instrument cluster CHRYSLER VOYAGER 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: VOYAGER, Model: CHRYSLER VOYAGER 2002Pages: 2399, PDF Size: 57.96 MB

Page 397 of 2399

The Check Gauges Lamp (if equipped) or Battery

Lamp monitors:charging system voltage,engine

coolant temperature and engine oil pressure. If an

extreme condition is indicated, the lamp will be illu-

minated. The signal to activate the lamp is sent via

the PCI bus circuits. The lamp is located on the

instrument panel. Refer to the Instrument Cluster

section for additional information.

The PCM uses the inlet air temperature sensor to

control the charge system voltage. This temperature,

along with data from monitored line voltage, is used

by the PCM to vary the battery charging rate. The

system voltage is higher at cold temperatures and is

gradually reduced as the calculated battery tempera-

ture increases.

The ambient temperature sensor is used to control

the battery voltage based upon ambient temperature

(approximation of battery temperature). The PCM

maintains the optimal output of the generator by

monitoring battery voltage and controlling it to a

range of 13.5 - 14.7 volts based on battery tempera-

ture.

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTIC SYSTEM

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the OBD system. Some

circuits are checked continuously and some are

checked only under certain conditions.

If the OBD system senses that a monitored circuit

is bad, it will put a DTC into electronic memory. The

DTC will stay in electronic memory as long as the

circuit continues to be bad. The PCM is programmed

to clear the memory after 50 engine starts if the

problem does not occur again.

DIAGNOSTIC TROUBLE CODES

A DTC description can be read using the DRBIIIt

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures manual for information.

A DTC does not identify which component in a cir-

cuit is bad. Thus, a DTC should be treated as a

symptom, not as the cause for the problem. In some

cases, because of the design of the diagnostic test

procedure, a DTC can be the reason for another DTC

to be set. Therefore, it is important that the test pro-

cedures be followed in sequence, to understand what

caused a DTC to be set.

ERASING DIAGNOSTIC TROUBLE CODES

The DRBIIItScan Tool must be used to erase a

DTC.The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp or battery lamp is illumi-

nated with the engine running

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE)

INSPECTION

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the On-Board Diagnostic

(OBD) system. Some charging system circuits are

checked continuously, and some are checked only

under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBIIItscan tool.

Perform the following inspections before attaching

the scan tool.

(1) Inspect the battery condition. Refer to the Bat-

tery section (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM - DIAGNOSIS AND TESTING) for proce-

dures.

(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications (Refer to 8 - ELECTRICAL/

CHARGING - SPECIFICATIONS).

(5) Inspect generator drive belt condition and ten-

sion. Tighten or replace belt as required. Refer to

Belt Tension Specifications(Refer to 7 - COOLING/

ACCESSORY DRIVE - SPECIFICATIONS).

8F - 22 CHARGINGRS

CHARGING (Continued)

ProCarManuals.com

Page 431 of 2399

CHARGING

TABLE OF CONTENTS

page page

CHARGING

DESCRIPTION - CHARGING SYSTEM.......20

OPERATION - CHARGING SYSTEM.........20

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTIC SYSTEM.................21

SPECIFICATIONS

GENERATOR........................22

TORQUE............................22

SPECIAL TOOLS.......................22

BATTERY TEMPERATURE SENSOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................23

GENERATOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL

REMOVAL - 2.4L......................23REMOVAL - 2.5L......................24

REMOVAL - 3.3/3.8L...................25

REMOVAL - 3.5L......................26

INSTALLATION

INSTALLATION - 2.4L..................27

INSTALLATION - 2.5L..................28

INSTALLATION - 3.3/3.8L................28

INSTALLATION - 3.5L..................28

GENERATOR DECOUPLER PULLEY

DESCRIPTION.........................28

OPERATION...........................28

DIAGNOSIS AND TESTING - GENERATOR

DECOUPLER PULLEY..................29

REMOVAL.............................29

INSTALLATION.........................30

VOLTAGE REGULATOR

DESCRIPTION.........................30

OPERATION...........................30

CHARGING

DESCRIPTION - CHARGING SYSTEM

The charging system consists of:

²Generator

²Decoupler Pulley (If equipped)

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM)

²Ignition switch (refer to the Ignition System sec-

tion for information)

²Battery (refer to the Battery section for informa-

tion)

²Inlet Air Temperature (calculated battery tem-

perature)

²Voltmeter (refer to the Instrument Cluster sec-

tion for information if equipped)

²Wiring harness and connections (refer to the

Wiring section for information)

²Accessory drive belt (refer to the Cooling section

for more information)

OPERATION - CHARGING SYSTEM

The charging system is turned on and off with the

ignition switch. The system is on when the engine is

running and the ASD relay is energized. The ASD

relay is energized when the PCM grounds the ASD

control circuit. This voltage is connected through the

PCM or IPM (intelligent power module) (if equipped)and supplied to one of the generator field terminals

(Gen. Source +) at the back of the generator.

The generator is driven by the engine through a

serpentine belt and pulley or decoupler pulley

arrangement.

