engine warning lamp CHRYSLER VOYAGER 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 504 of 2399

sage transmitted by the BCM to the FCM to turn off

the headlamps.

OPERATION

AUTOMATIC HEADLAMP SYSTEM

Automatic headlamps are controlled by the Body Con-

trol Module (BCM). With the headlamp switch in the

AUTO position, the BCM will control the headlamp, park-

ing, side marker, tail and instrumentation lamps based on

ambient light levels. Ambient light levels are monitored

by the BCM using the Day/Night signal and Electrochro-

matic Mirror (ECM) present from the Compass Mini Trip

(CMTC) located on the front windshield in front of the

rear view mirror ECM. Ambient light readings are aver-

aged to limit cycling the lamps ON and OFF when pass-

ing through areas with varying light levels. The

automatic headlamps will only function when the engine

is running with RPM > 450. When the headlamp switch is

in the AUTO position (Automatic mode), the Headlamp

Time Delay system will function when the ignition switch

is placed in any position other than run/start.

DAYTIME RUNNING LAMPS

Power is reduced using pulse-width modulation to

the high beams, where by the power is switched on

and off rapidly instead of remaining on continuously.

The duration and interval of the power pulses is pro-

grammed into the FCM.

HEADLAMP SYSTEM

The headlamp system will default to headlamps

ON position when ignition switch is ON and when an

open or short circuit failure occurs on the headlamp

switch input. The system will return to normal oper-

ation when the open or short is repaired. A fault will

be reported by the BCM when a failure occurs on the

dimmer or headlamp switch input.

If the exterior lamps are ON and the headlamp

switch is in any position other than OFF or AUTO

and with the ignition switch OFF (LOCK) after 3

minutes the BCM sends a message via PCI bus to

the FCM informing the FCM to turn off the head-

lamps, park lamps and fog lamps. This feature pre-

vents the vehicle battery from being discharged when

the vehicle lights have been left ON.

HEADLAMP TIME DELAY SYSTEM

The headlamp time delay system is activated by

turning the headlamps ON (high or low beam) while

the engine is running, turning the ignition switch

OFF, and then turning the headlamp switch OFF

within 45 seconds. The system will not activate if

more than 45 seconds elapse between ignition switch

OFF and headlamp switch OFF. The BCM will allow

the headlamps to remain ON for 90 seconds (config-urable) before they automatically turn off (If the key

is in the ignition during the headlamp time delay

mode, then both the headlamps and park lamps

(including panel dimming) will be ON). Refer to the

Owner's Manual for more information.

If the headlamp switch is in the Auto Headlamp

Position, the headlamps are ON due to the night sig-

nal from the CMTC and the ignition switch is in any

position other than run/start, the BCM shall enter a

90 second (configurable) Auto Headlamps time delay

mode. If the key is in the ignition during the head-

lamp time delay mode, then both the headlamps and

park lamps (including panel dimming) will be ON. If

the key is not in the ignition, then only the head-

lamps will be ON. The BCM will allow the head-

lamps to remain ON for 90 seconds before they

automatically turn OFF. Refer to the Owner's Man-

ual for more information.

OPTICAL HORN/HIGH BEAMS

When the multi-function switch is pulled to the

first detent (optical horn) signal, the headlamps are

ON, key-in the ignition the BCM shall send a mes-

sage via PCI bus to the FCM to turn on the head-

lamps drivers to illuminate all four filaments (Low

and High beams). When the multi-function switch is

pulled to the second detent (high beam) signal and

the headlamps are ON, the BCM shall send a mes-

sage via PCI bus to the FCM to turn on the head-

lamps drivers. The High Beams are illuminated and

the Low Beams and Fog Lamps (if ON) are extin-

guished. If the headlamps were in the high beam

configuration when power was removed from the

headlamps, the headlamps will be configured as low

beam the next time they are activated.

WARNING

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result. Do not use bulbs other than

those indicated in the Bulb Application table. Dam-

age to lamp and/or Daytime Running Lamp Module

can result. Do not use fuses, circuit breakers or

relays having greater amperage value than indi-

cated on the fuse panel or in the Owners Manual.

CAUTION: Do not use bulbs other than those listed

in the Bulb Application Table. Damage to lamp can

result. Do not touch halogen bulbs with fingers or

other oily surfaces. Bulb life will be reduced.

RSLAMPS/LIGHTING - EXTERIOR8L-3

LAMPS/LIGHTING - EXTERIOR (Continued)

ProCarManuals.com

Page 650 of 2399

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Hoist vehicle or support on jack stands.

(3) Disconnect the hose from the nozzle inlet. To

disconnect the headlamp washer hose, push down on

the latch with slight force and pull apart.

(4) Apply a regulated 20 psi of compressed air to

the inlet, so as to fully extend the telescopic unit.

WARNING: IF MORE THAN 20 PSI IS APPLIED TO

THE WASHER INLET, WASHER FLUID MAY SPRAY

OUT OF THE HEADLAMP WASHER. WEAR SAFETY

GLASSES AND DO NOT HAVE AIMING DIRECTLY

TOWARD FACE.

(5) Unsnap cover from telescopic assembly.

(6) Disconnect air supply from washer inlet to fully

retract the telescopic unit.

(7) Remove two screws holding the nozzle assem-

bly to the front fascia.

(8) Remove the nozzle assembly from behind fas-

cia.

INSTALLATION

(1) Place the nozzle assembly in behind the fascia.

(2) Install the two screws holding the nozzle

assembly to the front fascia.

(3) Snap cover onto telescopic assembly.

WARNING: IF MORE THAN 20 PSI IS APPLIED TO

THE WASHER INLET, WASHER FLUID MAY SPRAY

OUT OF THE HEADLAMP WASHER. WEAR SAFETY

GLASSES AND DO NOT HAVE AIMING DIRECTLY

TOWARD FACE.

On the new washer unit, there is a white tab with

pull ring holding the telescopic unit up approxi-

mately an inch. This is to ease the installation pro-

cess. Once cover is snapped on, you may either pull

up on the unit to remove the tab, or apply regulated

compressed air.

