refer to

POWER SLIDING DOOR SYSTEM in the ELECTRI-

CAL section.

PRELIMINARY CHECKS

(1) Close the sliding door, visually checking C-post

striker alignment entry into latch. Striker at this

point must not affect alignment. Striker should go

straight into the latching mechanism.

(2) On vehicles with left sliding doors, check the

fuel door blocker striker entry into latch. Striker at

this point must not affect alignment.

(3) Check C-post and B-post for door to aperture

gaps and door to door gaps. All gaps should be 5 mm

1 mm.

(4) Check door for height using character lines as

a reference. Also check roof contour as a controlling

factor.

Using the procedures noted below, adjust the side

door in the order the individual steps are called out.

DOOR FLUSHNESS ADJUSTMENT

(1) Check sliding door flushness at the C-pillar

striker.

(2) Adjust the C-pillar striker in or out until the

door is flush.

(3) Check upper B-pillar flushness to A-pillar

cover.

(4) Loosen one nut on upper hinge and adjust door

in or out until the door is flush.

(5) Check flushness at upper C-pillar.

(6) If upper C-pillar flushness is out of specifica-

tion use a heavy rubber mallet on the door assembly

until door is in specifications.

DOOR GAP ADJUSTMENT - UP/DOWN

(1) Visually inspect the sliding door for fitting low

at the top of the door by checking the alignment of

the top contour of the door to the quarter panel.

Fig. 11 SLIDING DOOR UPPER ROLLER

1 - SLIDING DOOR

2 - UPPER HINGE

3 - UPPER CHANNEL

Fig. 12 SLIDING DOOR CENTER ROLLER

1 - SLIDING DOOR

2 - QUARTER GLASS

3 - CENTER HINGE ROLLERS

4 - CENTER HINGE

23 - 30 DOORS - SLIDINGRS

SLIDING DOOR (Continued)

ProCarManuals.com

Page 2027 of 2399

EXTERIOR

TABLE OF CONTENTS

page page

BODY SIDE MOLDINGS

REMOVAL.............................44

INSTALLATION.........................45

COWL GRILLE

REMOVAL.............................50

INSTALLATION.........................50

EXTERIOR NAME PLATES - TAPE ATTACHED

REMOVAL.............................50

INSTALLATION.........................51

EXTERIOR NAME PLATES - ADHESIVE

ATTACHED

REMOVAL.............................51

INSTALLATION.........................51

FRONT FENDER

REMOVAL.............................51

INSTALLATION.........................51

FUEL FILL DOOR

REMOVAL.............................52

INSTALLATION.........................52

FUEL FILL DOOR BLOCKER LATCH

REMOVAL.............................52

INSTALLATION.........................52

FUEL FILL DOOR BLOCKER LATCH STRIKER

REMOVAL.............................53

INSTALLATION.........................53

FUEL FILL DOOR BLOCKER LOCKOUT LINK

REMOVAL.............................53INSTALLATION.........................54

GRILLE OPENING REINFORCEMENT

REMOVAL.............................54

INSTALLATION.........................54

FRONT WHEELHOUSE SPLASH SHIELD

REMOVAL.............................55

INSTALLATION.........................55

LUGGAGE RACK RISER

REMOVAL.............................55

INSTALLATION.........................56

LUGGAGE RACK CROSSBAR

REMOVAL.............................56

INSTALLATION.........................57

REAR QUARTER PANEL/FENDER AIR

EXHAUSTER

DESCRIPTION.........................57

REMOVAL.............................57

INSTALLATION.........................58

ROOF JOINT MOLDING

REMOVAL.............................58

INSTALLATION.........................58

SIDE VIEW MIRROR

REMOVAL.............................58

INSTALLATION.........................58

SIDE VIEW MIRROR GLASS

REMOVAL.............................59

INSTALLATION.........................59

BODY SIDE MOLDINGS

REMOVAL

Refer to (Fig. 1), (Fig. 2), (Fig. 3), (Fig. 4) or (Fig.

5)for proper location of fasteners holding the molding

to the wheelhouse lip and rocker panels.

(1) Warm the affected stick on molding and body

metal to approximately 38É C (100É F) using a suit-

able heat lamp or heat gun.(2) If equipped, remove pop rivets holding molding

edge to wheelhouse lip.

(3) Pull stick on molding from painted surface.

(4) Remove adhesive tape residue from painted

surface of vehicle. Use a 3M Scotch-BriteŸ Molding

Adhesive and Stripe Removal Disc, or equivalent, to

clean adhesive residue from painted surfaces. These

products are available from automotive paint suppli-

ers. Refer to instructions supplied with the specific

product for proper usage.

23 - 44 EXTERIORRS

ProCarManuals.com