The amount of DC current produced by the gener-

ator is controlled by the EVR (field control) circuitry

contained within the PCM. This circuitry is con-

nected in series with the second rotor field terminal

and ground.

An Inlet air temperature sensor is used to calcu-

late the temperature near the battery. This tempera-

ture data, along with data from monitored line

voltage (battery voltage sense circuit), is used by the

PCM to vary the battery charging rate. This is done

by cycling the ground path to control the strength of

the rotor magnetic field. The PCM then compensates

and regulates generator current output accordingly

to maintain system voltage at the targeted system

voltage based on battery temperature.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including EVR

(field control) circuitry, are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for certain failures it detects and

illuminate the (MIL) lamp. Refer to On-Board Diag-

nostics in the Electronic Control Modules(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

8Fa - 20 CHARGINGRG

ProCarManuals.com

Page 432 of 2399

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION) section for more DTC information.

The Check Gauges Lamp (if equipped) or Battery

Lamp monitors:charging system voltage,engine

coolant temperature and engine oil pressure. If an

extreme condition is indicated, the lamp will be illu-

minated. The signal to activate the lamp is sent via

the PCI bus circuits. The lamp is located on the

instrument panel. Refer to the Instrument Cluster

section for additional information.

The PCM uses the inlet air temperature sensor to

control the charge system voltage. This temperature,

along with data from monitored line voltage, is used

by the PCM to vary the battery charging rate. The

system voltage is higher at cold temperatures and is

gradually reduced as the calculated battery tempera-

ture increases.

The ambient temperature sensor is used to control

the battery voltage based upon ambient temperature

(approximation of battery temperature). The PCM

maintains the optimal output of the generator by

monitoring battery voltage and controlling it to a

range of 13.5 - 14.7 volts based on battery tempera-

ture.

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTIC SYSTEM

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the OBD system. Some

circuits are checked continuously and some are

checked only under certain conditions.

If the OBD system senses that a monitored circuit

is bad, it will put a DTC into electronic memory. The

DTC will stay in electronic memory as long as the

circuit continues to be bad. The PCM is programmed

to clear the memory after 50 engine starts if the

problem does not occur again.

DIAGNOSTIC TROUBLE CODES

A DTC description can be read using the DRBIIIt

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures manual for information.

A DTC does not identify which component in a cir-

cuit is bad. Thus, a DTC should be treated as a

symptom, not as the cause for the problem. In some

cases, because of the design of the diagnostic test

procedure, a DTC can be the reason for another DTC

to be set. Therefore, it is important that the test pro-

cedures be followed in sequence, to understand what

caused a DTC to be set.ERASING DIAGNOSTIC TROUBLE CODES

The DRBIIItScan Tool must be used to erase a

DTC.

The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp or battery lamp is illumi-

nated with the engine running

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE)

INSPECTION

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the On-Board Diagnostic

(OBD) system. Some charging system circuits are

checked continuously, and some are checked only

under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBIIItscan tool.

Perform the following inspections before attaching

the scan tool.

(1) Inspect the battery condition. Refer to the Bat-

tery section (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM - DIAGNOSIS AND TESTING) for proce-

dures.

(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) for tightness in

receptacles. They should be properly installed and

tight. Repair or replace as required.

(4) Inspect generator mounting bolts for tightness.

Replace or tighten bolts if required. Refer to the Gen-

erator Removal/Installation section of this group for

torque specifications (Refer to 8 - ELECTRICAL/

CHARGING - SPECIFICATIONS).

RGCHARGING8Fa-21

CHARGING (Continued)

ProCarManuals.com

Page 488 of 2399

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS.........................2

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS...........................2

REMOVAL.............................11

INSTALLATION.........................12CLUSTER LENS

REMOVAL.............................12

INSTALLATION.........................12

MECHANICAL TRANSMISSION RANGE

INDICATOR

REMOVAL.............................12

INSTALLATION.........................12

RED BRAKE WARNING INDICATOR

DESCRIPTION.........................13

OPERATION...........................13

INSTRUMENT CLUSTER

DESCRIPTION

The instrumentation gauges are contained in a

subdial assembly within the instrument cluster. The

individual gauges are not serviceable. If one of the

cluster gauges becomes faulty, the entire cluster

would require replacement.

The mechanical instrument cluster with a tachom-

eter is equipped with a electronic vacuum fluorescent

transmission range indicator (PRND3L), odometer,

and trip odometer display.

The mechanical instrument cluster without a

tachometer is equipped with a cable operated trans-

mission range indicator (PRND21) and a vacuum flu-

orescent odometer display. It also has the following

indicators:

²Turn Signals

²High Beam

²Oil Pressure

²MIL

The instrument cluster is equipped with the follow-

ing warning lamps.

²Lift Gate Ajar

²Low Fuel Level

²Low Windshield Washer Fluid Level

²Cruise

²Battery Voltage

²Fasten Seat Belt

²Door Ajar

²Coolant Temperature

²Anti-Lock Brake

²Brake

²Airbag

²Traction Control

²AutostickThe mechanical instrument cluster without a

tachometer also has the following warning lamps:

²Turns Signals

²High Beam

²Oil Pressure

²Malfunction Indicator Lamp (MIL)

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Lamp is located in the instru-

ment cluster. When moisture is found within the fuel

system, the sensor sends a message via the PCI data

bus to the instrument cluster. The sensor is located

underneath the vehicle, directly above the rear axle.