(4) Apply a regulated 20 psi of compressed air the

inlet, so as to fully extend the telescopic unit.

(5) With unit extended, pull white tab out from the

bottom of the telescopic unit and discard.

(6) Remove the air supply from the washer unit.

(7) Connect the washer hose to the telescopic unit.

Press firmly until snap is heard.

(8) Remove vehicle from hoist or jack stands.

(9) Connect the battery negative cable.

(10) Verify vehicle and system operation.

HEADLAMP WASHER HOSE -

EXPORT

REMOVAL

The headlamp washer hose is a special high pres-

sure hose with specific fittings, and must be replaced

as a unit.

(1) Disconnect and isolate the battery negative

cable.

(2) Hoist vehicle or support on jack stands.

(3) Remove parts as necessary to replace high

pressure headlamp washer hose. When disconnecting

hose, press down firmly on latch at headlamp washer

pump motor and telescopic washer assembly and pull

apart.

INSTALLATION

The headlamp washer hose is a special high pres-

sure hose with specific fittings, and must be replaced

as a unit.

(1) Install the new high pressure headlamp

washer hose assembly. Push fitting on until a snap is

heard.

(2) Install the parts that were removed to replace

high pressure headlamp washer hose.

(3) Remove vehicle from hoist or jack stands.

(4) Connect the battery negative cable.

(5) Verify vehicle and system operation.

HEADLAMP WASHER PUMP

MOTOR - EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

REMOVAL).

(3) Disconnect the washer hose at the in-line con-

nector forward of the cowl grille so that the in-line

connector remains with the washer hose from the

fresh air plenum.

(4) Disconnect the washer hose from the hose clip

located on the front fender side shield.

(5) Remove the filler tube screw.

(6) Hoist and support vehicle on hoist or jack

stands.

(7) Remove the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - REMOVAL).

(8) Disconnect the left right front wheelhouse

splash shield and move aside (Refer to 23 - BODY/

EXTERIOR/WHEELHOUSE SPLASH SHIELD -

REMOVAL).

RSWIPERS/WASHERS8R-13

HEADLAMP WASHERS - EXPORT (Continued)

ProCarManuals.com

Page 1425 of 2399

OPERATION

The exhaust system contains, quiets, and cleans

the exhaust gases generated by the engine.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - EXCESSIVE

EXHAUST SYSTEM NOISE

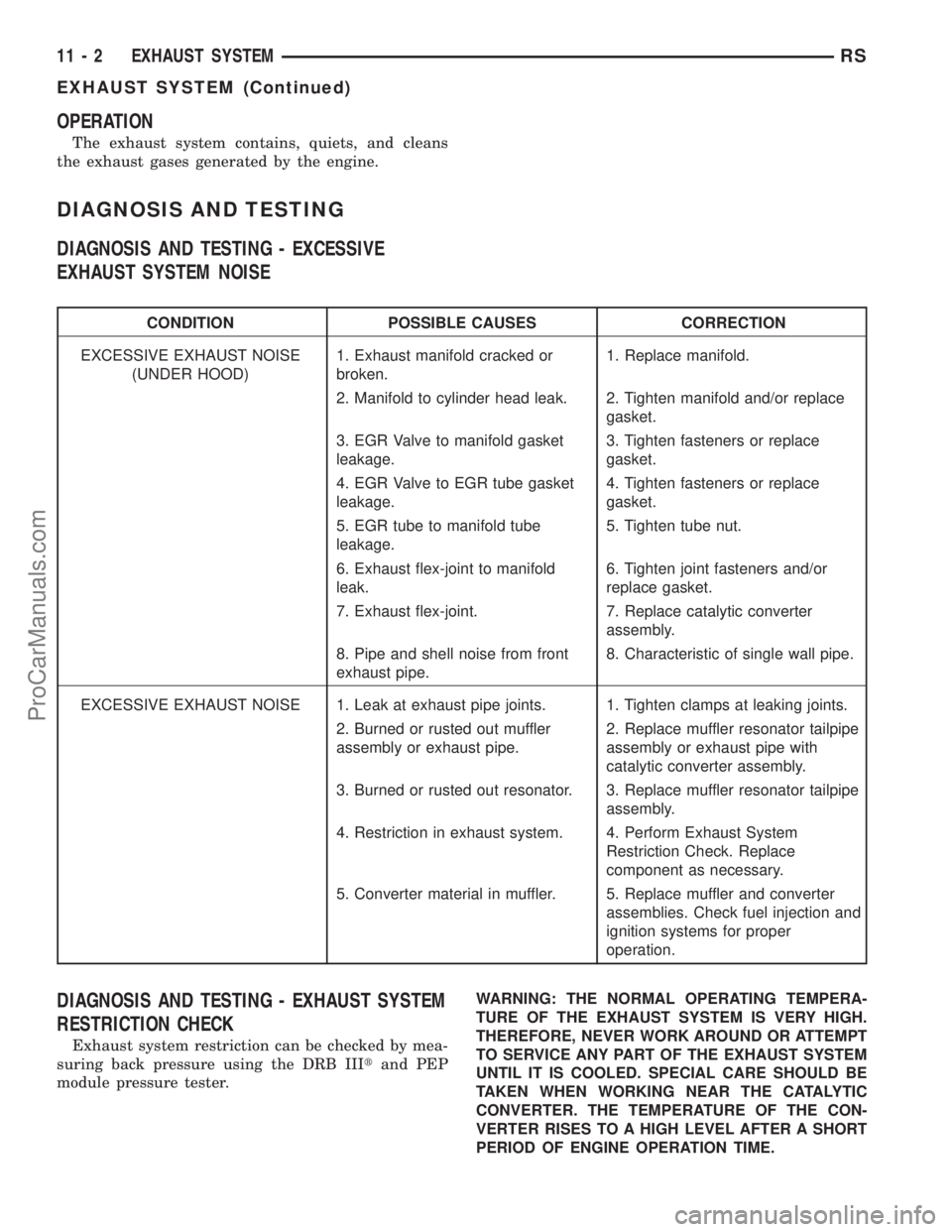

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or

broken.1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace

gasket.

