relay CHRYSLER VOYAGER 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 1160 of 2399

SPLICE NUMBER LOCATION FIG.

S177 In Right Headlamp Wiring Assembly N/S

S179 In Left Headlamp Wiring Assembly N/S

S187 (2.5L) Near T/O for Engine Control Module C1 11

S188 (2.5L) Near T/O for Radiator Fan Relay No.1 2

S201 In T/O to Instrument Panel Speaker 15, 21

S202 Near T/O for Instrument Panel Switch Bank 15, 21

S203 Near T/O for Instrument Panel Switch Bank 15, 21

S204 Near T/O to Instrument Panel Speaker 15, 21

S205 Near T/O for C201 15

S206 Near T/O for Instrument Cluster 15

S207 In A/C Unit Assembly N/S

S208 (RHD) Between T/O for Antenna Connector and T/O for Front

Cigar Lighter21

S209 (RHD) Between T/O for Front Cigar Lighter and T/O for Brake

Transmission Shift Interlock Solenoid21

S210 (RHD) Near T/O for C203 21

S211 In Steering Column Wiring Assembly N/S

S212 In Steering Column Wiring Assembly N/S

S302 In Floor Pan Track Wiring 31

S303 In T/O to Data Link Connector 31

S304 Near T/O for C307 32

S305 Near T/O for Memory Seat/Mirror Module - C2 N/S

S306 In Floor Pan Track Wiring 32

S307 Near T/O for Memory Power Seat Switch N/S

S308 In Floor Pan Track Wiring 31

S309 In Floor Pan Track Wiring 31

S310 Near T/O for C301 30

S311 In Floor Pan Track Wiring 29

S312 Near T/O for C320 N/S

S313 Near T/O for Power Liftgate Module 40

S314 In Floor Pan Track Wiring 29

S315 In Floor Pan Track Wiring 29

S316 In Floor Pan Track Wiring 29

S317 Near T/O for C101 30

S318 Near T/O for Power Seat Circuit Breaker N/S

S319 In Floor Pan Track Wiring 32

S320 Near T/O for C200 31

S321 In T/O to Data Link Connector 31

S322 Near T/O for C301 30

S323 In Floor Pan Track Wiring 31

S324 In Floor Pan Track Wiring 29

S325 In Floor Pan Track Wiring 29

S326 Near T/O for C101 30

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-13

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1196 of 2399

8W-97 POWER DISTRIBUTION SYSTEM

TABLE OF CONTENTS

page page

POWER DISTRIBUTION SYSTEM

DESCRIPTION..........................1

OPERATION............................1

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS.........2

ACCESSORY RELAY

DESCRIPTION..........................2

OPERATION............................2

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - ACCESSORY

RELAY...............................2

REMOVAL.............................3

INSTALLATION..........................3

INTEGRATED POWER MODULE

DESCRIPTION..........................3OPERATION............................3

REMOVAL.............................4

INSTALLATION..........................4

IOD FUSE

DESCRIPTION..........................4

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................5

POWER OUTLET

DESCRIPTION..........................5

OPERATION............................5

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - POWER OUTLET . . 5

REMOVAL.............................6

INSTALLATION..........................6

POWER DISTRIBUTION

SYSTEM

DESCRIPTION

This group covers the various standard and

optional power distribution components used on this

model. The power distribution system for this vehicle

consists of the following components:

²Integrated Power Module (IPM)

²Front Control Module (FCM)

²Power Outlets

Refer to Wiring Diagrams for complete circuit sche-

matics.

The power distribution system also incorporates

various types of circuit control and protection fea-

tures, including:

²Automatic resetting circuit breakers

²Blade-type fuses

²Bus bars

²Cartridge fuses

²Circuit splice blocks

²Flashers

²Fusible links

²Relays

Following are general descriptions of the major

components in the power distribution system. See the

owner's manual in the vehicle glove box for more

information on the features and use of all of the

power distribution system components.

OPERATION

The power distribution system for this vehicle is

designed to provide safe, reliable, and centralized dis-

tribution points for the electrical current required to

operate all of the many standard and optional facto-

ry-installed electrical and electronic powertrain,

chassis, safety, security, comfort and convenience sys-

tems. At the same time, the power distribution sys-

tem was designed to provide ready access to these

electrical distribution points for the vehicle techni-

cian to use when conducting diagnosis and repair of

faulty circuits. The power distribution system can

also prove useful for the sourcing of additional elec-

trical circuits that may be required to provide the

electrical current needed to operate many accessories

that the vehicle owner may choose to have installed

in the aftermarket.

