relay CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1587 of 2399

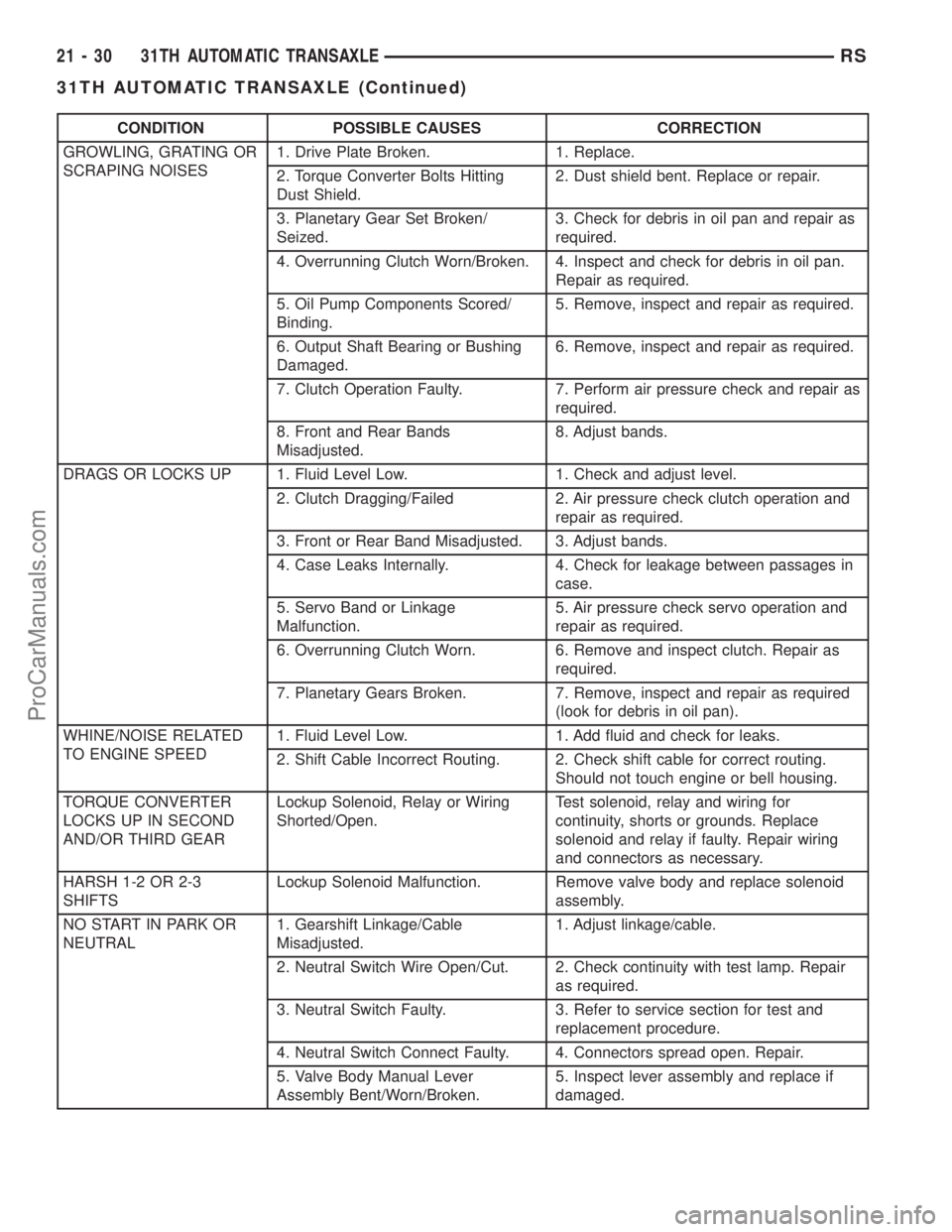

CONDITION POSSIBLE CAUSES CORRECTION

GROWLING, GRATING OR

SCRAPING NOISES1. Drive Plate Broken. 1. Replace.

2. Torque Converter Bolts Hitting

Dust Shield.2. Dust shield bent. Replace or repair.

3. Planetary Gear Set Broken/

Seized.3. Check for debris in oil pan and repair as

required.

4. Overrunning Clutch Worn/Broken. 4. Inspect and check for debris in oil pan.

Repair as required.

5. Oil Pump Components Scored/

Binding.5. Remove, inspect and repair as required.

6. Output Shaft Bearing or Bushing

Damaged.6. Remove, inspect and repair as required.

7. Clutch Operation Faulty. 7. Perform air pressure check and repair as

required.

8. Front and Rear Bands

Misadjusted.8. Adjust bands.

DRAGS OR LOCKS UP 1. Fluid Level Low. 1. Check and adjust level.

2. Clutch Dragging/Failed 2. Air pressure check clutch operation and

repair as required.

3. Front or Rear Band Misadjusted. 3. Adjust bands.

4. Case Leaks Internally. 4. Check for leakage between passages in

case.

5. Servo Band or Linkage

Malfunction.5. Air pressure check servo operation and

repair as required.

6. Overrunning Clutch Worn. 6. Remove and inspect clutch. Repair as

required.

7. Planetary Gears Broken. 7. Remove, inspect and repair as required

(look for debris in oil pan).

WHINE/NOISE RELATED

TO ENGINE SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing.

Should not touch engine or bell housing.

TORQUE CONVERTER

LOCKS UP IN SECOND

AND/OR THIRD GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

HARSH 1-2 OR 2-3

SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

NO START IN PARK OR

NEUTRAL1. Gearshift Linkage/Cable

Misadjusted.1. Adjust linkage/cable.

2. Neutral Switch Wire Open/Cut. 2. Check continuity with test lamp. Repair

as required.

3. Neutral Switch Faulty. 3. Refer to service section for test and

replacement procedure.

4. Neutral Switch Connect Faulty. 4. Connectors spread open. Repair.

5. Valve Body Manual Lever

Assembly Bent/Worn/Broken.5. Inspect lever assembly and replace if

damaged.