3. EGR Valve to manifold gasket

leakage.3. Tighten fasteners or replace

gasket.

4. EGR Valve to EGR tube gasket

leakage.4. Tighten fasteners or replace

gasket.

5. EGR tube to manifold tube

leakage.5. Tighten tube nut.

6. Exhaust flex-joint to manifold

leak.6. Tighten joint fasteners and/or

replace gasket.

7. Exhaust flex-joint. 7. Replace catalytic converter

assembly.

8. Pipe and shell noise from front

exhaust pipe.8. Characteristic of single wall pipe.

EXCESSIVE EXHAUST NOISE 1. Leak at exhaust pipe joints. 1. Tighten clamps at leaking joints.

2. Burned or rusted out muffler

assembly or exhaust pipe.2. Replace muffler resonator tailpipe

assembly or exhaust pipe with

catalytic converter assembly.

3. Burned or rusted out resonator. 3. Replace muffler resonator tailpipe

assembly.

4. Restriction in exhaust system. 4. Perform Exhaust System

Restriction Check. Replace

component as necessary.

5. Converter material in muffler. 5. Replace muffler and converter

assemblies. Check fuel injection and

ignition systems for proper

operation.

DIAGNOSIS AND TESTING - EXHAUST SYSTEM

RESTRICTION CHECK

Exhaust system restriction can be checked by mea-

suring back pressure using the DRB IIItand PEP

module pressure tester.WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATION TIME.

11 - 2 EXHAUST SYSTEMRS

EXHAUST SYSTEM (Continued)

ProCarManuals.com

Page 1457 of 2399

INSTALLATION

(1) Insert level sensor wires into bottom of opening

in module.

(2) Wrap wires into groove in back of level sensor

(Fig. 7) .

(3) While feeding wires into guide grooves, slide

level sensor up into channel until it snaps into place

(Fig. 8) . Ensure tab at bottom of sensor locks in

place.

(4) Install level sensor wires in connector. Push

the wires up through the connector and then pull

them down until they lock in place. Ensure signal

and ground wires are installed in the correct posi-

tion.

(5) Install locking wedge on connector.

(6) Push connector up into bottom of fuel pump

module electrical connector.(7) Install fuel pump module. Refer to Fuel Pump

Module in this section.

FUEL LINES

DESCRIPTION - FUEL LINES/HOSES AND

CLAMPS

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped:The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

STANDARD PROCEDURE - HOSES AND CLAMP

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure and

Fig. 7 Groove in Back Side of Level Sensor

1 - WRAP WIRES IN GROOVE

2 - REAR VIEW OF LEVEL SENSOR

Fig. 8 Installation Channel

1 - CHANNEL FOR LEVEL SENSOR

2 - PUMP MODULE

14 - 6 FUEL DELIVERYRS

FUEL LEVEL SENDING UNIT / SENSOR (Continued)