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-1

ProCarManuals.com

Page 1197 of 2399

SPECIAL TOOLS

POWER DISTRIBUTION SYSTEMS

ACCESSORY RELAY

DESCRIPTION

The accessory relay is an electromechanical device

that switches fused battery current to the accessory

powered vehicle circuits when the ignition switch is

turned to the Accessory or On positions. The delay

feature will maintain power to the accessories for 45

seconds after the ignition is shut off or until a door is

opened. This allows sufficient time to close windows

and park the windshield wipers. The accessory relay

is located in the Integrated Power Module (IPM) in

the engine compartment.

The accessory relay is a International Standards

Organization (ISO) relay. Relays conforming to the

ISO specifications have common physical dimensions,

current capacities, terminal patterns, and terminal

functions.

The accessory relay cannot be repaired or adjusted

and, if faulty or damaged, it must be replaced.

OPERATION

The ISO relay consists of an electromagnetic coil, a

resistor or diode, and three (two fixed and one movable)

electrical contacts. The movable (common feed) relay

contact is held against one of the fixed contacts (normal-

ly closed) by spring pressure. When the electromagnetic

coil is energized, it draws the movable contact away

from the normally closed fixed contact, and holds it

against the other (normally open) fixed contact.

When the electromagnetic coil is de-energized,

spring pressure returns the movable contact to the

normally closed position. The resistor or diode is con-

nected in parallel with the electromagnetic coil in the

relay, and helps to dissipate voltage spikes that are

produced when the coil is de-energized.