The sensor is housed within the fuel filter/water sep-

arator assembly cover. The sensor is not serviced sep-

arately. If found defective, the entire assembly cover

must be replaced.

OPERATION

Refer to the vehicle Owner's Manual for operation

instructions and conditions for the Instrument Clus-

ter Gauges.

WATER IN FUEL LAMP - EXPORT

The Water In Fuel Sensor is a resistive type

switch. It is calibrated to sense the different resis-

tance between diesel fuel and water. When water

enters the fuel system, it is caught in the bottom of

the fuel filter/water separator assembly, where the

sensor is located. Water has less resistance than die-

sel fuel. The sensor then sends a PCI data bus mes-

sage to the instrument cluster to illuminate the

lamp.

If the lamp is inoperative, perform the self diag-

nostic test on the instrument cluster to check the

lamp operation before continuing diagnosis.

RSINSTRUMENT CLUSTER8J-1

ProCarManuals.com

Page 489 of 2399

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic

problems. Prior to any test, perform the Self-Diag-

nostic Test. The self diagnostic system displays

instrument cluster stored fault codes in the odometer

display, sweeps the gauges to the calibration points,

and bulb checks the warning indicators. When the

key is in the ON position with the engine not run-

ning, the MIL will remain illuminated for regulatory

purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window then release the button. If a fault code is

present, the cluster will display it in the odometer

display. When all fault codes have been displayed,

the cluster will displayªendºin the odometer dis-

play. Refer to the INSTRUMENT CLUSTER DTC'S

table to determine what each trouble code means.

INSTRUMENT CLUSTER DTC'S

DTC DESCRIPTION

100.0 LOOP-BACK FAILURE

100.1 ABS COMMUNICATION FAULT

100.2 BCM COMMUNICATION FAULT

100.3 EATX COMMUNICATION FAULT

100.4 FCM COMMUNICATION FAULT

100.5 ORC COMMUNICATION FAULT

100.6SBEC/DEC/MCM COMMUNICATION

FAULT

200.0 AIRBAG LED SHORT

200.1 AIRBAG LED OPEN

200.2 ABS LED SHORT

200.3 ABS LED OPEN

200.6 EL INVERTER TIME-OUT

200.7 EATX MISMATCH

CALIBRATION TEST

The CLUSTER CALIBRATION table contains the

proper calibration points for each gauge. If the gauge

pointers are not calibrated, a problem exists in the

cluster. If any gauge is out of calibration, replace the

cluster.

CLUSTER CALIBRATION

SPEEDOMETER CALIBRATION POINT

1 0 MPH (0 KM/H)

2 20 MPH (40 KM/H)

3 60 MPH (100 KM/H)

4 100 MPH (160 KM/H)

TACHOMETER

1 0 RPM

2 1000 RPM

3 3000 RPM

4 6000 RPM

FUEL GAUGE

1 EMPTY

2 1/4 FILLED

3 1/2 FILLED

4 FULL

TEMPERATURE

GAUGE

1 COLD

2 1/4

3 3/4

4 HOT

ODOMETER SEGMENT TEST

If a segment in the odometer does not illuminate

normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE INDICATOR

SEGMENT TEST

If a segment in the transmission range indicator

does not illuminate normally, a problem exists in the

display.

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS

CONDITIONS

Refer to the following tables for possible problems,

causes, and corrections.

²INSTRUMENT CLUSTER DIAGNOSIS

²SPEEDOMETER DIAGNOSIS

²TACHOMETER DIAGNOSIS

²FUEL GAUGE DIAGNOSIS

²TEMPERATURE GAUGE DIAGNOSIS

²ODOMETER DIAGNOSIS

²ELECTRONIC GEAR INDICATOR DISPLAY

DIAGNOSIS

²MECHANICAL TRANSMISSION RANGE

INDICATOR (PRND21) DIAGNOSIS

8J - 2 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 490 of 2399

NOTE: Always check the functionality of the cluster

by running the self test prior to troubleshooting.

INSTRUMENT CLUSTER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

INSTRUMENT CLUSTER

INOPERATIVE. NO

RESPONSE FROM

INSTRUMENT CLUSTER.NO PCI BUS MESSAGES

FROM THE BCM.USE A DRB IIITSCAN TOOL TO CHECK THE BCM.

IF OK, LOOK FOR ANOTHER POSSIBLE CAUSE

FOR CLUSTER FAILURE. IF NOT OK, REFER TO

THE PROPER BODY DIAGNOSTIC PROCEDURES

MANUAL.

SPREAD TERMINAL(S)

ON WIRING HARNESS

CLUSTER CONNECTOR.REMOVE CLUSTER FROM INSTRUMENT PANEL

AND CHECK WIRING HARNESS CONNECTOR FOR

SPREAD TERMINAL. IF OK, LOOK FOR ANOTHER

POSSIBLE CAUSE FOR THE CLUSTER FAILURE. IF

NOT OK, REPAIR CONNECTOR.