21 - 30 31TH AUTOMATIC TRANSAXLERS

31TH AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1718 of 2399

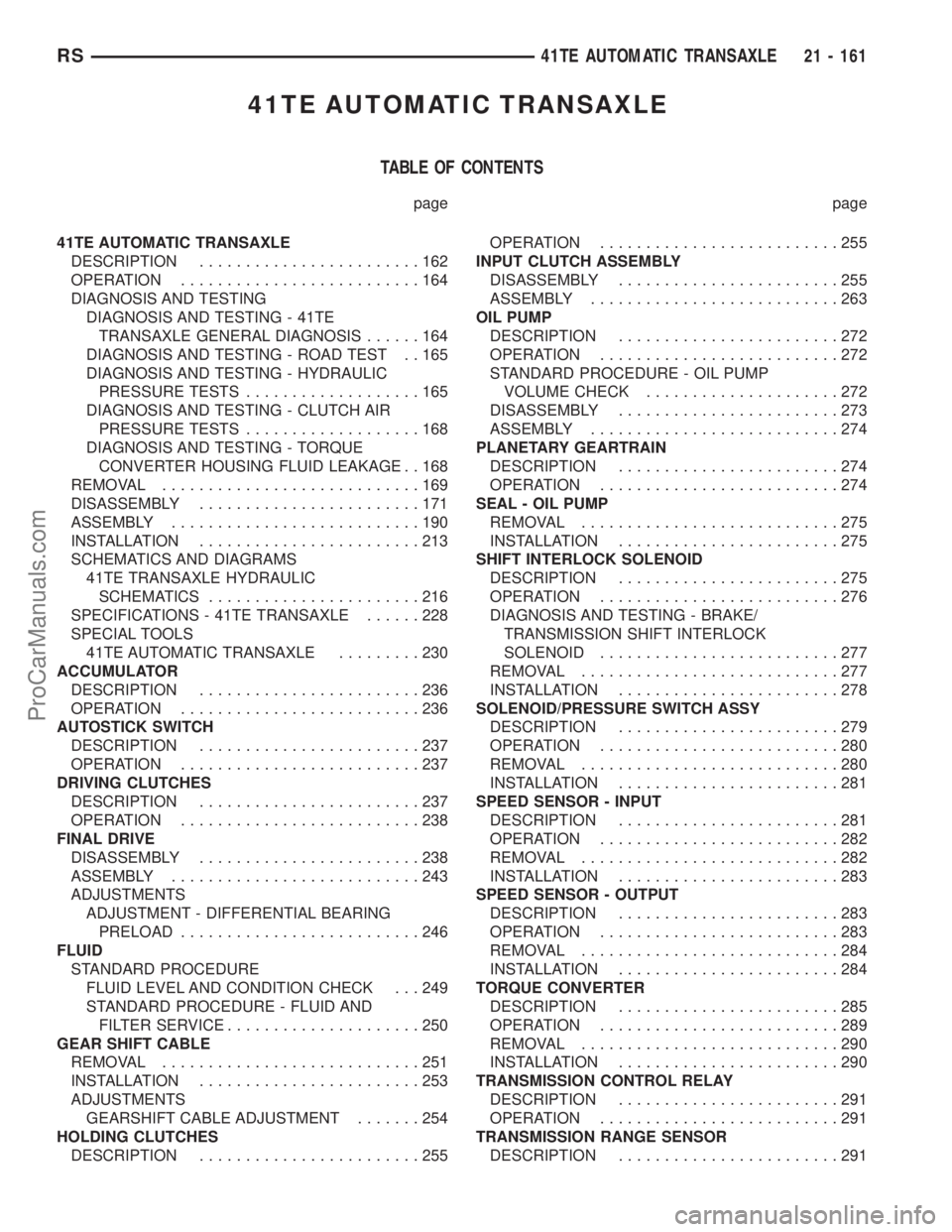

41TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

41TE AUTOMATIC TRANSAXLE

DESCRIPTION........................162

OPERATION..........................164

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 41TE

TRANSAXLE GENERAL DIAGNOSIS......164

DIAGNOSIS AND TESTING - ROAD TEST . . 165

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TESTS...................165

DIAGNOSIS AND TESTING - CLUTCH AIR

PRESSURE TESTS...................168

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE . . 168

REMOVAL............................169

DISASSEMBLY........................171

ASSEMBLY...........................190

INSTALLATION........................213

SCHEMATICS AND DIAGRAMS

41TE TRANSAXLE HYDRAULIC

SCHEMATICS.......................216

SPECIFICATIONS - 41TE TRANSAXLE......228

SPECIAL TOOLS

41TE AUTOMATIC TRANSAXLE.........230

ACCUMULATOR

DESCRIPTION........................236

OPERATION..........................236

AUTOSTICK SWITCH

DESCRIPTION........................237

OPERATION..........................237

DRIVING CLUTCHES

DESCRIPTION........................237

OPERATION..........................238

FINAL DRIVE

DISASSEMBLY........................238

ASSEMBLY...........................243

ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL BEARING

PRELOAD..........................246

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK . . . 249

STANDARD PROCEDURE - FLUID AND

FILTER SERVICE.....................250

GEAR SHIFT CABLE

REMOVAL............................251

INSTALLATION........................253

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT.......254

HOLDING CLUTCHES

DESCRIPTION........................255OPERATION..........................255

INPUT CLUTCH ASSEMBLY

DISASSEMBLY........................255

ASSEMBLY...........................263

OIL PUMP

DESCRIPTION........................272

OPERATION..........................272

STANDARD PROCEDURE - OIL PUMP

VOLUME CHECK.....................272

DISASSEMBLY........................273

ASSEMBLY...........................274

PLANETARY GEARTRAIN

DESCRIPTION........................274

OPERATION..........................274

SEAL - OIL PUMP

REMOVAL............................275

INSTALLATION........................275

SHIFT INTERLOCK SOLENOID

DESCRIPTION........................275

OPERATION..........................276

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK

SOLENOID..........................277

REMOVAL............................277

INSTALLATION........................278

SOLENOID/PRESSURE SWITCH ASSY

DESCRIPTION........................279

OPERATION..........................280

REMOVAL............................280

INSTALLATION........................281

SPEED SENSOR - INPUT

DESCRIPTION........................281

OPERATION..........................282

REMOVAL............................282

INSTALLATION........................283

SPEED SENSOR - OUTPUT

DESCRIPTION........................283

OPERATION..........................283

REMOVAL............................284

INSTALLATION........................284

TORQUE CONVERTER

DESCRIPTION........................285

OPERATION..........................289

REMOVAL............................290

INSTALLATION........................290

TRANSMISSION CONTROL RELAY

DESCRIPTION........................291

OPERATION..........................291

TRANSMISSION RANGE SENSOR

DESCRIPTION........................291

RS41TE AUTOMATIC TRANSAXLE21 - 161

ProCarManuals.com

Page 1719 of 2399

OPERATION..........................292

REMOVAL............................292

INSTALLATION........................292

TRD LINK

DESCRIPTION........................292

OPERATION..........................292

VALVE BODY

DESCRIPTION........................293OPERATION..........................293

REMOVAL

REMOVAL..........................294

REMOVAL..........................296

DISASSEMBLY........................297

ASSEMBLY...........................301

INSTALLATION........................306

41TE AUTOMATIC

TRANSAXLE

DESCRIPTION

The 41TE (Fig. 1) is a four-speed transaxle that is

a conventional hydraulic/mechanical assembly with

an integral differential, and is controlled with adap-

tive electronic controls and monitors. The hydraulic

system of the transaxle consists of the transaxle

fluid, fluid passages, hydraulic valves, and various

line pressure control components. An input clutch

assembly which houses the underdrive, overdrive,

and reverse clutches is used. It also utilizes separate

holding clutches: 2nd/4th gear and Low/Reverse. The

primary mechanical components of the transaxle con-

sist of the following:

²Three multiple disc input clutches

²Two multiple disc holding clutches

²Four hydraulic accumulators

²Two planetary gear sets

²Hydraulic oil pump²Valve body

²Solenoid/Pressure switch assembly

²Integral differential assembly

Control of the transaxle is accomplished by fully

adaptive electronics. Optimum shift scheduling is

accomplished through continuous real-time sensor

feedback information provided to the Transmission

Control Module (TCM).

The TCM is the heart of the electronic control sys-

tem and relies on information from various direct

and indirect inputs (sensors, switches, etc.) to deter-

mine driver demand and vehicle operating condi-

tions. With this information, the TCM can calculate

and perform timely and quality shifts through vari-

ous output or control devices (solenoid pack, trans-

mission control relay, etc.).

The TCM also performs certain self-diagnostic

functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

21 - 162 41TE AUTOMATIC TRANSAXLERS

ProCarManuals.com

Page 1837 of 2399

OPERATION

SOLENOIDS

The solenoids receive electrical power from the

Transmission Control Relay through a single wire.

The TCM energizes or operates the solenoids individ-

ually by grounding the return wire of the solenoid

needed. When a solenoid is energized, the solenoid

valve shifts, and a fluid passage is opened or closed

(vented or applied), depending on its default operat-

ing state. The result is an apply or release of a fric-

tional element.

The 2/4 and UD solenoids are normally applied,

which by design allow fluid to pass through in their

relaxed or ªoffº state. This allows transaxle limp-in

(P,R,N,2) in the event of an electrical failure.

The continuity of the solenoids and circuits are

periodically tested. Each solenoid is turned on or off

depending on its current state. An inductive spike

should be detected by the TCM during this test. It no

spike is detected, the circuit is tested again to verify

the failure. In addition to the periodic testing, the

solenoid circuits are tested if a speed ratio or pres-

sure switch error occurs.

PRESSURE SWITCHES

The TCM relies on three pressure switches to mon-

itor fluid pressure in the L/R, 2/4, and OD hydraulic

circuits. The primary purpose of these switches is to

help the TCM detect when clutch circuit hydraulic

failures occur. The range for the pressure switch clos-

ing and opening points is 11-23 psi. Typically the

switch opening point will be approximately one psi

lower than the closing point. For example, a switch

may close at 18 psi and open at 17 psi. The switches

are continuously monitored by the TCM for the cor-

rect states (open or closed) in each gear as shown in

the following chart:

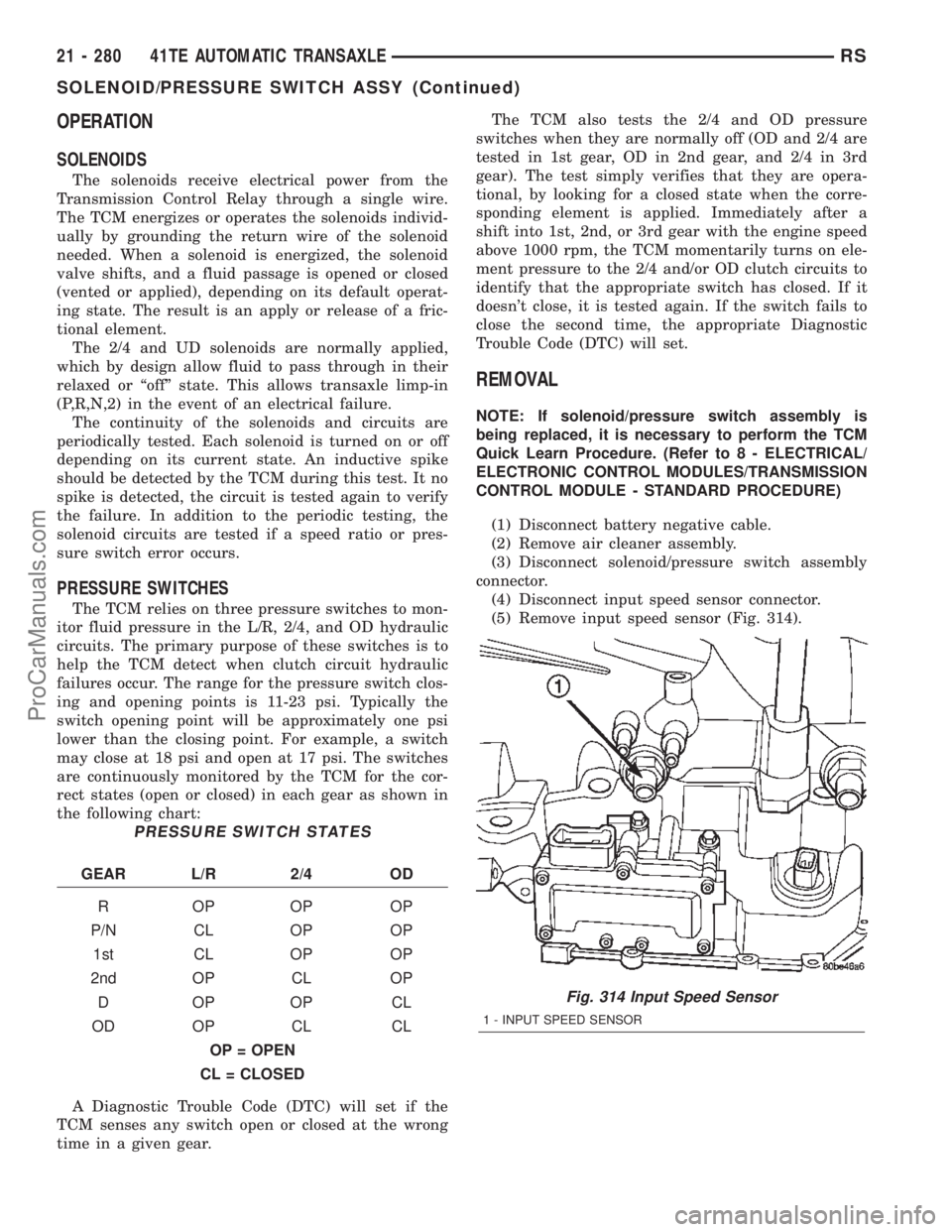

PRESSURE SWITCH STATES

GEAR L/R 2/4 OD

ROPOPOP

P/N CL OP OP

1st CL OP OP

2nd OP CL OP

DOPOPCL

OD OP CL CL

OP = OPEN

CL = CLOSED

A Diagnostic Trouble Code (DTC) will set if the

TCM senses any switch open or closed at the wrong

time in a given gear.The TCM also tests the 2/4 and OD pressure

switches when they are normally off (OD and 2/4 are

tested in 1st gear, OD in 2nd gear, and 2/4 in 3rd

gear). The test simply verifies that they are opera-

tional, by looking for a closed state when the corre-

sponding element is applied. Immediately after a

shift into 1st, 2nd, or 3rd gear with the engine speed

above 1000 rpm, the TCM momentarily turns on ele-

ment pressure to the 2/4 and/or OD clutch circuits to

identify that the appropriate switch has closed. If it

doesn't close, it is tested again. If the switch fails to

close the second time, the appropriate Diagnostic

Trouble Code (DTC) will set.

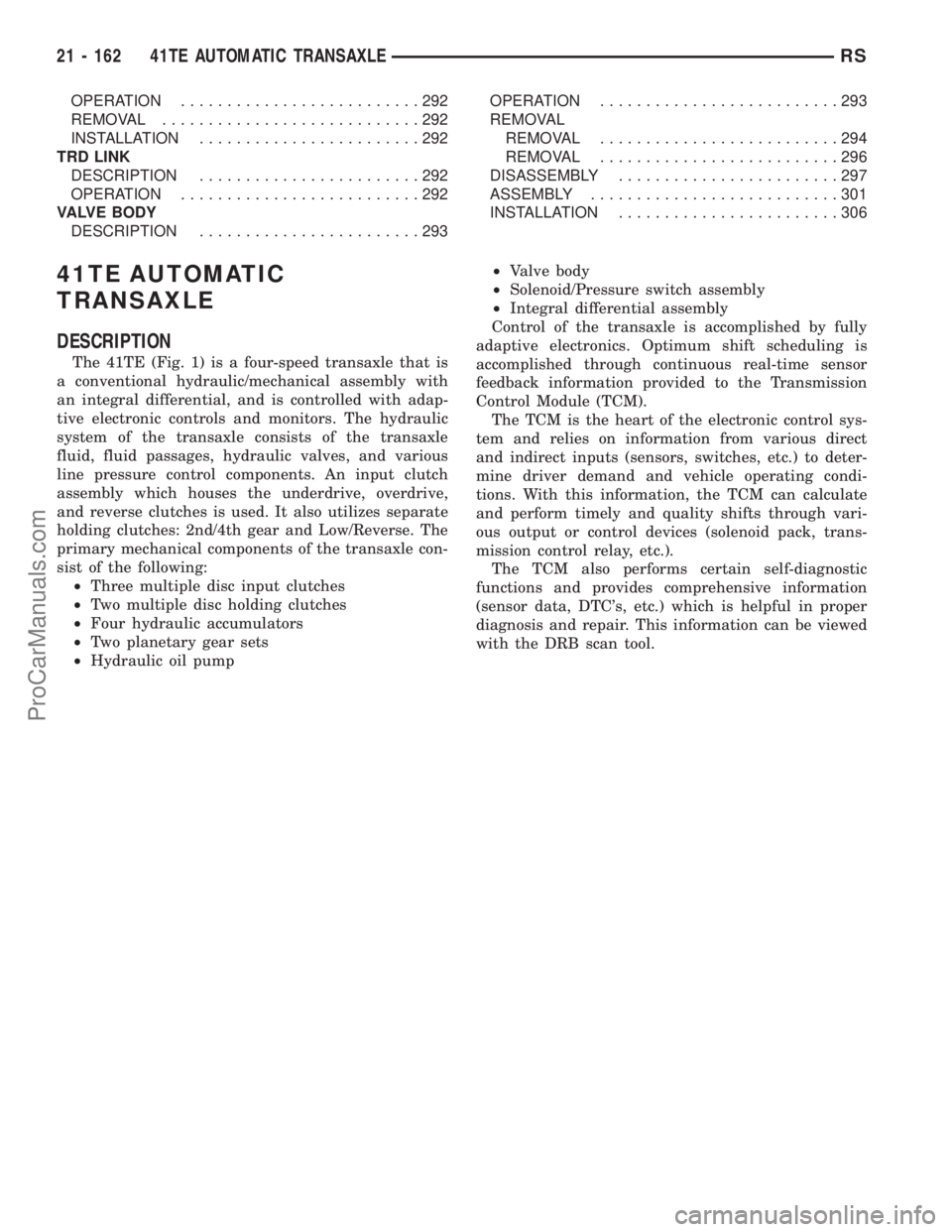

REMOVAL

NOTE: If solenoid/pressure switch assembly is

being replaced, it is necessary to perform the TCM

Quick Learn Procedure. (Refer to 8 - ELECTRICAL/

ELECTRONIC CONTROL MODULES/TRANSMISSION

CONTROL MODULE - STANDARD PROCEDURE)

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly.

(3) Disconnect solenoid/pressure switch assembly

connector.

(4) Disconnect input speed sensor connector.

(5) Remove input speed sensor (Fig. 314).

Fig. 314 Input Speed Sensor

1 - INPUT SPEED SENSOR

21 - 280 41TE AUTOMATIC TRANSAXLERS

SOLENOID/PRESSURE SWITCH ASSY (Continued)