ProCarManuals.com

Page 1460 of 2399

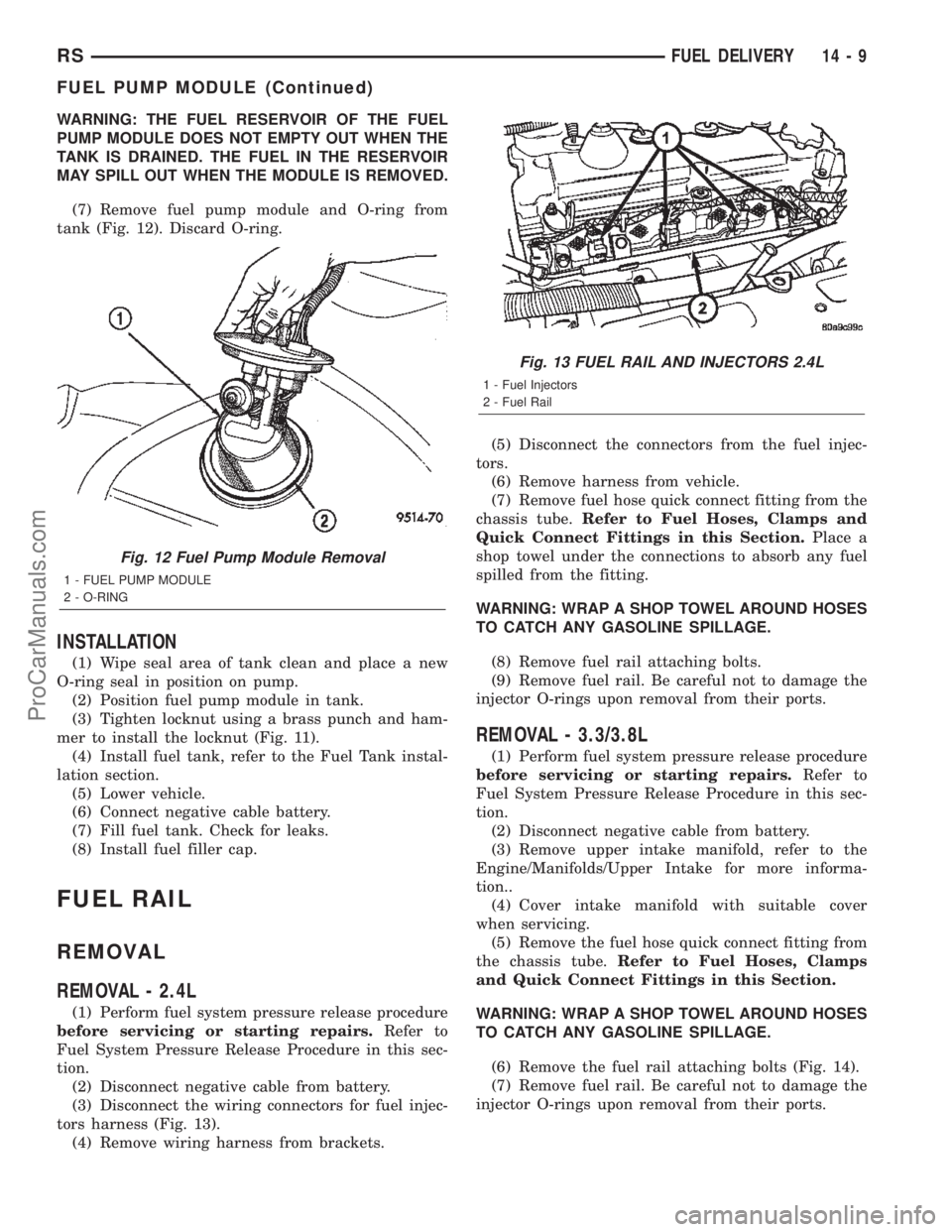

WARNING: THE FUEL RESERVOIR OF THE FUEL

PUMP MODULE DOES NOT EMPTY OUT WHEN THE

TANK IS DRAINED. THE FUEL IN THE RESERVOIR

MAY SPILL OUT WHEN THE MODULE IS REMOVED.

(7) Remove fuel pump module and O-ring from

tank (Fig. 12). Discard O-ring.

INSTALLATION

(1) Wipe seal area of tank clean and place a new

O-ring seal in position on pump.

(2) Position fuel pump module in tank.

(3) Tighten locknut using a brass punch and ham-

mer to install the locknut (Fig. 11).

(4) Install fuel tank, refer to the Fuel Tank instal-

lation section.

(5) Lower vehicle.

(6) Connect negative cable battery.

(7) Fill fuel tank. Check for leaks.

(8) Install fuel filler cap.

FUEL RAIL

REMOVAL

REMOVAL - 2.4L

(1) Perform fuel system pressure release procedure

before servicing or starting repairs.Refer to

Fuel System Pressure Release Procedure in this sec-

tion.

(2) Disconnect negative cable from battery.

(3) Disconnect the wiring connectors for fuel injec-

tors harness (Fig. 13).

(4) Remove wiring harness from brackets.(5) Disconnect the connectors from the fuel injec-

tors.

(6) Remove harness from vehicle.

(7) Remove fuel hose quick connect fitting from the

chassis tube.Refer to Fuel Hoses, Clamps and

Quick Connect Fittings in this Section.Place a

shop towel under the connections to absorb any fuel

spilled from the fitting.

WARNING: WRAP A SHOP TOWEL AROUND HOSES

TO CATCH ANY GASOLINE SPILLAGE.

(8) Remove fuel rail attaching bolts.

(9) Remove fuel rail. Be careful not to damage the

injector O-rings upon removal from their ports.

REMOVAL - 3.3/3.8L

(1) Perform fuel system pressure release procedure

before servicing or starting repairs.Refer to

Fuel System Pressure Release Procedure in this sec-

tion.

(2) Disconnect negative cable from battery.

(3) Remove upper intake manifold, refer to the

Engine/Manifolds/Upper Intake for more informa-

tion..

(4) Cover intake manifold with suitable cover

when servicing.

(5) Remove the fuel hose quick connect fitting from

the chassis tube.Refer to Fuel Hoses, Clamps

and Quick Connect Fittings in this Section.

WARNING: WRAP A SHOP TOWEL AROUND HOSES

TO CATCH ANY GASOLINE SPILLAGE.

(6) Remove the fuel rail attaching bolts (Fig. 14).

(7) Remove fuel rail. Be careful not to damage the

injector O-rings upon removal from their ports.

Fig. 12 Fuel Pump Module Removal

1 - FUEL PUMP MODULE

2 - O-RING

Fig. 13 FUEL RAIL AND INJECTORS 2.4L

1 - Fuel Injectors

2 - Fuel Rail

RSFUEL DELIVERY14-9

FUEL PUMP MODULE (Continued)