BCM IS NOT RECEIVING

PROPER INPUT FROM

THE IGNITION SWITCH.1. USE A DRB IIITSCAN TOOL TO VERIFY IGNITION

SWITCH STATUS INTO THE BCM. IF NOT OK, GO

TO STEP (2). IF OK, LOOK AT ANOTHER POSSIBLE

CAUSE OF FAILURE.

2. CHECK IGNITION SWITCH FUNCTION AND

WIRING.

INTERNAL CLUSTER

FAILURE.REPLACE CLUSTER.

WAKE UP CIRCUIT

FAULTY.VERIFY CONTINUITY OF WAKE UP CIRCUIT FROM

BCM TO MIC. CIRCUIT SHALL BE LOW WHENEVER

BCM IS AWAKE.

POWER OR GROUND

MISSING.IF NO RESPONSE FROM THE MIC, CHECK FOR

POWER AND GROUND AT THE MIC CONNECTOR.

REFER TO WIRING DIAGRAMS FOR CONNECTOR

CALL OUTS.

RSINSTRUMENT CLUSTER8J-3

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 491 of 2399

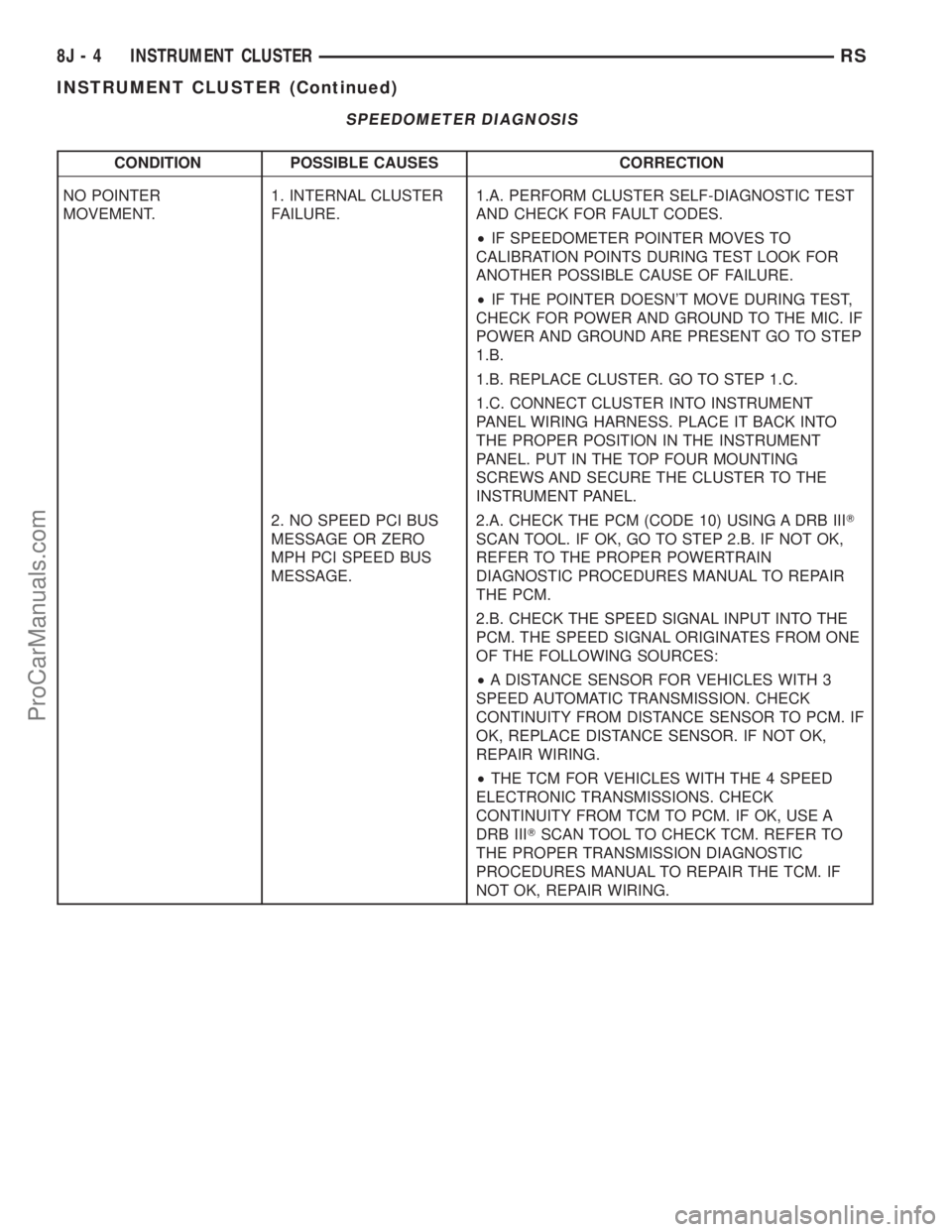

SPEEDOMETER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT.1. INTERNAL CLUSTER

FAILURE.1.A. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF SPEEDOMETER POINTER MOVES TO

CALIBRATION POINTS DURING TEST LOOK FOR

ANOTHER POSSIBLE CAUSE OF FAILURE.