ProCarManuals.com

Page 1848 of 2399

TRANSMISSION CONTROL

RELAY

DESCRIPTION

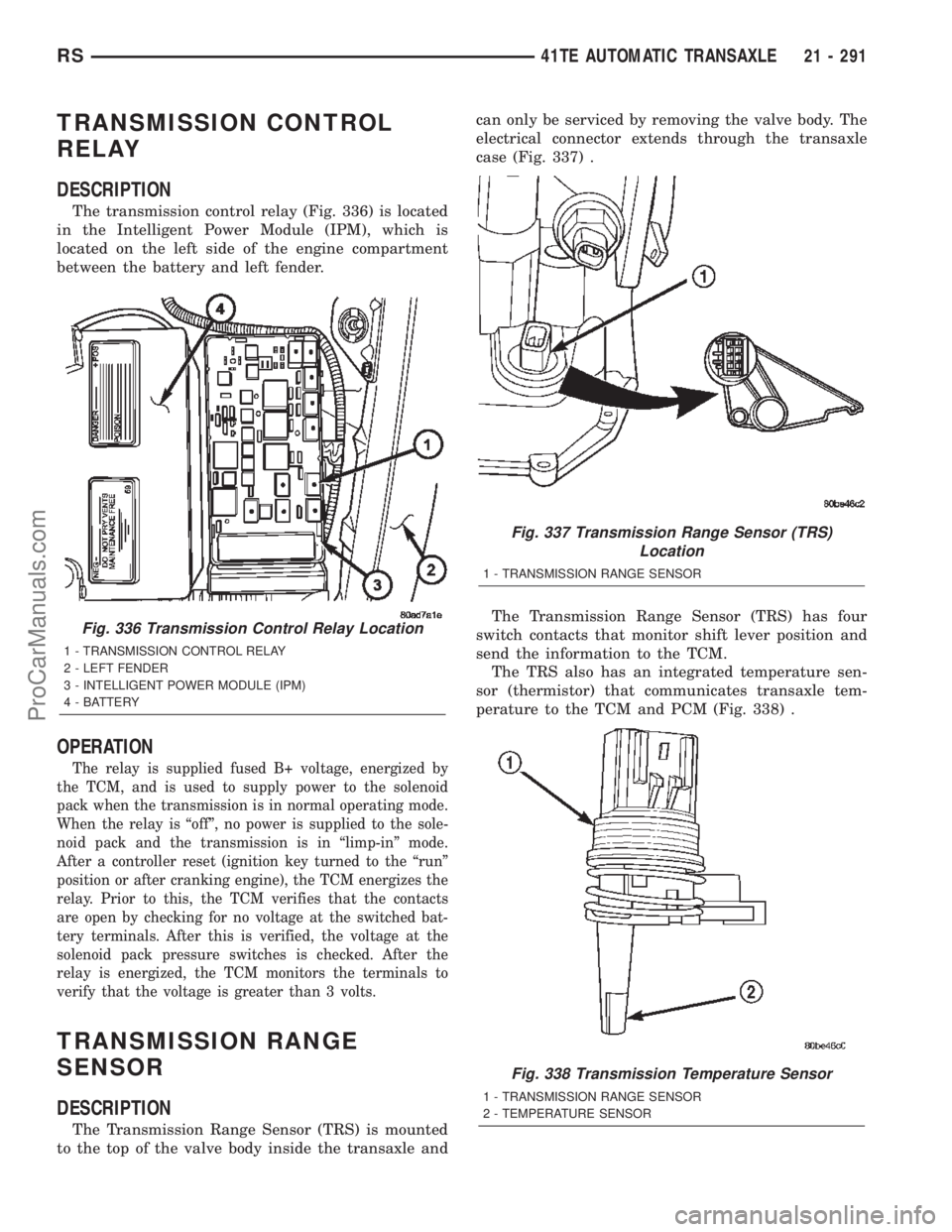

The transmission control relay (Fig. 336) is located

in the Intelligent Power Module (IPM), which is

located on the left side of the engine compartment

between the battery and left fender.

OPERATION

The relay is supplied fused B+ voltage, energized by

the TCM, and is used to supply power to the solenoid

pack when the transmission is in normal operating mode.

When the relay is ªoffº, no power is supplied to the sole-

noid pack and the transmission is in ªlimp-inº mode.

After a controller reset (ignition key turned to the ªrunº

position or after cranking engine), the TCM energizes the

relay. Prior to this, the TCM verifies that the contacts

are open by checking for no voltage at the switched bat-

tery terminals. After this is verified, the voltage at the

solenoid pack pressure switches is checked. After the

relay is energized, the TCM monitors the terminals to

verify that the voltage is greater than 3 volts.

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle andcan only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 337) .

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the TCM.

The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 338) .

Fig. 336 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 337 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 338 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

RS41TE AUTOMATIC TRANSAXLE21 - 291

ProCarManuals.com

Page 2245 of 2399

FRONT CONTROL PANEL

The front control panel and integral computer is

mounted in the instrument panel.

The instrument panel mounted control and inte-

gral computer contains:

²a power button which allows the system to be

completely turned off.

²rear window defogger on/off switch.

²slide controls for completely independent side-to-

side temperature control of the discharge air. The full

range of temperature that the system can produce in

any mode is available on either side of the vehicle by

independently positioning the slide controls on the

instrument panel.

²air recirculation button. The Recirculate button

contains an LED that illuminates to show when the

function is in operation.

²an air conditioning button that allows the com-

pressor to be turned on/off. The Snowflake button

contains an LED that illuminates to shown when the

function is in operation.

²rotary knobs for front and rear fan speed selec-

tion.

²a rotary knob for mode control.

REAR CONTROL PANEL

A rear control panel centrally mounted on the

headliner has a rotary adjustment for temperature

and fan speed control of the rear unit by intermedi-

ate seat passengers when the front control rear knob

is set to the rear position.

DESCRIPTION - THREE ZONE AUTOMATIC

TEMPERATURE CONTROL

The Three-Zone Automatic Temperature Control

(ATC) allows occupants to select a comfort tempera-

ture, which is the perceived temperature level not

the actual passenger compartment air temperature.

The Three Zone Automatic Temperature Control

system includes a dust and odor air filter. The filter

element is the same size as the air conditioning evap-

orator to ensure ample capacity. A door at the base of

the heater and air conditioning housing below the

glove box provides easy access to the filter element.

The ATC computer utilizes integrated circuitry and

information carried on the Programmable Communi-

cations Interface (PCI) data bus network to monitor

many sensors and switch inputs throughout the vehi-

cle. In response to those inputs, the internal circuitry

and programming of the ATC computer allow it to

control electronic functions and features of the ATC

system. The inputs to the ATC computer are:

²Vehicle Speed/Engine RPM± The ATC com-

puter monitors engine RPM, vehicle speed and Man-

ifold Absolute Pressure information from the PCM.²Coolant Temperature± ATC computer moni-

tors Coolant temperature received from the PCM and

converts it to degrees Fahrenheit.

²Ambient Temperature± ATC computer moni-

tors Ambient temperature from the Compass Mini

Trip Computer (CMTC) and converts it to degrees

Fahrenheit.

²Engine Miscellaneous Sensor Status±ATC

computer monitors A/C disable information from the

PCM.

²Refrigerant Pressure± ATC computer moni-

tors Barometric Pressure, Intake Air Temperature,

High Side Pressure and Methanol Content as broad-

cast by the PCM.