ProCarManuals.com

Page 1497 of 2399

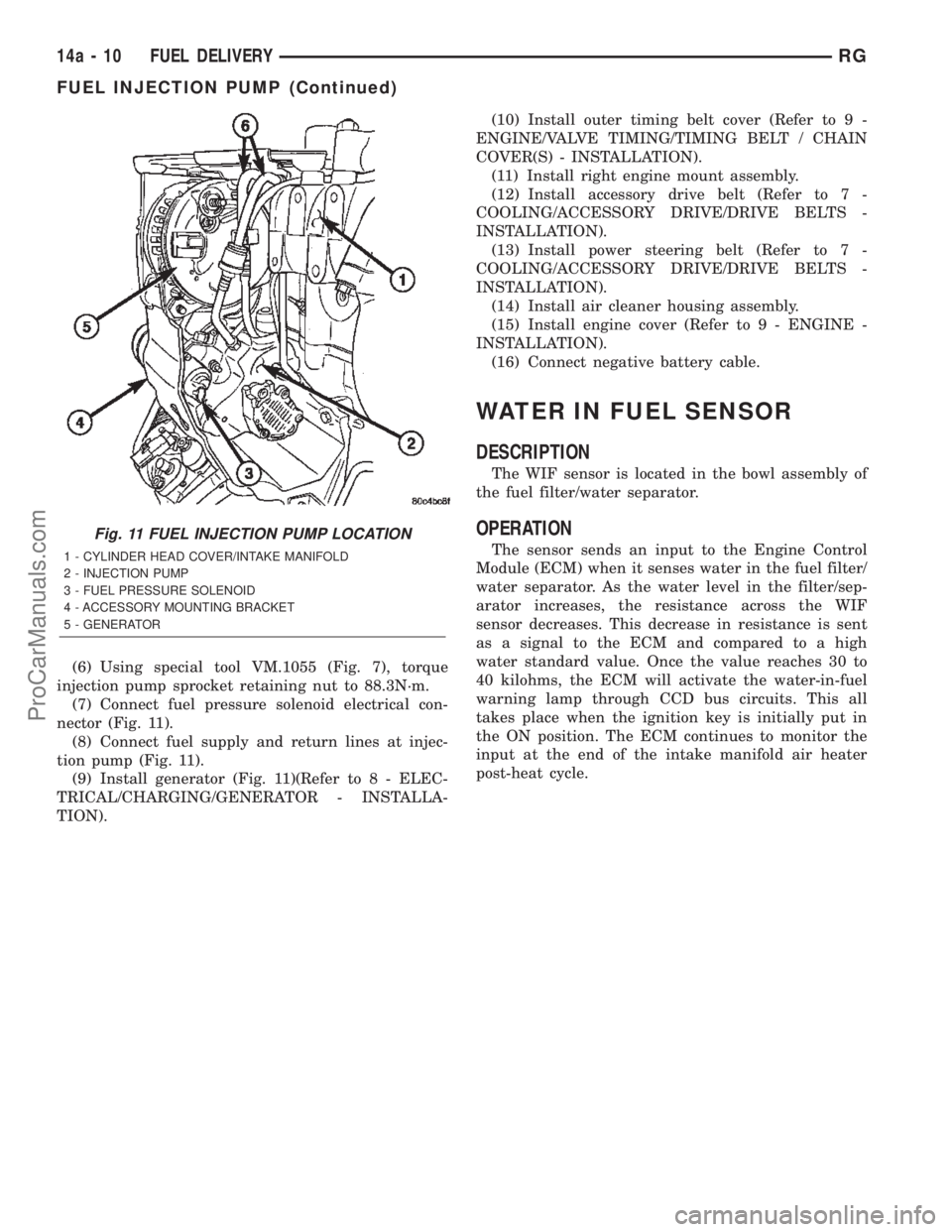

(6) Using special tool VM.1055 (Fig. 7), torque

injection pump sprocket retaining nut to 88.3N´m.

(7) Connect fuel pressure solenoid electrical con-

nector (Fig. 11).

(8) Connect fuel supply and return lines at injec-

tion pump (Fig. 11).

(9) Install generator (Fig. 11)(Refer to 8 - ELEC-

TRICAL/CHARGING/GENERATOR - INSTALLA-

TION).(10) Install outer timing belt cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT / CHAIN

COVER(S) - INSTALLATION).

(11) Install right engine mount assembly.

(12) Install accessory drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(13) Install power steering belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(14) Install air cleaner housing assembly.

(15) Install engine cover (Refer to 9 - ENGINE -

INSTALLATION).

(16) Connect negative battery cable.

WATER IN FUEL SENSOR

DESCRIPTION

The WIF sensor is located in the bowl assembly of

the fuel filter/water separator.

OPERATION

The sensor sends an input to the Engine Control

Module (ECM) when it senses water in the fuel filter/

water separator. As the water level in the filter/sep-

arator increases, the resistance across the WIF

sensor decreases. This decrease in resistance is sent

as a signal to the ECM and compared to a high

water standard value. Once the value reaches 30 to

40 kilohms, the ECM will activate the water-in-fuel

warning lamp through CCD bus circuits. This all

takes place when the ignition key is initially put in

the ON position. The ECM continues to monitor the

input at the end of the intake manifold air heater

post-heat cycle.

Fig. 11 FUEL INJECTION PUMP LOCATION

1 - CYLINDER HEAD COVER/INTAKE MANIFOLD

2 - INJECTION PUMP

3 - FUEL PRESSURE SOLENOID

4 - ACCESSORY MOUNTING BRACKET

5 - GENERATOR

14a - 10 FUEL DELIVERYRG

FUEL INJECTION PUMP (Continued)

ProCarManuals.com

Page 1547 of 2399

NOTE: Before installing power steering pressure

hose on power steering pump, inspect the O-ring

on the power steering pressure hose for damage

and replace if required.

(4) Install the power steering fluid pressure hose

fitting into the pressure port of the power steering

pump (Fig. 12). Tighten the pressure line to pump

fitting tube nut to a torque of 31 N´m (275 in. lbs.).

(5) Install the power steering fluid supply hose on

the power steering pump supply fitting (Fig. 12).Be

sure hose clamp is properly reinstalled.

(6) Install the accessary drive belt (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(7) Install the splash shields below the engine

compartment.

(8) Lower the vehicle.

(9) Connect the negative (-) battery cable on the

negative battery post.

(10) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE).

(11) Inspect for leaks.