²IF THE POINTER DOESN'T MOVE DURING TEST,

CHECK FOR POWER AND GROUND TO THE MIC. IF

POWER AND GROUND ARE PRESENT GO TO STEP

1.B.

1.B. REPLACE CLUSTER. GO TO STEP 1.C.

1.C. CONNECT CLUSTER INTO INSTRUMENT

PANEL WIRING HARNESS. PLACE IT BACK INTO

THE PROPER POSITION IN THE INSTRUMENT

PANEL. PUT IN THE TOP FOUR MOUNTING

SCREWS AND SECURE THE CLUSTER TO THE

INSTRUMENT PANEL.

2. NO SPEED PCI BUS

MESSAGE OR ZERO

MPH PCI SPEED BUS

MESSAGE.2.A. CHECK THE PCM (CODE 10) USING A DRB IIIT

SCAN TOOL. IF OK, GO TO STEP 2.B. IF NOT OK,

REFER TO THE PROPER POWERTRAIN

DIAGNOSTIC PROCEDURES MANUAL TO REPAIR

THE PCM.

2.B. CHECK THE SPEED SIGNAL INPUT INTO THE

PCM. THE SPEED SIGNAL ORIGINATES FROM ONE

OF THE FOLLOWING SOURCES:

²A DISTANCE SENSOR FOR VEHICLES WITH 3

SPEED AUTOMATIC TRANSMISSION. CHECK

CONTINUITY FROM DISTANCE SENSOR TO PCM. IF

OK, REPLACE DISTANCE SENSOR. IF NOT OK,

REPAIR WIRING.

²THE TCM FOR VEHICLES WITH THE 4 SPEED

ELECTRONIC TRANSMISSIONS. CHECK

CONTINUITY FROM TCM TO PCM. IF OK, USE A

DRB IIITSCAN TOOL TO CHECK TCM. REFER TO

THE PROPER TRANSMISSION DIAGNOSTIC

PROCEDURES MANUAL TO REPAIR THE TCM. IF

NOT OK, REPAIR WIRING.