DIAGNOSIS AND TESTING

DIAGNOSIS & TESTING - ACCESSORY RELAY

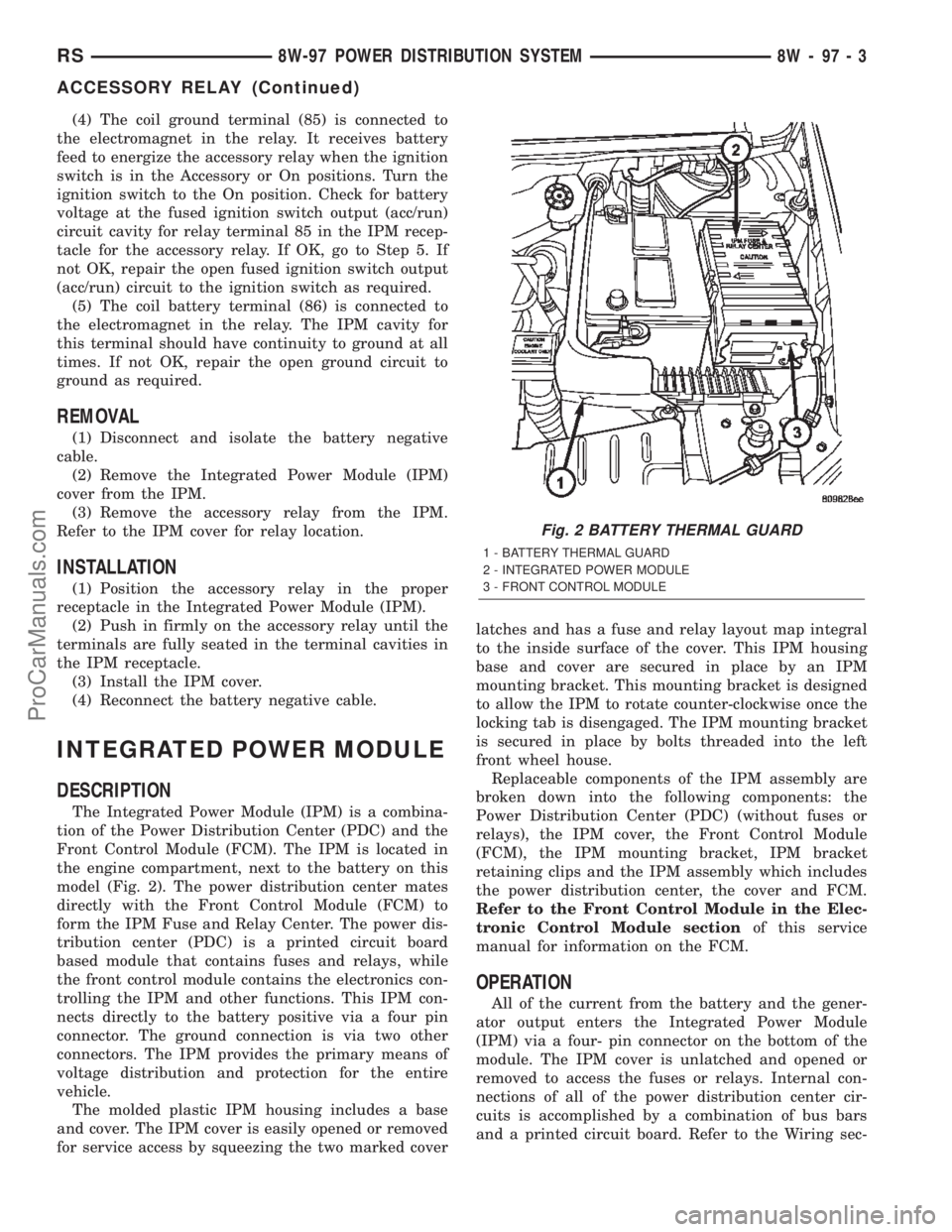

The accessory relay (Fig. 1) is located in the Inte-

grated Power Module (IPM), in the engine compart-

ment. For complete circuit diagrams, refer toWiring

Diagrams.

(1) Remove the accessory relay from the IPM.

Refer toAccessory Relayin the Removal and

Installation section of this group for the procedure.

(2) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 3. If not OK, replace the faulty relay.

(3) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

4. If not OK, replace the faulty relay.

(4) Connect a battery to terminals 85 and 86.

There should now be continuity between terminals

30 and 87, and no continuity between terminals 87A

and 30. If OK, perform the Relay Circuit Test that

follows. If not OK, replace the faulty relay.

DIAGNOSIS & TESTING - RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) of

the IPM is connected to battery voltage and should

be hot at all times. Check for battery voltage at the

fused B(+) circuit cavity in the IPM receptacle for the

accessory relay. If OK, go to Step 2. If not OK, repair

the fused B(+) circuit to the IPM fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the fused B(+) fuse in the IPM that feeds the

accessories when the relay is energized by the igni-

tion switch. There should be continuity between the

IPM cavity for relay terminal 87 and the fused B(+)

fuse in the IPM at all times. If OK, go to Step 4. If

not OK, repair the open fused B(+) circuit to the IPM

fuse as required.

Terminal Pick Kit 6680

Fig. 1 Accessory Relay

8W - 97 - 2 8W-97 POWER DISTRIBUTION SYSTEMRS

POWER DISTRIBUTION SYSTEM (Continued)

ProCarManuals.com

Page 1198 of 2399

(4) The coil ground terminal (85) is connected to

the electromagnet in the relay. It receives battery

feed to energize the accessory relay when the ignition

switch is in the Accessory or On positions. Turn the

ignition switch to the On position. Check for battery

voltage at the fused ignition switch output (acc/run)

circuit cavity for relay terminal 85 in the IPM recep-

tacle for the accessory relay. If OK, go to Step 5. If

not OK, repair the open fused ignition switch output

(acc/run) circuit to the ignition switch as required.

(5) The coil battery terminal (86) is connected to

the electromagnet in the relay. The IPM cavity for

this terminal should have continuity to ground at all

times. If not OK, repair the open ground circuit to

ground as required.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the Integrated Power Module (IPM)

cover from the IPM.

(3) Remove the accessory relay from the IPM.

Refer to the IPM cover for relay location.

INSTALLATION

(1) Position the accessory relay in the proper

receptacle in the Integrated Power Module (IPM).

(2) Push in firmly on the accessory relay until the

terminals are fully seated in the terminal cavities in

the IPM receptacle.

(3) Install the IPM cover.

(4) Reconnect the battery negative cable.