SPECIAL TOOLS

POWER STEERING PUMP

FLUID

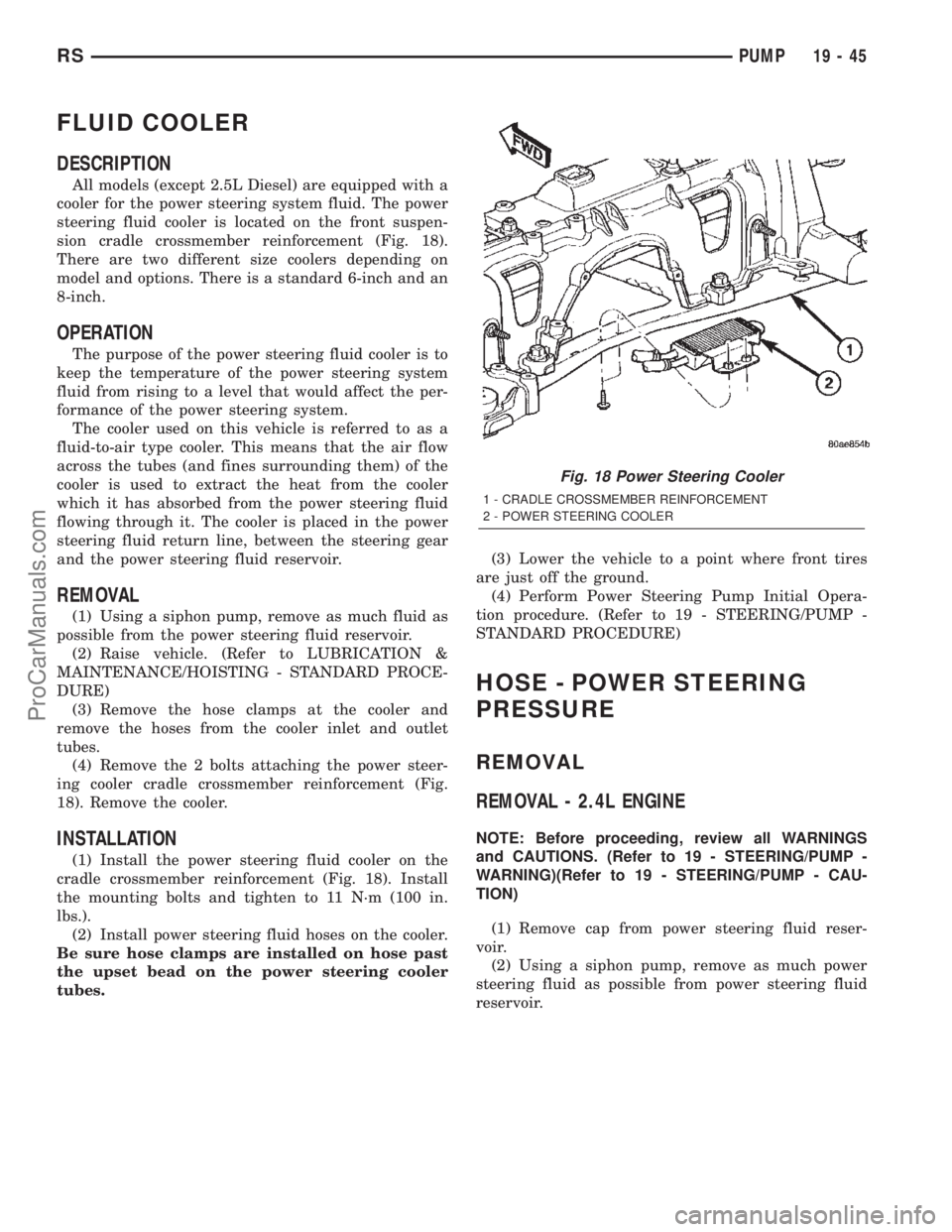

STANDARD PROCEDURE - POWER STEERING

FLUID LEVEL CHECKING

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT INJURY

FROM MOVING PARTS AND TO ENSURE ACCU-

RATE FLUID LEVEL READING.

The fluid level can be read on the exterior of the

power steering fluid reservoir. The fluid level should

be within the ªFILL RANGEº when the fluid is at

normal ambient temperature, approximately 21ÉC to

27ÉC (70ÉF to 80ÉF) (Fig. 17).

Before removing the power steering filler cap, wipe

the reservoir filler cap free of dirt and debris. Do not

overfill the power steering system.Use only

MopartATF+4 Automatic Transmission Fluid

(MS-9602) in the power steering system.For

additional information on Automatic Transmission

Fluid, (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION).

CAUTION: Use only MoparTATF+4 Automatic Trans-

mission Fluid (MS-9602). Use of other MoparT

power steering fluids (MS5931 and MS9933) should

be avoided to ensure peak performance of the

power steering system under all operating condi-

tions.

Installer C-4063B

Puller C-4333

Fig. 17 Power Steering Fluid Reservoir

19 - 44 PUMPRS

PUMP (Continued)