8J - 4 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 492 of 2399

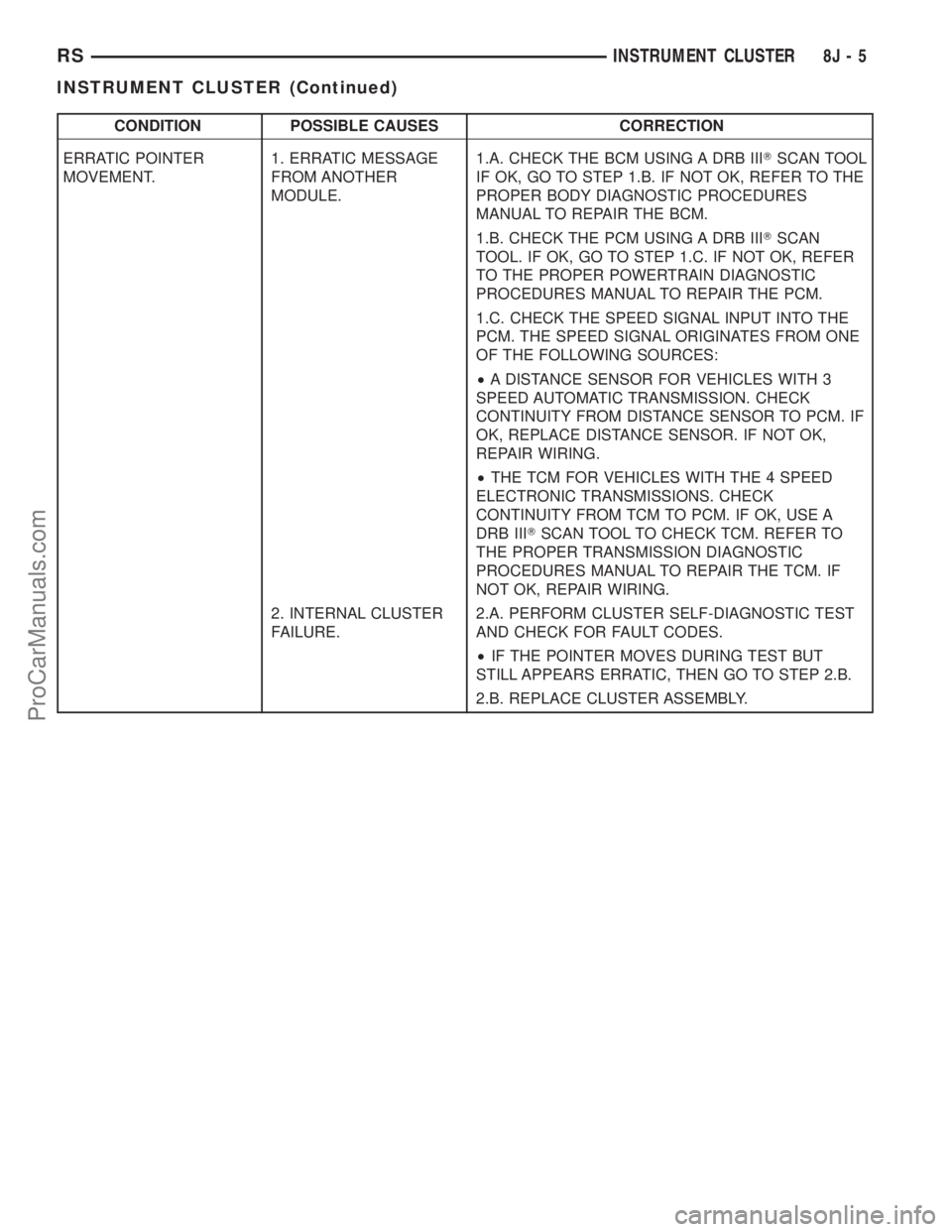

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. ERRATIC MESSAGE

FROM ANOTHER

MODULE.1.A. CHECK THE BCM USING A DRB IIITSCAN TOOL

IF OK, GO TO STEP 1.B. IF NOT OK, REFER TO THE

PROPER BODY DIAGNOSTIC PROCEDURES

MANUAL TO REPAIR THE BCM.

1.B. CHECK THE PCM USING A DRB IIITSCAN

TOOL. IF OK, GO TO STEP 1.C. IF NOT OK, REFER

TO THE PROPER POWERTRAIN DIAGNOSTIC

PROCEDURES MANUAL TO REPAIR THE PCM.

1.C. CHECK THE SPEED SIGNAL INPUT INTO THE

PCM. THE SPEED SIGNAL ORIGINATES FROM ONE

OF THE FOLLOWING SOURCES:

²A DISTANCE SENSOR FOR VEHICLES WITH 3

SPEED AUTOMATIC TRANSMISSION. CHECK

CONTINUITY FROM DISTANCE SENSOR TO PCM. IF

OK, REPLACE DISTANCE SENSOR. IF NOT OK,

REPAIR WIRING.

²THE TCM FOR VEHICLES WITH THE 4 SPEED

ELECTRONIC TRANSMISSIONS. CHECK

CONTINUITY FROM TCM TO PCM. IF OK, USE A

DRB IIITSCAN TOOL TO CHECK TCM. REFER TO

THE PROPER TRANSMISSION DIAGNOSTIC

PROCEDURES MANUAL TO REPAIR THE TCM. IF

NOT OK, REPAIR WIRING.

2. INTERNAL CLUSTER

FAILURE.2.A. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF THE POINTER MOVES DURING TEST BUT

STILL APPEARS ERRATIC, THEN GO TO STEP 2.B.

2.B. REPLACE CLUSTER ASSEMBLY.