INTEGRATED POWER MODULE

DESCRIPTION

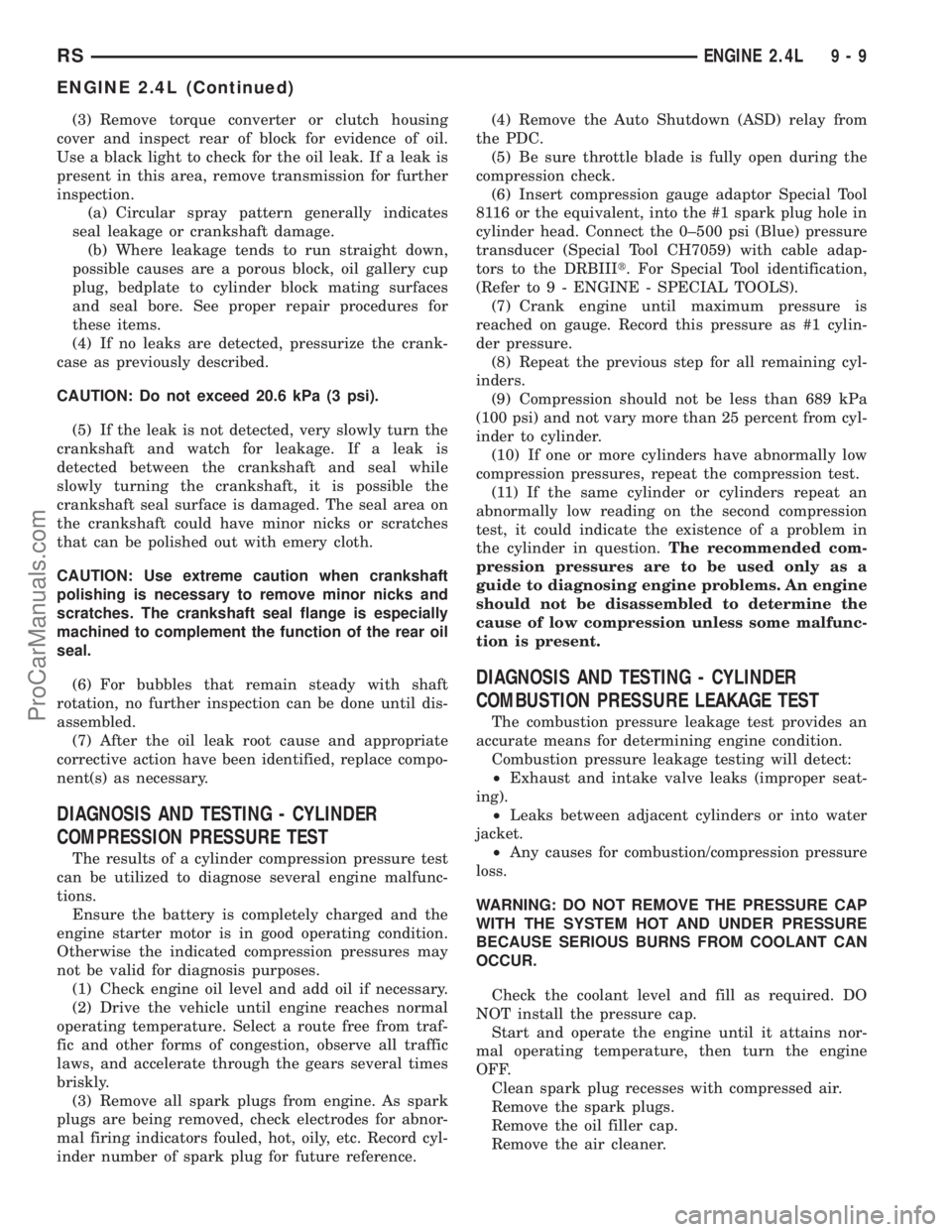

The Integrated Power Module (IPM) is a combina-

tion of the Power Distribution Center (PDC) and the

Front Control Module (FCM). The IPM is located in

the engine compartment, next to the battery on this

model (Fig. 2). The power distribution center mates

directly with the Front Control Module (FCM) to

form the IPM Fuse and Relay Center. The power dis-

tribution center (PDC) is a printed circuit board

based module that contains fuses and relays, while

the front control module contains the electronics con-

trolling the IPM and other functions. This IPM con-

nects directly to the battery positive via a four pin

connector. The ground connection is via two other

connectors. The IPM provides the primary means of

voltage distribution and protection for the entire

vehicle.