ProCarManuals.com

Page 1548 of 2399

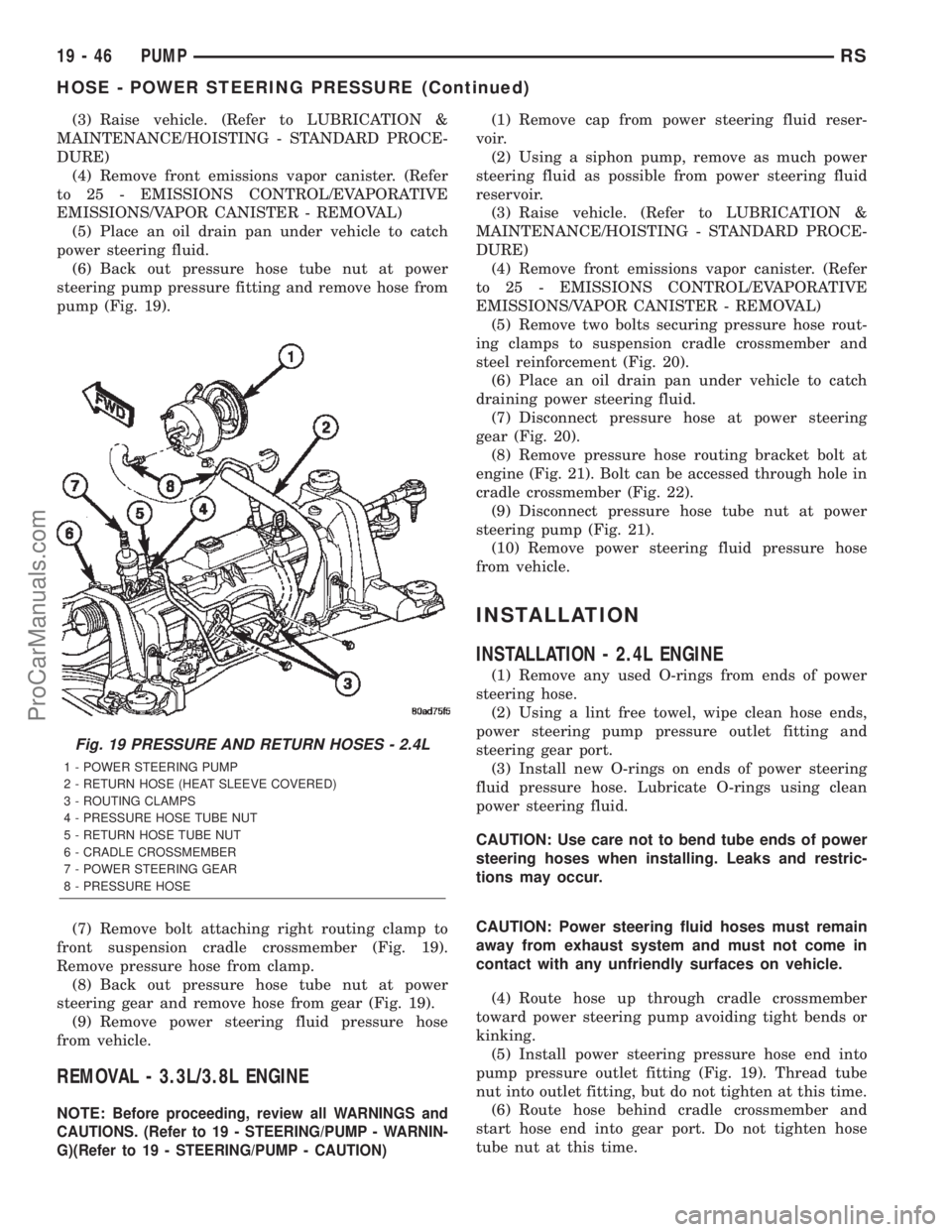

FLUID COOLER

DESCRIPTION

All models (except 2.5L Diesel) are equipped with a

cooler for the power steering system fluid. The power

steering fluid cooler is located on the front suspen-

sion cradle crossmember reinforcement (Fig. 18).

There are two different size coolers depending on

model and options. There is a standard 6-inch and an

8-inch.

OPERATION

The purpose of the power steering fluid cooler is to

keep the temperature of the power steering system

fluid from rising to a level that would affect the per-

formance of the power steering system.

The cooler used on this vehicle is referred to as a

fluid-to-air type cooler. This means that the air flow

across the tubes (and fines surrounding them) of the

cooler is used to extract the heat from the cooler

which it has absorbed from the power steering fluid

flowing through it. The cooler is placed in the power

steering fluid return line, between the steering gear

and the power steering fluid reservoir.

REMOVAL

(1) Using a siphon pump, remove as much fluid as

possible from the power steering fluid reservoir.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(3) Remove the hose clamps at the cooler and

remove the hoses from the cooler inlet and outlet

tubes.

(4) Remove the 2 bolts attaching the power steer-

ing cooler cradle crossmember reinforcement (Fig.

18). Remove the cooler.

INSTALLATION

(1) Install the power steering fluid cooler on the

cradle crossmember reinforcement (Fig. 18). Install

the mounting bolts and tighten to 11 N´m (100 in.

lbs.).

(2) Install power steering fluid hoses on the cooler.

Be sure hose clamps are installed on hose past

the upset bead on the power steering cooler

tubes.(3) Lower the vehicle to a point where front tires

are just off the ground.

(4) Perform Power Steering Pump Initial Opera-

tion procedure. (Refer to 19 - STEERING/PUMP -

STANDARD PROCEDURE)

HOSE - POWER STEERING

PRESSURE

REMOVAL

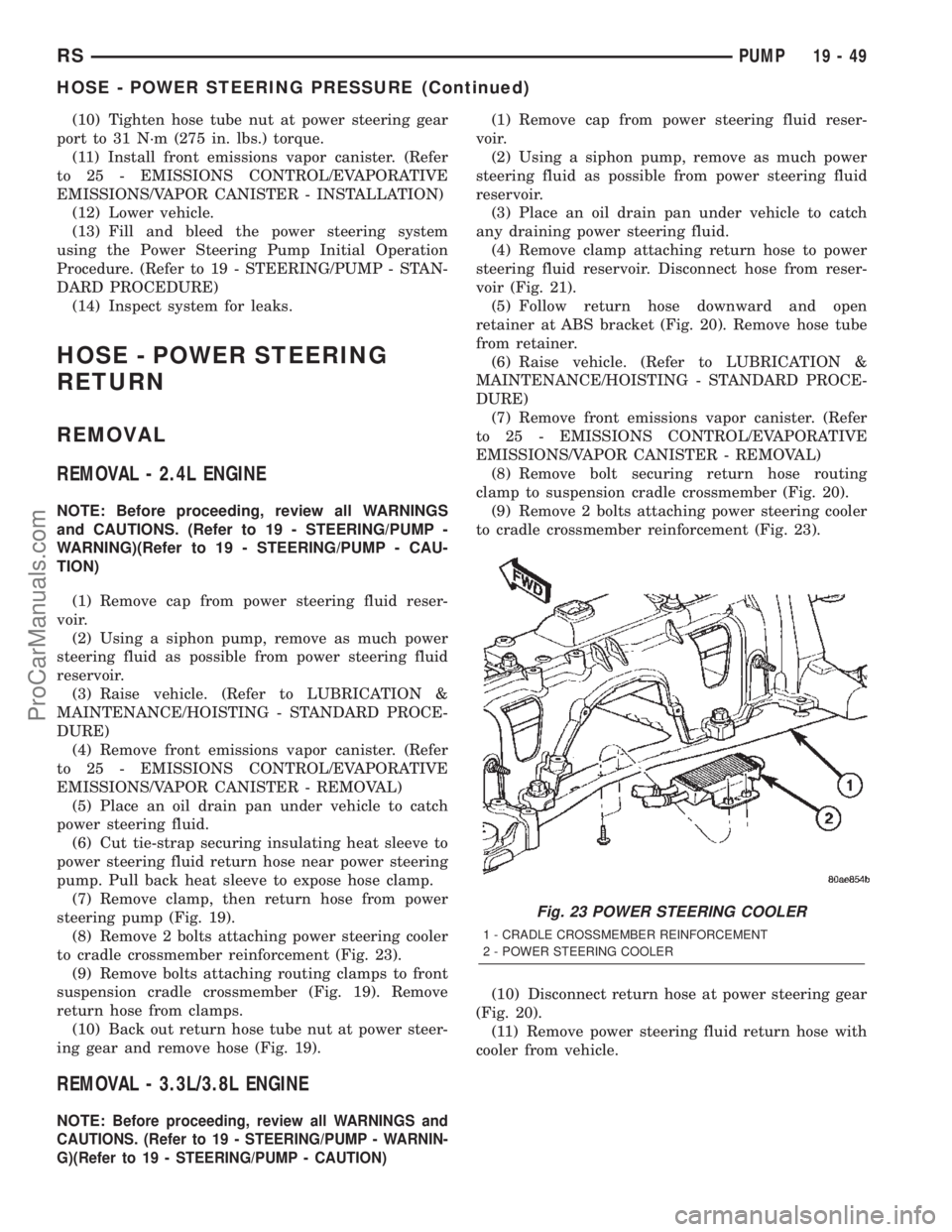

REMOVAL - 2.4L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

Fig. 18 Power Steering Cooler

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

RSPUMP19-45

ProCarManuals.com

Page 1549 of 2399

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(5) Place an oil drain pan under vehicle to catch

power steering fluid.