RSINSTRUMENT CLUSTER8J-5

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 493 of 2399

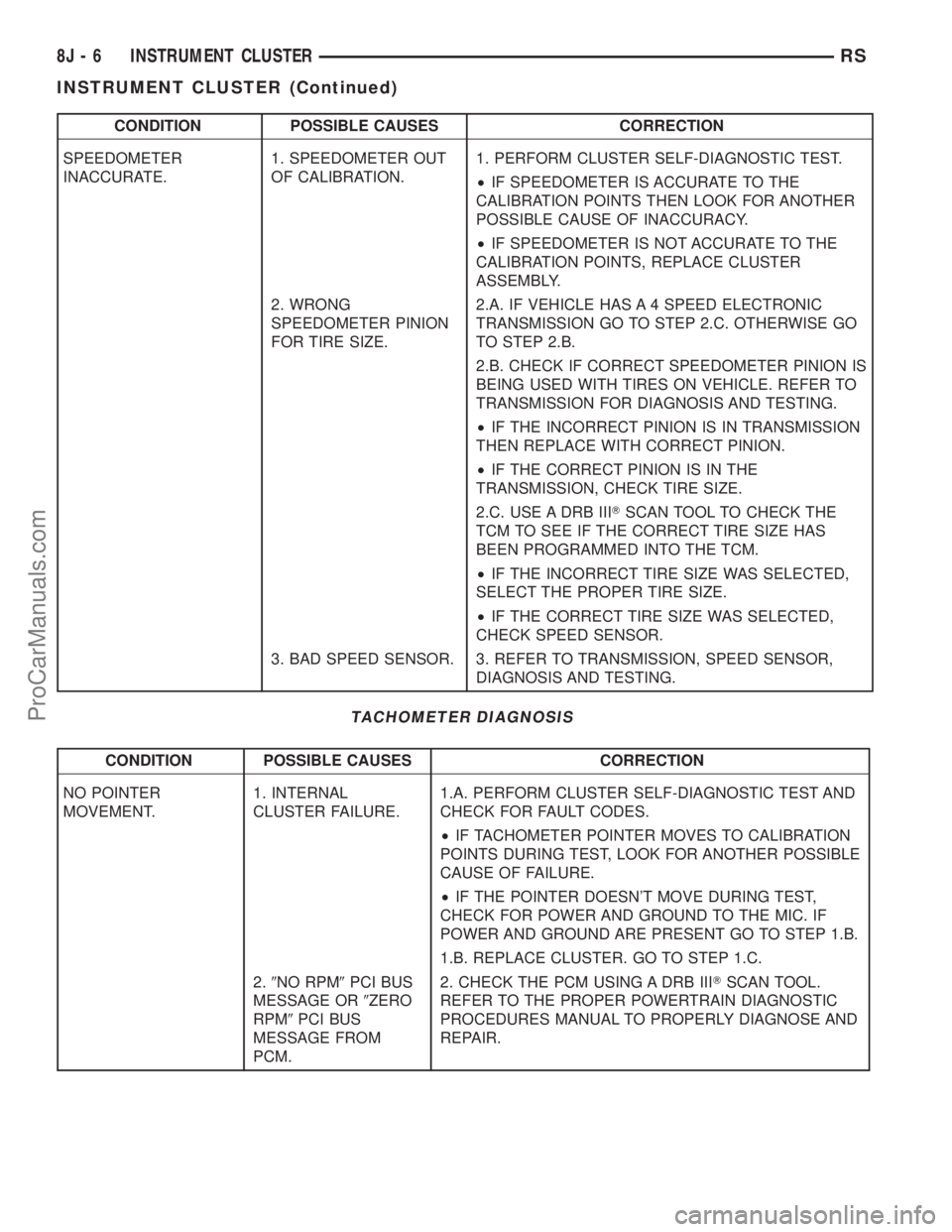

CONDITION POSSIBLE CAUSES CORRECTION

SPEEDOMETER

INACCURATE.1. SPEEDOMETER OUT

OF CALIBRATION.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

²IF SPEEDOMETER IS ACCURATE TO THE

CALIBRATION POINTS THEN LOOK FOR ANOTHER

POSSIBLE CAUSE OF INACCURACY.

²IF SPEEDOMETER IS NOT ACCURATE TO THE

CALIBRATION POINTS, REPLACE CLUSTER

ASSEMBLY.

2. WRONG

SPEEDOMETER PINION

FOR TIRE SIZE.2.A. IF VEHICLE HAS A 4 SPEED ELECTRONIC

TRANSMISSION GO TO STEP 2.C. OTHERWISE GO

TO STEP 2.B.

2.B. CHECK IF CORRECT SPEEDOMETER PINION IS

BEING USED WITH TIRES ON VEHICLE. REFER TO

TRANSMISSION FOR DIAGNOSIS AND TESTING.

²IF THE INCORRECT PINION IS IN TRANSMISSION

THEN REPLACE WITH CORRECT PINION.

²IF THE CORRECT PINION IS IN THE

TRANSMISSION, CHECK TIRE SIZE.

2.C. USE A DRB IIITSCAN TOOL TO CHECK THE

TCM TO SEE IF THE CORRECT TIRE SIZE HAS

BEEN PROGRAMMED INTO THE TCM.

²IF THE INCORRECT TIRE SIZE WAS SELECTED,

SELECT THE PROPER TIRE SIZE.

²IF THE CORRECT TIRE SIZE WAS SELECTED,

CHECK SPEED SENSOR.

3. BAD SPEED SENSOR. 3. REFER TO TRANSMISSION, SPEED SENSOR,

DIAGNOSIS AND TESTING.

TACHOMETER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT.1. INTERNAL

CLUSTER FAILURE.1.A. PERFORM CLUSTER SELF-DIAGNOSTIC TEST AND

CHECK FOR FAULT CODES.

²IF TACHOMETER POINTER MOVES TO CALIBRATION

POINTS DURING TEST, LOOK FOR ANOTHER POSSIBLE

CAUSE OF FAILURE.

²IF THE POINTER DOESN'T MOVE DURING TEST,

CHECK FOR POWER AND GROUND TO THE MIC. IF

POWER AND GROUND ARE PRESENT GO TO STEP 1.B.

1.B. REPLACE CLUSTER. GO TO STEP 1.C.

2.9NO RPM9PCI BUS

MESSAGE OR9ZERO

RPM9PCI BUS

MESSAGE FROM

PCM.2. CHECK THE PCM USING A DRB IIITSCAN TOOL.

REFER TO THE PROPER POWERTRAIN DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE AND

REPAIR.