The molded plastic IPM housing includes a base

and cover. The IPM cover is easily opened or removed

for service access by squeezing the two marked coverlatches and has a fuse and relay layout map integral

to the inside surface of the cover. This IPM housing

base and cover are secured in place by an IPM

mounting bracket. This mounting bracket is designed

to allow the IPM to rotate counter-clockwise once the

locking tab is disengaged. The IPM mounting bracket

is secured in place by bolts threaded into the left

front wheel house.

Replaceable components of the IPM assembly are

broken down into the following components: the

Power Distribution Center (PDC) (without fuses or

relays), the IPM cover, the Front Control Module

(FCM), the IPM mounting bracket, IPM bracket

retaining clips and the IPM assembly which includes

the power distribution center, the cover and FCM.

Refer to the Front Control Module in the Elec-

tronic Control Module sectionof this service

manual for information on the FCM.

OPERATION

All of the current from the battery and the gener-

ator output enters the Integrated Power Module

(IPM) via a four- pin connector on the bottom of the

module. The IPM cover is unlatched and opened or

removed to access the fuses or relays. Internal con-

nections of all of the power distribution center cir-

cuits is accomplished by a combination of bus bars

and a printed circuit board. Refer to the Wiring sec-

Fig. 2 BATTERY THERMAL GUARD

1 - BATTERY THERMAL GUARD

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

RS8W-97 POWER DISTRIBUTION SYSTEM8W-97-3

ACCESSORY RELAY (Continued)

ProCarManuals.com

Page 1199 of 2399

tion of the service manual for complete IPM circuit

schematics.

REMOVAL

(1) Disconnect the negative and positive battery

cables.

(2) Remove the battery thermal guard from the

vehicle. Refer to the Battery section for the proce-

dure.

(3) Remove the battery from the vehicle. Refer to

the Battery section for the procedure.

(4) Using a flat-bladed screwdriver, twist the Inte-

grated Power Module (IPM) bracket retaining latch

outward to free the intelligent power module from its

mounting bracket (Fig. 3).

(5) Rotate the IPM counter-clockwise to access and

disconnect the various electrical connectors (Fig. 4).

(6) Free the IPM from its mounting bracket by

removing the IPM bracket clips from the hinge. A

screwdriver slipped up from under the hinge will free

the clips.

INSTALLATION

(1) Snap the left side of the Integrated Power Mod-

ule (IPM) housing in its mounting bracket and con-

nect the various electrical connectors. Care must be

taken that the Connector Positive Assurance (CPA)

on the five-pin B+ connector is positively engaged to

prevent generating a Diagnostic Trouble Code (DTC).

NOTE: IPM electrical connectors are color coded to

ease location reference.(2) Being certain no wires are stressed or pinched,

rotate the IPM clock-wise until secured in mounting

bracket. An audible click may be heard.

(3) Install the battery in the vehicle. Refer to the

Battery section for the procedure.

(4) Install the battery thermal guard in the vehi-

cle. Refer to the Battery section for the procedure.

(5)

Connect the negative and positive battery cables.

(6) Using a diagnostic scan tool, check for any

stored diagnostic trouble codes and correct, check

that all vehicle options are operational before return-

ing the vehicle to service.

IOD FUSE

DESCRIPTION

All vehicles are equipped with an Ignition-Off

Draw (IOD) fuse that is removed from its normal

cavity in the Integrated Power Module (IPM) when

the vehicle is shipped from the factory. Dealer per-

sonnel are to remove the IOD fuse from the storage

location and install it into the IPM fuse cavity

marked IOD as part of the preparation procedures

performed just prior to new vehicle delivery.

The IPM has a molded plastic cover that can be

removed to provide service access to all of the fuses

and relays in the IPM. An integral latch and hinges

are molded into the IPM cover for easy removal. A

fuse layout map is integral to the underside of the

IPM cover to ensure proper fuse and relay identifica-

Fig. 3 RELEASING INTEGRATED POWER MODULE

FROM ITS MOUNTING BRACKET

Fig. 4 DISCONNECTING IPM

1 - INTEGRATED POWER MODULE FUSE & RELAY CENTER

8W - 97 - 4 8W-97 POWER DISTRIBUTION SYSTEMRS

INTEGRATED POWER MODULE (Continued)

ProCarManuals.com

Page 1210 of 2399

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 2.4L9-9

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1284 of 2399

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak. If a leak is

present in this area, remove transmission for further

inspection.