(6) Back out pressure hose tube nut at power

steering pump pressure fitting and remove hose from

pump (Fig. 19).

(7) Remove bolt attaching right routing clamp to

front suspension cradle crossmember (Fig. 19).

Remove pressure hose from clamp.

(8) Back out pressure hose tube nut at power

steering gear and remove hose from gear (Fig. 19).

(9) Remove power steering fluid pressure hose

from vehicle.

REMOVAL - 3.3L/3.8L ENGINE

NOTE:Before proceeding, review all WARNINGS and

CAUTIONS. (Refer to 19 - STEERING/PUMP - WARNIN-

G)(Refer to 19 - STEERING/PUMP - CAUTION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(5) Remove two bolts securing pressure hose rout-

ing clamps to suspension cradle crossmember and

steel reinforcement (Fig. 20).

(6) Place an oil drain pan under vehicle to catch

draining power steering fluid.

(7) Disconnect pressure hose at power steering

gear (Fig. 20).

(8) Remove pressure hose routing bracket bolt at

engine (Fig. 21). Bolt can be accessed through hole in

cradle crossmember (Fig. 22).

(9) Disconnect pressure hose tube nut at power

steering pump (Fig. 21).

(10) Remove power steering fluid pressure hose

from vehicle.

INSTALLATION

INSTALLATION - 2.4L ENGINE

(1) Remove any used O-rings from ends of power

steering hose.

(2) Using a lint free towel, wipe clean hose ends,

power steering pump pressure outlet fitting and

steering gear port.

(3) Install new O-rings on ends of power steering

fluid pressure hose. Lubricate O-rings using clean

power steering fluid.

CAUTION: Use care not to bend tube ends of power

steering hoses when installing. Leaks and restric-

tions may occur.

CAUTION: Power steering fluid hoses must remain

away from exhaust system and must not come in

contact with any unfriendly surfaces on vehicle.

(4) Route hose up through cradle crossmember

toward power steering pump avoiding tight bends or

kinking.

(5) Install power steering pressure hose end into

pump pressure outlet fitting (Fig. 19). Thread tube

nut into outlet fitting, but do not tighten at this time.

(6) Route hose behind cradle crossmember and

start hose end into gear port. Do not tighten hose

tube nut at this time.

Fig. 19 PRESSURE AND RETURN HOSES - 2.4L

1 - POWER STEERING PUMP

2 - RETURN HOSE (HEAT SLEEVE COVERED)

3 - ROUTING CLAMPS

4 - PRESSURE HOSE TUBE NUT

5 - RETURN HOSE TUBE NUT

6 - CRADLE CROSSMEMBER

7 - POWER STEERING GEAR

8 - PRESSURE HOSE

19 - 46 PUMPRS

HOSE - POWER STEERING PRESSURE (Continued)

ProCarManuals.com

Page 1552 of 2399

(10) Tighten hose tube nut at power steering gear

port to 31 N´m (275 in. lbs.) torque.

(11) Install front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - INSTALLATION)

(12) Lower vehicle.

(13) Fill and bleed the power steering system

using the Power Steering Pump Initial Operation

Procedure. (Refer to 19 - STEERING/PUMP - STAN-

DARD PROCEDURE)

(14) Inspect system for leaks.

HOSE - POWER STEERING

RETURN

REMOVAL

REMOVAL - 2.4L ENGINE

NOTE: Before proceeding, review all WARNINGS

and CAUTIONS. (Refer to 19 - STEERING/PUMP -

WARNING)(Refer to 19 - STEERING/PUMP - CAU-

TION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(5) Place an oil drain pan under vehicle to catch

power steering fluid.

(6) Cut tie-strap securing insulating heat sleeve to

power steering fluid return hose near power steering

pump. Pull back heat sleeve to expose hose clamp.

(7) Remove clamp, then return hose from power

steering pump (Fig. 19).

(8) Remove 2 bolts attaching power steering cooler

to cradle crossmember reinforcement (Fig. 23).

(9) Remove bolts attaching routing clamps to front

suspension cradle crossmember (Fig. 19). Remove

return hose from clamps.

(10) Back out return hose tube nut at power steer-

ing gear and remove hose (Fig. 19).

REMOVAL - 3.3L/3.8L ENGINE

NOTE:Before proceeding, review all WARNINGS and

CAUTIONS. (Refer to 19 - STEERING/PUMP - WARNIN-

G)(Refer to 19 - STEERING/PUMP - CAUTION)

(1) Remove cap from power steering fluid reser-

voir.

(2) Using a siphon pump, remove as much power

steering fluid as possible from power steering fluid

reservoir.

(3) Place an oil drain pan under vehicle to catch

any draining power steering fluid.

(4) Remove clamp attaching return hose to power

steering fluid reservoir. Disconnect hose from reser-

voir (Fig. 21).

(5) Follow return hose downward and open

retainer at ABS bracket (Fig. 20). Remove hose tube

from retainer.

(6) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(7) Remove front emissions vapor canister. (Refer

to 25 - EMISSIONS CONTROL/EVAPORATIVE

EMISSIONS/VAPOR CANISTER - REMOVAL)

(8) Remove bolt securing return hose routing

clamp to suspension cradle crossmember (Fig. 20).

(9) Remove 2 bolts attaching power steering cooler

to cradle crossmember reinforcement (Fig. 23).

(10) Disconnect return hose at power steering gear

(Fig. 20).

(11) Remove power steering fluid return hose with

cooler from vehicle.

Fig. 23 POWER STEERING COOLER

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

RSPUMP19-49

HOSE - POWER STEERING PRESSURE (Continued)

ProCarManuals.com