8J - 6 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 494 of 2399

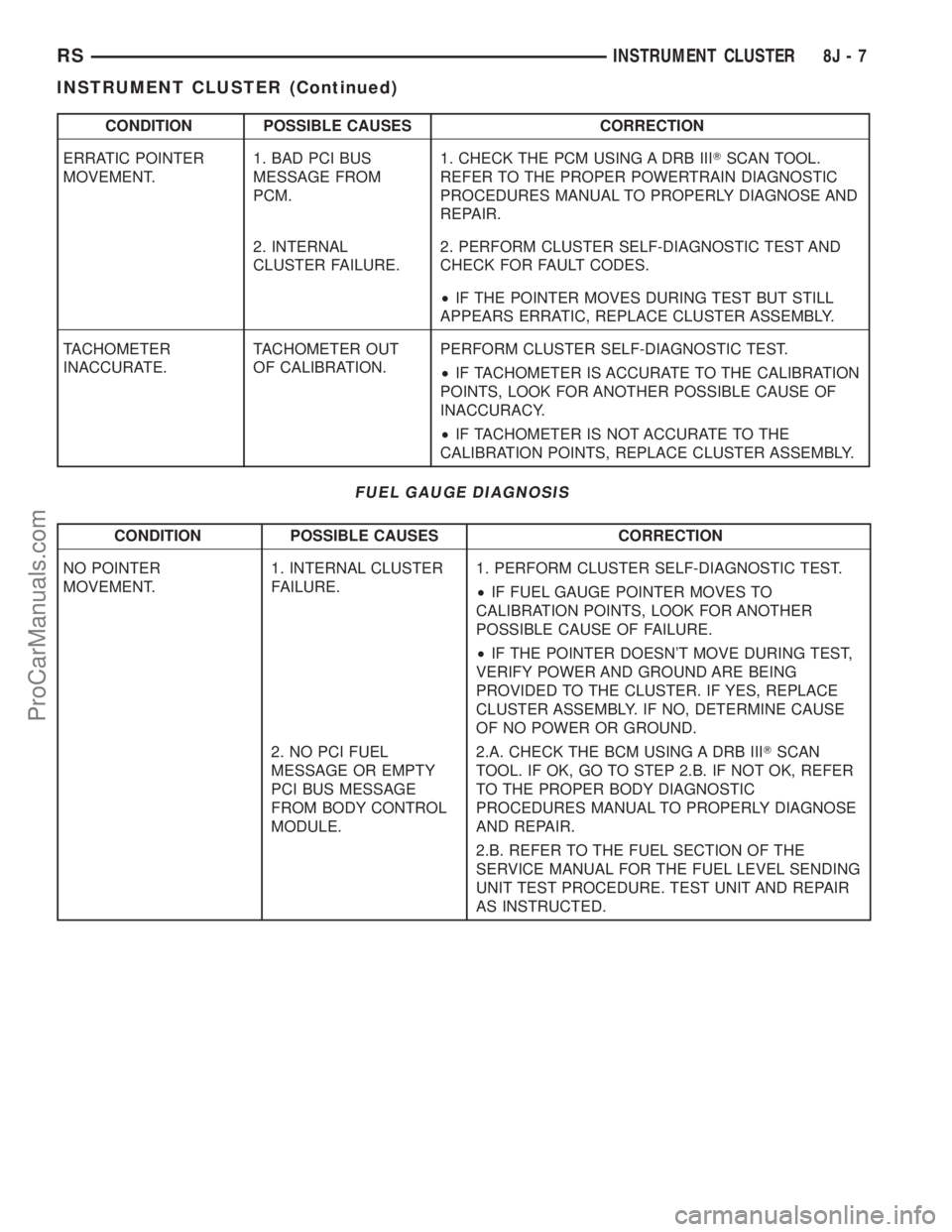

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. BAD PCI BUS

MESSAGE FROM

PCM.1. CHECK THE PCM USING A DRB IIITSCAN TOOL.

REFER TO THE PROPER POWERTRAIN DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE AND

REPAIR.

2. INTERNAL

CLUSTER FAILURE.2. PERFORM CLUSTER SELF-DIAGNOSTIC TEST AND

CHECK FOR FAULT CODES.

²IF THE POINTER MOVES DURING TEST BUT STILL

APPEARS ERRATIC, REPLACE CLUSTER ASSEMBLY.

TACHOMETER

INACCURATE.TACHOMETER OUT

OF CALIBRATION.PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

²IF TACHOMETER IS ACCURATE TO THE CALIBRATION

POINTS, LOOK FOR ANOTHER POSSIBLE CAUSE OF

INACCURACY.

²IF TACHOMETER IS NOT ACCURATE TO THE

CALIBRATION POINTS, REPLACE CLUSTER ASSEMBLY.

FUEL GAUGE DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO POINTER

MOVEMENT.1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

²IF FUEL GAUGE POINTER MOVES TO

CALIBRATION POINTS, LOOK FOR ANOTHER

POSSIBLE CAUSE OF FAILURE.

²IF THE POINTER DOESN'T MOVE DURING TEST,

VERIFY POWER AND GROUND ARE BEING

PROVIDED TO THE CLUSTER. IF YES, REPLACE

CLUSTER ASSEMBLY. IF NO, DETERMINE CAUSE

OF NO POWER OR GROUND.

2. NO PCI FUEL

MESSAGE OR EMPTY

PCI BUS MESSAGE

FROM BODY CONTROL

MODULE.2.A. CHECK THE BCM USING A DRB IIITSCAN

TOOL. IF OK, GO TO STEP 2.B. IF NOT OK, REFER

TO THE PROPER BODY DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE

AND REPAIR.

2.B. REFER TO THE FUEL SECTION OF THE

SERVICE MANUAL FOR THE FUEL LEVEL SENDING

UNIT TEST PROCEDURE. TEST UNIT AND REPAIR

AS INSTRUCTED.

RSINSTRUMENT CLUSTER8J-7

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com