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, oil gallery cup

plug, bedplate to cylinder block mating surfaces

and seal bore. See proper repair procedures for

these items.

(4) If no leaks are detected, pressurize the crank-

case as previously described.

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks and

scratches. The crankshaft seal flange is especially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled.

(7) After the oil leak root cause and appropriate

corrective action have been identified, replace compo-

nent(s) as necessary.

DIAGNOSIS AND TESTING - CYLINDER

COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.(4) Remove the Auto Shutdown (ASD) relay from

the PDC.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gauge adaptor Special Tool

8116 or the equivalent, into the #1 spark plug hole in

cylinder head. Connect the 0±500 psi (Blue) pressure

transducer (Special Tool CH7059) with cable adap-

tors to the DRBIIIt. For Special Tool identification,

(Refer to 9 - ENGINE - SPECIAL TOOLS).

(7) Crank engine until maximum pressure is

reached on gauge. Record this pressure as #1 cylin-

der pressure.

(8) Repeat the previous step for all remaining cyl-

inders.

(9) Compression should not be less than 689 kPa

(100 psi) and not vary more than 25 percent from cyl-

inder to cylinder.

(10) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(11) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

DIAGNOSIS AND TESTING - CYLINDER

COMBUSTION PRESSURE LEAKAGE TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE PRESSURE CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the pressure cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

RSENGINE 3.3/3.8L9-83

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1453 of 2399

FUEL DELIVERY

DESCRIPTION

DESCRIPTION

The front wheel drive car uses a plastic fuel tank

located rear center of the vehicle.

The Fuel Delivery System consists of: the following

items:

²Electric fuel pump module

²Fuel filter

²Tubes/lines/hoses

²Fuel injectors

The in-tank fuel pump module contains the fuel

pump. The pump is serviced as part of the fuel pump

module. Refer to Fuel Pump Module.

The fuel filter is replaceable, it is mounted on the

outside, on top of, the fuel tank. Refer to the Main-

tenance Schedules in the Introduction section of this

manual for recommended fuel filter replacement

intervals.

DESCRIPTION - FFV REPLACEMENT PARTS

Many components in a Flexible Fuel Vehicle (FFV)

are designed to be compatible with ethanol. Always

be sure that the vehicle is serviced with correct etha-

nol compatible parts.

CAUTION: Replacing fuel system components with

non-ethanol compatible components can damage

your vehicle and may void the warranty.

OPERATION

The fuel system provides fuel pressure by an

in-tank pump module. The PCM controls the opera-

tion of the fuel system by providing battery voltage

to the fuel pump through the fuel pump relay. The

PCM requires only three inputs and a good ground to

operate the fuel pump relay. The three inputs are:²Ignition voltage

²Crankshaft Position (CKP) sensor

²Camshaft Position (CMP) sensor

DIAGNOSIS AND TESTING - FUEL DELIVERY

SYSTEM

(Refer to Appropriate Diagnostic Information)

STANDARD PROCEDURE

STANDARD PROCEDURE - FUEL SYSTEM

PRESSURE RELEASE PROCEDURE

(1) Remove Fuel Pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(2) Start and run engine until it stalls.

(3) Attempt restarting engine until it will no

longer run.

(4) Turn ignition key to OFF position.

(5) Return fuel pump relay to PDC.

(6) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRB IIItscan tool must be

used to erase a DTC.

STANDARD PROCEDURE - DRAINING FUEL

TANK

(1) Release fuel system pressure, refer to the Fuel

System Release Procedure in this section.

(2) Insert a 1/4 inch siphon (max. O. D. 5/16) hose

from a portable fuel siphoning tank through the fuel

filler neck opening into the fuel tank. Hose most

have a 30 degree angle cut on the end to bypass the

check valve in the end of the filler neck. Refer to the

siphoning tank's Manufacturing Instructions.

(3) Drain fuel from fuel tank into siphoning tank.

14 - 2 FUEL DELIVERYRS

ProCarManuals.com

Page 1458 of 2399

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube.

Replace as necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the plastic fuel lines/tubes are

properly routed to prevent pinching and to avoid heat

sources.