²Door Ajar Status± The ATC computer moni-

tors Driver Front Door, Passenger Front Door, Left

Rear Door, Right Rear Door and Liftgate ajar infor-

mation, as identified by the Body Control Module

(BCM), to determine if all in-car temperatures should

be maintained.

²Dimming± The ATC computer monitors dim-

ming status from the BCM to determine the required

level of brightness and will dim accordingly.

²Vehicle Odometer± The ATC computer moni-

tors the vehicle odometer information from the BCM

to prevent flashing the VF tube icons if the manual

motor calibration or manual cool down tests have

failed. Flashing of the display icons will cease when

the vehicle odometer is greater than 3 miles.

²English Metric± The ATC computer monitors

the English/Metric information broadcast by the

CMTC. The set temp displays for both the front and

rear control heads will be set accordingly.

²Vehicle Identification Number± The ATC

computer monitors the last eight characters of the

VIN broadcast by the PCM and compares it to the

information stored in EEPROM. If it is different, the

new number will be stored over the old one and a

motor calibration shall be initiated.

²A/C System Information± The ATC computer

will send a message for Evaporator Temperature too

Low, Fan Blower Relay status, Evaporator Sensor

Failure, Rear Window Defogger Relay and A/C Select.

FRONT CONTROL PANEL

The front control panel and integral computer is

mounted in the instrument panel.

The instrument panel mounted control and inte-

gral computer contains:

²A power button which allows the system to be

completely turned off. The display is blank when the

system is off.

²Three rocker switches that select comfort tem-

peratures from 15É to 30É C (59É to 85É F), which are

shown in the vacuum-fluorescent digital control dis-

play. If the set temp is 59 and the down button is

24 - 2 HEATING & AIR CONDITIONINGRS

HEATING & AIR CONDITIONING (Continued)

ProCarManuals.com

Page 2250 of 2399

If coolant flow is verified and the heater floor out-

let temperature is insufficient, a mechanical problem

may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT HEAT

²Obstructed cowl air intake.

²Obstructed heater system outlets.

²Blend-air door not functioning properly.TEMPERATURE CONTROL

If heater floor outlet temperature cannot be

adjusted with the heater-A/C control temperature

control lever, one of the following could require ser-

vice:

²Blend-air door binding.

²Faulty blend-air door motor.

²Improper engine coolant temperature.

²Faulty heater-A/C control.

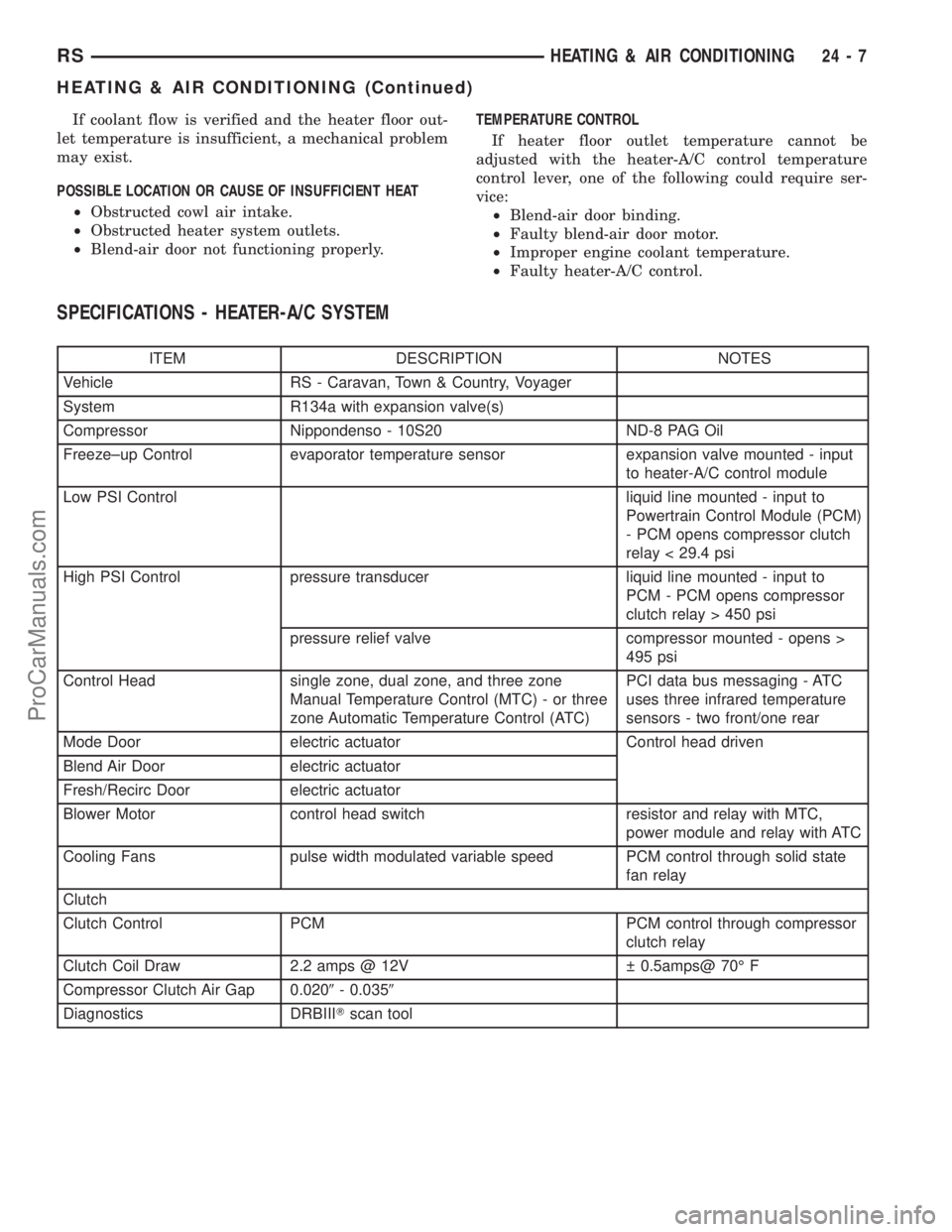

SPECIFICATIONS - HEATER-A/C SYSTEM

ITEM DESCRIPTION NOTES

Vehicle RS - Caravan, Town & Country, Voyager

System R134a with expansion valve(s)

Compressor Nippondenso - 10S20 ND-8 PAG Oil

Freeze±up Control evaporator temperature sensor expansion valve mounted - input

to heater-A/C control module

Low PSI Control liquid line mounted - input to

Powertrain Control Module (PCM)

- PCM opens compressor clutch

relay < 29.4 psi

High PSI Control pressure transducer liquid line mounted - input to

PCM - PCM opens compressor

clutch relay > 450 psi

pressure relief valve compressor mounted - opens >

495 psi

Control Head single zone, dual zone, and three zone

Manual Temperature Control (MTC) - or three

zone Automatic Temperature Control (ATC)PCI data bus messaging - ATC

uses three infrared temperature

sensors - two front/one rear

Mode Door electric actuator Control head driven

Blend Air Door electric actuator

Fresh/Recirc Door electric actuator

Blower Motor control head switch resistor and relay with MTC,

power module and relay with ATC

Cooling Fans pulse width modulated variable speed PCM control through solid state

fan relay

Clutch

Clutch Control PCM PCM control through compressor

clutch relay

Clutch Coil Draw 2.2 amps @ 12V 0.5amps@ 70É F

Compressor Clutch Air Gap 0.0209- 0.0359

Diagnostics DRBIIITscan tool

RSHEATING & AIR CONDITIONING24-7

HEATING & AIR CONDITIONING (Continued)

ProCarManuals.com

Page 2251 of 2399

CONTROLS - FRONT

TABLE OF CONTENTS

page page

A/C HEATER CONTROL

STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION................8

REMOVAL.............................9

INSTALLATION..........................9

A/C PRESSURE TRANSDUCER

DESCRIPTION - A/C PRESSURE

TRANSDUCER.......................10

OPERATION...........................10

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER.......................10

REMOVAL.............................11

INSTALLATION.........................11

BLEND DOOR ACTUATOR

DESCRIPTION.........................11

OPERATION...........................11

REMOVAL.............................12

INSTALLATION.........................12

BLOWER MOTOR RELAY

DESCRIPTION.........................13

OPERATION...........................13

DIAGNOSIS AND TESTING - BLOWER

MOTOR RELAY.......................14

REMOVAL.............................14

INSTALLATION.........................14

BLOWER MOTOR RESISTOR

DESCRIPTION.........................15

OPERATION...........................15

DIAGNOSIS AND TESTING - BLOWER

MOTOR RESISTOR....................15

REMOVAL.............................16

INSTALLATION.........................16

COMPRESSOR CLUTCH

DESCRIPTION.........................16

OPERATION...........................17

STANDARD PROCEDURE

STANDARD PROCEDURE - COMPRESSOR

CLUTCH AIR GAP.....................17STANDARD PROCEDURE - COMPRESSOR

CLUTCH BREAK-IN....................17

REMOVAL.............................17

INSPECTION - COMPRESSOR CLUTCH/COIL . 18

INSTALLATION.........................19

COMPRESSOR CLUTCH COIL

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL........................20

COMPRESSOR CLUTCH RELAY

DESCRIPTION.........................21

OPERATION...........................21

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH RELAY......................22

REMOVAL.............................22

INSTALLATION.........................22

EVAPORATOR TEMPERATURE SENSOR

DESCRIPTION.........................22

OPERATION...........................23

REMOVAL.............................23

INSTALLATION.........................23

INFRARED TEMPERATURE SENSOR

DESCRIPTION.........................24

OPERATION...........................24

MODE DOOR ACTUATOR

DESCRIPTION.........................24

OPERATION...........................25

REMOVAL.............................25

INSTALLATION.........................25

POWER MODULE

DESCRIPTION.........................26

OPERATION...........................26

REMOVAL.............................26

INSTALLATION.........................27

RECIRCULATION DOOR ACTUATOR

DESCRIPTION.........................27

OPERATION...........................27

REMOVAL.............................28

INSTALLATION.........................28

A/C HEATER CONTROL

STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION

The heater-A/C control module must be recali-

brated each time an actuator motor or the control

module is replaced. If the vehicle is so equipped, the

calibration procedure also includes rear HVAC posi-

tions for each actuator motor.(1) Turn the ignition switch to the On position.

(2) Simultaneously depress and hold the Power

and Recirculation buttons on the heater-A/C control

for at least five seconds. The manual heater-A/C con-

trol power Light Emitting Diode (LED) and Recircu-

lation LED, or the Automatic Temperature Control

(ATC) heater-A/C control Delay and Recirculation

graphics will begin to flash when the calibration pro-

cedure has begun.

24 - 8 CONTROLS - FRONTRS

ProCarManuals.com

Page 2256 of 2399

(5) Install and tighten the three screws that secure

the heater core shield to the left end of the heater/air

conditioner housing. Tighten the screws to 2 N´m (17

in. lbs.).

(6) Reinstall the silencer under the driver side end

of the instrument panel. (Refer to 23 - BODY/IN-

STRUMENT PANEL/INSTRUMENT PANEL

SILENCER - INSTALLATION).

(7) Reconnect the battery negative cable.

(8) Perform the heater-A/C control calibration pro-

cedure. (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

BLOWER MOTOR RELAY

DESCRIPTION

The blower motor relay (Fig. 6) is a International

Standards Organization (ISO) mini-relay. Relays con-

forming to the ISO specifications have common phys-

ical dimensions, current capacities, terminal

patterns, and terminal functions. The ISO mini-relay

terminal functions are the same as a conventional

ISO relay. However, the ISO mini-relay terminal pat-

tern (or footprint) is different, the current capacity is

lower, and the physical dimensions are smaller than

those of the conventional ISO relay. The blower

motor relay is located in the Intelligent Power Mod-

ule (IPM), which is in the engine compartment near

the battery. See the fuse and relay layout mapmolded into the inner surface of the IPM cover for

blower motor relay identification and location.

The black, molded plastic case is the most visible

component of the blower motor relay. Five male

spade-type terminals extend from the bottom of the

base to connect the relay to the vehicle electrical sys-

tem, and the ISO designation for each terminal is

molded into the base adjacent to each terminal.

OPERATION

The blower motor relay is an electromechanical

switch that uses a low current input from the Front

Control Module (FCM) to control the high current

output to the blower motor resistor (manual heater-

A/C control) or blower power module (ATC control).

The movable common feed contact point is held

against the fixed normally closed contact point by

spring pressure. When the relay coil is energized, an

electromagnetic field is produced by the coil wind-

ings. This electromagnetic field draws the movable

relay contact point away from the fixed normally

closed contact point, and holds it against the fixed

normally open contact point. When the relay coil is

de-energized, spring pressure returns the movable

contact point back against the fixed normally closed

contact point. The resistor or diode is connected in

parallel with the relay coil in the relay, and helps to

dissipate voltage spikes and electromagnetic interfer-

ence that can be generated as the electromagnetic

field of the relay coil collapses.

The blower motor relay terminals are connected to

the vehicle electrical system through a receptacle in

the Intelligent Power Module (IPM). The inputs and

outputs of the blower motor relay include:

²The common feed terminal (30) receives a bat-

tery current input from the battery through a B(+)

circuit at all times.