FUEL PRESSURE REGULATOR

OPERATION

The fuel system uses a nonadjustable pressure reg-

ulator that maintains fuel system pressure at

approximately 400 34 kPa (58 5 psi). The fuel

pressure regulator contains a diaphragm, calibrated

spring and a fuel return valve. The spring pushes

down on the diaphragm and closes off the fuel return

port. System fuel pressure reflects the amount of fuel

pressure required to open the return port.

The pressure regulator is a mechanical device that

is NOT controlled by the PCM or engine vacuum.

REMOVAL

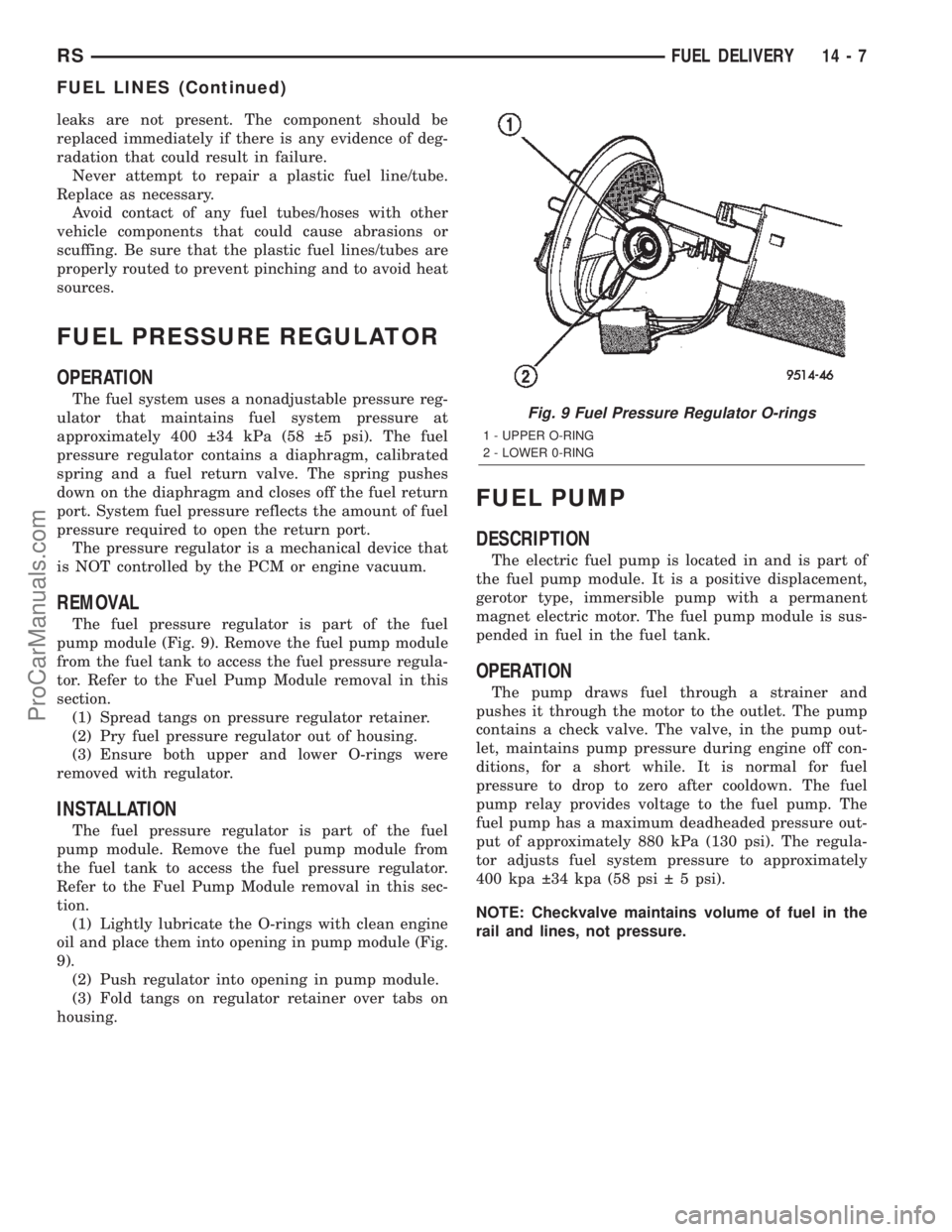

The fuel pressure regulator is part of the fuel

pump module (Fig. 9). Remove the fuel pump module

from the fuel tank to access the fuel pressure regula-

tor. Refer to the Fuel Pump Module removal in this

section.