²The coil ground terminal (85) receives a ground

input through the front/rear blower motor relay con-

trol circuit only when the FCM electronically pulls

the control circuit to ground.

²The coil battery terminal (86) receives a battery

current input from the battery through a B(+) circuit

at all times.

²The normally open terminal (87) provides a bat-

tery current output to the blower motor resistor

(manual heater-A/C control) or blower power module

(automatic heater-A/C control) through a fuse in the

IPM on the fused front blower motor relay output cir-

cuit only when the blower motor relay coil is ener-

gized.

²The normally closed terminal (87A) is not con-

nected to any circuit in this application, but provides

a battery current output only when the blower motor

relay coil is de-energized.

Fig. 6 Blower Motor Relay

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

RSCONTROLS - FRONT24-13

BLEND DOOR ACTUATOR (Continued)

ProCarManuals.com

Page 2257 of 2399

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices, and grounds.

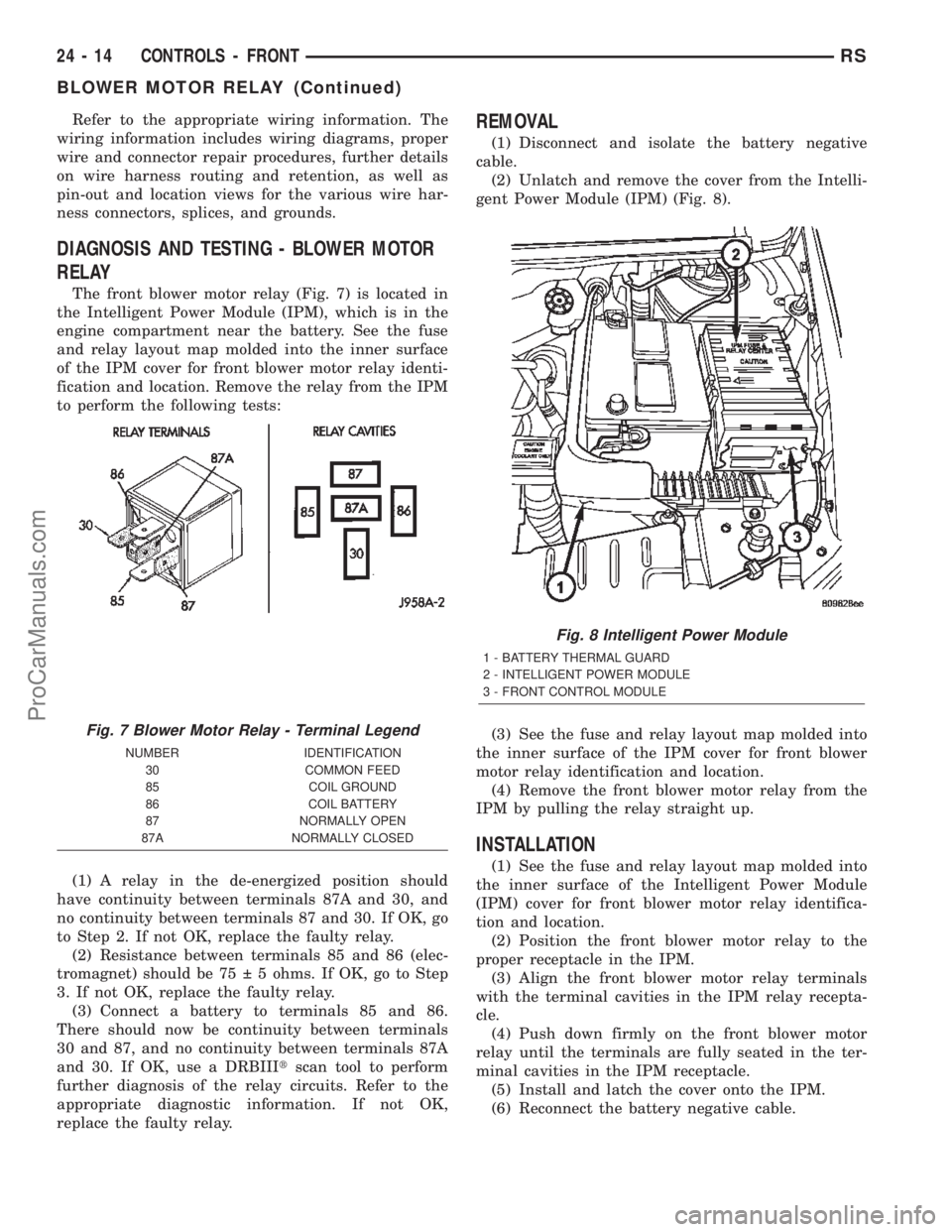

DIAGNOSIS AND TESTING - BLOWER MOTOR

RELAY

The front blower motor relay (Fig. 7) is located in

the Intelligent Power Module (IPM), which is in the

engine compartment near the battery. See the fuse

and relay layout map molded into the inner surface

of the IPM cover for front blower motor relay identi-

fication and location. Remove the relay from the IPM

to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, use a DRBIIItscan tool to perform

further diagnosis of the relay circuits. Refer to the

appropriate diagnostic information. If not OK,

replace the faulty relay.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Unlatch and remove the cover from the Intelli-

gent Power Module (IPM) (Fig. 8).

(3) See the fuse and relay layout map molded into

the inner surface of the IPM cover for front blower

motor relay identification and location.

(4) Remove the front blower motor relay from the

IPM by pulling the relay straight up.

INSTALLATION

(1) See the fuse and relay layout map molded into

the inner surface of the Intelligent Power Module

(IPM) cover for front blower motor relay identifica-

tion and location.

(2) Position the front blower motor relay to the

proper receptacle in the IPM.

(3) Align the front blower motor relay terminals

with the terminal cavities in the IPM relay recepta-

cle.

(4) Push down firmly on the front blower motor

relay until the terminals are fully seated in the ter-

minal cavities in the IPM receptacle.

(5) Install and latch the cover onto the IPM.

(6) Reconnect the battery negative cable.

Fig. 7 Blower Motor Relay - Terminal Legend

NUMBER IDENTIFICATION

30 COMMON FEED

85 COIL GROUND

86 COIL BATTERY

87 NORMALLY OPEN

87A NORMALLY CLOSED

Fig. 8 Intelligent Power Module

1 - BATTERY THERMAL GUARD

2 - INTELLIGENT POWER MODULE

3 - FRONT CONTROL MODULE

24 - 14 CONTROLS - FRONTRS

BLOWER MOTOR RELAY (Continued)

ProCarManuals.com