(1) Spread tangs on pressure regulator retainer.

(2) Pry fuel pressure regulator out of housing.

(3) Ensure both upper and lower O-rings were

removed with regulator.

INSTALLATION

The fuel pressure regulator is part of the fuel

pump module. Remove the fuel pump module from

the fuel tank to access the fuel pressure regulator.

Refer to the Fuel Pump Module removal in this sec-

tion.

(1) Lightly lubricate the O-rings with clean engine

oil and place them into opening in pump module (Fig.

9).

(2) Push regulator into opening in pump module.

(3) Fold tangs on regulator retainer over tabs on

housing.

FUEL PUMP

DESCRIPTION

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor. The fuel pump module is sus-

pended in fuel in the fuel tank.

OPERATION

The pump draws fuel through a strainer and

pushes it through the motor to the outlet. The pump

contains a check valve. The valve, in the pump out-

let, maintains pump pressure during engine off con-

ditions, for a short while. It is normal for fuel

pressure to drop to zero after cooldown. The fuel

pump relay provides voltage to the fuel pump. The

fuel pump has a maximum deadheaded pressure out-

put of approximately 880 kPa (130 psi). The regula-

tor adjusts fuel system pressure to approximately

400 kpa 34 kpa (58 psi 5 psi).

NOTE: Checkvalve maintains volume of fuel in the

rail and lines, not pressure.

Fig. 9 Fuel Pressure Regulator O-rings

1 - UPPER O-RING

2 - LOWER 0-RING

RSFUEL DELIVERY14-7

FUEL LINES (Continued)

ProCarManuals.com

Page 1459 of 2399

FUEL PUMP MODULE

DESCRIPTION

The fuel pump module is installed in the top of the

fuel tank (Fig. 10) .

The fuel pump module contains the following:

²Electric fuel pump

²Fuel pump reservoir

²Inlet strainer

²Fuel pressure regulator

²Fuel gauge sending unit

²Fuel supply line connection

The inlet strainer, fuel pressure regulator

and fuel level sensor are the only serviceable

items. If the fuel pump or electrical wiring har-

ness requires service, replace the fuel pump

module.

The electric fuel pump is located in and is part of

the fuel pump module. It is a positive displacement,

gerotor type, immersible pump with a permanent

magnet electric motor.

OPERATION

The pump draws fuel through a strainer and

pushes it through the motor to the outlet. The pump

contains one check valve. The check valve, in the

pump outlet, maintains pump pressure during engine

off conditions. The fuel pump relay provides voltage

to the fuel pump.

The fuel pump has a maximum deadheaded pres-

sure output of approximately 880 kPa (130 psi). The

regulator adjusts fuel system pressure to approxi-

mately 400 34 kPa (58 5 psi).

FUEL PUMP ELECTRICAL CONTROL

Voltage to operate the electric pump is supplied

through the fuel pump relay. For an electrical opera-tional description of the fuel pump refer to fuel Pump

RelayÐPCM Output.

ELECTRICAL PUMP REPLACEMENT

The electric fuel pump is not serviceable. If the

fuel pump or electrical wiring harness needs replace-

ment, the complete fuel pump module must be

replaced. Perform the Fuel System Pressure Release

procedure before servicing the fuel pump.

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap and perform Fuel Sys-

tem Pressure Release procedure.

(2) Disconnect negative cable from auxiliary

jumper terminal.

(3) Drain fuel tank, refer to the Fuel Tank proce-

dure in the Fuel Delivery section.

(4) Remove fuel tank, refer to the Fuel Tank

removal section.

(5) Clean top of tank to remove loose dirt and

debris.

(6) Using a brass punch and hammer remove lock-

nut to release pump module (Fig. 11).

Fig. 10 Fuel Pump Module

1 - INLET STRAINER

2 - FUEL RESERVOIR

3 - FUEL PRESSURE REGULATOR

4 - FUEL LEVEL SENSOR

Fig. 11 FUEL PUMP MODULE LOCKING RING

14 - 8 FUEL DELIVERYRS

ProCarManuals.com